An Investigation of the Microstructure and Wear Resistance of Laser Clad 316 Stainless Steel/TiC Coatings Containing Different LaB6 Contents

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Characterizations of the Samples

3. Results and Discussion

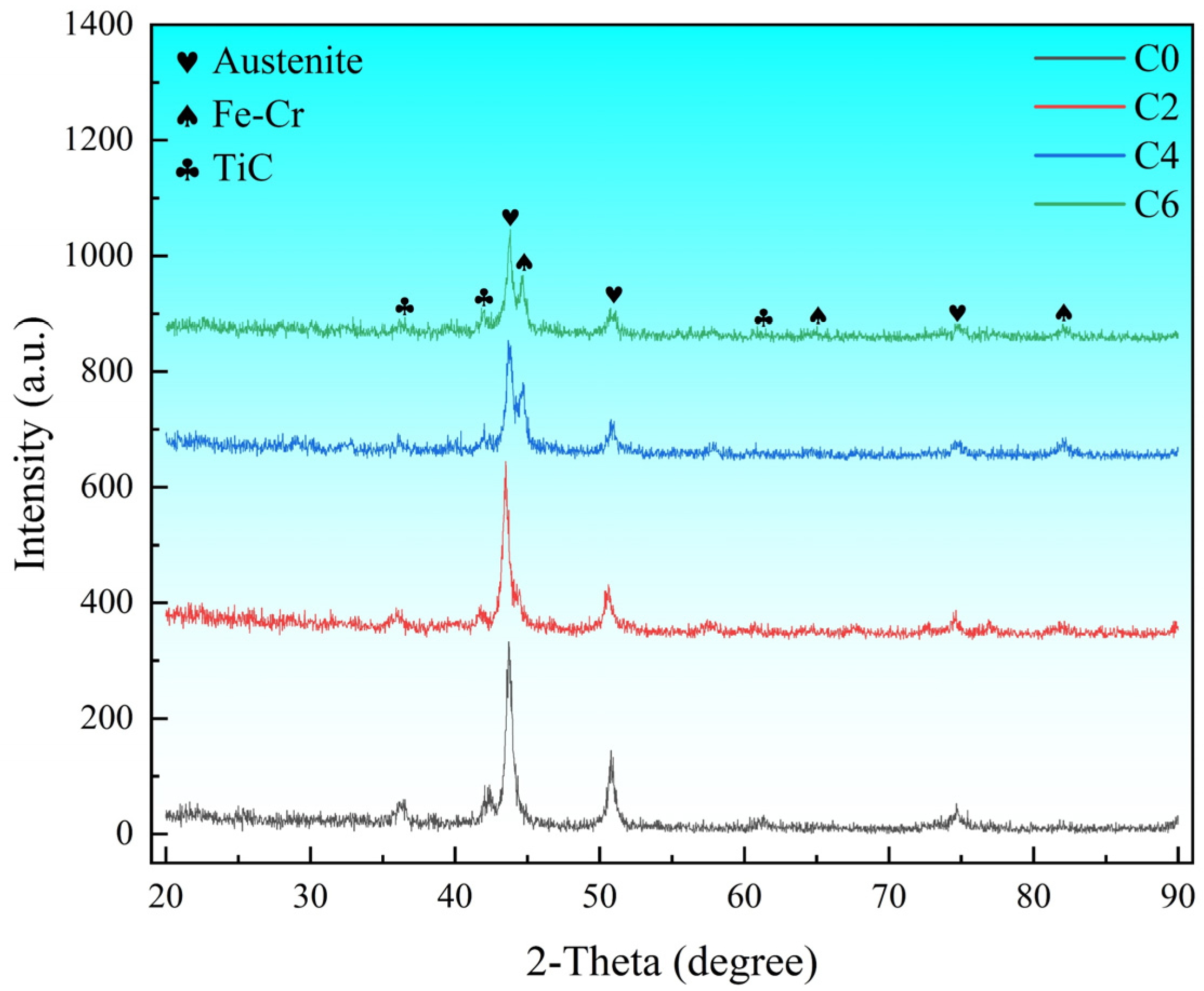

3.1. Phase Analysis

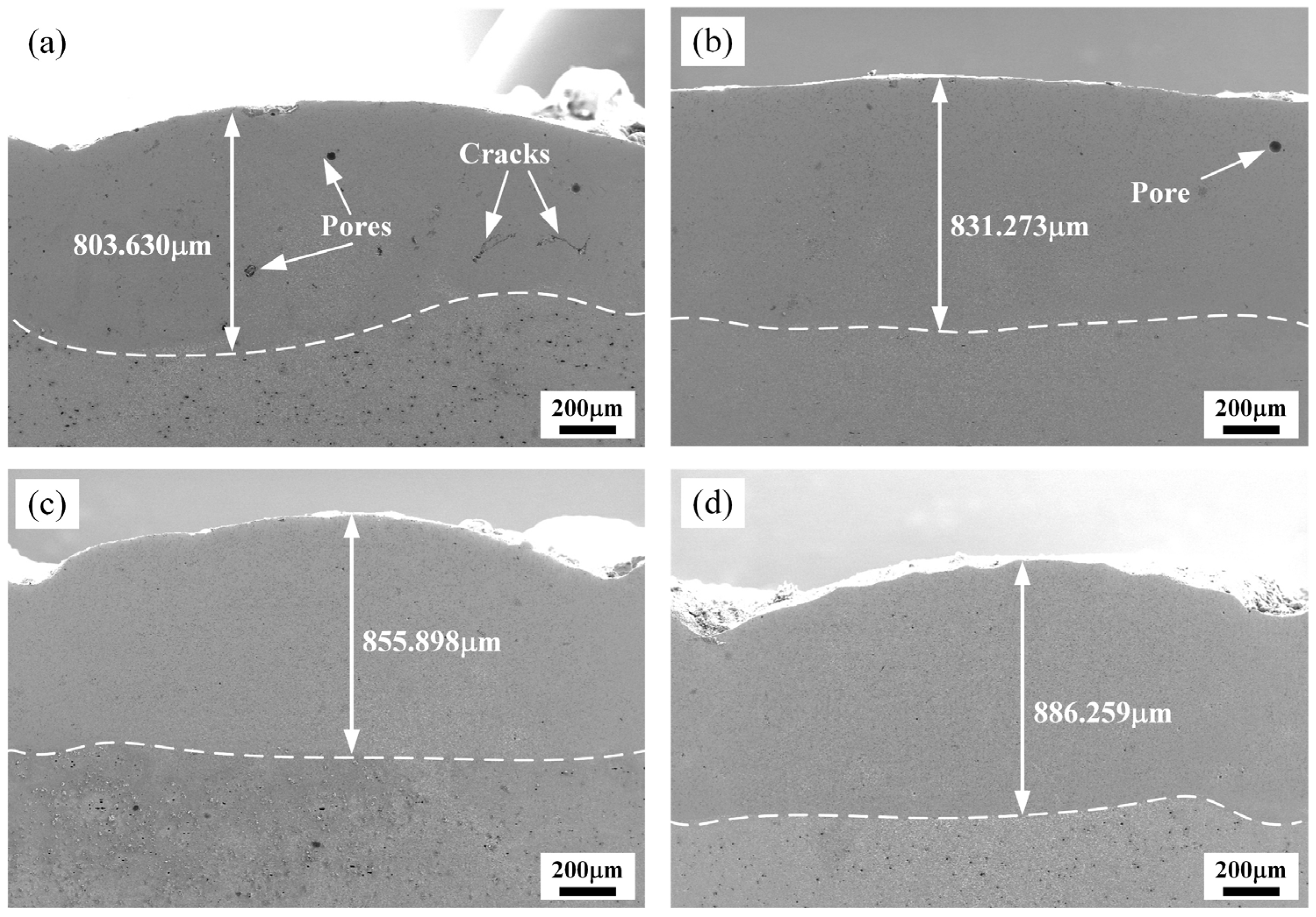

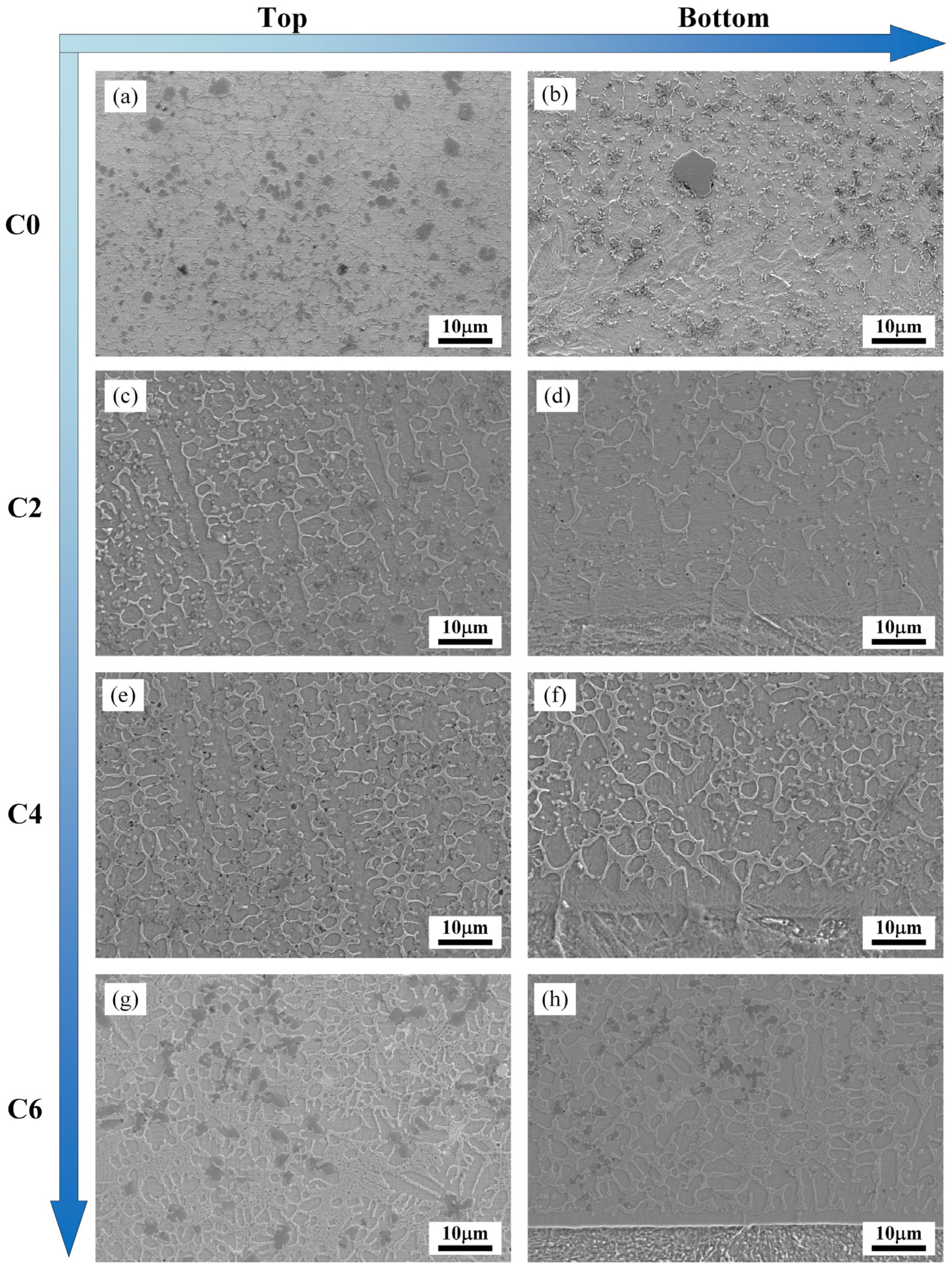

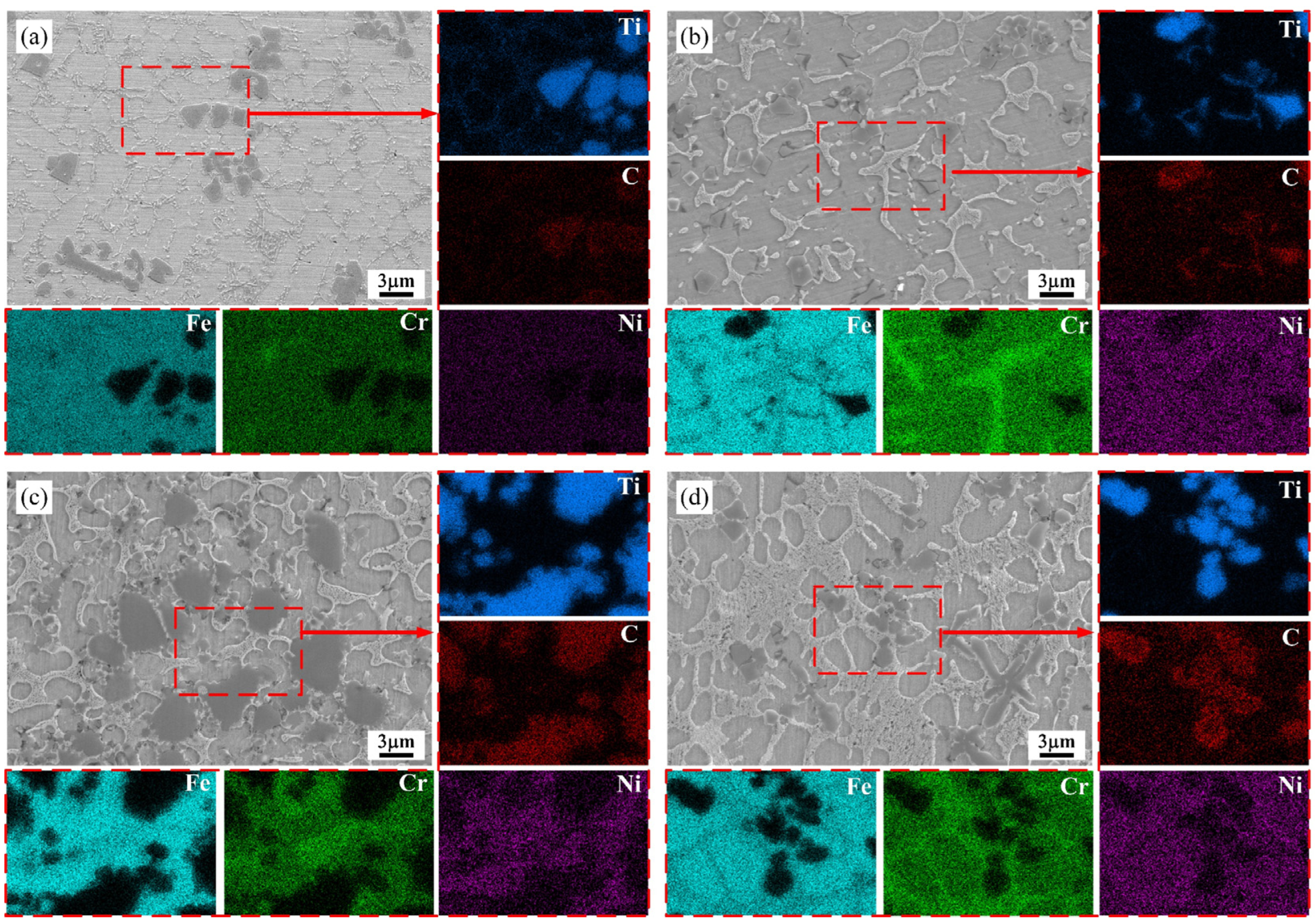

3.2. Macroscopic Morphology and Microstructure Analysis

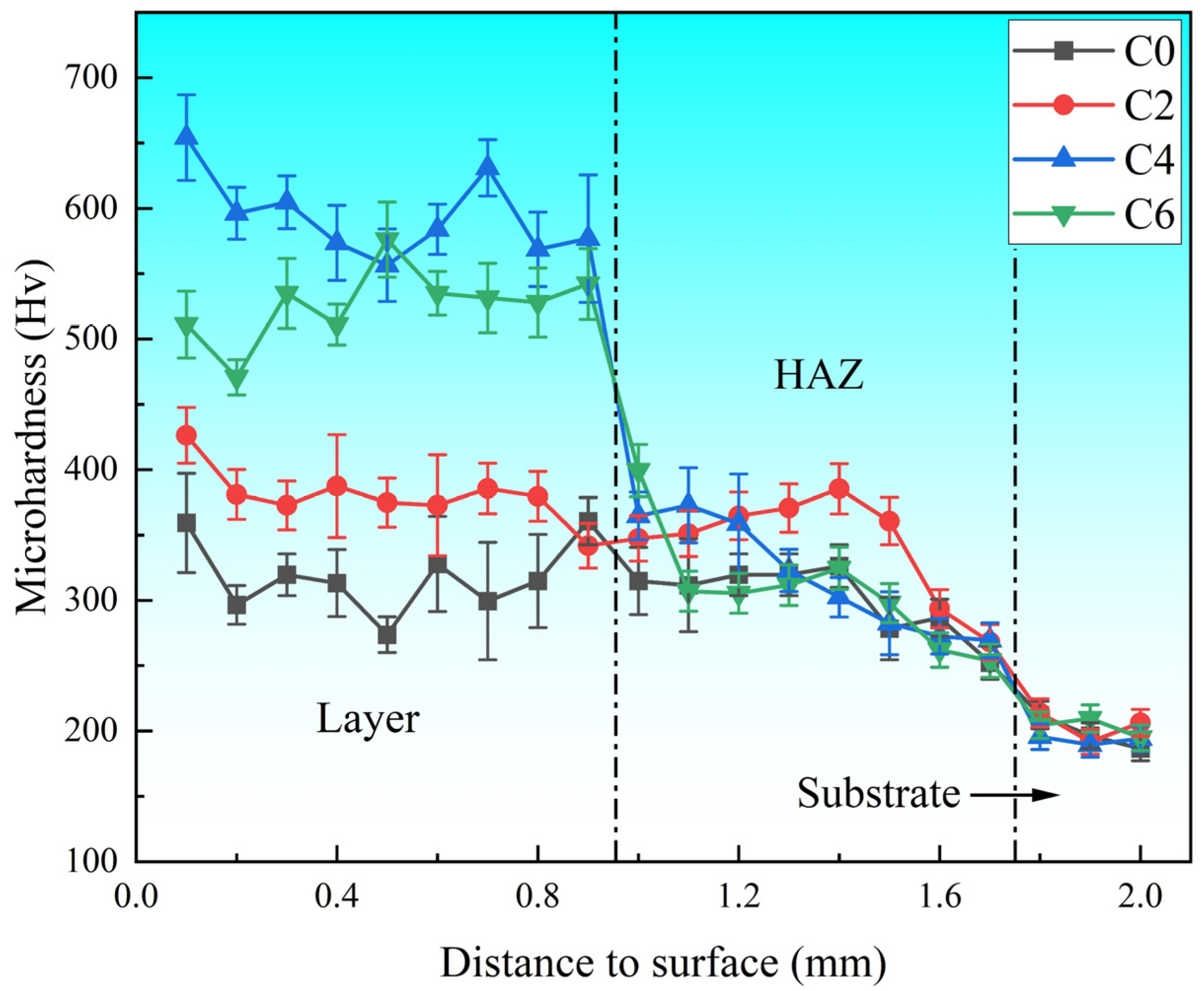

3.3. Microhardness Analysis

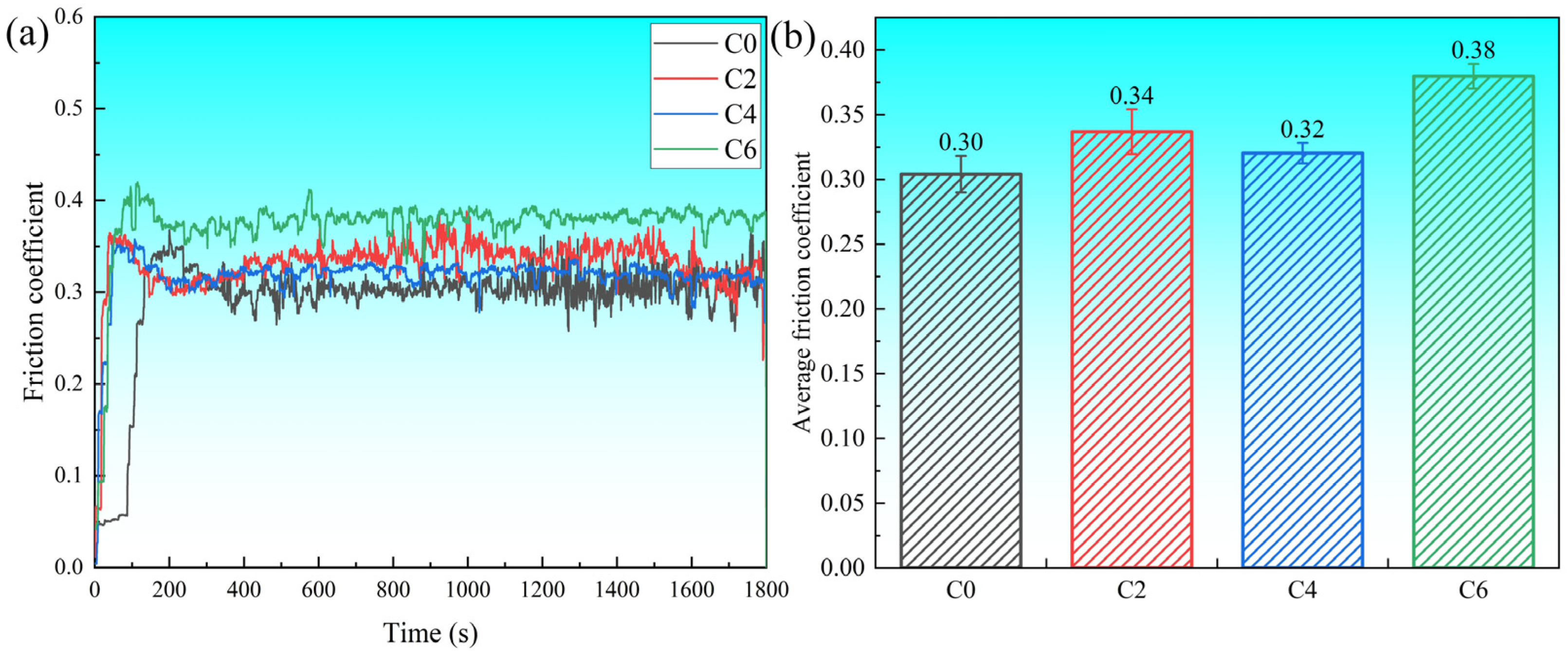

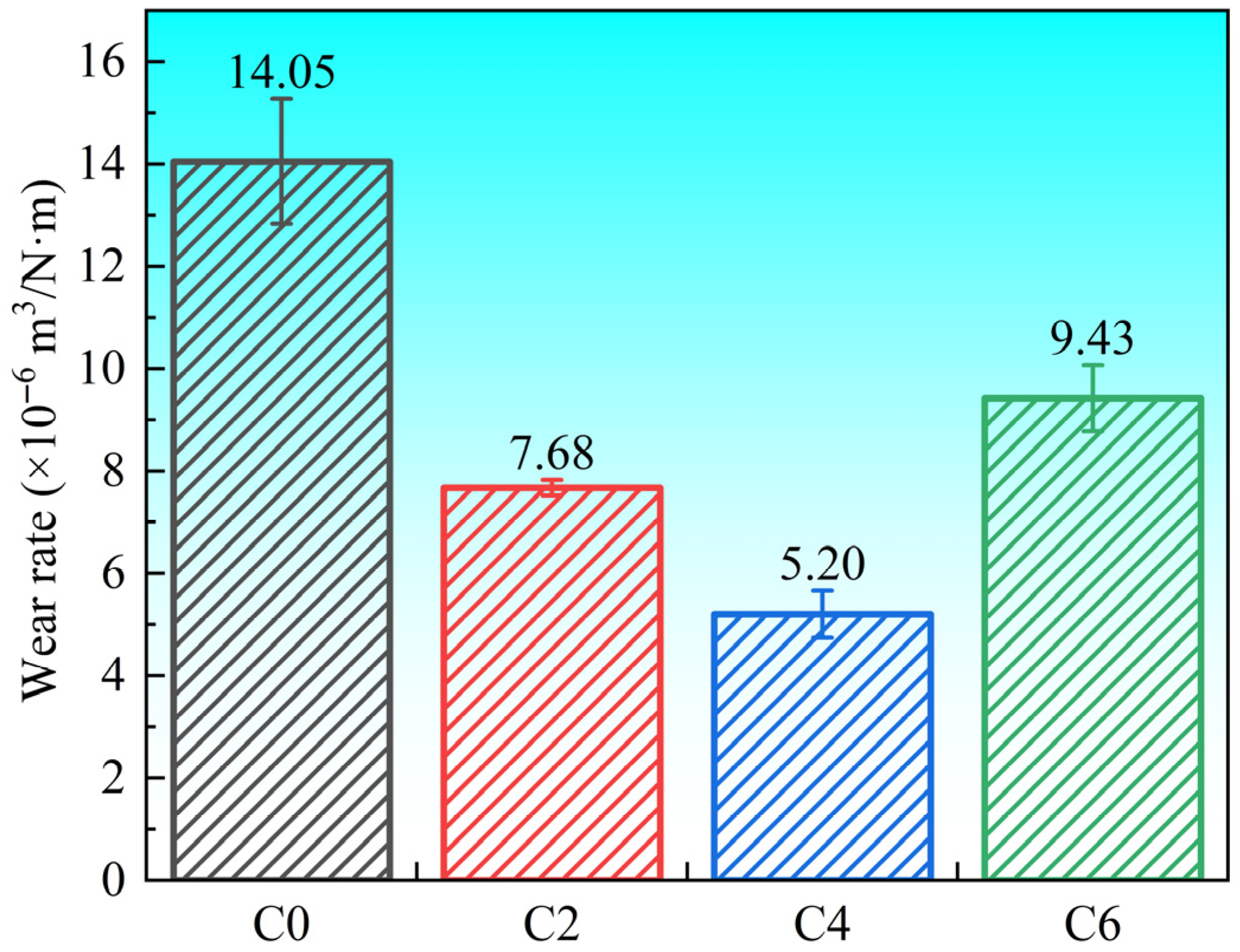

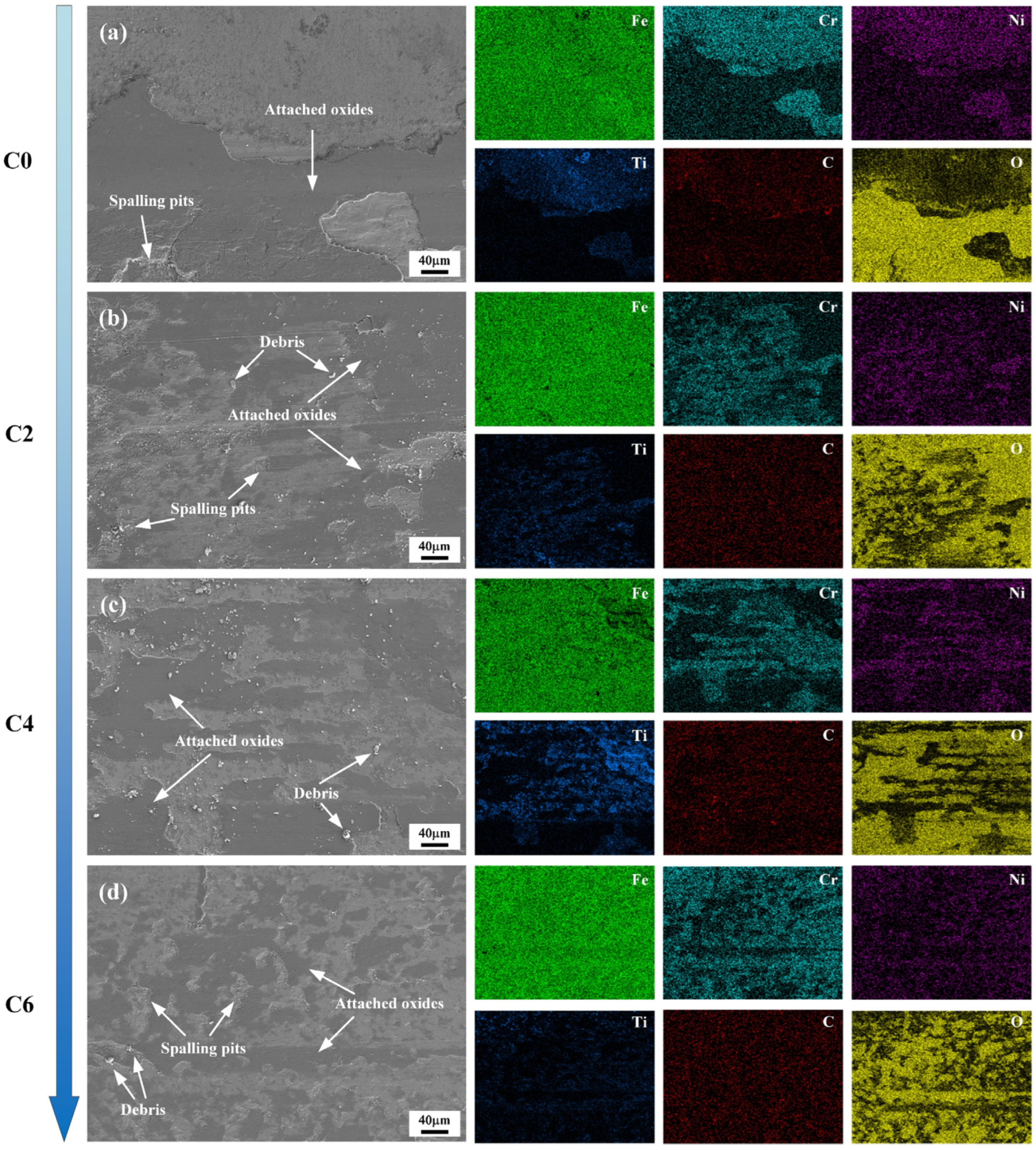

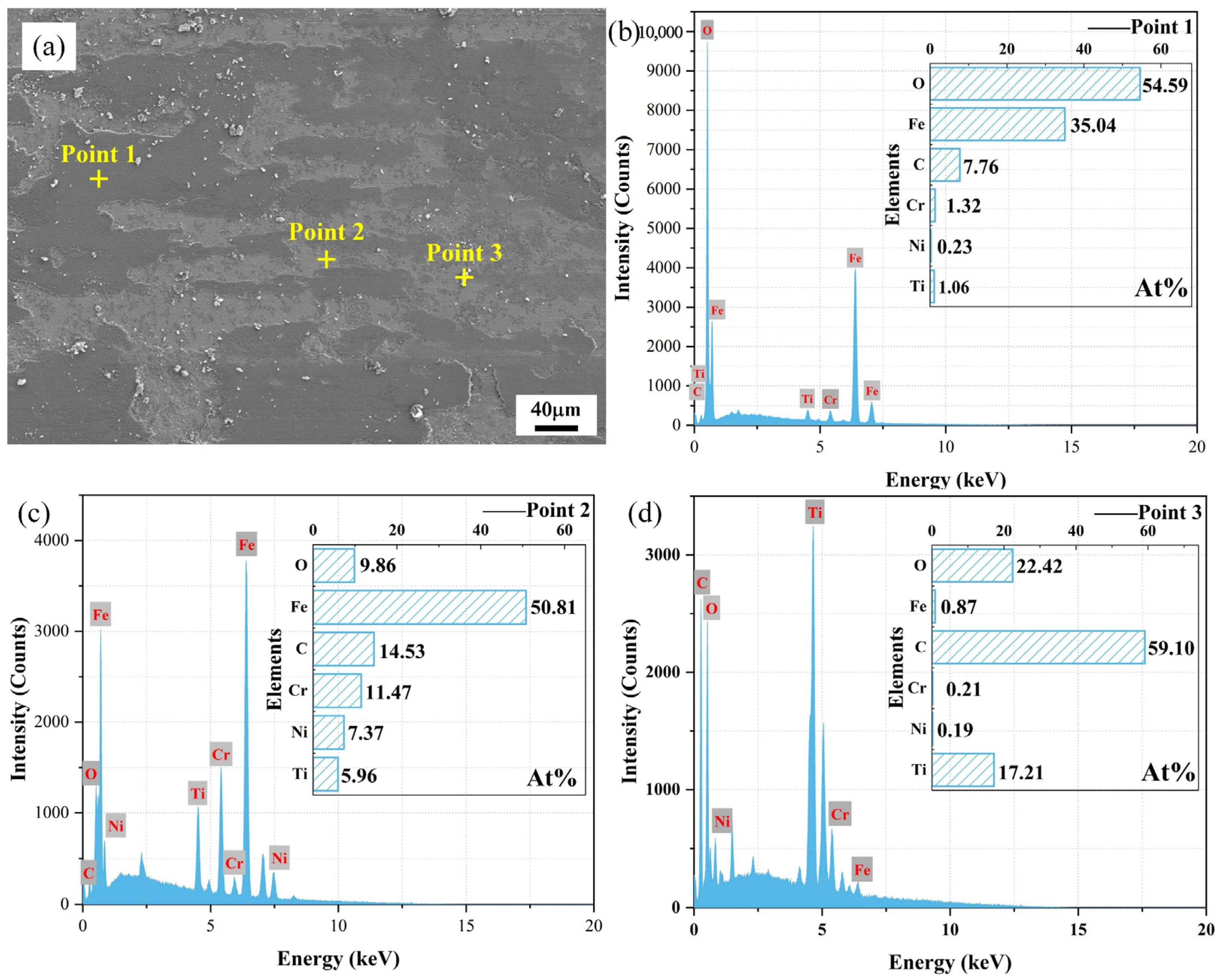

3.4. Tribological Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Y.B.; Zhou, J.Z.; Li, P.F.; Huo, K.; Meng, X.K. Effect of Electromagnetic Field on Wear Resistance of Fe901/Al2O3 Metal Matrix Composite Coating Prepared by Laser Cladding. Materials 2022, 15, 1531. [Google Scholar] [CrossRef]

- Hu, Z.W.; Li, W.G.; Zhao, Y.T. The Effect of Laser Power on the Properties of M3B2-Type Boride-Based Cermet Coatings Prepared by Laser Cladding Synthesis. Materials 2020, 13, 1867. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Niu, W.; Lei, Y.W.; Zheng, Y. The Effect of SiC Content on the Microstructure and Mechanical Properties of AlCoCrFeNiTi Laser Cladding High-Entropy Alloy Coatings. J. Therm. Spray Technol. 2025, 34, 1195–1207. [Google Scholar] [CrossRef]

- Liu, Q.S.; Liu, X.B.; Wang, G.; Liu, Y.F.; Meng, Y.; Zhang, S.H. Effect of Cu content on microstructure evolution and tribological behaviors of Ni60 composite coatings on 45# steel by laser cladding. Opt. Laser Technol. 2022, 156, 14. [Google Scholar] [CrossRef]

- Chen, W.J.; Yang, X.C.; Li, X.M.; Chai, C.; Liu, W.B. Study on Microstructure and Properties of Nickel-Based Self-Lubricating Coating by Laser Cladding. Coatings 2022, 12, 753. [Google Scholar] [CrossRef]

- Chen, L.Y.; Chen, Y.; Chen, X.; Yu, T.B.; Wang, Z.X. Microstructure and properties of in situ TiC/Ni functionally gradient coatings by powder-fed laser cladding. Ceram. Int. 2022, 48, 36789–36801. [Google Scholar] [CrossRef]

- Li, Y.J.; Dong, S.Y.; Yan, S.X.; Liu, X.T.; He, P.; Xu, B.S. Surface remanufacturing of ductile cast iron by laser cladding Ni-Cu alloy coatings. Surf. Coat. Technol. 2018, 347, 20–28. [Google Scholar] [CrossRef]

- Wu, Q.L.; Li, W.G.; Zhong, N.; Gang, W.; Wang, H.S. Microstructure and wear behavior of laser cladding VC-Cr7C3 ceramic coating on steel substrate. Mater. Des. 2013, 49, 10–18. [Google Scholar] [CrossRef]

- Jia, D.H.; Shi, W.Q.; Zhang, H.; Wu, T.; Diao, Y.L.; Li, K.Y.; Lu, C. Effects of Y2O3 Content on Wear Resistance and Corrosion Resistance of 316L/TiC Coating Fabricated by Laser Cladding. Coatings 2023, 13, 1348. [Google Scholar] [CrossRef]

- Ge, H.H.; Ding, S.J.; Zhang, P.Z.; Fang, H.; Hu, Y.; Yao, J.H. Influence of overlapping process on the distribution of Cr element in laser cladding 316L powder on 45# steel substrate. Surf. Coat. Technol. 2024, 493, 12. [Google Scholar] [CrossRef]

- Liu, Y.H.; Li, J.; Xuan, F.Z. Fabrication of TiC reinforced Ni based coating by laser cladding. Surf. Eng. 2012, 28, 560–563. [Google Scholar] [CrossRef]

- Li, D.M.; Sun, X.F.; Li, Z.M.; Wei, S.; Zhao, H.X.; Peng, S.; Zheng, B.J. Effect of TiC content on the microstructure and properties of large-area laser-cladded TiC Ni-based composite coatings. Mater. Res. Express 2021, 8, 11. [Google Scholar] [CrossRef]

- He, X.; Song, R.G.; Kong, D.J. Effects of TiC on the microstructure and properties of TiC/TiAl composite coating prepared by laser cladding. Opt. Laser Technol. 2019, 112, 339–348. [Google Scholar] [CrossRef]

- Bu, R.; Jin, A.X.; Sun, Q.; Zan, W.; He, R.L. Study on laser cladding and properties of AZ63-Er alloy for automobile engine. J. Mater. Res. Technol. 2020, 9, 5154–5160. [Google Scholar] [CrossRef]

- Xu, S.Y.; Cai, Q.; Li, G.; Lu, X.F.; Zhu, X.L. Effect of scanning speed on microstructure and properties of TiC/Ni60 composite coatings on Ti6Al4V alloy by laser cladding. Opt. Laser Technol. 2022, 154, 12. [Google Scholar] [CrossRef]

- Wu, Q.L.; Long, W.M.; Zhang, L.; Zhao, H.W. A review on ceramic coatings prepared by laser cladding technology. Opt. Laser Technol. 2024, 176, 25. [Google Scholar] [CrossRef]

- Li, G.S.; Wang, Z.Y.; Yao, L.G.; Xie, D.Z.; Chen, G. Concentration mixing and melt pool solidification behavior during the magnetic field assisted laser cladding of Fe-Cr-based alloy on 45 steel surface. Surf. Coat. Technol. 2022, 445, 16. [Google Scholar] [CrossRef]

- Tao, L.; Yang, Y.; Zhu, W.L.; Sun, J.; Wu, J.L.; Xu, H.; Yan, L.; Yang, A.H.; Xu, Z.L. Stress Distribution in Wear Analysis of Nano-Y2O3 Dispersion Strengthened Ni-Based μm-WC Composite Material Laser Coating. Materials 2024, 17, 121. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.J.; Jiang, W.Y.; Xu, K.G.; Wen, X.; Huang, B.S. Microhardness, wear resistance, and corrosion resistance of AlCoCrFe Ni2.1+xCeO2 high-entropy alloy coatings by laser cladding. Mater. Today Commun. 2025, 43, 14. [Google Scholar] [CrossRef]

- Meng, L.Y.; Hu, M.; Zhao, H.Q.; Lv, P.; Wang, A.M. Influence of Nano Rare-Earth Oxides on the Microstructure and Wear Resistance of Laser Clad Micro-nanostructure Al2O3-NiCr Coating. J. Mater. Eng. Perform. 2025, 12. [Google Scholar] [CrossRef]

- Mohammed, S.; Rajamure, R.S.; Zhang, Z.; Balu, P.; Dahotre, N.B.; Kovacevic, R. Tailoring corrosion resistance of laser-cladded Ni/WC surface by adding rare earth elements. Int. J. Adv. Manuf. Technol. 2018, 97, 4043–4054. [Google Scholar] [CrossRef]

- Li, Z.Y.; Chen, W.A.; Li, D.Y.; Yang, J.W.; Zhang, Y.; Yang, X.D.; Dai, B.G.; Zhang, J.H.; Qiu, Z.L. Frictional wear properties of different nano La2O3 composite FeCoNiCrMo high-entropy alloy coatings under soil conditions. J. Mater. Res. Technol. 2025, 35, 6874–6888. [Google Scholar] [CrossRef]

- Wang, L.-M.; Lin, Q.; Yue, L.-J.; Liu, L.; Guo, F.; Wang, F.-M. Study of application of rare earth elements in advanced low alloy steels. J. Alloys Compd. 2007, 451, 534–537. [Google Scholar] [CrossRef]

- Nie, M.H.; Zhang, S.; Wang, Z.Y.; Zhang, C.H.; Chen, H.T.; Chen, J. Effect of laser power on microstructure and interfacial bonding strength of laser cladding 17-4PH stainless steel coatings. Mater. Chem. Phys. 2022, 275, 125236. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Ni | Cr | Cu | Fe |

|---|---|---|---|---|---|---|---|

| Component | 0.42~0.50 | 0.17~0.37 | 0.50~0.80 | ≤0.30 | ≤0.25 | ≤0.25 | Bal. |

| Element | C | Si | Mn | Mo | Ni | Cr | Fe |

|---|---|---|---|---|---|---|---|

| Component | 0.06 | 0.92 | 1.51 | 2.55 | 13.23 | 17.24 | Bal. |

| Sample | Mixed Powders (wt.%) | LaB6 Powder (wt.%) |

|---|---|---|

| C0 | 100 | 0 |

| C2 | 98 | 2 |

| C4 | 96 | 4 |

| C6 | 94 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Li, H.; Liu, Y.; Jiang, J.; Gao, Y. An Investigation of the Microstructure and Wear Resistance of Laser Clad 316 Stainless Steel/TiC Coatings Containing Different LaB6 Contents. Ceramics 2025, 8, 121. https://doi.org/10.3390/ceramics8040121

Zhang D, Li H, Liu Y, Jiang J, Gao Y. An Investigation of the Microstructure and Wear Resistance of Laser Clad 316 Stainless Steel/TiC Coatings Containing Different LaB6 Contents. Ceramics. 2025; 8(4):121. https://doi.org/10.3390/ceramics8040121

Chicago/Turabian StyleZhang, Dongdong, Haozhe Li, Yu Liu, Jingyu Jiang, and Yali Gao. 2025. "An Investigation of the Microstructure and Wear Resistance of Laser Clad 316 Stainless Steel/TiC Coatings Containing Different LaB6 Contents" Ceramics 8, no. 4: 121. https://doi.org/10.3390/ceramics8040121

APA StyleZhang, D., Li, H., Liu, Y., Jiang, J., & Gao, Y. (2025). An Investigation of the Microstructure and Wear Resistance of Laser Clad 316 Stainless Steel/TiC Coatings Containing Different LaB6 Contents. Ceramics, 8(4), 121. https://doi.org/10.3390/ceramics8040121