Synthesis of Ceramic Foams, Development of Insulating Panels, and Energy Performance Evaluation for Social Housing Using Thermal Simulation

Abstract

1. Introduction

2. Materials and Methods

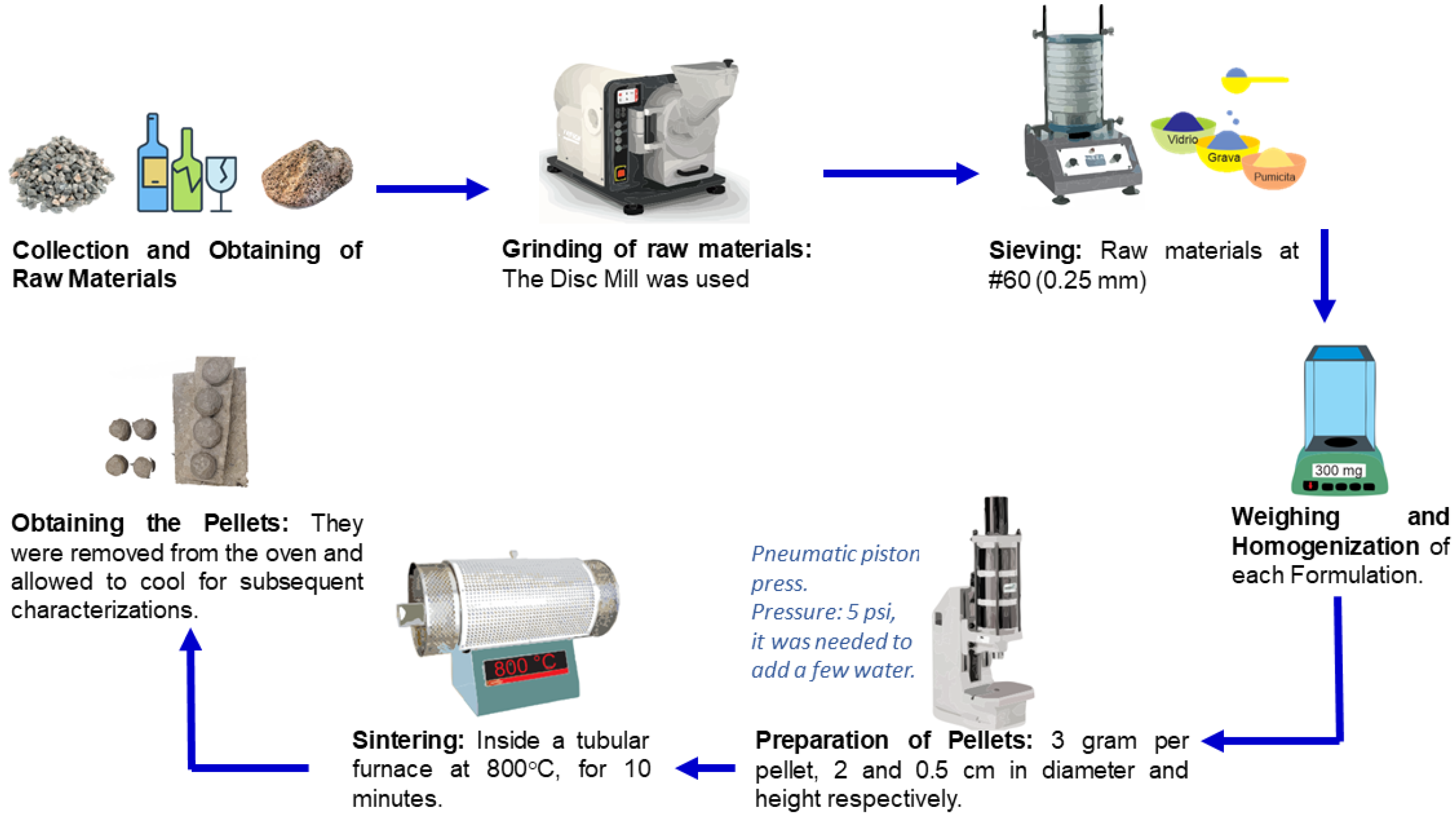

2.1. Synthesis of Ceramic Foams

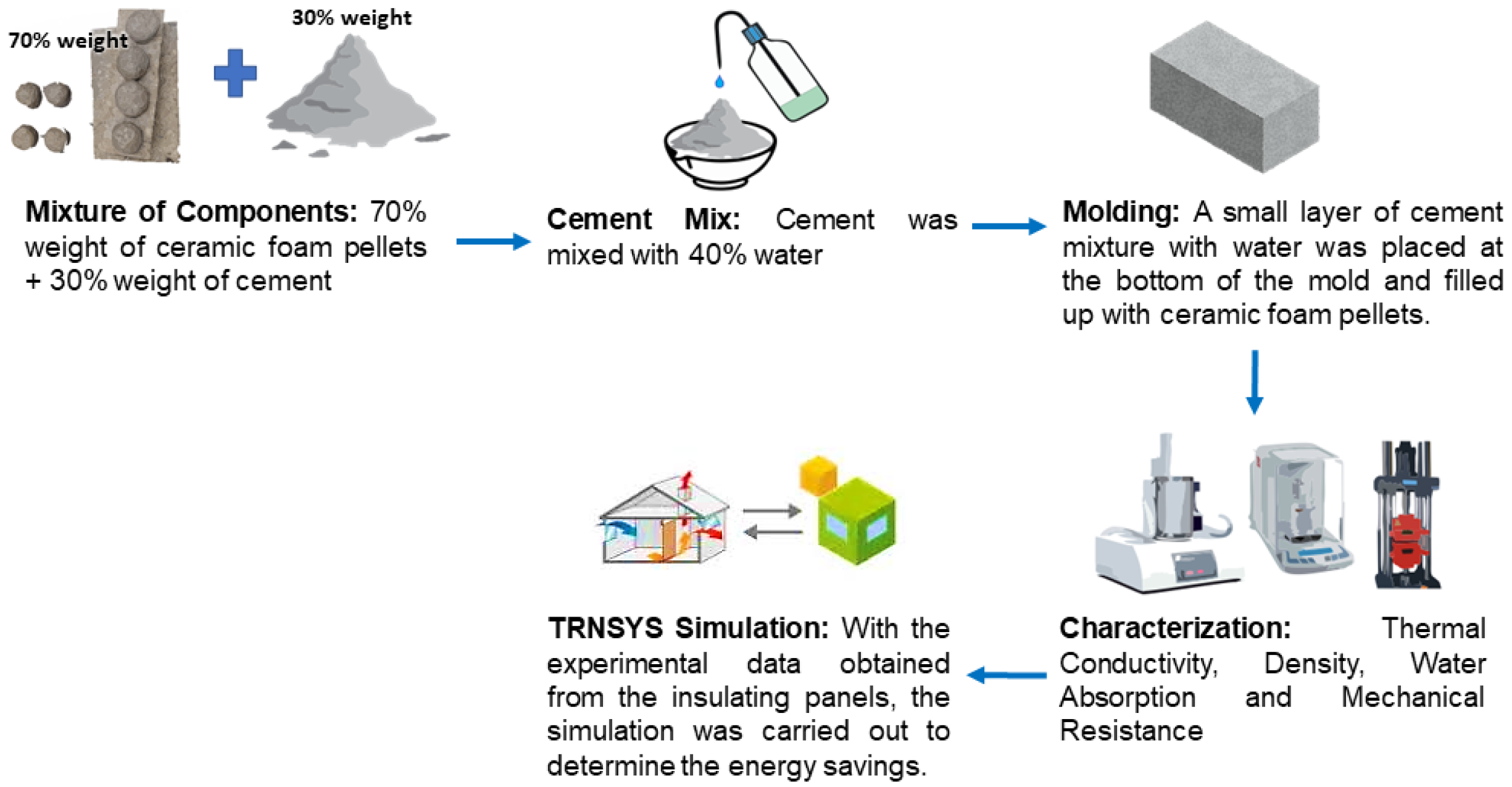

2.2. Manufacturing of Insulating Panels (Ceramic Foam–Cement)

2.3. Material Characterization

3. Results and Discussion

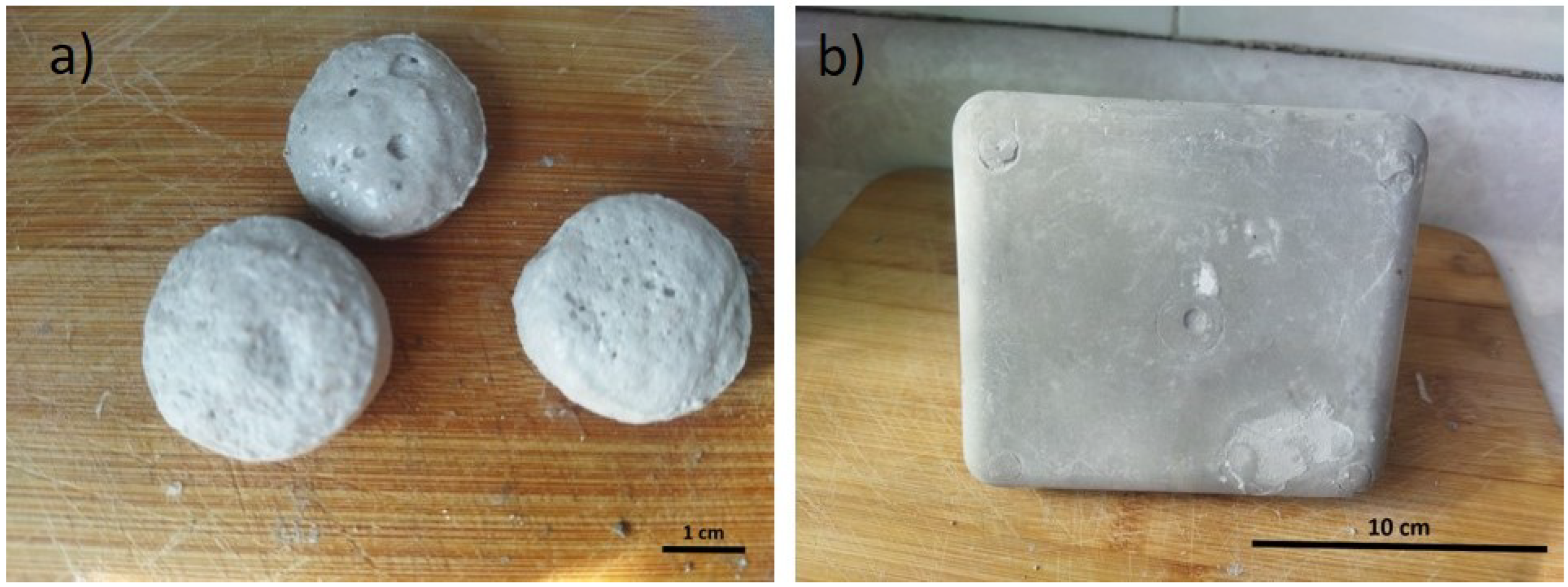

3.1. Morphology and Expansion Behavior of Pellets

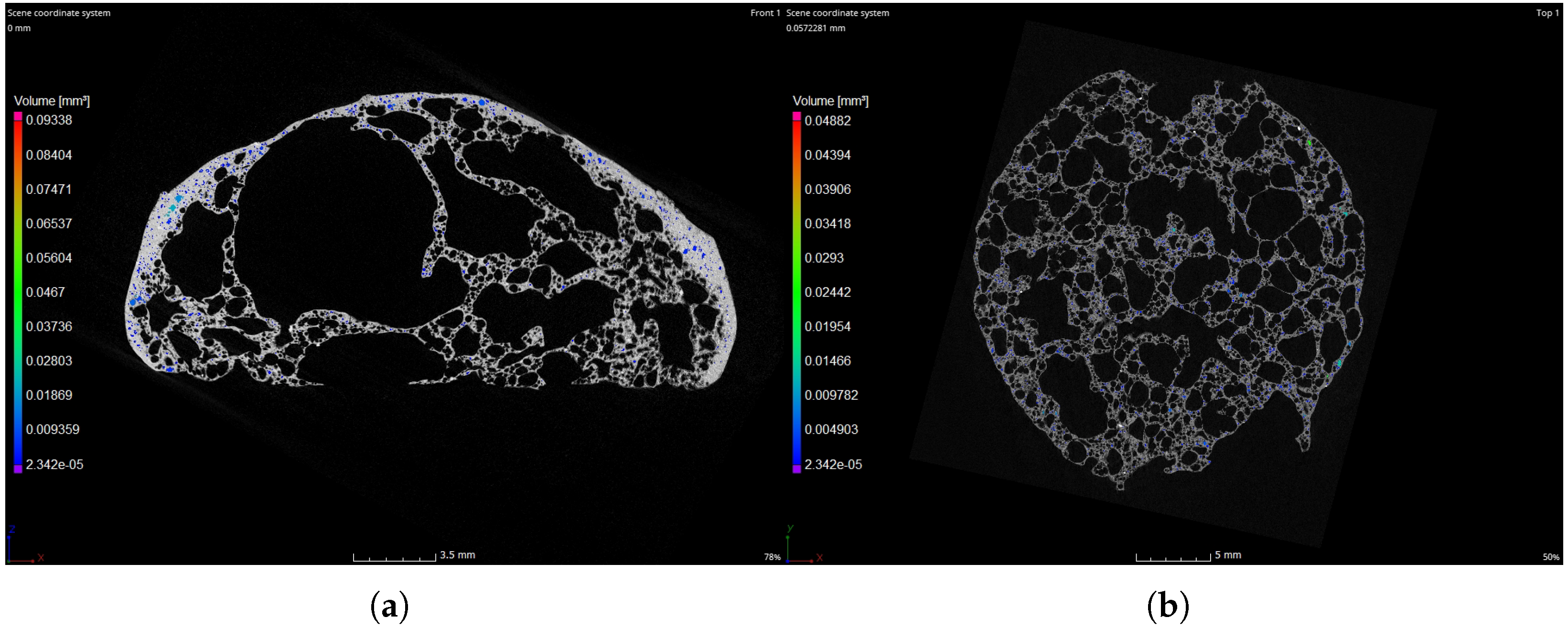

3.2. Internal Microstructure of Ceramic Pellets

3.3. Density and Thermal Conductivity

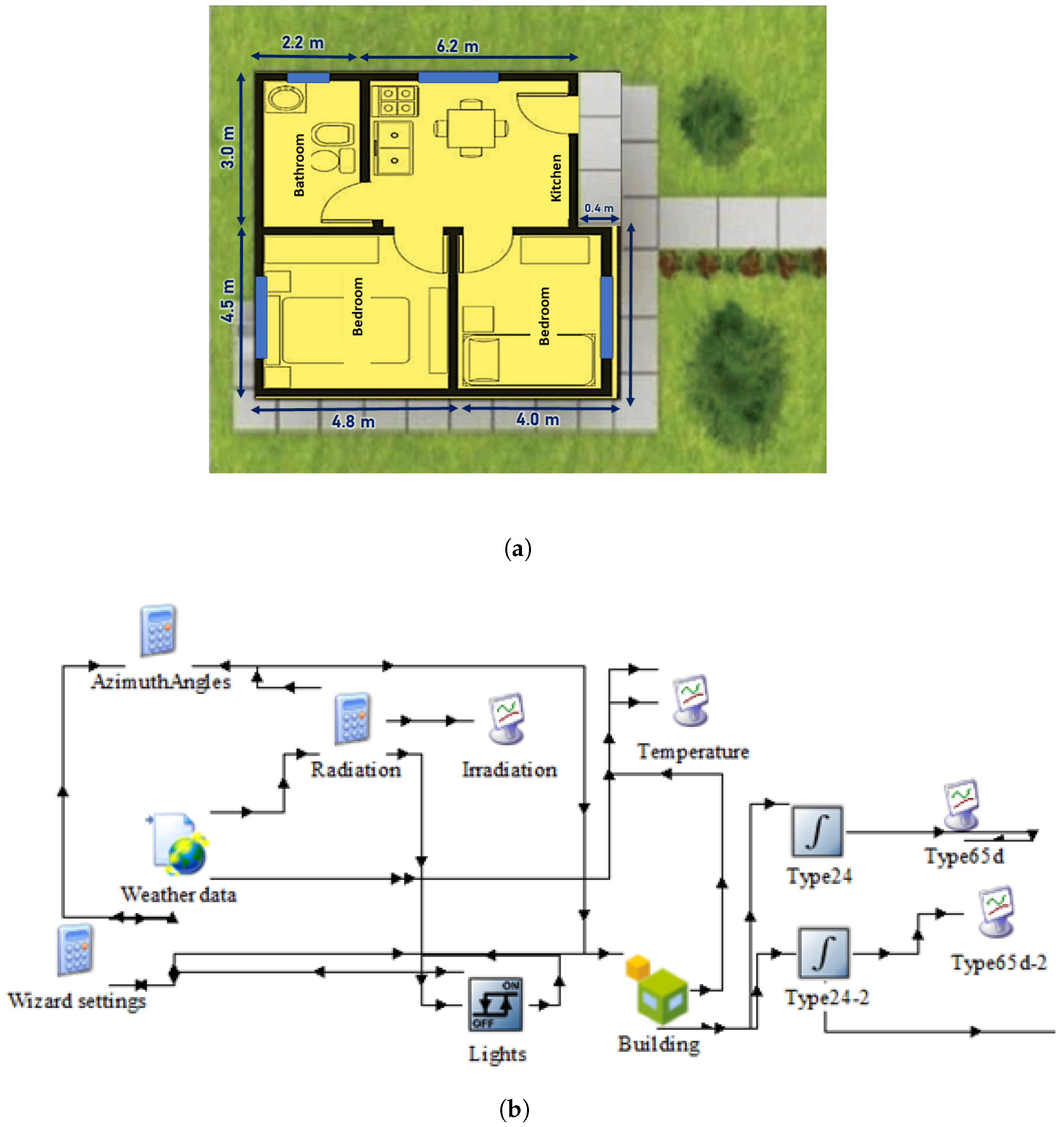

3.4. Housing Model and Simulation Setup

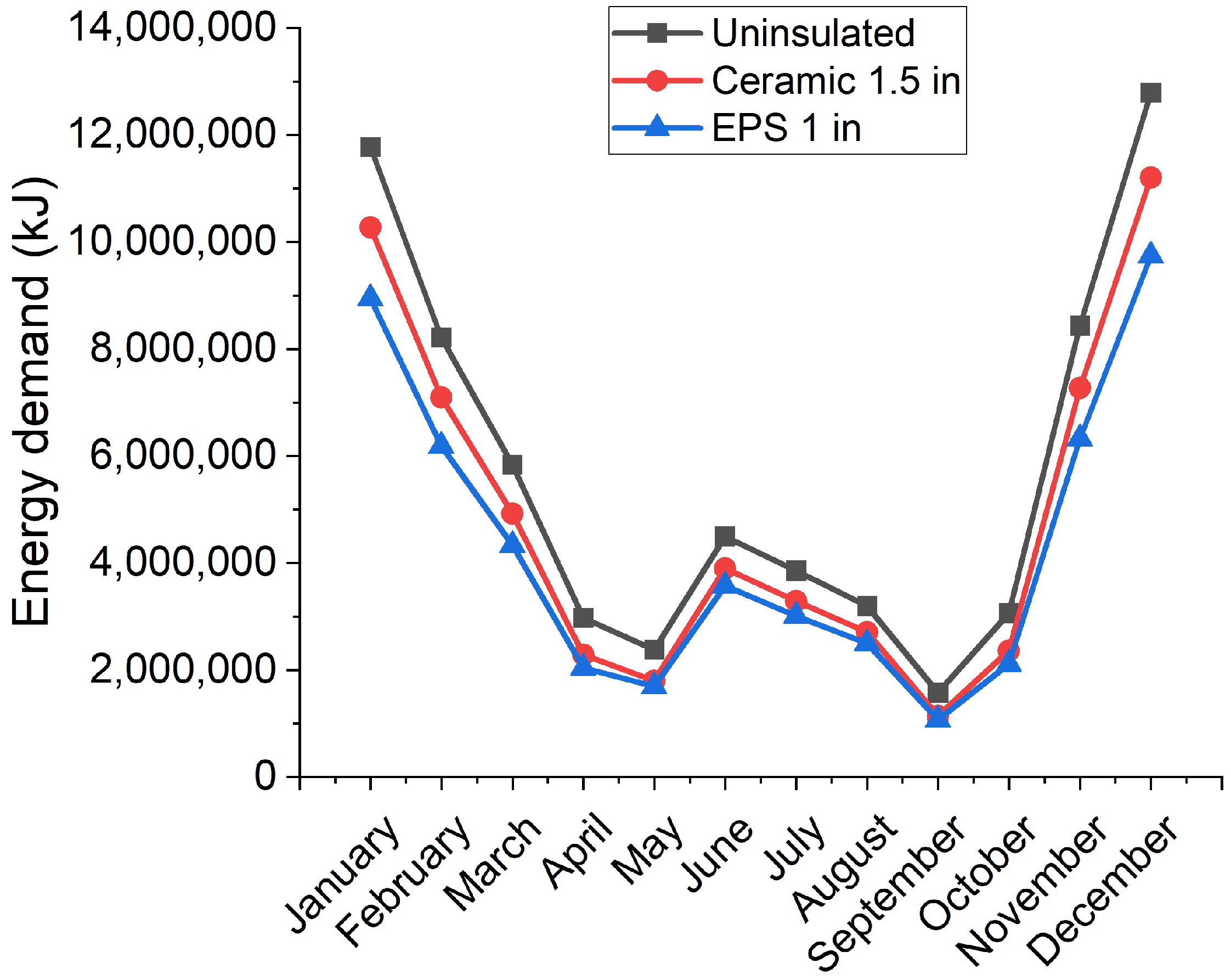

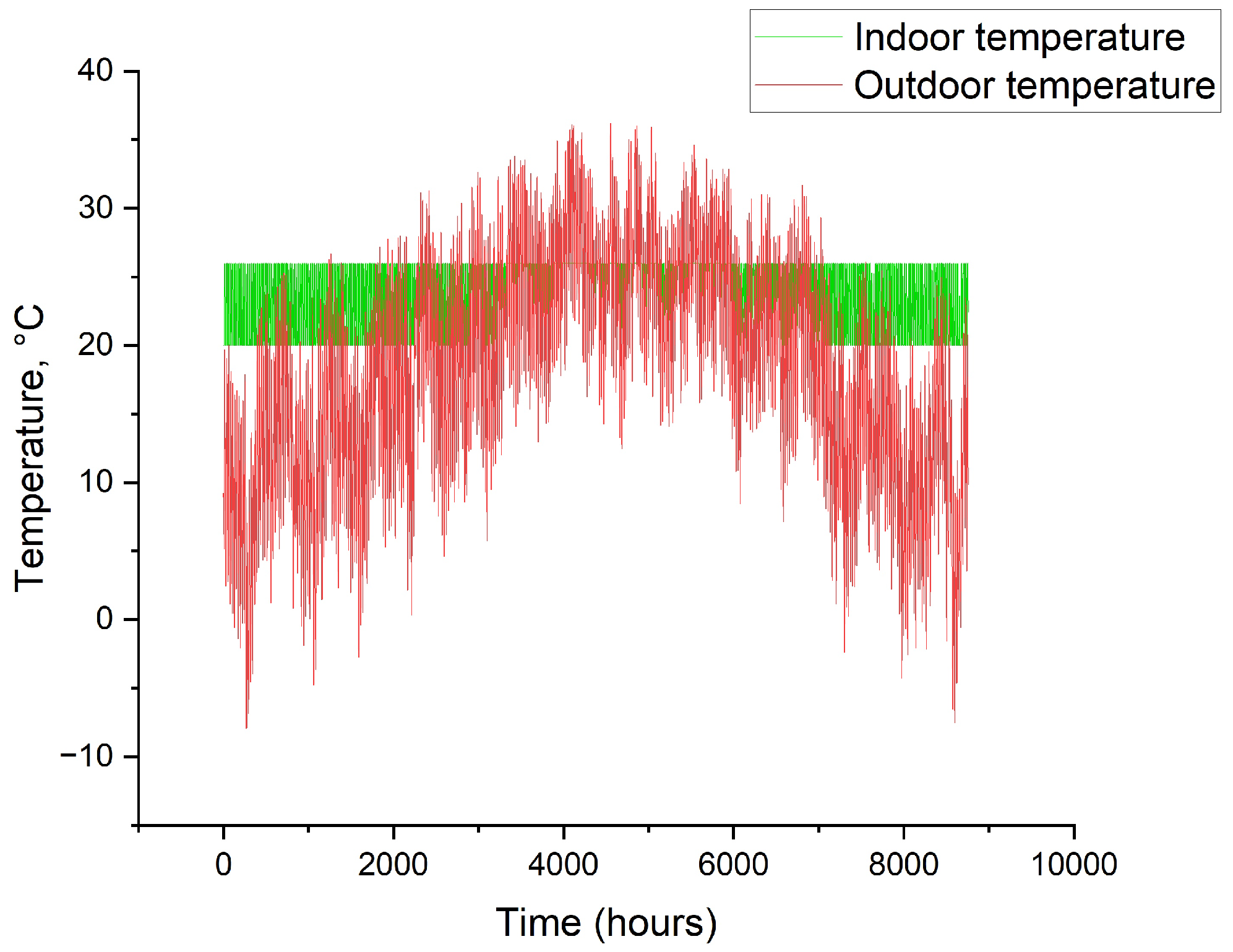

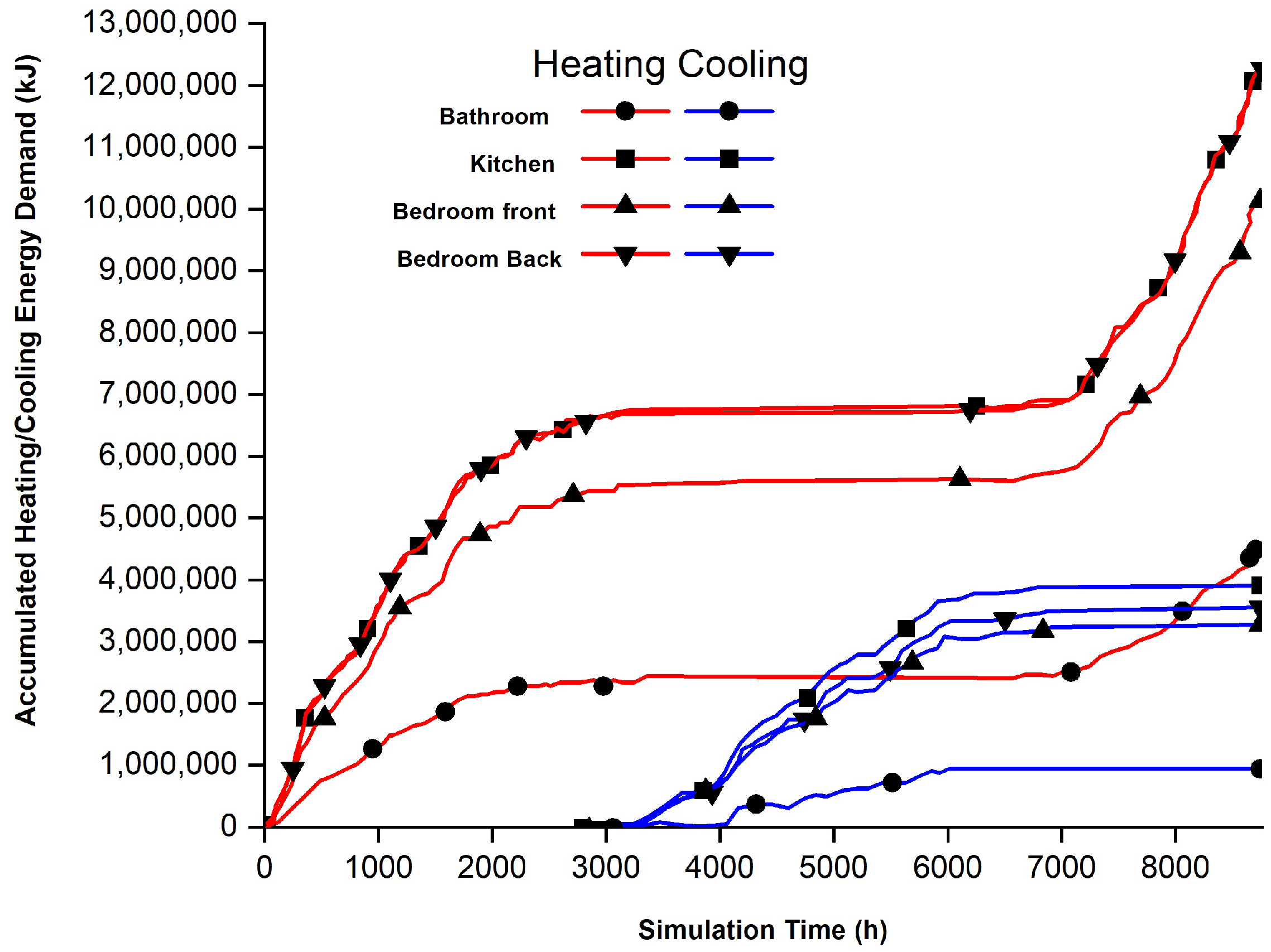

3.5. Energy Performance of Insulating Systems

3.6. Hourly Energy Demand Analysis

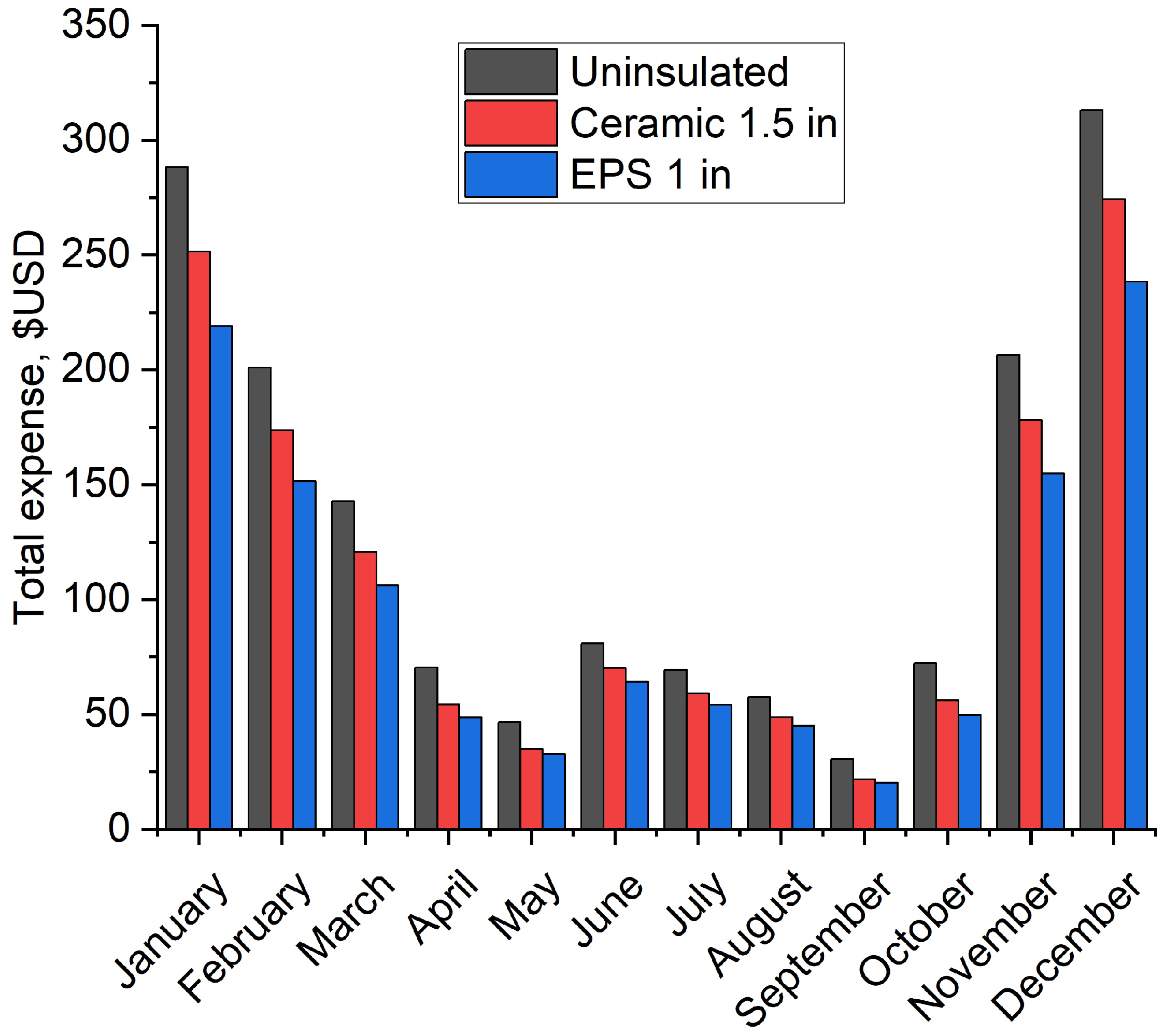

3.7. Economic Analysis

3.8. Economic Cost Estimation

- No insulation;

- 1.5-inch ceramic foam panel;

- 2-inch ceramic foam panel;

- 1-inch expanded polystyrene (EPS) panel.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aydin, E.; Brounen, D. The impact of policy on residential energy consumption. Energy 2019, 169, 115–129. [Google Scholar] [CrossRef]

- Xie, L.; Yan, H.; Zhang, S.; Wei, C. Does urbanization increase residential energy use? Evidence from the Chinese residential energy consumption survey 2012. China Econ. Rev. 2020, 59, 101374. [Google Scholar] [CrossRef]

- Xu, Q.; Lu, Y.; Hwang, B.G.; Kua, H.W. Reducing residential energy consumption through a marketized behavioral intervention: The approach of Household Energy Saving Option (HESO). Energy Build. 2021, 232, 110621. [Google Scholar] [CrossRef]

- Giraldo, W.; Herrera, C.A. Ventilación pasiva y confort térmico en vivienda de interés social en clima ecuatorial. Ing. Desarro. 2017, 35, 77–101. [Google Scholar]

- Cabrera, F. Aislantes térmicos para viviendas de la costa ecuatoriana. Yachana Rev. Cient. 2012, 1. [Google Scholar] [CrossRef]

- Falcón Duran, A. Propuesta y Diseño de un Sistema Modular para la Construcción de Viviendas de Interés Social en México. Bachelor’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2013. [Google Scholar]

- Pérez, J.B.; Cabanillas, R.E.; Hinojosa, J.F.; Borbón, A.C. Estudio numérico de la resistencia térmica en muros de bloques de concreto hueco con aislamiento térmico. Inf. Tecnol. 2011, 22, 27–38. [Google Scholar] [CrossRef]

- Czajkowski, J.D.; Gómez, A.F.; Calisto Aguilar, M.; Diulio, M.d.l.P.; Basualdo, D.E.; Reus Netto, G.; Berardi, R.N.; Camporeale, P.; Giraldo, W.; Fuentealba, M.d.l.Á.; et al. Hacia un modelo de certificación de edificios sustentables adecuado al contexto regional. In Proceedings of the XXXVI Encuentro y XXI Congreso ARQUISUR (San Juan, 2017), San Juan, Argentina, 6–8 September 2017. [Google Scholar]

- Mercier, D.; Dutil, Y.; Rousse, D.; Pronovost, F.; Boudreau, D.; Hudon, N.; Castonguay, M. Los aislamientos térmicos naturales: Construcción ecológica y eficiencia energética. In Proceedings of the Coloquio Universitario Franco-Québécois, Saguenay, QC, Canada, 18 May 2011. [Google Scholar]

- Sánchez, J.F.P.; Fernández, P.M.E. Propuestas de Mejora para Incrementar la Calidad del Hábitat en Viviendas de Interés Social en México: Caso de Estudio Las Dunas. Master’s Thesis, Universidad de Sevilla, Sevilla, Spain, 2021. [Google Scholar]

- Pimentel Bolaños, Á.; ATEPA. El aislamiento con poliuretano en la construcción sostenible. In Proceedings of the Congreso Nacional de Construcción Sostenible y Soluciones Ecoeficientes (2º. 2012. Sevilla), Seville, Spain, 21–23 November 2012. [Google Scholar]

- Shojaei, B.; Najafi, M.; Yazdanbakhsh, A.; Abtahi, M.; Zhang, C. A review on the applications of polyurea in the construction industry. Polym. Adv. Technol. 2021, 32, 2797–2812. [Google Scholar] [CrossRef]

- Mistry, M.; Prajapati, V.; Dholakiya, B.Z. Redefining construction: An in-depth review of sustainable polyurethane applications. J. Polym. Environ. 2024, 32, 3448–3489. [Google Scholar] [CrossRef]

- Somarathna, H.; Raman, S.; Mohotti, D.; Mutalib, A.; Badri, K. The use of polyurethane for structural and infrastructural engineering applications: A state-of-the-art review. Constr. Build. Mater. 2018, 190, 995–1014. [Google Scholar] [CrossRef]

- Álvarez-Barragán, J.; Domínguez-Malfavón, L.; Vargas-Suárez, M.; González-Hernández, R.; Aguilar-Osorio, G.; Loza-Tavera, H. Biodegradative activities of selected environmental fungi on a polyester polyurethane varnish and polyether polyurethane foams. Appl. Environ. Microbiol. 2016, 82, 5225–5235. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Boccaccini, A.; Lee, P.; Kershaw, M.; Rawlings, R. Glass ceramic foams from coal ash and waste glass: Production and characterisation. Adv. Appl. Ceram. 2006, 105, 32–39. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, B.; Zhang, S. A review of glass ceramic foams prepared from solid wastes: Processing, heavy-metal solidification and volatilization, applications. Sci. Total Environ. 2021, 781, 146727. [Google Scholar] [CrossRef] [PubMed]

- Fernandez Campos, E.D. Vidrio Espuma a Partir de Desecho de Vidrio y Perlita Mineral Como Aislante Térmico. Ph.D. Thesis, Universidad Autónoma de Nuevo León, San Nicolás de los Garza, Mexico, 2021. [Google Scholar]

- de Salazar, J.G.; Barrena, M.; Soria, A.; Menéndez, M.; González, A. Obtención de recubrimientos vitrocerámicos esponjosos sobre materiales de naturaleza férrea. Boletín Soc. Espa Nola Cerámica Vidr. 2001, 40, 295–299. [Google Scholar]

- Hamzawy, E.M.; El-Bassyouni, G.T.; Abd El-Shakour, Z.A.; Nabawy, B.S. Manufacture of low thermal conductivity anorthite ceramic foam using silica fume, aluminum slag, and limestone. Ceram. Int. 2025, 51, 7977–7985. [Google Scholar] [CrossRef]

- Appoloni, C.R.; Fernandes, C.P.; Innocentini, M.D.d.M.; Macedo, Á. Ceramic foams porous microstructure characterization by X-ray microtomography. Mater. Res. 2004, 7, 557–564. [Google Scholar] [CrossRef]

- Zhu, M.; Ji, R.; Li, Z.; Wang, H.; Liu, L.; Zhang, Z. Preparation of glass ceramic foams for thermal insulation applications from coal fly ash and waste glass. Constr. Build. Mater. 2016, 112, 398–405. [Google Scholar] [CrossRef]

- Sousa, J. Energy simulation software for buildings: Review and comparison. In Proceedings of the International Workshop on Information Technology for Energy Applicatons-IT4Energy, Lisabon, Portugal, 6–7 September 2012; pp. 1–12. [Google Scholar]

- Hisham, N.A.N.; Zaid, M.H.M.; Aziz, S.H.A.; Muhammad, F.D. Comparison of foam glass-ceramics with different composition derived from ark clamshell (ACS) and soda lime silica (SLS) glass bottles sintered at various temperatures. Materials 2021, 14, 570. [Google Scholar] [CrossRef] [PubMed]

- König, J.; Petersen, R.R.; Yue, Y. Influence of the glass–calcium carbonate mixture’s characteristics on the foaming process and the properties of the foam glass. J. Eur. Ceram. Soc. 2014, 34, 1591–1598. [Google Scholar] [CrossRef]

- ASTM D792-08; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 1991.

- ASTM E1530-19; Standard Test Method for Evaluating the Resistance to Thermal Transmission by the Guarded Heat Flow Meter Technique. ASTM International: West Conshohocken, PA, USA, 2019.

- Batool, F.; Rafi, M.M.; Bindiganavile, V. Microstructure and thermal conductivity of cement-based foam: A review. J. Build. Eng. 2018, 20, 696–704. [Google Scholar] [CrossRef]

- Gaspar, J. Google SketchUp Pro 8 paso a paso en Español; GetProBooks: Brea, CA, USA, 2013. [Google Scholar]

- Delcroix, B.; Kummert, M.; Daoud, A.; Hiller, M. Improved conduction transfer function coefficients generation in TRNSYS multizone building model. In Proceedings of the Building Simulation 2013, IBPSA, Chambéry, France, 25–28 August 2013; Volume 13, pp. 2667–2674. [Google Scholar]

- Remund, J. Quality of meteonorm version 6.0. Europe 2008, 6, 389. [Google Scholar]

| Sample | Density (kg/) | Thermal Conductivity (W/m·K) |

|---|---|---|

| Pellets | 684.0 | 0.09 |

| Panels | 926.7 | 0.18 |

| Building Element | Material | Thickness (m) | Thermal Conductivity (W/m K) | Density (kg/) |

|---|---|---|---|---|

| Exterior Wall | Cement mortar | 0.01 | 5.04 | 2000 |

| Hollow block | 0.15 | 1.836 | 1400 | |

| Cement mortar | 0.01 | 5.04 | 2000 | |

| Plaster wall | 0.01 | 4.68 | 2200 | |

| Interior Wall | Plaster wall | 0.01 | 4.68 | 2200 |

| Hollow block | 0.15 | 1.836 | 1400 | |

| Plaster wall | 0.01 | 4.68 | 2200 | |

| Roof | Cement mortar | 0.01 | 5.04 | 2000 |

| Losa cement/slab | 0.2 | 1.04 | 800 | |

| Cement mortar | 0.01 | 5.04 | 2000 | |

| Plaster wall | 0.01 | 4.68 | 2200 | |

| Floor | Concrete | 0.10 | 4.068 | 2000 |

| Insulation Scenario | Annual Energy Cost (USD) | Savings (%) |

|---|---|---|

| No insulation | 1579.36 | — |

| Ceramic foam (1.5 in) | 1343.07 | 14.7 |

| Ceramic foam (2.0 in) | 1288.64 | 18.4 |

| EPS (1.0 in) | 1184.36 | 24.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tercero-González, N.M.; Lardizábal-Gutiérrez, D.; Escobedo-Bretado, J.; Vásquez-Duarte, I.; Beltran-Chacon, R.; Carreño-Gallardo, C. Synthesis of Ceramic Foams, Development of Insulating Panels, and Energy Performance Evaluation for Social Housing Using Thermal Simulation. Ceramics 2025, 8, 153. https://doi.org/10.3390/ceramics8040153

Tercero-González NM, Lardizábal-Gutiérrez D, Escobedo-Bretado J, Vásquez-Duarte I, Beltran-Chacon R, Carreño-Gallardo C. Synthesis of Ceramic Foams, Development of Insulating Panels, and Energy Performance Evaluation for Social Housing Using Thermal Simulation. Ceramics. 2025; 8(4):153. https://doi.org/10.3390/ceramics8040153

Chicago/Turabian StyleTercero-González, Nahyr Michelle, Daniel Lardizábal-Gutiérrez, Jorge Escobedo-Bretado, Ivan Vásquez-Duarte, Ricardo Beltran-Chacon, and Caleb Carreño-Gallardo. 2025. "Synthesis of Ceramic Foams, Development of Insulating Panels, and Energy Performance Evaluation for Social Housing Using Thermal Simulation" Ceramics 8, no. 4: 153. https://doi.org/10.3390/ceramics8040153

APA StyleTercero-González, N. M., Lardizábal-Gutiérrez, D., Escobedo-Bretado, J., Vásquez-Duarte, I., Beltran-Chacon, R., & Carreño-Gallardo, C. (2025). Synthesis of Ceramic Foams, Development of Insulating Panels, and Energy Performance Evaluation for Social Housing Using Thermal Simulation. Ceramics, 8(4), 153. https://doi.org/10.3390/ceramics8040153