Arc Ignition Methods and Combustion Characteristics of Small-Current Arc Faults in High-Voltage Cables

Abstract

1. Introduction

2. Test Method for Small-Current Arc Ignition

2.1. Moving Electrode Ignition Method

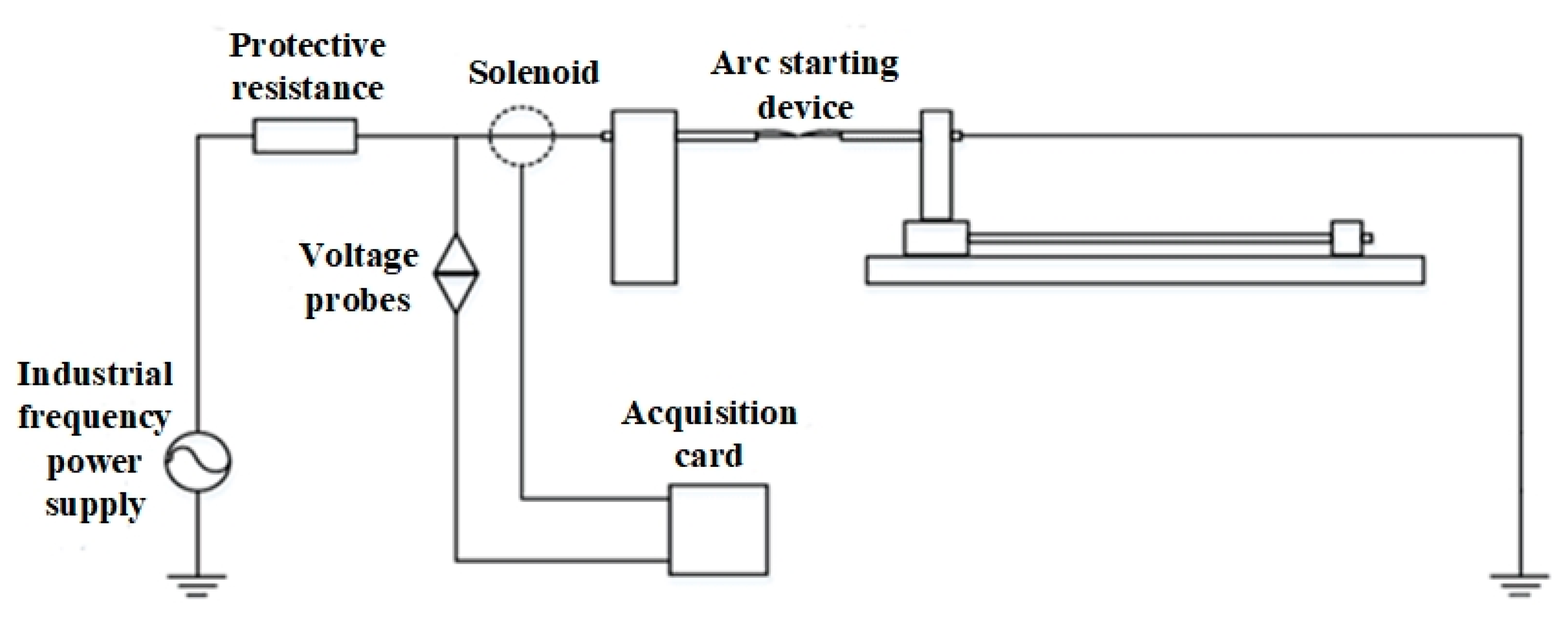

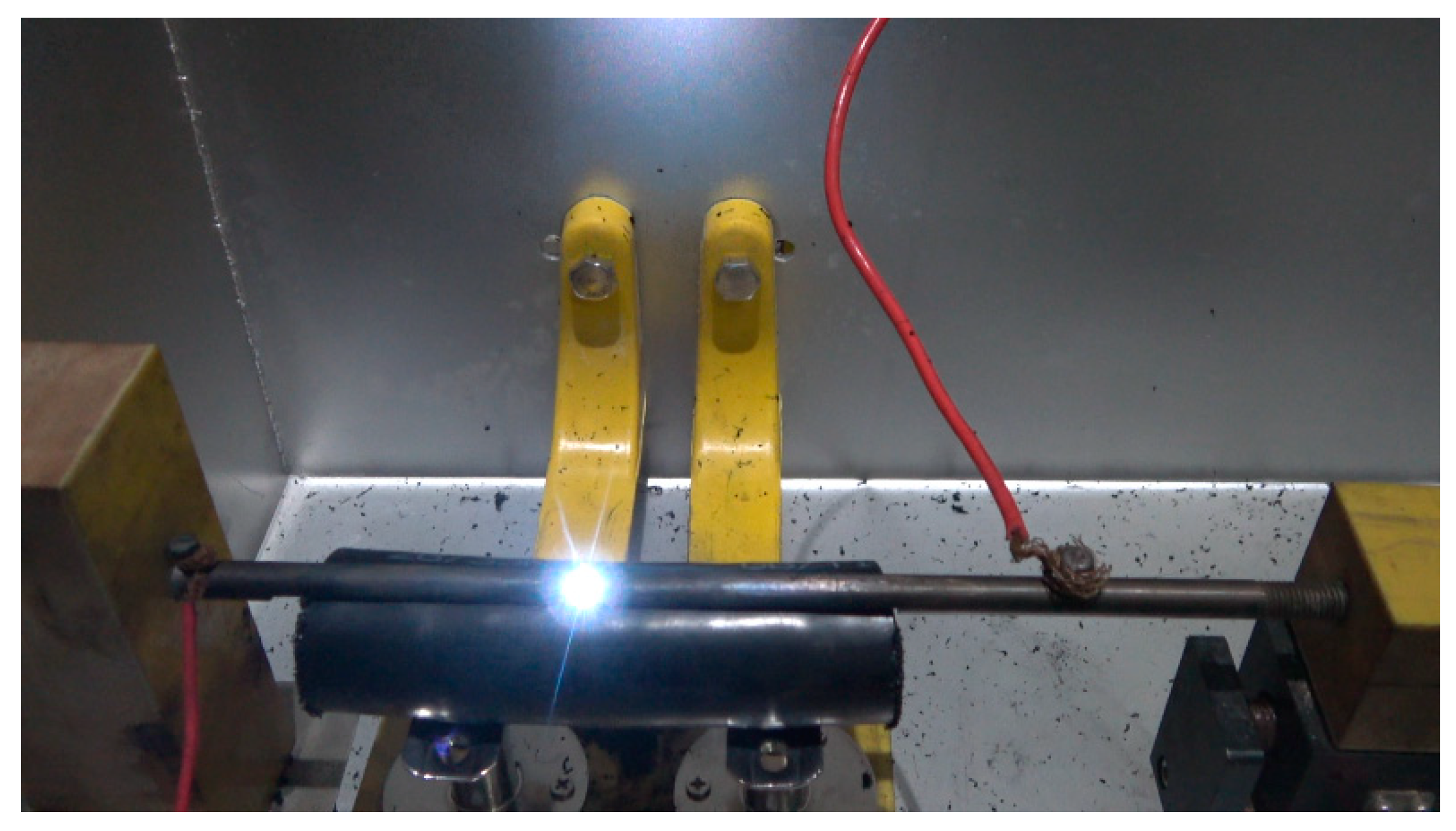

2.1.1. Building the Test Platform

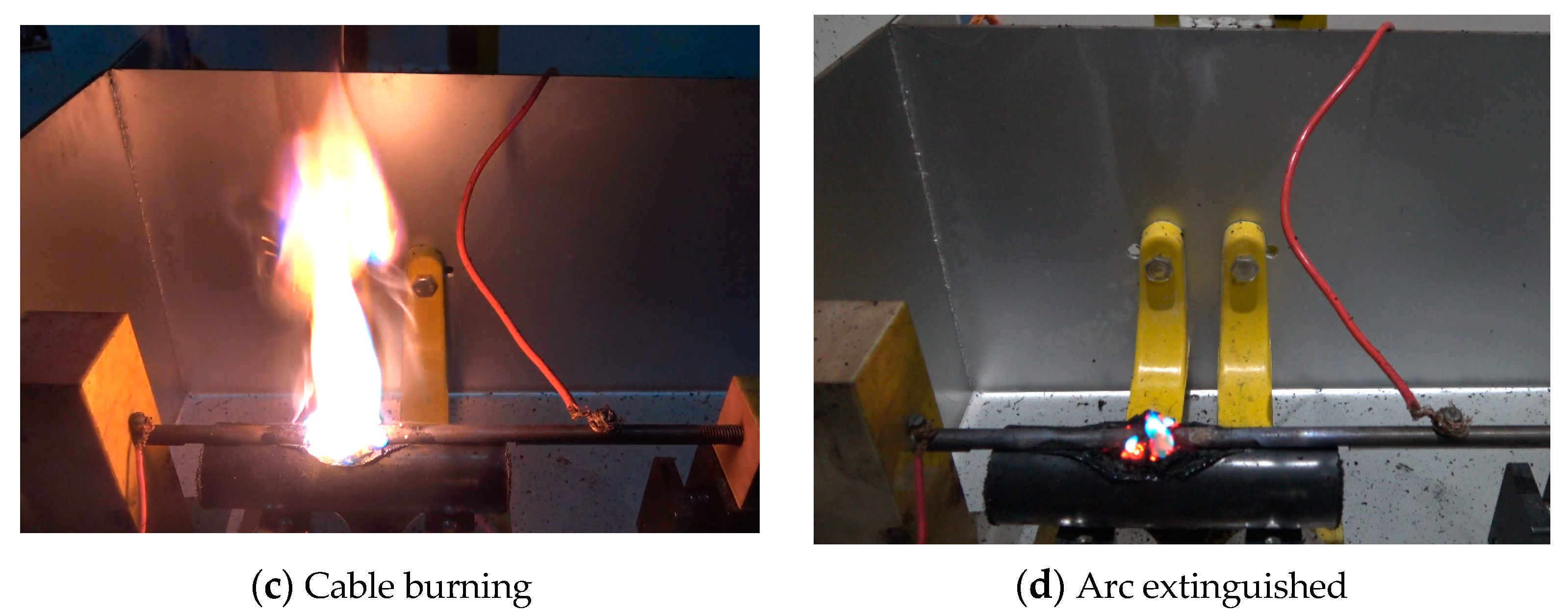

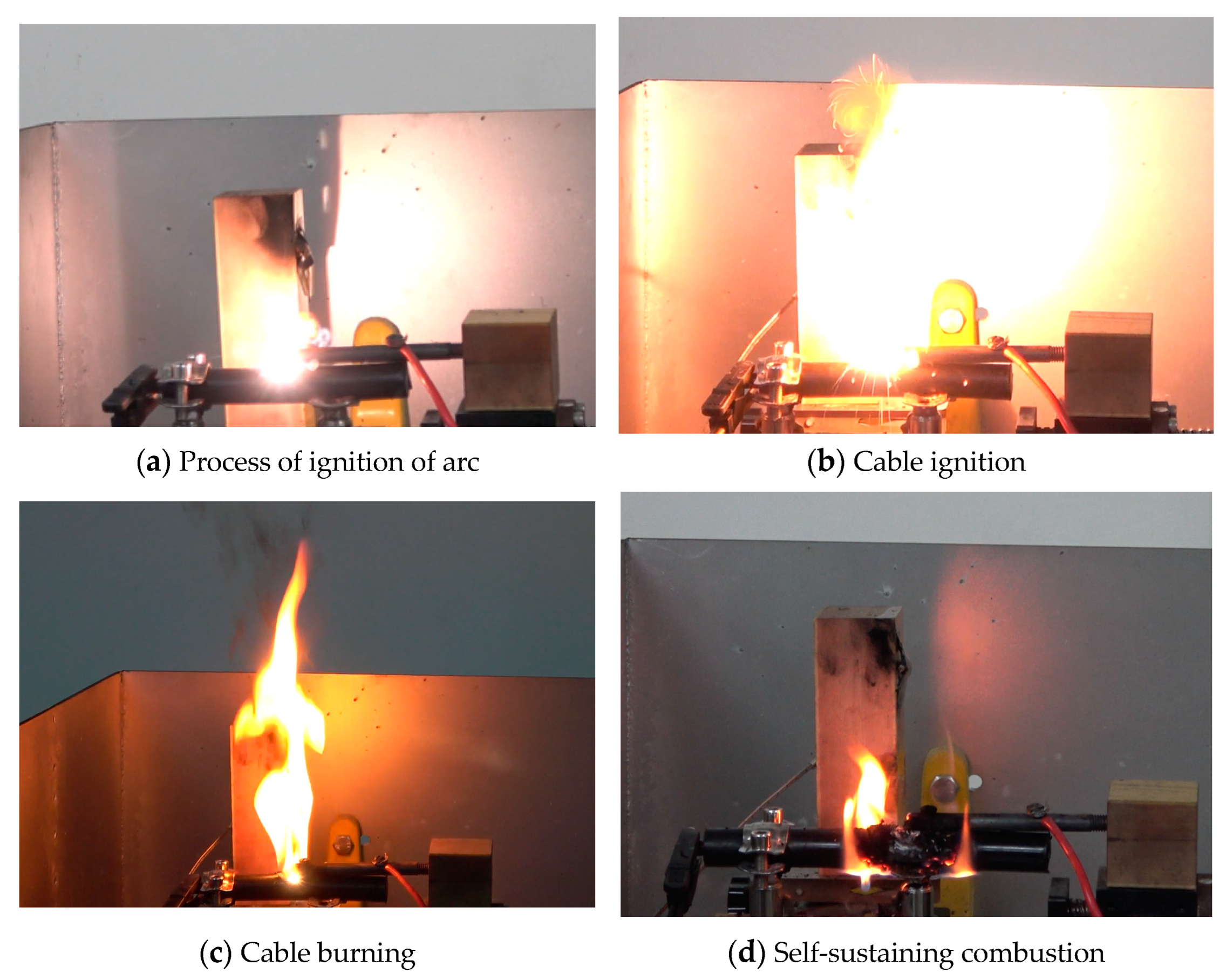

2.1.2. Realisation of Continuous Arc Ignition and Cable Ignition Processes

2.2. Fuse Melting Ignition Method

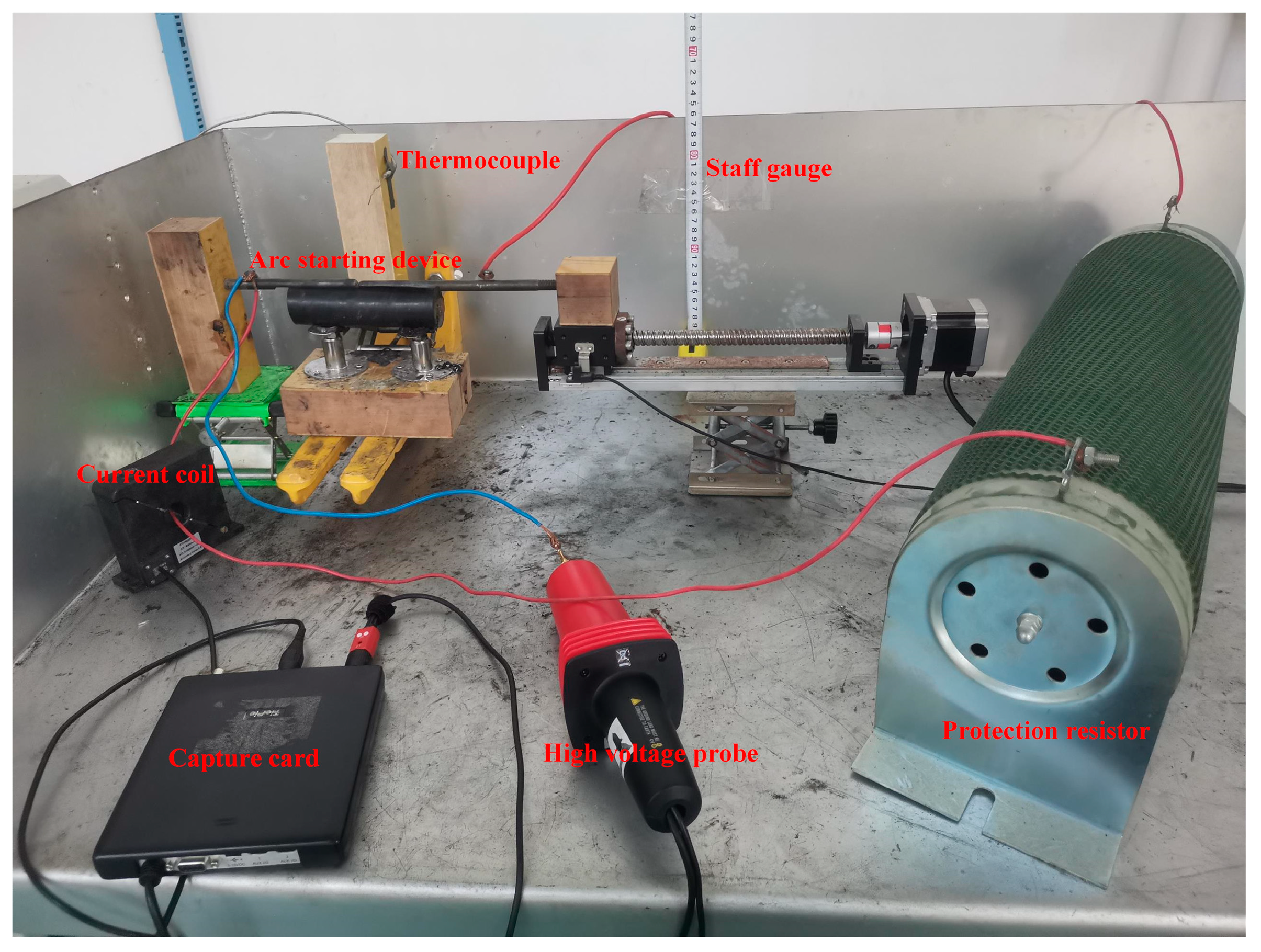

2.2.1. Building a Test Platform

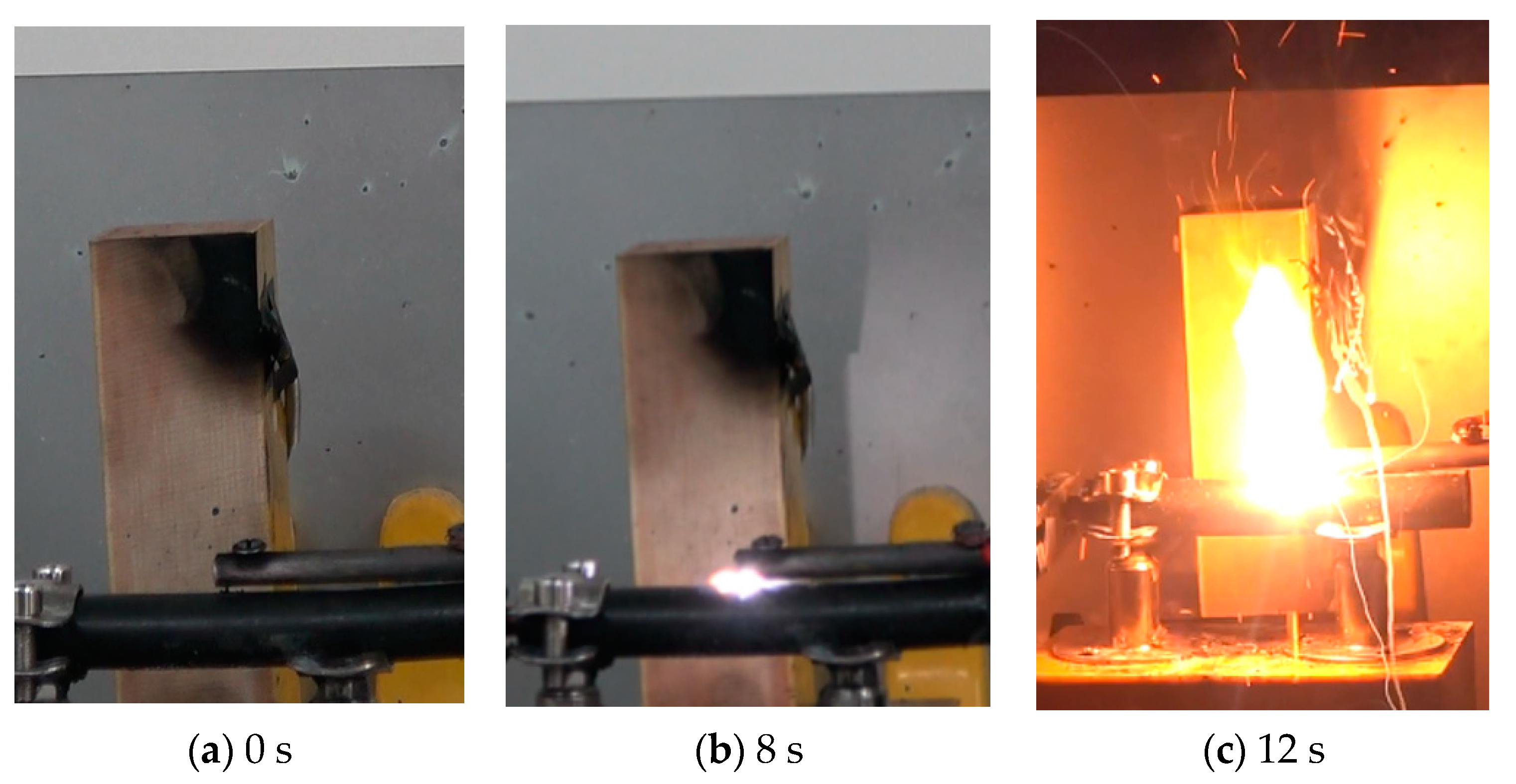

2.2.2. Realization of Continuous Arc Ignition and Cable Ignition Processes

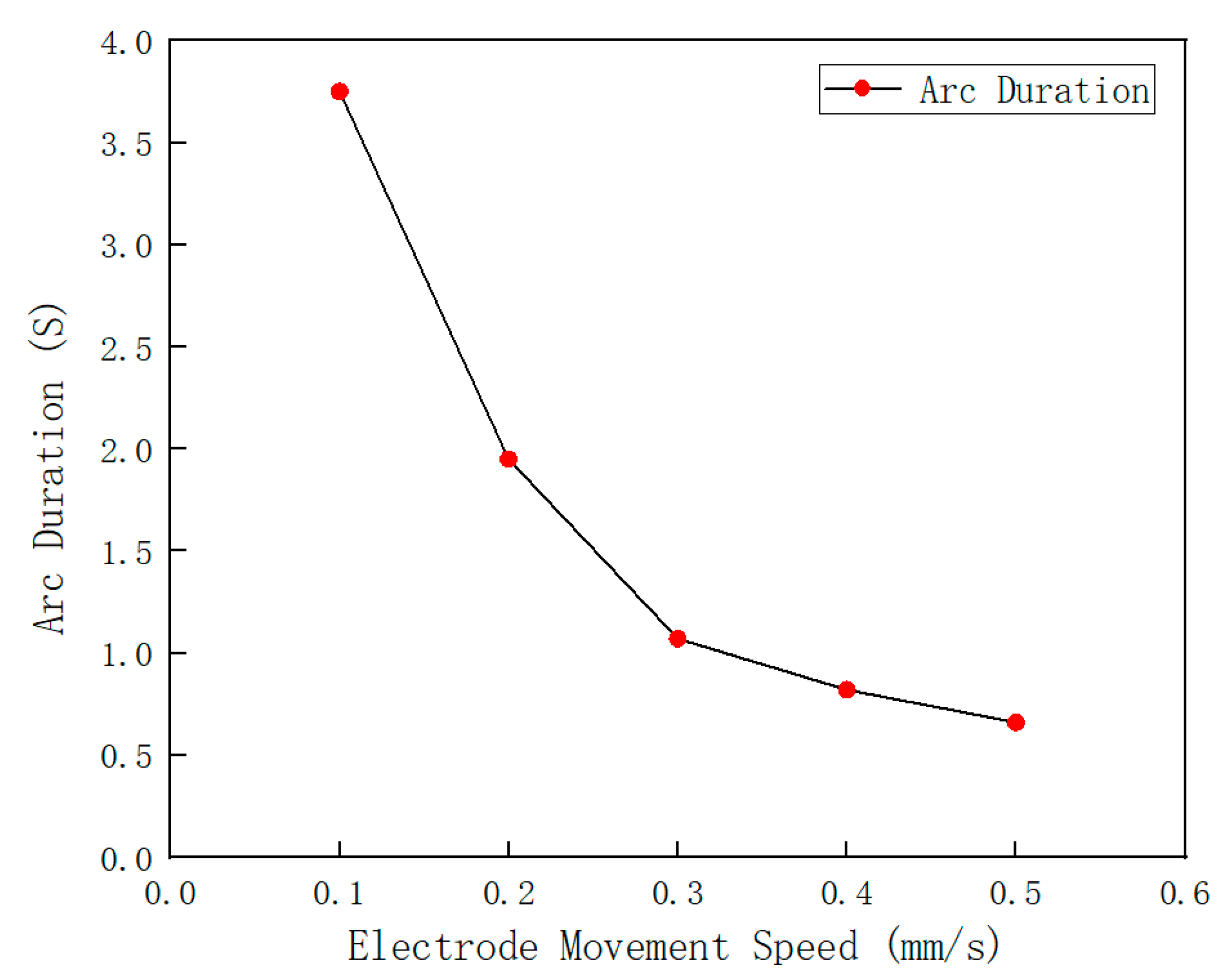

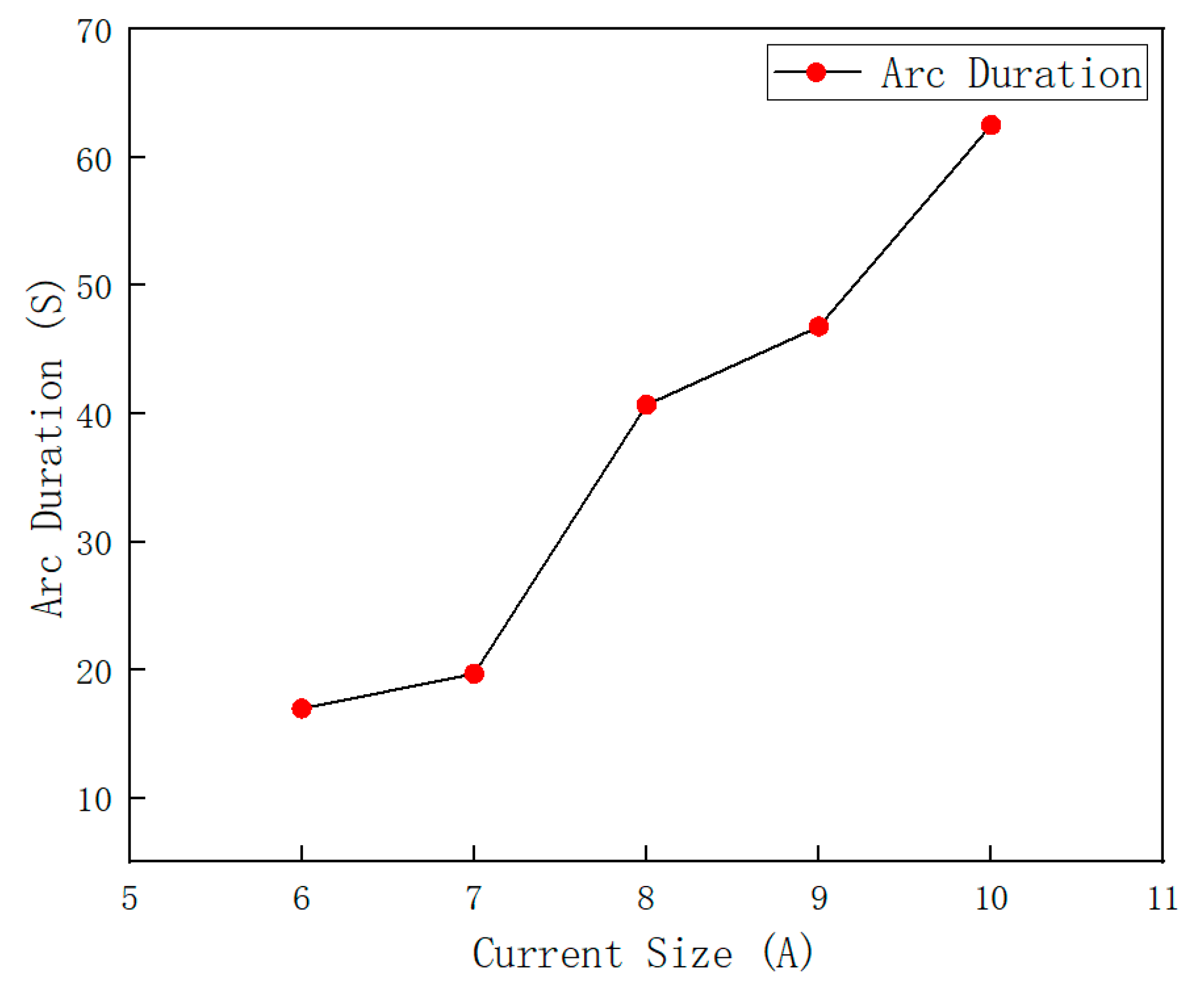

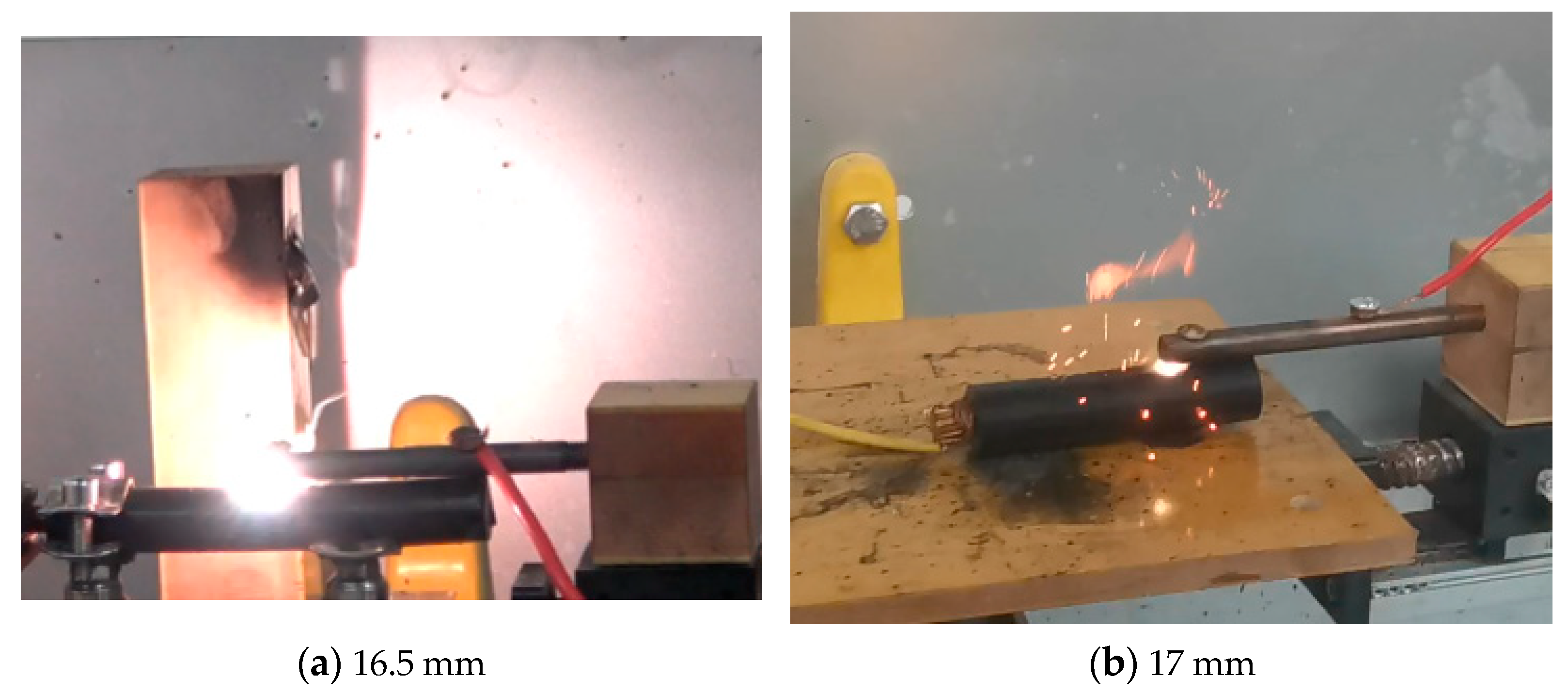

2.3. Analysis of Ignition Effects under Two Methods

3. Analysis of Arc Waveform Characteristics and Ignition Characteristics

3.1. Arc Ignition Conditions

- (1)

- Multiple sets of cable test samples with a length of 15 cm and a diameter of 4.5 cm were prepared. The main materials for the cable sample from the outside to the inside were insulation layer and copper conductor.

- (2)

- A hole defect of about 5 mm was manufactured on the cable insulation layer. According to the data in Table 3, the corresponding specifications of lead wire were selected based on the current situation, and the lead wire was used to short-circuit the metal conductor inside the hole with the external grounding electrode. The ambient temperature was 33 °C, and the humidity was 43%. A thermocouple 7.5 cm was placed directly above the cable. The environment was open and windless.

- (3)

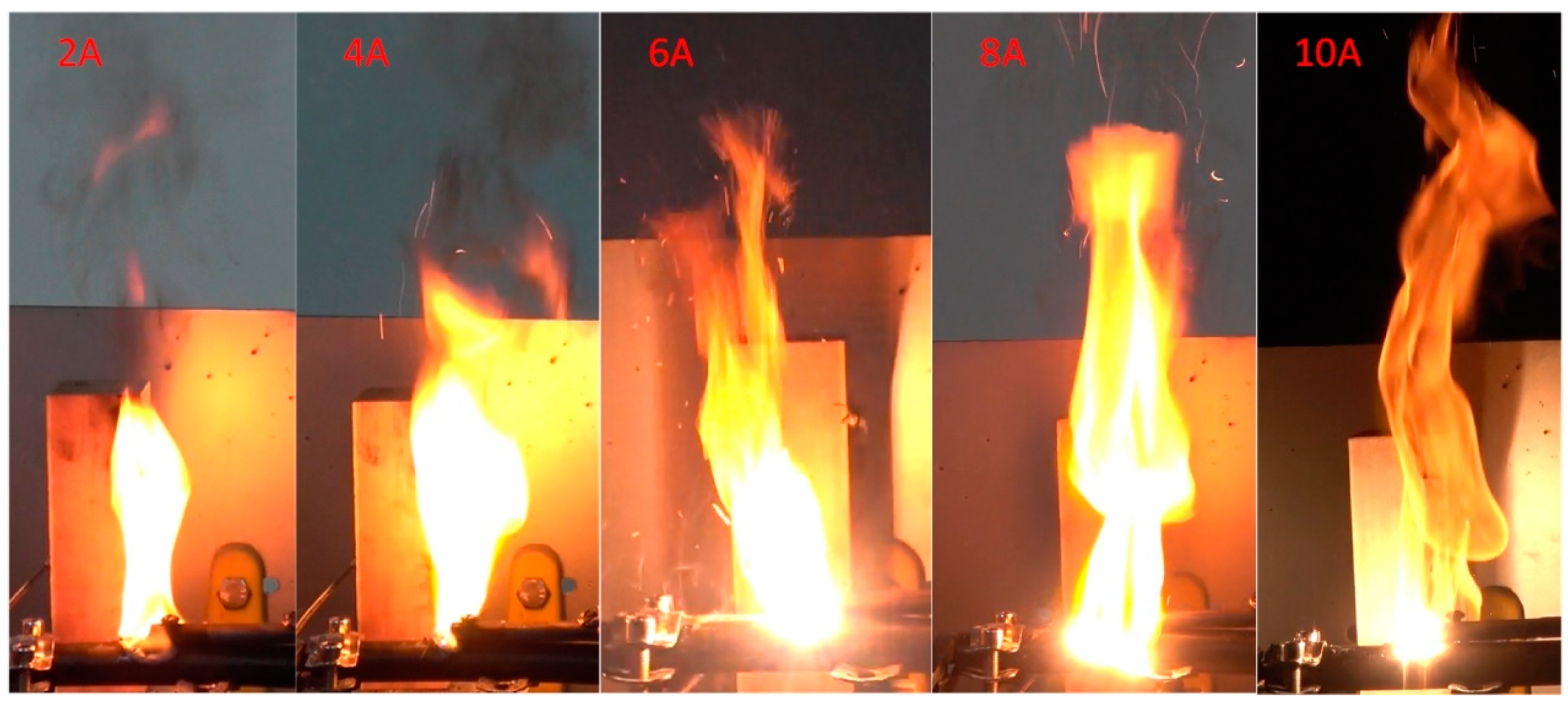

- Five current conditions (2 A, 4 A, 6 A, 8 A, and 10 A) were selected to conduct ignition tests on cables. An arc is generated between the metal conductor of the cable and the grounding electrode after the fuse is blown, and the arc continues to act on the cable hole position. The ignition arc times of cables under several current conditions were determined through experimental phenomena.

- (4)

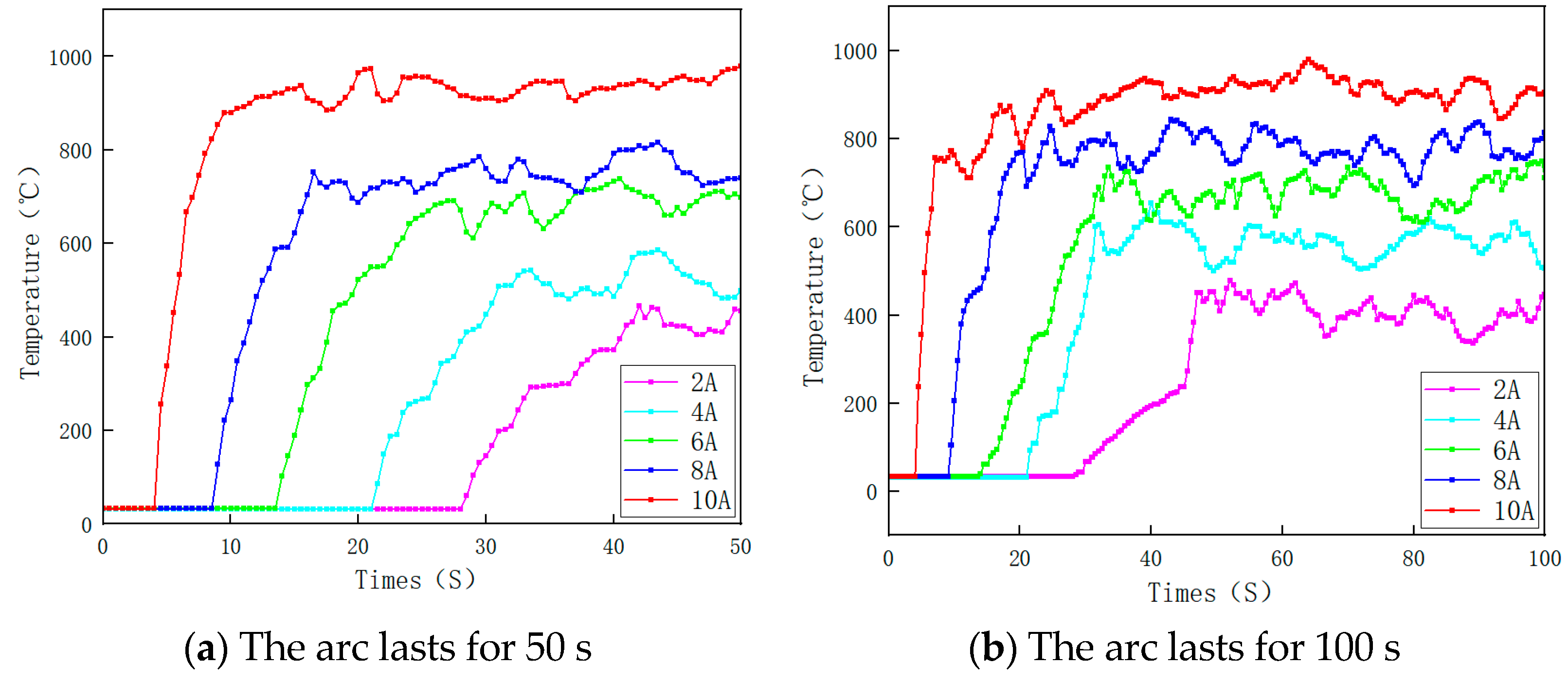

- Under these five current conditions, two different arcing durations were selected to carry out cable ignition tests under different currents and arcing durations. The flame height, flame temperature, arc voltage, and current waveform characteristics during the combustion process after cable ignition and the spontaneous combustion of the cable after arc extinction were obtained. The ignition and combustion characteristics under different currents and arc durations were analyzed.

3.2. Cable Ignition and Combustion Characteristics

- (1)

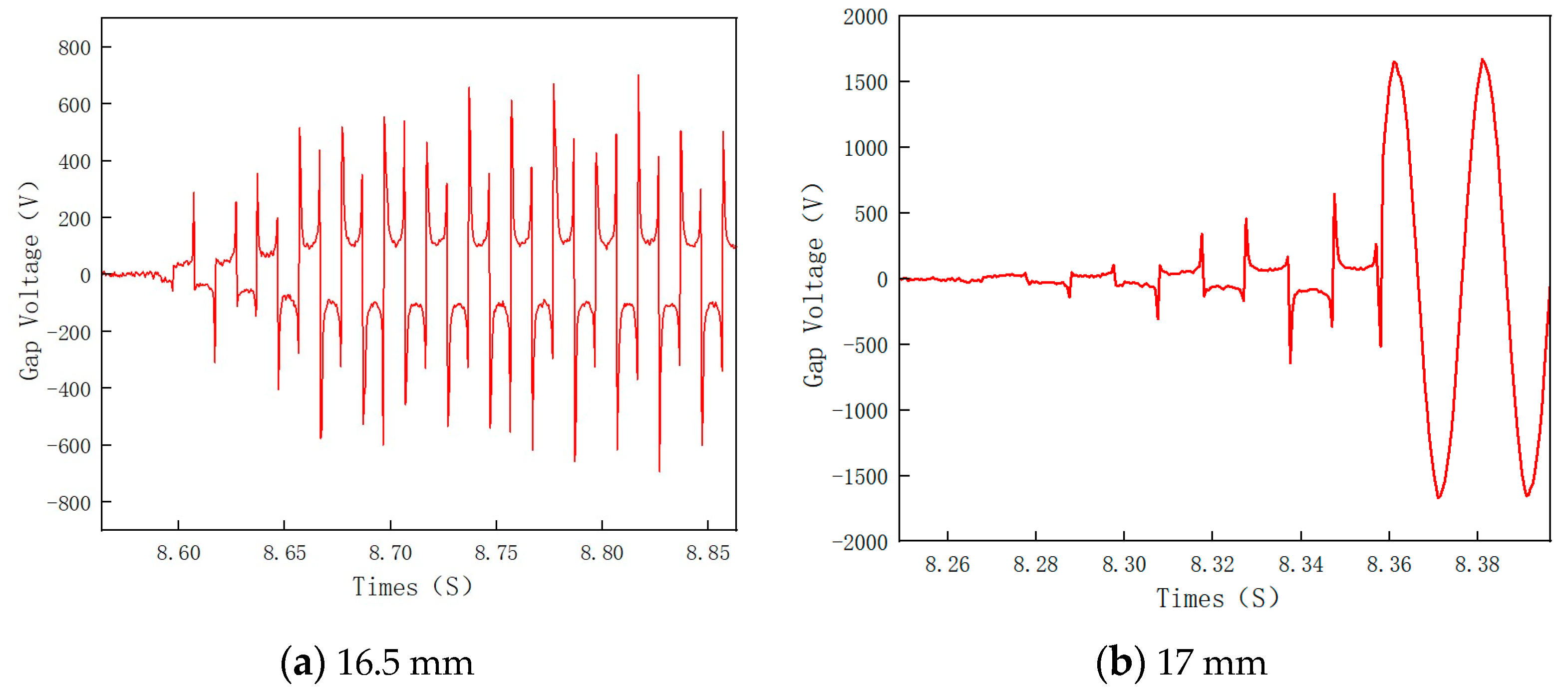

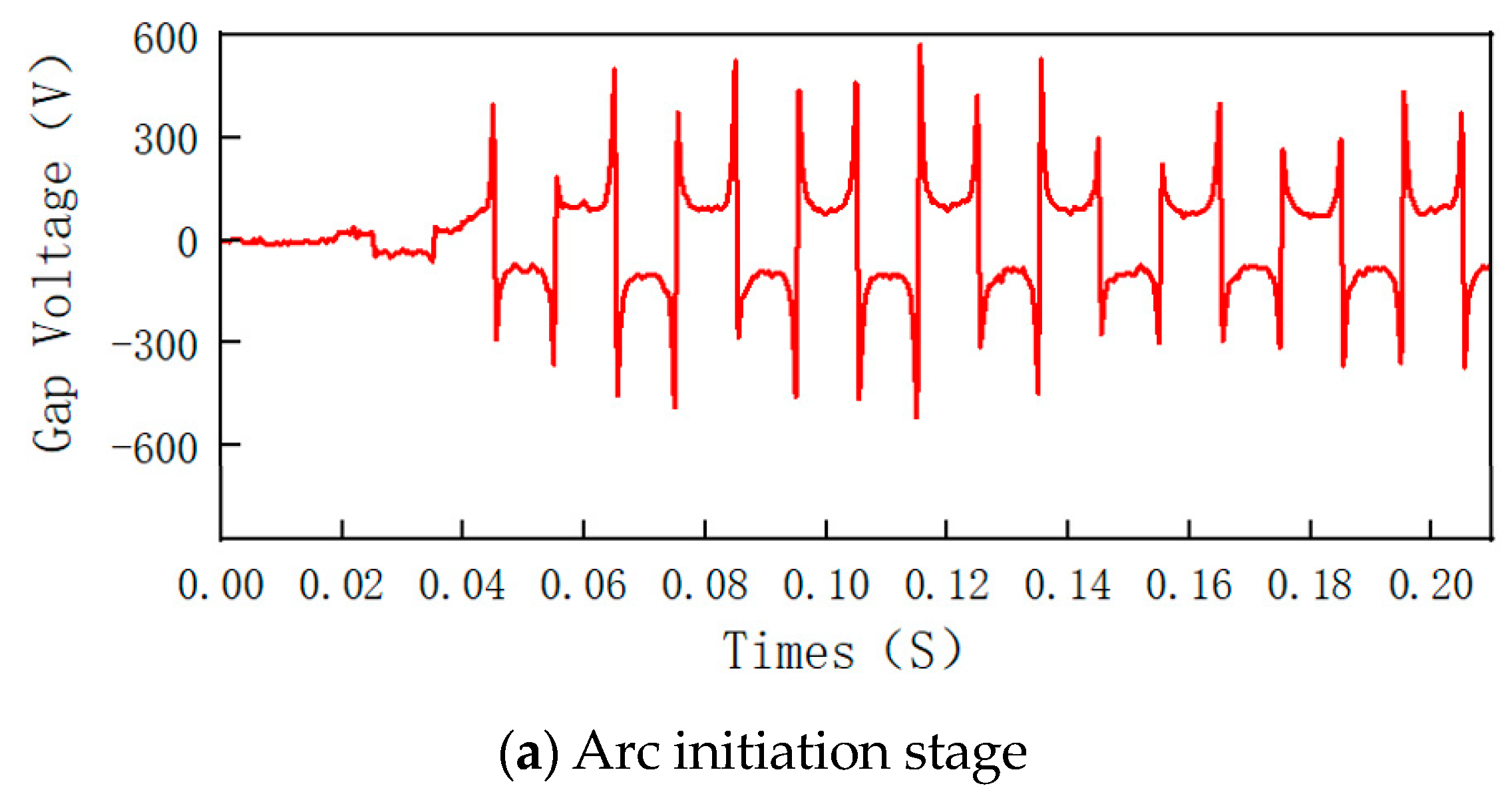

- Characteristics of arc voltage waveform

- (2)

- Cable ignition time

- (3)

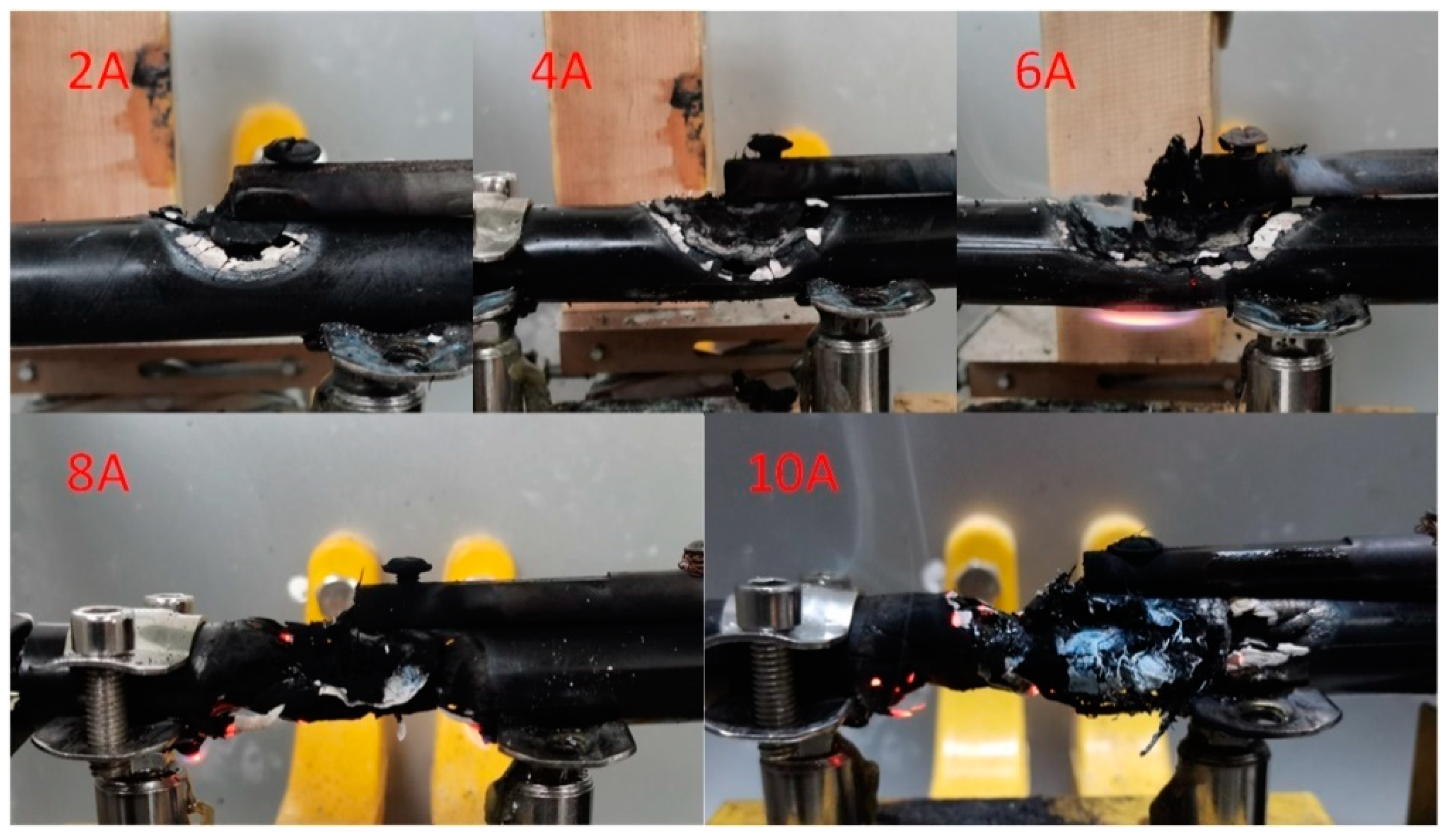

- Cable burning degree

- (4)

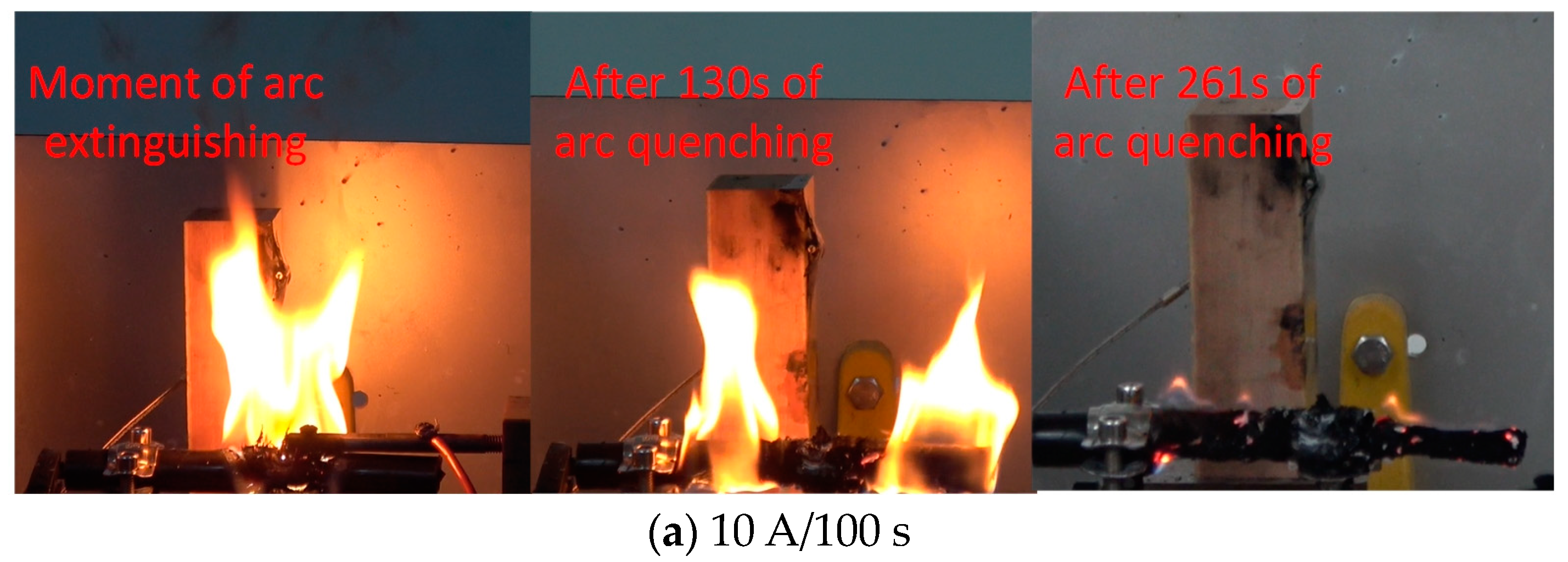

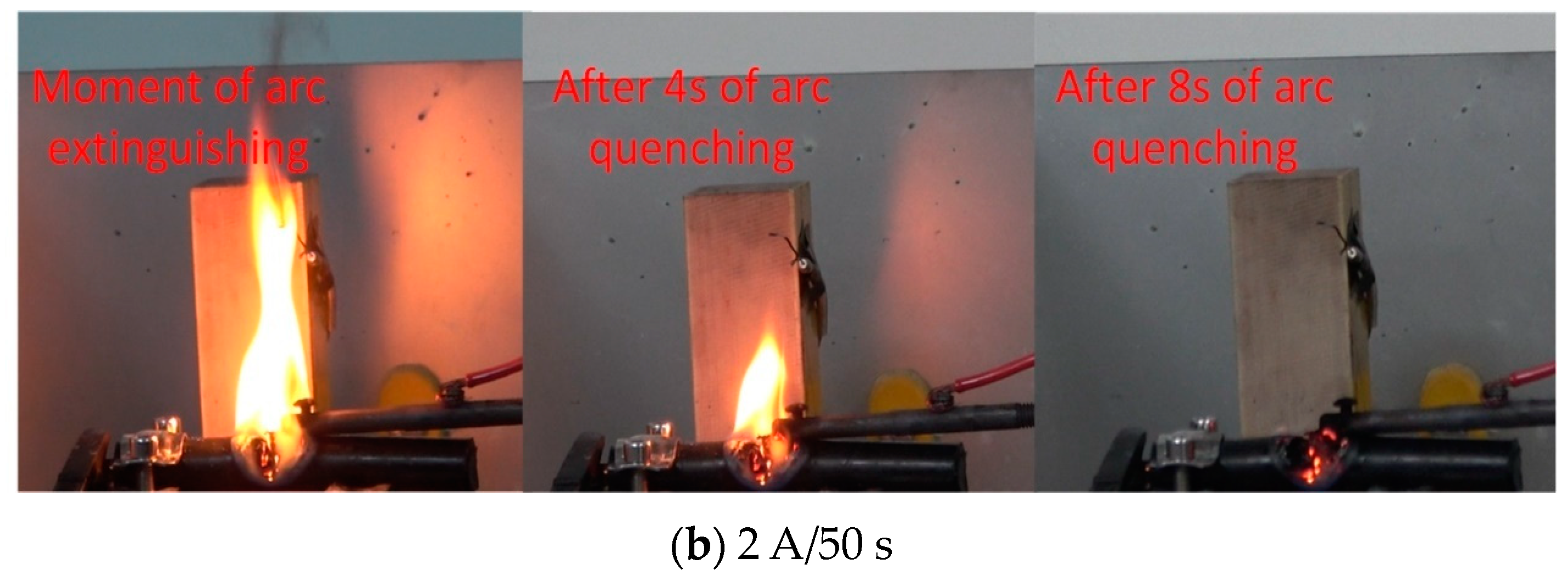

- Cable self-sustaining combustion

4. Conclusions

- (1)

- The moving electrode method can achieve long-distance arc ignition when the current is small. By controlling the moving speed of the electrode, it can be ensured that the arc will not be interrupted during the movement of the electrode. This method is suitable for simulating the ignition situation of cable outer sheath damage. The test operation of the fuse melting method is relatively simple and does not require moving electrodes. The arc burning process is stable. This method is suitable for simulating the arc ignition situation of single-phase breakdown of the insulation layer.

- (2)

- After improving the fuse melting ignition method, arc ignition tests under five current conditions were carried out on the cable body sample. Under the continuous action of the arc under five different working conditions of 2 A, 4 A, 6 A, 8 A, and 10 A, the time of cable ignition is 28 s, 21 s, 14 s, 9 s, and 4 s, respectively.

- (3)

- The flame height and the burning time of the cable under the action of the arc are positively correlated with the current and the arcing time. The flame temperature changes with the current when the cable burns. When the current rises to 10 A and the arcing time reaches 100 s, the maximum height of flame combustion can reach 63 cm, and the maximum temperature can reach 979 °C. After the cable is burned for 261 s, the whole cable sample is completely ablated. The ignition characteristics of the cable under several different current conditions from 2 A to 10 A obtained in this paper, combined with the actual fault record data, can provide a reference for judging whether it is necessary to remove the fault within a certain period of time so as to avoid the cable burning after a long-term operation fault, causing more serious short-circuit or fire accidents.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, W. Fault Locating Method for 110 kV Cable Sheath and Preventive Measures. Sci. Technol. Vis. 2015, 5, 305–306. [Google Scholar]

- Wang, E.; Chen, X.; Zhang, T.; Yin, K.; Paramane, A. Fault current calculation and grounding scattering optimization of 220 kV tunnel cable systems. Electr. Power Syst. Res. 2024, 232, 110417. [Google Scholar] [CrossRef]

- Kuai, S.; Li, N.; Zheng, W.; Tong, J.; Zhao, F.; Xu, L.; Qi, Z. Experimental study on electric fire based on nitrogen injection technology. J. Phys. Conf. Ser. 2023, 2656, 012008. [Google Scholar] [CrossRef]

- Yu, F.; Wang, S.; Tang, K.; Lin, Y.; Wang, S.; Zhang, Y. Research Progress on the Fire Characteristics of Electric Cables and Wires. Fire 2024, 7, 186. [Google Scholar] [CrossRef]

- Jung, B.Y.; Je, S.M.; Lee, H.G.; Kim, H.S.; Park, J.Y.; Oh, B.Y.; Park, J.W.; Huh, J.H.; Lee, J.H. Enhanced Anti-Freezing Heating Cable Standard for Fire Prevention. Fire 2022, 5, 216. [Google Scholar] [CrossRef]

- Sun, W.; Gao, H.; Li, C. High-performance real-time fire detection and forecasting framework for industrial cables. Fire Saf. J. 2024, 148, 104228. [Google Scholar] [CrossRef]

- Zhou, H.; Yu, H.; Zou, Z.; Su, Z.; Zhao, Q.; Yang, W.; He, C. Evaluation of Single Event Upset on a Relay Protection Device. Electronics 2023, 13, 64. [Google Scholar] [CrossRef]

- Liu, D.; Hao, C. Research on Accurate Fault Location of Small Current Grounding System. J. Phys. Conf. Ser. 2023, 2584, 012097. [Google Scholar] [CrossRef]

- Gao, J.; Yang, S.; Xu, S.; Du, Z.; Xu, Y. Research on single-phase grounding fault of power system based on new small current grounding system. J. Phys. Conf. Ser. 2024, 2781, 012019. [Google Scholar] [CrossRef]

- Li, J.; Zhang, G.; Li, H.; Wang, G.; Hou, Y.; Liu, W. A Review of Fault Location Methods for Small Current Grounding Systems. IOP Conf. Ser. Mater. Sci. Eng. 2019, 677, 052045. [Google Scholar] [CrossRef]

- Tartakowski, Z.; Pietrzak-Mantiuk, A. Resistance of high-content polypropylene/wood composites to low-current arc discharges. Polym. Test. 2006, 25, 342–346. [Google Scholar] [CrossRef]

- He, J.; Zhang, W.; Xiao, X. Simulation and Experimental Study of Cable Arc Faults. Electr. Appl. 2018, 37, 78–83. [Google Scholar]

- Liu, S.R.; Hu, Y.X.; Zheng, J.K.; Su, X.T.; Xu, Y. Dynamics Simulation of 10kV Cable Tunnel Fire for Single-phase Arc Grounding Fault. High Volt. Eng. 2021, 47, 4341–4348. [Google Scholar]

- Li, C.; Chen, J.; Zhang, W.; Wu, S. Influence of Cable Surface Temperature on Arc Ignition Cable and Flame Spread. Fire Sci. Technol. 2022, 41, 180–184. [Google Scholar]

- Xu, Z.; Zhu, Z.; Jing, Z.; Wu, S. Study On 1 kV Distribution Cable Fire Ignited by Arc Discharge. Fire Saf. Sci. 2023, 32, 135–143. [Google Scholar]

| Test Current (A) | Electrode Speed (mm/s) |

|---|---|

| 2 | 0.02–0.11 |

| 4 | 0.08–0.22 |

| 6 | 0.18–0.73 |

| 8 | 0.29–0.95 |

| 10 | 0.46–1.28 |

| Test Current (A) | Rated Current 1 A Fuse | Rated Current 2 A Fuse | Rated Current 3 A Fuse | Rated Current 4 A Fuse |

|---|---|---|---|---|

| 2 | 56 s | >300 s | >300 s | >300 s |

| 4 | 3 s | 34 s | 34 s | >300 s |

| 6 | / | 7 s | 56 s | >300 s |

| 8 | / | / | 28 s | 75 s |

| 10 | / | / | 8 s | 37 s |

| Test Current (A) | Spacing Size (mm) |

|---|---|

| 2 | 3 |

| 4 | 5.5 |

| 6 | 7 |

| 8 | 10.5 |

| 10 | 16.5 |

| Testing Current | Arc Power | Ignition Time |

|---|---|---|

| 2 | 75 W | 28 s |

| 4 | 112 W | 21 s |

| 6 | 189 W | 14 s |

| 8 | 507 W | 9 s |

| 10 | 820 W | 4 s |

| Arc Duration | 2 A | 4 A | 6 A | 8 A | 10 A |

|---|---|---|---|---|---|

| 50 s | 9 cm | 24 cm | 29 cm | 44 cm | 52 cm |

| 100 s | 16 cm | 32 cm | 38 cm | 51 cm | 63 cm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, W.; Cai, J.; Ji, H.; Li, H.; Ren, Z.; Men, Y.; Pan, Z. Arc Ignition Methods and Combustion Characteristics of Small-Current Arc Faults in High-Voltage Cables. Fire 2024, 7, 352. https://doi.org/10.3390/fire7100352

Guo W, Cai J, Ji H, Li H, Ren Z, Men Y, Pan Z. Arc Ignition Methods and Combustion Characteristics of Small-Current Arc Faults in High-Voltage Cables. Fire. 2024; 7(10):352. https://doi.org/10.3390/fire7100352

Chicago/Turabian StyleGuo, Wei, Jing Cai, Hongquan Ji, Huachun Li, Zhigang Ren, Yekun Men, and Zehua Pan. 2024. "Arc Ignition Methods and Combustion Characteristics of Small-Current Arc Faults in High-Voltage Cables" Fire 7, no. 10: 352. https://doi.org/10.3390/fire7100352

APA StyleGuo, W., Cai, J., Ji, H., Li, H., Ren, Z., Men, Y., & Pan, Z. (2024). Arc Ignition Methods and Combustion Characteristics of Small-Current Arc Faults in High-Voltage Cables. Fire, 7(10), 352. https://doi.org/10.3390/fire7100352