Fabrication and Properties of ITTO Segments for Cylindrical Targets by Pressureless Oxygen Atmosphere Sintering Method

Abstract

1. Introduction

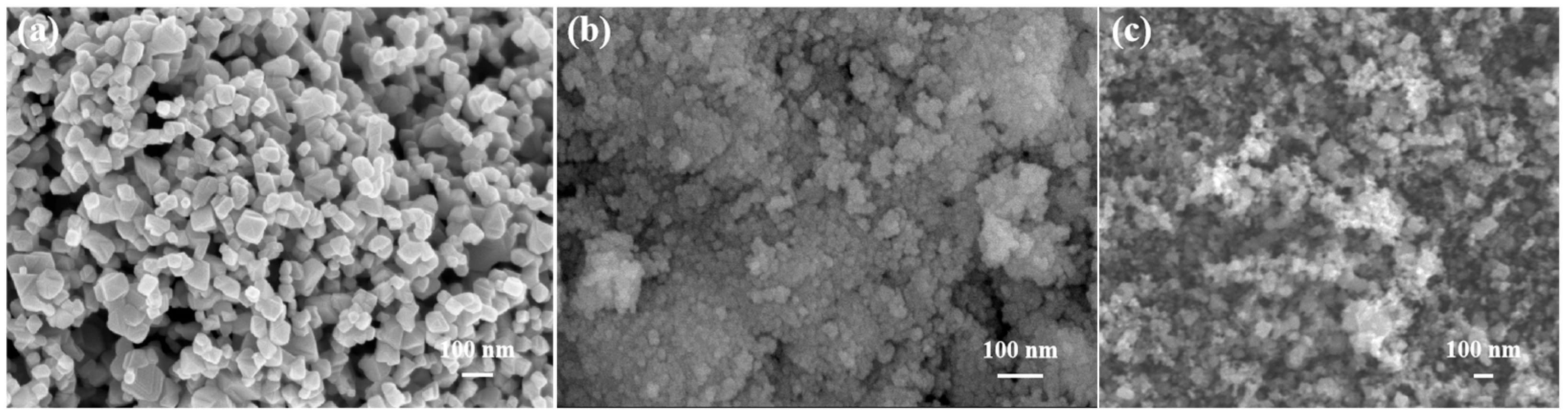

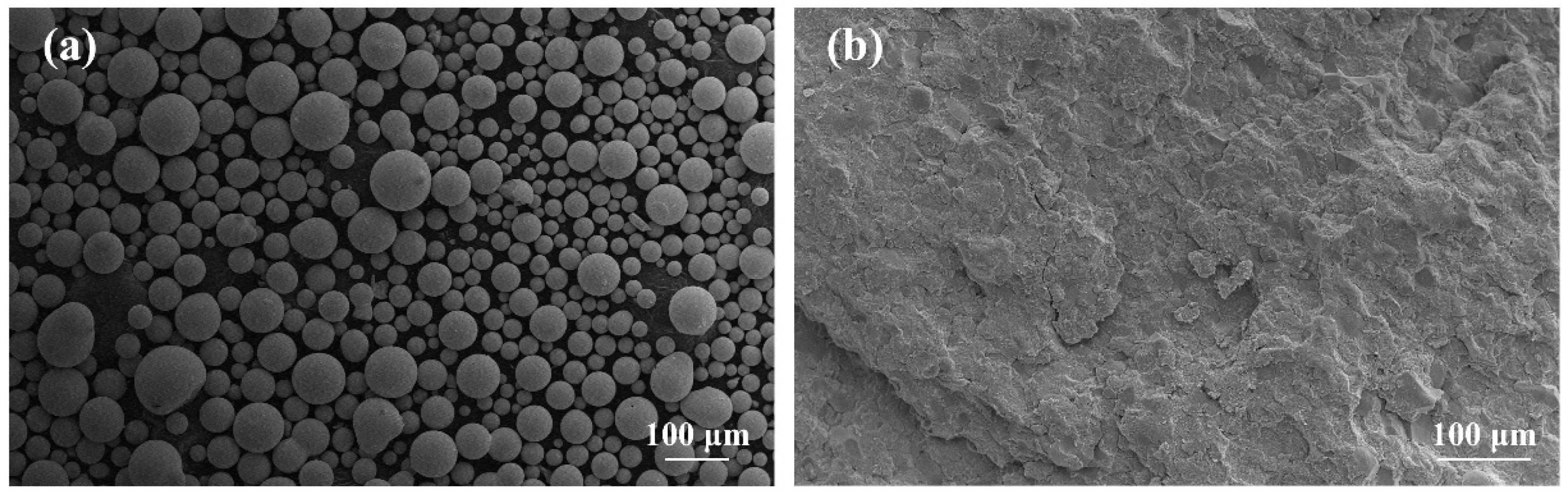

2. Materials and Methods

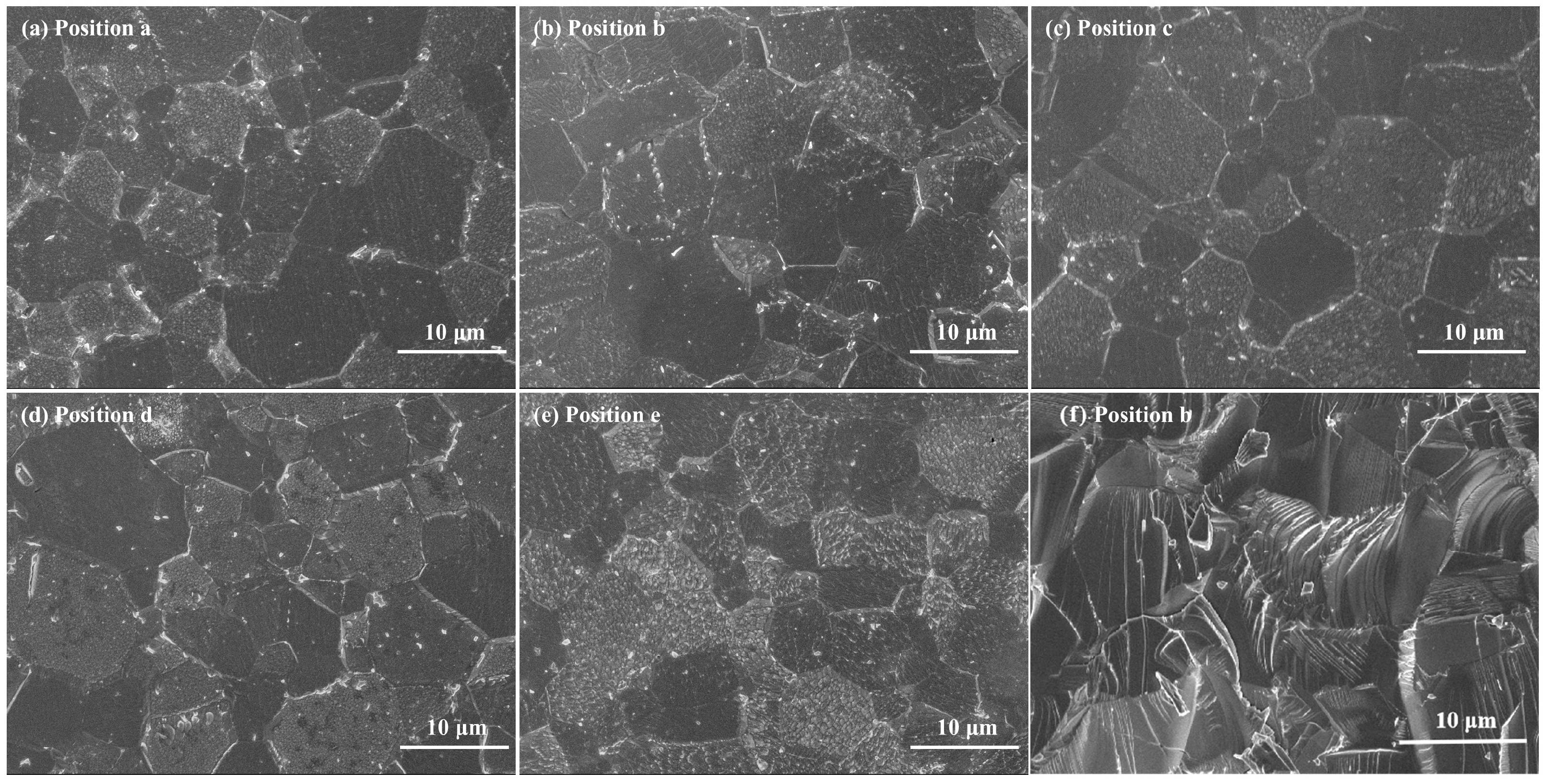

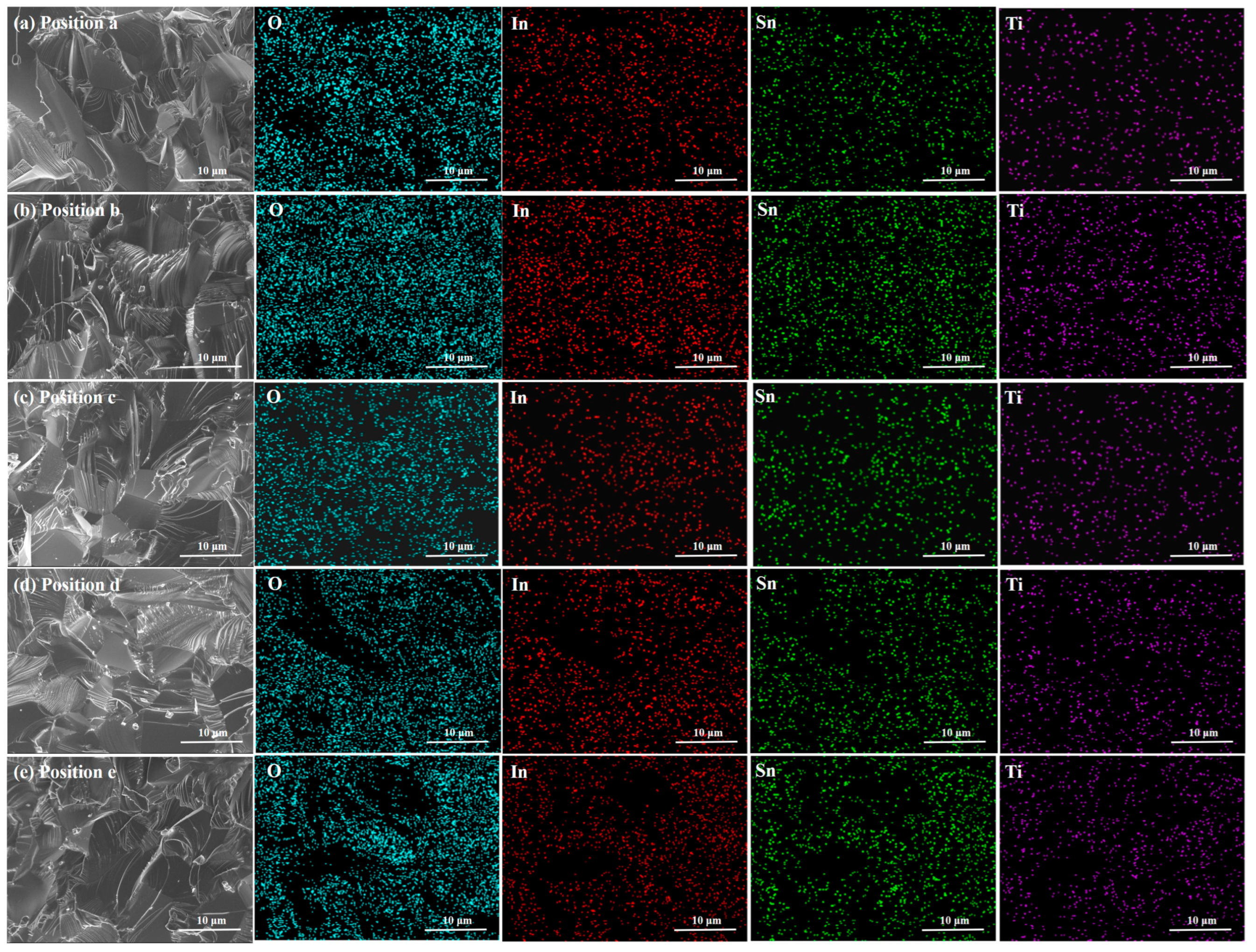

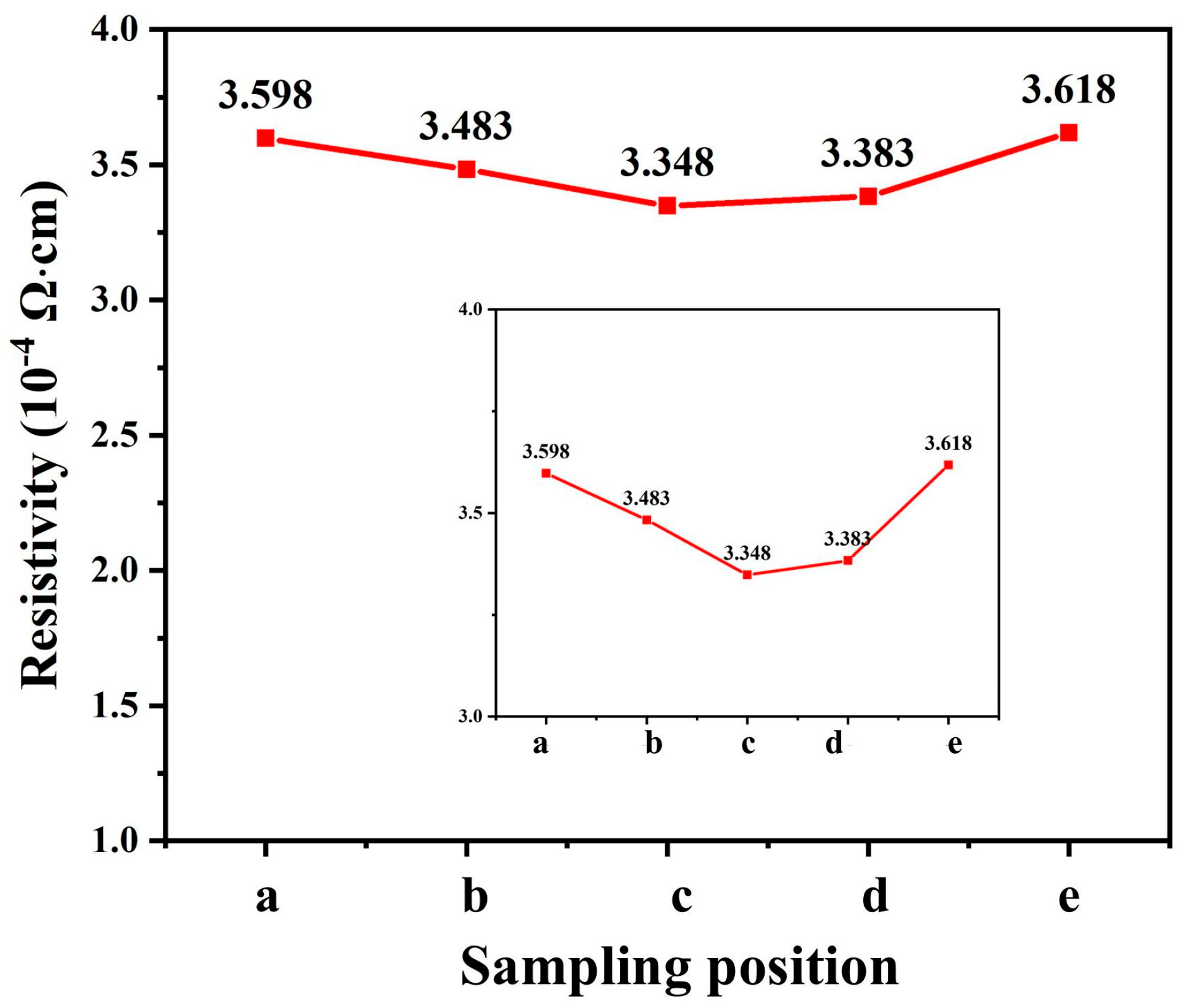

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Varshney, D.; Prakash, J.; Singh, G. Indium tin oxide nanoparticles induced tunable dual alignment in nematic liquid crystal. J. Mol. Liq. 2023, 374, 121264. [Google Scholar] [CrossRef]

- Koh, T.; Choi, J.; Lee, S.; Yoo, S. Optical outcoupling enhancement in organic light-emitting diodes: Highly conductive polymer as a low-index layer on microstructured ITO electrodes. Adv. Mater. 2010, 22, 1849–1853. [Google Scholar] [CrossRef]

- Li, W.; Liu, X.; Zhang, J.; Wang, H.; Yuan, C.; Lin, S.; Chen, C.; Shen, C.; Tang, J.; Li, J.; et al. Reactive plasma deposition of ITO as an efficient buffer layer for inverted perovskite solar cells. Adv. Mater. 2025, 37, 2417094. [Google Scholar] [CrossRef] [PubMed]

- Park, D.-P.; Park, W.-H.; Song, J.-K.; Kim, S.S. High-performance ITO thin films for on-cell touch sensor of foldable OLED displays. J. Inf. Disp. 2022, 23, 77–85. [Google Scholar] [CrossRef]

- Yamamoto, A.; Yokoyama, D.; Takahashi, M.; Fuke, T.; Shibayama, S.; Yamasaki, A.; Lin, C. Highly reliable dielectric interlayers for flexible displays and E-paper. Inf. Disp. 2022, 38, 19–23. [Google Scholar] [CrossRef]

- Robb, A.J.; Duca, Z.A.; White, N.; Woodell, P.; Ward, P.A. Influence of oxygen on the optical and electrical properties of magnetron-sputtered indium tin oxide thin films at ambient temperature. Thin Solid Film. 2024, 788, 140152. [Google Scholar] [CrossRef]

- Seok, H.J.; Lee, D.K.; Kim, H.K. Multicoated flexible indium tin oxide electrodes fabricated using magnetron sputtering and arc plasma ion plating for flexible perovskite solar cells. ACS Appl. Mater. Interfaces 2024, 16, 47961–47972. [Google Scholar] [CrossRef]

- Musschoot, J.; Depla, D.; Buyle, G.; Haemers, J.; De Gryse, R. Influence of the geometrical configuration on the plasma ionization distribution and erosion profile of a rotating cylindrical magnetron: A Monte Carlo simulation. J. Phys. D Appl. Phys. 2006, 39, 3989. [Google Scholar] [CrossRef]

- Garg, R.; Gonuguntla, S.; Sk, S.; Iqbal, M.S.; Dada, A.O.; Pal, U.; Ahmadipour, M. Sputtering thin films: Materials, applications, challenges and future directions. Adv. Colloid Interface Sci. 2024, 330, 103203. [Google Scholar] [CrossRef]

- Li, X.Y.; Depla, D.; Leroy, W.P.; Haemers, J.; De Gryse, R. Influence of deposition on the reactive sputter behaviour during rotating cylindrical magnetron sputtering. J. Phys. D Appl. Phys. 2008, 41, 035203. [Google Scholar] [CrossRef]

- Brodie, I.; Lamont, L.T., Jr.; Jepsen, R.L. Production of high-energy neutral atoms by scattering of ions at solid surfaces and its relation to sputtering. Phys. Rev. Lett. 1968, 21, 1224. [Google Scholar] [CrossRef]

- Depla, D.; Li, X.Y.; Mahieu, S.; Van Aeken, K.; Leroy, W.P.; Haemers, J.; De Gryse, R.; Bogaerts, A. Rotating cylindrical magnetron sputtering: Simulation of the reactive process. J. Appl. Phys. 2010, 107, 113307. [Google Scholar] [CrossRef]

- Carreri, F.; Sabelfeld, A.; Gerdes, H.; Bandorf, R.; Vergöhl, M.; Bräuer, G. HIPIMS ITO films from a rotating cylindrical cathode. Surf. Coat. Technol. 2016, 290, 65–72. [Google Scholar] [CrossRef]

- De Gryse, R.; Haemers, J.; Leroy, W.; Depla, D. Thirty years of rotatable magnetrons. Thin Solid Film. 2012, 520, 5833–5845. [Google Scholar] [CrossRef]

- Linss, V. Challenges in the industrial deposition of transparent conductive oxide materials by reactive magnetron sputtering from rotatable targets. Thin Solid Film. 2017, 634, 149–154. [Google Scholar] [CrossRef]

- Utsumi, K.; Iigusa, H.; Tokumaru, R.; Song, P.K.; Shigesato, Y. Study on In2O3-SnO2 transparent and conductive films prepared by dc sputtering using high density ceramic targets. Thin Solid Film. 2003, 445, 229–234. [Google Scholar] [CrossRef]

- Li, W.-B.; La, Z.-B.; Wu, W.-Q.; Li, Y.-Z.; Pe, X.-J.; Xu, G.-Q. Application progress of hot isostatic pressing technology in transparent ceramics. Adv. Ceram. 2023, 44, 117–128. [Google Scholar]

- Langer, J.; Hoffmann, M.J.; Guillon, O. Electric field-assisted sintering and hot pressing of semiconductive zinc oxide: A comparative study. J. Am. Ceram. Soc. 2011, 94, 2344–2353. [Google Scholar] [CrossRef]

- Bocanegra-Bernal, M.H. Hot isostatic pressing (HIP) technology and its applications to metals and ceramics. J. Mater. Sci. 2004, 39, 6399–6420. [Google Scholar] [CrossRef]

- Zheng, L.; Liu, M.; Zhang, H.; Zheng, Z.; Wang, Z.; Cheng, H.; Wang, P.; Liu, Y.; Huang, B. Fabrication of ZnO ceramics with defects by spark plasma sintering method and investigations of their photoelectrochemical properties. Nanomaterials 2021, 11, 2506. [Google Scholar] [CrossRef]

- Liang, F.; Liu, J. Sintering, microstructure and electricity properties of ITO targets with Bi2O3-Nb2O5 addition. Ceram. Int. 2017, 43, 5856–5861. [Google Scholar] [CrossRef]

- Akhmedov, A.K.; Asvarov, A.S.; Makhmudov, S.S.; Kanevsky, V.M. Fabrication of segments for ZnO-based tube ceramic targets by the spark plasma sintering method. Ceramics 2023, 6, 1302–1313. [Google Scholar] [CrossRef]

- Qin, K.; Mei, F.; Yuan, T.; Li, R.; Jiang, J.; Niu, P.; Chen, H. Effects of sintering processes on the element chemical states of In, Sn and O in ITO targets. J. Mater. Sci. Mater. Electron. 2018, 29, 7931–7940. [Google Scholar] [CrossRef]

- Mei, F.; Qin, K.; Mei, F.; Yuan, T.; Liu, W.; Li, R.; Chen, L. Microstructure, grain orientation, and properties of ITO ceramics sintered with various heating rates. Int. J. Appl. Ceram. Technol. 2019, 16, 654–665. [Google Scholar] [CrossRef]

- Kim, J.H.; Seong, T.Y.; Ahn, K.J.; Chung, K.B.; Seok, H.J.; Seo, H.J.; Kim, H.K. The effects of film thickness on the electrical, optical, and structural properties of cylindrical, rotating, magnetron-sputtered ITO films. Appl. Surf. Sci. 2018, 440, 1211–1218. [Google Scholar] [CrossRef]

- Lippens, P.; Büchel, M.; Chiu, D.; Szepesi, C. Indium-tin-oxide coatings for applications in photovoltaics and displays deposited using rotary ceramic targets: Recent insights regarding process stability and doping level. Thin Solid Film. 2013, 532, 94–97. [Google Scholar] [CrossRef]

- Medvedovski, E.; A Alvarez, N.; Szepesi, C.J.; Yankov, O.; Lippens, P. Advanced indium tin oxide ceramic sputtering targets (rotary and planar) for transparent conductive nanosized films. Adv. Appl. Ceram. 2013, 112, 243–256. [Google Scholar] [CrossRef]

- David, C.; Tinkham, B.; Prunici, P.; Panckow, A. Highly conductive and transparent ITO films deposited at low temperatures by pulsed DC magnetron sputtering from ceramic and metallic rotary targets. Surf. Coat. Technol. 2017, 314, 113–117. [Google Scholar] [CrossRef]

- Zhu, H.H.; Fuh, J.Y.H.; Lu, L. The influence of powder apparent density on the density in direct laser-sintered metallic parts. Int. J. Mach. Tools Manuf. 2007, 47, 294–298. [Google Scholar] [CrossRef]

- Wu, F.; Wang, T.; Xu, J.; Zhu, G.; Shang, F.; Xu, H. Microstructure and resistivity of ITO targets sintered by cold and microwave sintering for solar cell applications. Adv. Appl. Ceram. 2024, 123, 121–129. [Google Scholar] [CrossRef]

- Kim, S.M.; Seo, K.H.; Lee, J.H.; Kim, J.J.; Lee, H.Y.; Lee, J.S. Preparation and sintering of nanocrystalline ITO powders with different SnO2 content. J. Eur. Ceram. Soc. 2006, 26, 73–80. [Google Scholar] [CrossRef]

- Xu, J.W.; Yang, L.; Wang, H.; Zhu, G.; Xu, H.; Zhou, C.; Yuan, C.; Yang, Z. Sintering behavior and refining grains of high density tin doped indium oxide targets with low tin oxide content. J. Mater. Sci. Mater. Electron. 2016, 27, 3298–3304. [Google Scholar] [CrossRef]

- Yi, C.X.; Zhang, H.T.; Wang, S.K.; Han, G.S.; Liu, Z.L.; Tian, Y.F.; Bao, M.D. Comprehensive effect of grain size and original target morphology on sputtering behavior of magnetron sputtering target. Vacuum 2023, 210, 111866. [Google Scholar] [CrossRef]

- Wang, Y.; Chao, Y.; Li, S.; Ze, C.; Wen, M. Mechanisms of nodule formation on Ni-Pt targets during sputtering. Appl. Surf. Sci. 2025, 680, 161420. [Google Scholar] [CrossRef]

- Nadaud, N.; Bock, P. Influence of TiO2 additives on the microstructure of In2O3 ceramics. Ceram. Int. 1996, 22, 207–209. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, J.; Wu, F.; Yao, Y.; Yang, L.; Zhu, G.; Xu, H. Fabrication and Properties of ITTO Segments for Cylindrical Targets by Pressureless Oxygen Atmosphere Sintering Method. Ceramics 2025, 8, 75. https://doi.org/10.3390/ceramics8020075

Xu J, Wu F, Yao Y, Yang L, Zhu G, Xu H. Fabrication and Properties of ITTO Segments for Cylindrical Targets by Pressureless Oxygen Atmosphere Sintering Method. Ceramics. 2025; 8(2):75. https://doi.org/10.3390/ceramics8020075

Chicago/Turabian StyleXu, Jiwen, Fangzhou Wu, Yuan Yao, Ling Yang, Guisheng Zhu, and Huarui Xu. 2025. "Fabrication and Properties of ITTO Segments for Cylindrical Targets by Pressureless Oxygen Atmosphere Sintering Method" Ceramics 8, no. 2: 75. https://doi.org/10.3390/ceramics8020075

APA StyleXu, J., Wu, F., Yao, Y., Yang, L., Zhu, G., & Xu, H. (2025). Fabrication and Properties of ITTO Segments for Cylindrical Targets by Pressureless Oxygen Atmosphere Sintering Method. Ceramics, 8(2), 75. https://doi.org/10.3390/ceramics8020075