Evaluating the Combustion Performance of the Usual Timbers in Furniture Using a Grey Correlation Method Based on Thermolysis, Ignition, and Flame Spread

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Thermogravimetric Measurements

2.2.2. Cone Calorimeter Experiment

2.2.3. Flame Spread Experiment

2.2.4. Comprehensive Evaluation Methods

Normalization of Data Processing

Entropy Weight Method

CRITIC Method

Game Theory Method

Grey Correlation Method

3. Results and Discussion

3.1. Combustion Performance Analysis

3.1.1. Analysis of Thermolysis

3.1.2. Analysis of Heat Characteristic

3.1.3. Analysis of Smoke Production Characteristic

3.1.4. Analysis of Flame Spread

3.2. Evaluation of Combustion Performance of Timber

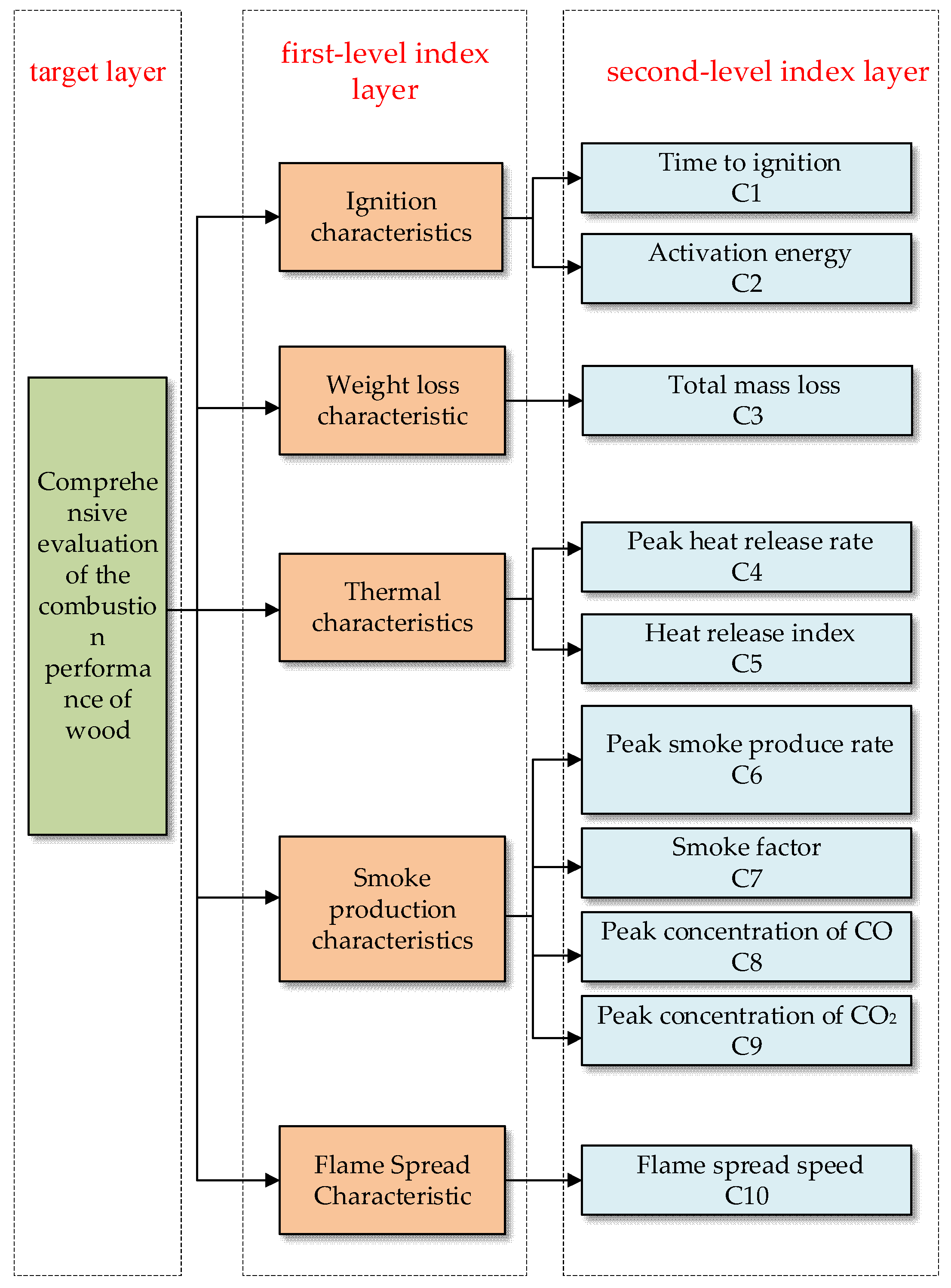

3.2.1. Comprehensive Evaluation Index System

3.2.2. Weights of Indexes

3.2.3. Evaluation of Combustion Characteristics of the Grey Correlation Method

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Zhu, J.; Qi, Q. Research on the Recyclable Design of Wooden Furniture Based on the Recyclability Evaluation. Sustainability 2023, 15, 16758. [Google Scholar] [CrossRef]

- Richter, F.; Jervis, F.X.; Huang, X.; Rein, G. Effect of oxygen on the burning rate of wood. Combust. Flame 2021, 234, 111591. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M. Evaluation of the efficiency and sustainability of timber-based construction. J. Clean. Prod. 2020, 259, 120835. [Google Scholar] [CrossRef]

- Wimmers, G. Wood: A construction material for tall buildings. Nat. Rev. Mater. 2017, 2, 17051. [Google Scholar] [CrossRef]

- Caniato, M.; Marzi, A.; da Silva, S.M.; Gasparella, A. A review of the thermal and acoustic properties of materials for timber building construction. J. Build. Eng. 2021, 43, 103066. [Google Scholar] [CrossRef]

- Alexakis, D.E. Suburban areas in flames: Dispersion of potentially toxic elements from burned vegetation and buildings. Estimation of the associated ecological and human health risk. Environ. Res. 2020, 183, 109153. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Sjöblom, J.; Ström, H. Numerical investigations of soot generation during wood-log combustion. Appl. Energy 2022, 325, 119841. [Google Scholar] [CrossRef]

- Singh, D.; Tassew, D.D.; Nelson, J.; Chalbot, M.C.G.; Kavouras, I.G.; Tesfaigzi, Y.; Demokritou, P. Physicochemical and toxicological properties of wood smoke particulate matter as a function of timber species and combustion condition. J. Hazard. Mater. 2023, 441, 129874. [Google Scholar] [CrossRef]

- BS EN 13501-1: 2018; Fire Classification of Construction Products and Building Elements. Classification Using Data from Reaction to Fire Tests. BSl Standards Publication: London, UK, 2019.

- GB 8624-2012; Classification for Burning Behavior of Building Materials and Products, General Administration of Quality Supervision, Inspection and Quarantine (AOSIQ). The Standardization Administration (SAC) of the People’s Republic of China: Beijing, China, 2012.

- Spearpoint, M.J.; Quintiere, J.G. Predicting the piloted ignition of wood in the cone calorimeter using an integral model—Effect of species, grain orientation and heat flux. Fire Saf. J. 2001, 36, 391–415. [Google Scholar] [CrossRef]

- Massuque, J.; de Sousa, K.I.R.; Trugilho, P.F. Effect of fibre and vessel biometry on wood combustibility of native Miombo tree species. South. For. 2021, 83, 269–275. [Google Scholar] [CrossRef]

- Xu, W.; Wu, X.; Wen, Q.; Li, S.; Song, Y.; Shi, B. Effects of collagen fiber addition on the combustion and thermal stability of natural rubber. J. Leather Sci. Eng. 2020, 2, 27. [Google Scholar] [CrossRef]

- Islam, M.T.; Reza, M.T. Evaluation of fuel and combustion properties of hydrochar derived from Co-hydrothermal carbonization of biomass and plastic. Biomass Bioenergy 2023, 172, 106750. [Google Scholar] [CrossRef]

- Renner, J.-S.; Mensah, R.-A.; Jiang, L.; Xu, Q. A critical assessment of the fire properties of different wood species and bark from small-and bench-scale fire experiments. J. Therm. Anal. Calorim. 2023, 148, 1423–1434. [Google Scholar] [CrossRef]

- Hansen-Bruhn, I.; Hull, T.R. Flammability and burning behaviour of fire protected timber. Fire Saf. J. 2023, 140, 103918. [Google Scholar] [CrossRef]

- Zhang, J.-Q.; Huang, D.-Y.; Luo, S.; Huang, Y.-B.; Guo, Y.; Liu, R.; Ding, Y. Assessment of micro-scale thermal behaviors and combustion performance of organic fireproof plugging material in air atmosphere. J. Vinyl Addit. Technol. 2022, 28, 788–798. [Google Scholar] [CrossRef]

- Zhu, H.-M.; He, D.-L.; Duan, H.; Yin, H.; Chen, Y.-F.; Chao, X.; Zhang, X.-M.; Gong, H.-F. Study on coupled combustion behaviors and kinetics of plastic pyrolysis by-product for oil. Energy 2023, 262, 125452. [Google Scholar] [CrossRef]

- Li, Y.-C.; Wang, Y.-L.; Wang, J.-F.; Cui, S.-P.; Li, Z.-M.; Meng, W.-Y. Research on coal combustion catalysts for cement kiln via comprehensive evaluation method based on combustion characteristics. Case Stud. Therm. Eng. 2023, 50, 103440. [Google Scholar] [CrossRef]

- Janković, B.; Dodevski, V. The combustion performances and thermo-oxidative degradation kinetics of plane tree seeds (PTS) (Platanus orientalis L.). Energy 2018, 154, 308–318. [Google Scholar] [CrossRef]

- Wang, W.-F.; Huo, Y.-H.; Kang, F.; Ren, H.; Wang, Z.-X.; Yang, B. Comprehensive evaluation of mine cable fire hazards based on entropy weight-grey correlation method. J. Therm. Anal. Calorim. 2023, 148, 4843–4851. [Google Scholar] [CrossRef]

- Manoj, T.; Ranga, C.; Abu-Siada, A.; Ghoneim, S.S. Analytic Hierarchy Processed Grey Relational Fuzzy Approach for Health Assessment of Power Transformers. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 1480–1489. [Google Scholar] [CrossRef]

- Qi, Y.; Xue, K.-L.; Wang, W.; Cui, X.-C.; Liang, R.; Wu, Z.-W. Coal and gas protrusion risk evaluation based on cloud model and improved combination of assignment. Sci. Rep. 2024, 14, 4551. [Google Scholar] [CrossRef]

- ISO 5660-1:2015; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate. Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). The International Organization for Standardization (ISO): Geneva, Switzerland, 2015.

- Ma, L.; Zuo, Z.; Zhao, B.; Li, L. Weight Calculation of GSM-R Network Quality of Service Evaluation Indexes Based on Analytic Hierarchy Process and Entropy Weight Method. In Proceedings of the 2020 International Symposium on Automation, Information and Computing (ISAIC 2020), Beijing, China, 2–4 December 2020. [Google Scholar]

- Chen, Y.-L.; Shen, S.-L.; Zhou, A.-N. Assessment of red tide risk by integrating CRITIC weight method, TOPSIS-ASSETS method, and Monte Carlo simulation. Environ. Pollut. 2022, 314, 120254. [Google Scholar] [CrossRef]

- Gao, Z.; Ma, D.; Guo, X.; Wang, W.; Wang, Z. The comprehensive assessment method of concrete damage after disastrous fire based on game theory-normal cloud model. Math. Probl. Eng. 2019, 2019, 5159497. [Google Scholar] [CrossRef]

- Shi, D.-C.; Guo, Y.-J.; Gu, X.-X.; Feng, G.-Z.; Xu, Y.; Sun, S. Evaluation of the ventilation system in an LNG cargo tank construction platform (CTCP) by the AHP-entropy weight method. Build. Simul. 2022, 15, 1277–1294. [Google Scholar] [CrossRef]

- Wan, Q.; Yu, Y. Power load pattern recognition algorithm based on characteristic index dimension reduction and improved entropy weight method. Energy Rep. 2020, 6, 797–806. [Google Scholar] [CrossRef]

- Chen, Z. Port logistics function evaluation model based on entropy weight TOPSIS method. Discret. Dyn. Nat. Soc. 2022, 2022, 5006900. [Google Scholar] [CrossRef]

- Haktanir, E.; Kahraman, C. A Novel CRITIC Based Weighted FMEA Method: Application to COVID-19 Blood Testing Process. J. Mult.-Valued Log. Soft Comput. 2021, 37, 247–275. [Google Scholar]

- Zhang, Q.; Liu, C.; Guo, S.; Wang, W.; Luo, H.; Jiang, Y. Evaluation of the rock burst intensity of a Cloud Model based on the CRITIC method and the Order Relation Analysis Method. Min. Metall. Explor. 2023, 40, 1849–1863. [Google Scholar] [CrossRef]

- Han, X.; Zhao, S.; Wei, Z.; Bai, W. Planning and overall economic evaluation of photovoltaic-energy storage station based on game theory and analytic hierarchy process. IEEE Access 2019, 7, 110972–110981. [Google Scholar] [CrossRef]

- Ju, W.; Wu, J.; Kang, Q.; Jiang, J.; Xing, Z. Fire risk assessment of subway stations based on combination weighting of game theory and topsis method. Sustainability 2022, 14, 7275. [Google Scholar] [CrossRef]

- Ren, S.-J.; Wang, C.-P.; Xiao, Y.; Deng, J.; Tian, Y.; Song, J.-J.; Cheng, X.-J.; Sun, G.-F. Thermal properties of coal during low temperature oxidation using a grey correlation method. Fuel 2020, 260, 116287. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, M.; Yang, Z.; Liu, Y.; Yu, J. Exothermic characteristics of coal during low-temperature oxidation based on grey correlation method. Energy Rep. 2022, 8, 6744–6752. [Google Scholar] [CrossRef]

- Wang, S.-S.; Zou, C.; Yang, H.-P.; Lou, C.; Cheng, S.-Z.; Peng, C.; Wang, C.; Zou, H.-R. Effects of cellulose, hemicellulose, and lignin on the combustion behaviours of biomass under various oxygen concentrations. Bioresour. Technol. 2021, 320, 124375. [Google Scholar] [CrossRef]

- Hu, J.; Jiang, X.-X. Pyrolysis characteristics and kinetics of lignin: Effect of starting lignins. Energy Sources Part A 2022, 44, 8096–8108. [Google Scholar] [CrossRef]

- Hao, H.-L.; Tam, L.H.; Lu, Y.; Lau, D. An atomistic study on the mechanical behavior of bamboo cell wall constituents. Compos. Part B 2018, 151, 222–231. [Google Scholar] [CrossRef]

- Elmay, Y.; Jeguirim, M.; Trouvé, G.; Said, R. Kinetic analysis of thermal decomposition of date palm residues using Coats–Redfern method. Energy Sources Part A 2016, 38, 1117–1124. [Google Scholar] [CrossRef]

- Huang, X.-J.; Mo, W.-L.; Ma, Y.-Y.; He, C.-Q.; Syls, Y.; Wei, X.-Y.; Fan, X.; Yang, X.-Q.; Zhang, S.-P. Pyrolysis kinetic analysis of sequential extract residues from Hefeng subbituminous coal based on the Coats-Redfern method. ACS Omega 2022, 7, 21397–21406. [Google Scholar] [CrossRef]

- Chen, L.; Hu, J.; Han, Q.; Xie, A.-Q.; Zhou, Z.; Yang, Z.-K.; Tang, Q.-W.; Mi, B.-B.; Wu, F.-F. Application of distributed activation energy model and Coats-Redfern integration method in the study of industrial lignin pyrolysis kinetics. Biomass Convers. Biorefinery 2022, 1–11. [Google Scholar] [CrossRef]

- Sanned, E.; Mensah, R.A.; Försth, M.; Das, O. The curious case of the second/end peak in the heat release rate of wood: A cone calorimeter investigation. Fire Mater. 2023, 47, 498–513. [Google Scholar] [CrossRef]

- Ngohe-Ekam, P.S.; Meukam, P.; Menguy, G.; Girard, P. Thermophysical characterisation of tropical wood used as building materials: With respect to the basal density. Constr. Build. Mater. 2006, 20, 929–938. [Google Scholar] [CrossRef]

- Wang, E.; Shi, Z.; Chen, M.; Tang, S.; Zhang, X.; Zhang, W. Investigation of effective thermal conductivity of SIC foam ceramics with various pore densities. Open Phys. 2022, 20, 58–65. [Google Scholar] [CrossRef]

- Shen, Z.; Zhao, Q.; Fang, Q. Analysis of green traffic development in Zhoushan based on entropy weight TOPSIS. Sustainability 2021, 13, 8109. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Q.; Wang, L.; Liang, L. Regional environmental efficiency in China: An empirical analysis based on entropy weight method and non-parametric models. J. Clean. Prod. 2020, 276, 124147. [Google Scholar] [CrossRef]

| Sample | Density (g/cm3) | Moisture Content (%) |

|---|---|---|

| Chinese fir | 0.290 | 6.95 |

| Pine | 0.533 | 6.02 |

| Elm | 0.635 | 6.32 |

| Plywood | 0.545 | 6.35 |

| Density board | 0.658 | 6.90 |

| OSB | 0.566 | 5.98 |

| Sample | TTI(s) | HRRpeak (kW/m2) | HRI |

|---|---|---|---|

| Chinese fir | 9 | 135.13 | 1.90 |

| Pine | 17 | 180.10 | 1.99 |

| Elm | 21 | 251.71 | 1.94 |

| plywood | 35 | 247.18 | 1.92 |

| Density board | 19 | 210.68 | 1.95 |

| OSB | 17 | 186.79 | 2.02 |

| Sample | SPRpeak (m2/s) | Peak Concentration of CO (%) | Peak Concentration of CO2 (%) | SF (kW/m2) |

|---|---|---|---|---|

| Chinese fir | 0.023700 | 0.012 | 0.277 | 24.95 |

| Pine | 0.013200 | 0.008 | 0.350 | 49.17 |

| Elm | 0.028300 | 0.017 | 0.586 | 80.12 |

| Plywood | 0.027200 | 0.009 | 0.521 | 67.99 |

| Density board | 0.028400 | 0.021 | 0.474 | 64.12 |

| OSB | 0.028084 | 0.009 | 0.394 | 104.34 |

| Index Factors | Ej | 1-Ej | Weight |

|---|---|---|---|

| C1 | 0.8451 | 0.1549 | 0.0836 |

| C2 | 0.8646 | 0.1354 | 0.0730 |

| C3 | 0.8238 | 0.1762 | 0.0951 |

| C4 | 0.7864 | 0.2136 | 0.1152 |

| C5 | 0.8653 | 0.1365 | 0.0737 |

| C6 | 0.5151 | 0.4849 | 0.2616 |

| C7 | 0.8655 | 0.1345 | 0.0726 |

| C8 | 0.8716 | 0.1284 | 0.0693 |

| C9 | 0.8432 | 0.1568 | 0.0846 |

| C10 | 0.8679 | 0.1321 | 0.0713 |

| Index Factors | Rj | Cj | Weight | |

|---|---|---|---|---|

| C1 | 0.329 | 9.191 | 3.022 | 0.0852 |

| C2 | 0.320 | 10.791 | 3.457 | 0.0975 |

| C3 | 0.400 | 11.038 | 4.411 | 0.1244 |

| C4 | 0.379 | 9.187 | 3.484 | 0.0983 |

| C5 | 0.371 | 9.492 | 3.526 | 0.0995 |

| C6 | 0.392 | 8.948 | 3.509 | 0.0990 |

| C7 | 0.340 | 9.147 | 3.109 | 0.0877 |

| C8 | 0.403 | 8.677 | 3.498 | 0.0987 |

| C9 | 0.371 | 9.588 | 3.554 | 0.1002 |

| C10 | 0.376 | 10.327 | 3.879 | 0.1094 |

| Sample | Ri | Sample | Ri |

|---|---|---|---|

| Chinese fir | 0.8568 | Plywood | 0.8087 |

| Pine | 0.8696 | Density board | 0.8122 |

| Elm | 0.7909 | OSB | 0.8425 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Z.; Song, J.; Xu, L.; Zhang, H. Evaluating the Combustion Performance of the Usual Timbers in Furniture Using a Grey Correlation Method Based on Thermolysis, Ignition, and Flame Spread. Fire 2024, 7, 218. https://doi.org/10.3390/fire7070218

Yu Z, Song J, Xu L, Zhang H. Evaluating the Combustion Performance of the Usual Timbers in Furniture Using a Grey Correlation Method Based on Thermolysis, Ignition, and Flame Spread. Fire. 2024; 7(7):218. https://doi.org/10.3390/fire7070218

Chicago/Turabian StyleYu, Zhijin, Jiani Song, Lan Xu, and Hao Zhang. 2024. "Evaluating the Combustion Performance of the Usual Timbers in Furniture Using a Grey Correlation Method Based on Thermolysis, Ignition, and Flame Spread" Fire 7, no. 7: 218. https://doi.org/10.3390/fire7070218

APA StyleYu, Z., Song, J., Xu, L., & Zhang, H. (2024). Evaluating the Combustion Performance of the Usual Timbers in Furniture Using a Grey Correlation Method Based on Thermolysis, Ignition, and Flame Spread. Fire, 7(7), 218. https://doi.org/10.3390/fire7070218