To determine temperature distribution, load-bearing capacity and spalling behavior of FGC slabs in the case of fire, numerical and experimental investigations were performed. For the experimental investigations, cut-outs of a FGC component were exposed to fire from underneath in a small-scale test furnace according to [

14]. The setup of the numerical simulation is based on the boundary conditions present in the furnace. In addition, a cut-out of a conventional solid slab was numerically simulated to obtain a comparison with the FGC slabs.

2.1. Experimental Setup

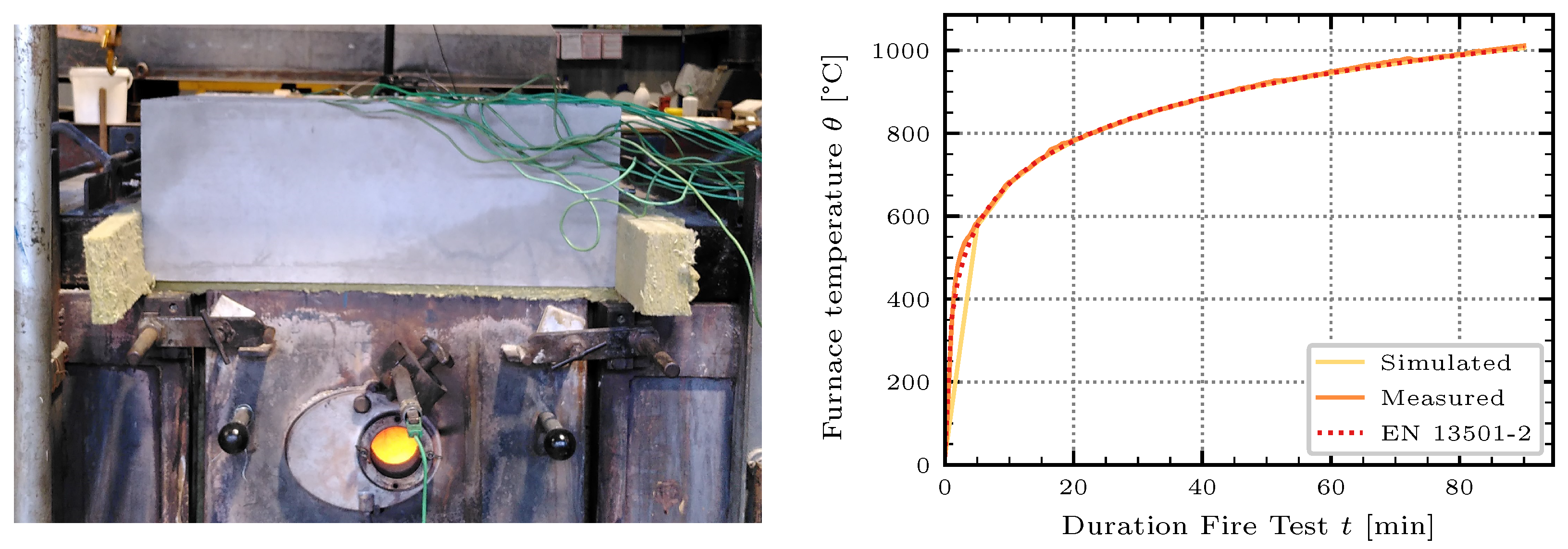

The experiments were conducted in a small-scale test furnace at the

Materials Testing Institute at the University of Stuttgart, Germany (MPA Stuttgart). The small-scale test furnace consists of a combustion chamber and an atomizing oil burner in accordance with the specifications of [

14]. The combustion chamber is bounded on all sides by firebricks and refractory concrete, with an opening at the top to place the test specimens (cf.

Figure 1).

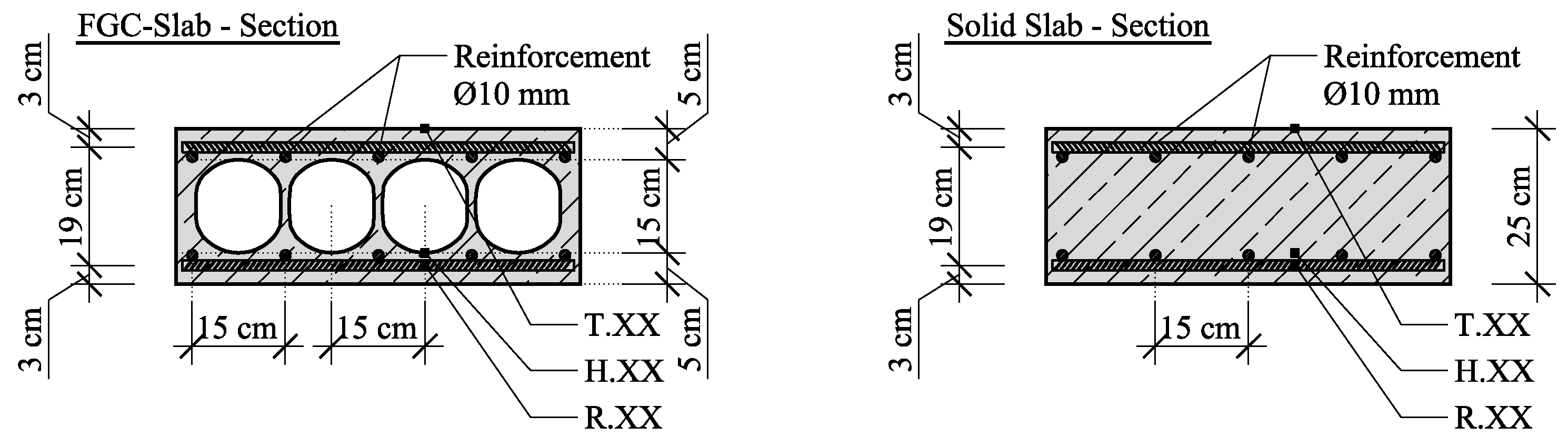

The dimensions of the slab cutout are 65 cm × 65 cm with a thickness of 25 cm. The nearly spherical mineral hollow bodies have a diameter of 15 cm and a wall thickness of 1 to 4mm, with a cover layer of 5 cm below and above the hollow bodies.

The concrete mixture used in this study was provided by

Godel Beton GmbH, Stuttgart, Germany and produced in a local concrete plant. The binder composition included Portland cement (CEM I 42.5 R), blast furnace cement (CEM III/B 32.5 N-LH/SR), and fly ash (FA). River sand (RS) was used as fine aggregate 0/2mm with a density of

. The coarse aggregates (CAs) 2/16mm had a density of

. Superplasticizer and stabilizer were added as additives (AD) to the mixture.

Table 1 shows the composition of the mixture adopted in this study.

Prior to concreting, the reinforcement, hollow bodies, and thermocouples were installed in the formwork (cf.

Figure 1). The specimens were demolded after 7 days. To ensure that the concrete had a low moisture content, the test specimens were stored for 100 days in a closed storage chamber at 50 to 70% relative humidity in accordance with [

15] before they were subjected to the fire test. The moisture content of the specimens was not determined.

The three test specimens, denoted with

A –

C, were each exposed over

to fire from underneath with the Standard Time Temperature Curve (STTC) according to [

16]. The curve describes the temperature profile in the event of a fire. The combustion temperature

at a given time

t can be calculated as a function of the fire duration using the following equation:

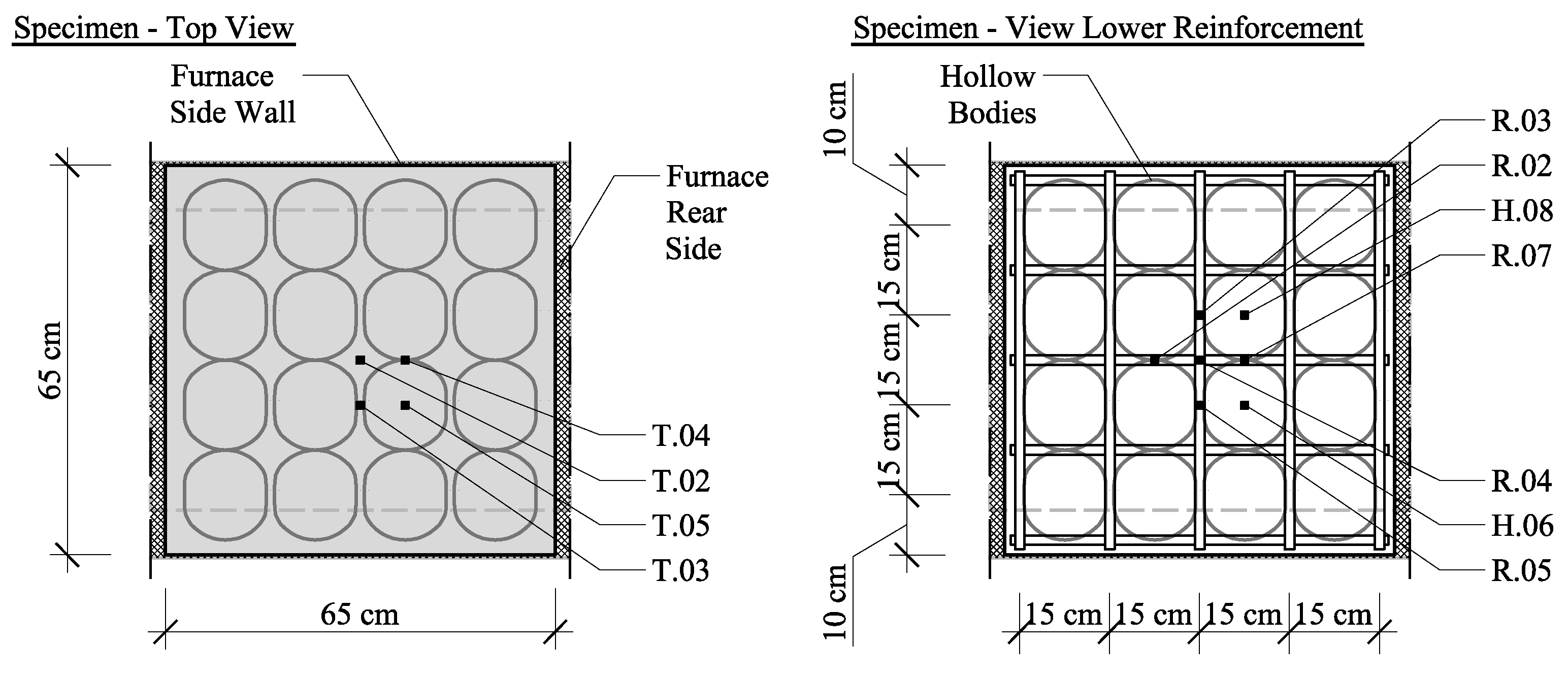

Two sheathed thermocouples of type K (NiCr-Ni), IEC 60584-1 Class 1 [

17] are installed in the combustion chamber to continuously monitor and control the combustion temperature and therefore the fire exposure of the test specimens. The results of the temperature measurements in the combustion chamber compared to the STTC can be taken from

Figure 2.

To measure the temperature distribution of the cut-outs during the fire test, thermocouples of type K (NiCr-Ni), IEC 60584-1 Class 1 [

17] were installed at characteristic points both inside and on the surface of the specimens. The experimental setup and the location of the sensors are shown in

Figure 3 and

Figure 4.

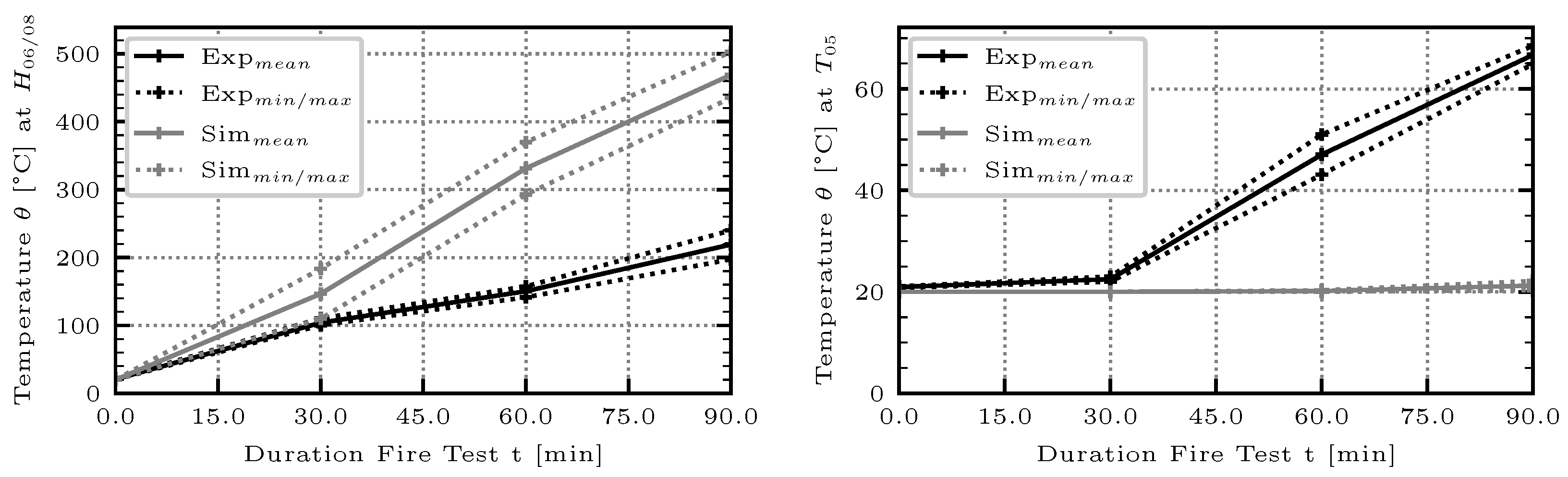

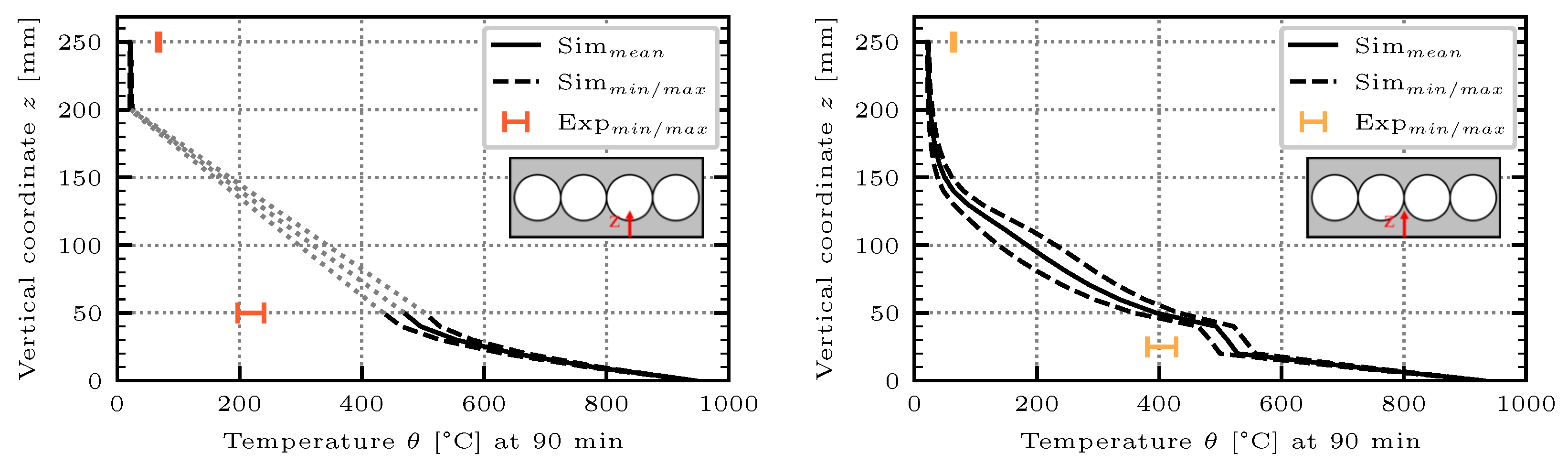

To compare the FGC and the solid concrete components in terms of their fire behavior, analytical calculations and numerical simulations of a cut-out of a solid slab were performed. The geometric dimensions and material properties of both were selected identically.

Compared to the applicable permissible values for solid cross-sections [

18], the reinforcement cover of the FGC components was increased by

, as preliminary investigations [

12] indicated an increased steel temperature when maintaining the same reinforcement cover. This assumption will be subsequently validated.

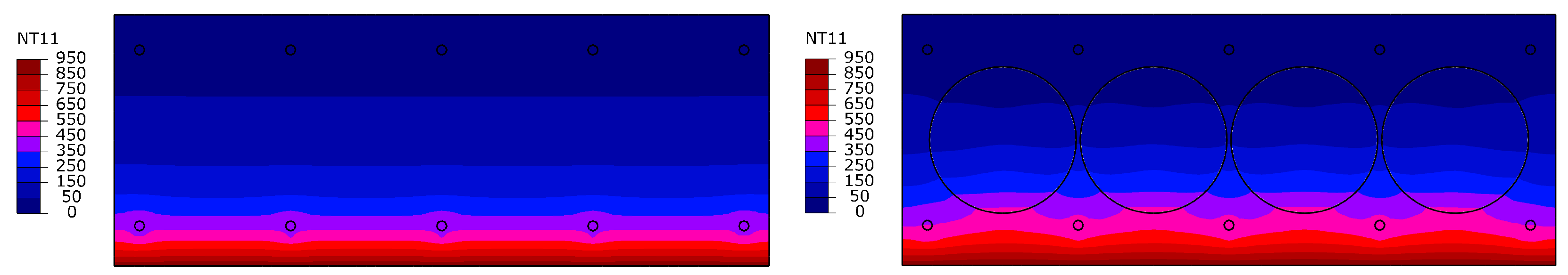

2.2. Numerical Investigations

To obtain a comprehensive understanding of the temperature distribution within the component, a non-linear heat transfer analysis was performed in the

Abaqus 2021 FEM software environment. All input data required to perform the simulation are contained in [

19].

The concrete as well as the reinforcement were simulated using eight-node linear heat transfer solid elements (DC3D8), see also

Figure 5. The wall thickness of the mineral hollow bodies was considered to be

. As an approximation, the air contained in the hollow bodies was not considered in the numerical model due to the comparatively low thermal conductivity (

1.4–2.0

); for discussions, see also

Section 4. This means that a heat flow in the numerical model can only occur through the concrete cross-section.

The mechanical properties of the utilized concrete and reinforcement can be found in

Table 2, and the thermal properties are given and discussed in

Section 2.4. The heat flux on the surfaces of the specimens due to convection and radiation from the underneath fire exposure and the surrounding air was modeled using surface film and surface radiative interactions (

Figure 6).

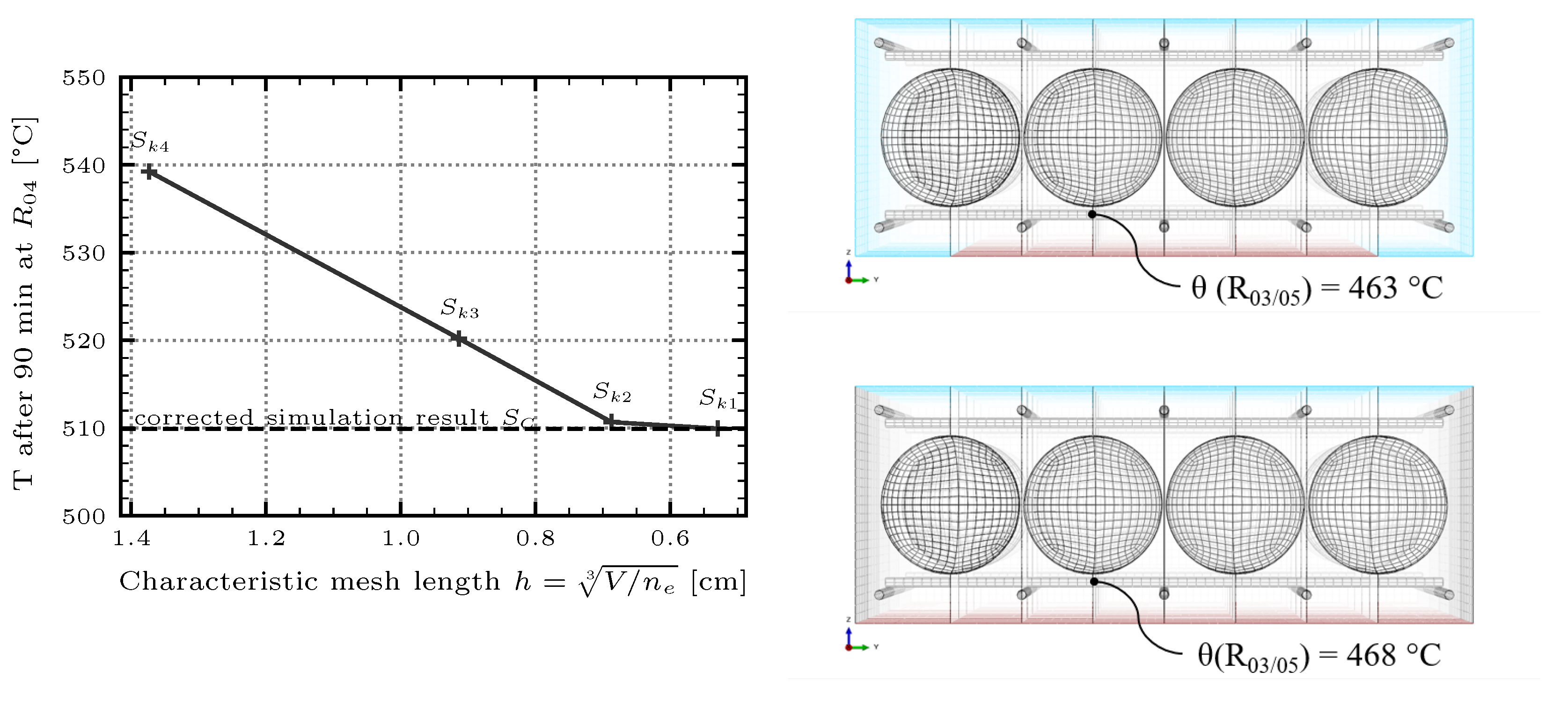

2.3. Influence of Mesh Size and Boundary Conditions

A convergence study according to [

23] was conducted to determine the influence of the mesh size on the results. Therefore, the edge length of the solid elements was refined in multiple steps by a factor of

. The temperature determined at the measurement point

was used as the convergence parameter. The results are shown in

Figure 6.

As a result, iterative convergence could be identified, and the approximate numerical error of the simulation could be estimated according to [

23]. For all subsequent simulations, the mesh with the parameter

was selected, as this provided sufficiently accurate results within reasonable computing time. The relative error between the solution

computed on the grid

and the corrected simulation result

is less than 2%. Detailed results of the convergence study can be found in [

19].

Furthermore, the influence of the boundary conditions of the small-scale test furnace was analyzed. Images from a thermographic camera indicated that heat is radiated from the uninsulated side faces of the specimen. Likewise, due to the lateral support on the walls of the fire chamber, a lateral strip underneath the specimen with a width of approximately was not directly exposed to fire from the combustion chamber.

In order to demonstrate that the influence of the aforementioned boundary conditions at the measurement locations in the center of the specimen can be neglected, a numerical model with the boundary conditions of the small-scale test furnace was created (cf.

Figure 6). A conservative approach was chosen in which both the two uninsulated faces as well as the lateral strip underneath the specimen were modeled as a heat sink at room temperature.

The comparison of the results of the modeling as a quasi-infinite cut-out and with the boundary conditions in the small-scale test furnace is shown in

Figure 6. Although the influence on the temperature on the exterior faces can be observed, it becomes evident that the temperature differences due to the boundary conditions at the measurement points distant from the exterior faces are negligible (max. 1.5%). The detailed results are shown in [

19]. Consequently, it can be stated that the results from the tests performed in the small-scale test furnace provide reliable temperature profiles also for concrete components with larger lateral dimensions such as continuous slabs.

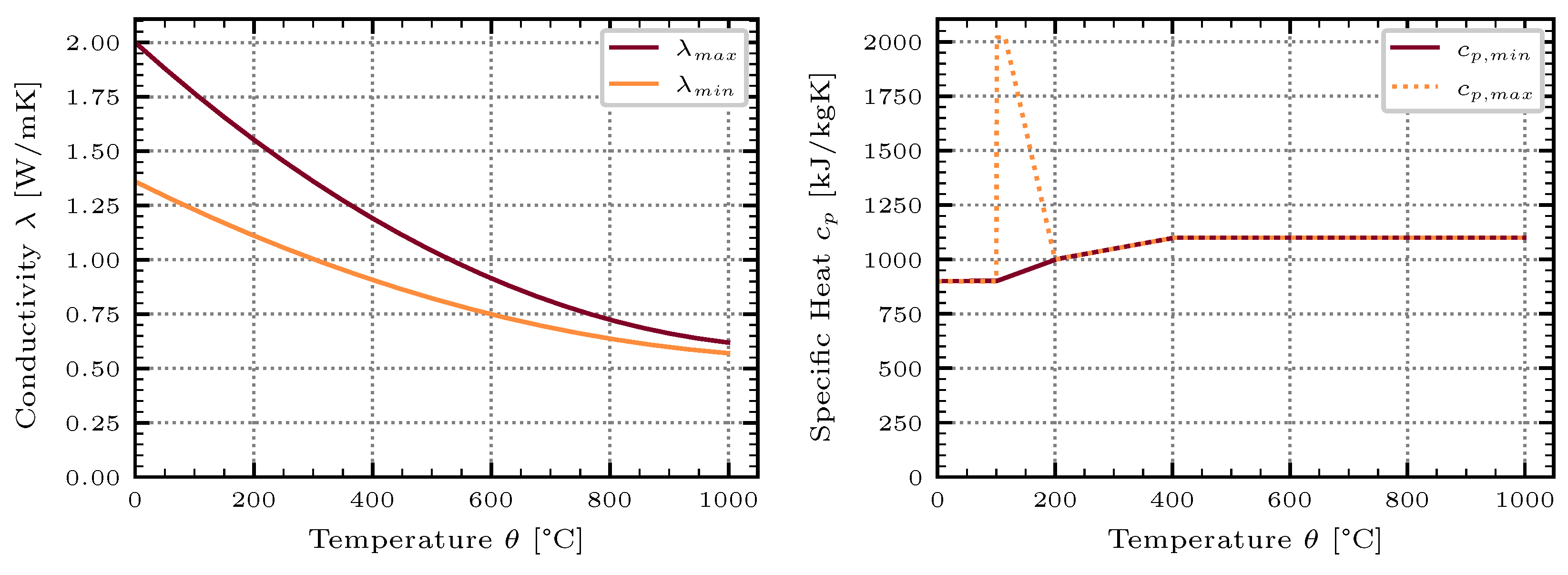

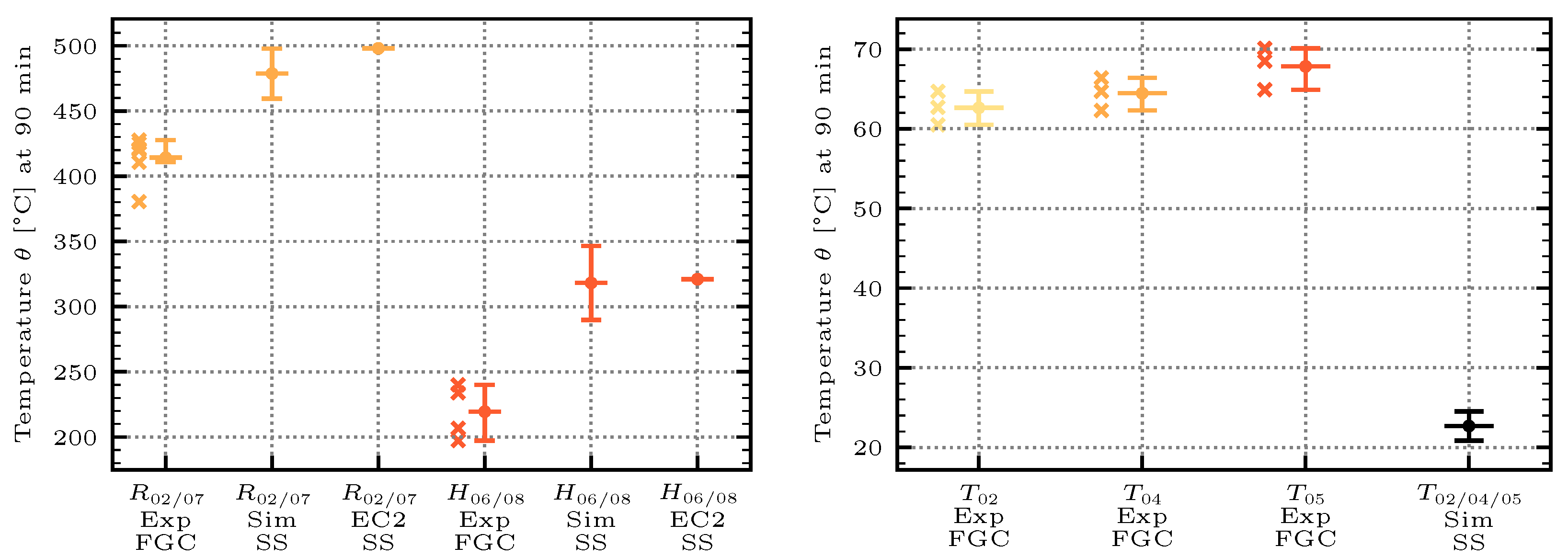

2.4. Influence of Thermal Conductivity and Specific Heat

In addition to the mesh parameters, the temperature-dependent thermal conductivity

and specific heat capacity

of the concrete have a significant influence on the quality of the results of the numerical simulation. These depend, in particular, on the moisture content, mixture composition, and density of the utilized concrete. As these parameters can generally be subject to large variations, upper and lower limits that lead to rapid (low specific heat capacity, high thermal conductivity) and slow (high specific heat capacity, low thermal conductivity) heating of the examined component were investigated (cf.

Figure 7). The corresponding values are based on [

18]. All subsequent simulations were conducted with both, the lower and upper limits of the temperature-dependent curves of

and

.