Study on Lightning-Induced Plasma Extinguishing in 10 kV Distribution Network Lines Based on Electronegative Gas Trifluoroiodomethane

Abstract

1. Introduction

2. Mathematical Model of Plasma Arc and Principle of Deionization

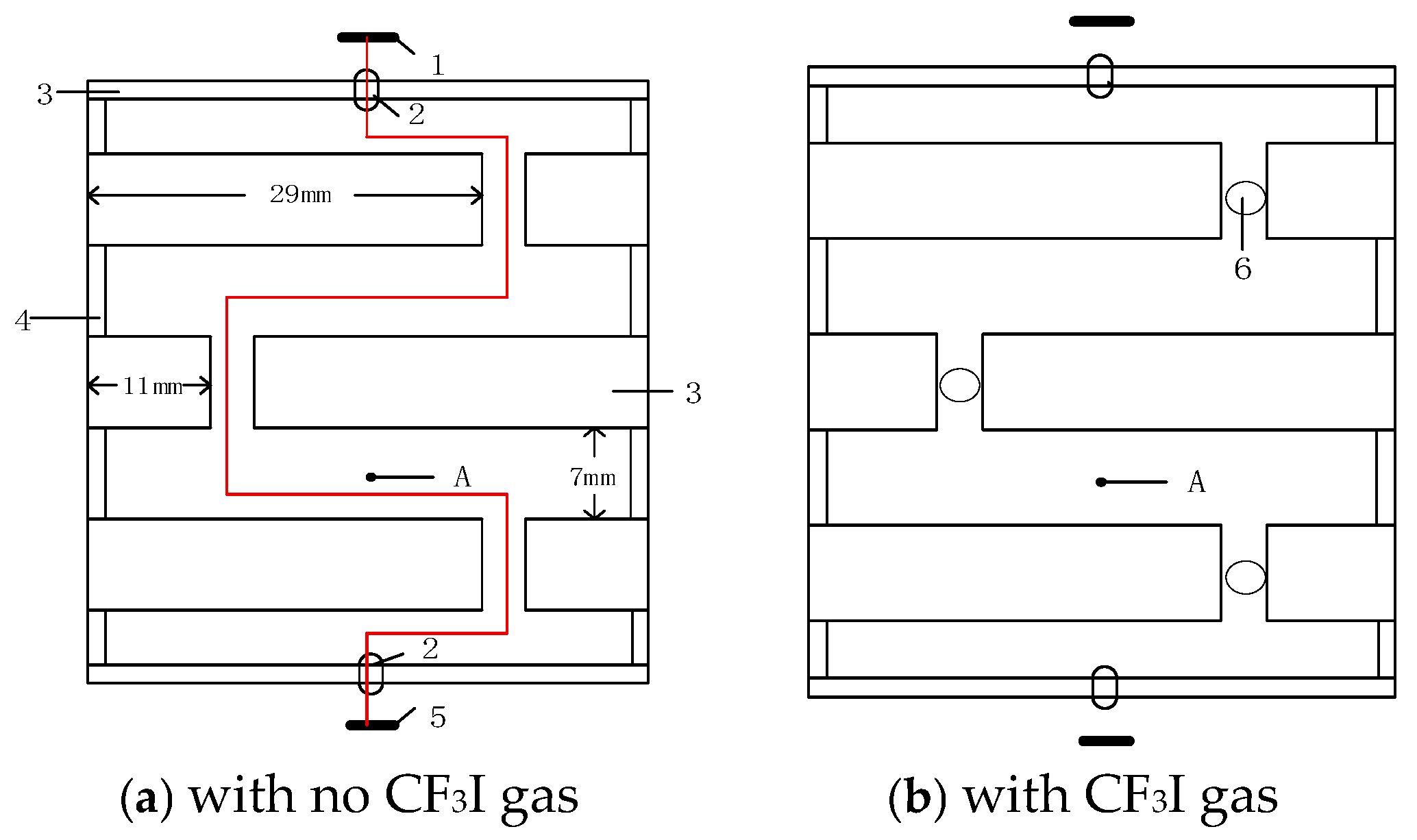

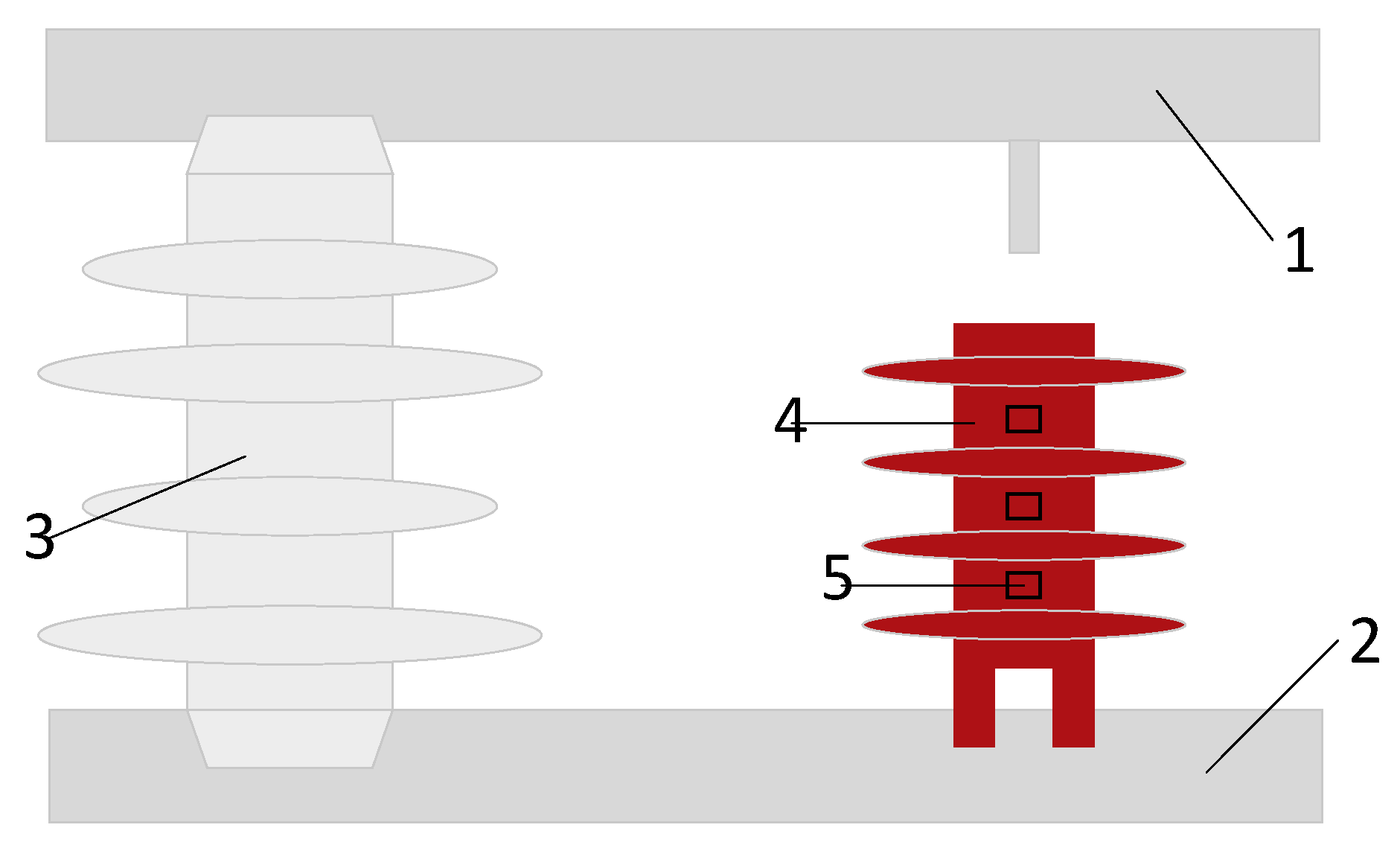

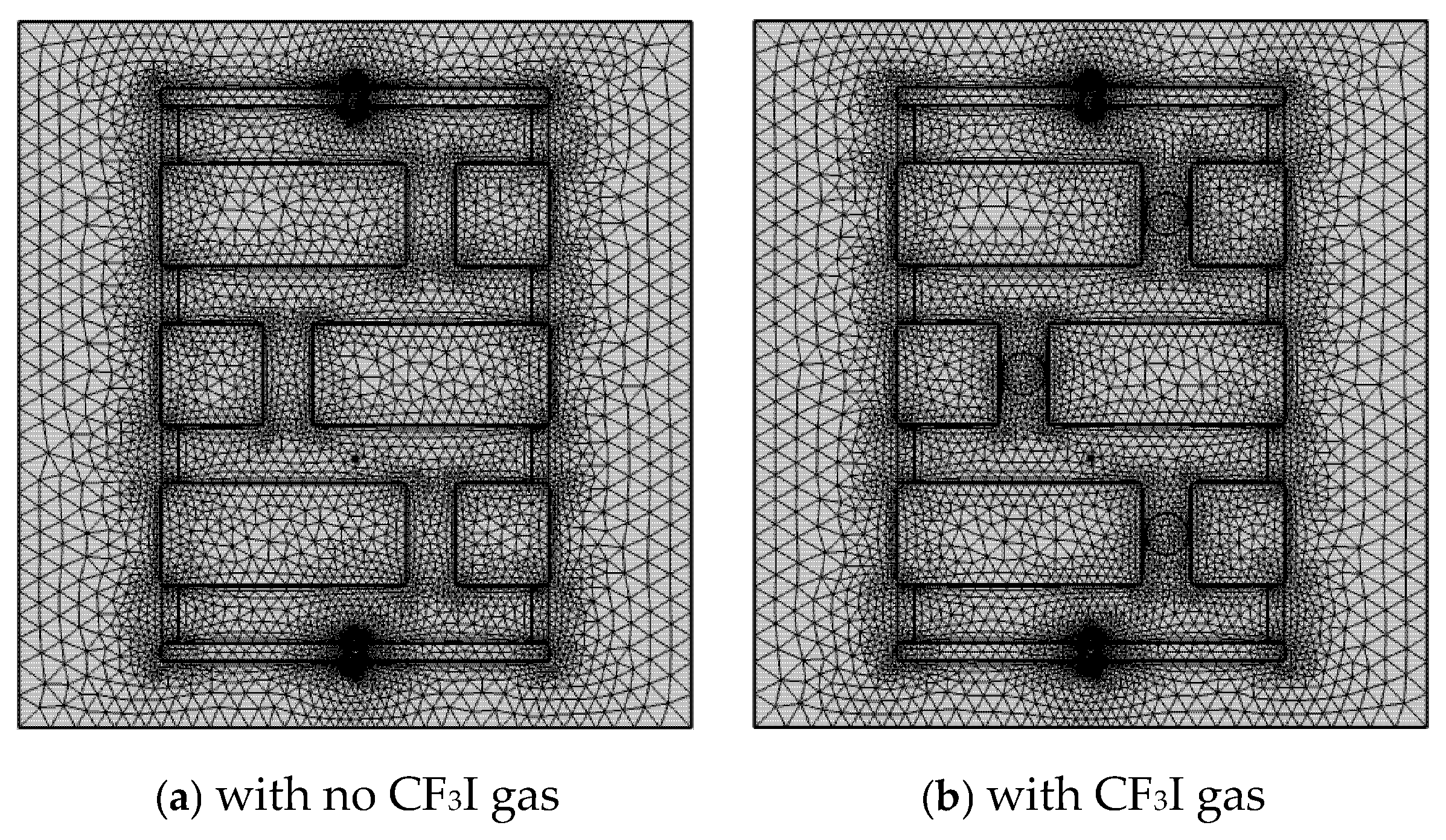

2.1. Structure of the Same-Layer Double-Break Compressed Lightning Protection Device

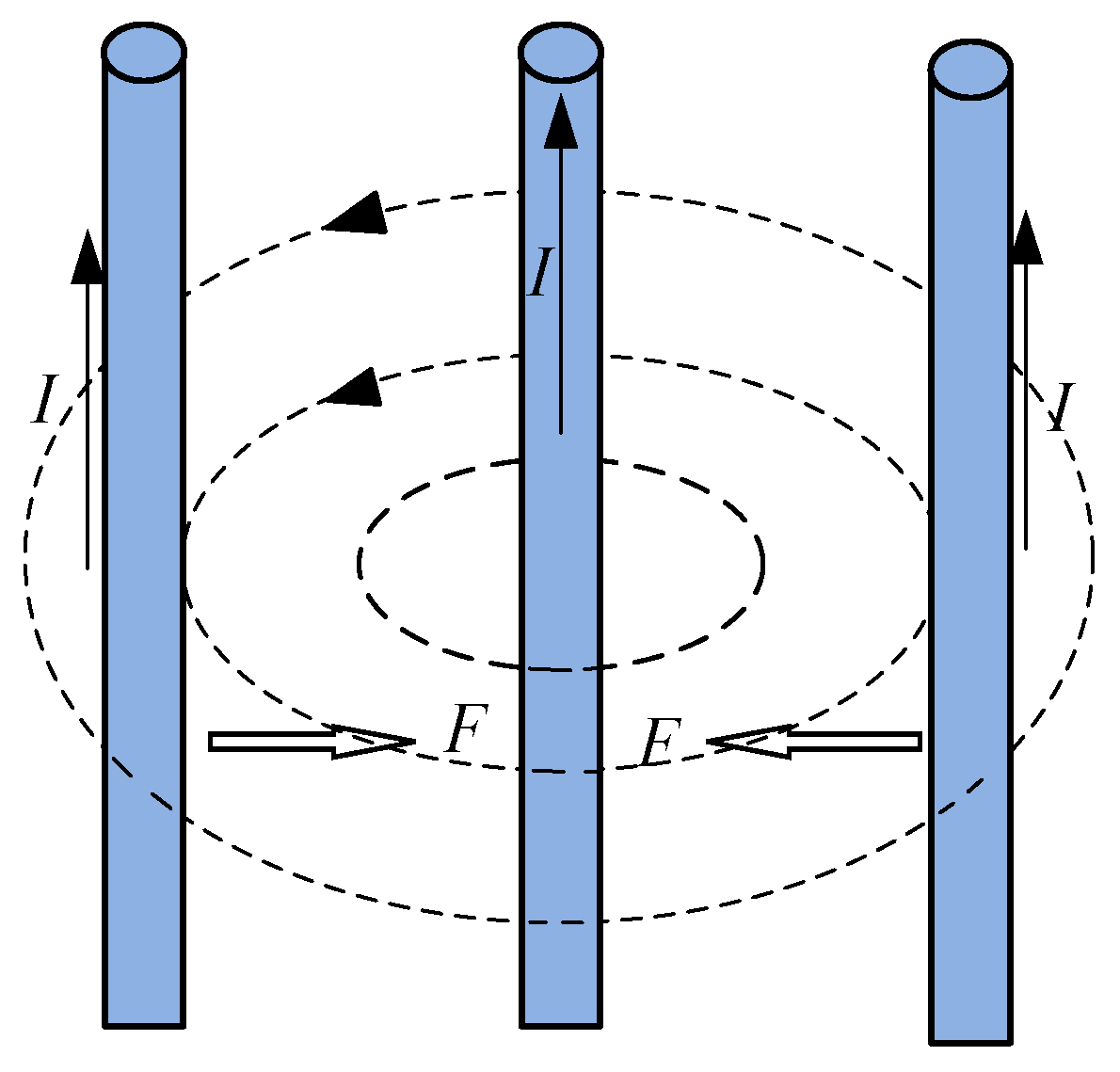

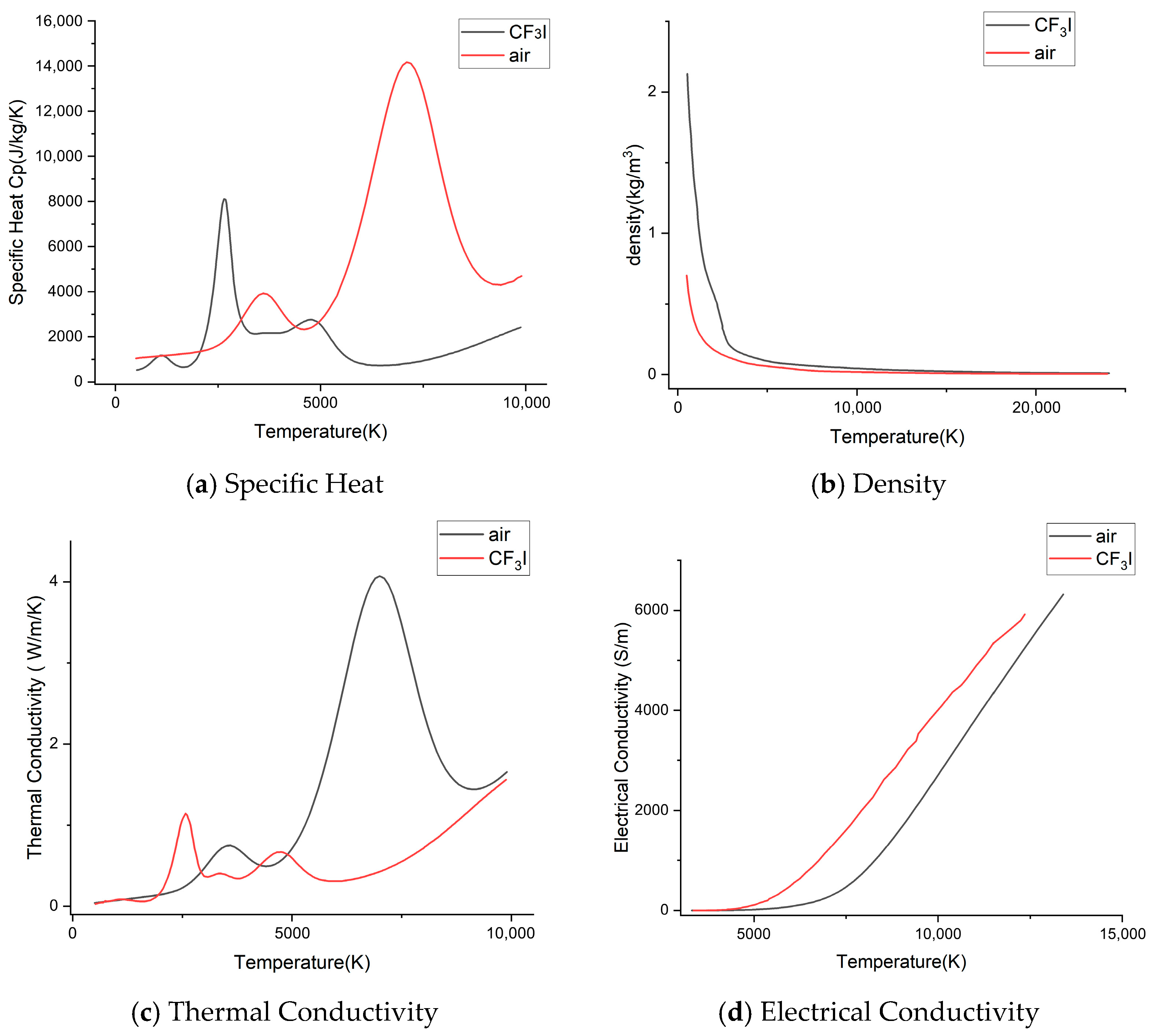

2.2. Plasma Model Analysis

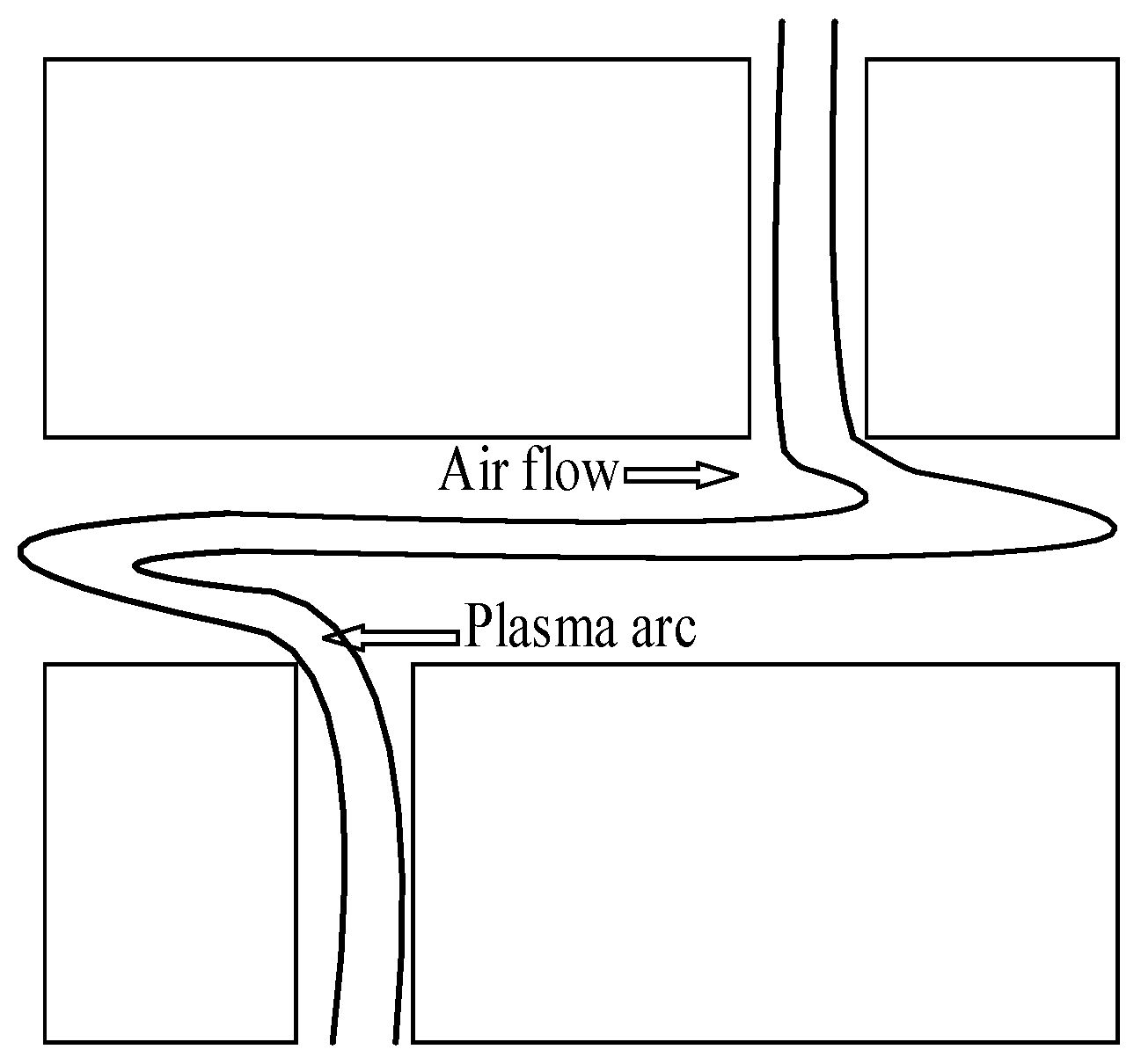

2.3. Analysis of Plasma Deionization Process in a Same-Layer Double-Break Compression Lightning Protection Device

2.4. Plasma Arc Extinction Criteria

3. Simulation Analysis

3.1. Simulation Condition

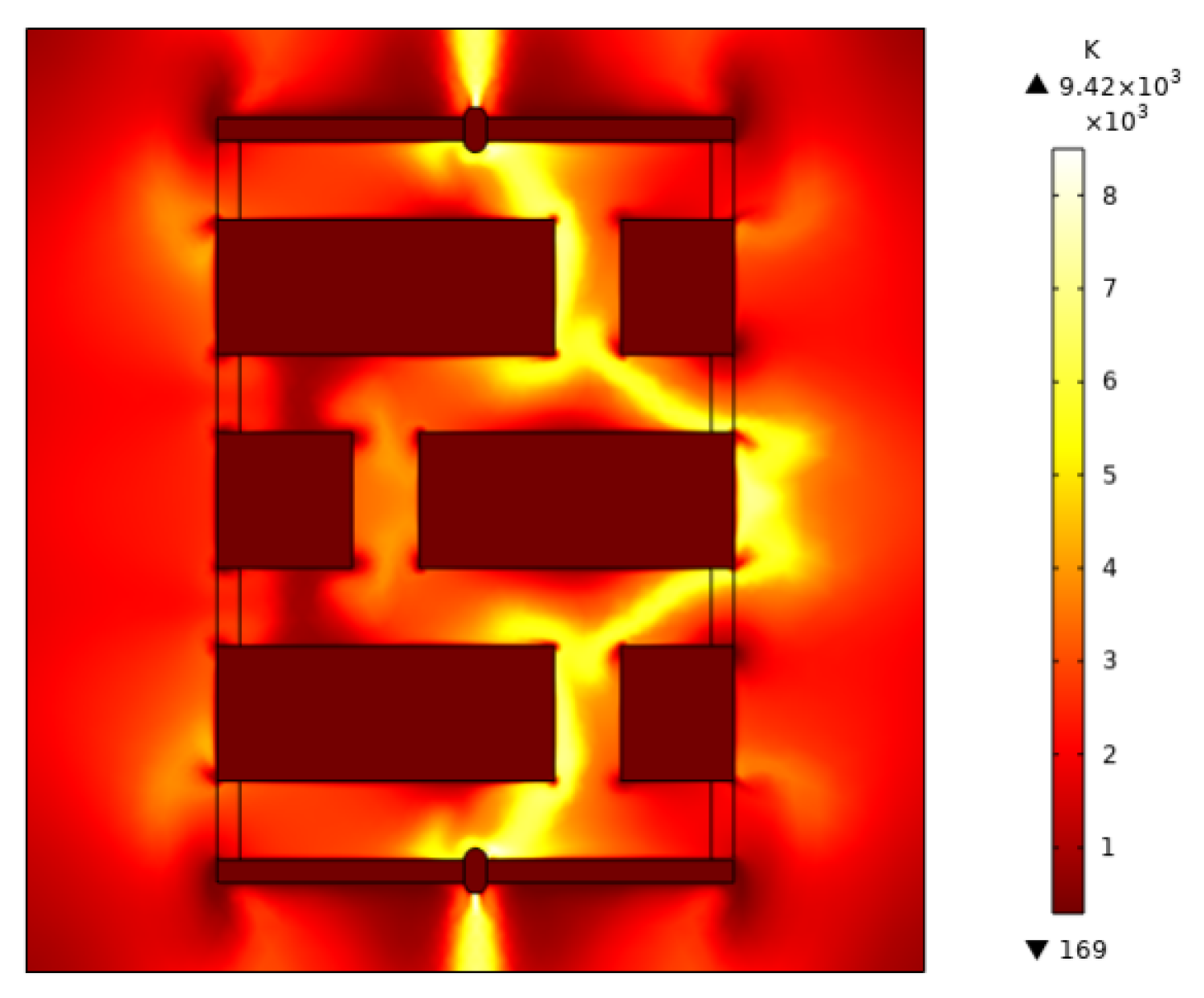

3.2. Comparison of Arc-Extinguishing Effects at Different Horizontal Distances of Compressed Pipelines

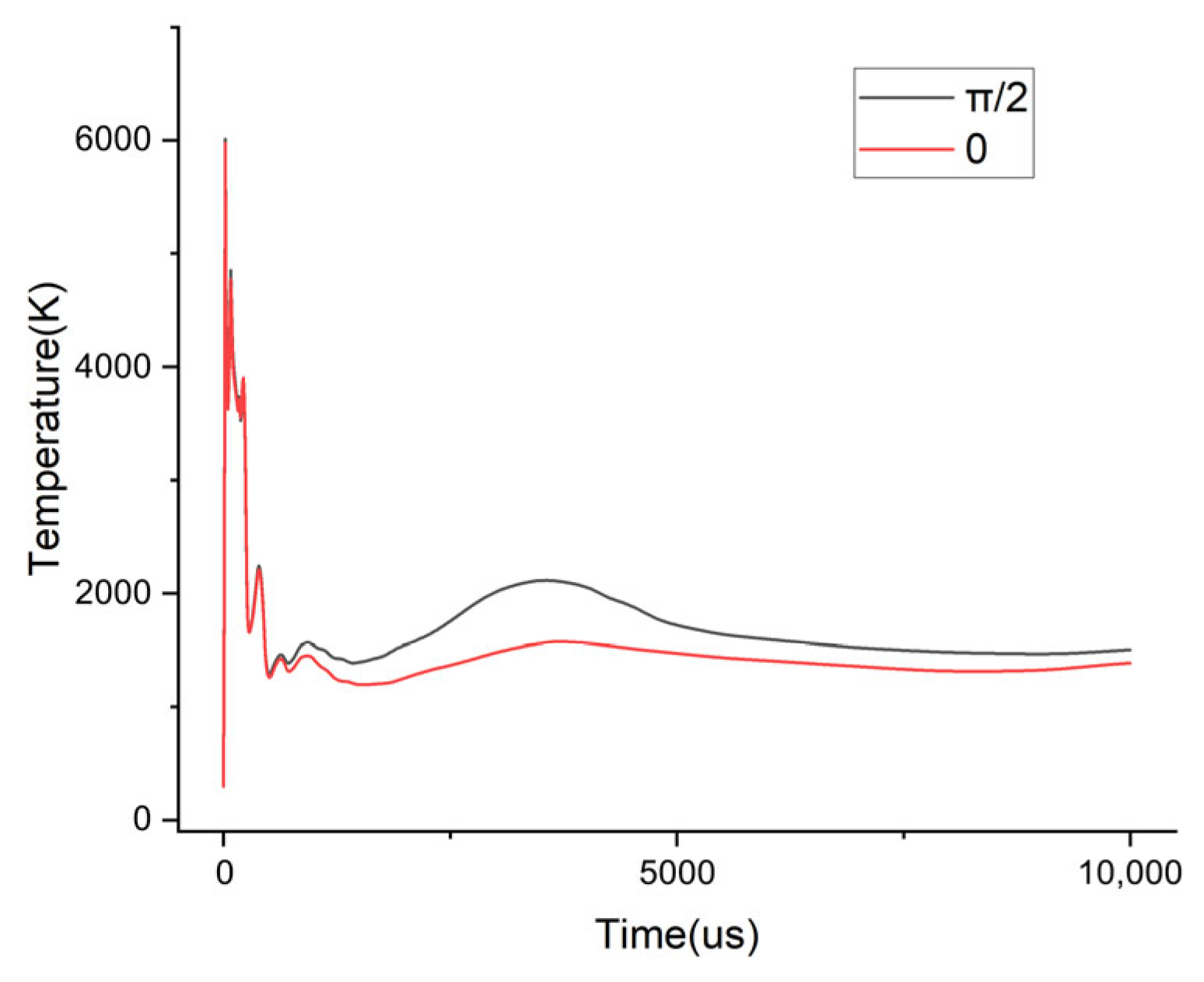

3.3. Comparison of Arc-Extinguishing Effects Based on Different Initial Phases

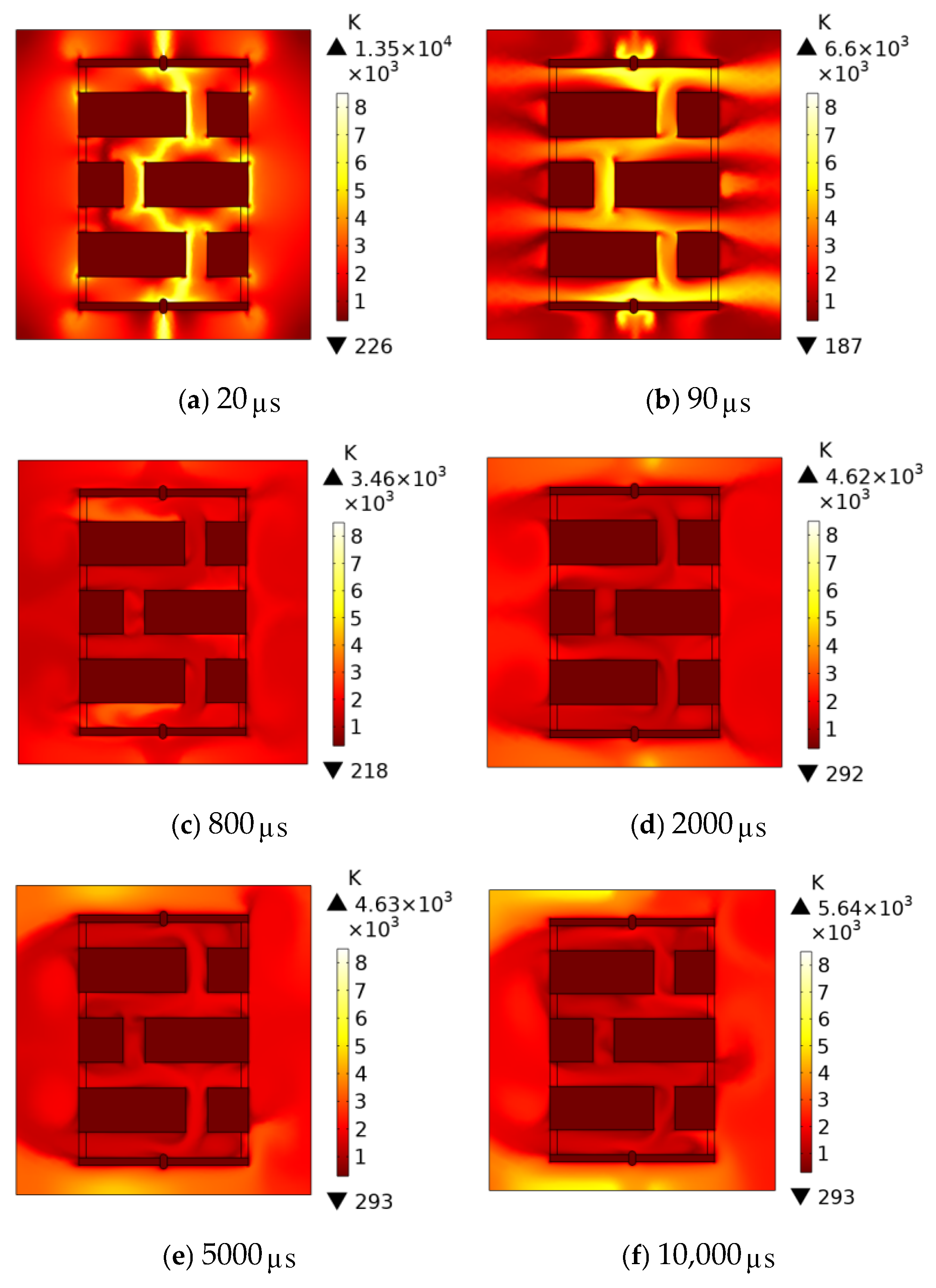

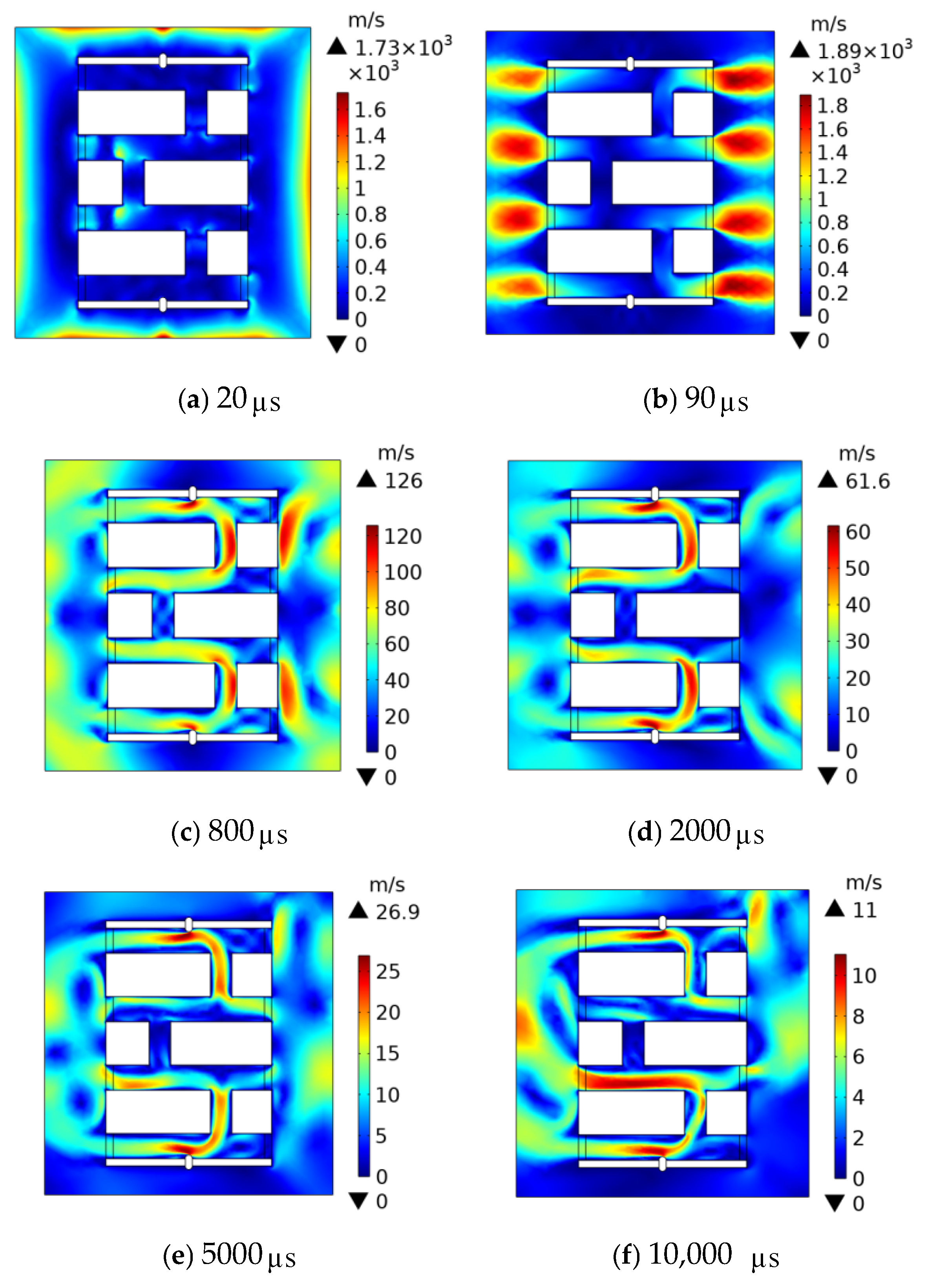

3.3.1. Analysis of the Overall Arc-Extinguishing Effect of Power Frequency Current with an Initial Phase of

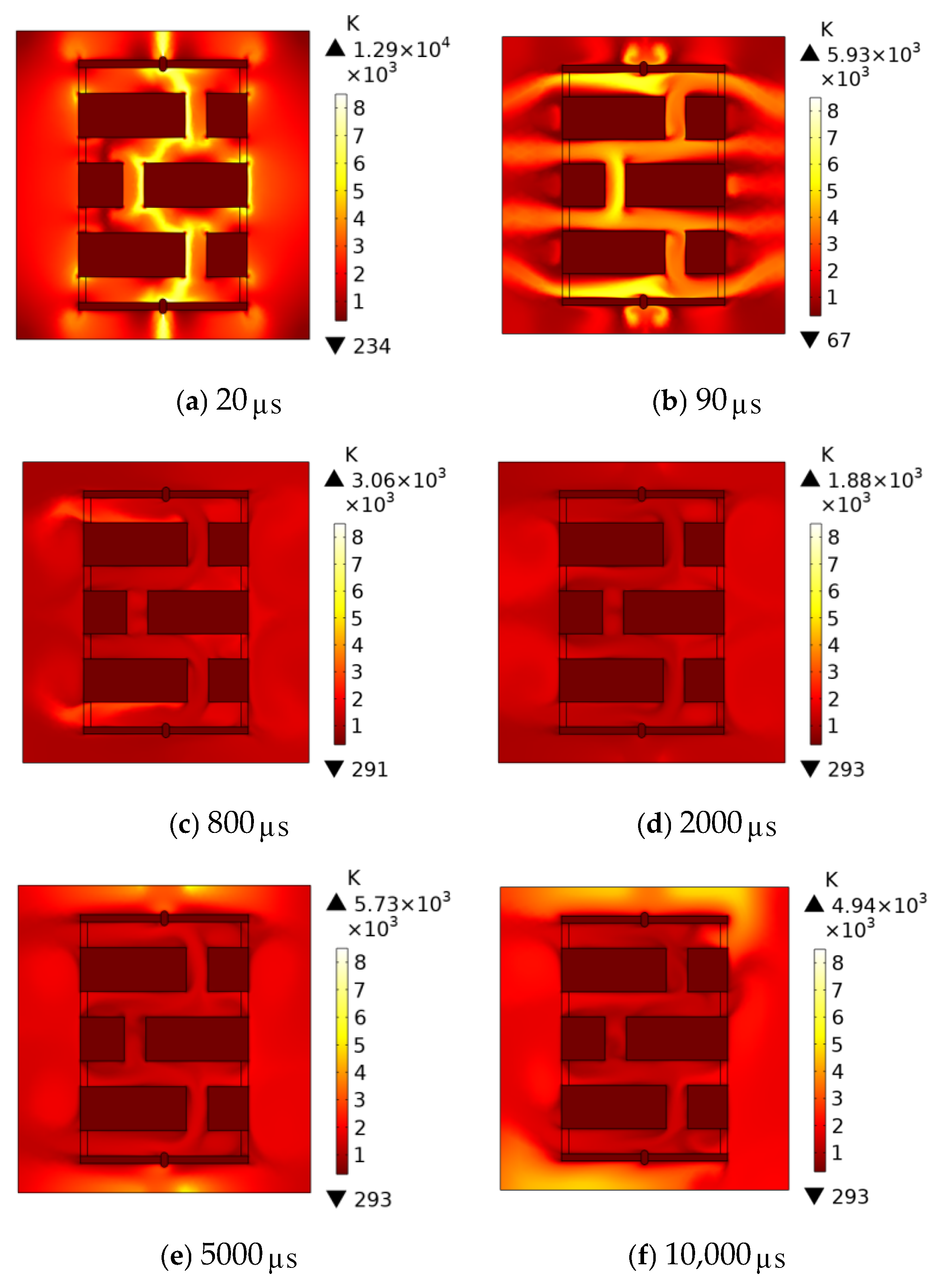

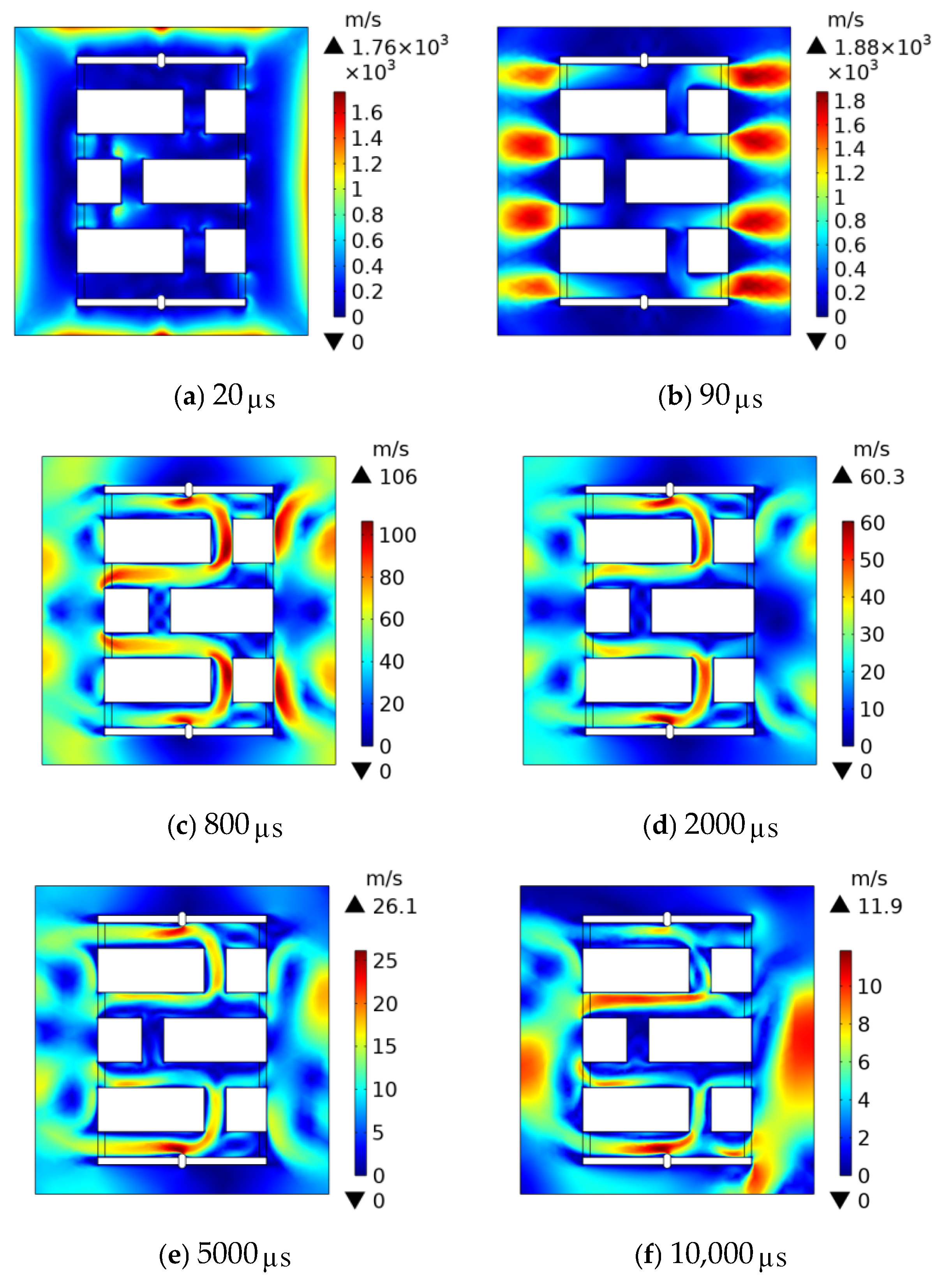

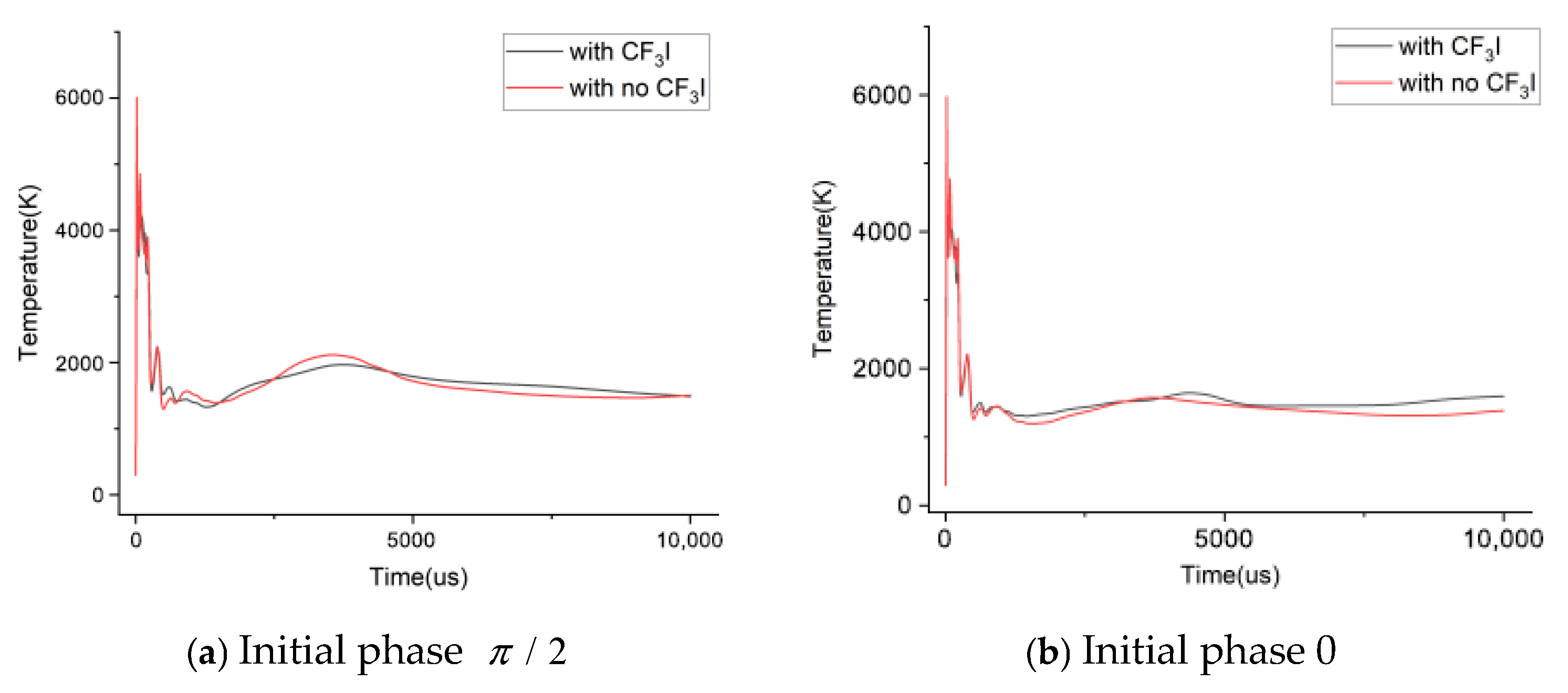

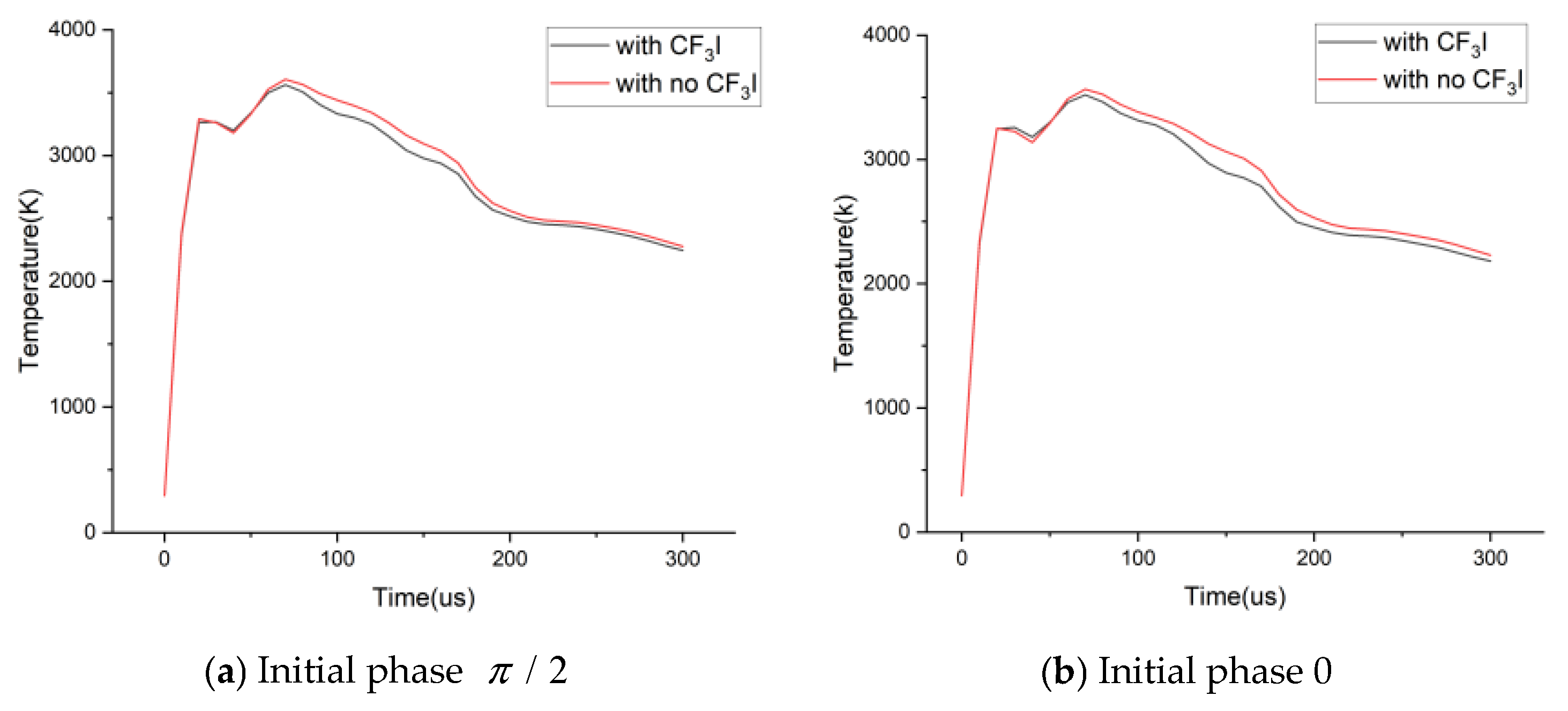

3.3.2. Analysis of the Overall Arc-Extinguishing Effect of Power Frequency Current with an Initial Phase of 0

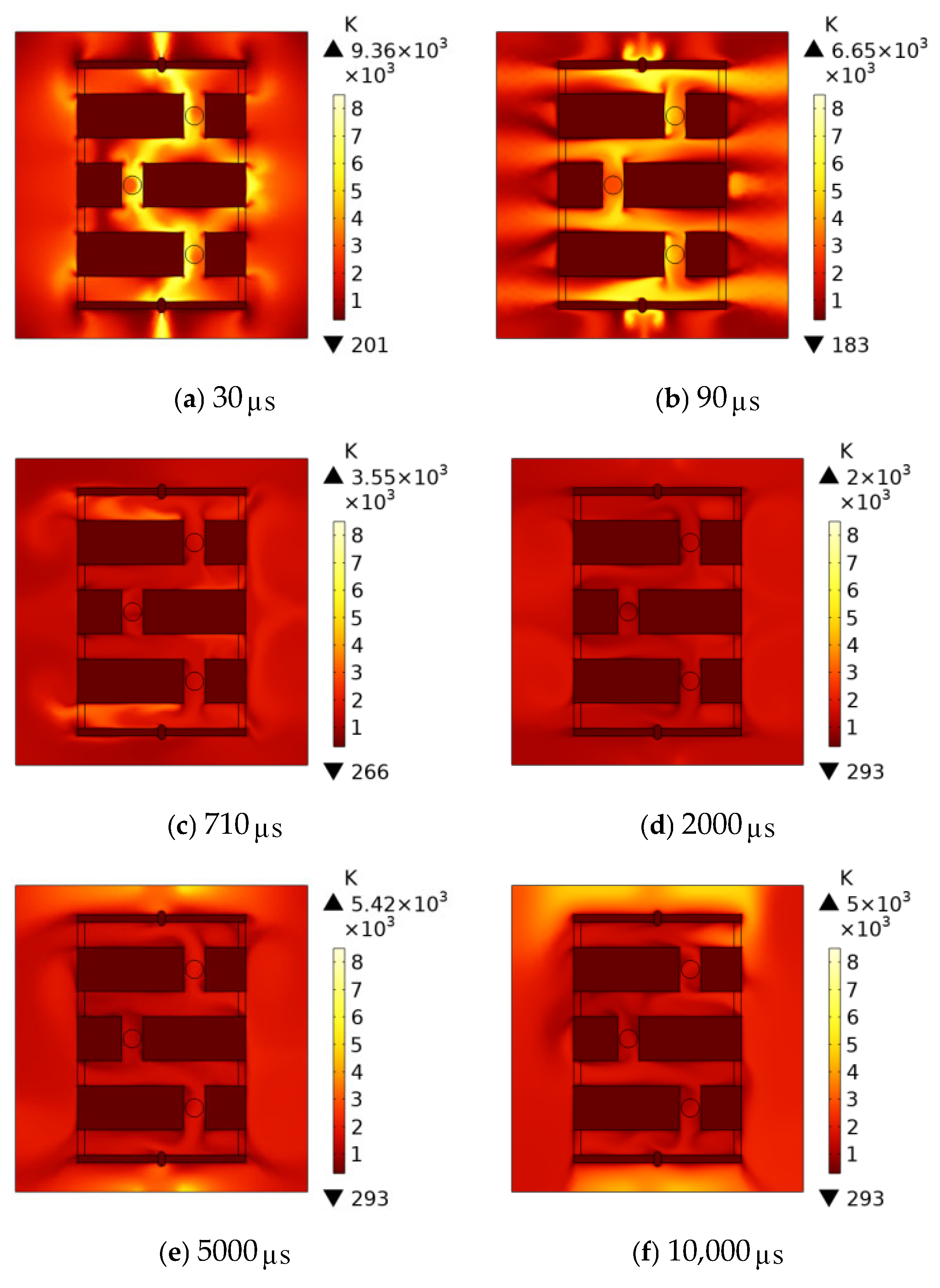

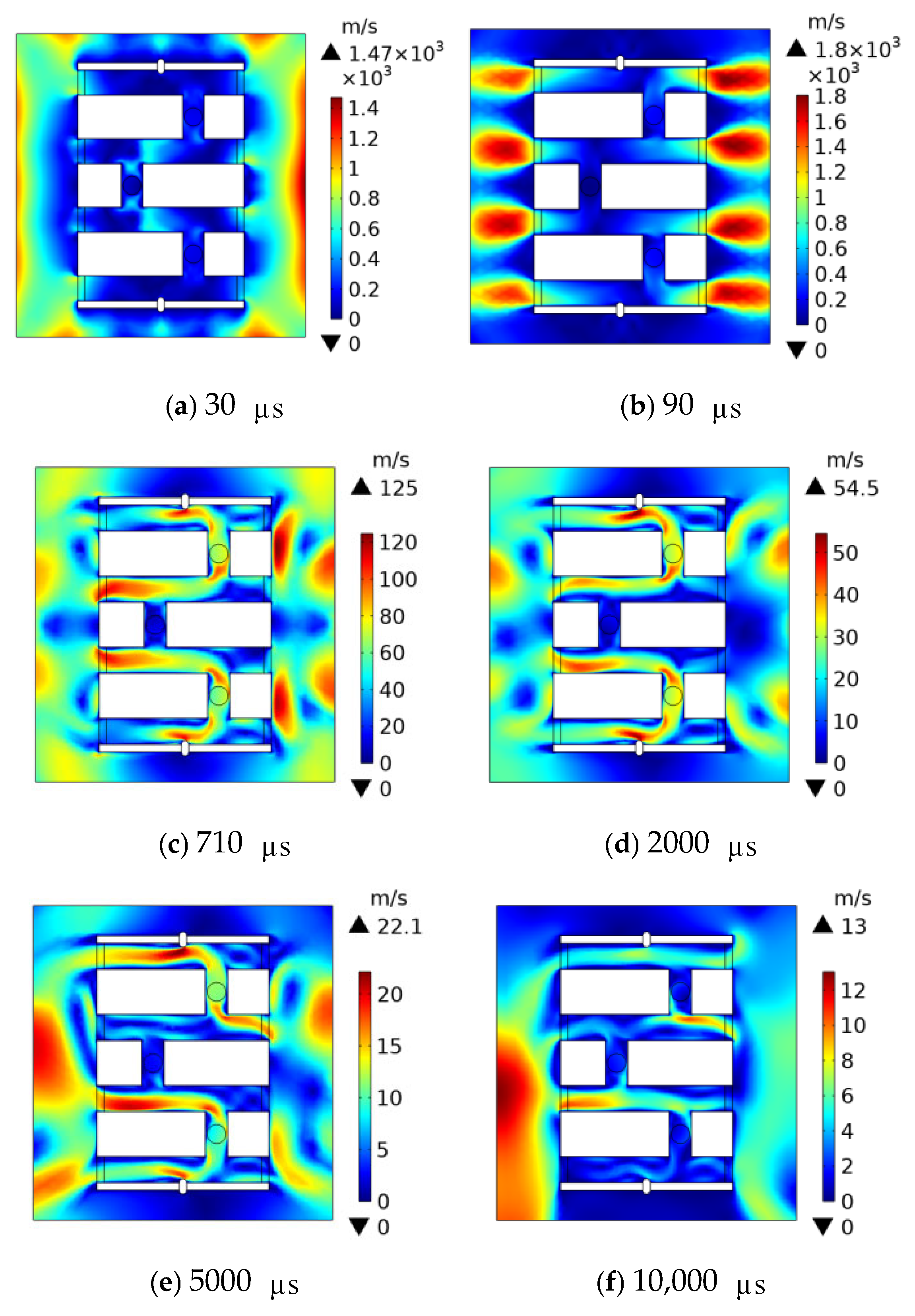

3.4. Arc-Extinguishing Process with the Participation of Electronegative Gas

4. Conclusions

- (1)

- Based on the shortcomings in the field of lightning protection for 10 kV distribution lines, this study proposes a new type of arc-extinguishing lightning protection device with same-layer double break, and applies the environmentally friendly electronegative gas trifluoroiodomethane () to lightning protection and arc extinguishing. Combined with the specifications of 10 kV lines, this paper reasonably sets the power frequency current for simulation and achieves a good arc-extinguishing effect.

- (2)

- Through analysis and simulation research on the arc-extinguishing device, this study reveals that when the horizontal distance of the compression channel is set to 9 mm, and the arc temperature exhibits the fastest cooling rate. Under this structural parameter, no flashover phenomenon is observed outside the device, and the arc-extinguishing performance of the device reaches an optimal state.

- (3)

- This study compares the arc-extinguishing performance of the proposed device under the action of power frequency currents with two different initial phases of and 0. The simulation results indicate that the device can achieve arc extinction within 800 , and no arc re-ignition phenomenon is observed in the subsequent monitoring period.

- (4)

- A systematic study was carried out on the arc-extinguishing process of the device using an environment-friendly electronegative gas (trifluoroiodomethane). The simulation results demonstrate that the arc is successfully extinguished within 710 , and the arc-extinguishing time is shortened by 11.2% compared with the reference group. Meanwhile, the internal temperature of the device shows a decreasing trend in the initial stage of the arc-extinguishing process. Taking monitoring Point A inside the device as an example, under two different initial phases and 0 of the power frequency current, the maximum temperature at this point decreases by 500 K and 1000 K, respectively. This significant temperature reduction effectively mitigates the risk of damage to the arc-extinguishing device caused by excessive internal pressure induced by high temperatures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hu, Y. Analysis and Prevention of Operational Faults in Transmission Lines. High Volt. Eng. 2007, 1–8. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, C.; Gu, S.; Xiang, N.; Wang, Y.; Lei, M. Current Status and Development Trend of Lightning Monitoring and Protection Technology for Power Grids in China. High Volt. Eng. 2016, 42, 3361–3375. [Google Scholar] [CrossRef]

- Yang, J.; Yao, P.; Li, M.; Long, T.; He, W. Analysis and Countermeasures of Lightning Strike Accidents on Overhead Transmission Lines. Hunan Electr. Power 2019, 39, 23–25. [Google Scholar] [CrossRef]

- Zhao, C.; Ruan, J.; Li, X.; Xie, Y.; Huang, D.; Gu, S. Technical and Economic Evaluation of Comprehensive Lightning Protection Measures for Transmission Lines. High Volt. Eng. 2011, 37, 290–297. [Google Scholar] [CrossRef]

- He, J.; Zeng, R.; Chen, S. Research on Lightning Protection Technologies for Transmission Lines (III): Protection Measures. High Volt. Eng. 2009, 35, 2917–2923. [Google Scholar] [CrossRef]

- Chino, T.; Iwata, M.; Imoto, S.; Nakayama, M.; Sakamoto, H.; Matsushita, R. Development of arcing horn device for interrupting ground-fault current of 77 kV overhead lines. IEEE Trans. Power Deliv. 2005, 20, 2570–2575. [Google Scholar] [CrossRef]

- Podporkin, G.V.; Sivaev, A.D. Lightning protection of distribution lines by long flashover arresters (LFA). IEEE Trans. Power Deliv. 1998, 13, 814–823. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, X.; Feng, Z.; Zhang, Y.; Wang, J. Mechanism and experimental study of arc suppression by polyphase longitudinal airflow. AIP Adv. 2021, 11, 105309. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Zhou, X.; Huang, S.; Yan, R.; Xia, Z. Influence of chamber structure on arc quenching in multigap system. High Volt. 2020, 5, 313–318. [Google Scholar] [CrossRef]

- Huang, P.; Wang, S.; Wang, G.F.; Wang, J.F.; Zheng, J.P. Study on lightning protection of collector line in wind farm by multi-fracture active arc extinguishing device. Electr. Power Syst. Res. 2022, 213, 108684. [Google Scholar] [CrossRef]

- Li, Q.; Wang, J.; Zhang, Y.; Wang, Y.; Chen, Y.; Yang, Z.; Tan, S.; Wang, X. Research on the Performance of Gas-Blown Arc-Extinguishing Devices Based on Magnetohydrodynamics Theory. Power Syst. Technol. 2022, 46, 2025–2031. [Google Scholar] [CrossRef]

- Peng, F.; Wang, J.; Zhang, Q.; Li, Z.; Xu, Y.; Wang, G.; Pang, Z. Optimization of Airflow Channel for Arc-Extinguishing Lightning Protection Gap with Jet Airflow. South. Power Syst. Technol. 2021, 15, 43–48. [Google Scholar] [CrossRef]

- Bi, J.; Wang, J. Study on the Causes and Countermeasures of High Lightning Trip-Out Rate on Electric Transmission Lines. Energies 2025, 18, 857. [Google Scholar] [CrossRef]

- Wang, J.F.; Huang, P.; Guo, W.; Wu, D.; Liu, Q.L. Research and application of a new jet stream arc extinguishing gap lightning protection device. Electr. Power Syst. Res. 2016, 139, 161–169. [Google Scholar] [CrossRef]

- Congzhen, X.; Yancheng, L.; Yan, D.; Xinhao, X.; Xihan, X.; Xiyang, C. Arc-Extinguishing Simulation of 35 kV Self-Detaching Lightning Protection Device Based on Magnetohydrodynamics. Electr. Power Eng. Technol. 2023, 42, 61–69. [Google Scholar] [CrossRef]

- Zhou, H.; Yang, T.; Luo, Y.; Yi, W.; Xie, Z.; Wang, R.; Dan, S. A Rapid Arc-Extinguishing Method for Integrated Lightning Protection Gaps Based on the Air-Blowing Principle. South. Power Syst. Technol. 2023, 17, 119–126. [Google Scholar] [CrossRef]

- Xiao, S.; Zhang, X.; Tang, J.; Liu, S. A review on SF6 substitute gases and research status of CF3I gases. Energy Rep. 2018, 4, 486–496. [Google Scholar] [CrossRef]

- Widger, P.; Haddad, A.; Griffiths, H. Breakdown performance of vacuum circuit breakers using alternative CF3I-CO2 insulation gas mixture. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 14–21. [Google Scholar] [CrossRef]

- Widger, P. Investigation into CF3I-CO2 Gas Mixtures for Insulation of Gas-Insulated Distribution Equipment. Doctoral Dissertation, Cardiff University, Cardiff, UK, 2014. [Google Scholar]

- Zhang, X.; Zhou, J.; Tang, J.; Xiao, S.; Zhang, M. Experimental Study on Partial Discharge Characteristics of CF3I/N2 Mixed Gas. High Volt. Eng. 2013, 39, 287–293. [Google Scholar] [CrossRef]

- Zhao, X. Study on Arc-Extinguishing and Insulating Properties of Environmentally Friendly Insulating Gas CF3I. Doctoral Dissertation, Shanghai Jiao Tong University, Shanghai, China, 2018. [Google Scholar] [CrossRef]

- Schlitz, L.Z.; Garimella, S.V.; Chan, S.H. Gas dynamics and electromagnetic processes in high-current arc plasmas. Part I. Model formulation and steady-state solutions. J. Appl. Phys. 1999, 85, 2540–2546. [Google Scholar] [CrossRef]

- Ghorui, S.; Heberlein, J.V.R.; Pfender, E. Thermodynamic and transport properties of two-temperature nitrogen-oxygen plasma. Plasma Chem. Plasma Process. 2008, 28, 553–582. [Google Scholar] [CrossRef]

- Fusheng, W.; Xiangteng, M.A.; Han, C. Evolution simulation of lightning discharge based on a magnetohydrodynamics method. Plasma Sci. Technol. 2018, 20, 075301. [Google Scholar] [CrossRef]

- Liao, M.; Wu, H.; Wang, C.; Xia, W. Discussion on Steenbeck’s Minimum Arc Voltage Principle in Arc Discharge. High Volt. Eng. 2018, 44, 926–931. [Google Scholar] [CrossRef]

- Li, Z.; Wang, J.; Zhang, H.; Dai, Q.; Feng, D. Research on the Mechanism of Arc-Extinguishing Lightning Protection Gaps Based on Multi-Point Truncation of Compressed Arcs. Insul. Surge Arresters 2017, 150–155+160. [Google Scholar] [CrossRef]

- Liao, M.R.; Li, H.; Xia, W.D. Approximate explicit analytic solution of the Elenbaas-Heller equation. J. Appl. Phys. 2016, 120, 063304. [Google Scholar] [CrossRef]

- Cong, H.; Li, Q.; Xing, J.; Li, J.; Chen, Q. A Calculation Method for Arcing Time of Induced Arcs Based on Energy Balance. Proc. CSEE 2015, 35, 3450–3458. [Google Scholar] [CrossRef]

- Zhang, X.; Dai, Q.; Han, Y.; Xiao, S. Study on Discharge Decomposition Components of CF3I Under Micro-Water Conditions. High Volt. Eng. 2016, 42, 172–178. [Google Scholar] [CrossRef]

- Huang, P.; Xu, S.; Qin, H.; Yang, G.; Huang, J.; Li, Z. Magnetohydrodynamic simulation and test of compression arc-extinguishing device under icing condition. AIP Adv. 2024, 14, 015337. [Google Scholar] [CrossRef]

- Sima, W.-X.; Jia, W.-B.; Yuan, T.; Xu, H.; Yang, M. Magnetohydrodynamic model of electric arc in multi-segment microporous structure and simulation of gas-blast arc extinguishing performance. High Volt. Eng. 2016, 42, 3376–3382. [Google Scholar] [CrossRef]

- Naghizadeh-Kashani, Y.; Cressault, Y.; Gleizes, A. Net emission coefficient of air thermal plasmas. J. Phys. D Appl. Phys. 2002, 35, 2925. [Google Scholar] [CrossRef]

- Yokomizu, Y.; Ochiai, R.; Matsumura, T. Electrical and thermal conductivities of high-temperature CO2–CF3I mixture and transient conductance of residual arc during its extinction process. J. Phys. D Appl. Phys. 2009, 42, 215204. [Google Scholar] [CrossRef]

- Cressault, Y.; Connord, V.; Hingana, H.; Teulet, P.; Gleizes, A. Transport properties of CF3I thermal plasmas mixed with CO2, air or N2 as an alternative to SF6 plasmas in high-voltage circuit breakers. J. Phys. D Appl. Phys. 2011, 44, 495202. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, P.; Wu, Z.; Tian, L.; Zhang, B.; Long, Y.; Liu, Z.; Zhang, Y. Study on Lightning-Induced Plasma Extinguishing in 10 kV Distribution Network Lines Based on Electronegative Gas Trifluoroiodomethane. Plasma 2025, 8, 37. https://doi.org/10.3390/plasma8030037

Huang P, Wu Z, Tian L, Zhang B, Long Y, Liu Z, Zhang Y. Study on Lightning-Induced Plasma Extinguishing in 10 kV Distribution Network Lines Based on Electronegative Gas Trifluoroiodomethane. Plasma. 2025; 8(3):37. https://doi.org/10.3390/plasma8030037

Chicago/Turabian StyleHuang, Ping, Zhipeng Wu, Li Tian, Biao Zhang, Yuang Long, Zhenyu Liu, and Yiyi Zhang. 2025. "Study on Lightning-Induced Plasma Extinguishing in 10 kV Distribution Network Lines Based on Electronegative Gas Trifluoroiodomethane" Plasma 8, no. 3: 37. https://doi.org/10.3390/plasma8030037

APA StyleHuang, P., Wu, Z., Tian, L., Zhang, B., Long, Y., Liu, Z., & Zhang, Y. (2025). Study on Lightning-Induced Plasma Extinguishing in 10 kV Distribution Network Lines Based on Electronegative Gas Trifluoroiodomethane. Plasma, 8(3), 37. https://doi.org/10.3390/plasma8030037