Inductive Medium Pressure UV-Source

Abstract

:1. Introduction

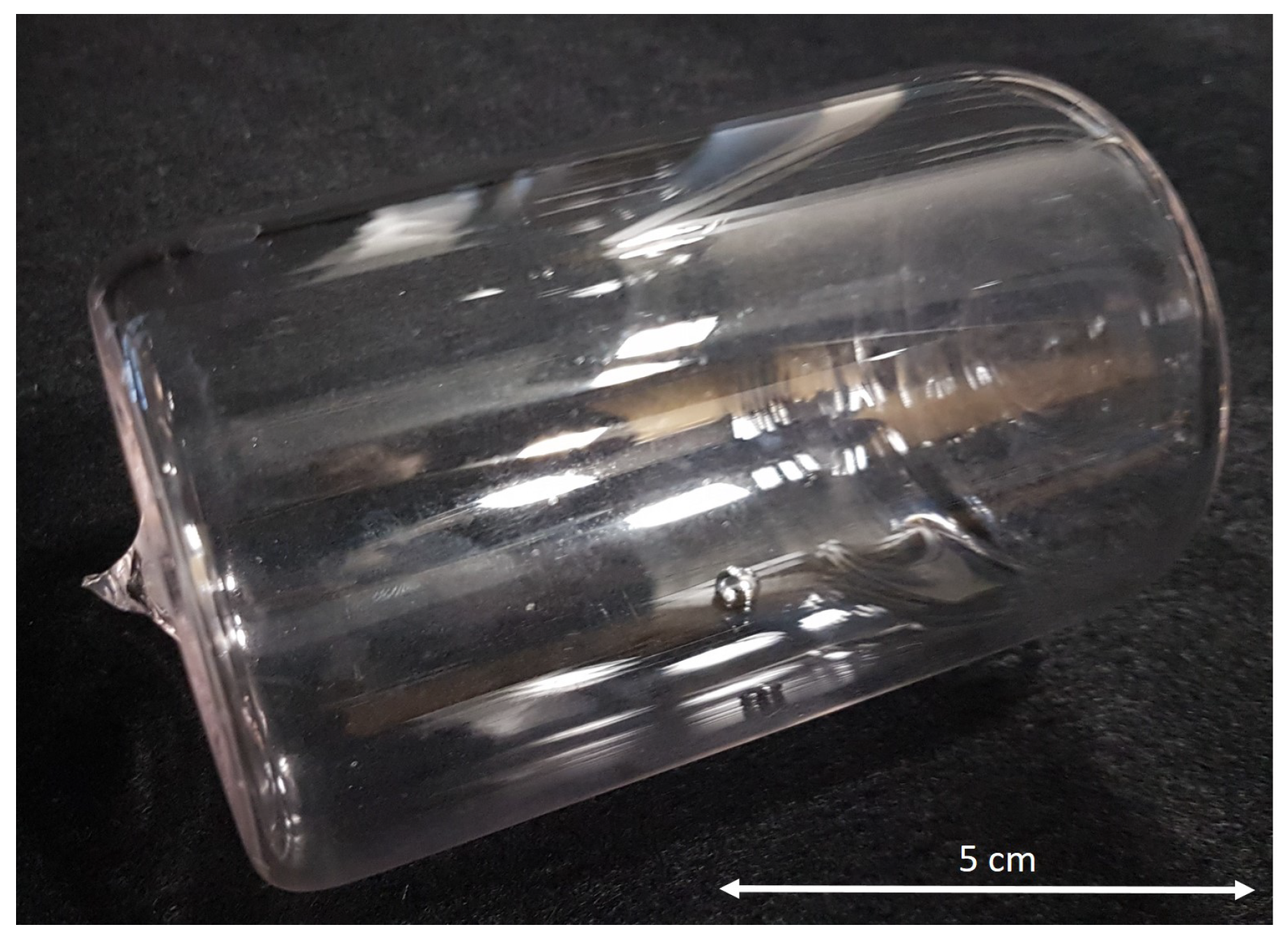

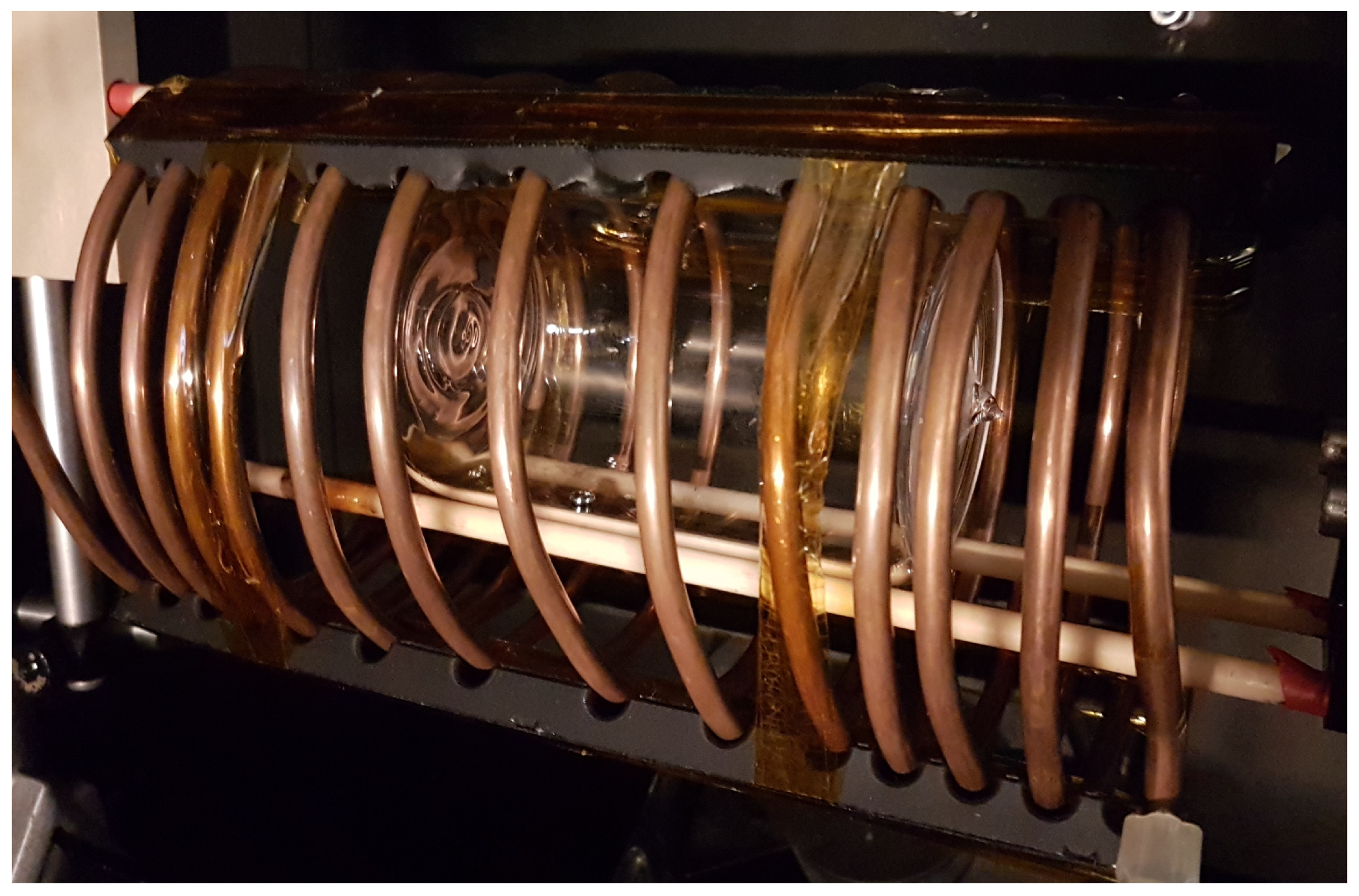

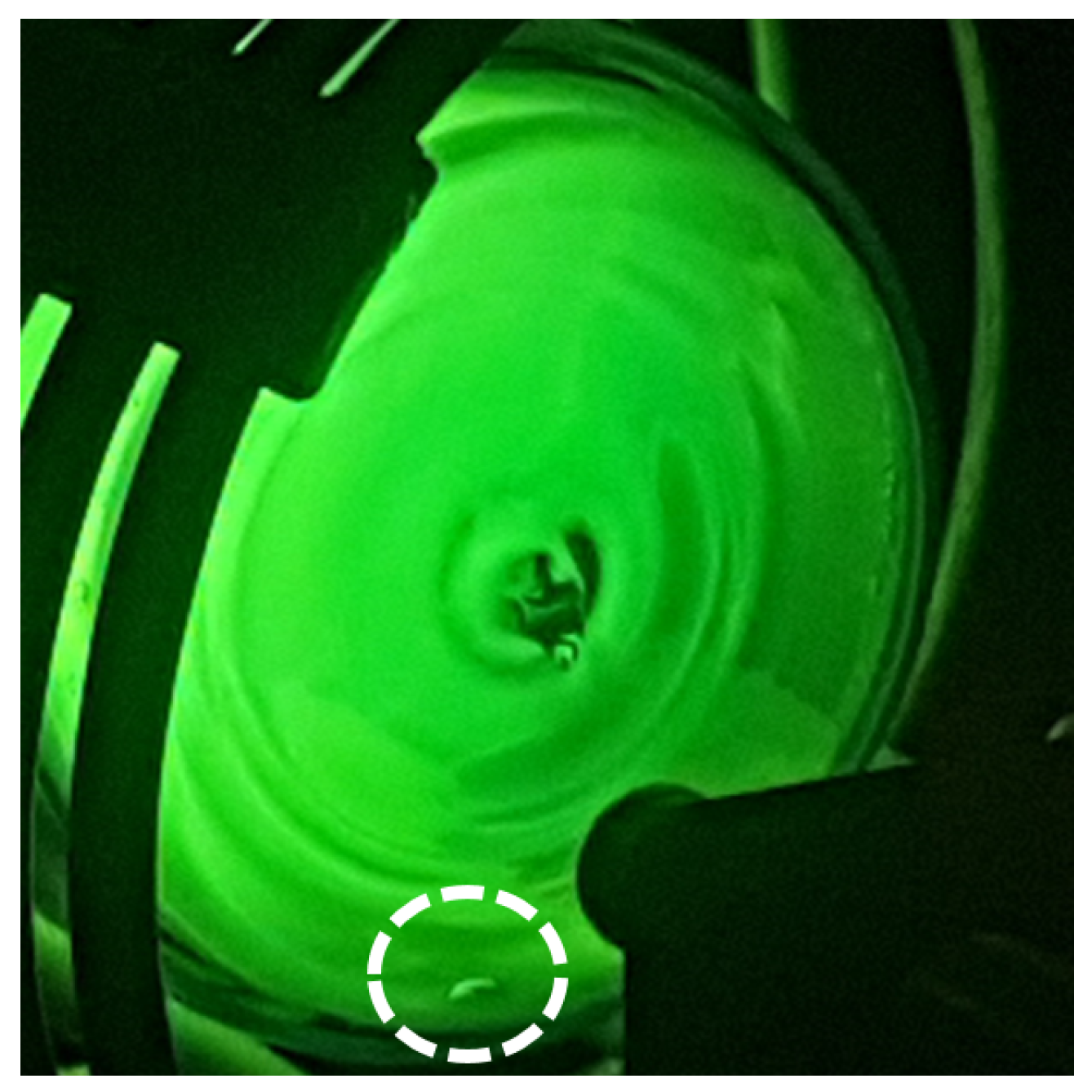

2. Lamp Geometry and Filling

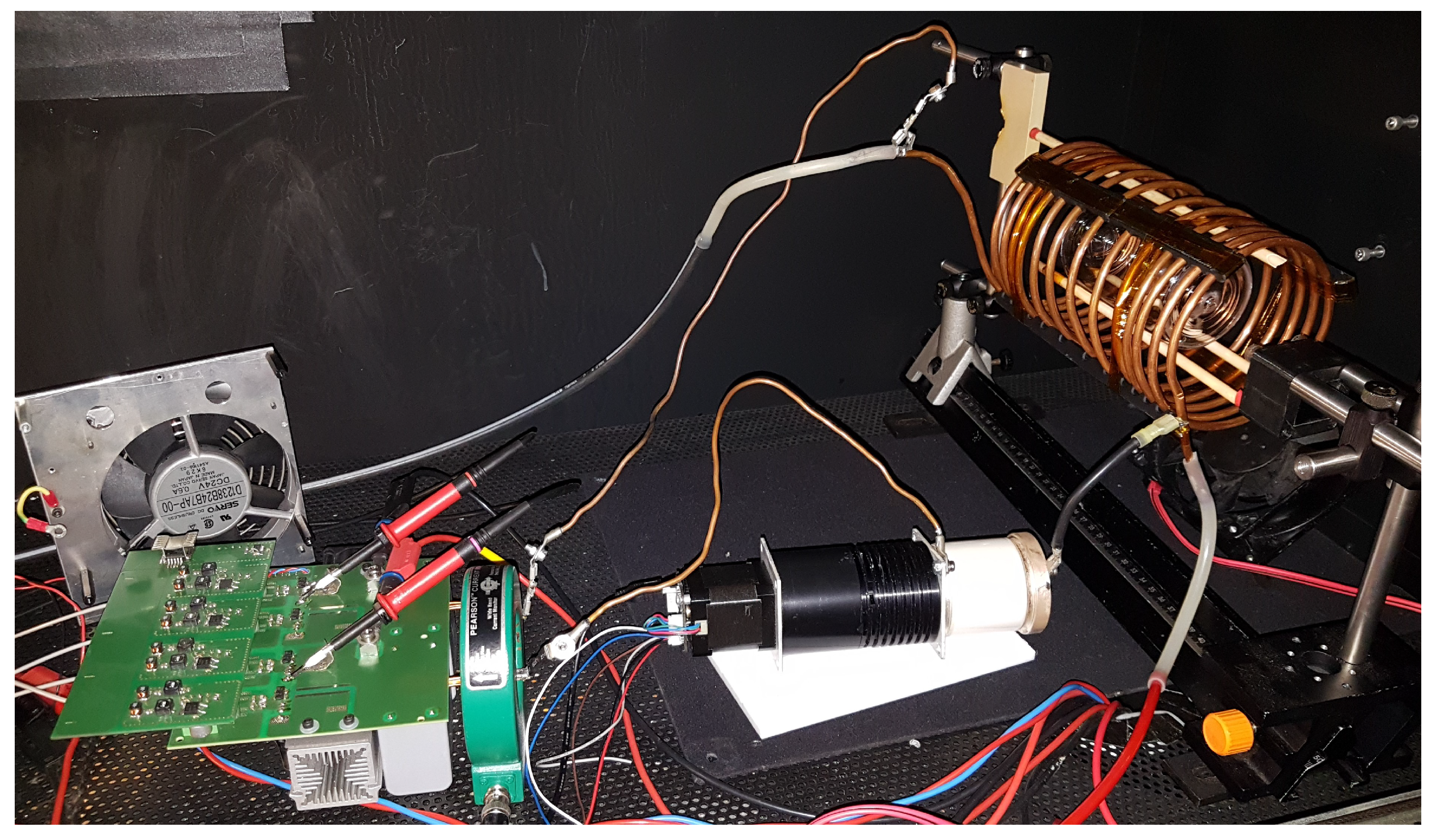

3. Electronic Ballast

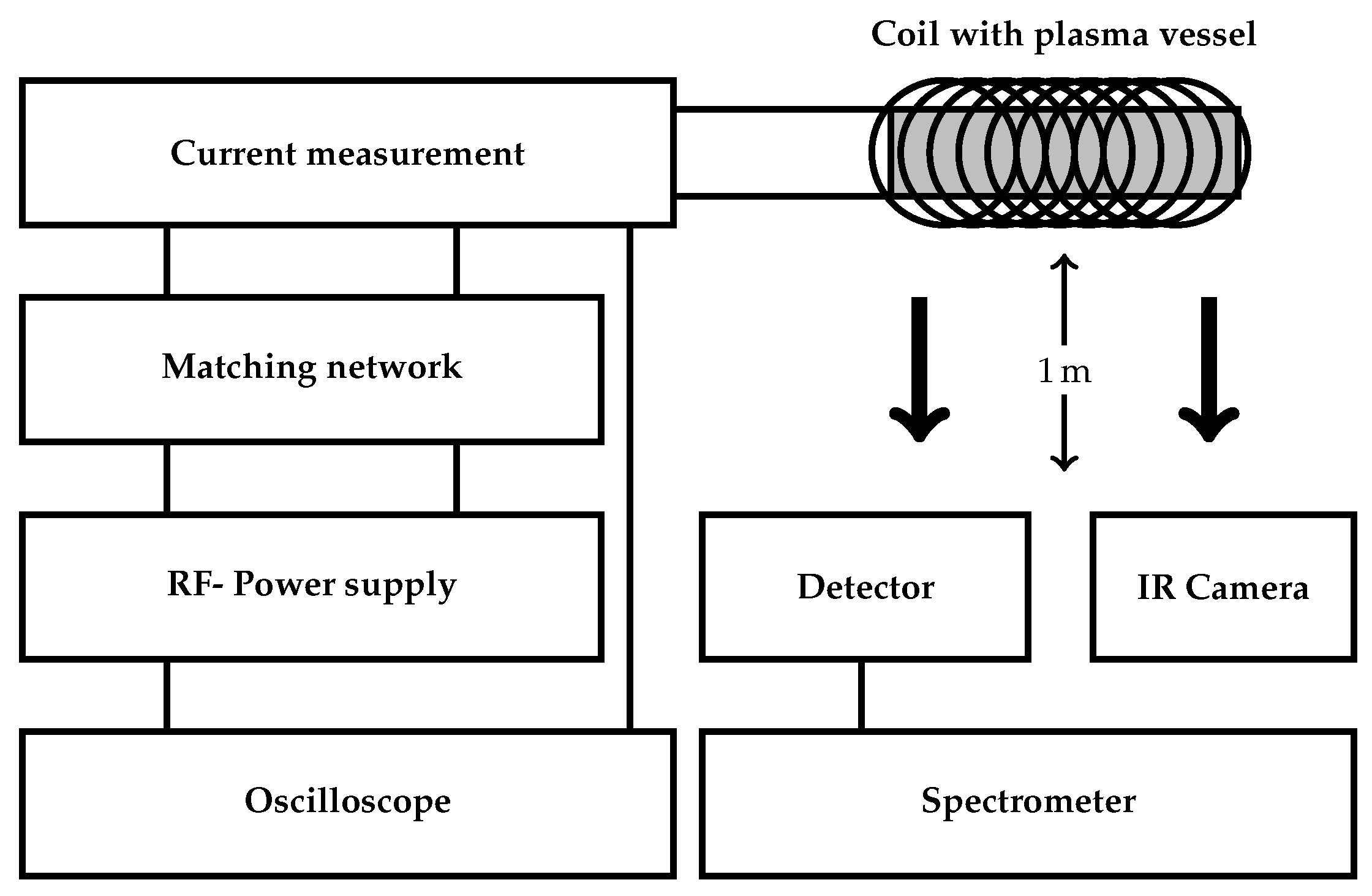

4. Experimental Setup

5. Results and Discussion

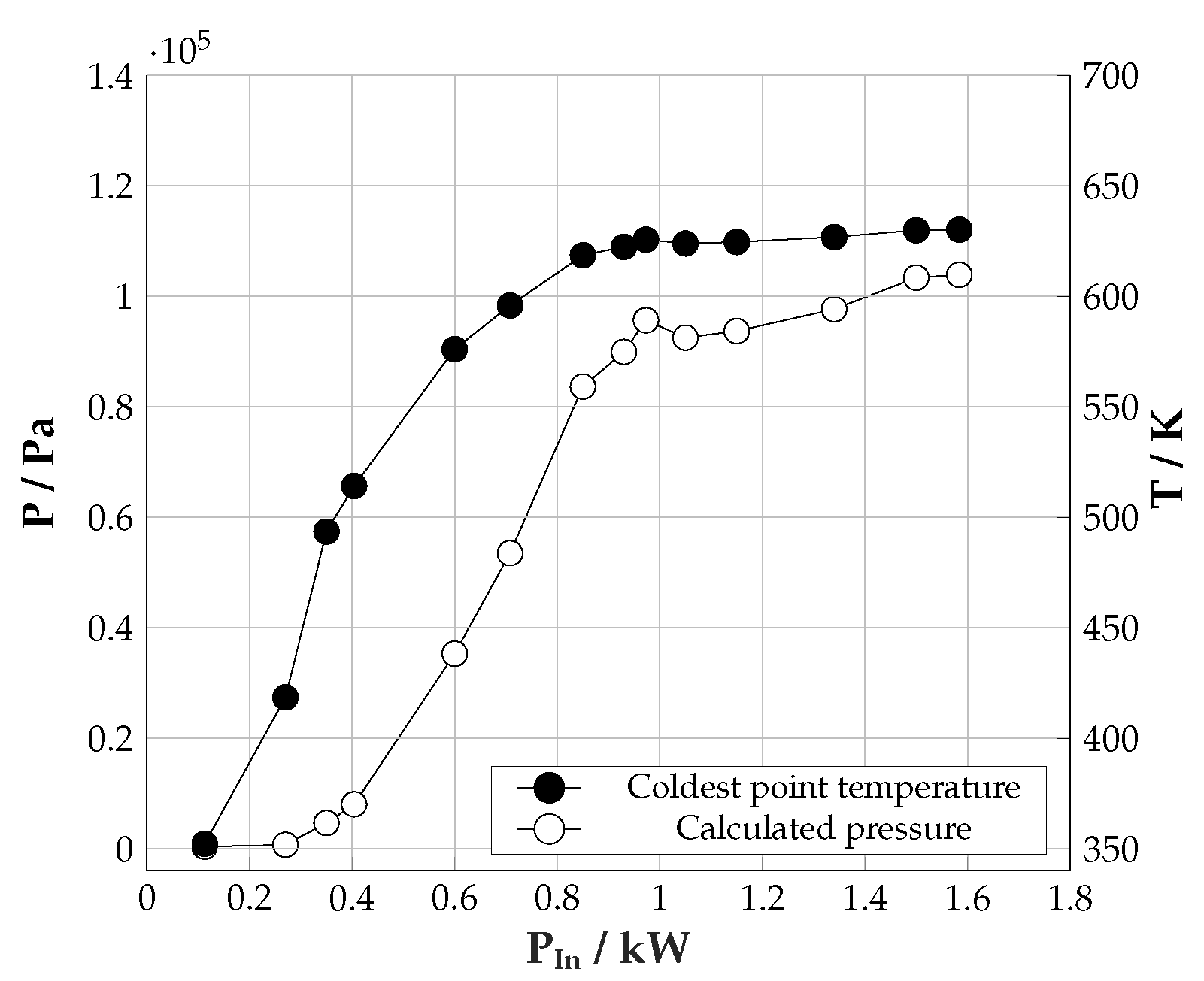

5.1. Temperature and Pressure

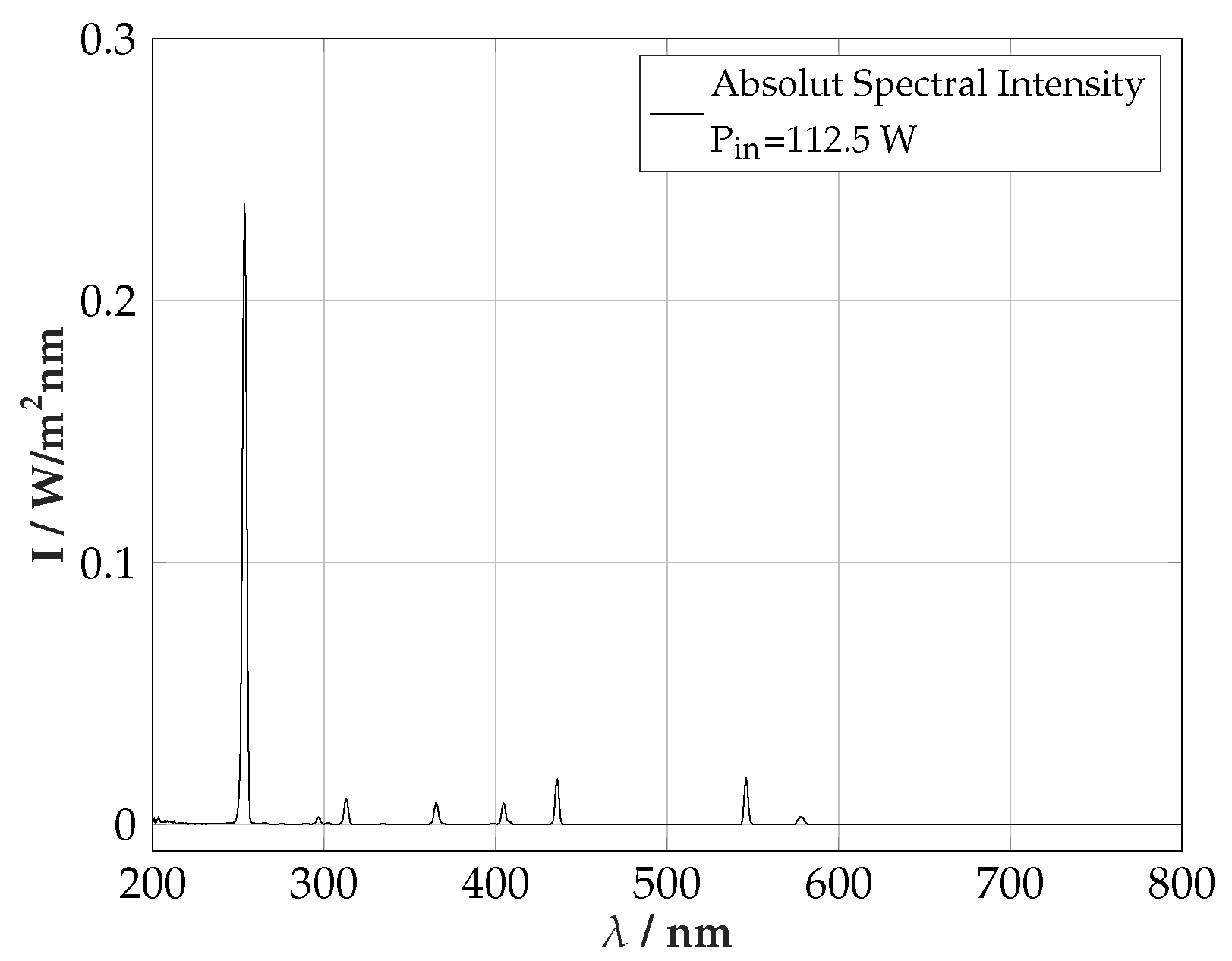

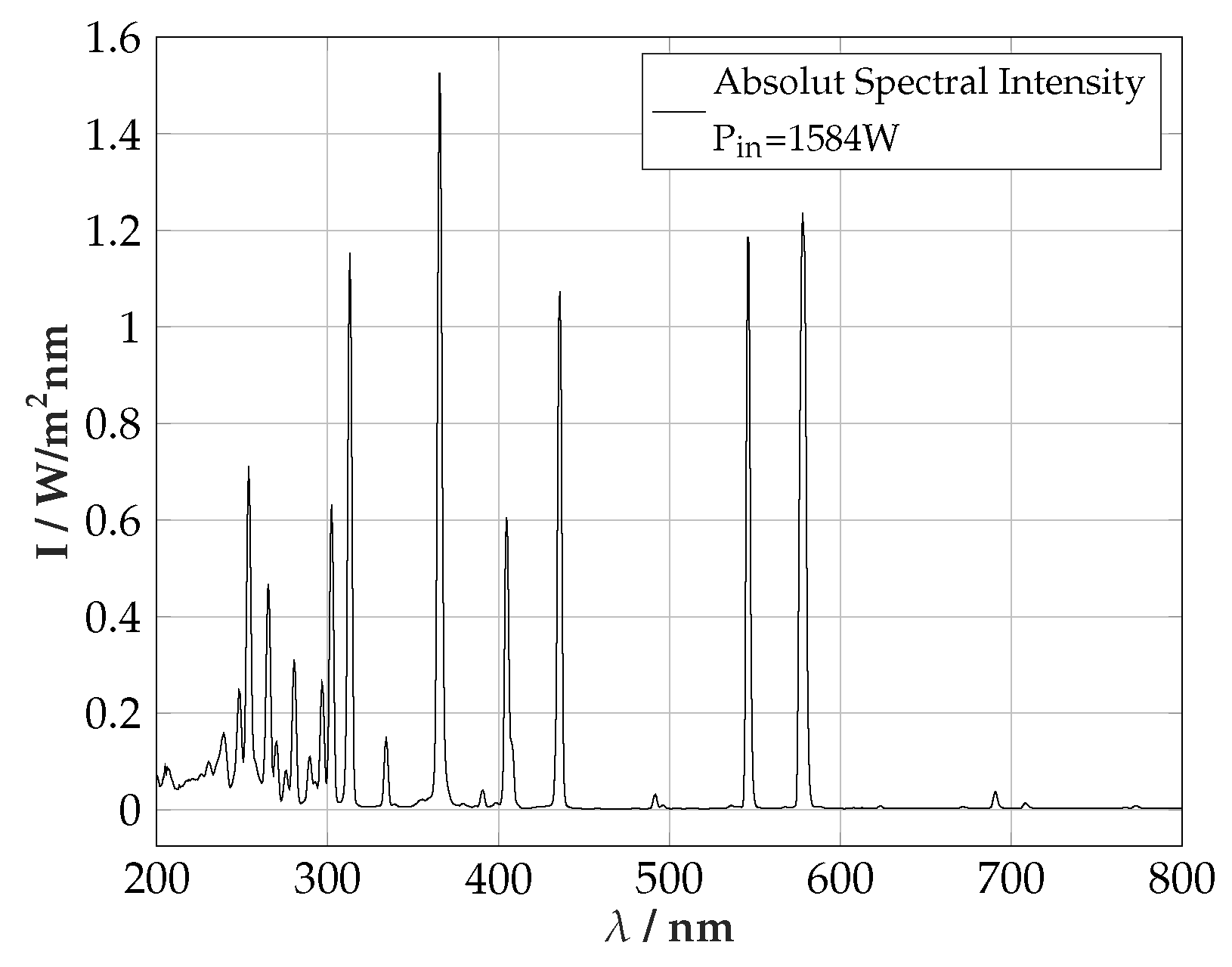

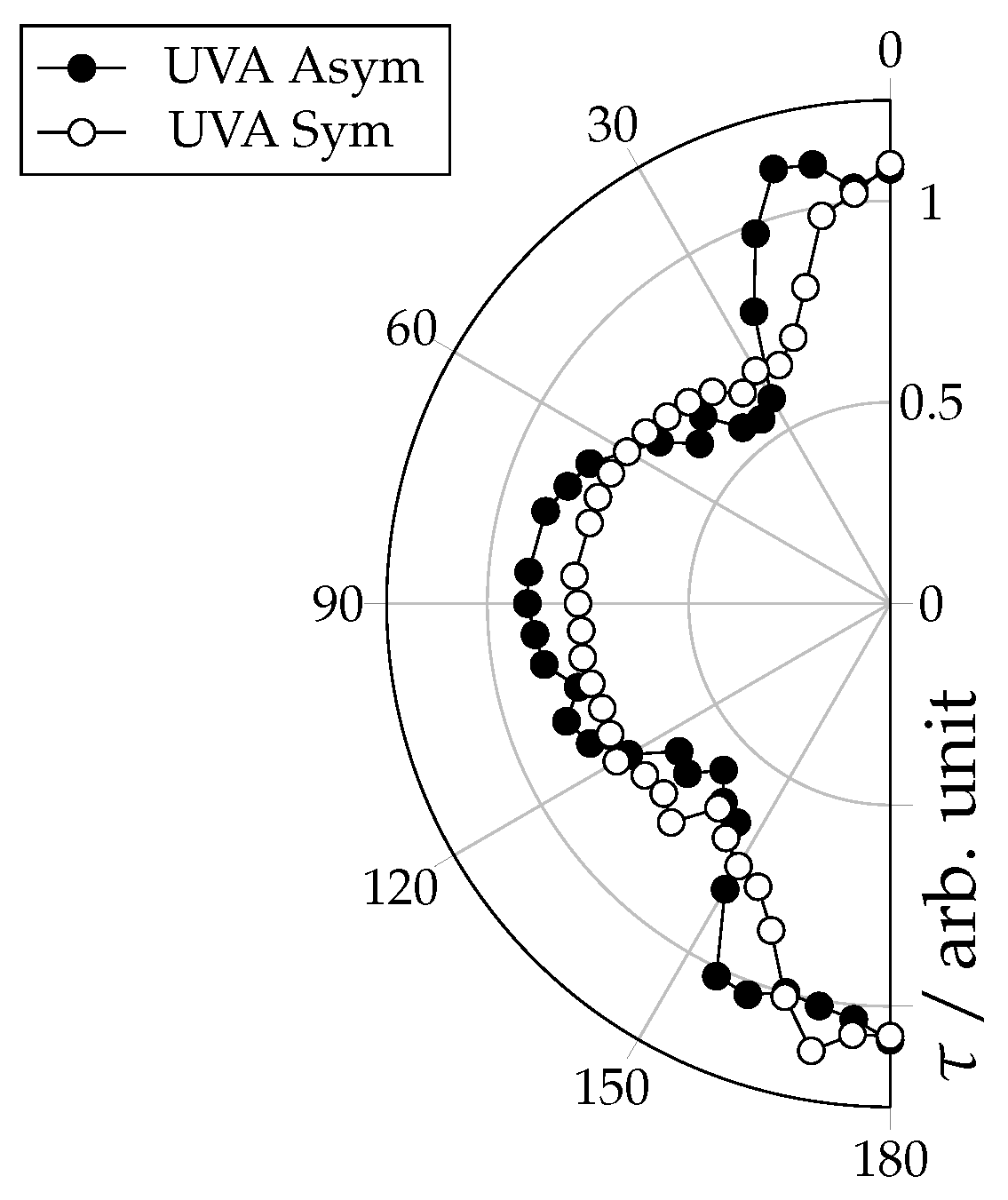

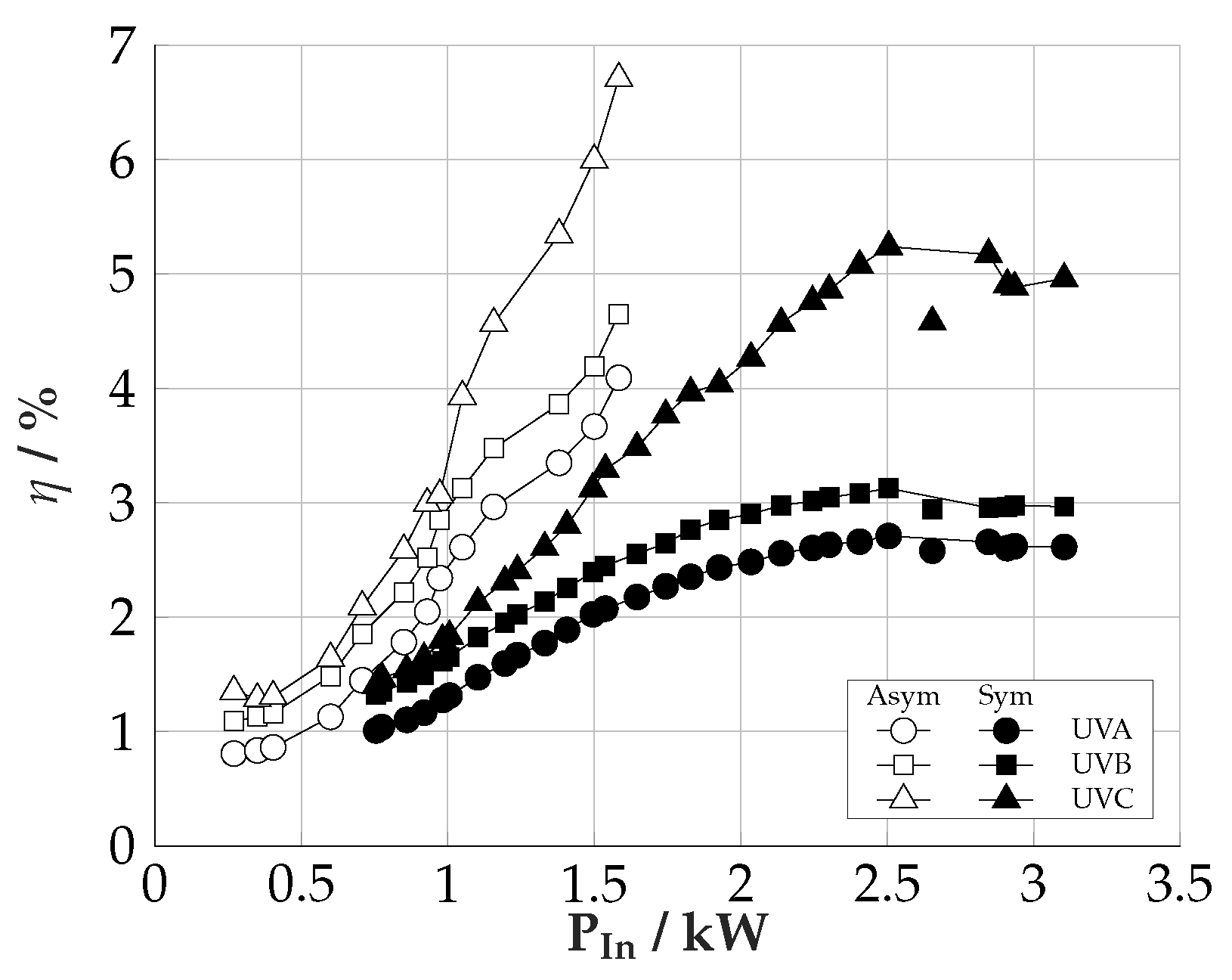

5.2. Spectral Output and Efficiency

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kneissl, M.; Rass, J. III-Nitride Ultraviolet Emitters; Springer International Publishing: Cham, Switzerland, 2016; Volume 227. [Google Scholar] [CrossRef]

- Popov, O.A. Efficient Light Source Based on a Inductive Ferrite-Free Discharge at Frequencies of 300–3000 kHz. Tech. Phys. 2007, 52, 751–758. [Google Scholar] [CrossRef]

- OSRAM. The High-Performance Electrodeless Fluorescent Lamp. Available online: https://www.osram.com/media/resource/HIRES/333886/554635/ENDURA-QUICKTRONIC-System-QT-ENDURA.pdf (accessed on 16 December 2019).

- Armbruster, C.; Hensel, A.; Wienhausen, A.H.; Kranzer, D. Application of GaN power transistors in a 2.5 MHz LLC DC/DC converter for compact and efficient power conversion. Eur. Conf. Power Electron. Appl. 2016, 1–7. [Google Scholar] [CrossRef]

- Denk, F.; Haehre, K.; Kling, R.; Heering, W. Investigations of SMPD SiC-MOSFET phase-leg modules for MHz inverters Keywords. In Proceedings of the 18th European Conference on Power Electronics and Applications, EPE-PEMC 2016 ECCE Europe, Karlsruhe, Germany, 5–9 September 2016. [Google Scholar]

- Denk, F.; Simon, C.; Heidinger, M.; Kling, R.; Heering, W. Compact highly efficient 3-kW MHz inverter based on SMT SiC MOSFETs. In Proceedings of the Power Conversion and Intelligent Motion Conference (PCIM Europe 2017), Nuremberg, Germany, 1 May 2017; pp. 16–18. [Google Scholar]

- Denk, F.; Haehre, K.; Simon, C.; Eizaguirre, S.; Heidinger, M.; Kling, R.; Heering, W. 25 kW High Power Resonant Inverter Operating at 2.5 MHz based on SiC SMD phase-leg modules. In Proceedings of the PCIM Europe 2018: International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nürnberg, Germany, 6–7 May 2018; pp. 1–7. [Google Scholar]

- Denk, F.; Haehre, K.; Simon, C.; Eizaguirre, S.; Heidinger, M.; Kling, R.; Heering, W. RDS(on) vs. inductance: Comparison of SiC MOSFETs in 7pin D2Pak and 4pin TO-247 and their benefits for high power MHz inverters. IET Power Electron. 2019, 8. [Google Scholar] [CrossRef]

- Burm, K.T.A.L. Breakdown minimum in magnetic field-driven metal plasmas. J. Plasma Phys. 2011, 77, 675–678. [Google Scholar] [CrossRef]

- Kortshagen, U.; Gibson, N.D.; Lawler, J.E. On the E–H mode transition in RF inductive discharges. J. Phys. D Appl. Phys. 1996, 1996, 1224–1236. [Google Scholar] [CrossRef]

- Hansen, S.; Getchius, J.; Steward, R.; Brumleve, T. Vapor Pressure of Metal Bromides and Iodides: With Selected Metal Chlorides and Metals, 2nd ed.; APL Engineered Materials, Inc.: Urbana, IL, USA, 2006. [Google Scholar]

- Chen, J.; Loeb, S.; Kim, J.H. LED revolution: Fundamentals and prospects for UV disinfection applications. Environ. Sci. Water Res. Technol. 2017, 3, 188–202. [Google Scholar] [CrossRef]

| n | l | d | L | ||

|---|---|---|---|---|---|

| symmetrical | 17 | ||||

| asymmetrical | 13 |

| Nomenclature | Meaning |

|---|---|

| Intensity of the ICP lamp | |

| Intensity of the ICP lamp in the symmetrical coil | |

| Intensity of the ICP lamp in the asymmetrical coil | |

| Intensity of the conventional lamp without coil | |

| Intensity of the conventional lamp in the symmetrical coil | |

| Intensity of the conventional lamp in the asymmetrical coil |

| Reference lamp | Symmetrical Coil | Asymmetrical Coil | |||

|---|---|---|---|---|---|

| = 500 W | = 2526 W | = 1548 W | |||

| UVA | 3.6% | 2.7% | 4.1% | ||

| UVB | 3.9% | 3.1% | 4.7% | ||

| UVC | 4.5% | 5.2% | 6.7% | ||

| ∑ UV | 12.3% | 10.9% | 15.5% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gehring, T.; Denk, F.; Jin, Q.; Eizaguirre, S.; Kling, R. Inductive Medium Pressure UV-Source. Plasma 2020, 3, 1-9. https://doi.org/10.3390/plasma3010001

Gehring T, Denk F, Jin Q, Eizaguirre S, Kling R. Inductive Medium Pressure UV-Source. Plasma. 2020; 3(1):1-9. https://doi.org/10.3390/plasma3010001

Chicago/Turabian StyleGehring, Tim, Fabian Denk, Qihao Jin, Santiago Eizaguirre, and Rainer Kling. 2020. "Inductive Medium Pressure UV-Source" Plasma 3, no. 1: 1-9. https://doi.org/10.3390/plasma3010001

APA StyleGehring, T., Denk, F., Jin, Q., Eizaguirre, S., & Kling, R. (2020). Inductive Medium Pressure UV-Source. Plasma, 3(1), 1-9. https://doi.org/10.3390/plasma3010001