Flame Resistance Performance of Silicone Pad for Application in Railway Industry

Abstract

1. Introduction

2. Materials and Methods

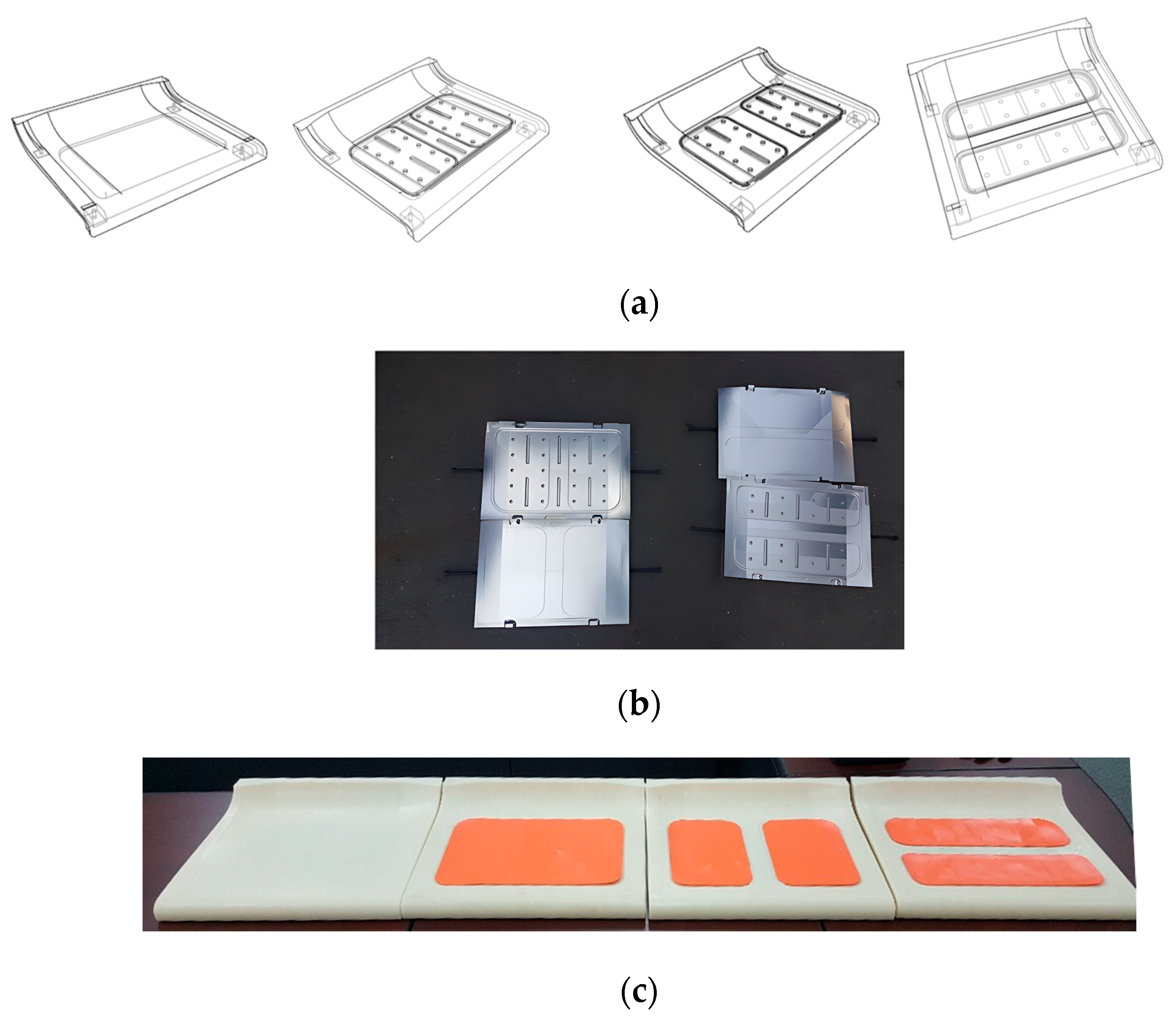

2.1. Design and Fabrication of Railway Cabin Seat Assemblages with Silicone Pads

2.2. Flame Retardancy Test

2.3. Human Pressure Distribution Test

2.4. Flame Retardancy Test of Cabin Seat Assemblage

3. Results and Discussion

3.1. Thermal Resistance Analysis of Silicone Pads

3.2. Smoke Density and Toxicity Analyses of Silicone Pads

3.3. Shape Effect of Silicone Pad on Seat Comfort

3.4. Thermal Resistance Analysis on Cabin Seat Assemblage

3.5. Fire Safety Assessment of Silicone Pad for Railway Vehicle

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fridolf, K.; Ronchi, E.; Nilsson, D.; Frantzich, H. Movement speed and exit choice in smoke-filled rail tunnels. Fire Saf. J. 2013, 59, 8–21. [Google Scholar] [CrossRef]

- Roh, J.S.; Ryou, H.S.; Park, W.H.; Jang, Y.J. CFD simulation and assessment of life safety in a subway train fire. Tunn. Undergr. Space Technol. 2009, 24, 447–453. [Google Scholar] [CrossRef]

- Lee, D.H.; Park, W.H.; Hwang, J.; Hadjisophocleous, G. Full-scale fire test of an intercity train car. Fire Technol. 2016, 52, 1559–1574. [Google Scholar] [CrossRef]

- Kim, J.S.; Jeong, J.C.; Cho, S.H.; Seo, S.I. Fire resistance evaluation of a train carbody made of composite material by large scale tests. Compos. Struct. 2008, 83, 295–303. [Google Scholar] [CrossRef]

- Ingason, H. Model scale railcar fire tests. Fire Saf. J. 2007, 42, 271–282. [Google Scholar] [CrossRef]

- Chen, J.M.; Yao, X.L.; Yan, G.; Guo, X.H. Comparative study on heat release rate of high-speed passenger train compartments. Procedia Eng. 2014, 71, 107–113. [Google Scholar] [CrossRef]

- Capote, J.A.; Alvear, D.; Lázaro, M.; Espina, P. Heat release rate and computer fire modelling vs real-scale fire tests in passenger trains. Fire Mater. 2008, 32, 213–229. [Google Scholar] [CrossRef]

- Hu, X.; Wang, Z.; Jia, F.; Galea, E.R. Numerical investigation of fires in small rail car compartments. J. Fire Prot. Eng. 2012, 22, 245–270. [Google Scholar] [CrossRef]

- White, N.; Dowling, V.; Barnett, J. Full-scale fire experiment on a typical passenger train. Fire Saf. Sci. 2005, 8, 1157–1168. [Google Scholar] [CrossRef]

- NFPA 286; Standard Methods of Fire Tests for Evaluating Contribution of Wall and Ceiling Interior Finish to Room Fire Growth. National Fire Protection Association: Quincy, MA, USA, 2024.

- Luo, C.; Yazdani, S.; Lattimer, B.Y. Fire Growth in Standard Tests and Railcars. In Proceedings of the ASME/IEEE Joint Rail Conference, American Society of Mechanical Engineers, Pittsburgh, PA, USA, 18–20 April 2018; Volume 50978, p. V001T06A022. [Google Scholar]

- Zhou, Y.; Wang, H.; Bi, H.; Liu, X.; Gou, Q. Heat release rate of high-speed train fire in railway tunnels. Tunn. Undergr. Space Technol. 2020, 105, 103563. [Google Scholar] [CrossRef]

- Rie, D.; Ryu, J. Sustainable urban planning technique of fire disaster prevention for subway. Sustainability 2020, 12, 372. [Google Scholar] [CrossRef]

- Zisis, T.; Vasilopoulos, K.; Sarris, I. Numerical simulation of a fire accident in a longitudinally ventilated railway tunnel and tenability analysis. Appl. Sci. 2022, 12, 5667. [Google Scholar] [CrossRef]

- Peacock, R.D.; Bukowski, R.W.; Jones, W.J.; Reneke, P.A.; Babrauskas, V.; Brown, J.E. Fire Safety of Passenger Trains: A Review of US and Foreign Approaches; Federal Railroad Administration: Washington, DC, USA, 1993. [Google Scholar]

- Prine, B. A methodology for global comparison of fire testing standards in transportation applications. Master’s Thesis, University of Waterloo, Ontario, Canada, 2013. [Google Scholar]

- EN 45545-1; Railway Applications—Fire protection on Railway Vehicles—Part 1: General. European Committee for Standardization: Brussels, Belgium, 2013.

- EN 45545-2; Railway Applications—Fire Protection on Railway Vehicles—Part 2: Requirements for Fire Behavior of Materials and Components. European Committee for Standardization: Brussels, Belgium, 2020.

- Tooley, D. A comparison of New European fire standards with UK standards and the impact on UK vehicle design. Proc. Inst. Mech. Eng. Part. F J. Rail Rapid Transit. 2011, 225, 403–416. [Google Scholar] [CrossRef]

- Troitzsch, J.H. Fires, fire safety and trends. Regulations, standards and the role of flame retardancy. Int. Polym. Sci. Technol. 2013, 40, 1–6. [Google Scholar] [CrossRef]

- Radziszewska-Wolinska, J.M.; Kaźmierczak, A. Implementation of EU Requirements in the Field of Fire Safety of Passenger Rolling Stock. Eur. J. Eng. Technol. Res. 2019, 4, 86–89. [Google Scholar]

- Cho, Y.O.; Kwak, S.L.; Wang, J.B.; Park, C.W. An Integrated R & D Program for the Railway Safety Improvement in Korea. Int. J. Performability Eng. 2007, 3, 19. [Google Scholar]

- Rao, B.N.; Arunjothi, R.; Srinivasan, A.R.; Rajashekhar, P.; Sudhindra, A. Fire Safety Assessment of Polymeric Cables and Materials based on Heat Release Rate, Combustion Smoke and Toxicity. Power Res. 2008, 4, 195–212. [Google Scholar]

- ISO 9705-1; Reaction to Fire Tests—Room Corner Test for Wall and Ceiling Lining Products—Part 1: Test Method for a Small Room Configuration. International Organization for Standardization: Geneva, Switzerland, 2016.

- Bi, H.; Zhou, Y.; Wang, H.; Gou, Q.; Liu, X. Characteristics of fire in high-speed train carriages. J. Fire Sci. 2020, 38, 75–95. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, C.; Teng, W.; Kapahi, A.; Gao, Y.; Tian, X.; Cui, E. Modeling evaluation for fire resistance design of rail car floor assembly. Case Stud. Therm. Eng. 2022, 39, 102463. [Google Scholar] [CrossRef]

- Yuan, R.N.; Qin, Y.R.; Lu, S.X. Study on Fire Resistance of Floor Structures in High-speed Train. In Proceedings of the Journal of Physics: Conference Series, Sanya, China, 17–19 November 2021; IOP Publishing: Bristol, UK, 2021; Volume 2085, p. 012041. [Google Scholar]

- Peacock, R.D.; Bukowski, R.W.; Markos, S.H. Evaluation of passenger train car materials in the cone calorimeter. Fire Mater. 1999, 23, 53–62. [Google Scholar] [CrossRef]

- Lattimer, B.Y.; Luo, C.; Kraft, S.; Hodges, J.L. Rail car interior finish heat release rate requirements. In Proceedings of the 15th International Conference and Exhibition on Fire Science and Engineering (Interflam 2019), London, UK, 14 July 2019; pp. 1317–1327. [Google Scholar]

- Skripinets, A.; Saienko, N.V.; Hryhorenko, O.; Berezovskiy, A. Development and Evaluation of the Possibility of Using Epoxyurethane Mastic in Railway Transport. In Materials Science Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2020; Volume 1006, pp. 273–281. [Google Scholar]

- Zhu, C.; Li, S.; Li, J.; Clement, M.; Rudd, C.; Yi, X.; Liu, X. Fire performance of sandwich composites with intumescent mat protection: Evolving thermal insulation, post-fire performance and rail industry testing. Fire Saf. J. 2020, 116, 103205. [Google Scholar] [CrossRef]

- Försth, M.; Modin, H.; Sundström, B. A comparative study of test methods for assessment of fire safety performance of bus interior materials. Fire Mater. 2013, 37, 350–357. [Google Scholar] [CrossRef]

- Johansson, P.; Axelsson, J. Fire safety in buses WP2 report: Fire safety review of interior materials in buses. Fire Mater. 2023, 47, 910–924. [Google Scholar]

- Morgan, A.B.; Gilman, J.W. An overview of flame retardancy of polymeric materials: Application, technology, and future directions. Fire Mater. 2013, 37, 259–279. [Google Scholar] [CrossRef]

- Buch, R.R. Rates of heat release and related fire parameters for silicones. Fire Saf. J. 1991, 17, 1–12. [Google Scholar] [CrossRef]

- Hanu, L.G.; Simon, G.P.; Cheng, Y.B. Thermal stability and flammability of silicone polymer composites. Polym. Degrad. Stab. 2006, 91, 1373–1379. [Google Scholar] [CrossRef]

- Hamdani, S.; Longuet, C.; Perrin, D.; Lopez-Cuesta, J.M.; Ganachaud, F. Flame retardancy of silicone-based materials. Polym. Degrad. Stab. 2009, 94, 465–495. [Google Scholar] [CrossRef]

- Englert, M.; Minister, F.; Moussaoui, A.; Pisula, W. Mechanical properties of thermo-oxidative aged silicone rubber thermally stabilized by titanium oxide based fillers. Polym. Test. 2022, 115, 107726. [Google Scholar] [CrossRef]

- Li, Z.; Liang, W.; Shan, Y.; Wang, X.; Yang, K.; Cui, Y. Study of flame-retarded silicone rubber with ceramifiable property. Fire Mater. 2020, 44, 487–496. [Google Scholar] [CrossRef]

- Han, Y.; Yang, L.; Yu, Z.; Zhao, Y.; Zhang, Z.X. Lightweight and flame retardant silicone rubber foam prepared by supercritical nitrogen: The influence of flame retardants combined with ceramicizable fillers. Constr. Build. Mater. 2023, 370, 130735. [Google Scholar] [CrossRef]

- Shang, K.; Lin, G.D.; Jiang, H.J.; Jin, X.; Zhao, J.; Liu, D.; Wang, J.S. Flame retardancy, combustion, and ceramization behavior of ceramifiable flame-retardant room temperature vulcanized silicone rubber foam. Fire Mater. 2023, 47, 1082–1091. [Google Scholar] [CrossRef]

- Eduok, U.; Faye, O.; Szpunar, J. Recent developments and applications of protective silicone coatings: A review of PDMS functional materials. Prog. Org. Coat. 2017, 111, 124–163. [Google Scholar] [CrossRef]

- ISO 5660-1; Reaction to Fire Tests—Heat Release, Smoke Production and Mass Loss Rate—Part 1: Heat Release Rate (Cone Calorimeter Method). International Organization for Standardization: Geneva, Switzerland, 2015.

- ASTM E 662; Standard Test Method for Specific Optical Density of Smoke Generated by Solid Materials. ASTM International: West Conshohocken, PA, USA, 2021.

- Hemmes, B.; Brink, P.R.; Poeze, M. Effects of unconsciousness during spinal immobilization on tissue-interface pressures: A randomized controlled trial comparing a standard rigid spineboard with a newly developed soft-layered long spineboard. Injury 2014, 45, 1741–1746. [Google Scholar] [CrossRef] [PubMed]

- Zhao, S.; Wang, W.; Guo, W.; Zhang, C. A human body pressure distribution imaging system based on wavelet analysis and resistance tomography. Sensors 2017, 17, 2634. [Google Scholar] [CrossRef] [PubMed]

- Ma, K.; Liu, Q.L.; Wang, D.Y. Interval scoring method on vehicle seat comfort evaluation. IOP Conf. Ser. Mater. Sci. Eng. 2018, 439, 032071. [Google Scholar] [CrossRef]

- De Looze, M.P.; Kuijt-Evers, L.F.; Van Dieen, J.A.A.P. Sitting comfort and discomfort and the relationships with objective measures. Ergonomics 2003, 46, 985–997. [Google Scholar] [CrossRef]

- KRTS-VE-Part51-2017(R1); Technical Specifications for Rolling Stock—Metro and Subway. Korea Railroad Research Institute: Uiwang, Republic of Korea, 2017.

- BS 6853; Code of Practice for Fire Precautions in the Design and Construction of Passenger Carrying Trains. British Standards Institution: London, UK, 1999.

| Common Silicone | Flame-Retardant Silicone A | Flame-Retardant Silicone B | |

|---|---|---|---|

| Components |

|

|

|

| kW/m2 | Common Silicone: 1 mm | Common Silicone: 2 mm | Flame-Retardant Sheet A: 1 mm | Flame-Retardant Sheet A: 2 mm | Flame-Retardant Sheet B: 1 mm | Flame-Retardant Sheet B: 2 mm |

|---|---|---|---|---|---|---|

| 25 | 28.1 | 32.9 | Non-ignited | |||

| 50 | 58.9 | 62.6 | 47.4 | 51.0 | 40.2 | 44.5 |

| Material | Thickness | Testing Mode | Average Smoke Density | |||

|---|---|---|---|---|---|---|

| 1.5 min | 4 min | 10 min | Maximum | |||

| Flame-retardant sheet A | 1 mm | Non-flaming mode | 27.1 | 161 | 226 | 230 |

| Flaming mode | 28.7 | 101 | 119 | 120 | ||

| 2 mm | Non-flaming mode | 6.3 | 162 | 280 | 284 | |

| Flaming mode | 16.3 | 73.7 | 106 | 108 | ||

| Flame-retardant sheet B | 1 mm | Non-flaming mode | 34.8 | 234 | 339 | 341 |

| Flaming mode | 36.9 | 138 | 143 | 147 | ||

| 2 mm | Non-flaming mode | 4.7 | 99 | 231 | 265 | |

| Flaming mode | 10.8 | 76.6 | 123 | 124 | ||

| Gas | Reference Values (mg/g or g/m2) |

|---|---|

| Carbon dioxide (CO2) | 14,000 |

| Carbon monoxide (CO) | 280 |

| Hydrogen fluoride (HF) | 4.9 |

| Hydrogen chloride (HCl) | 15 |

| Hydrogen bromide (HBr) | 20 |

| Hydrogen cyanide (HCN) | 11 |

| Nitrogen dioxide (NOx) | 7.6 |

| Sulfur dioxide (SO2) | 53 |

| Sheet A: 1 mm | Sheet A: 2 mm | Sheet B: 1 mm | Sheet B: 2 mm | |

|---|---|---|---|---|

| R Value | 0.149 | 0.147 | 0.147 | 0.162 |

| Fire Safety Requirements | Pass Criteria | |||

|---|---|---|---|---|

| Hazard Class 1 | Hazard Class 2 | Hazard Class 3 | Hazard Class 4 | |

| Interior plate | ≤3.6 | ≤2.7 | ≤1.6 | ≤1.6 |

| Seat cover | ≤3.2 | ≤2.7 | ≤2.3 | ≤2.0 |

| Seat cushion | ≤3.6 | ≤3.6 | ≤3.2 | ≤3.2 |

| Seat body | ≤3.2 | ≤2.7 | ≤2.3 | ≤2.0 |

| Floor | ≤5.0 | ≤4.0 | ≤3.0 | ≤3.0 |

| MARHE (kW) | Max HRR (kW) | Reference | |

|---|---|---|---|

| Design 1 | 4.42 | 10.89 | MARHE ≤ 20 kW (KRTS Hazard class 4) |

| Design 2 | 3.49 | 8.94 |

| Requirements | Test Standards | Test Items | Pass Criteria for Each Hazard Class | ||||

|---|---|---|---|---|---|---|---|

| [1] | [2] | [3] | [4] | ||||

| Seats | Cover | ISO 5660-1 [43] | MARHE (kW/m2, @ 25 kW/m2) | ≤75 | ≤50 | ≤50 | ≤50 |

| ASTM E 662 [44] | Ds (1.5 min) | ≤150 | ≤125 | ≤100 | ≤100 | ||

| ASTM E 662 [44] | Ds (4.0 min) | ≤300 | ≤250 | ≤200 | ≤200 | ||

| BS 6853 Annex B.2 [50] | Toxic index (R) | ≤3.2 | ≤2.7 | ≤2.3 | ≤2.0 | ||

| Cushion | ISO 5660-1 [43] | MARHE (kW/m2, @ 25 kW/m2) | ≤75 | ≤50 | ≤50 | ≤50 | |

| ASTM E 662 [44] | Ds (1.5 min) | ≤175 | ≤175 | ≤125 | ≤100 | ||

| ASTM E 662 [44] | Ds (4.0 min) | ≤300 | ≤300 | ≤200 | ≤175 | ||

| BS 6853 Annex B.2 [50] | Toxic index (R) | ≤3.6 | ≤3.6 | ≤3.2 | ≤3.2 | ||

| Body | ISO 5660-1 [43] | MARHE (kW/m2, @ 50 kW/m2) | ≤90 | ≤90 | ≤90 | ≤60 | |

| ASTM E 662 [44] | Ds (1.5 min) | - | - | - | ≤100 | ||

| ASTM E 662 [44] | Ds (4.0 min) | ≤300 | ≤300 | ≤200 | ≤200 | ||

| BS 6853 Annex B.2 [50] | Toxic index (R) | ≤3.2 | ≤2.7 | ≤2.3 | ≤2.0 | ||

| Assembly | EN 45545-2 Annex B [18] | MARHE (kW) | ≤75 | ≤55 | ≤45 | ≤20 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, H.-L.; Kwon, T.-S.; Kang, S.-W.; Choi, K. Flame Resistance Performance of Silicone Pad for Application in Railway Industry. Fire 2024, 7, 255. https://doi.org/10.3390/fire7070255

Jang H-L, Kwon T-S, Kang S-W, Choi K. Flame Resistance Performance of Silicone Pad for Application in Railway Industry. Fire. 2024; 7(7):255. https://doi.org/10.3390/fire7070255

Chicago/Turabian StyleJang, Hong-Lae, Tae-Soon Kwon, Seok-Won Kang, and Kyungwho Choi. 2024. "Flame Resistance Performance of Silicone Pad for Application in Railway Industry" Fire 7, no. 7: 255. https://doi.org/10.3390/fire7070255

APA StyleJang, H.-L., Kwon, T.-S., Kang, S.-W., & Choi, K. (2024). Flame Resistance Performance of Silicone Pad for Application in Railway Industry. Fire, 7(7), 255. https://doi.org/10.3390/fire7070255