Simulation Study on Suppressing Shielded Fires by Water Mist Systems

Abstract

1. Introduction

2. Methodology

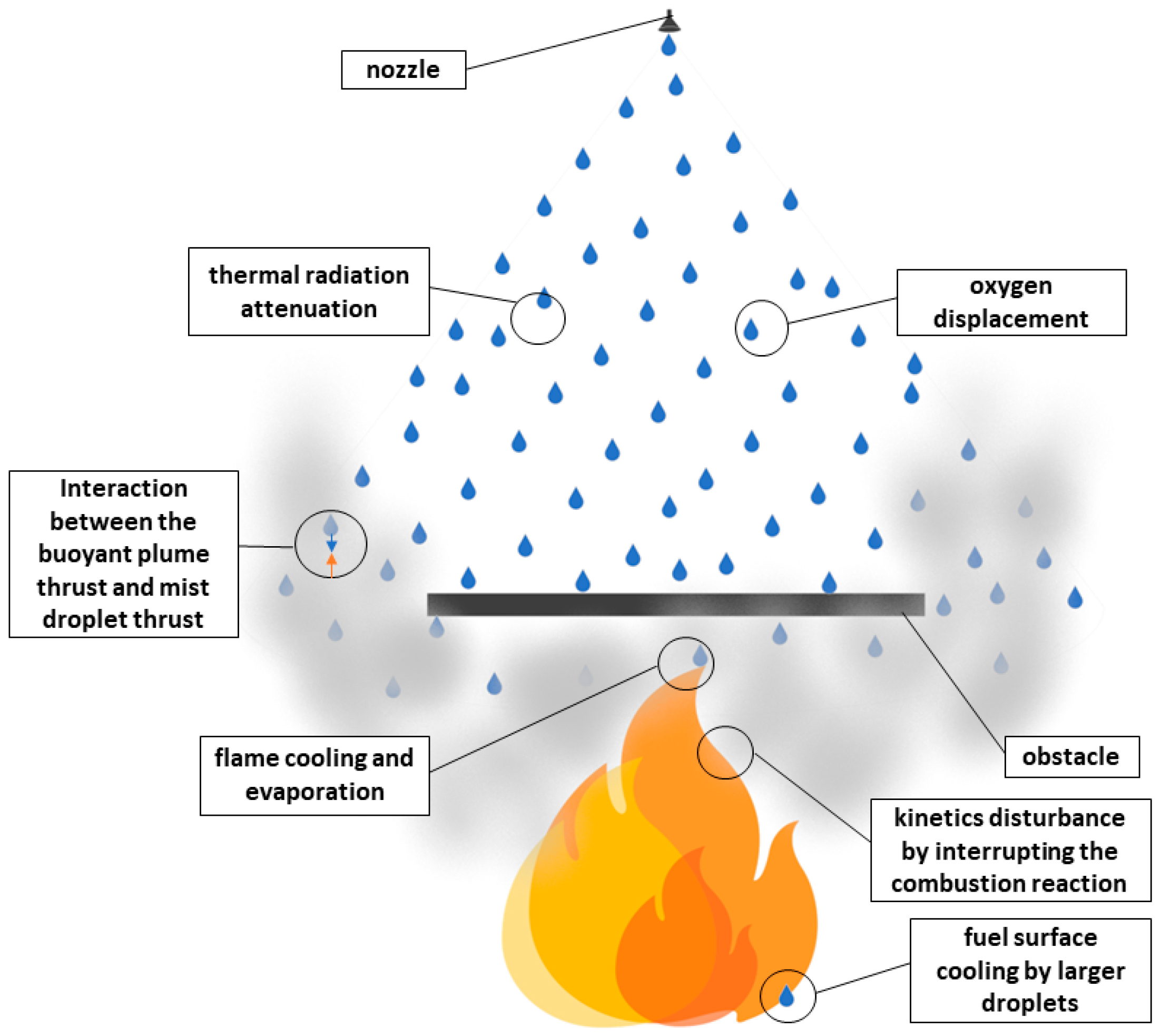

2.1. Numerical Procedure in FDS

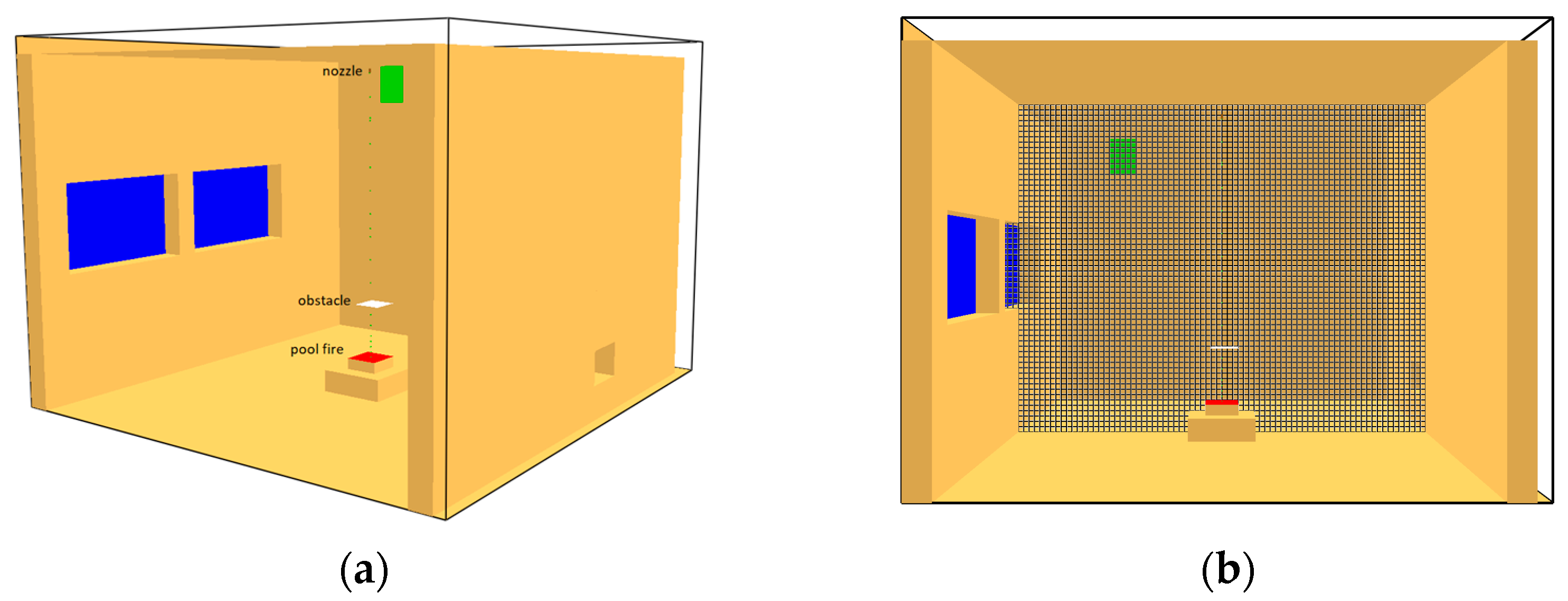

2.2. Simulation Model

3. Results and Discussion

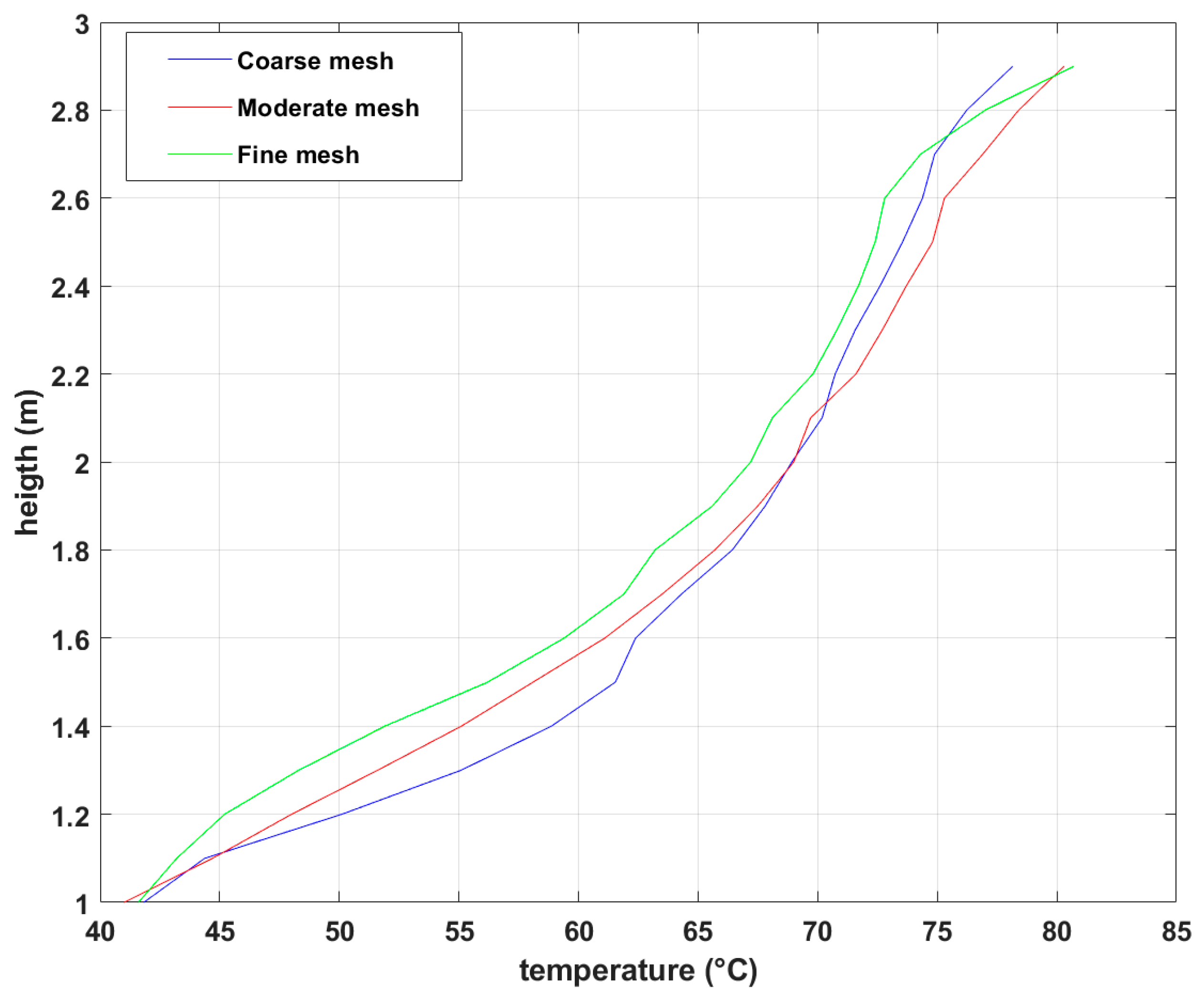

3.1. Grid Sensitivity Analysis

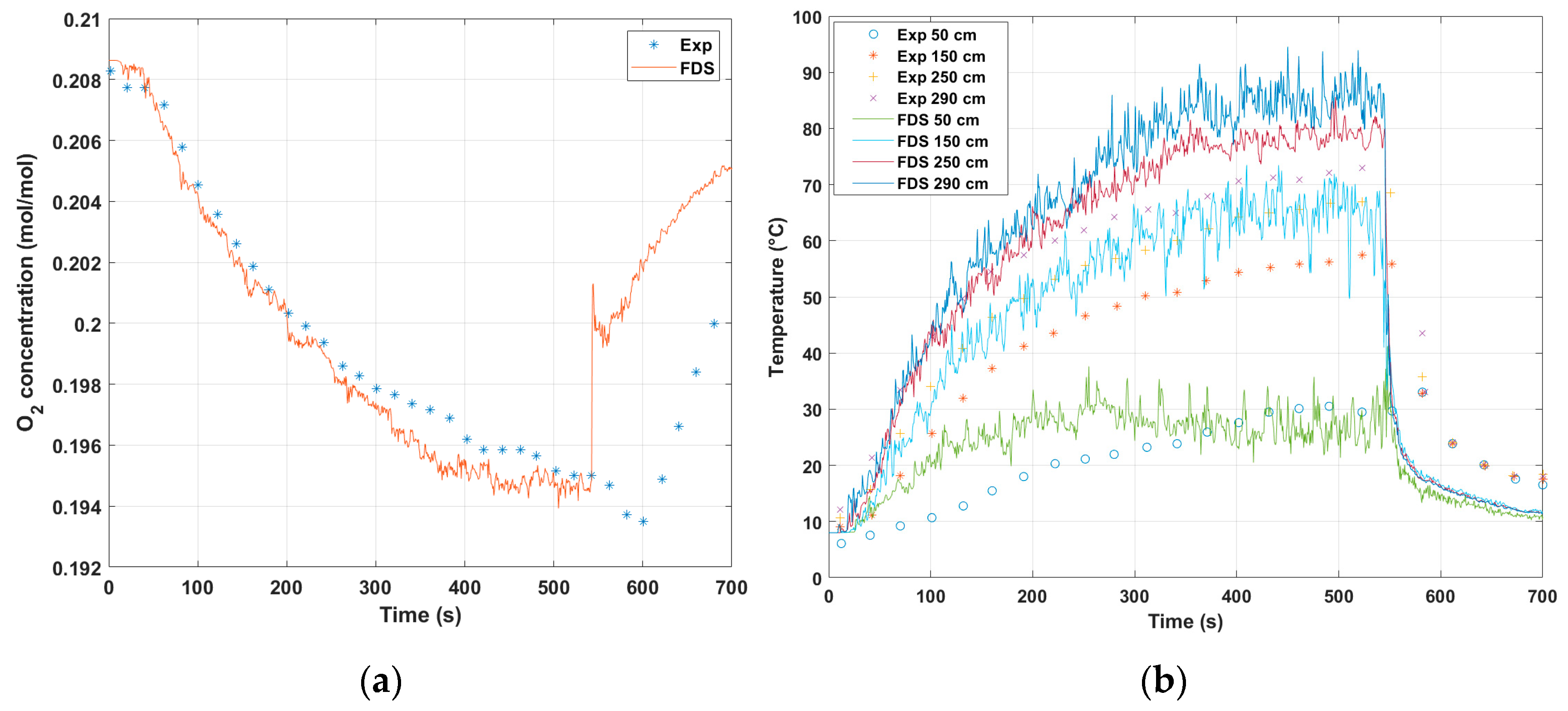

3.2. Model Validation

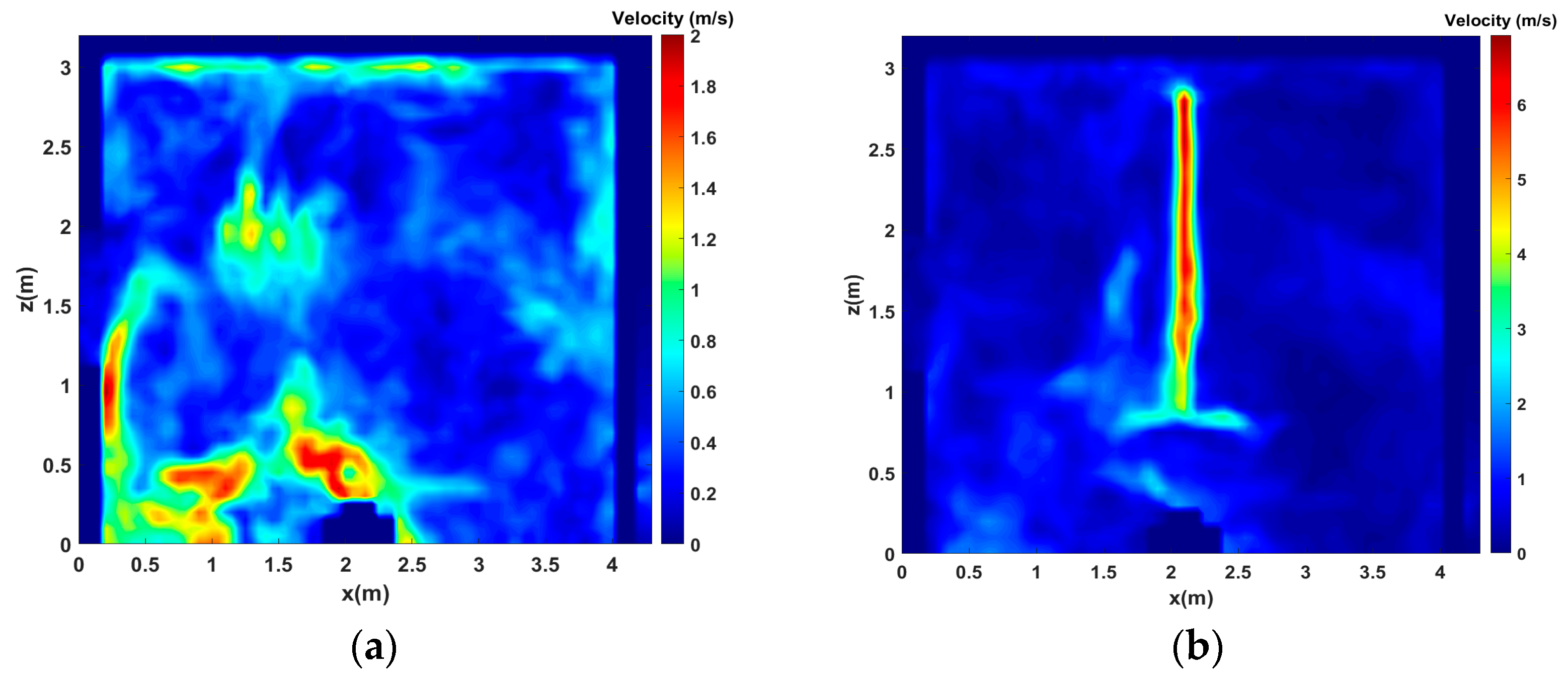

3.2.1. Dry Test Validation

3.2.2. Wet Test Validation

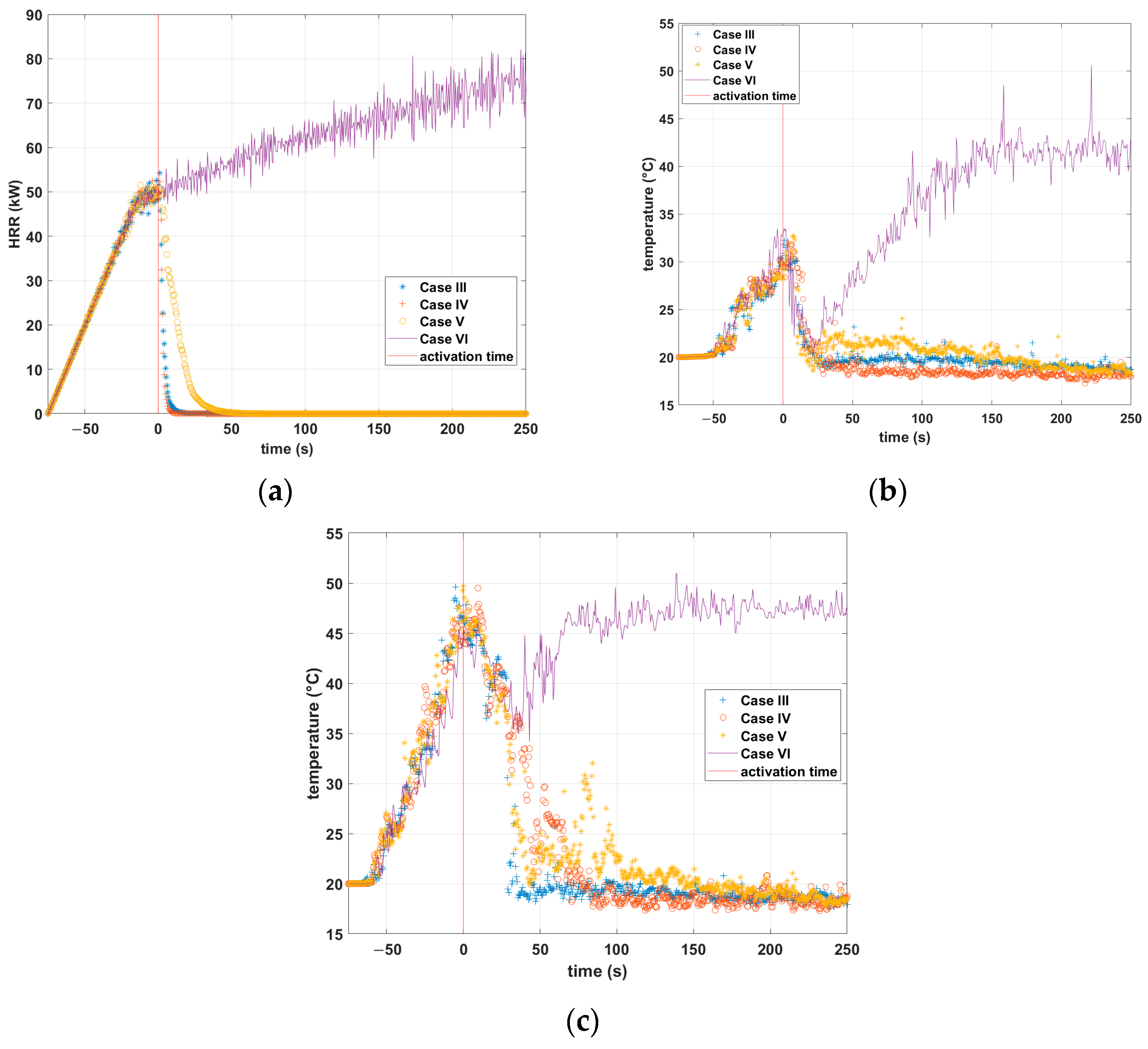

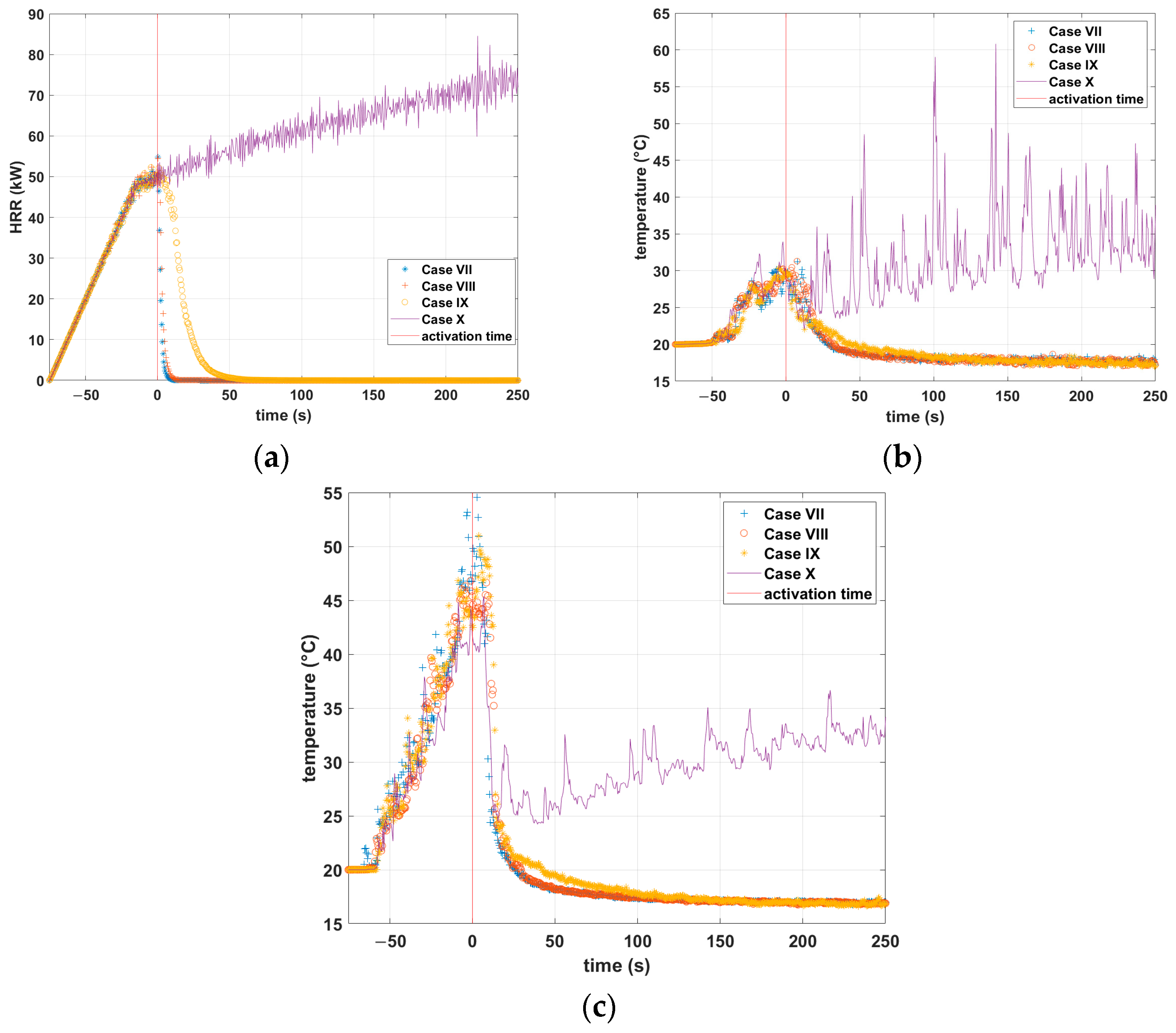

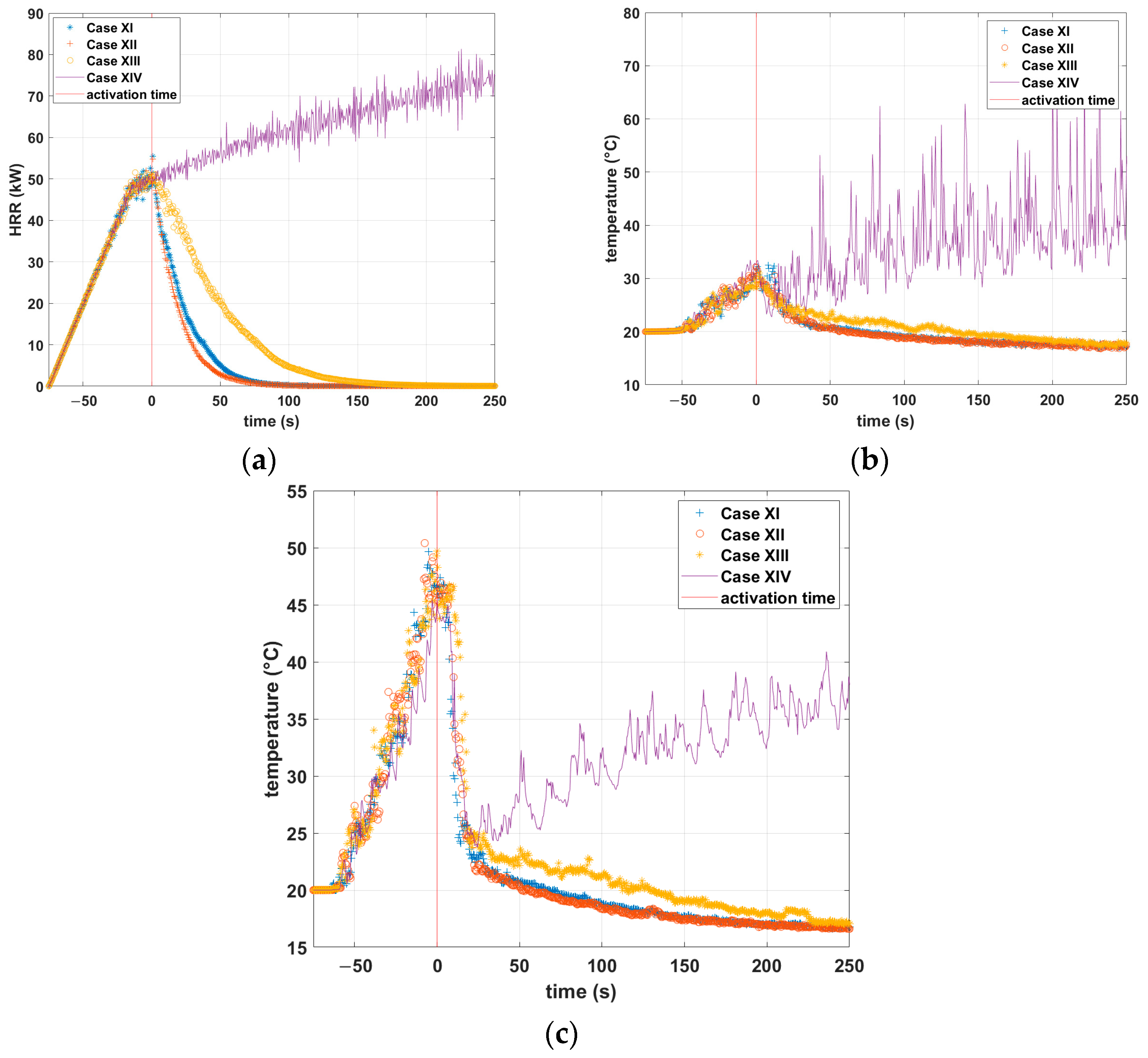

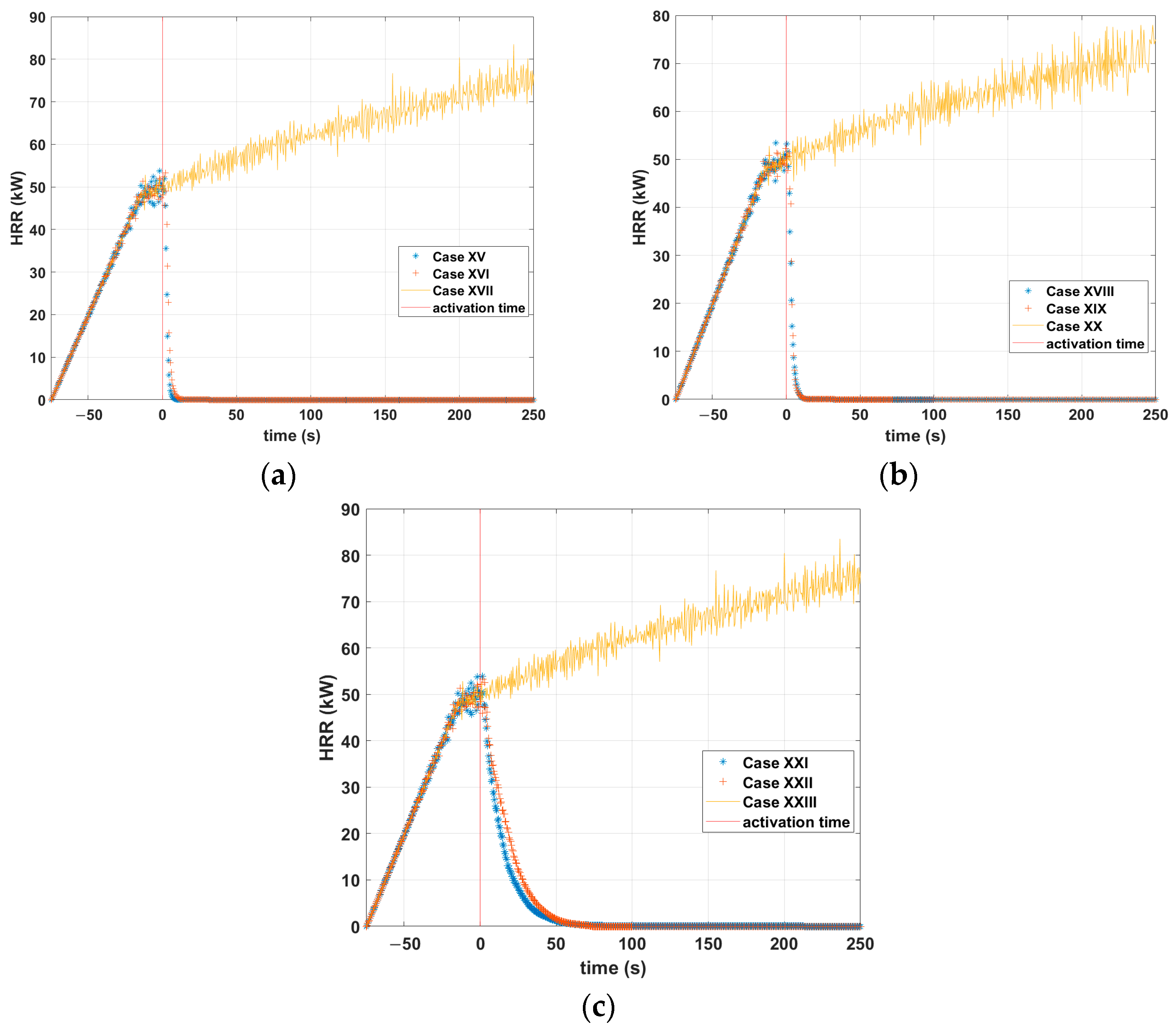

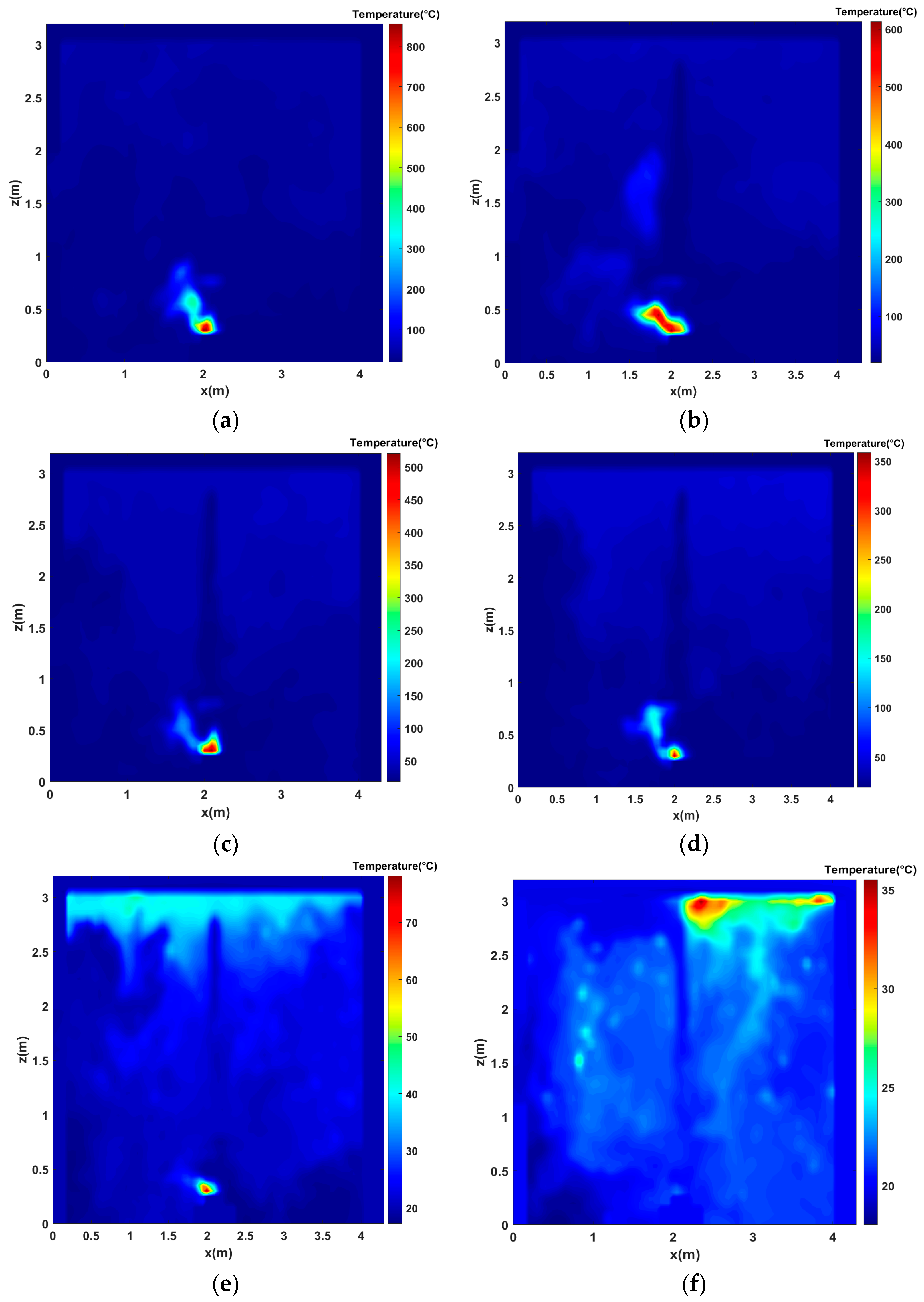

3.3. HRR and Temperature Fields

4. Conclusions

- The maximum deviation in O2 concentration between the FDS predictions and the experimental measurements was 1% for the dry test and less than 5% for the wet test. Moreover, the discrepancy in the temperature values did not exceed about 18 °C in both cases;

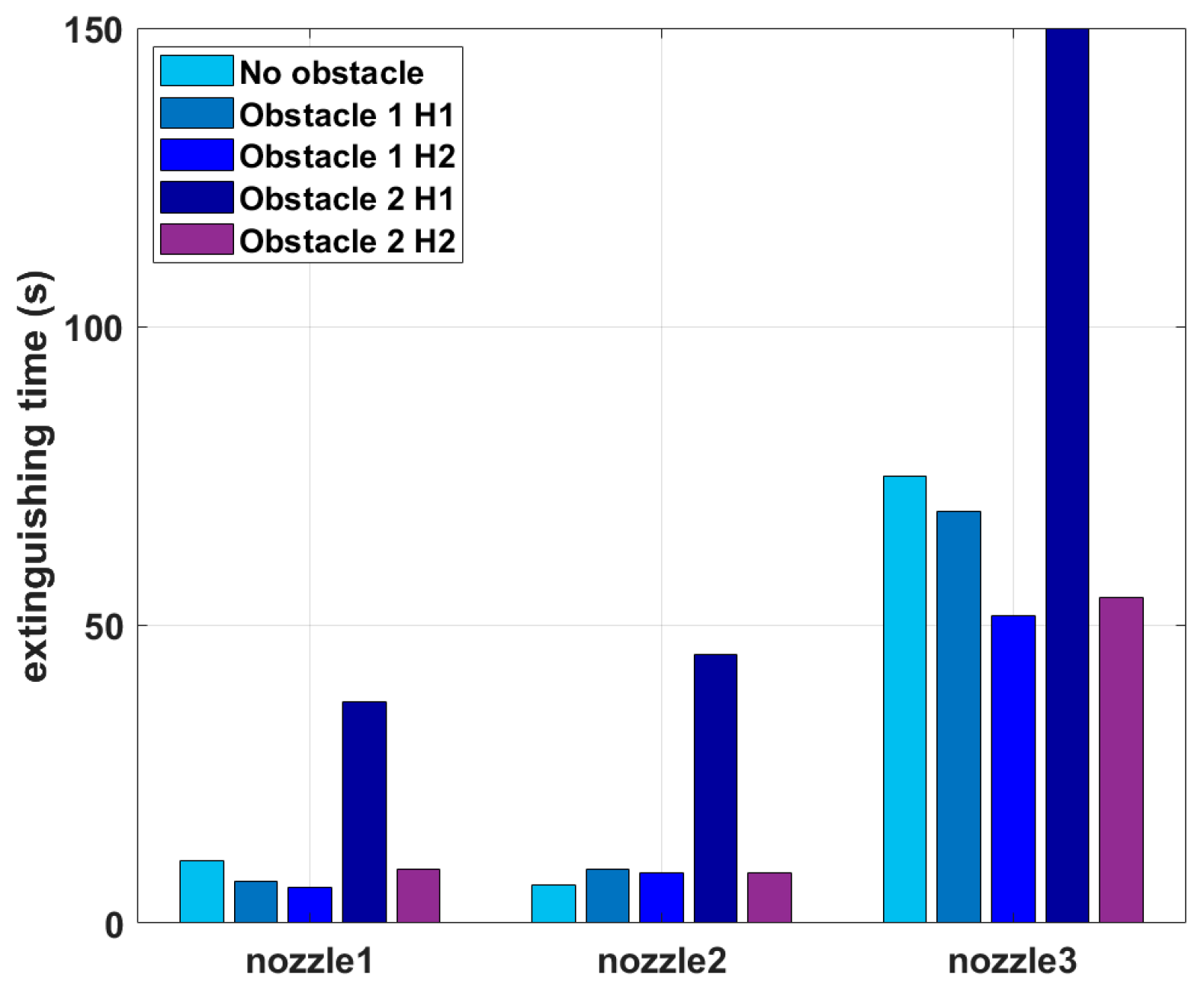

- The first two nozzles (nozzles 1 and 2) were able to suppress the fire completely in the absence of obstacles in a very short time. However, all three nozzles failed to suppress the shielded fire where the obstacle size was 1 m × 1 m, located at any distance from the nozzle;

- The high-pressure spray system performed better in terms of the extinguishing time of the shielded fire compared to nozzles 2 and 3, where the obstacle sizes were 25 cm × 25 cm and 50 cm × 50 cm. However, the suppression time using nozzle 2 (low-pressure) was close to nozzle 1 (high-pressure) due to the higher flow rate;

- Although nozzles 2 and 3 had the same pressure (10 bar) and almost the same droplet size, nozzle 3 had a longer extinguishing time due to a lower flow rate;

- In the successful cases of extinguishment, the temperature inside the enclosure decreased sharply after nozzle activation;

- The obstacle size, its distance from the nozzle, and the nozzle characteristics are critical parameters in the study of shielded fire suppression;

- When the fire is not fully covered by the obstacle, a portion of droplets can penetrate the flame by overcoming the plume thrust and bypassing the obstacle.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- NFPA 750; Standard on Water Mist Fire Protection Systems. National Fire Protection Association: Quincy, MA, USA, 2006.

- Li, Q.; Tang, Z.; Fang, Z.; Yuan, J.; Wang, J. Experimental study of the effectiveness of a water mist segment system in blocking fire-induced smoke and heat in mid-scale tunnel tests. Tunn. Undergr. Space Technol. 2019, 88, 237–249. [Google Scholar] [CrossRef]

- Gupta, M.; Pasi, A.; Ray, A.; Kale, S.R. An experimental study of the effects of water mist characteristics on pool fire suppression. Exp. Therm. Fluid Sci. 2013, 44, 768–778. [Google Scholar] [CrossRef]

- Tian, G.; Li, H.; Xu, H.; Li, Y.; Raj, S.M. Spray characteristics study of DMF using phase doppler particle analyzer. SAE Int. J. Passeng. Cars Mech. Syst. 2010, 3, 948–958. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Huang, Y.; Tao, C.; Zhang, H. Experimental study on fire smoke control using water mist curtain in channel. J. Hazard. Mater. 2018, 342, 231–241. [Google Scholar] [CrossRef]

- Jeong, C.S.; Lee, C.Y. Experimental investigation on spray characteristics of twin-fluid nozzle for water mist and its heptane pool fire extinguishing performance. Process Saf. Environ. Prot. 2021, 148, 724–736. [Google Scholar] [CrossRef]

- Husted, B.P.; Petersson, P.; Lund, I.; Holmstedt, G. Comparison of PIV and PDA droplet velocity measurement techniques on two high-pressure water mist nozzles. Fire Saf. J. 2009, 44, 1030–1045. [Google Scholar] [CrossRef]

- Ditch, B.; Yu, H.-Z. Characterization of Water Mist Sprays Using a Phase-Doppler-Particle-Analyzer and an Iso-Kinetic Sampling Probe. In Proceedings of the ASME 2004 Heat Transfer/Fluids Engineering Summer Conference, Charlotte, NC, USA, 11–15 July 2004; pp. 221–230. [Google Scholar] [CrossRef]

- Qin, J.; Chow, W.K. Experimental Data on Water Mist Suppression. Procedia Eng. 2013, 62, 868–877. [Google Scholar] [CrossRef]

- Santangelo, P.E.; Tarozzi, L.; Tartarini, P. Full-Scale Experiments of Water-Mist Systems for Control and Suppression of Sauna Fires. Fire 2022, 5, 214. [Google Scholar] [CrossRef]

- Yang, P.; Liu, T.; Qin, X. Experimental and numerical study on water mist suppression system on room fire. Build. Environ. 2010, 45, 2309–2316. [Google Scholar] [CrossRef]

- Zhou, Y.; Bu, R.; Zhang, X.; Fan, C.; Gong, J. Performance evaluation of water mist fire suppression: A clean and sustainable fire-fighting technique in mechanically-ventilated place. J. Clean. Prod. 2019, 209, 1319–1331. [Google Scholar] [CrossRef]

- Yinshui, L.; Zhuo, J.; Dan, W.; Xiaohui, L. Experimental research on the water mist fire suppression performance in an enclosed space by changing the characteristics of nozzles. Exp. Therm. Fluid Sci. 2014, 52, 174–181. [Google Scholar] [CrossRef]

- Fan, C.; Bu, R.; Xie, X.; Zhou, Y. Full-scale experimental study on water mist fire suppression in a railway tunnel rescue station: Temperature distribution characteristics. Process Saf. Environ. Prot. 2021, 146, 396–411. [Google Scholar] [CrossRef]

- Ferng, Y.-M.; Liu, C.-H. Numerically investigating fire suppression mechanisms for the water mist with various droplet sizes through FDS code. Nucl. Eng. Des. 2011, 241, 3142–3148. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, W.; Wang, Q. Optimization of water mist droplet size by using CFD modeling for fire suppressions. J. Loss Prev. Process Ind. 2016, 44, 626–632. [Google Scholar] [CrossRef]

- Sikanen, T.; Vaari, J.; Hostikka, S.; Paajanen, A. Modeling and Simulation of High Pressure Water Mist Systems. Fire Technol. 2014, 50, 483–504. [Google Scholar] [CrossRef]

- Liang, Q.; Li, Y.; Li, J.; Xu, H.; Li, K. Numerical studies on the smoke control by water mist screens with transverse ventilation in tunnel fires. Tunn. Undergr. Space Technol. 2017, 64, 177–183. [Google Scholar] [CrossRef]

- Wang, J.; Nie, Q.; Fang, Z.; Tang, Z. CFD Simulations of the Interaction of the Water Mist Zone and Tunnel Fire Smoke in Reduced-scale Experiments. Procedia Eng. 2018, 211, 726–735. [Google Scholar] [CrossRef]

- Magdolenová, P. CFD Modelling of High-Pressure Water Mist System in Road Tunnels. Transp. Res. Procedia 2021, 55, 1163–1170. [Google Scholar] [CrossRef]

- De Cachinho Cordeiro, I.M.; Liu, H.; Yuen, A.C.; Chen, T.B.; Li, A.; Wang, C.; Cao, R.; Yeoh, G.H. On the Large Eddy Simulation Modelling of Water Suppression Systems Droplet Impact and Coverage Area. Fire 2022, 5, 165. [Google Scholar] [CrossRef]

- Kim, S.C.; Ryou, H.S. An experimental and numerical study on fire suppression using a water mist in an enclosure. Build. Environ. 2003, 38, 1309–1316. [Google Scholar] [CrossRef]

- Mawhinney, J.R.; Back, G.G. Water mist fire suppression systems. In SFPE Handbook of Fire Protection Engineering; Springer: Berlin/Heidelberg, Germany, 2016; pp. 1587–1645. [Google Scholar]

- Liu, Y.; Wang, X.; Liu, T.; Ma, J.; Li, G.; Zhao, Z. Preliminary study on extinguishing shielded fire with water mist. Process Saf. Environ. Prot. 2020, 141, 344–354. [Google Scholar] [CrossRef]

- Liu, Y.; Fang, Z.; Tang, Z.; Beji, T.; Merci, B. The combined effect of a water mist system and longitudinal ventilation on the fire and smoke dynamics in a tunnel. Fire Saf. J. 2021, 122, 103351. [Google Scholar] [CrossRef]

- Beihua, C.; Guangxuan, L.; Zhen, H. Extinction Limit of Diesel Pool Fires Suppressed by Water Mist. J. Fire Sci. 2009, 27, 5–26. [Google Scholar] [CrossRef]

- Alpert, R.L. Numerical modeling of the interaction between automatic sprinkler sprays and fire plumes. Fire Saf. J. 1985, 9, 157–163. [Google Scholar] [CrossRef]

- McGrattan, K.; Hostikka, S.; McDermott, R.; Floyd, J.; Weinschenk, C.; Overhold, K. Fire Dynamics Simulator User ’s Guide (FDS), 6th ed.; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2020.

- Forney, G.P. Smokeview, A Tool for Visualizing Fire Dynamics Simulation Data, Volume I: User’s Guide; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2015; pp. 1011–1017.

- McGrattan, K.; Hostikka, S.; Floyd, J.; McDermott, R.; Vanella, M. Fire dynamics simulator technical reference guide volume 1: Mathematical model. NIST Spec. Publ. 2020, 1018, 175. [Google Scholar]

- Cheremisinoff, N.P. Encyclopedia of Fluid Mechanics. Vol. 3: Gas-Liquid Flows; Gulf Publishing Company: Houston, TX, USA, 1986. [Google Scholar]

- Jenft, A.; Collin, A.; Boulet, P.; Pianet, G.; Breton, A.; Muller, A. Experimental and numerical study of pool fire suppression using water mist. Fire Saf. J. 2014, 67, 1–12. [Google Scholar] [CrossRef]

| Material | Conductivity (k) W/mk | Specific Heat (cp) j/kgk | Density (ρ) kg/m3 |

|---|---|---|---|

| Concrete | 1.575 | 1000 | 2100 |

| glass | 1 | 750 | 2500 |

| steel | 50 | 450 | 7800 |

| wood | 0.13 | 1600 | 500 |

| Common Formula | Heat of Combustion (ΔHc) kj/kg | Soot Yield kg/kg | |

|---|---|---|---|

| Diesel | C12H23 | 42,200 | 0.059 |

| Nozzle 1 | Nozzle 2 | Nozzle 3 |

|---|---|---|

| D = 46 µm | D = 124.6 µm | D = 112 µm |

| Operating pressure = 100 bar | Operating pressure = 10 bar | Operating pressure: 10 bar |

| Flow rate = 11.9 L/min | Flow rate = 22.8 L/min | Flow rate: 6.3 L/min |

| Velocity = 10 m/s | Velocity = 42.5 m/s | Nozzle exit diameter: 0.0008 m |

| Cone angle = 0–48° | Cone angle = 0–90° | half injection angle: 65° |

| K factor = 1.9 L/min/bar1/2 | K factor = 7.2 L/min/bar1/2 | K factor: 1.9 L/min/bar1/2 |

| Category | Case No. | Obstacle No. | Distance between Obstacle and Floor | Nozzle Number | Activation Time |

|---|---|---|---|---|---|

| Validation | I—dry validation | - | - | - | - |

| II—wet validation | - | - | 3 | 540 s | |

| III | - | - | 1 | 75 s | |

| N1H1 | IV | 1 | H1 | 1 | 75 s |

| V | 2 | H1 | 1 | 75 s | |

| VI | 3 | H1 | 1 | 75 s | |

| VII | - | - | 2 | 75 s | |

| N2H1 | VIII | 1 | H1 | 2 | 75 s |

| IX | 2 | H1 | 2 | 75 s | |

| X | 3 | H1 | 2 | 75 s | |

| XI | - | - | 3 | 75 s | |

| N3H1 | XII | 1 | H1 | 3 | 75 s |

| XIII | 2 | H1 | 3 | 75 s | |

| XIV | 3 | H1 | 3 | 75 s | |

| N1H2 | XV | 1 | H2 | 1 | 75 s |

| XVI | 2 | H2 | 1 | 75 s | |

| XVII | 3 | H2 | 1 | 75 s | |

| N2H2 | XVIII | 1 | H2 | 2 | 75 s |

| XIX | 2 | H2 | 2 | 75 s | |

| XX | 3 | H2 | 2 | 75 s | |

| N3H2 | XXI | 1 | H2 | 3 | 75 s |

| XXII | 2 | H2 | 3 | 75 s | |

| XXIII | 3 | H2 | 3 | 75 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamzehpour, A.; Verda, V.; Borchiellini, R. Simulation Study on Suppressing Shielded Fires by Water Mist Systems. Fire 2023, 6, 129. https://doi.org/10.3390/fire6040129

Hamzehpour A, Verda V, Borchiellini R. Simulation Study on Suppressing Shielded Fires by Water Mist Systems. Fire. 2023; 6(4):129. https://doi.org/10.3390/fire6040129

Chicago/Turabian StyleHamzehpour, Azad, Vittorio Verda, and Romano Borchiellini. 2023. "Simulation Study on Suppressing Shielded Fires by Water Mist Systems" Fire 6, no. 4: 129. https://doi.org/10.3390/fire6040129

APA StyleHamzehpour, A., Verda, V., & Borchiellini, R. (2023). Simulation Study on Suppressing Shielded Fires by Water Mist Systems. Fire, 6(4), 129. https://doi.org/10.3390/fire6040129