Fire Behaviour of Insulation Panels Commonly Used in High-Rise Buildings

Abstract

:1. Introduction

2. Material and Methods

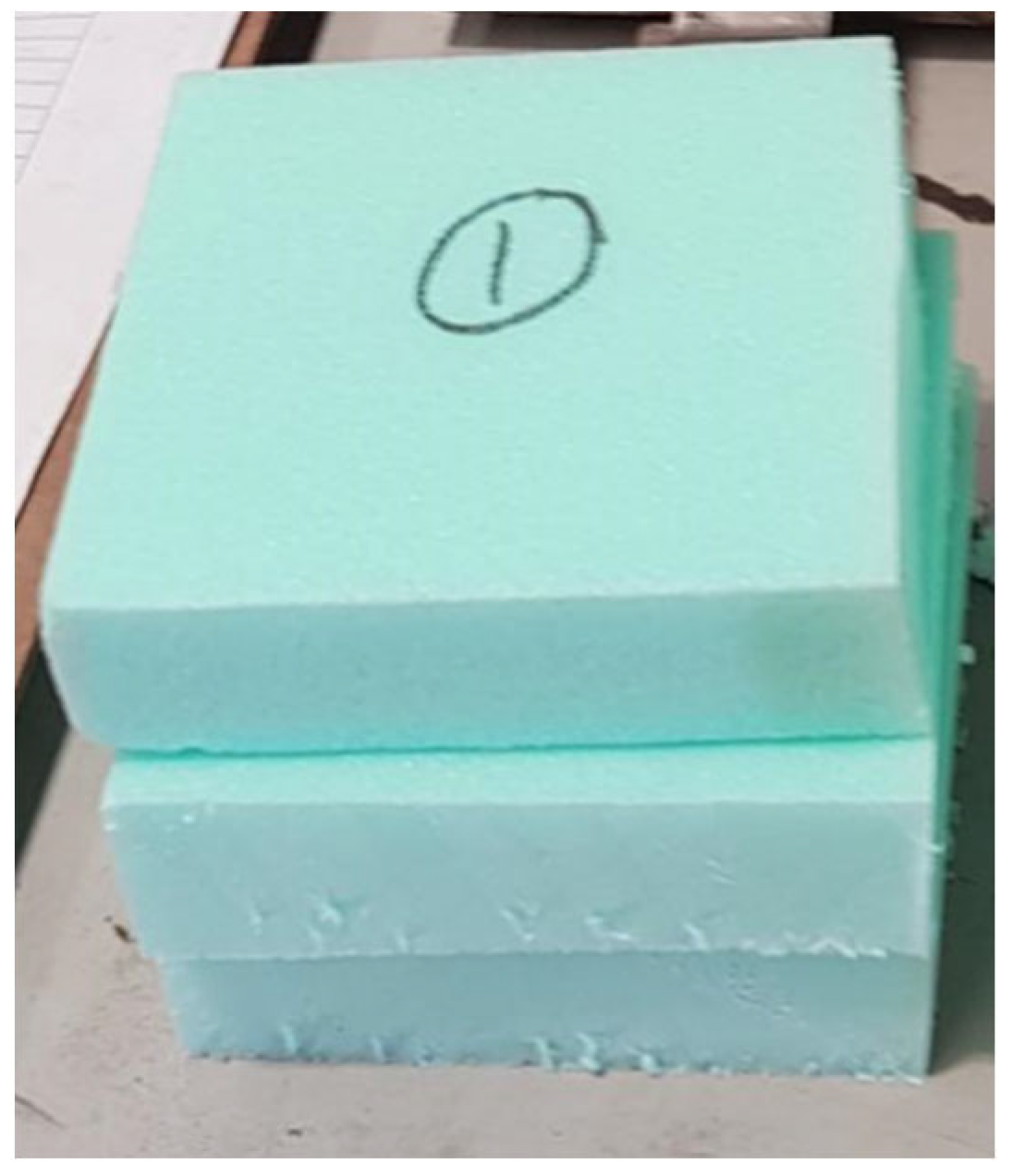

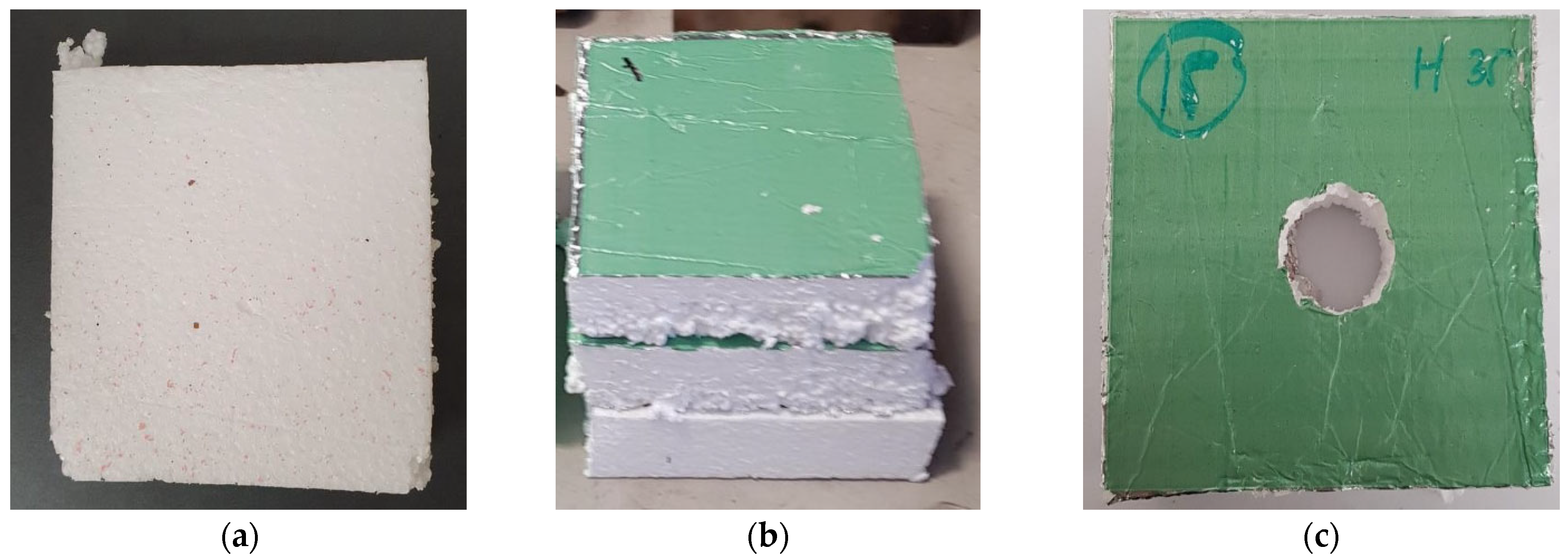

2.1. Materials and Test Specimens

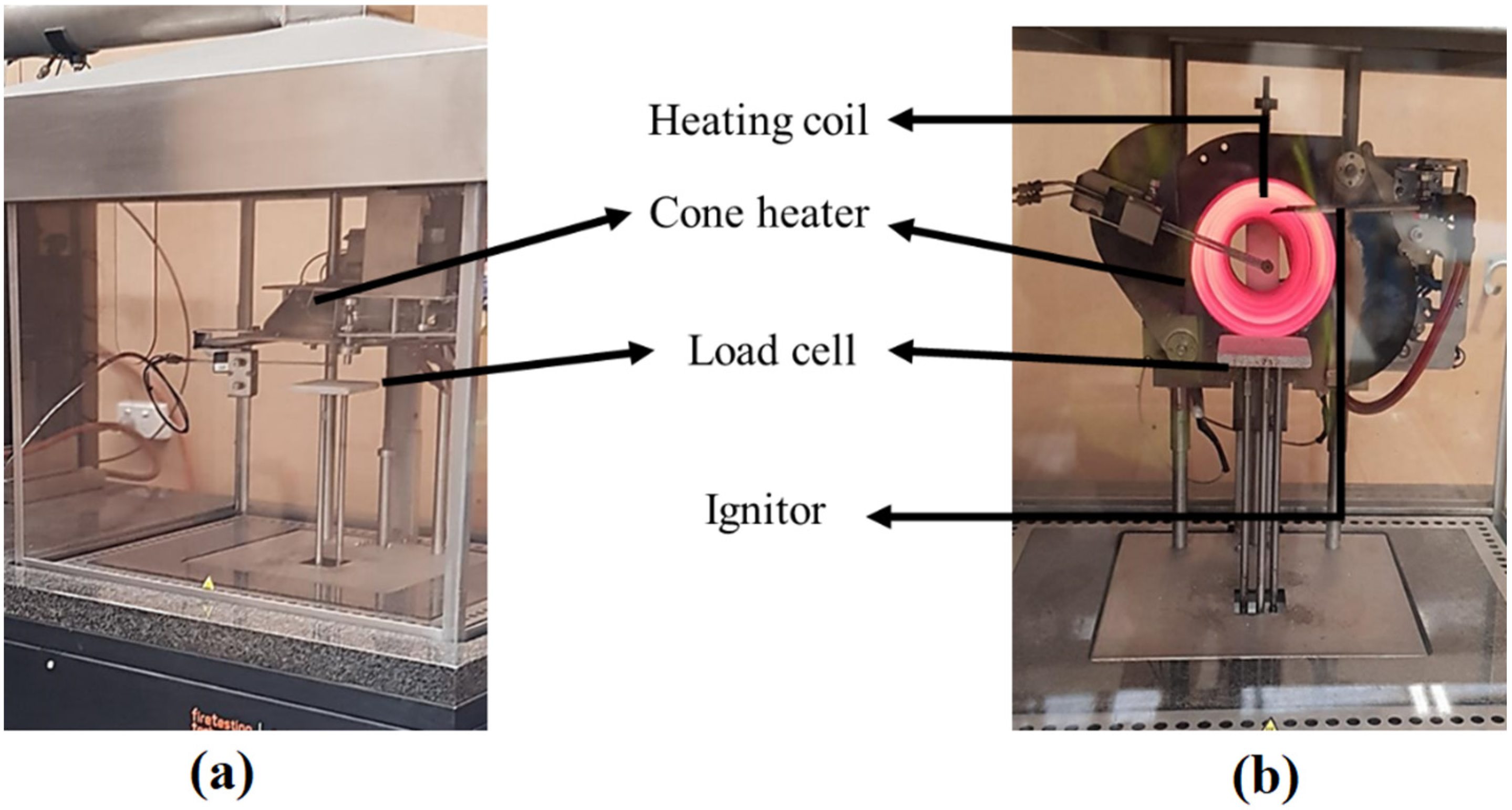

2.2. Test Procedure Using Cone Calorimeter

3. Results and Discussion

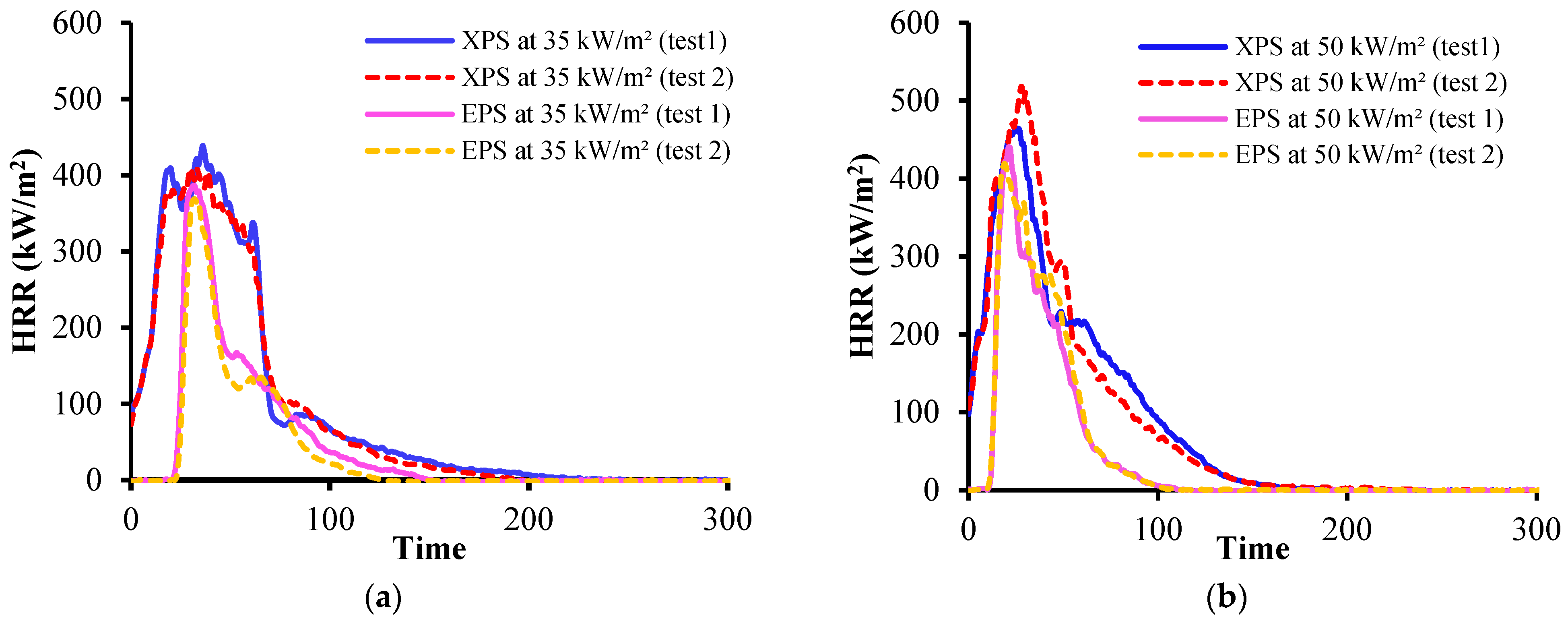

3.1. Fire Performance of EPS and XPS

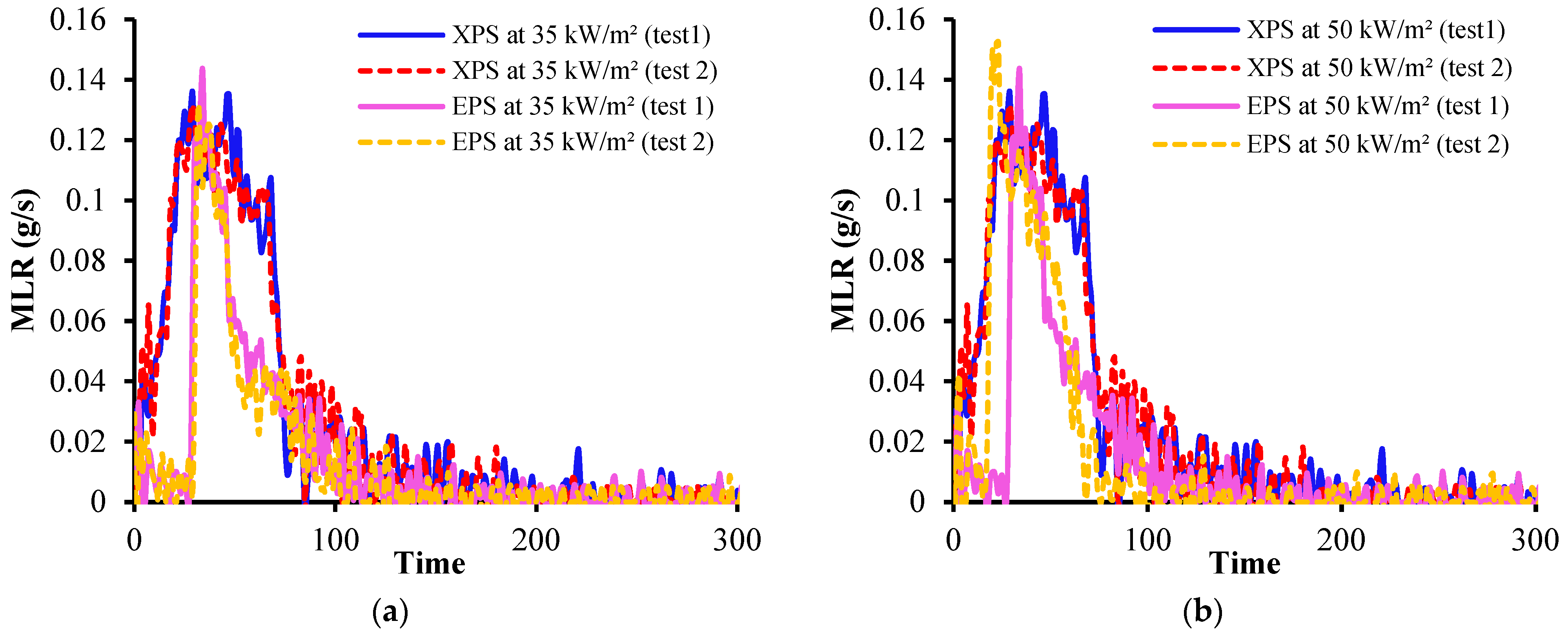

3.1.1. Reaction-to-Fire Properties

3.1.2. Fire Hazard Assessment

3.1.3. Smoke Hazard

3.2. Influencing Fire Testing Parameters of EPS

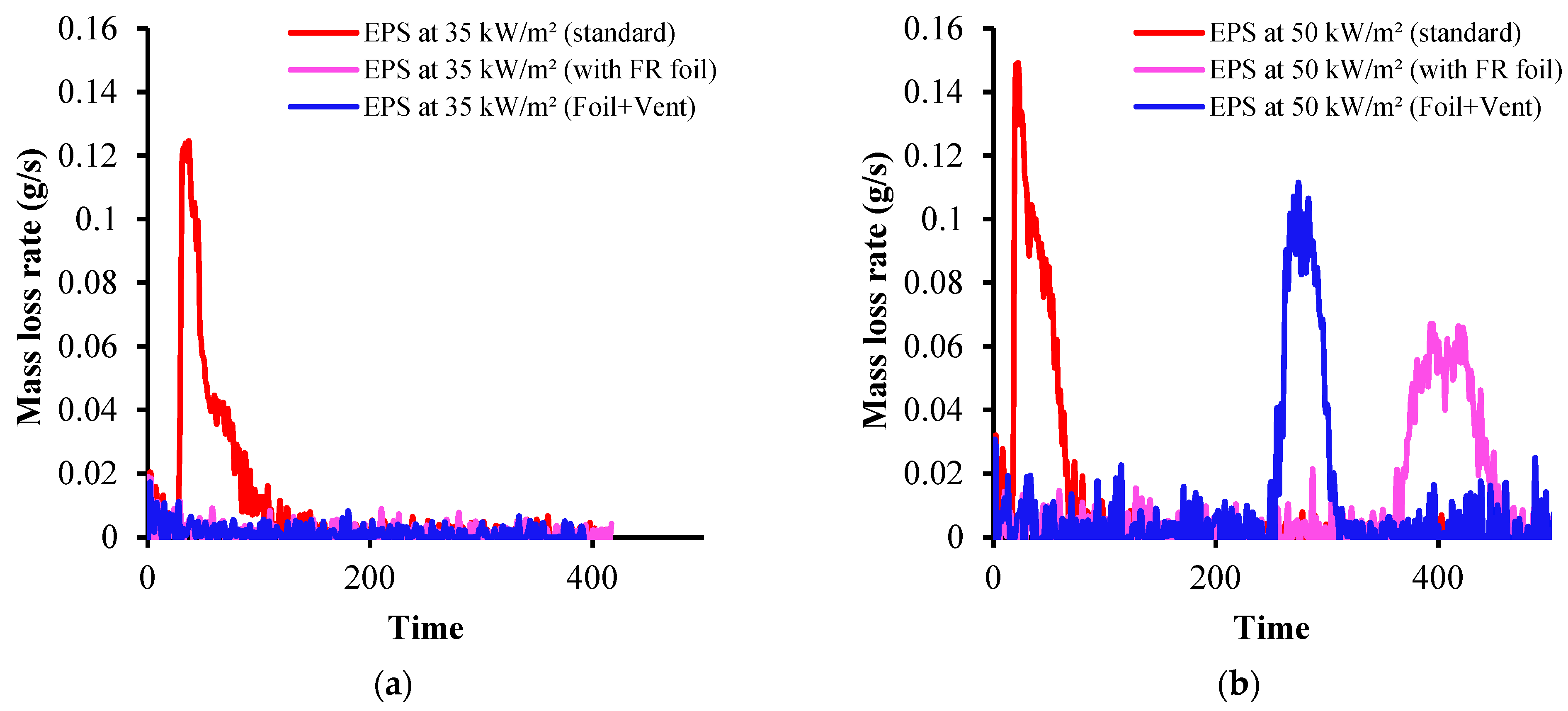

3.2.1. Effect of Sample Configuration and Heat Flux

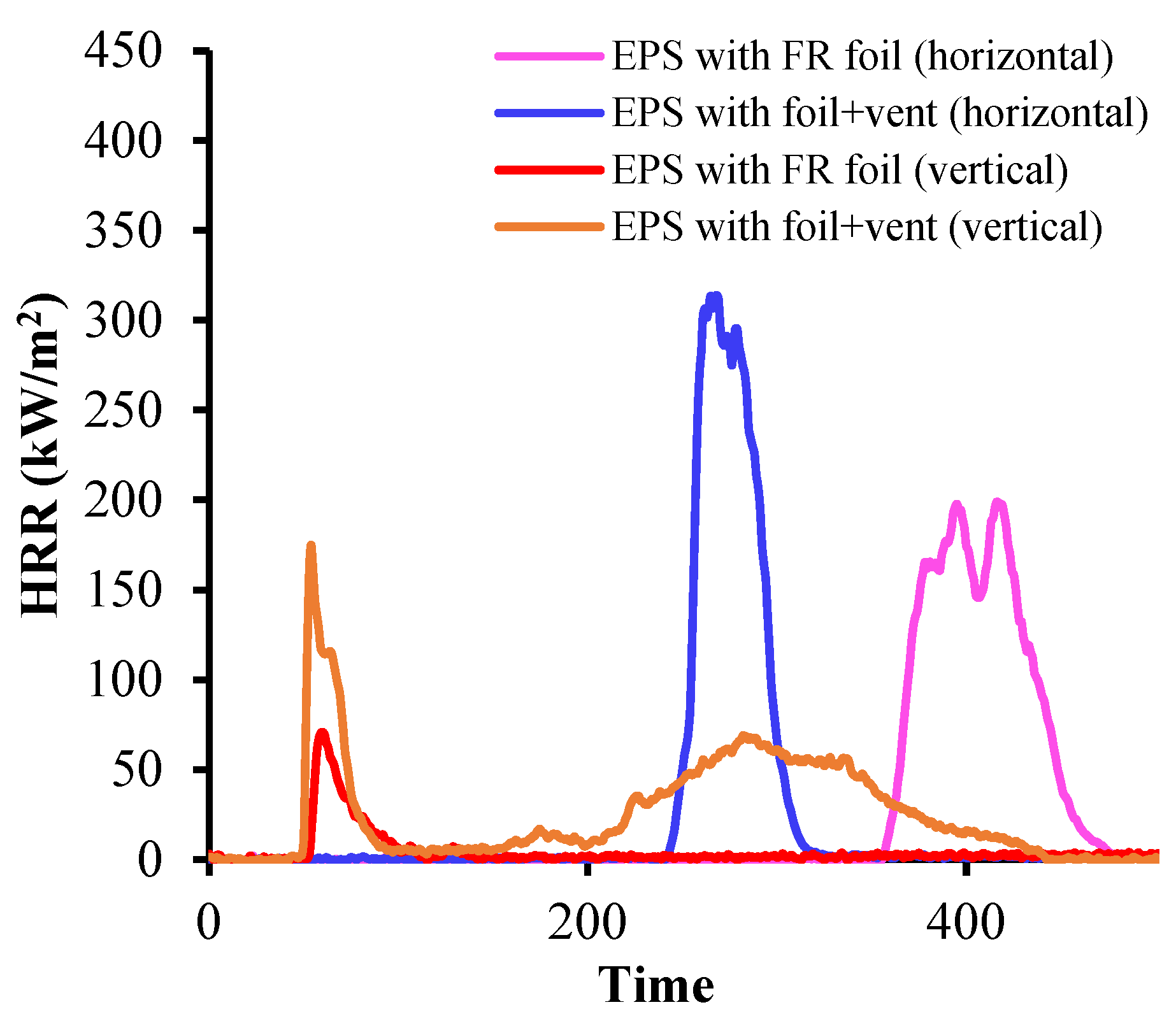

3.2.2. Effect of Test Orientation

4. Conclusions

- (i)

- EPS takes six times as long to ignite (TTI) than XPS. In the current experiment, ignition time is shown to have a negative relationship with external heat flow. The time to pHRR for XPS and EPS samples is more sensitive for the heat flux of 35 kW/m2 than that of 50 kW/m2. In comparison to EPS, however, XPS has a longer overall burning duration and a greater pHRR, but the same patterns are observed for EHC, average HRR, specific mass-loss rate, and THR;

- (ii)

- The EPS samples show a higher FPI value than the XPS samples. According to the FIGRA value, the fire risk of XPS samples is higher compared to the EPS samples. The trends of MARHE ranking seem similar to FIGRA ranking. The FIGRA value is more than two times higher for XPS at 35 kW/m2. The values for XPS and EPS are 321.81 and 137.51 kW/m2, respectively. The analyses indicate that the fire hazard for XPS could be higher than for EPS;

- (iii)

- TSP and SEA values of EPS samples are two times higher compared to XPS samples for both test heat fluxes. However, in the case of smoke hazards, the STI index of EPS is 10 to 20% higher compared to XPS;

- (iv)

- For the sample panels with an FR foil layer, it is observed that a 35 kW/m2 irradiance heat flux is ineffectual in generating the subsequent combustion process. However, at 50 kW/m2, a successive combustion process is observed;

- (v)

- Although the FR foil layer performs better in small to medium fires, the fire can spread more quickly if the foil collapses and exposes the combustible core. Even a damaged section of a panel might operate as a fire carrier, allowing the fire to spread quickly. During testing, the foil collapse is more visible in the vertical orientation. As a consequence, shorter ignition times are noticed for the specimens.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hossain, M.D.; Hassan, M.K.; Yuen, A.C.Y.; He, Y.; Saha, S.; Hittini, W. Flame behaviour, fire hazard and fire testing approach for lightweight composite claddings—A review. J. Struct. Fire Eng. 2021, 12, 257–292. [Google Scholar] [CrossRef]

- Di Foggia, G. Energy efficiency measures in buildings for achieving sustainable development goals. Heliyon 2018, 4, e00953. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Wang, L.; Wang, C.; Liu, P.; Jing, Z.; Ge, X.; Jiang, Y. The flame resistance properties of expandable polystyrene foams coated with a cheap and effective barrier layer. Constr. Build. Mater. 2018, 176, 403–414. [Google Scholar] [CrossRef]

- Crewe, R.J.; Hidalgo, J.P.; Sørensen, M.X.; McLaggan, M.; Molyneux, S.; Welch, S.; Jomaas, G.; Torero, J.L.; Stec, A.A.; Hull, T.R. Fire performance of sandwich panels in a modified ISO 13784-1 small room test: The influence of increased fire load for different insulation materials. Fire Technol. 2018, 54, 819–852. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Huang, X.; Wang, Q.; Ji, J.; Sun, J.; Yin, Y. Experimental study on the characteristics of horizontal flame spread over XPS surface on plateau. J. Hazard. Mater. 2011, 189, 34–39. [Google Scholar] [CrossRef]

- Jiang, L.; Xiao, H.; Zhou, Y.; An, W.; Yan, W.; He, J.; Sun, J. Theoretical and experimental study of width effects on horizontal flame spread over extruded and expanded polystyrene foam surfaces. J. Fire Sci. 2014, 32, 193–209. [Google Scholar] [CrossRef]

- Bonner, M.; Wegrzynski, W.; Papis, B.K.; Rein, G. KRESNIK: A top-down, statistical approach to understand the fire performance of building facades using standard test data. Build. Environ. 2020, 169, 1–10. [Google Scholar] [CrossRef]

- Babrauskas, V. Heat Release Rates, SFPE Handbook of Fire Protection Engineering; Springer: New York, NY, USA, 2016; pp. 799–904. [Google Scholar]

- An, W.; Sun, J.; Liew, K.; Zhu, G. Effects of building concave structure on flame spread over extruded polystyrene thermal insulation material. Appl. Therm. Eng. 2017, 121, 802–809. [Google Scholar] [CrossRef]

- Hajduković, M.; Knez, N.; Knez, F.; Kolšek, J. Fire performance of external thermal insulation composite system (ETICS) facades with expanded polystyrene (EPS) insulation and thin rendering. Fire Technol. 2017, 53, 173–209. [Google Scholar] [CrossRef]

- Zhou, B.; Yoshioka, H.; Noguchi, T.; Ando, T. Experimental study of expanded polystyrene (EPS) External Thermal Insulation Composite Systems (ETICS) masonery façade reaction-to-fire performance. Therm. Sci. Eng. Prog. 2018, 8, 83–92. [Google Scholar] [CrossRef]

- Mensah, R.A.; Xu, Q.; Asante-Okyere, S.; Jin, C.; Bentum-Micah, G. Correlation analysis of cone calorimetry and microscale combustion calorimetry experiments. J. Therm. Anal. Calorim. 2019, 136, 589–599. [Google Scholar] [CrossRef]

- Hossain, M.D.; Saha, S.; Hassan, M.K.; Yuen, A.C.Y.; Wang, C.; Hittini, W.; George, L.; Wuhrer, R. Testing of aluminium composite panels in a cone calorimeter: A new specimen preparation method. Polym. Test. 2022, 106, 107454. [Google Scholar] [CrossRef]

- Hossain, D.; Hassan, K.; Yuen, A.C.Y.; Wang, C.; Hittini, W. Influencing factors in small-scale fire testing of aluminium composite panels. In Proceedings of the 12th Asia-Oceania Symposium on Fire Science and Technology (AOSFST 2021), Virtual, 7–9 December 2021; The University of Queensland: Brisbane, Australia, 2021. [Google Scholar]

- Bakhtiyari, S.; Taghi, A.L.; Barikani, M. The effective parameters for reaction-to-fire properties of expanded polystyrene foamsin bench scale. Iran. Polym. J. 2010, 19, 27–37. [Google Scholar]

- ISO 5660-1:2015; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate—Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). International Standards Organization: Geneva, Switzerland, 2015.

- Schartel, B.; Hull, T.R. Development of fire-retarded materials—interpretation of cone calorimeter data. Fire Mater. Int. J. 2007, 31, 327–354. [Google Scholar] [CrossRef]

- Hansen, A.S.; Hovde, P.J. Prediction of time to flashover in the ISO 9705 room corner test based on cone calorimeter test results. Fire Mater. 2002, 26, 77–86. [Google Scholar] [CrossRef]

- Chow, W. Fire hazard assessment on polyurethane sandwich panels for temporary accommodation units. Polym. Test. 2004, 23, 973–977. [Google Scholar] [CrossRef]

- Morrisset, D.; Thorncroft, G.; Hadden, R.; Law, A.; Emberley, R. Statistical uncertainty in bench-scale flammability tests. Fire Saf. J. 2021, 122, 103335. [Google Scholar] [CrossRef]

- EN 13501; Fire Classification of Construction Products and Building Elements-Part 1: Classification Using Data from Reaction to Fire Tests. British Standard Institute: London, UK, 2002.

- Quintiere, J.G. Fundamentals of Fire Phenomena; Wiley: New York, NY, USA, 2006. [Google Scholar]

- An, W.; Jiang, L.; Sun, J.; Liew, K. Correlation analysis of sample thickness, heat flux, and cone calorimetry test data of polystyrene foam. J. Therm. Anal. Calorim. 2015, 119, 229–238. [Google Scholar] [CrossRef]

- Xu, Q.; Jin, C.; Jiang, Y. Compare the flammability of two extruded polystyrene foams with micro-scale combustion calorimeter and cone calorimeter tests. J. Therm. Anal. Calorim. 2017, 127, 2359–2366. [Google Scholar] [CrossRef]

- Hirschler, M.M. Flame retardants and heat release: Review of data on individual polymers. Fire Mater. 2015, 39, 232–258. [Google Scholar] [CrossRef] [Green Version]

- Sacristán, M.; Hull, T.R.; Stec, A.A.; Ronda, J.C.; Galià, M.; Cádiz, V. Cone calorimetry studies of fire retardant soybean-oil-based copolymers containing silicon or boron: Comparison of additive and reactive approaches. Polym. Degrad. Stab. 2010, 95, 1269–1274. [Google Scholar] [CrossRef] [Green Version]

- Stec, A.A.; Hull, T.R. (Eds.) Introduction to Fire Toxicity. In Fire Toxicity; Woodhead Publishing Limited: Cambridge, UK, 2010; pp. 1–25. [Google Scholar]

- Mulholland, G.; Janssens, M.; Yusa, S.; Twilley, W.; Babrauskas, V. The effect of oxygen concentration on CO and smoke produced by flames. Fire Saf. Sci. 1991, 3, 585–594. [Google Scholar] [CrossRef] [Green Version]

- Drysdale, D. Smoke: Its Formation, Composition and Movement, An introduction to Fire Dynamics. In An Introduction to Fire Dynamics, 3rd ed.; 2011; pp. 441–474. Available online: https://onlinelibrary.wiley.com/doi/10.1002/9781119975465.ch11 (accessed on 20 April 2022).

- Khan, A.A.; Lin, S.; Huang, X.; Usmani, A. Facade Fire Hazards of Bench-Scale Aluminum Composite Panel with Flame-Retardant Core. Fire Technol. 2021; 1–19, pre-print. Available online: https://www.grenfelltowerinquiry.org.uk/evidence/professor-luke-bisbys-expert-report(accessed on 20 May 2022). [CrossRef]

- Bisby, L.A. Grenfell Tower Inquiry: Phase 1-Final Expert Report; Grenfell Tower Enquiry: London, UK, 2018. [Google Scholar]

- Deepak, D.; Drysdale, D. Flammability of solids: An apparatus to measure the critical mass flux at the firepoint. Fire Saf. J. 1983, 5, 167–169. [Google Scholar] [CrossRef]

| Types of Materials | Density (kg/m3) | Mass (g) | Size (mm) | Thickness (mm) |

|---|---|---|---|---|

| Extruded polystyrene (XPS) | 28.0 | 8.0 | 100 × 100 | 30 |

| Expanded polystyrene (EPS) | 18.0 | 5.4 | 100 × 100 | 30 * |

| Sl. No | Sample Label | Sample Type | Size (mm × mm) | Orientation | Heat-Flux (kW/m2) | Configuration |

|---|---|---|---|---|---|---|

| 1 | XPS-H-S-35 | XPS | 100 × 100 | Horizontal | 35 | Standard |

| 2 | XPS-H-S-50 | 100 × 100 | Horizontal | 50 | Standard | |

| 3 | EPS-H-F-35 | EPS | 100 × 100 | Horizontal | 35 | With FR foil |

| 4 | EPS-H-S-35 | 100 × 100 | Horizontal | 35 | Standard (No foil) | |

| 5 | EPS-H-H-35 | 100 × 100 | Horizontal | 35 | Foil and vent | |

| 6 | EPS-H-F-50 | 100 × 100 | Horizontal | 50 | With FR foil | |

| 7 | EPS-H-S-50 | 100 × 100 | Horizontal | 50 | Standard (No foil) | |

| 8 | EPS-H-H-50 | 100 × 100 | Horizontal | 50 | Foil and vent | |

| 9 | EPS-V-F-50 | 100 × 100 | Vertical | 50 | With FR foil | |

| 10 | EPS-V-H-35 | 100 × 100 | Vertical | 50 | Foil and Vent |

| Parameters | XPS | EPS * | ||

| Heat-flux (kW/m2) | 35 | 50 | 35 | 50 |

| Reaction-to-fire properties: | ||||

| Time to ignition (s) | 5 | 3 | 29 | 17 |

| Time to flameout (s) | 174 | 143 | 135 | 98 |

| Total burning time (s) | 169 | 140 | 106 | 81 |

| pHRR (kW/m2) | 423 | 492 | 377 | 442 |

| Time to pHRR (s) | 33 | 28 | 32 | 20 |

| Avg. EHC (MJ/kg) | 28.39 | 27.88 | 24.81 | 24.44 |

| Avg. specific mass loss rate (g/s·m2) | 8.73 | 9.11 | 5.97 | 9.09 |

| Avg. HRR (kW/m2) | 73.24 | 65.50 | 29.31 | 33.37 |

| THR (MJ/m2) | 26.21 | 26.60 | 11.23 | 12.90 |

| Fire hazard: | ||||

| FIGRA | 12.90 | 18.19 | 11.80 | 22.09 |

| FPI | 0.0106 | 0.0052 | 0.0756 | 0.0385 |

| MARHE (kW/m2) | 321.81 | 357.50 | 137.51 | 224.35 |

| Smoke hazard: | ||||

| TSP (m2) | 9.35 | 10.09 | 4.38 | 5.585 |

| Avg. SEA (m2/kg) | 1147.50 | 1207.88 | 1120.26 | 1202.08 |

| CO yield (kg/kg) | 0.18 | 0.17 | 0.19 | 0.21 |

| CO2 Yield (kg/kg) | 2.06 | 2.00 | 1.95 | 1.90 |

| Smoke toxicity index (STI) | 0.0874 | 0.0850 | 0.0974 | 0.1105 |

| Parameters | Horizontal | Vertical | ||

|---|---|---|---|---|

| FR Foil | FR Foil and Vent | FR Foil | FR Foil and Vent | |

| TTI (s) | 360 | 247 | 50 | 50 |

| Time to pHRR (s) | 415 | 267 | 62 | 54 |

| pHRR (kW/m2) | 199 | 311 | 70.94 | 128.40 |

| Avg. HRR (kW/m2) | 53.70 | 57.88 | 4.02 | 22.09 |

| THR (MJ/m2) | 12.80 | 11.86 | 2.41 | 11.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hossain, M.D.; Hassan, M.K.; Akl, M.; Pathirana, S.; Rahnamayiezekavat, P.; Douglas, G.; Bhat, T.; Saha, S. Fire Behaviour of Insulation Panels Commonly Used in High-Rise Buildings. Fire 2022, 5, 81. https://doi.org/10.3390/fire5030081

Hossain MD, Hassan MK, Akl M, Pathirana S, Rahnamayiezekavat P, Douglas G, Bhat T, Saha S. Fire Behaviour of Insulation Panels Commonly Used in High-Rise Buildings. Fire. 2022; 5(3):81. https://doi.org/10.3390/fire5030081

Chicago/Turabian StyleHossain, Md Delwar, Md Kamrul Hassan, Mahmoud Akl, Sameera Pathirana, Payam Rahnamayiezekavat, Grahame Douglas, Tanmay Bhat, and Swapan Saha. 2022. "Fire Behaviour of Insulation Panels Commonly Used in High-Rise Buildings" Fire 5, no. 3: 81. https://doi.org/10.3390/fire5030081

APA StyleHossain, M. D., Hassan, M. K., Akl, M., Pathirana, S., Rahnamayiezekavat, P., Douglas, G., Bhat, T., & Saha, S. (2022). Fire Behaviour of Insulation Panels Commonly Used in High-Rise Buildings. Fire, 5(3), 81. https://doi.org/10.3390/fire5030081