An Experimental Investigation of the Influence of Flow and Pipe Diameter on the Fire Extinguishing Efficiency of Nitrogen Injection in a Narrow Confined Underground Space

Abstract

:1. Introduction

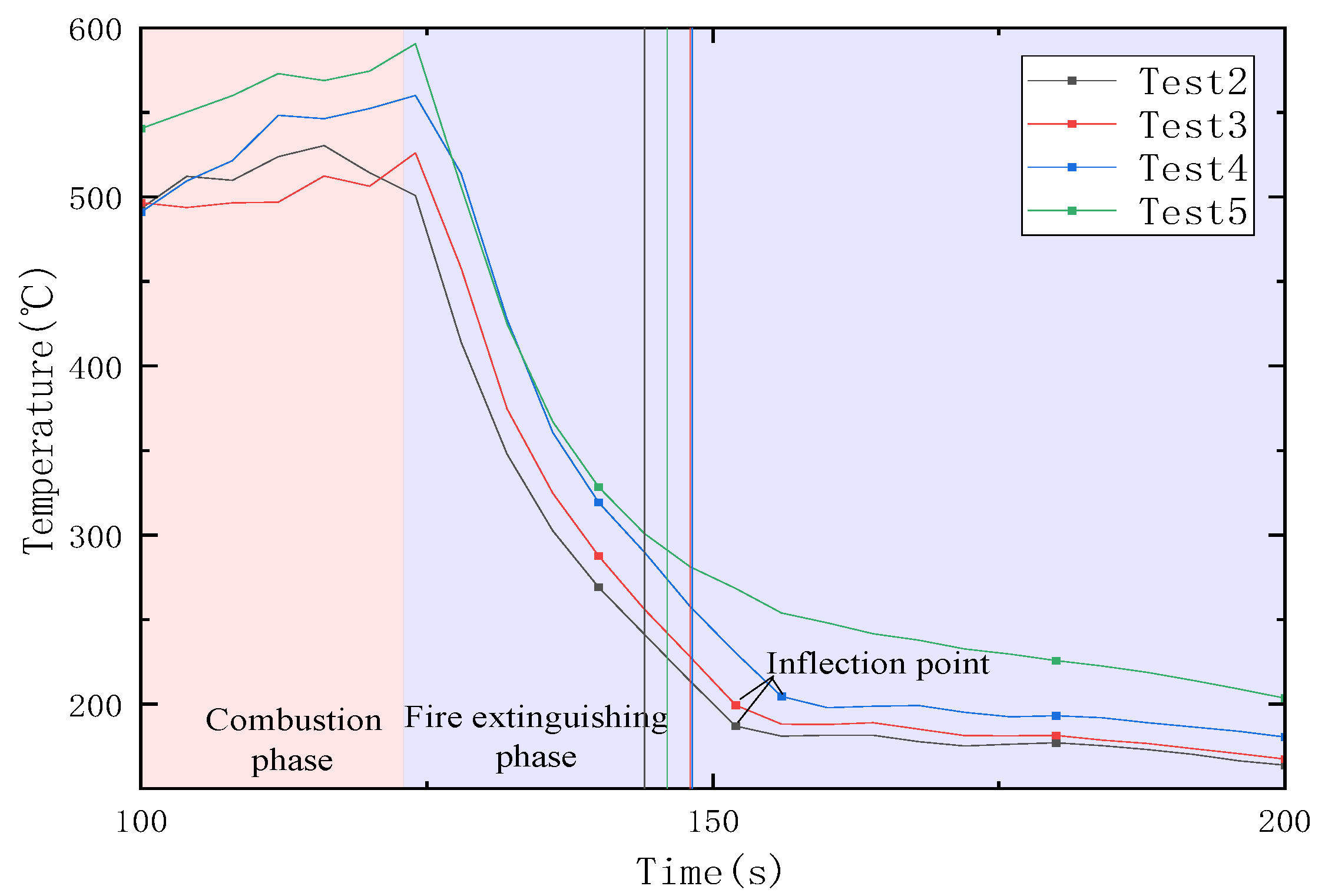

2. Performance Indexes for Evaluating Liquid Nitrogen Fire Extinguishing Efficiency

3. Test Design

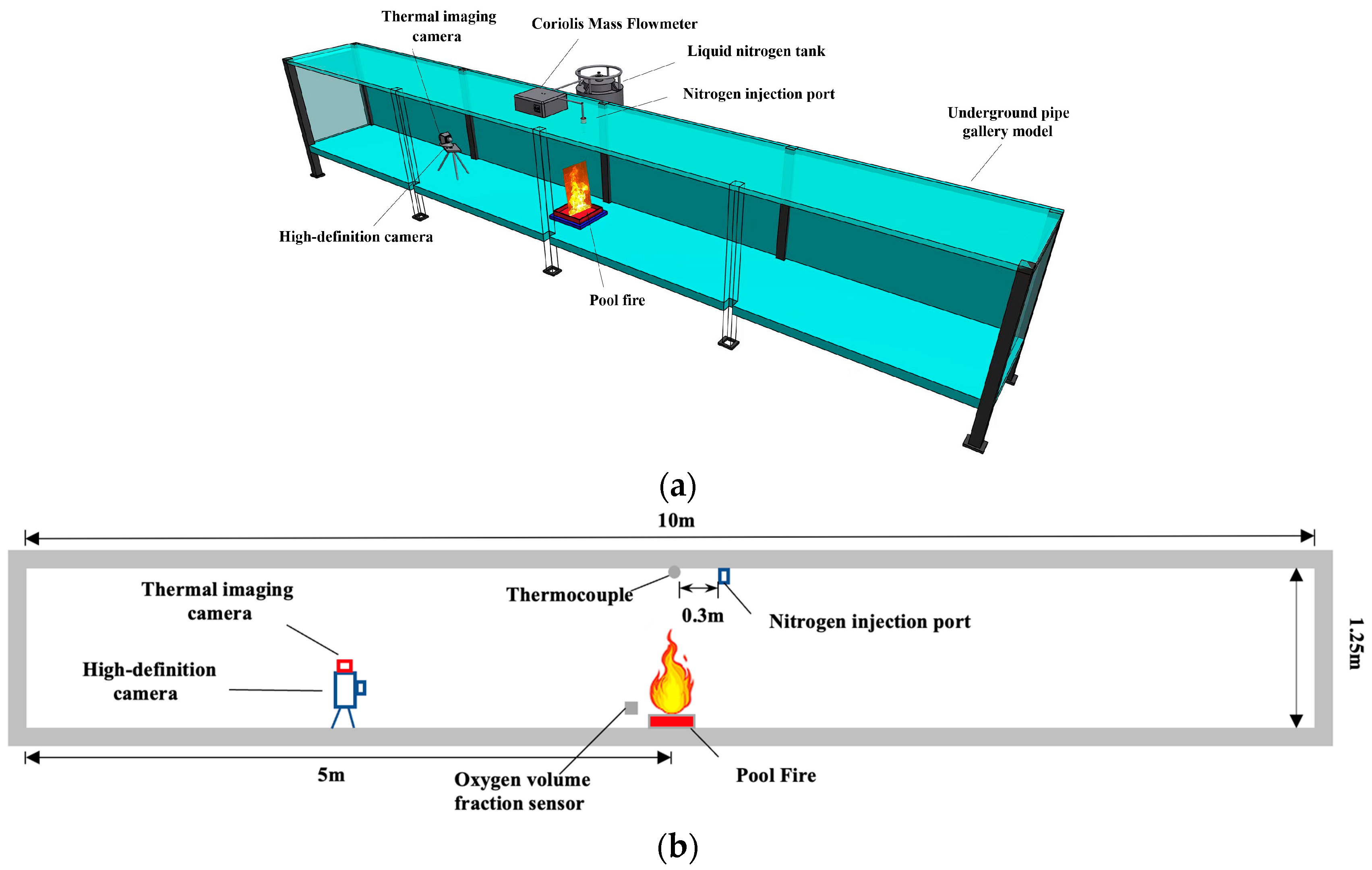

3.1. Test Devices

3.2. Test Method

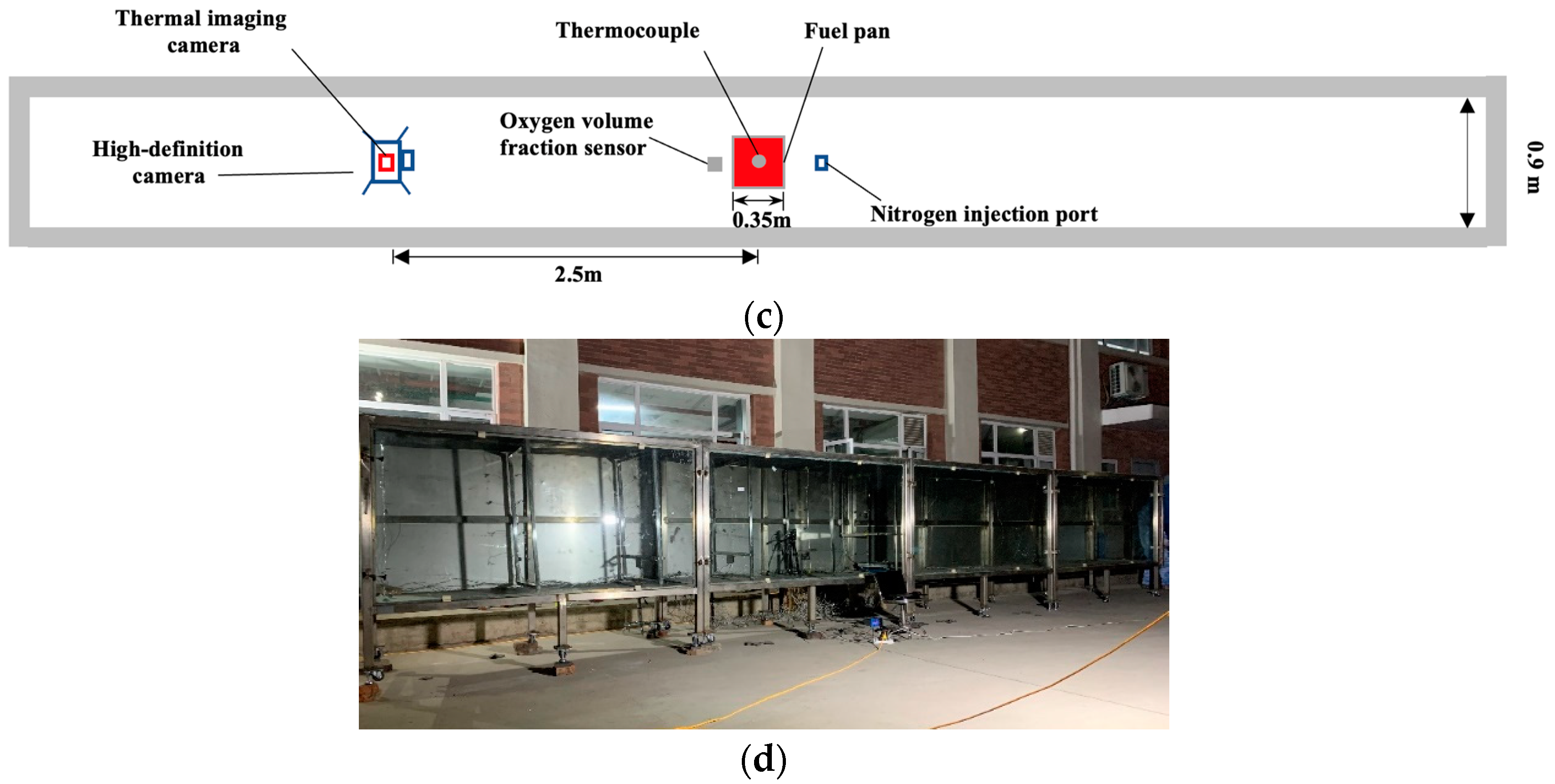

3.3. Test Phenomenon

4. Analysis of the Influence of Nitrogen Injection Flow on Liquid Nitrogen Extinguishing Efficiency

4.1. A Comparative Analysis of the Time of Fire Extinguishment

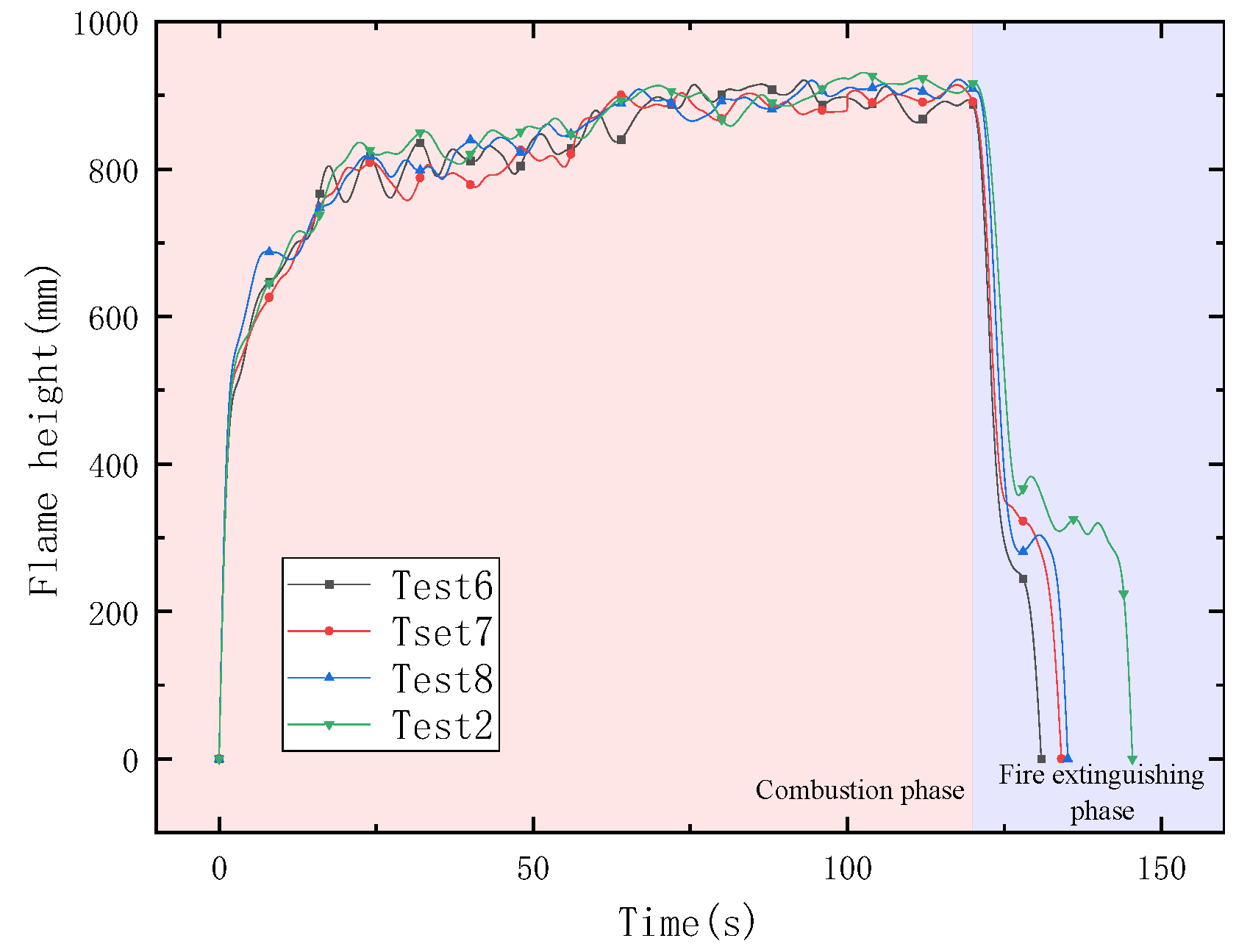

4.2. A Comparative Analysis of Fire Extinguishing Efficiency Based on the Average Flame Height

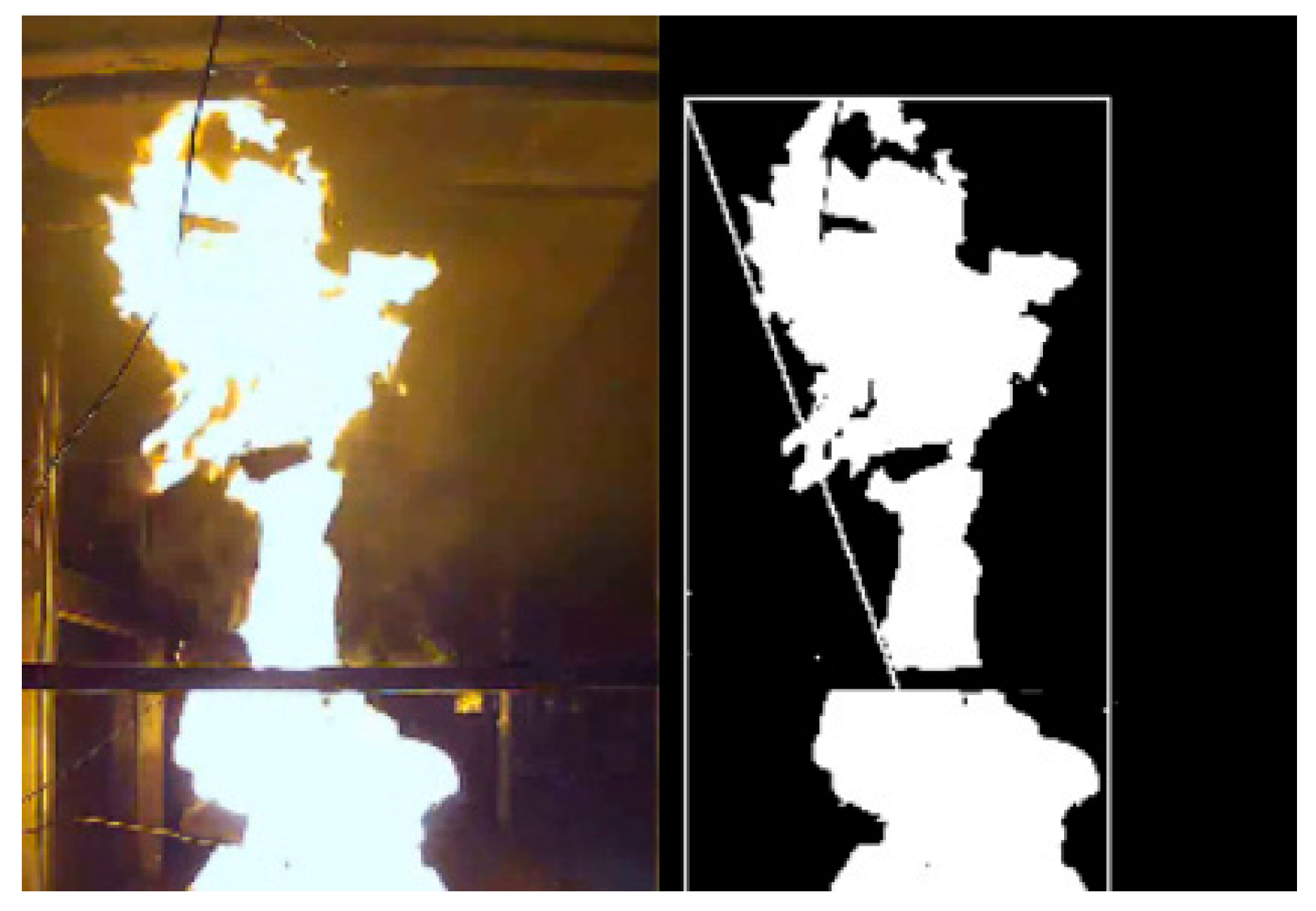

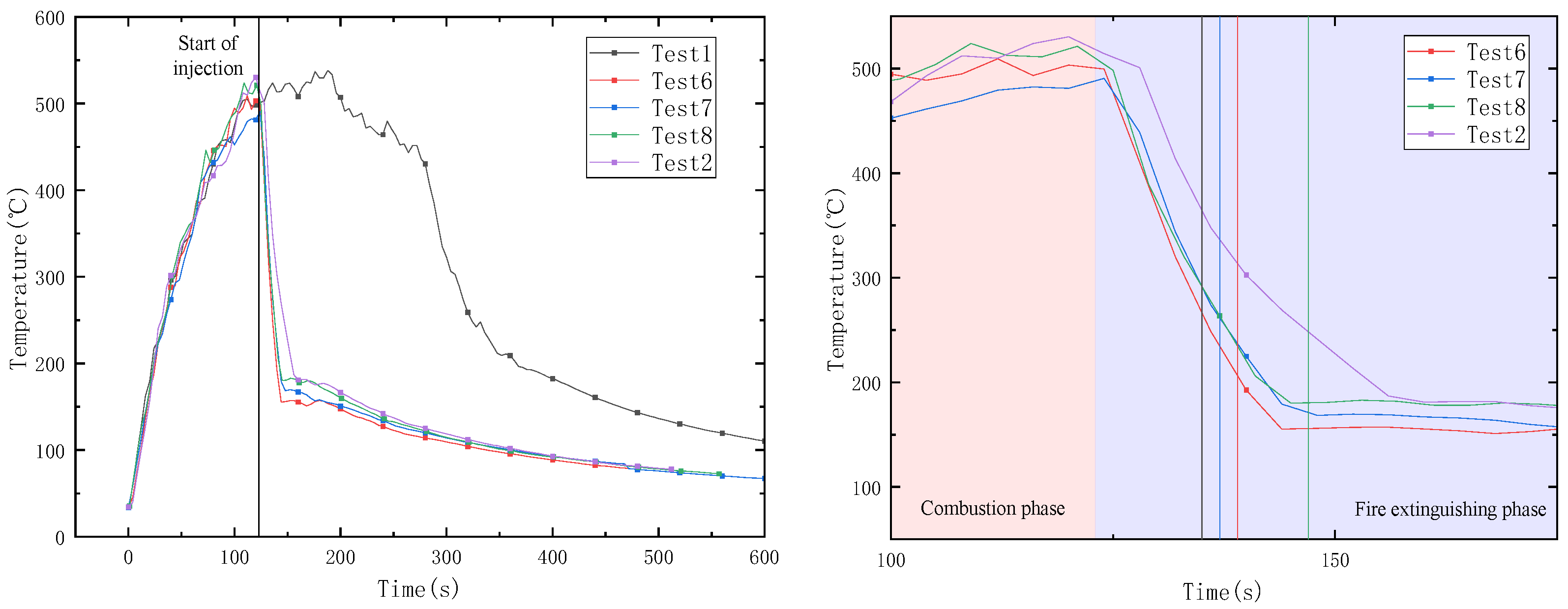

4.3. A Comparative Analysis of Fire Extinguishing Efficiency Based on Temperature

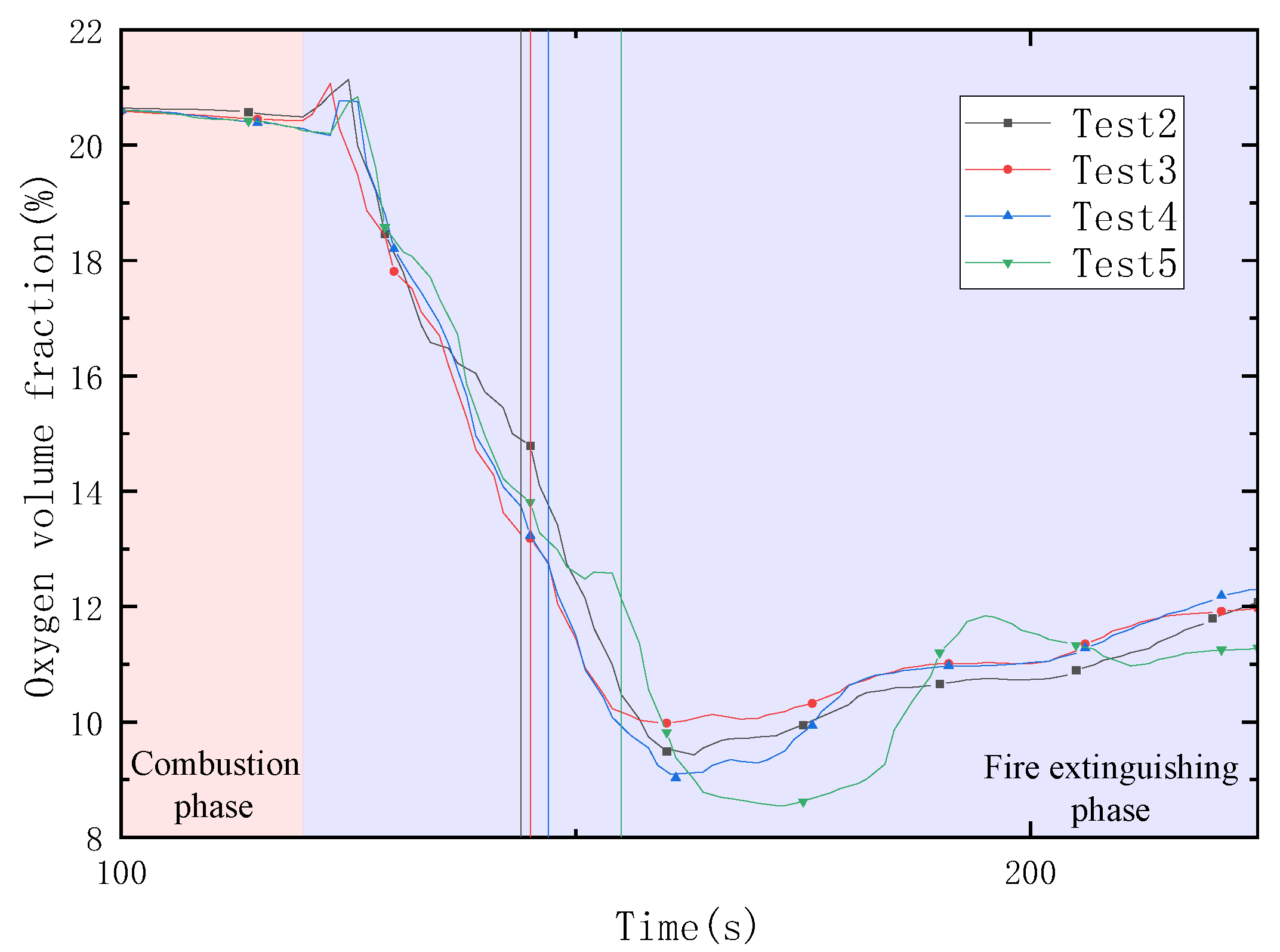

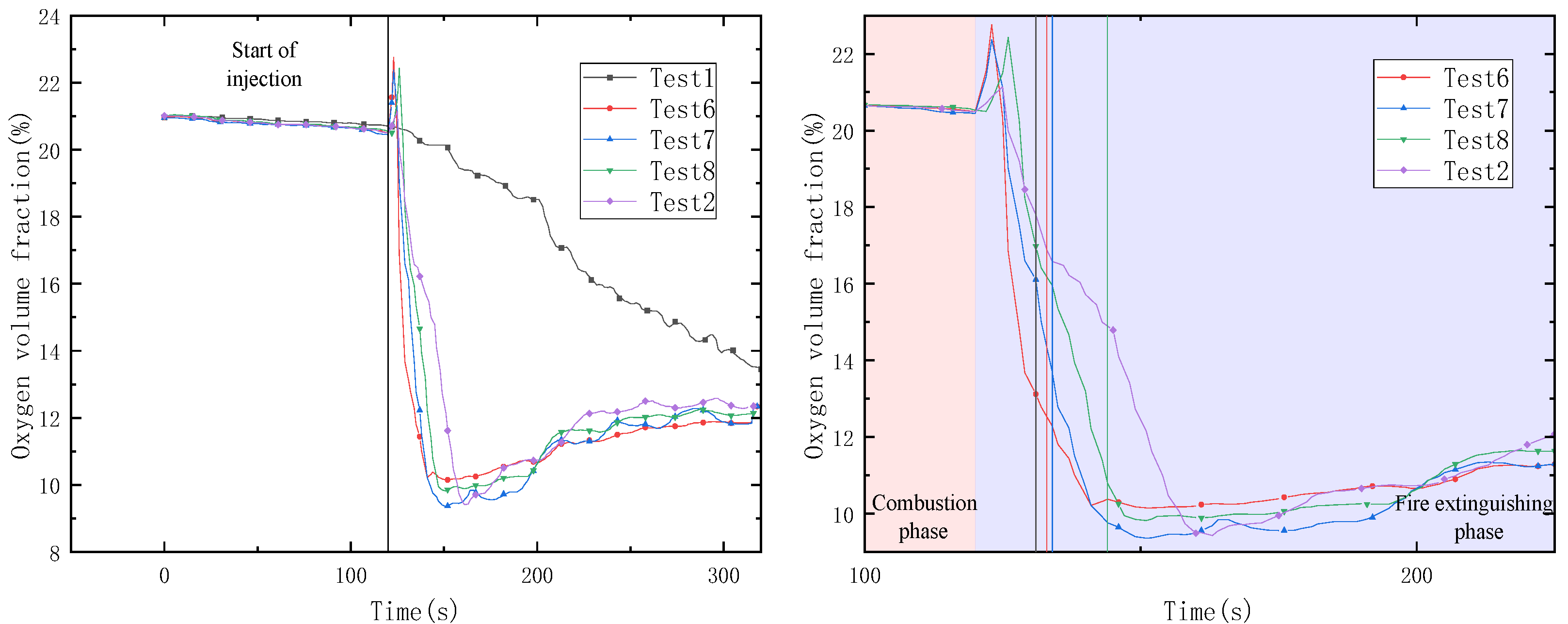

4.4. A Comparative Analysis of Fire Extinguishing Effectiveness Based on Oxygen Volume Fraction

5. The Effect of Injection Pipe Diameter on Liquid Nitrogen Extinguishing Effectiveness

5.1. A Comparative Analysis of Fire Extinguishing Times

5.2. A Comparative Analysis of Fire Extinguishing Efficiency Based on the Average Flame Height

5.3. A Comparative Analysis of Fire Extinguishing Efficiency Based on Temperature

5.4. A Comparative Analysis of Fire Extinguishing Effectiveness Based on Oxygen Volume Fraction

6. Conclusions

- The fire extinguishing performance of liquid nitrogen in long and narrow confined underground spaces was excellent. The shortest fire extinguishing time in the nitrogen injection tests was 11 s, which was 95.5% faster than in the self-extinguishing test.

- The fire suppression efficiency of the nitrogen injection was positively correlated with the nitrogen flow rate, while the cooling efficiency of the nitrogen injection was less affected by the nitrogen flow. The role of cooling in the overall fire extinguishing efficiency of liquid nitrogen was very limited, which proved that asphyxiation was the main fire extinguishing mechanism of liquid nitrogen.

- The nitrogen asphyxiation was reduced when the nitrogen injection rate was too high or too low. Therefore, besides the cost consideration in the engineering application of liquid nitrogen, the most appropriate nitrogen injection flow rate should also be selected to achieve the maximum possible effectiveness of liquid nitrogen fire extinguishment.

- The fire extinguishing efficiency was affected by the change in the injection pipe diameter. In particular, the asphyxiation and fire suppression factors were highly sensitive to the pipe diameter. This also confirmed that asphyxiation was the main fire extinguishing mechanism in liquid nitrogen.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liang, K.; Hao, X.; An, W.; Tang, Y.; Cong, Y. Study on cable fire spread and smoke temperature distribution in T-shaped utility tunnel. Case Stud. Therm. Eng. 2019, 14, 100433. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, L.; Liao, R.; Yue, R.; Hong, Q. Application analysis of dry powder fire extinguishing equipment used in utility tunnel. Fire Sci. Technol. 2018, 37, 1682–1684. [Google Scholar]

- Liu, X.; Wu, C.; Chen, Y. Progress in the research of factors affecting the extinguishing property of water mist. Fire Sci. Technol. 2010, 29, 269–272. [Google Scholar]

- Marke, P. Cable tunnels an integrated fire detection suppression system for rapid extinguishment. Fire Technol. 1991, 27, 219–233. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, L.; Ni, Y.; Wang, S.; Wang, J.; Zhu, H. Selection Analysis of Automatic Fire Extinguishing System for Utility Tunnel & Full Life Cycle Cost Accounting. China Munic. Eng. 2020, 5, 62–65+117. [Google Scholar]

- Hu, G.; Gao, G. Inert gas fire extinguishing in large confined space. Fire Sci. Technol. 1988, 38–39+44. [Google Scholar]

- Levendis, Y.; Ergut, A.; Delichatsios, M. Cryogenic extinguishment of liquid pool fires. Process Saf. Prog. 2010, 29, 79–86. [Google Scholar] [CrossRef]

- Ding, X. Numerical Simulation of Microthermal Nitrogen Injection for Fire Prevention and Extinguishing in Gob; China University of Mining and Technology: Jiangsu, China, 2014. [Google Scholar]

- An, D.; Sunderland, P.B.; Lathrop, D.P. Suppression of sodium fires with liquid nitrogen. Fire Saf. J. 2013, 58, 204–207. [Google Scholar] [CrossRef]

- Zhang, H.; Fu, P.; Ma, K.; Dai, F. The liquid nitrogen extinguishes fire the device and extinguishes for the function experiment analysis. Fire Sci. Technol. 2003, 4, 303–304. [Google Scholar]

- Yang, S. Research on the Nitrogen Fire Extinguishing Technology in Tanks Fires; Northeastern University: Shenyang, China, 2011. [Google Scholar]

- Li, H.; Zhang, G.; Jia, B.; Zhu, G.; Guo, D.; Zhang, P. Research on extinguishing characteristics of liquid nitrogen in urban underground utility tunnel. China Saf. Sci. J. 2020, 30, 143–150. [Google Scholar]

- Zhang, G.; Guo, D.; Zhu, G.; Yuan, D.; Zhang, Z.; Li, X. Influence of injection method on the fire extinguishing efficiency of liquid nitrogen in urban underground utility tunnel. Case Stud. Therm. Eng. 2021, 28, 101427. [Google Scholar] [CrossRef]

- Jia, B.; Zhang, P.; Zhang, Y. Study on the effectiveness of liquid nitrogen fire extinguishing in the cable cabin of underground utility tunnels. J. Saf. Environ. 2022, 22, 8. [Google Scholar]

- Lan, M.; Feng, T.; Tu, J.; Tao, C.F. Study on the effectiveness of extinguishing cable fires under the combined action of liquid nitrogen and smoke. Fire Sci. Technol. 2021, 40, 7. [Google Scholar]

- Zhang, G.; Li, B. Application Research of Liquid Nitrogen Fire Prevention and Extinguishing Technology in Withdrawal Period of Fully Mechanized Top-coal Caving Face in Inflammable Thick Coal Seam. Coal Technol. 2020, 39, 102–104. [Google Scholar]

- Kang, J.; Zhang, X.; Wu, J.; Zhu, J.P. Numerical simulation of liquid nitrogen fire prevention in computer data center. Fire Sci. Technol. 2020, 39, 904–907. [Google Scholar]

- Chen, J.; He, Y.; Wang, J. Multi-feature fusion based fast video flame detection. Build. Environ. 2010, 45, 1113–1122. [Google Scholar] [CrossRef]

| Test Number | Mode | Distance/m | Diameter/mm | Flow Rate/Maximum Flow Percentage | Remarks |

|---|---|---|---|---|---|

| 1 | - | - | - | - | Control group |

| 2 | Vertical Down | 0.3 m away from the fire source | 10 | 1 | Change flow rate |

| 3 | 3/4 | ||||

| 4 | 1/2 | ||||

| 5 | 1/4 | ||||

| 6 | Vertical Down | 0.3 m away from the fire source | 25 | 1 | Change diameter |

| 7 | 20 | 1 | |||

| 8 | 15 | 1 |

| Test Number | Flow Rate /Maximum Flow Percentage | Time of Fire Extinguishment/s | Time1/2/s | Remark |

|---|---|---|---|---|

| 1 | - | 246 | 204 | Control group |

| 2 | 1 | 24 | 24 | Change flow rate |

| 3 | 3/4 | 25 | 28 | |

| 4 | 1/2 | 27 | 28 | |

| 5 | 1/4 | 35 | 26 |

| Test Number | /mm | /mm | Fire Suppression Factor a/mm/s |

|---|---|---|---|

| 1 | 877.59 | 426.70 | 3.22 |

| 2 | 916.09 | 338.52 | 40.96 |

| 3 | 918.94 | 308.52 | 38.15 |

| 4 | 917.16 | 319.58 | 35.15 |

| 5 | 949.62 | 364.19 | 27.88 |

| Test Number | /°C | /°C | Cooling Factor b/°C/s |

|---|---|---|---|

| 1 | 498.529 | 199.890 | 1.21 |

| 2 | 530.370 | 269.174 | 10.88 |

| 3 | 506.396 | 249.070 | 10.29 |

| 4 | 552.310 | 265.721 | 10.91 |

| 5 | 590.646 | 253.900 | 9.62 |

| Test Number | /% | /% | Asphyxiation Factor c/%/s |

|---|---|---|---|

| 1 | 20.70 | 13.22 | 0.03 |

| 2 | 20.52 | 14.90 | 0.24 |

| 3 | 20.43 | 13.18 | 0.29 |

| 4 | 20.29 | 12.73 | 0.28 |

| 5 | 20.25 | 12.13 | 0.23 |

| Test Number | Diameter/mm | Extinguishing Time/s |

|---|---|---|

| 1 | - | 246 |

| 6 | 25 | 11 |

| 7 | 20 | 13 |

| 8 | 15 | 14 |

| 2 | 10 | 24 |

| Test Number | /mm | /mm | Fire Suppression Factor a/mm/s |

|---|---|---|---|

| 1 | 877.59 | 426.70 | 3.22 |

| 6 | 887.70 | 253.13 | 90.65 |

| 7 | 891.29 | 323.35 | 70.99 |

| 8 | 908.91 | 300.18 | 45.09 |

| 2 | 916.09 | 338.52 | 40.96 |

| Test Number | /°C | /°C | Cooling Factor b/°C/s |

|---|---|---|---|

| 1 | 498.529 | 199.890 | 1.21 |

| 6 | 503.378 | 342.729 | 14.60 |

| 7 | 481.149 | 326.560 | 11.89 |

| 8 | 518.826 | 320.046 | 14.20 |

| 2 | 530.370 | 269.174 | 10.88 |

| Test Number | /% | /% | Asphyxiation Factor c/%/s |

|---|---|---|---|

| 1 | 20.70 | 13.22 | 0.03 |

| 6 | 20.49 | 13.12 | 0.67 |

| 7 | 20.44 | 14 | 0.50 |

| 8 | 20.53 | 15.95 | 0.33 |

| 2 | 20.52 | 14.90 | 0.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Guo, D.; Li, B.; Zhang, Z.; Yuan, D. An Experimental Investigation of the Influence of Flow and Pipe Diameter on the Fire Extinguishing Efficiency of Nitrogen Injection in a Narrow Confined Underground Space. Fire 2022, 5, 202. https://doi.org/10.3390/fire5060202

Zhang G, Guo D, Li B, Zhang Z, Yuan D. An Experimental Investigation of the Influence of Flow and Pipe Diameter on the Fire Extinguishing Efficiency of Nitrogen Injection in a Narrow Confined Underground Space. Fire. 2022; 5(6):202. https://doi.org/10.3390/fire5060202

Chicago/Turabian StyleZhang, Guowei, Dong Guo, Bin Li, Zhiwei Zhang, and Diping Yuan. 2022. "An Experimental Investigation of the Influence of Flow and Pipe Diameter on the Fire Extinguishing Efficiency of Nitrogen Injection in a Narrow Confined Underground Space" Fire 5, no. 6: 202. https://doi.org/10.3390/fire5060202

APA StyleZhang, G., Guo, D., Li, B., Zhang, Z., & Yuan, D. (2022). An Experimental Investigation of the Influence of Flow and Pipe Diameter on the Fire Extinguishing Efficiency of Nitrogen Injection in a Narrow Confined Underground Space. Fire, 5(6), 202. https://doi.org/10.3390/fire5060202