Enhanced Electrical Property and Thermal Stability in Lead-Free BNT–BT–BF Ceramics

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Phase and Structural Analysis

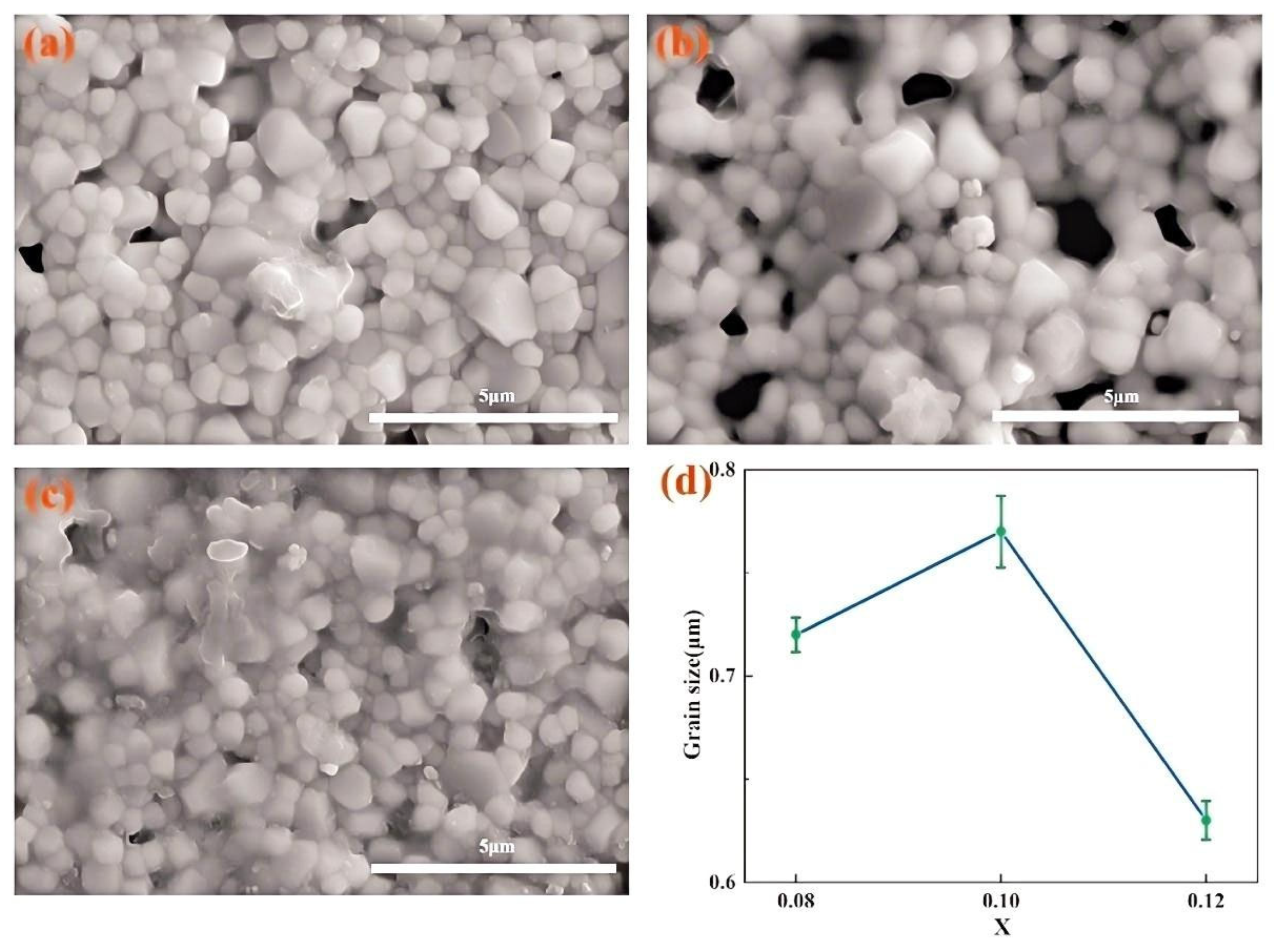

3.2. Microstructure and Grain Size

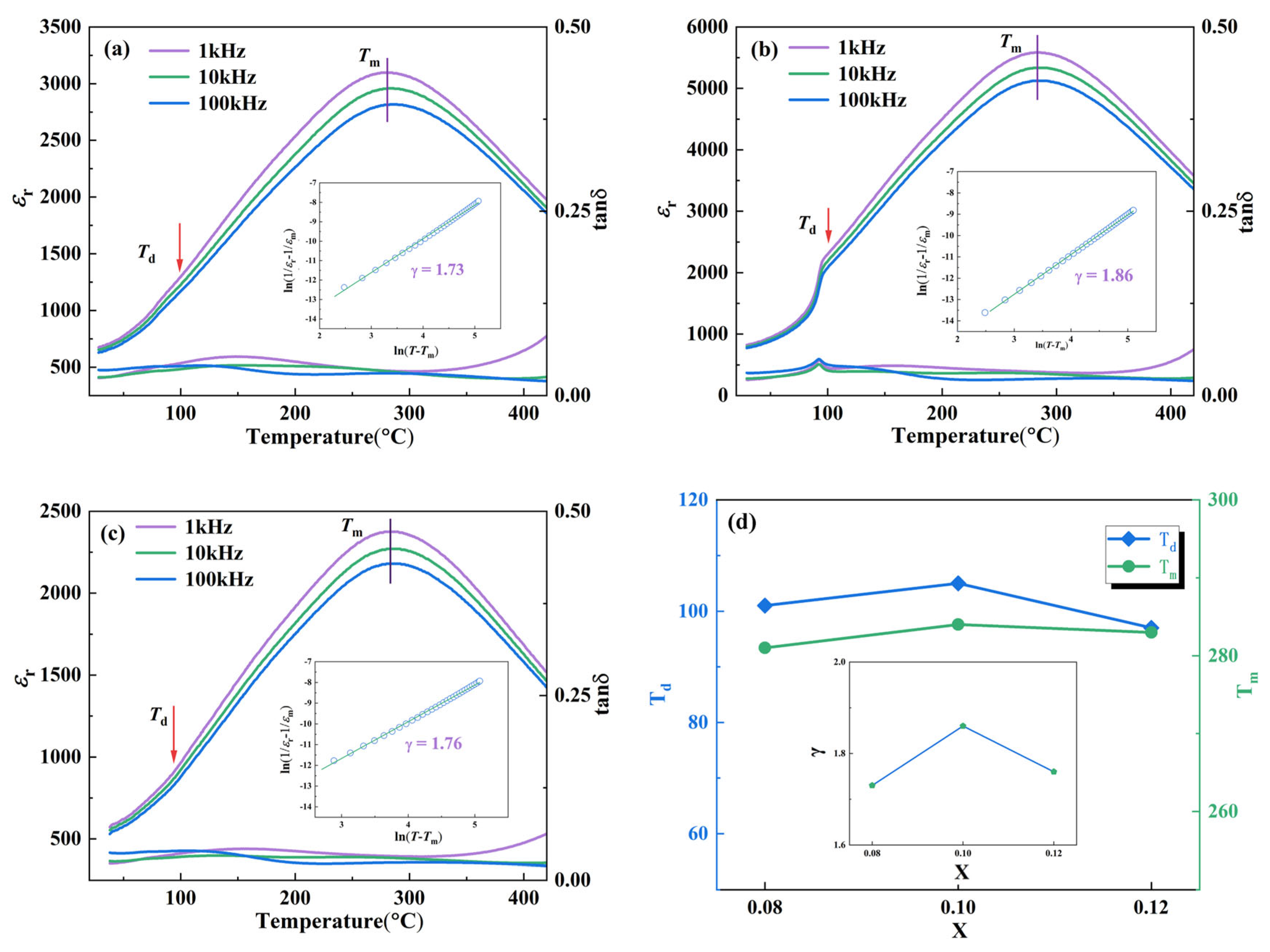

3.3. Dielectric and Thermal Properties

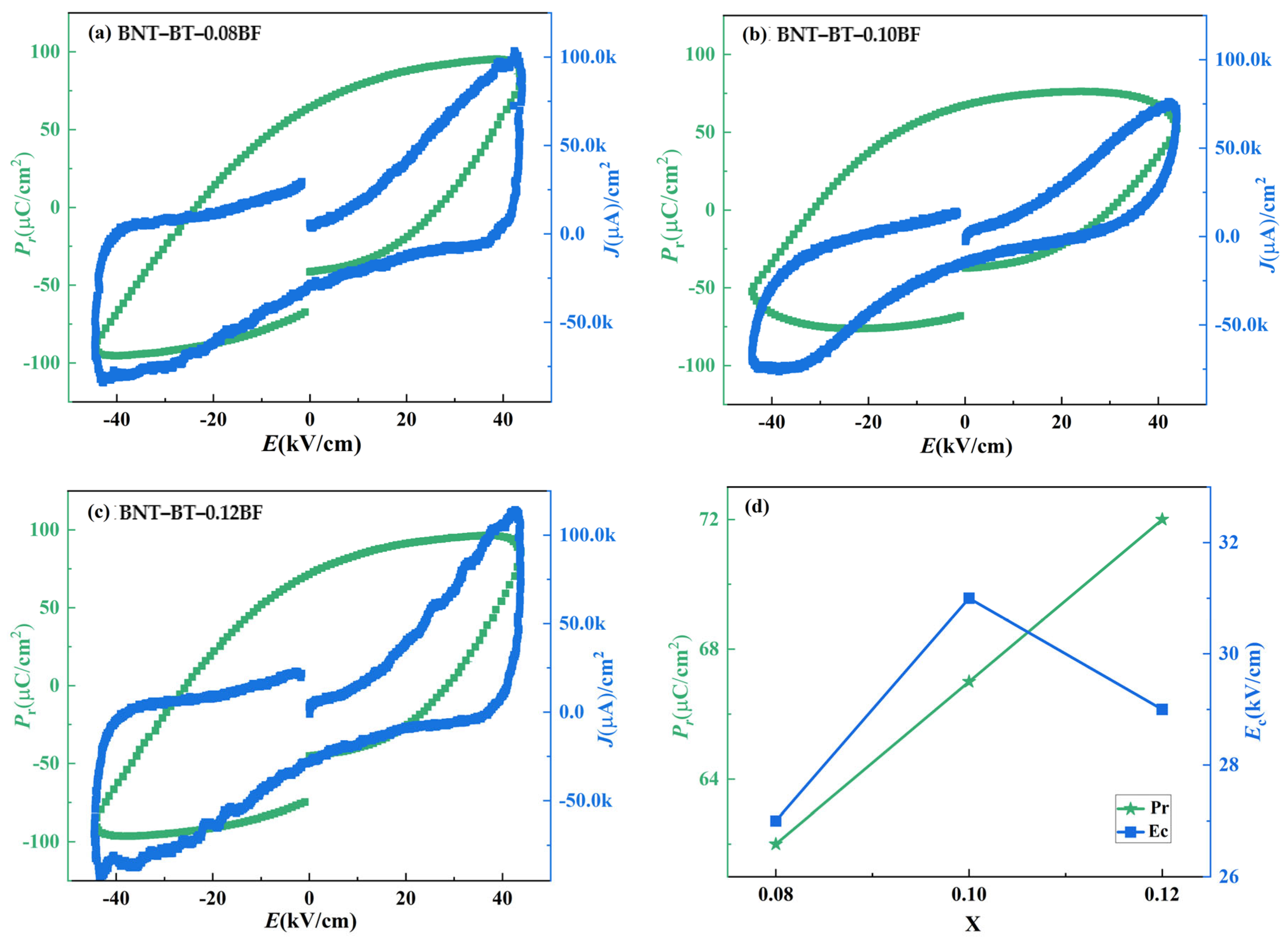

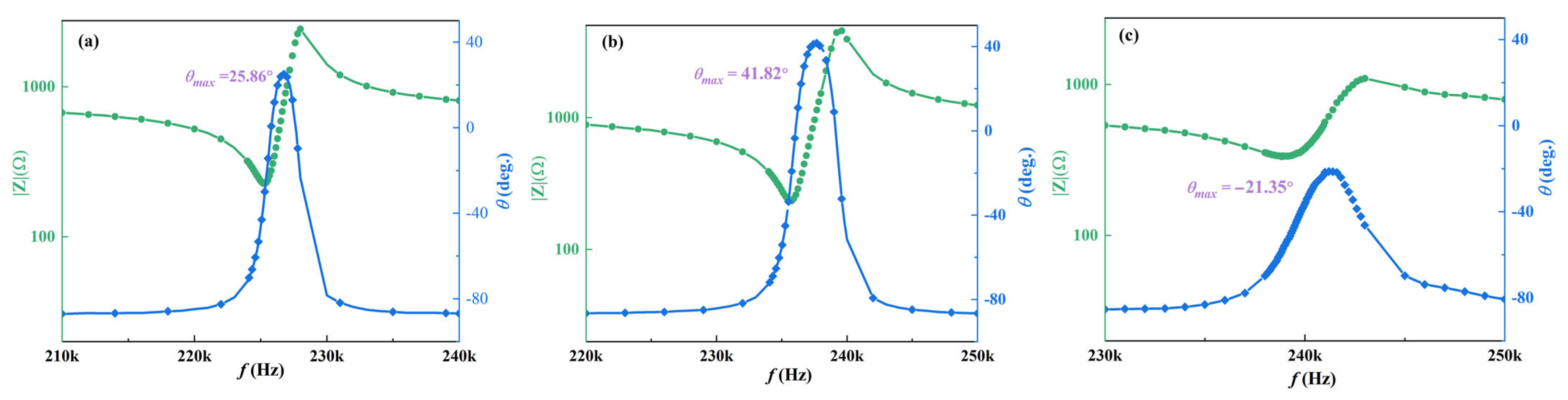

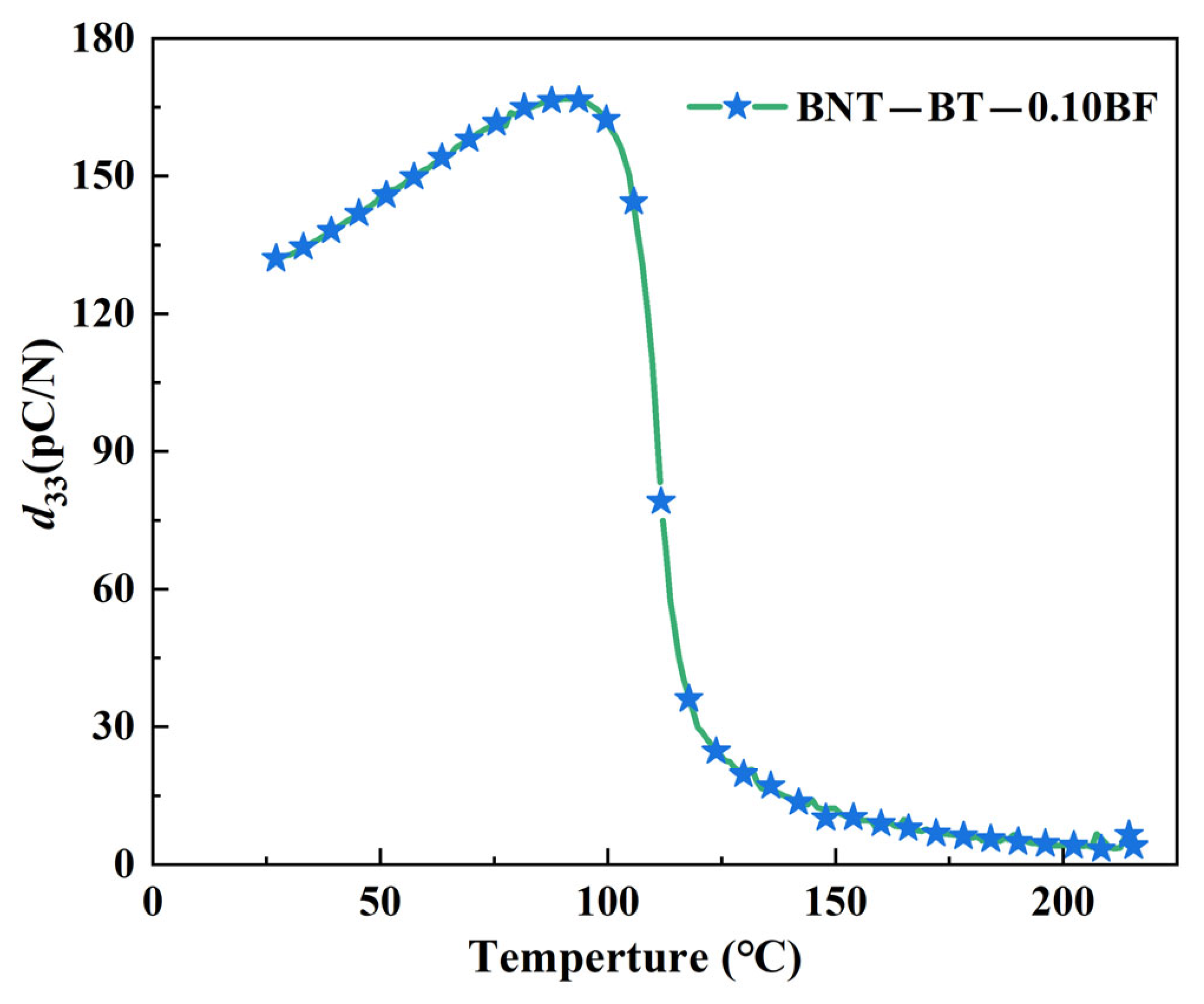

3.4. Ferroelectric and Piezoelectric Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Panda, P.K.; Sahoo, B. PZT to Lead Free Piezo Ceramics: A Review. Ferroelectrics 2015, 474, 128–143. [Google Scholar] [CrossRef]

- Zhu, R.; Fang, B.; Zhang, S.; Lu, X.; Ding, J. Composition design of PMN-PH-PT piezoelectric ceramics for high-temperature actuator applications. Mater. Res. Express 2020, 7, 046304. [Google Scholar] [CrossRef]

- Liu, Z.; Zhao, C.; Li, J.F.; Wang, K.; Wu, J.G. Large strain and temperature-insensitive piezoelectric effect in high-temperature piezoelectric ceramics. J. Mater. Chem. C 2018, 6, 456–463. [Google Scholar] [CrossRef]

- Li, F.; Lin, D.; Chen, Z.B.; Cheng, Z.X.; Wang, J.L.; Li, C.C.; Xu, Z.; Huang, Q.W.; Liao, X.Z.; Chen, L.Q.; et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 2018, 17, 349–354. [Google Scholar] [CrossRef] [PubMed]

- Safari, A.; Zhou, Q.; Zeng, Y. Advances in development of Pb-free piezoelectric materials for transducer applications. Jpn. J. Appl. Phys. 2023, 62, 0801. [Google Scholar] [CrossRef]

- Sun, Z.; Ma, C.; Liu, M.; Cui, J.; Lu, L.; Lu, J. Ultrahigh Energy Storage Performance of Lead-Free Oxide Multilayer Film Capacitors via Interface Engineering. Adv. Mater. 2017, 29, 1604427. [Google Scholar] [CrossRef]

- Lee, M.H.; Choi, H.I.; Kim, D.J.; Kim, J.S.; Song, T.K. Hard piezoelectric properties of lead-free BiFeO3–BaTiO3 ceramics. J. Am. Ceram. Soc. 2024, 107, 244–252. [Google Scholar] [CrossRef]

- Panda, P.K. Review: Environmental friendly lead-free piezoelectric materials. J. Mater. Sci. 2009, 44, 5049–5062. [Google Scholar] [CrossRef]

- Zidani, J.; Alaoui, I.H.; Zannen, M.; Birks, E.; Chchiyai, Z.; Majdoub, M.; Manoun, B.; El Marssi, M.; Lahmar, A. On the Lanthanide Effect on Functional Properties of 0.94Na0.5Bi0.5TiO3-0.06BaTiO3 Ceramic. Materials 2024, 17, 1783. [Google Scholar] [CrossRef]

- Yang, Y.L.; Jing, R.Y.; Wang, J.J.; Zhang, L.Y.; Huang, Y.Y.; Jin, L. Nonstoichiometric effect on dielectric and large-signal electromechanical properties of environmentally friendly BNT-6BT ferroelectric ceramics. Ceram. Int. 2022, 48, 14329–14337. [Google Scholar] [CrossRef]

- Srikanth, K.S.; Patel, S.; Vaish, R. Enhanced Electrocaloric Effect In Glass-Added 0.94Bi0.5Na0.5TiO3-0.06Batio3 Ceramics. J. Aust. Ceram. Soc. 2017, 53, 523–529. [Google Scholar] [CrossRef]

- Chandrasekhar, M.; Kumar, P. Synthesis and characterizations of BNT–BT and BNT–BT–KNN ceramics for actuator and energy storage applications. Ceram. Int. 2015, 41, 5574–5580. [Google Scholar] [CrossRef]

- Fan, X.; Li, P.; Du, J.; Chen, C.; Fu, P.; Hao, J.G.; Yue, Z.X.; Li, W. High-energy storage performance of (1 − x)[0.935(Bi0.5Na0.5)TiO3–0.065BaTiO3]–xBa(Zr0.3Ti0.7)O3 ceramics with wide temperature range. J. Mater. Sci. Mater. Electron. 2020, 31, 9974–9981. [Google Scholar] [CrossRef]

- Wu, L.; Xiao, D.Q.; Zhou, F.; Teng, Y.C.; Li, Y.X. Microstructure, ferroelectric, and piezoelectric properties of (1 − x − y)Bi0.5Na0.5TiO3–xBaTiO3–yBi0.5Ag0.5TiO3 lead-free ceramics. J. Alloys Compd. 2011, 509, 466–470. [Google Scholar] [CrossRef]

- Li, P.; Liu, B.H.; Shen, B.; Zhai, J.W.; Li, L.Y.; Zeng, H.R. Large strain response in Bi4Ti3O12 modified BNT-BT piezoelectric ceramics. Ceram. Int. 2017, 43, 1008–1013. [Google Scholar] [CrossRef]

- Patel, S.; Chauhan, A.; Chauhan, A.; Vaish, R. Temperature dependence scaling behavior of the dynamic hysteresis in 0.715Bi0.5Na0.5TiO3-0.065BaTiO3-0.22SrTiO3 ferroelectric ceramics. Mater. Res. Express 2015, 2, 035501. [Google Scholar] [CrossRef]

- Li, J.M.; Wang, F.F.; Qin, X.M.; Xu, M.; Shi, W.Z. Large electrostrictive strain in lead-free Bi0.5Na0.5TiO3–BaTiO3–KNbO3 ceramics. Appl. Phys. A Mater. 2011, 104, 117–122. [Google Scholar] [CrossRef]

- Wu, L.; Shen, B.; Hu, Q.R.; Chen, J.; Wang, Y.P.; Xia, Y.D.; Yin, J.; Liu, Z.G. Giant electromechanical strain response in lead-free SrTiO3-doped (Bi0.5Na0.5TiO3–BaTiO3)–LiNbO3 piezoelectric ceramics. J. Am. Ceram. Soc. 2017, 100, 4670–4679. [Google Scholar] [CrossRef]

- Zhou, X.F.; Qi, H.; Yan, Z.N.; Xue, G.L.; Luo, H.; Zhang, D. Large energy density with excellent stability in fine-grained (Bi0.5Na0.5)TiO3-based lead-free ceramics. J. Eur. Ceram. Soc. 2019, 39, 4053–4059. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Liang, G.C.; Tang, S.L.; Peng, B.L.; Zhang, Q.; Liu, L.J.; Sun, W.H. Phase-transition induced optimization of electrostrain, electrocaloric refrigeration and energy storage of LiNbO3 doped BNT-BT ceramics. Ceram. Int. 2020, 46, 1343–1351. [Google Scholar] [CrossRef]

- Ullah, S.; Pramanik, T.; Kong, J.; Zheng, G.P.; Li, Y.; Pramanick, A. Highly enhanced electrothermal properties of 001-textured Pb-free ferroelectric (Ba, Ca) (Ti, Zr, Sn)O3 for energy harvesting and solid-state cooling. J. Eur. Ceram. Soc. 2025, 1, 116830. [Google Scholar] [CrossRef]

- Catalan, G.; Scott, J.F. Physics and Applications of Bismuth Ferrite. Adv. Mater. 2009, 21, 2463–2485. [Google Scholar] [CrossRef]

- Yu, Z.; Zeng, J.; Kassiba, A.; Zheng, L.Y.; Peng, J.G.L.; Li, G.R. Enhanced electrical properties of BiFeO3–PbTiO3 based ceramics with suitable raw material. J. Mater. Sci. Mater. Electron. 2019, 30, 14500–14507. [Google Scholar] [CrossRef]

- Rojac, T.; Bencan, A.; Malic, B.; Tutuncu, G.; Jones, J.L.; Daniels, J.E.; Damjanovic, D. BiFeO3 Ceramics: Processing, Electrical, and Electromechanical Properties. J. Am. Ceram. Soc. 2014, 97, 1993–2011. [Google Scholar] [CrossRef]

- Kumar, M.M.; Srinivas, A.; Suryanarayana, S.V. Structure property relations in BiFeO3/BaTiO3 solid solutions. J. Appl. Phys. 2000, 87, 855–862. [Google Scholar] [CrossRef]

- Woodward, D.I.; Reaney, I.M.; Eitel, R.E.; Randall, C.A. Crystal and domain structure of the BiFeO3-PbTiO3 solid solution. J. Appl. Phys. 2003, 94, 3313–3318. [Google Scholar] [CrossRef]

- Leontsev, S.O.; Eitel, R.E. Dielectric and Piezoelectric Properties in Mn-Modified (1−x)BiFeO3–xBaTiO3 Ceramics. J. Am. Ceram. Soc. 2009, 92, 2957–2961. [Google Scholar] [CrossRef]

- Dorcet, V.; Marchet, P.; Trolliard, G. Structural and dielectric studies of the Na0.5Bi0.5TiO3-BiFeO3 system. J. Eur. Ceram. Soc. 2007, 27, 4371–4374. [Google Scholar] [CrossRef]

- Gao, C.; Yan, X.D.; Zheng, M.P.; Gao, X.; Zhao, K.; Li, L.; Zhu, M.K.; Hou, Y.D. Boosting transduction coefficient in BaTiO3-Based piezoceramic through phase boundary engineering. J. Eur. Ceram. Soc. 2022, 42, 2180–2187. [Google Scholar] [CrossRef]

- Sung, Y.S.; Kim, J.M.; Cho, J.H.; Song, T.K.; Kim, M.H.; Park, T.G. notRoles of lattice distortion in (1− x)(Bi0.5Na0.5) TiO3-xBaTiO3 ceramics. Appl. Phys. Lett. 2010, 96, 202901. [Google Scholar] [CrossRef]

- Zhou, C.R.; Liu, X.Y.; Li, W.Z.; Yuan, C.L. Structure and piezoelectric properties of Bi0.5Na0.5TiO3–Bi0.5K0.5TiO3–BiFeO3 lead-free piezoelectric ceramics. Mater. Chem. Phys. 2009, 114, 832–836. [Google Scholar] [CrossRef]

- Fu, P.; Xu, Z.J.; Chu, R.Q.; Li, W.; Zang, G.Z.; Hao, J.G. Piezoelectric, ferroelectric and dielectric properties of Nd2O3-doped (Bi0.5Na0.5)0.94Ba0.06TiO3 lead-free ceramics. Mater. Sci. Eng. B. 2010, 167, 161–166. [Google Scholar] [CrossRef]

- Sun, Y.; Yang, H.; Guan, S.; Xu, J.; Huang, W.; Jiang, M.; Chen, Q. The (1 − x)BiFeO3–xBaTiO3–Bi(Zn0.5Ti0.5)O3 high-temperature lead-free piezoelectric ceramics with strong piezoelectric properties. J. Mater. Sci. Mater. Electron. 2021, 32, 19713–19723. [Google Scholar] [CrossRef]

- Shi, H.L.; Zhao, M.; Zhang, D.Y.; Li, Z.M.; Zhang, M.L.; Wang, J.Y.; Jin, L.; Yan, Y.X. Effect of Sb-induced oxygen octahedral distortion on piezoelectric performance and thermal stability of Pb(In,Nb)O3-Pb(Hf,Ti)O3 ceramics. J. Mater. Sci. Technol. 2023, 161, 101–110. [Google Scholar] [CrossRef]

- Mudinepalli, V.R.; Feng, L.; Lin, W.C.; Murty, B.S. Effect of grain size on dielectric and ferroelectric properties of nanostructured Ba0.8Sr0.2TiO3 ceramics. J. Adv. Ceram. 2015, 4, 46–53. [Google Scholar] [CrossRef]

- Wei, X.Y.; Feng, Y.J.; Yao, X. Dielectric relaxation behavior in barium stannate titanate ferroelectric ceramics with diffused phase transition. Appl. Phys. Lett. 2003, 83, 2031–2033. [Google Scholar]

- Zhou, C.R.; Liu, X.Y.; Li, W.Z.; Yuan, C.L. Dielectric relaxor behavior of A-site complex ferroelectrics of Bi0.5Na0.5TiO3–Bi0.5K0.5TiO3–BiFeO3. Solid State Commun. 2009, 149, 481–485. [Google Scholar] [CrossRef]

- Tou, T.; Hamaguti, Y.; Maida, Y.; Yamamori, H.; Takahashi, K.; Terashima, Y. Properties of (Bi0.5Na0.5)TiO3–BaTiO3–(Bi0.5Na0.5)(Mn1/3Nb2/3)O3 Lead-Free Piezoelectric Ceramics and Its Application to Ultrasonic Cleaner. Jpn. J. Appl. Phys. 2009, 48, 07GM03. [Google Scholar] [CrossRef]

- Bai, W.F.; Li, P.; Li, L.Y.; Zhang, J.J.; Shen, B.; Zhai, J.W. Structure evolution and large strain response in BNT–BT lead-free piezoceramics modified with Bi(Ni0.5Ti0.5)O3. J. Alloys Compd. 2015, 649, 772–781. [Google Scholar] [CrossRef]

- Zhang, S.T.; Yang, B.; Cao, W.W. The temperature-dependent electrical properties of Bi0.5Na0.5TiO3–BaTiO3–Bi0.5K0.5TiO3 near the morphotropic phase boundary. Acta Mater. 2012, 60, 469–475. [Google Scholar] [CrossRef]

- Wannasut, P.; Promsawat, M.; Watcharapasorn, A.; Eitssayeam, S.; Ananta, S.; Khamman, O. Correlation between phase, microstructure and electrical properties of Ba0.7Sr0.3TiO3-modified Bi0.5Na0.5TiO3-0.06BaTiO3 lead free ceramics. J. Asian Ceram. Soc. 2024, 12, 117–128. [Google Scholar] [CrossRef]

- Rianyoi, R.; Potong, R.; Ngamjarurojana, A.; Chaipanich, A. Mechanical, dielectric, ferroelectric and piezoelectric properties of 0–3 connectivity lead-free piezoelectric ceramic 0.94Bi0.5Na0.5TiO3–0.06BaTiO3/Portland cement composites. J. Mater. Sci. Mater. Electron. 2021, 32, 4695–4704. [Google Scholar] [CrossRef]

| Composition | d33 (pC/N) | Qm | εr (1kHz) | g33 (10−3 Vm/N) | kp | Td (°C) | Ref. |

|---|---|---|---|---|---|---|---|

| BNT–BT–0.08BF | 124 | 111 | 542 | 25.84 | 0.18 | 101 | This work |

| BNT–BT–0.10BF | 132 | 124 | 571 | 26.11 | 0.20 | 105 | This work |

| BNT–BT–0.12BF | 111 | 55 | 558 | 22.47 | 0.20 | 97 | This work |

| 0.82BNT–0.15BT–0.03BNMN | 110 | 500 | 520 | - | - | - | [38] |

| BNT–BT–0.025BNiT | 160 | - | 1000 | - | - | 39 | [39] |

| 0.884BNT–0.036BT–0.08BKT | 116 | - | 2300 | - | 0.27 | 121 | [40] |

| BNT–BT–0.04BST | 277 | - | 1081 | 15.79 | - | 130 | [41] |

| BNT–BT/PC | 42 | - | 280 | 17.99 | [42] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, K.; Hou, E.; Qu, Y.; Mu, Y.; Wang, J. Enhanced Electrical Property and Thermal Stability in Lead-Free BNT–BT–BF Ceramics. Ceramics 2025, 8, 70. https://doi.org/10.3390/ceramics8020070

Zhou K, Hou E, Qu Y, Mu Y, Wang J. Enhanced Electrical Property and Thermal Stability in Lead-Free BNT–BT–BF Ceramics. Ceramics. 2025; 8(2):70. https://doi.org/10.3390/ceramics8020070

Chicago/Turabian StyleZhou, Kangle, Enxiang Hou, Yanfeng Qu, Yan Mu, and Junjun Wang. 2025. "Enhanced Electrical Property and Thermal Stability in Lead-Free BNT–BT–BF Ceramics" Ceramics 8, no. 2: 70. https://doi.org/10.3390/ceramics8020070

APA StyleZhou, K., Hou, E., Qu, Y., Mu, Y., & Wang, J. (2025). Enhanced Electrical Property and Thermal Stability in Lead-Free BNT–BT–BF Ceramics. Ceramics, 8(2), 70. https://doi.org/10.3390/ceramics8020070