1. Introduction

The planar magnetron discharge [

1,

2], among all coating technologies [

3] (pp. 77–139), [

4] (pp. 30–30-10) over an extremely wide range of applications [

4], is undoubtedly the most widely used due to the high rate of coating deposition, stable and sustainable parameters, and the ability to vary and control the physical, mechanical, electrical, chemical, optical, magnetic and other properties of deposited coatings. The use of a magnetron discharge plasma for ion beam production is limited by the significantly high operating pressure required for the discharge operation, usually 10

−3 Torr and greater. Such high pressure is problematic for voltage hold-off in the ion beam accelerating gap, as well as for beam transport. Gasless sputtering has been proposed and studied [

5,

6], using a planar magnetron discharge initiated and supported by a supplementary vacuum arc discharge unit which is positioned off the magnetron axis. Disadvantages of this approach are that the vacuum arc plasma impacts the magnetron target surface asymmetrically, and the vacuum arc cathode is located relatively far from the magnetron target. Even though this kind of set-up has been investigated [

5,

6], it has not been used for ion beam formation, and the discharge plasma composition has not been studied. In prior work [

7] we have developed and explored a planar gasless magnetron discharge initiated by a vacuum arc plasma gun located on the axis of a planar magnetron. The ion composition of the discharge plasma was measured. Here we describe the parameters of an ion source based on a gasless magnetron discharge initiated by a vacuum arc unit positioned on the magnetron axis.

The implementation of a gasless magnetron will provide generation of a purely metallic plasma in the discharge. The use of such a plasma in an ion source will ensure the formation of metal ion beams. The demand for metal ions is associated with their use in accelerator technology [

8], ion thrusters [

9], as well as in technological installations of ion implantation for hardening the surface properties of various materials [

10]. At present, ion sources based on a vacuum arc with a cathode spot are mainly used to generate beams of metal ions [

11]. Compared to a vacuum arc, the principal advantage of the gasless magnetron system is the absence of a micro-droplet fraction. Another positive feature of a gasless magnetron is the fact that the ions of the metal plasma are mainly single charged. As a result, the generation of metal ion beams based on a gasless magnetron will ensure the absence of micro-drop impurities in the ion beam and make energy spread of such a beam less than a metal ion beam extracted from a vacuum arc ion source. Taking also into account higher stability and lower noising of the plasma parameters, the advantages of a gasless magnetron make ion sources based on it a real alternative to vacuum arc metal ion sources.

2. Materials and Methods

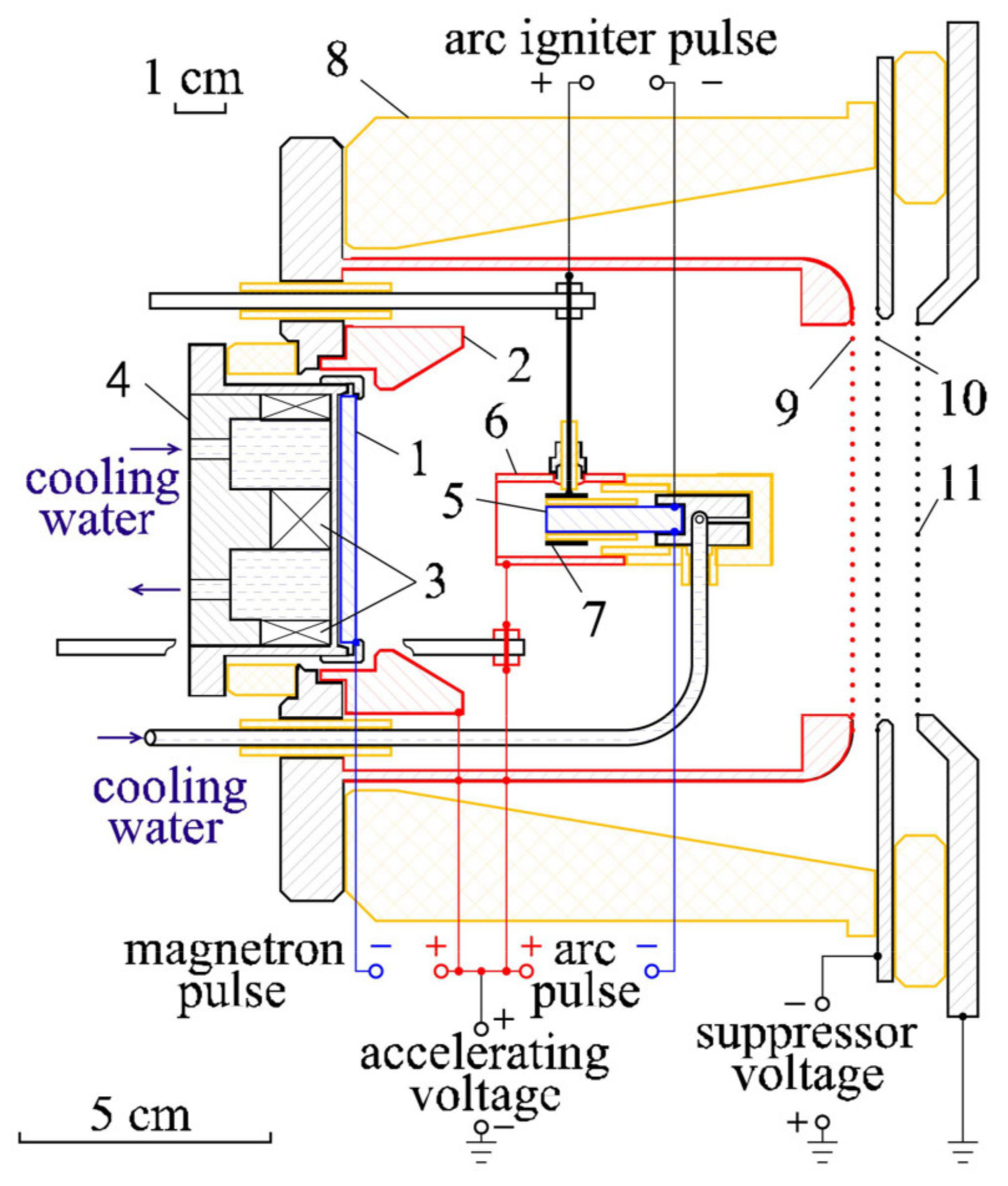

A schematic diagram of the ion source is shown in

Figure 1. A planar magnetron discharge operates between target (

Figure 1, point 1), with diameter 50 mm, and anode (2). A magnetic field in the magnetron discharge system is established by axially symmetric NdFeB permanent magnets (3) and a magnetic core (4) made of ferromagnetic steel. A vacuum arc discharge system (plasma gun) with cathode (5), anode (6) and initiating electrode (7) is installed on the axis of the magnetron discharge system. The vacuum arc plasma flow formed by the vacuum arc propagates toward the magnetron target. In conventional magnetrons [

2], the discharge is ignited and operated in the working gas. In this work, the flow of the vacuum arc plasma onto the magnetron discharge target played the role of a medium in which the magnetron discharge was ignited and operated.

The anodes of the magnetron and vacuum arc are electrically connected and isolated from ground potential by high-voltage insulator (8). Water cooling of the cathode units of both the magnetron and the vacuum arc is supplied through insulating water decoupling with a channel length of 5 m and diameter 3 mm. The discharge plasma of a magnetron discharge, supported by the plasma of a vacuum arc, fills the expander (9), which is electrically connected to anodes 2 and 6 unless otherwise specified. The expander metal grid with mesh size of 0.7 mm × 0.7 mm forms the plasma emission surface. The expander, the grid and the discharge anodes are held at a steady high accelerating potential of up to +20 kV respect to ground potential. The emission grid of the expander (9), the suppressor grid (10) and the grounded grid (11) together form the ion beam extraction system.

A photograph of the ion source plasma generation system is shown in

Figure 2a.

Figure 2b shows the vacuum arc plasma generator as viewed from the magnetron surface (in the photo it is dismounted).

The magnetron discharge is powered using an APEL-M-2HIPIMS-1500 pulsed power supply [

12] with output voltage adjustable over the range 150–1500 V, pulse duration from 5 μs to 300 μs and current from 1 A to 100 A. The vacuum arc power supply employs a pulse forming network (PFN) to generate a current pulse with amplitude adjustable up to 200 A and duration 30 μs. A trigger pulse initiates the vacuum arc by flashover across a ceramic ring which was located between vacuum arc igniter electrode (

Figure 1, point 7) and vacuum arc cathode (5). The voltage of trigger pulse was up to 10 kV and a pulse trigger current and the pulse duration were about of 15 A and 1 μs, respectively.

Power supplies of magnetron discharge, vacuum arc and trigger pulse are held at high positive accelerating voltage up to +20 kV. The pulse repetition rate is 2 pulses per second. It is possible to switch on all three power supplies at different times, but we have found that the magnetron and arc discharges are initiated most stably when all three power supplies are triggered simultaneously.

The mass-to-charge composition of the ion beam is analyzed by a time-of-flight spectrometer described in full elsewhere [

13,

14], utilizing a gate made in the form of a set of five pairs of concentric metal rings (plates) located in a plane perpendicular to the beam direction at a distance of 0.4 m from the ion source. The principle of operation of spectrometer gate is similar to the Bradbury–Nielson gate [

15]. For each pair of rings, the outer ring is grounded and the inner ring is connected to electronics that provide an ion-deflecting voltage pulse of amplitude of up to 2 kV and duration of 150 ns. The central part of the gate is flat metal plate of diameter of 5 cm that blocks the direct passage of ion beam to ion beam detector when ion-deflecting voltage is not applied. The application of an ion-deflecting voltage pulse to the gate ensures that the ion beam is focused on the ion detector during the duration of this pulse. The ion detector is located on the beam axis at a distance of 1.2 m from the gate, and it was a secondary electron multiplier (SEM) VEU-1A operating in analog mode. The output current of the SEM anode is recorded by an oscilloscope, and beam ions with different charge to ion mass ratios on the oscillogram are formed peaks (see, for example, Figure 4 further in the

Section 3) from which the composition of the ion beam was analyzed. Synchronization of the moment of application of the gate pulse relative to the moment of application of magnetron discharge and vacuum arc pulses was carried out from a six-channel generator of triggering pulses GI-1.

A titanium ion-beam collector plate 10 cm in diameter was located 25 cm from the ion source. When measuring the ion composition of the beam, the collector was turned (though a movable vacuum feed-through) so that its surface plane is parallel to the beam propagation direction. The radial distribution of ion beam current density was measured by a linear set of flat probes with common flat guard electrode. The ion beam collected surface area of each flat probe was 0.5 × 0.5 cm and distance between nearby probes was 1 cm.

The cylindrical vacuum chamber, with diameter 0.3 m and length 2 m, is pumped by a Varian TV 1001 Navigator turbomolecular pump with pumping speed 900 l/s. No working gas inlet for magnetron discharge was used. The base pressure in the vacuum chamber and in the discharge system is 3 × 10−6 Torr.

3. Results

Typical magnetron discharge voltage and current and vacuum arc current pulses are shown in

Figure 3; here, a Pb magnetron target and Pb vacuum arc cathode were used. We have also used Cu, Ag, and Zn as magnetron target and vacuum arc cathode materials [

7]. One can see from

Figure 3 that the self-sustained vacuum magnetron discharge voltage is about 600 V for a Pb target. At the beginning of the pulse, during vacuum arc ignition, the voltage drops to about 300 V due to support of the magnetron discharge by the vacuum arc plasma.

With no vacuum arc, application of voltage between the magnetron cathode and anode does not lead to magnetron discharge ignition. A specific vacuum arc current threshold is needed for the magnetron discharge to be ignited. For instance, using a copper arc cathode and a copper magnetron target, a 50 A, 30 μs vacuum arc pulse leads to ignition of a Table 50 A, 300 μs magnetron discharge.

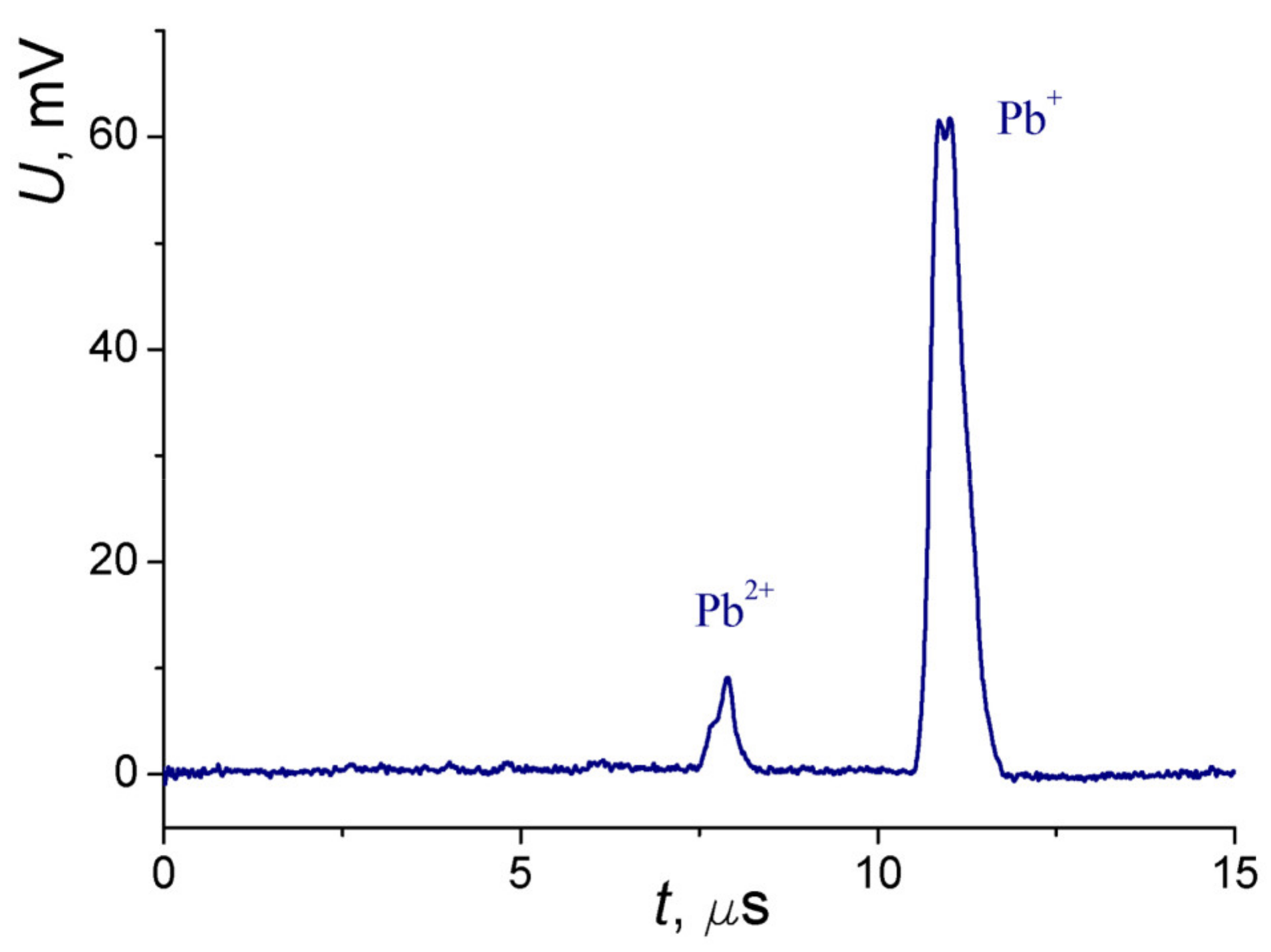

A time-of-flight spectrum of the ion beam formed using a Pb magnetron target and Pb vacuum arc cathode is shown in

Figure 4. For approximately 30–40 μs after discharge current pulse initiation, the beam contains ions of residual gas (hydrogen, nitrogen and oxygen of various charge states) in addition to ions of the cathode material. After this 30–40 μs period, the fraction of gaseous ions decreases from several tens of percent to less than 1%. This thus implies that the magnetron discharge takes place exclusively in the vapor of the magnetron target material after the end of the vacuum arc current pulse.

Note that when using different vacuum arc and magnetron metals, for example copper vacuum arc cathode and lead magnetron target, the fraction of vacuum arc material (e.g., copper ions) decreases to less than 1% by the end of the vacuum arc current pulse. This may be because, despite the fact that the arc current is significantly greater than the magnetron current, the contribution of magnetron sputtering to the plasma composition exceeds the contribution from the vacuum arc plasma gun because of the higher magnetron discharge voltage. Thus, a persistent copper film does not form on the magnetron target surface.

The mean ion charge states of the magnetron target materials studied, (Cu, Ag, Zn, Pb) are much lower than those for a vacuum arc plasma [

16]. For example, a mean ion charge state for Pb of 1.64 has been reported [

16], but for the vacuum magnetron plasma studied in the present work the mean charge state is 1.13. This may be related to a lower discharge current for the magnetron and thus lower plasma density. The current-voltage characteristics of the ion source for a copper magnetron target and copper vacuum arc cathode (

Figure 5) show that the ion beam current is up to 0.5% of the magnetron discharge current.

The total ion emission current from the magnetron plasma was measured (current to the expander 9 (

Figure 1), plus current to the emission grid when the expander and grid are biased negative with respect to grounded anodes 2 and 6). The current had a distinct saturation at an expander bias of 50 V and was 0.34, 0.7 and 1.25 A for magnetron discharge currents of 6, 10 and 17 A, respectively (5.7%, 6.9% and 7.4% of the magnetron current, respectively) at zero vacuum arc discharge current (the ion current from the magnetron discharge plasma was measured 150 μs after the beginning of the magnetron discharge current pulse; the vacuum arc was off at this time) for a copper magnetron target and vacuum arc. The current in the collector circuit was several times less than the current in the accelerating voltage circuit. We note that the application of a negative voltage to the suppressor electrode (

Figure 1, point 10) leads to a decrease in collector current of about 20%, implying that the suppressor indeed impedes the back-streaming secondary electron flux from the downstream beam transport region. However, we used a grid (wire mesh) system and not a multi-aperture beam acceleration system, and thus the electron flux emitted by the grid electrode (10) is not suppressed, in turn leading to increased emission current with increasing accelerating voltage (see

Figure 5). Clearly it is prudent to use a multi-aperture ion-optical system for the formation of ion beams at higher accelerating voltages.

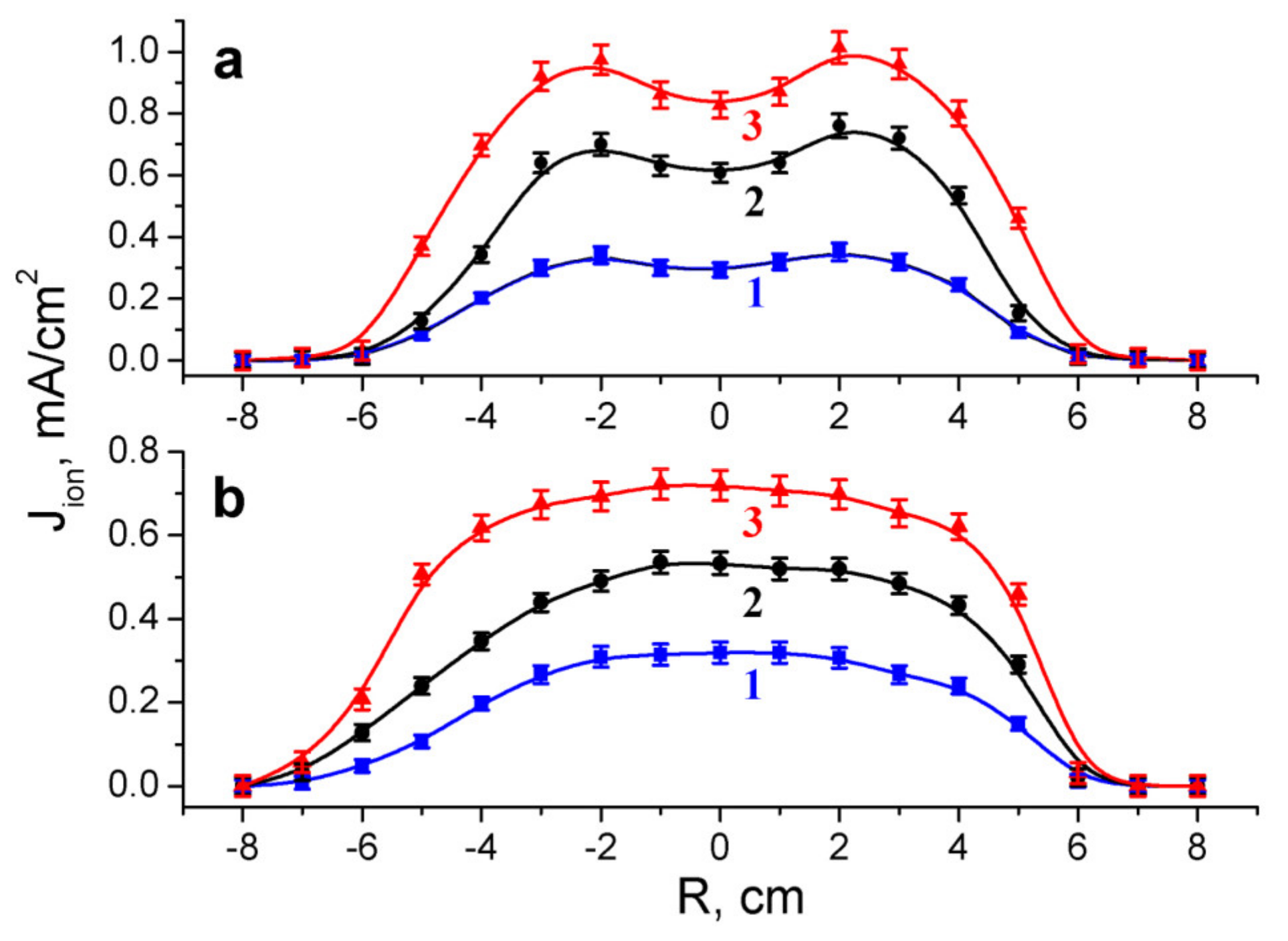

To study how the uniformity of the ion beam changes at different distances from the ion source, the radial distributions of the ion beam current density were measured. The radial distribution of ion beam current density (

Figure 6a) has a minimum on the system axis for downstream distances from the ion source less than 30 cm, evidently related to the central positioning of the vacuum arc plasma gun. At a downstream distance of 55 cm the distribution is more uniform, with no central minimum. At the same time, the beam diameter slightly increases.

For a magnetron discharge current of 17 A (

Figure 6b, curve 3) the radial non-uniformity of the ion beam is ±5% over a diameter of 6.6 cm, which is the diameter of the ion source output aperture of the expander with emission grid.

4. Conclusions

We have developed and characterized a metal ion source based on a pulsed vacuum planar magnetron discharge operating without gas feed at a residual pressure of 3 × 10−6 Torr and initiated by an on-axis vacuum arc plasma gun. The source forms ion beams of the magnetron target material, with a singly charged ion fraction about 90% and doubly charged ion fraction about 10%. At an accelerating voltage of 16 kV, the ion current reaches 80 mA with a magnetron discharge current of 17 A and vacuum arc current of 0 A. The radial non-uniformity of the beam current density is ±5% over a diameter of 6.6 cm, which is the diameter of the source output aperture.

The achieved parameters of the metal ion beam current are comparable to the ion current of a vacuum arc source. Higher efficiency of ion extraction from plasma, stability and low noise level of ion beam parameters, together with the absence of a droplet fraction, makes an ion source based on a gasless magnetron attractive for use in those areas where vacuum arc sources of metal ions dominate today. Further development of sources of metal ions based on a gasless magnetron will be associated with the generation of a wide range of ions of various metals and the study of the possibilities of increasing the current of the ion beam and its density while maintaining the high quality of the parameters of the ion beam.