Enhancing the Performance of PZT-5H Piezoelectric Ceramics by Vacuum Sintering

Abstract

1. Introduction

2. Materials and Methods

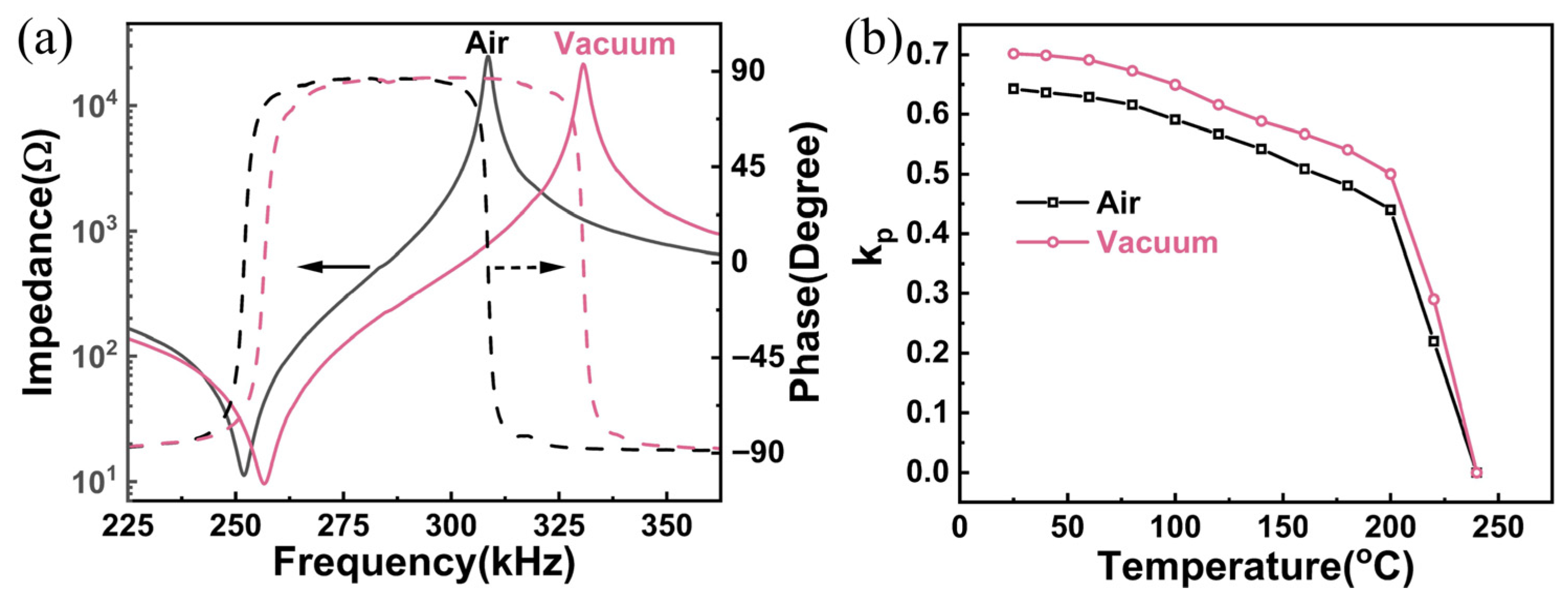

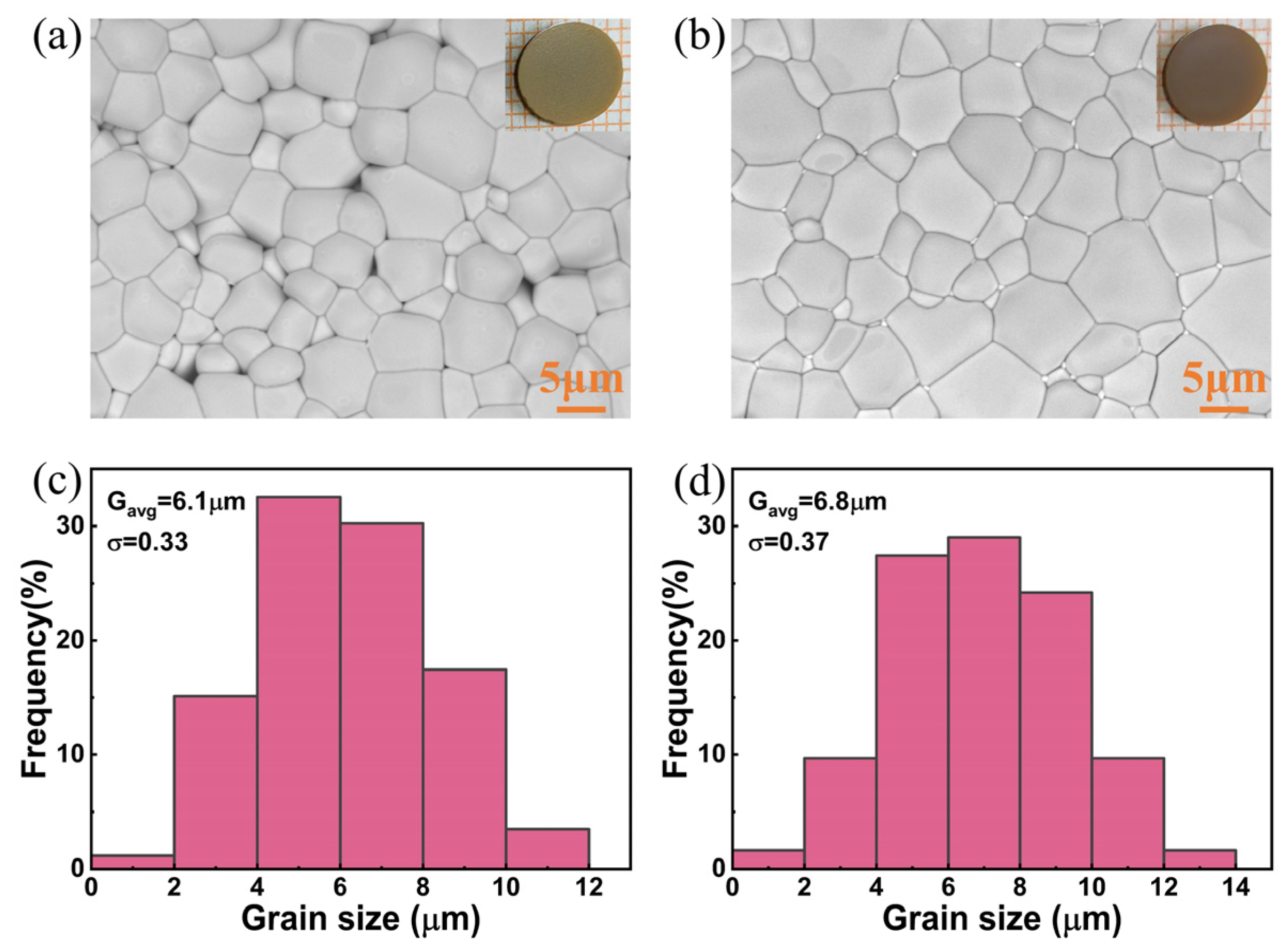

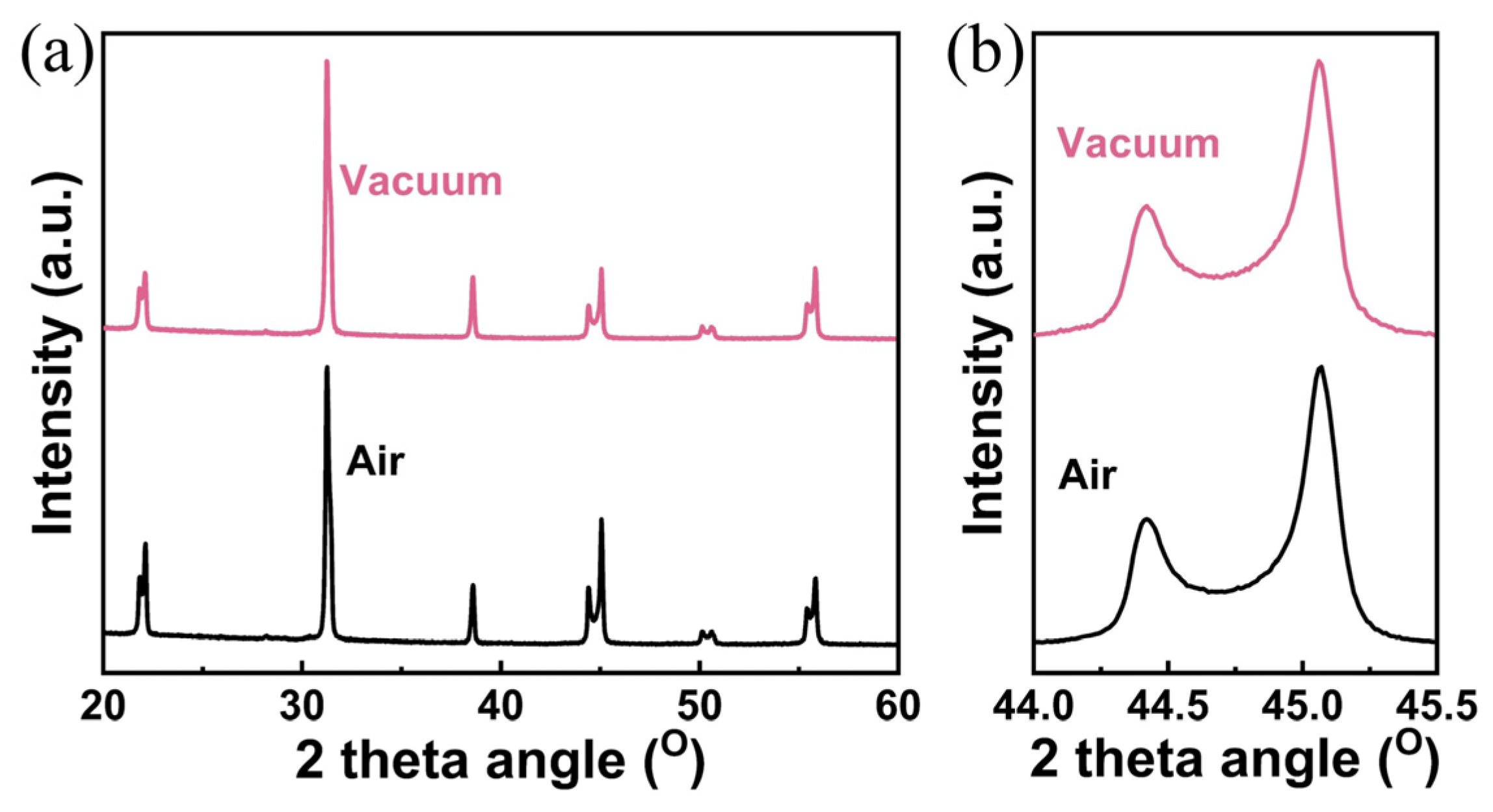

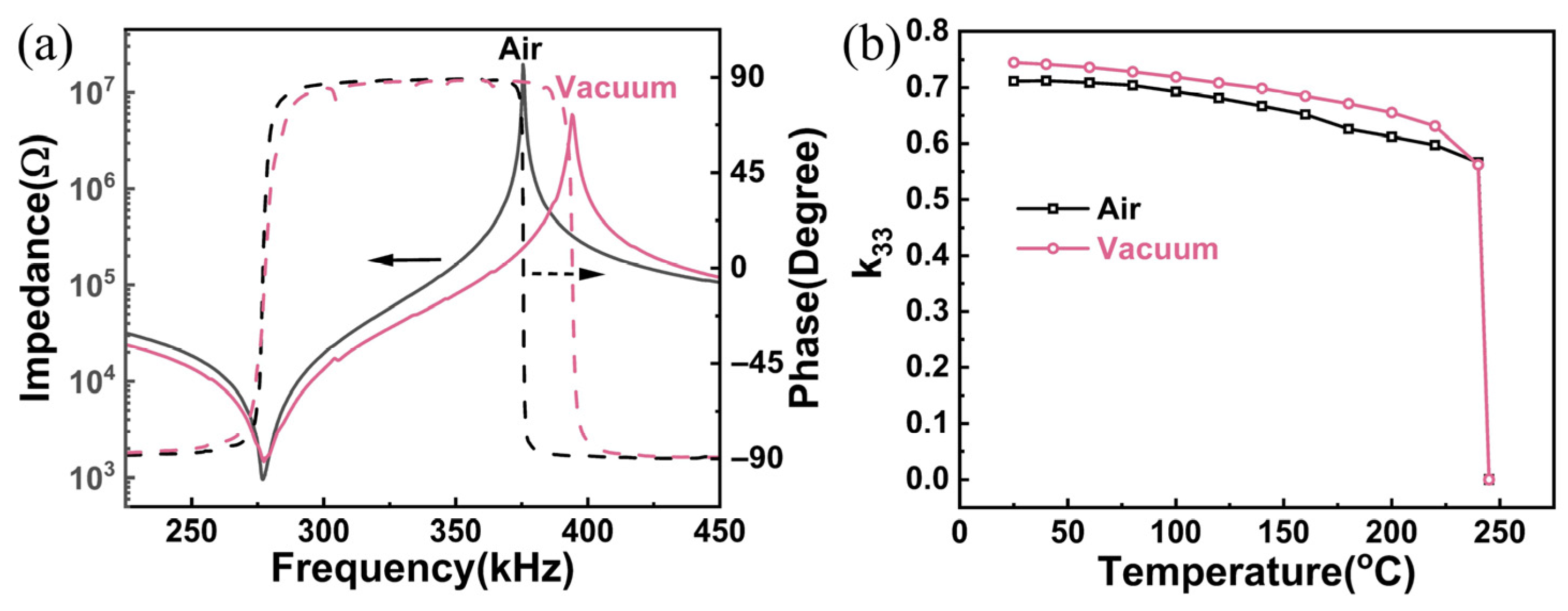

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.; Yang, N.; Chen, Y.; Li, X.; Wang, L.; Wang, P.; Dong, G. Ferroelectric and Piezoelectric Properties of (Mg1/3Nb2/3)4+-Doped Bismuth Sodium Titanate Ceramics. Ceramics 2025, 8, 88. [Google Scholar] [CrossRef]

- Clementi, G.; Costanza, M.; Ouhabaz, M.; Bartasyte, A.; Dulmet, B.; Margueron, S. 2D+1 degree of freedom equivalent circuit model for LiNbO3/metal/LiNbO3 bimorph bending cantilever. Sens. Actuators A Phys. 2023, 362, 114606. [Google Scholar] [CrossRef]

- Jaffe, H. Piezoelectric Ceramics. J. Am. Ceram. Soc. 1958, 41, 494–498. [Google Scholar] [CrossRef]

- Guo, Y.; Guo, S.; Yao, C.; Pan, Z.; Wang, G. A Large Voltage Responsivity Pyroelectric Sensor Based on Hot-Pressed Lead Zirconate Titanate Ceramic. Sensors 2025, 25, 917. [Google Scholar] [CrossRef]

- Sotnikova, G.Y.; Ankudinov, A.V.; Voronin, A.V.; Gavrilov, G.A.; Glazov, A.L.; Goryainov, V.Y.; Zaitseva, N.V.; Nashchekin, A.V.; Passet, R.S.; Vorob’ev, A.A.; et al. Effect of High Heat Flux of Helium and Hydrogen Plasma Jet on the Material Properties of Piezoelectric PZT-Ceramics. Ceramics 2024, 7, 1695–1710. [Google Scholar] [CrossRef]

- Xu, A.; Yuan, J.; Gao, J. Leveling Method of Working Platform Based on PZT Electromechanical Coupling Effect. Micromachines 2025, 16, 796. [Google Scholar] [CrossRef]

- Selicani, G.V.; Mobin, M.; Esposito, V.; Insinga, A.R.; Haugen, A.B. Shape engineering and manufacturing of piezoceramics for energy conversion—A review. J. Phys. Energy 2025, 7, 022004. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, X.S.; Li, Y.X.; Yao, X. Effect of Polarization on Mechanical Properties of Lead Zirconate Titanate Ceramics. J. Inorg. Mater. 2015, 30, 219–224. [Google Scholar] [CrossRef]

- Bochenek, D.; Brzezińska, D.; Niemiec, P.; Zubko, M.; Osińska, K. Technology and Electrophysical Properties of PZT-Type Ceramics Doped by Samarium. Materials 2025, 18, 1773. [Google Scholar] [CrossRef]

- Ma, J.P.; Zhu, K.; Huo, D.; Qi, X.D.; Sun, E.W.; Zhang, R. Performance enhancement of the piezoelectric ceramics by alternating current polarizing. Appl. Phys. Lett. 2021, 118, 022901. [Google Scholar] [CrossRef]

- Ma, Z.; Yuan, Z.; Yao, Z.; Chen, J.; Hao, H.; Cao, M.; Liu, H. Ultralow Temperature Sintering of High-Performance Sm-Doped Pb(Zr,Ti)O3-Based Piezoelectric Ceramics. Materials 2025, 18, 512. [Google Scholar]

- Kong, S.Y.; Hong, C.H.; Zhang, W.J.; Liu, Y.; Wang, Z.J.; Yang, X.M.; Su, R.B.; Long, X.F.; He, C. Performance enhancement of soft-PZT5 piezoelectric ceramics using poling technique. J. Am. Ceram. Soc. 2022, 105, 4744–4750. [Google Scholar] [CrossRef]

- Mao, W.Z.; Xu, Q.; Huang, D.P.; Sun, H.J.; Zhang, F.; Xie, X.B. Low-Temperature Sintering Properties of Bi2O3 Doped PZT-5H Piezoelectric Ceramics. J. Electron. Mater. 2023, 52, 3334–3342. [Google Scholar] [CrossRef]

- Katta, M.; Sandanalakshmi, R. Simultaneous tropical disease identification with PZT-5H piezoelectric material including molecular mass biosensor microcantilever collection. Sens. Bio-Sens. Res. 2021, 32, 100413. [Google Scholar] [CrossRef]

- Xu, W.D.; Ao, H.R.; Zhou, N.N.; Song, Z.H.; Jiang, H.Y. Analysis of Output Performance of a Novel Symmetrical T-Shaped Trapezoidal Micro Piezoelectric Energy Harvester Using a PZT-5H. Micromachines 2022, 13, 282. [Google Scholar] [CrossRef]

- Jaiswal, R.; Saeed, A.M.; Gupta, V.; Seema; Singhal, A. An evaluation of SH and anti-plane SH wave signals for nanosensor applications using two distinct models of piezoelectric materials lead zirconate titanate (PZT-2) and PZT-5H. Acta Mech. 2025, 236, 1135–1150. [Google Scholar] [CrossRef]

- Xue, W.C.; Wang, X.B.; Zhu, Y.L.; Luo, C.T. Studies on the High-Power Piezoelectric Property Measurement Methods and Decoupling the Power and Temperature Effects on PZT-5H. Sensors 2025, 25, 349. [Google Scholar] [CrossRef]

- Liu, S.; Yan, M.; Hu, Z.; Yuan, X.; Zhang, Y.; Zhang, D. Tailoring the Microstructure and Porosity of Porous Piezoelectric Ceramics for Ultrasonic Transducer Application. ACS Appl. Mater. Interfaces 2024, 16, 55731–55740. [Google Scholar] [CrossRef]

- Randall, C.A.; Nishiyama, H.; Shimizu, H. Impact of volatility, non-stoichiometry, and atmospheres in perovskite piezoelectric and dielectric materials. J. Am. Ceram. Soc. 2024, 107, 7921–7938. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Xu, X.F.; Wang, S.Y.; Wang, L.; Du, G.; Zeng, J.T. Electrical properties of Pb(Ni1/3Nb2/3)O3-Pb(Zr,Ti)O3 ceramics sintered in different atmospheres. Appl. Phys. A—Mater. Sci. Process. 2023, 129, 657. [Google Scholar] [CrossRef]

- Liu, C.; Mao, R.Y.; Wu, Q.Y.; Li, J.L.; Zheng, D.Y.; Fei, Z.H.; Pang, C. Modification of BCZT piezoelectric ceramics by modulating oxygen vacancies in different sintering atmospheres. AIP Adv. 2023, 13, 065217. [Google Scholar] [CrossRef]

- Feng, X.Y.; Liu, J.T.; Teng, D.; Yang, Y.H.; Liao, L.Q.; Liu, Y.W.; Chen, Q.; Xu, J.; Gao, F. Effect of sintering atmosphere on the microstructure and electrical properties of Pb(Zr1/2Ti1/2)O3-Pb(Zn1/3Nb2/3)O3-Pb(Ni1/3Nb2/3)O3 ceramics. J. Mater. Sci.-Mater. Electron. 2022, 33, 11613–11622. [Google Scholar] [CrossRef]

- Cen, Z.Y.; Dong, Z.H.; Xu, Z.; Yao, F.Z.; Guo, L.M.; Li, L.T.; Wang, X.H. Improving fatigue properties, temperature stability and piezoelectric properties of KNN-based ceramics via sintering in reducing atmosphere. J. Eur. Ceram. Soc. 2021, 41, 4462–4472. [Google Scholar] [CrossRef]

- Gerson, R.; Jaffe, H. Electrical Conductivity in Lead Titanate Zirconate Ceramics. J. Phys. Chem. Solids 1963, 24, 979–984. [Google Scholar] [CrossRef]

- Atkin, R.B.; Fulrath, R.M. Point Defects and Sintering of Lead Zirconate-Titanate. J. Am. Ceram. Soc. 1971, 54, 265–270. [Google Scholar] [CrossRef]

- Wang, Z.X.; Huan, Y.; Feng, Y.; Qiu, Y.; Wei, T.; Zuo, R.Z. Design of p-type NKN-based piezoelectric ceramics sintered in low oxygen partial pressure by defect engineering. J. Am. Ceram. Soc. 2020, 103, 3667–3675. [Google Scholar] [CrossRef]

- Tsai, C.-C.; Liao, W.-H.; Chu, S.-Y.; Hong, C.-S.; Yu, M.-C.; Lin, Y.-Y.; Wei, Z.-Y. Investigation of the piezoelectric and anti-reduction properties of (Ba, Ca) (Ti, Sn, Hf) textured ceramics prepared under low oxygen partial pressure conditions at low sintering temperatures. J. Eur. Ceram. Soc. 2021, 41, 2472–2481. [Google Scholar] [CrossRef]

- Wang, X.; Huan, Y.; Zhu, Y.; Zhang, P.; Yang, W.; Li, P.; Wei, T.; Li, L.; Wang, X. Defect engineering of BCZT-based piezoelectric ceramics with high piezoelectric properties. J. Adv. Ceram. 2021, 11, 184–195. [Google Scholar] [CrossRef]

- Liu, W.; Lv, L.; Li, Y.; Wang, Y.; Wang, J.; Xue, C.; Dong, Y.; Yang, J. Effects of slurry composition on the properties of 3-1 type porous PZT ceramics prepared by ionotropic gelation. Ceram. Int. 2017, 43, 6542–6547. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef]

- Fu, J.; Qi, H.; Xie, A.W.; Tian, A.; Zuo, R.Z. Understanding the correlation between intermediate monoclinic phase (Cc) and piezoelectric properties in NaNbO3-BaTiO3-CaZrO3 ternary system with octahedral tilt. Acta Mater. 2021, 215, 117100. [Google Scholar] [CrossRef]

- Pottharst, J.; Schichl, H. Improved Preparation Technique for Ferroelectric Ceramics. Ferroelectrics 1976, 10, 191–194. [Google Scholar] [CrossRef]

- Karajagikar, P.; Butee, S.P.; Kambale, K.R.; Kumar, B.P. Evaluation of the effect of excess PbO on piezoelectric properties of high Zr-PZT ceramics. Mater. Today Proc. 2022, 67, 438–443. [Google Scholar] [CrossRef]

- Uchino, K.; Nomura, S. Critical exponents of the dielectric constants in diffused-phase-transition crystals. Ferroelectrics 2011, 44, 55–61. [Google Scholar]

- Han, F.; Hu, Y.; Peng, B.; Liu, L.; Yang, R.; Ren, K. High dielectric tunability with high thermal stability of the (111) highly oriented 0.85Pb(Mg1/3Nb2/3)-0.15PbTiO3 thin film prepared by a sol-gel method. J. Eur. Ceram. Soc. 2021, 41, 6482–6489. [Google Scholar] [CrossRef]

- Yang, X.; Fang, B.; Zhang, S.; Lu, X.; Ding, J. Reducing Sintering Temperature While Optimizing Electrical Properties of BCZT-Based Lead-Free Ceramics by Adding MnO2 as Sintering Aid. Materials 2025, 18, 1888. [Google Scholar] [CrossRef]

- Chen, Z.; Liang, R.; Zhang, C.; Zhou, Z.; Li, Y.; Liu, Z.; Dong, X. High-performance and high-thermally stable PSN-PZT piezoelectric ceramics achieved by high-temperature poling. J. Mater. Sci. Technol. 2022, 116, 238–245. [Google Scholar] [CrossRef]

- Devonshire, A.F. Theory of Barium Titanate 2. Philos. Mag. 1951, 42, 1065–1079. [Google Scholar] [CrossRef]

- Song, A.; Liu, Y.; Feng, T.; Li, H.; Zhang, Y.; Wang, X.; Liu, L.; Zhang, B.P.; Li, J.F. Simultaneous enhancement of piezoelectricity and temperature stability in KNN-based lead-free ceramics via layered distribution of dopants. Adv. Funct. Mater. 2022, 32, 2204385. [Google Scholar] [CrossRef]

- Li, T.; Zhuo, H.; Hu, S.; Shao, B.; Zhang, J.; Wu, Y.; Xu, L.; Chen, F. Interfacial stress-insensitive tetragonal (Ba, Ca)TiO3-doped BiFeO3 films with superior ferroelectricity and piezoelectricity. Appl. Phys. Lett. 2025, 127, 051901. [Google Scholar] [CrossRef]

- Zhang, S.J.; Alberta, E.F.; Eitel, R.E.; Randall, C.A.; Shrout, T.R. Elastic, piezoelectric, and dielectric characterization of modified BiScO3-PbTiO3 ceramics. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2005, 52, 2131–2139. [Google Scholar] [CrossRef]

- Wang, H.; Ma, M.; Xia, S.; Zhang, N.; Li, Z. Ultrahigh-performance [001]-oriented porous PZT-5H single crystal grown by the solid state crystal growth method. J. Eur. Ceram. Soc. 2023, 43, 5503–5510. [Google Scholar] [CrossRef]

- Zhang, F.; Zhu, Y.; Fan, S.; Yu, H.; Yang, Y.; Zheng, L.; Zhang, Y.; Liu, B.; Wang, X.; Wang, J. Achieving High Piezoelectric Performance Across Multidomains Design in K(Ta,Nb)O3-Based Lead-free Single Crystals. ACS Appl. Mater. Interfaces 2024, 16, 65004–65011. [Google Scholar] [CrossRef]

- Tang, M.; Liu, X.; Wang, Y.; Ren, X.; Yang, Z.; Xu, Z.; Geng, L.D.; Yan, Y. Dielectric, elastic, and piezoelectric matrices of [001]-textured Mn-PMN-PZT ceramics. J. Appl. Phys. 2024, 135, 184103. [Google Scholar] [CrossRef]

- Li, K.; Cong, S.; Bian, L.; Zhao, Z.; Wu, J.; Zhao, J.; Zhang, D.; Mei, H.; Sun, E.; Qi, X.; et al. Simultaneous enhancement of piezoelectricity and temperature stability in Pb (Ni1/3Nb2/3)O3-PbZrO3-PbTiO3 piezoelectric ceramics via Sm-modification. J. Adv. Ceram. 2024, 13, 1578–1589. [Google Scholar] [CrossRef]

- Li, F.; Lin, D.B.; Chen, Z.B.; Cheng, Z.X.; Wang, J.L.; Li, C.C.; Xu, Z.; Huang, Q.W.; Liao, X.Z.; Chen, L.Q.; et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 2018, 17, 349–354. [Google Scholar] [CrossRef]

- Damjanovic, D. Stress and frequency dependence of the direct piezoelectric effect in ferroelectric ceramics. J. Appl. Phys. 1997, 82, 1788–1797. [Google Scholar] [CrossRef]

- Cole, K.S.; Cole, R.H. Dispersion and absorption in dielectrics I. Alternating current characteristics. J. Chem. Phys. 1941, 9, 341–351. [Google Scholar] [CrossRef]

- Li, Q.; Dong, G.; Zhao, Y.; Liu, R.; Zhang, J.; Lin, X.; Huang, S. High piezoelectric properties and excellent thermal stability in PNN-modified lead zirconate titanate piezoceramics. J. Am. Ceram. Soc. 2025, 108, e20643. [Google Scholar] [CrossRef]

- Prakash, H.; Kumar, N.; Kumar, A.; Singh, R.P.; Mahale, B.; Anil, A.; Saha, S. On the origin of high piezoelectric response in PbNi1/3Nb2/3O3-PbZrO3-PbTiO3 ternary system. J. Mater. Sci. Mater. Electron. 2025, 36, 1–15. [Google Scholar] [CrossRef]

- Dabour, M.M.; Mousa, M.A.; Qasim, K.F. Compounds, Preparation, structural, electrical, and ferroelectric properties of solid and lead zirconium titanate ink. J. Alloys Compd. 2024, 1006, 176390. [Google Scholar] [CrossRef]

- Kapadi, N.J.; Jadhav, T.K.; Kambale, R.C. Impact of rare earth Er3+, Y3+, Gd3+ substituents on electrical properties of BaTiO3-CaTiO3-BaZrO3 lead-free electroceramics with an emphasis on complex impedance spectroscopy. J. Mater. Sci. Mater. Electron. 2025, 36, 1295. [Google Scholar] [CrossRef]

- Khan, A.H.; Prabu, M.; Steephan, M.; Saravanan, M.; Sreeja, T.K. Enhancing dielectric and ferroelectric properties of PZT (52/48) electroceramics by niobium doping. J. Mater. Sci. Mater. Electron. 2025, 36, 592. [Google Scholar] [CrossRef]

- Jalaja, M.; Dutta, S. Complex Impedance Spectroscopy studies to unravel electrical properties and processes in Al+3-modified PLZT. J. Mater. Sci. Mater. Electron. 2022, 33, 26943–26953. [Google Scholar] [CrossRef]

- Rosa, T.H.T.; Oliveira, M.A.; Mendez-González, Y.; Guerrero, F.; Guo, R.; Bhalla, A.S.; Guerra, J.D.S. Polaron-assisted dielectric relaxation processes in donor-doped BaTiO3-based ceramics. J. Alloys Compd. 2024, 1008, 176510. [Google Scholar] [CrossRef]

- Nanda, A.; Fox, J.J.; Fanton, M.; Yan, Y.; Priya, S.; Poudel, B.; Lanagan, M.T. Enhanced Electrical and Thermal Stability in (K, Na)NbO3 Ceramics via Compositional Engineering. ACS Appl. Eng. Mater. 2025, 3, 2933–2942. [Google Scholar] [CrossRef]

- Cai, W.; Zhang, Q.; Zhou, C.; Gao, R.; Wang, F.; Chen, G.; Deng, X.; Wang, Z.; Deng, N.; Cheng, L.; et al. Effects of oxygen partial pressure on the electrical properties and phase transitions in (Ba,Ca)(Ti,Zr)O3 ceramics. J. Mater. Sci. 2020, 55, 9972–9992. [Google Scholar] [CrossRef]

- Donnelly, N.J.; Randall, C.A. Pb loss in Pb(Zr,Ti)O3 ceramics observed by in situ ionic conductivity measurements. J. Appl. Phys. 2011, 109, 104107. [Google Scholar] [CrossRef]

- Slouka, C.; Holzlechner, G.; Andrejs, L.; Navickas, E.; Hutter, H.; Fleig, J. Oxygen Ion Conduction in Bulk and Grain Boundaries of Nominally Donor-Doped Lead Zirconate Titanate (PZT): A Combined Impedance and Tracer Diffusion Study. J. Am. Ceram. Soc. 2015, 98, 3259–3269. [Google Scholar] [CrossRef]

- Chen, Y.; Li, L.; Zhou, Z.; Wang, Y.; Chen, Q.; Wang, Q. La2O3-modified BiYbO3-Pb(Zr,Ti)O3 ternary piezoelectric ceramics with enhanced electrical properties and thermal depolarization temperature. J. Adv. Ceram. 2023, 12, 1593–1611. [Google Scholar] [CrossRef]

- Cao, W.-T.; Xu, Z.; Zhu, Z.; Geng, Z.; Lu, J.-T.; Zhong, Z.; Huang, H.-F.; Liu, J.-X.; Jiang, Y.; Liu, Y.-X.; et al. High-power performance enhancement in PZT-based piezoceramics via hot-pressing. Nat. Commun. 2025, 16, 9778. [Google Scholar] [CrossRef] [PubMed]

| Sintering Method | εr | d33 (pC/N) by Resonance | d33 (pC/N) by d33 Meter | d33* (pm/V) | kp | k33 |

|---|---|---|---|---|---|---|

| Traditional sintering | 3117 | 511 | 708 | 1171 | 0.64 | 0.71 |

| Vacuum sintering | 4228 | 613 | 791 | 1383 | 0.70 | 0.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhang, P. Enhancing the Performance of PZT-5H Piezoelectric Ceramics by Vacuum Sintering. Ceramics 2025, 8, 139. https://doi.org/10.3390/ceramics8040139

Wang H, Zhang P. Enhancing the Performance of PZT-5H Piezoelectric Ceramics by Vacuum Sintering. Ceramics. 2025; 8(4):139. https://doi.org/10.3390/ceramics8040139

Chicago/Turabian StyleWang, Honghui, and Pengcheng Zhang. 2025. "Enhancing the Performance of PZT-5H Piezoelectric Ceramics by Vacuum Sintering" Ceramics 8, no. 4: 139. https://doi.org/10.3390/ceramics8040139

APA StyleWang, H., & Zhang, P. (2025). Enhancing the Performance of PZT-5H Piezoelectric Ceramics by Vacuum Sintering. Ceramics, 8(4), 139. https://doi.org/10.3390/ceramics8040139