Comparative Theoretical and Experimental Validation of the Shielding Effectiveness of Ceramic Composite-Based Medical Radiation Protection Tools

Abstract

1. Introduction

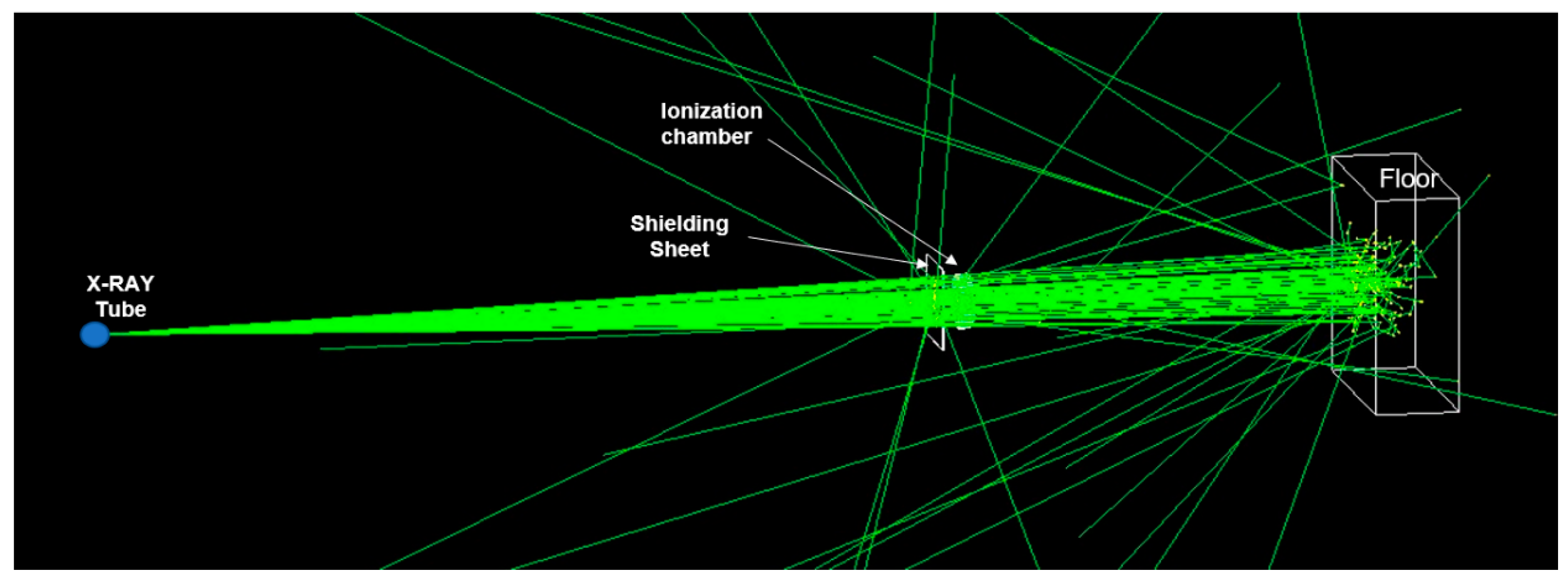

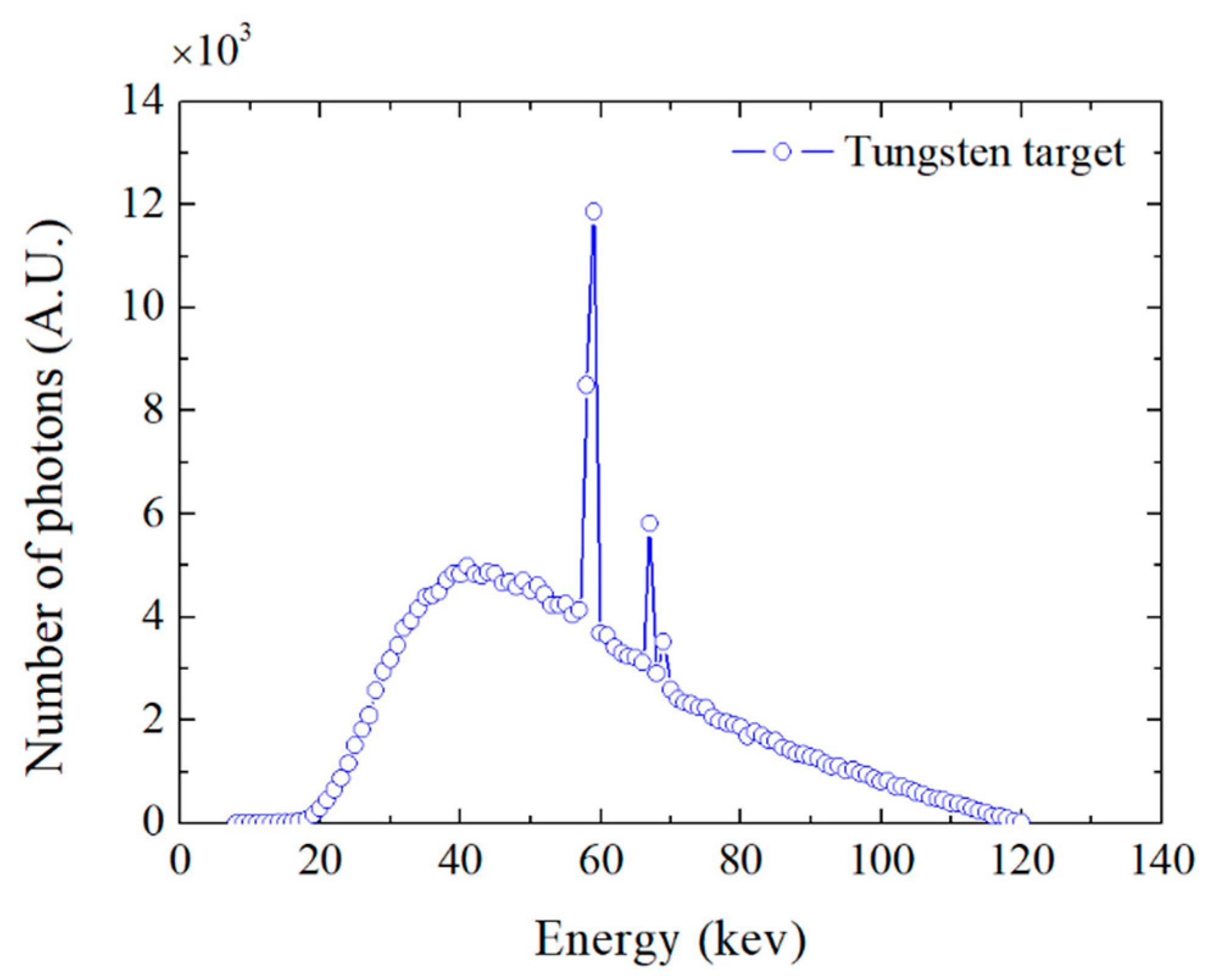

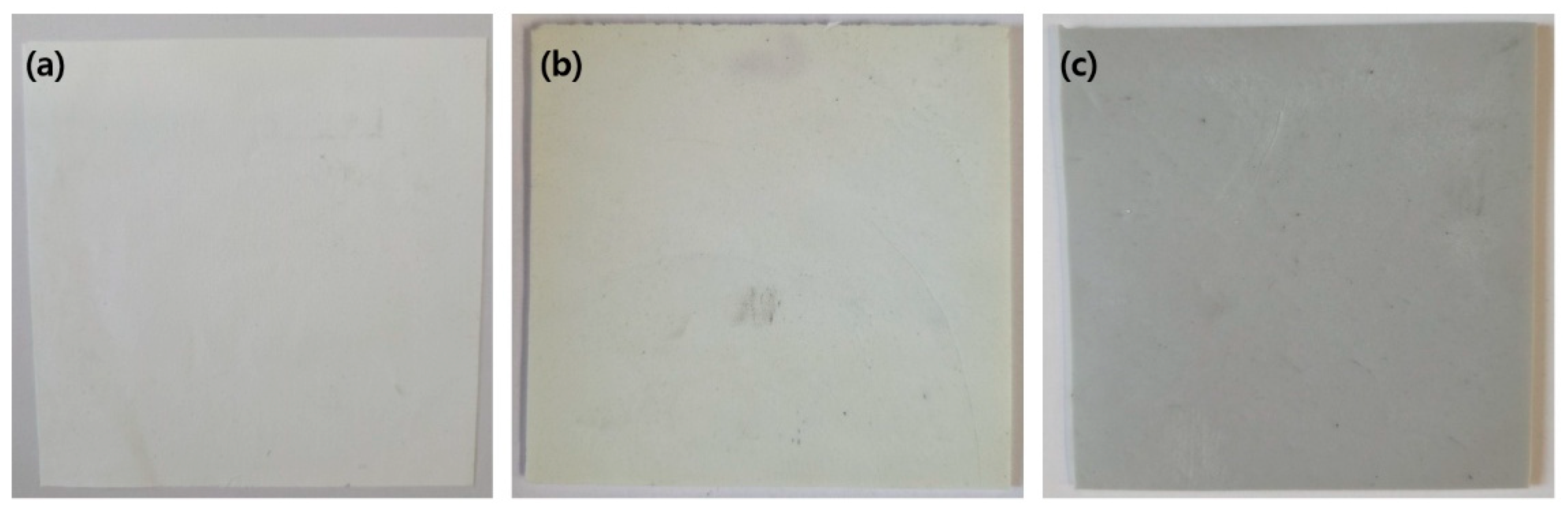

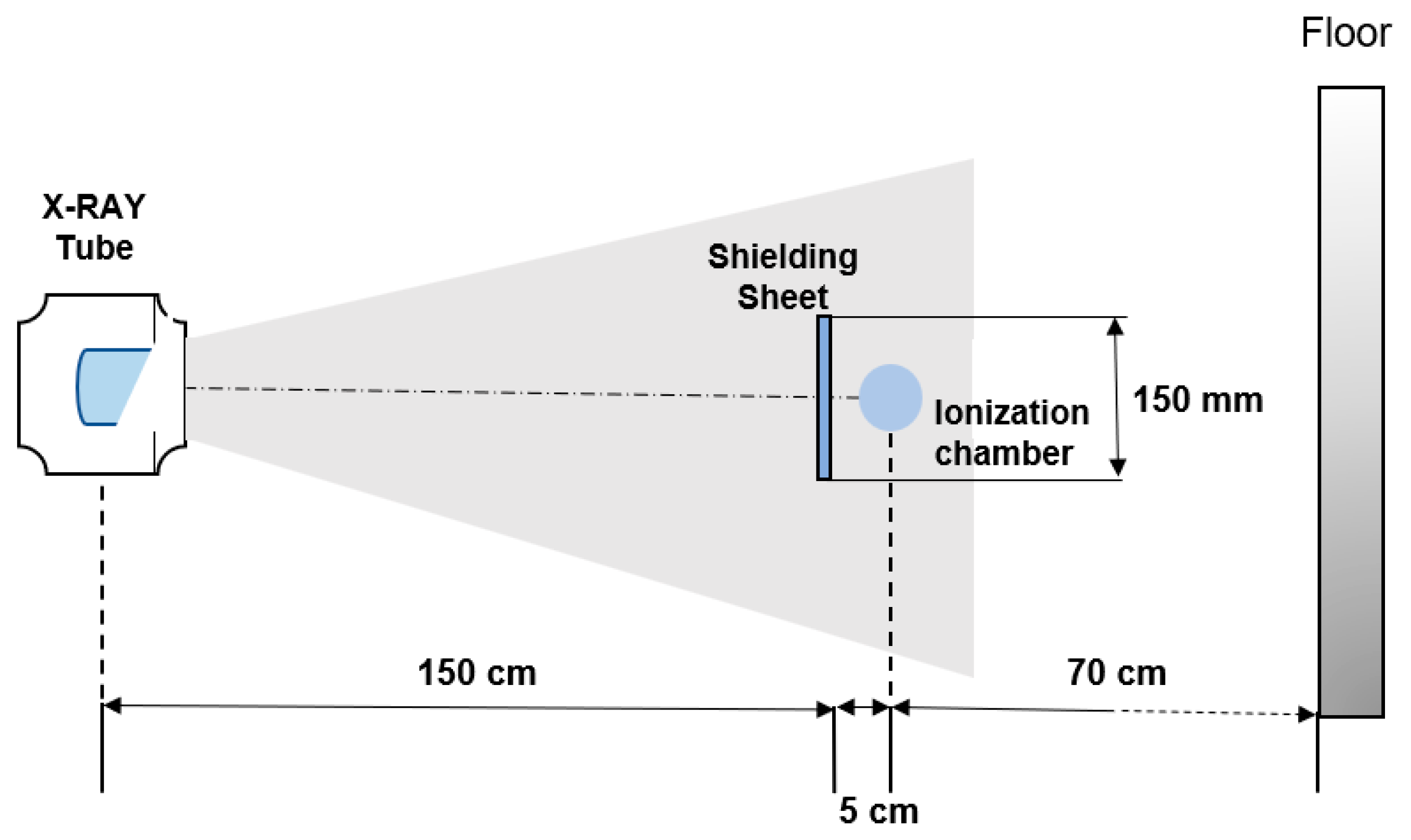

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

- 1.

- The obtained densities of Ta2O5, CeO2, and Bi2O3 composites were 3.315, 3.228, and 3.091 g/cm3, respectively.

- 2.

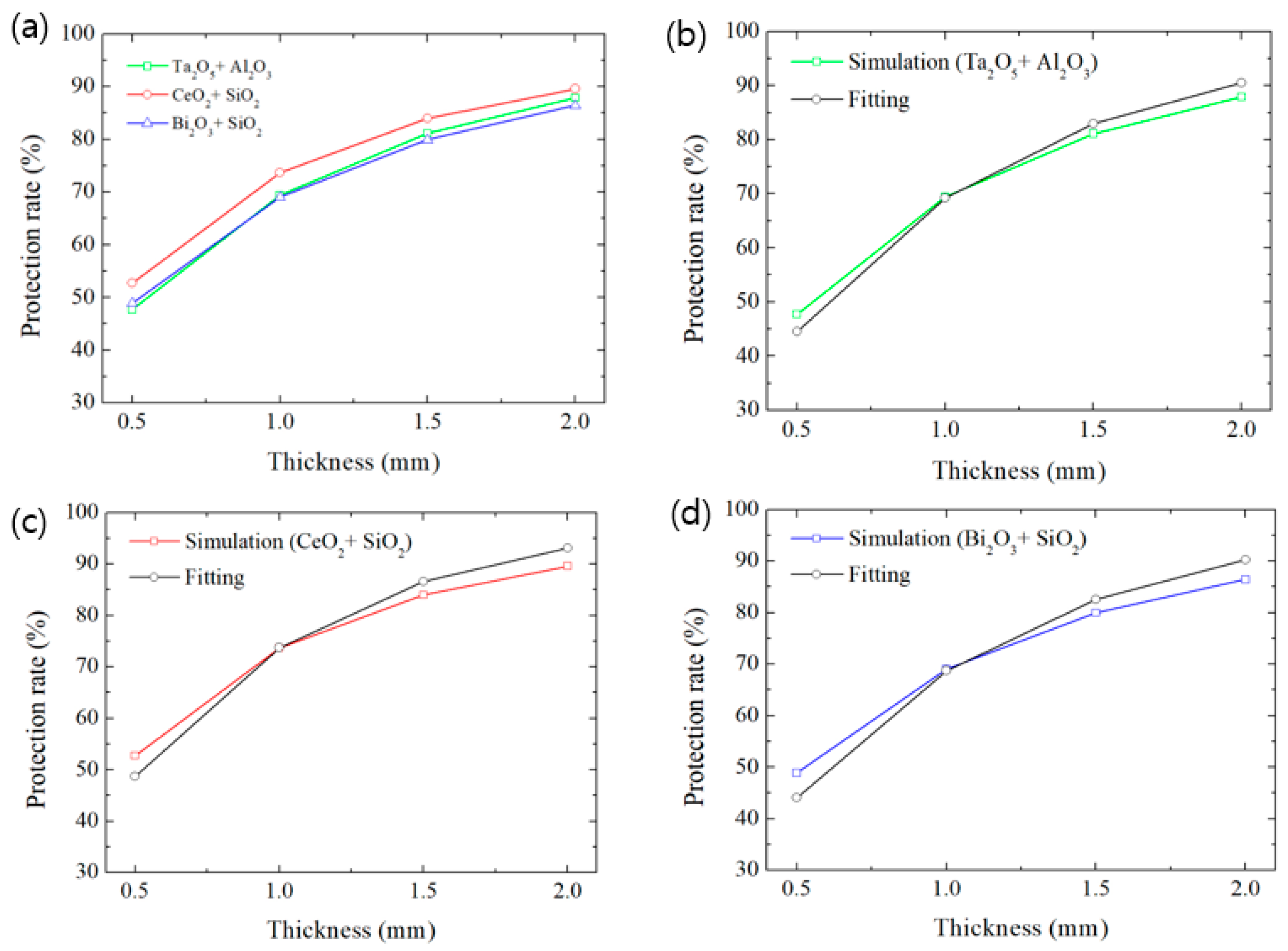

- In theoretical simulations, all three composites exhibited similar shielding performance; however, CeO2—with a relatively higher linear attenuation coefficient—demonstrated the best shielding effectiveness.

- 3.

- In experimental evaluations, similar shielding performance was also observed, although Bi2O3 exhibited comparatively lower performance, whereas Ta2O5 yielded the most superior results.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Candela-Juan, C.; Ciraj-Bjelac, O.; Merce, M.S.; Dabin, J.; Faj, D.; Gallagher, A.; Gala, H.H.; Knežević, Ž.; Malchair, F.; Monte, F.D.; et al. Use of out-of-field contact shielding on patients in medical imaging: A review of current guidelines, recommendations and legislative documents. Phys. Med. 2021, 86, 44–56. [Google Scholar] [CrossRef]

- Ihsani, R.N.; Heryanto, H.; Gareso, P.L.; Tahir, D. Innovative radiation shielding: A review natural polymer-based aprons with metal nanoparticle fillers. Polym.-Plast. Technol. Mater. 2024, 63, 738–755. [Google Scholar] [CrossRef]

- Okonkwo, U.C.; Okafor, C.E.; Perişanoğlu, U.; Kavaz Perişanoğlu, E.; Saltık, S.; Okokpujie, I.P.; Idumah, C.I.; Aronu, M.E.; Ohagwu, C.C.; Chukwu, N.N.; et al. Sustainable hybrid epoxy composites with natural fillers for radiation shielding applications. Polym. Bull. 2025, 82, 9359–9389. [Google Scholar] [CrossRef]

- More, C.V.; Alsayed, Z.; Badawi, M.S.; Thabet, A.A.; Pawar, P.P. Polymeric composite materials for radiation shielding: A review. Environ. Chem. Lett. 2021, 19, 2057–2090. [Google Scholar] [CrossRef]

- Tochaikul, G.; Tanadchangsaeng, N.; Panaksri, A.; Moonkum, N. Enhancing radiation shielding capabilities with epoxy-resin composites reinforced with coral-derived calcium carbonate fillers. Polymers 2025, 17, 113. [Google Scholar] [CrossRef]

- Gouda, M.M.; Osman, A.F.; Awad, R.; Badawi, M.S. Enhanced radiation shielding efficiency of polystyrene nanocomposites with tailored lead oxide nanoparticles. Sci. Rep. 2024, 14, 19970. [Google Scholar] [CrossRef] [PubMed]

- AbuAlRoos, N.J.; Amin, N.A.B.; Zainon, R. Conventional and new lead-free radiation shielding materials for radiation protection in nuclear medicine: A review. Radiat. Phys. Chem. 2019, 165, 108439. [Google Scholar] [CrossRef]

- Safari, A.; Rafie, P.; Taeb, S.; Najafi, M.; Mortazavi, S.M.J. Development of lead-free materials for radiation shielding in medical settings: A review. J. Biomed. Phys. Eng. 2024, 14, 229. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Zhang, W.; Yang, Y. Progress in flexible and wearable lead-free polymer composites for radiation protection. Polymers 2024, 16, 3274. [Google Scholar] [CrossRef] [PubMed]

- Baamer, M.A.; Alshahri, S.; Basfar, A.A.; Alsuhybani, M.; Alrwais, A. Novel polymer composites for lead-free shielding applications. Polymers 2024, 16, 1020. [Google Scholar] [CrossRef]

- Toto, E.; Lambertini, L.; Laurenzi, S.; Santonicola, M.G. Recent advances and challenges in polymer-based materials for space radiation shielding. Polymers 2024, 16, 382. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B.; Norman, P.; Qureshi, T. A comprehensive review of radiation shielding concrete: Properties, design, evaluation, and applications. Struct. Concr. 2025, 26, 1809–1855. [Google Scholar] [CrossRef]

- Crank, B.; Fricker, B.; Hubbard, A.; Hitawala, H.; Muna, F.I.; Okunlola, O.S.; Doherty, A.; Hulteen, A.; Powers, L.; Purtell, G.; et al. Electromagnetic radiation shielding using carbon nanotube and nanoparticle composites. Appl. Sci. 2025, 15, 8696. [Google Scholar] [CrossRef]

- Abou Hussein, E.M.; Madbouly, A.M. Fabrication and characterization of different PbO borate glass systems as radiation-shielding containers. Sci. Rep. 2024, 14, 2638. [Google Scholar] [CrossRef]

- El-Ghany, S.A.; Nabhan, E.; Saudi, H.A. Effect of gamma ray on some properties of bismuth borate glasses containing different transition metals. SN Appl. Sci. 2020, 2, 832. [Google Scholar] [CrossRef]

- Cureton, W.F.; Tracy, C.L.; Lang, M. Review of swift heavy ion irradiation effects in CeO2. Quantum Beam Sci. 2021, 5, 19. [Google Scholar] [CrossRef]

- Hughart, D.R.; Lohn, A.J.; Mickel, P.R.; Dalton, S.M.; Dodd, P.E.; Shaneyfelt, M.R.; Silva, A.I.; Bielejec, E.; Vizkelethy, G.; Marshall, M.T.; et al. A comparison of the radiation response of TaOx and TiO2 memristors. IEEE Trans. Nucl. Sci. 2013, 60, 4512–4519. [Google Scholar] [CrossRef]

- Alhindawy, I.G.; Mahmoud, K.A. Engineered zirconia nanomaterials for circular environmental and nuclear applications: Dual-function design for photocatalytic pollutant degradation and gamma-ray shielding. Adv. Compos. Hybrid Mater. 2025, 8, 317. [Google Scholar] [CrossRef]

- Sayyed, M.I.; Almuqrin, A.H.; Al-Balawi, S.M.; Hedaya, A.; Elsafi, M. Efficiency of flexible shielding materials against gamma rays: Silicon rubber with different sizes of Bi2O3 and SnO. E-Polymers 2025, 25, 20250031. [Google Scholar] [CrossRef]

- Beck, D.; Bickus, J.; Klein, E.; Miller, P.; Di Cecca, S.; Benz, R.; Barney, A.; Longton, R.; Coon, A.; Smith, M.; et al. Additive manufacturing of multimaterial composites for radiation shielding and thermal management. ACS Appl. Mater. Interfaces 2023, 15, 35400–35410. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Q.; Zhang, S. Ta2O5 nanocrystals strengthened mechanical, magnetic, and radiation shielding properties of heavy metal oxide glass. Molecules 2021, 26, 4494. [Google Scholar] [CrossRef]

- Aloraini, D.A.; Almuqrin, A.H.; Kaky, K.M.; Sayyed, M.I.; Elsafi, M. Radiation shielding capability and exposure buildup factor of cerium (IV) oxide-reinforced polyester resins. E-Polymers 2023, 23, 20230128. [Google Scholar] [CrossRef]

- Kuluozturk, Z.N.; Kurtulus, R.; Demir, N.; Kavas, T. Synthesis and characterization of La2O3–BaO–Na2O–SiO2–Bi2O3 glass as a potent shield against ionizing radiation. Arab. J. Sci. Eng. 2024, 49, 9923–9936. [Google Scholar] [CrossRef]

- Dorostkar, M.M.; Saray, A.A. Comparative analysis of Monte Carlo simulations and experimental evaluation of PMMA reinforced with hgo for gamma radiation shielding. Sci. Rep. 2025, 15, 28286. [Google Scholar] [CrossRef] [PubMed]

- Al-Saleh, W.M.; Almutairi, H.M.; Sayyed, M.I.; Elsafi, M. Multilayer radiation shielding system with advanced composites containing heavy metal oxide nanoparticles: A free-lead solution. Sci. Rep. 2023, 13, 18429. [Google Scholar] [CrossRef]

- Naito, M.; Kitamura, H.; Koike, M.; Kusano, H.; Kusumoto, T.; Uchihori, Y.; Endo, T.; Hagiwara, T.; Kiyono, N.; Kodama, H.; et al. Applicability of composite materials for space radiation shielding of spacecraft. Life Sci. Space Res. 2021, 31, 71–79. [Google Scholar] [CrossRef]

- Alsufyani, S.J.; Almurayshid, M.; Almalki, S.A.; Alresheedi, N.M.; Al-Naggar, T.I. Investigating radiation shielding parameters for X-ray attenuation at various energies in locally produced ceramic materials used in Saudi Arabia. Results Phys. 2024, 66, 108006. [Google Scholar] [CrossRef]

- Junior, T.A.A.; Nogueira, M.S.; Santos, M.A.P.; Campos, L.L.; Araújo, F.G.S. Mass attenuation coefficients of X-rays in different barite concrete used in radiation protection as shielding against ionizing radiation. Radiat. Phys. Chem. 2017, 140, 349–354. [Google Scholar] [CrossRef]

- Daneshvar, H.; Milan, K.G.; Sadr, A.; Sedighy, S.H.; Malekie, S.; Mosayebi, A. Multilayer radiation shield for satellite electronic components protection. Sci. Rep. 2021, 11, 20657. [Google Scholar] [CrossRef] [PubMed]

- Yılmaz, D.; Kurucu, Y.; Gürol, A. Effective atomic numbers and number, energy and dose albedos of different colored thermoplastic materials. Radiat. Eff. Defect. S. 2023, 178, 325–334. [Google Scholar] [CrossRef]

- AlMisned, G.; Baykal, D.S.; Alkarrani, H.; Susoy, G.; Tekin, H.O. Advancing mechanical durability and radiation shielding properties in silicon dioxide (SiO2) glasses through various incorporations: A comparative analysis. Results Phys. 2024, 61, 107717. [Google Scholar] [CrossRef]

- Un, A.; Caner, T. The Direct-Zeff software for direct calculation of mass attenuation coefficient, effective atomic number and effective electron number. Ann. Nucl. Energy 2014, 65, 158–165. [Google Scholar] [CrossRef]

- Gunaseelan, N.; Saha, P.; Maher, N.; Pan, D. Nanoparticles with “k-edge” metals bring “color” in multiscale spectral photon counting x-ray imaging. ACS Nano 2014, 18, 34464–34491. [Google Scholar] [CrossRef]

- Karabul, Y. Ionizing radiation shielding properties of tantalum pentoxide doped high-density polyethylene composites: A theoretical study. J. Eng. Technol. Appl. Sci. 2023, 8, 143–154. [Google Scholar] [CrossRef]

- Jagdale, P.; Serino, G.; Oza, G.; Audenino, A.L.; Bignardi, C.; Tagliaferro, A.; Alvarez-Gayosso, C. Physical characterization of bismuth oxide nanoparticle based ceramic composite for future biomedical application. Materials 2021, 14, 1626. [Google Scholar] [CrossRef] [PubMed]

- Zeng, C.; Kang, Q.; Duan, Z.; Qin, B.; Feng, X.; Lu, H.; Lin, Y. Development of polymer composites in radiation shielding applications: A review. J. Inorg. Organomet. Polym. Mater. 2023, 33, 2191–2239. [Google Scholar] [CrossRef]

- Akhdar, H.; Alotaibi, R. Geant4 simulation of the effect of different composites on polyimide photon and neutron shielding properties. Polymers 2023, 15, 1973. [Google Scholar] [CrossRef]

- Cruz, B.D.S.M.D.; Tienne, L.G.P.; Santos, E.D.S.; Jorge, F.E.; Marques, M.D.F.V.; Chaves, E.G. Polyethylene of raised temperature resistance (PE-RT) nanocomposites reinforced with graphene oxide for application in flexible pipelines. Mater. Res. 2024, 27, e20240124. [Google Scholar] [CrossRef]

- Fang, L.; Sun, W.; Hou, W.; Mao, Y.; Wang, Z.; Sun, K. Quasi-solid-state polymer electrolyte based on highly concentrated LiTFSI complexing DMF for ambient-temperature rechargeable lithium batteries. Ind. Eng. Chem. Res. 2022, 61, 7971–7981. [Google Scholar] [CrossRef]

- Hemamalini, T.; Giri Dev, V.R. Wet laying nonwoven using natural cellulosic fibers and their blends: Process and technical applications. a review. J. Nat. Fibers 2021, 18, 1823–1833. [Google Scholar] [CrossRef]

- Hak, C.R.C.; Foo, C.T.; Othman, N.A.F.; Shukri, N.A.; Ripin, M.S.; Sulaiman, M.Y.M.; Abdullah, Y. Field Emission Scanning Electron Microscope (FESEM) Facility in BTI. In Proceedings of the Nuclear Technical Convention 2015 (NTC 2015), Bangi, Malaysia, 3–5 November 2015. [Google Scholar]

- Browne, T.; Crotogino, R. Future directions in calendering research. Bioresources 2018, 1001, 36. [Google Scholar] [CrossRef]

- Nazarov, V.; Doronin, F.; Dedov, A.; Evdokimov, A.; Rytikov, G.; Savel’ev, M. Design of a hybrid 3D-printed composite material based on non-woven needle-punched fabrics with radio-absorbing properties. Polymers 2025, 17, 2324. [Google Scholar] [CrossRef] [PubMed]

- Duan, X.; Zhao, J.; Song, S.; Zhou, N.; Fan, J.; Tian, B.; Du, Y. Layered structural engineering of Bi2O3/PP and WO3/PP composites for γ-ray shielding in high energy range: Anisotropic attenuation mechanisms via Monte Carlo simulation and experiments. J. Mater. Res. Technol. 2025, 56, 3608–3615. [Google Scholar] [CrossRef]

- Abdullah, W.; Ramli, R.M.; Khazaalah, T.H.; Azman, N.Z.N.; Nawafleh, T.M.; Salem, F. Enhancing X-ray radiation protection with novel liquid silicone rubber composites: A promising alternative to lead aprons. Nucl. Eng. Technol. 2024, 56, 3608–3615. [Google Scholar] [CrossRef]

- Li, H.; Shen, Y.; Wu, X.; Wang, D.; Yang, Y. Advances in laser powder bed fusion of tungsten, tungsten alloys, and tungsten-based composites. Micromachines 2024, 15, 966. [Google Scholar] [CrossRef]

- Katubi, K.M.; A.Alzahrani, F.M.; Eke, C.; Alrowaili, Z.A.; Çalişkan, F.; Olarinoye, I.O.; Al-Buriahi, M.S. Environmentally friendly and cost-effective gamma shielding based on waste CRT screen glasses. J. Electron. Mater. 2024, 53, 2609–2619. [Google Scholar] [CrossRef]

- Paek, S.W.; Balasubramanian, S.; Stupples, D. Composites additive manufacturing for space applications: A review. Materials 2022, 15, 4709. [Google Scholar] [CrossRef]

- Kim, S.C.; Yun, J.H.; Byun, H.S.; Hou, J. Verification of optimal X-ray shielding properties based on material composition and coating design of shielding materials. Coatings 2024, 14, 1450. [Google Scholar] [CrossRef]

- Giuliani, C.; De Stefano, I.; Mancuso, M.; Fiaschini, N.; Hein, L.A.; Mirabile Gattia, D.; Scatena, E.; Zenobi, E.; Gaudio, C.D.; Galante, F.; et al. Advanced electrospun composites based on polycaprolactone fibers loaded with micronized tungsten powders for radiation shielding. Polymers 2024, 16, 2590. [Google Scholar] [CrossRef]

- Li, J.; Cheng, J.; Zhang, Y.; Chen, Z.; Nasr, M.; Farghali, M.; Rooney, D.W.; Yap, P.S.; Osman, A.I. Advancements in solid oxide fuel cell technology: Bridging performance gaps for enhanced environmental sustainability. Adv. Energ. Sust. Res. 2024, 5, 2400132. [Google Scholar] [CrossRef]

- Bijanu, A.; Arya, R.; Agrawal, V.; Tomar, A.S.; Gowri, V.S.; Sanghi, S.K.; Mishra, D.; Salammal, S.T. Metal-polymer composites for radiation protection: A review. J. Polym. Res. 2021, 28, 392. [Google Scholar] [CrossRef]

- Simões, S. High-performance advanced composites in multifunctional material design: State of the art, challenges, and future directions. Materials 2024, 17, 5997. [Google Scholar] [CrossRef] [PubMed]

- Luches, P.; Boscherini, F. Insights into the electronic and atomic structures of cerium oxide-based ultrathin films and nanostructures using high-brilliance light sources. Beilstein J. Nanotechnol. 2025, 16, 860–871. [Google Scholar] [CrossRef]

- Okafor, C.E.; Okonkwo, U.C.; Okokpujie, I.P. Trends in reinforced composite design for ionizing radiation shielding applications: A review. J. Mater. Sci. 2021, 56, 11631–11655. [Google Scholar] [CrossRef]

- Shahzad, K.; Kausar, A.; Manzoor, S.; Rakha, S.A.; Uzair, A.; Sajid, M.; Arif, A.; Khan, A.F.; Diallo, A.; Ahmad, I. Views on radiation shielding efficiency of polymeric composites/nanocomposites and multi-layered materials: Current state and advancements. Radiation 2022, 3, 1–20. [Google Scholar] [CrossRef]

- Abualroos, N.J.; Idris, M.I.; Ibrahim, H.; Kamaruzaman, M.I.; Zainon, R. Physical, mechanical, and microstructural characterisation of tungsten carbide-based polymeric composites for radiation shielding application. Sci. Rep. 2024, 14, 1375. [Google Scholar] [CrossRef]

- Bonifácio, D.A.B.; Murata, H.M.; Moralles, M. Monte Carlo Simulation of X-ray Spectra in Diagnostic Radiology and Mammography Using Geant4. In Proceedings of the 2005 International Nuclear Atlantic Conference—INAC 2005, Santos, SP, Brazil, 28 August–2 September 2005. [Google Scholar]

- Naikwadi, A.T.; Sharma, B.K.; Bhatt, K.D.; Mahanwar, P.A. Gamma radiation processed polymeric materials for high performance applications: A review. Front. Chem. 2022, 10, 837111. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, W.; Zhang, X.; Gao, Y.; Guo, S. High-efficiency, flexibility and lead-free X-ray shielding multilayered polymer composites: Layered structure design and shielding mechanism. Sci. Rep. 2021, 11, 4384. [Google Scholar] [CrossRef] [PubMed]

- Chang, Q.; Guo, S.; Zhang, X. Radiation shielding polymer composites: Ray-interaction mechanism, structural design, manufacture and biomedical applications. Mater. Des. 2023, 233, 112253. [Google Scholar] [CrossRef]

| Radiation Type | X-Ray Energy (kVp) Tube Voltage | Composites_RPE * (%) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ta2O5_AI2O3 | CeO2_SiO2 | Bi2O3_SiO2 | |||||||||||

| Thickness (mm) | |||||||||||||

| 0.5 | 1.0 | 1.5 | 2.0 | 0.5 | 1.0 | 1.5 | 2.0 | 0.5 | 1.0 | 1.5 | 2.0 | ||

| X-ray | 40 | 80 | 84 | 88 | 92 | 74 | 77 | 82 | 87 | 71 | 76 | 79 | 82 |

| 60 | 76 | 80 | 84 | 90 | 71 | 75 | 80 | 86 | 67 | 72 | 75 | 80 | |

| 80 | 72 | 75 | 78 | 86 | 68 | 72 | 77 | 80 | 65 | 68 | 70 | 74 | |

| 100 | 68 | 71 | 74 | 82 | 67 | 69 | 73 | 76 | 62 | 64 | 68 | 71 | |

| 120 | 65 | 68 | 70 | 80 | 63 | 65 | 68 | 74 | 59 | 60 | 67 | 70 | |

| Thickness (mm) | Ta2O5_AI2O3 | CeO2_SiO2 | Bi2O3_SiO2 | |||

|---|---|---|---|---|---|---|

| Charge (nC) | RPE * (%) | Charge (nC) | RPE * (%) | Charge (nC) | RPE * (%) | |

| 0.5 | 1.332 | 47.7 | 1.205 | 52.7 | 1.302 | 48.9 |

| 1.0 | 0.779 | 69.4 | 0.671 | 73.7 | 0.789 | 69.0 |

| 1.5 | 0.481 | 81.1 | 0.409 | 84.0 | 0.511 | 79.9 |

| 2.0 | 0.309 | 87.9 | 0.265 | 89.6 | 0.346 | 86.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.-C.; Chon, K.S. Comparative Theoretical and Experimental Validation of the Shielding Effectiveness of Ceramic Composite-Based Medical Radiation Protection Tools. Ceramics 2025, 8, 143. https://doi.org/10.3390/ceramics8040143

Kim S-C, Chon KS. Comparative Theoretical and Experimental Validation of the Shielding Effectiveness of Ceramic Composite-Based Medical Radiation Protection Tools. Ceramics. 2025; 8(4):143. https://doi.org/10.3390/ceramics8040143

Chicago/Turabian StyleKim, Seon-Chil, and Kwon Su Chon. 2025. "Comparative Theoretical and Experimental Validation of the Shielding Effectiveness of Ceramic Composite-Based Medical Radiation Protection Tools" Ceramics 8, no. 4: 143. https://doi.org/10.3390/ceramics8040143

APA StyleKim, S.-C., & Chon, K. S. (2025). Comparative Theoretical and Experimental Validation of the Shielding Effectiveness of Ceramic Composite-Based Medical Radiation Protection Tools. Ceramics, 8(4), 143. https://doi.org/10.3390/ceramics8040143