Synergistic Effects of Furfurylated Natural Fibers and Nanoclays on the Properties of Fiber–Cement Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Simulation of Alkaline Fiber Degradation

2.3. Fabrication of Fiber–Cement Composites

2.4. Characterization of Fiber–Cement Composites

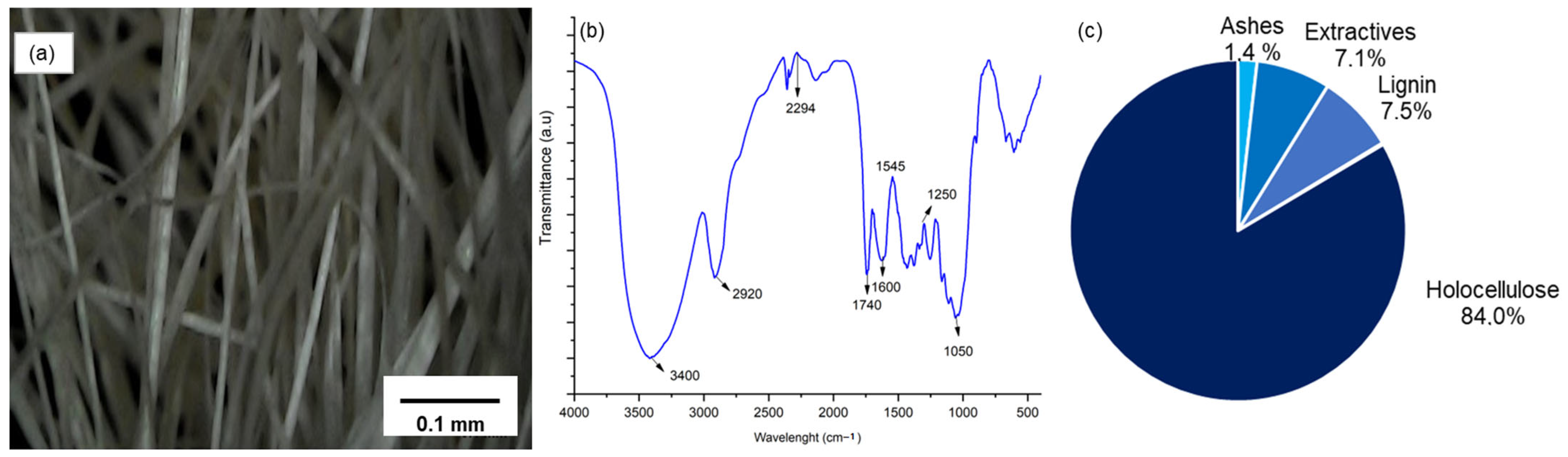

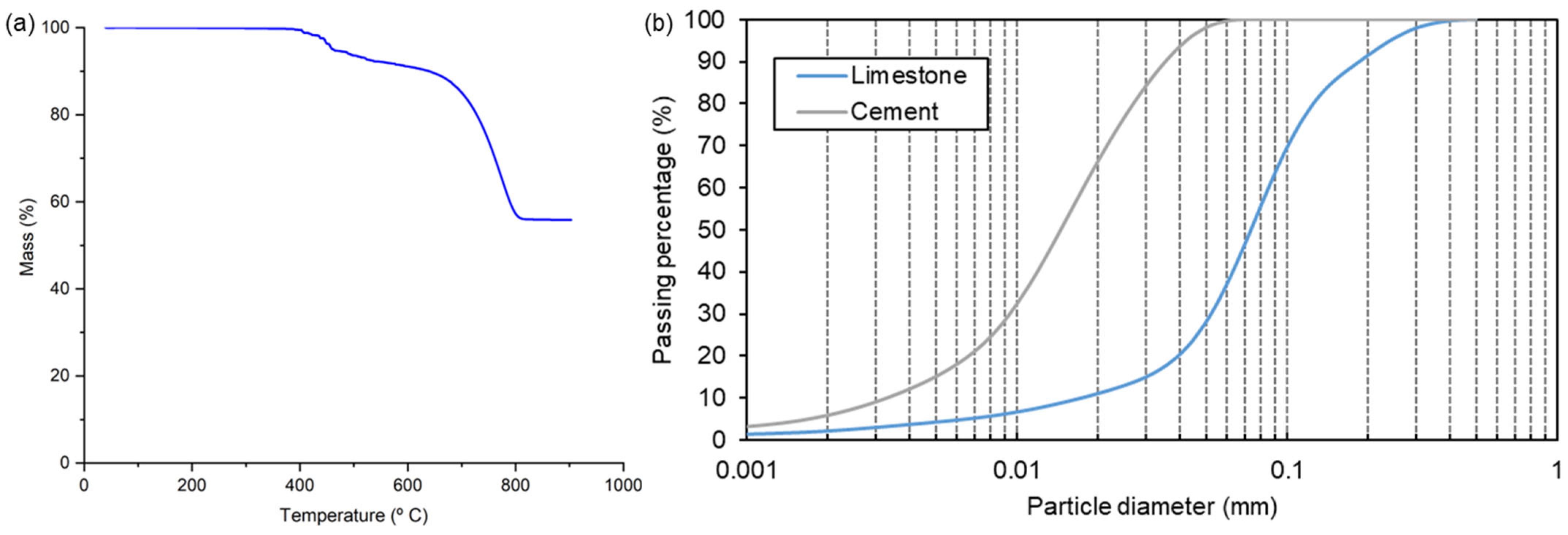

2.5. Characteristics of the Raw Materials

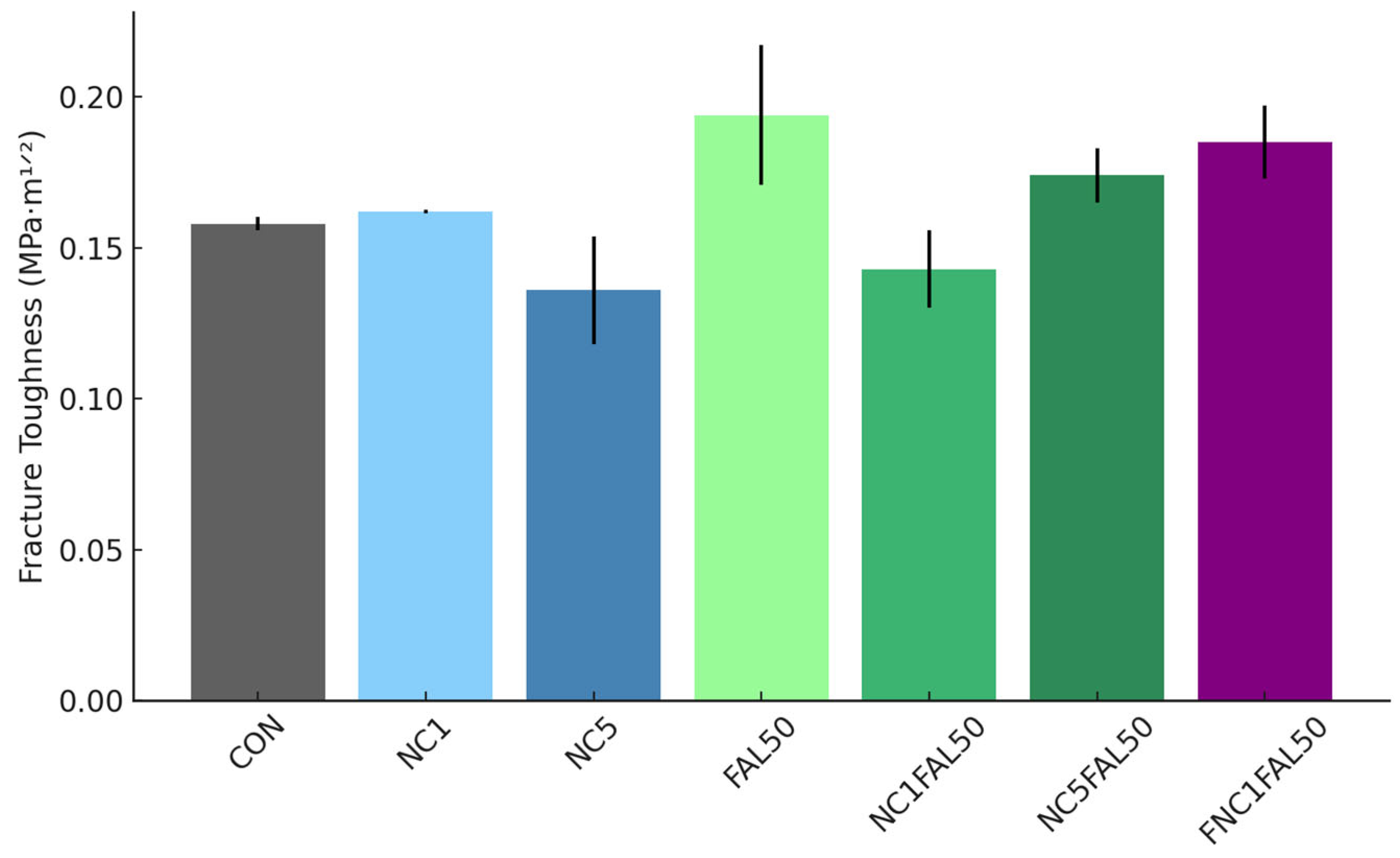

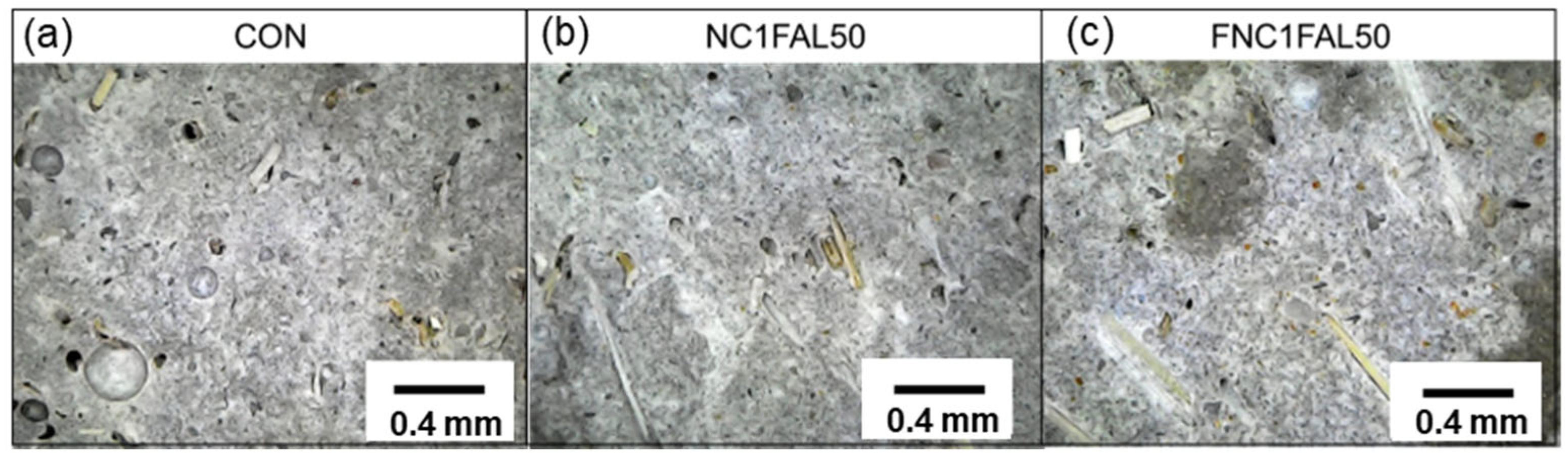

3. Results and Discussion

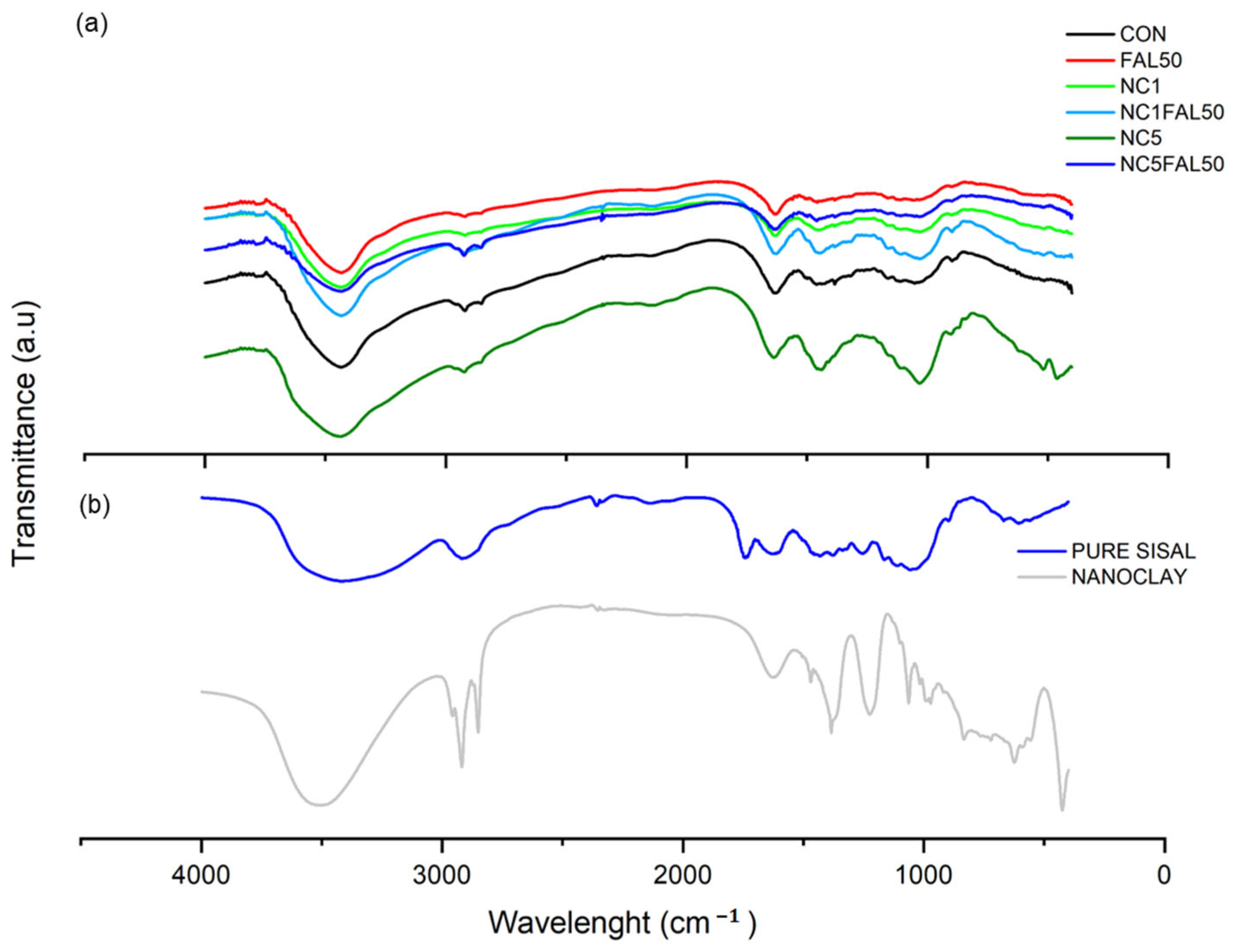

3.1. Physicochemical Evaluation of the Treated Sisal Fibers

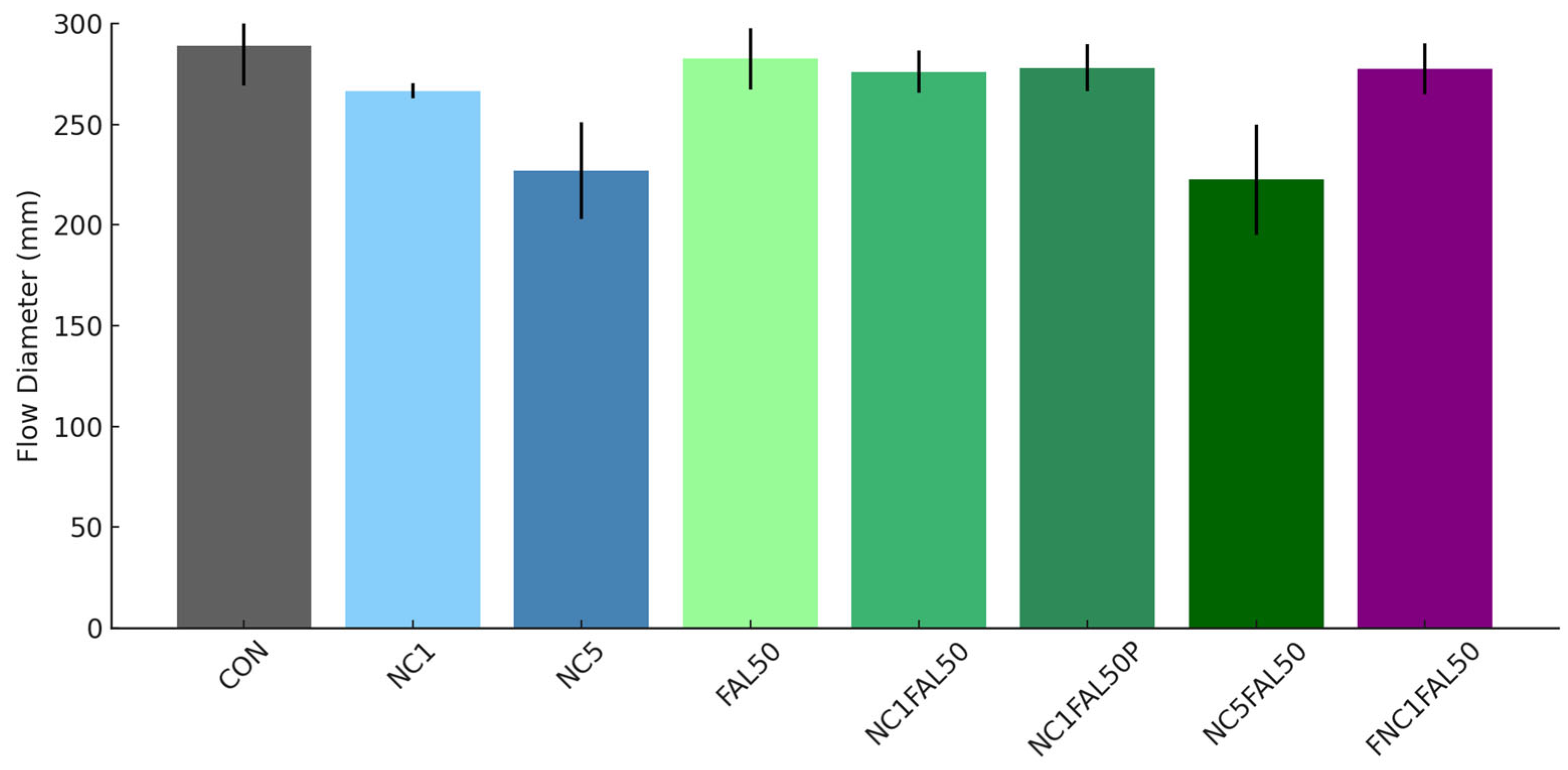

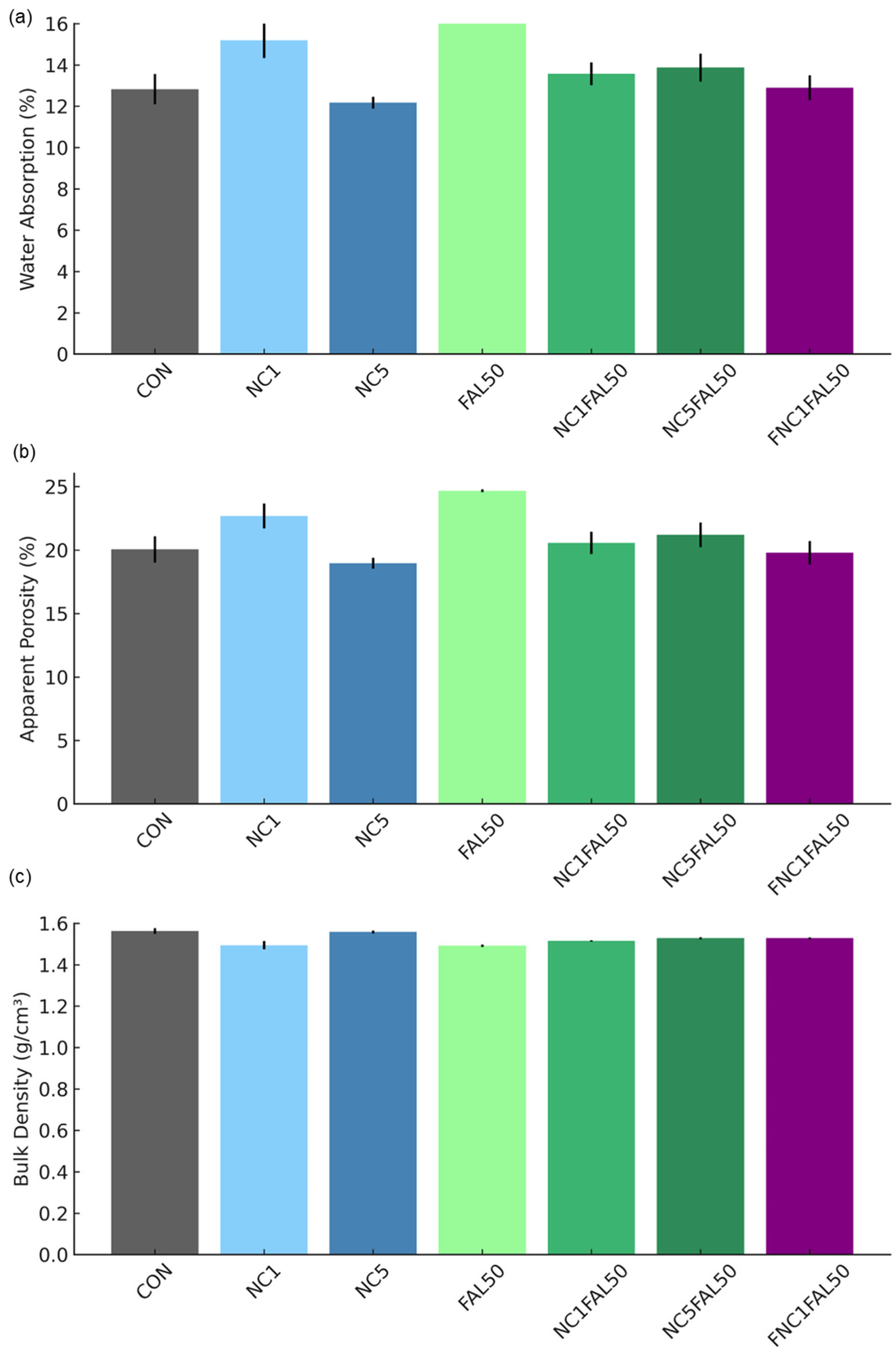

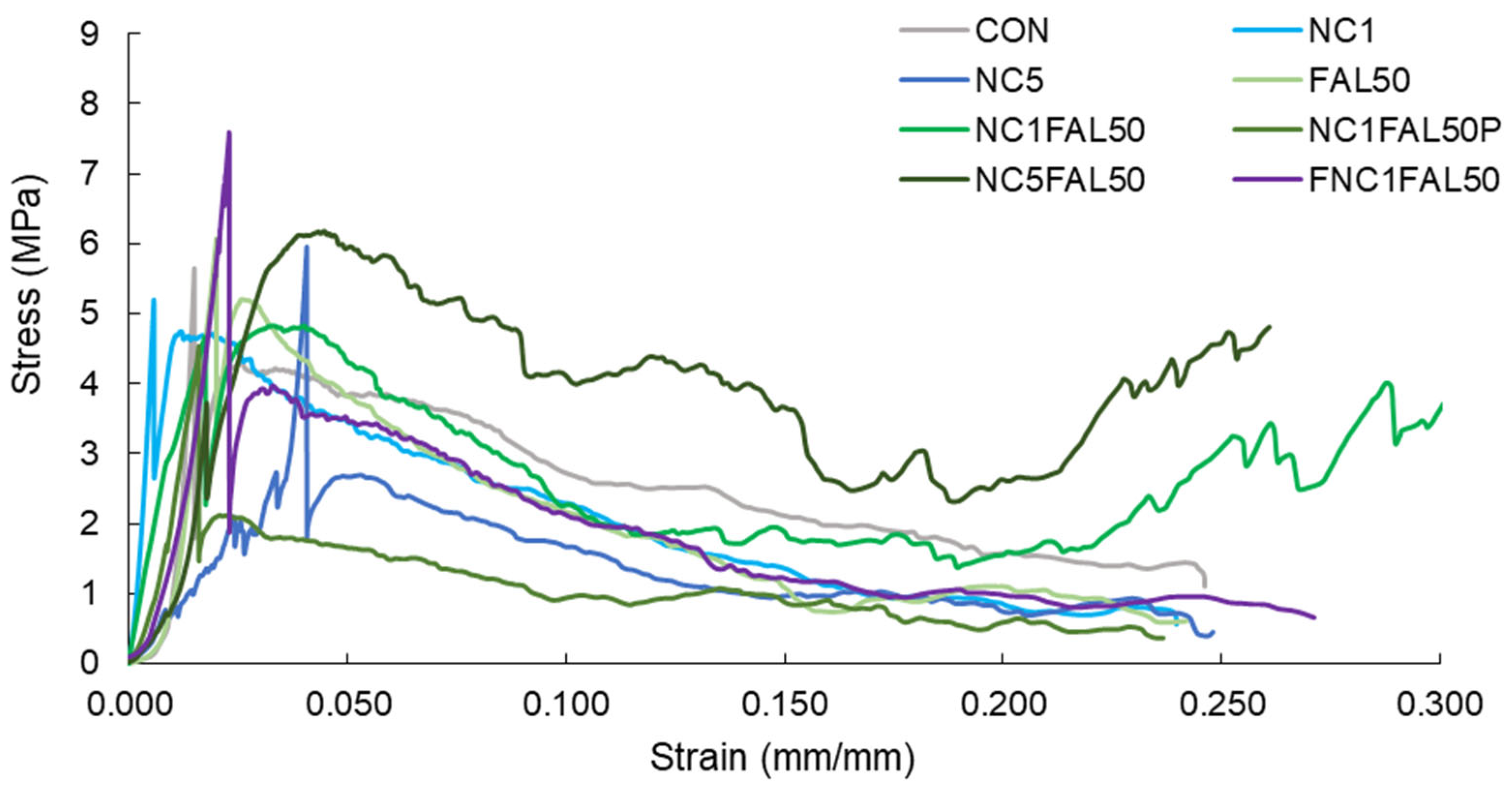

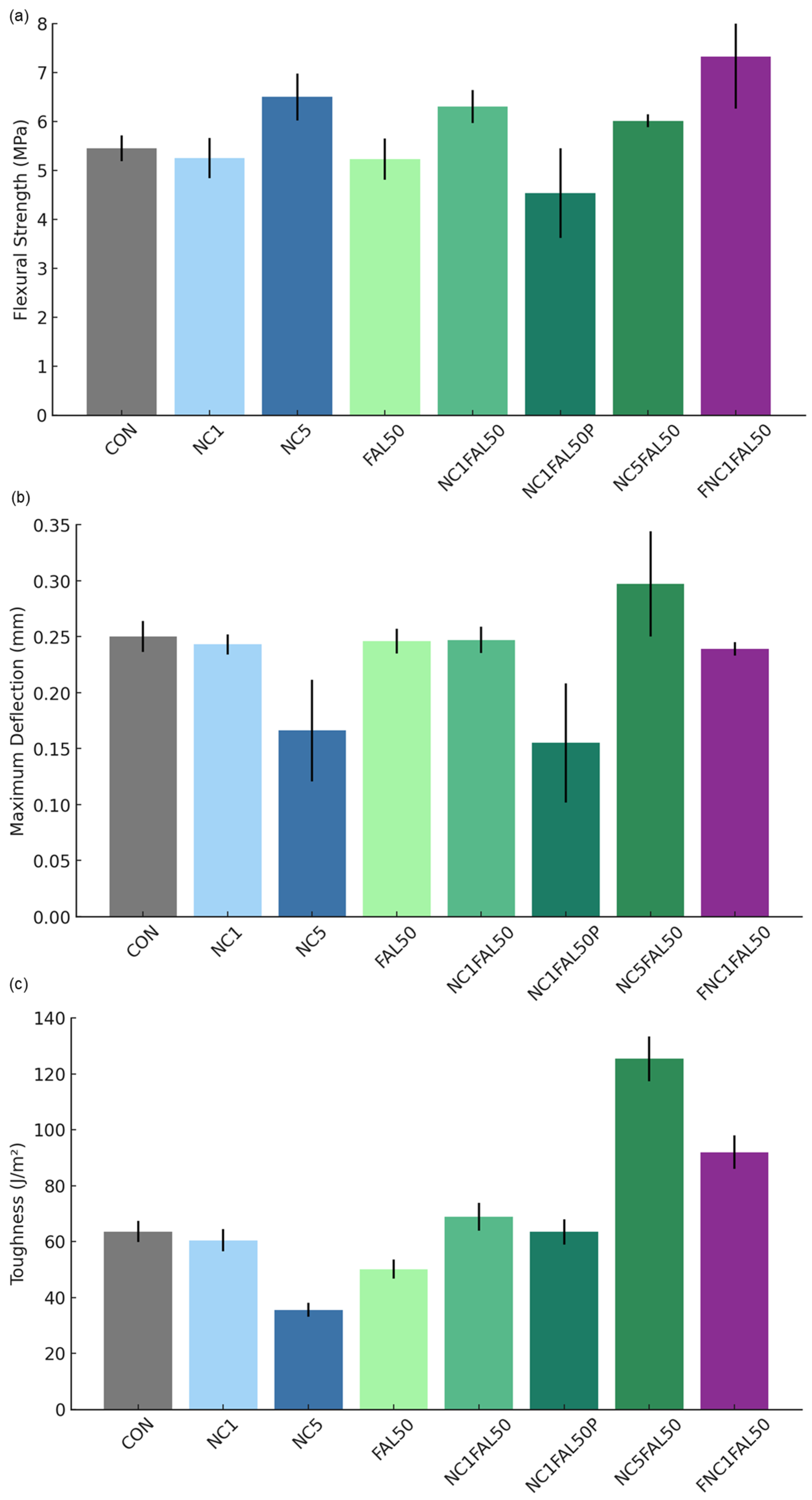

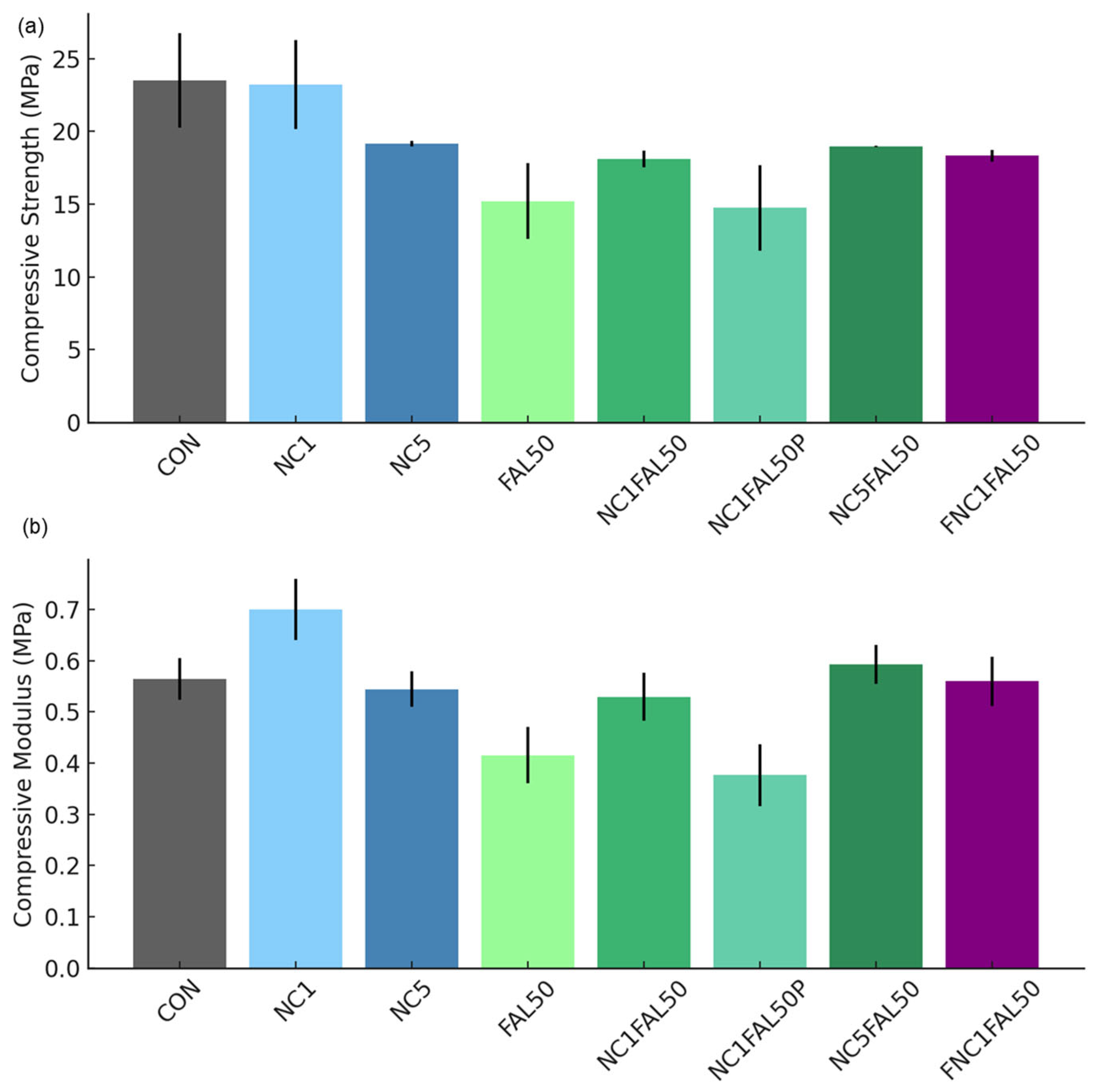

3.2. Characteristics of the Fiber–Cement Composites

4. Conclusions

- (i)

- optimization of the furfurylation process for other lignocellulosic fibers;

- (ii)

- evaluation of long-term durability;

- (iii)

- exploration of additional pozzolanic nanomaterials to enhance interfacial compatibility;

- (iv)

- evaluation of workability retention over time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Munaro, M.R.; Tavares, S.F.; Bragança, L. Towards Circular and More Sustainable Buildings: A Systematic Literature Review on the Circular Economy in the Built Environment. J. Clean. Prod. 2020, 260, 121–134. [Google Scholar] [CrossRef]

- Chong, B.W.; Othman, R.; Ramadhansyah, P.J.; Doh, S.I.; Li, X. Properties of Concrete with Eggshell Powder: A Review. Phys. Chem. Earth 2020, 120, 102951. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; García-hortal, J.A.; Filho, R.D. The Hornification of Vegetable Fibers to Improve the Durability of Cement Mortar Composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Jaber, H.A.; Mahdi, R.S.; Hassan, A.K. Influence of Eggshell Powder on the Portland Cement Mortar Properties. Mater. Today Proc. 2020, 20, 391–396. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic Fiber Reinforced Cement-Based Composites: A Review of Recent Research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Insaurriaga, G.L.; Gomes, C.C.; Ribeiro, F.V.; Calegaro, G.L.; Silveira, T.A.; Cruz, L.F.; Cruz, J.A.; Amico, S.C.; Delucis, R.A. Effect of Hybridization of Carbon Fibers on Mechanical Properties of Cellulose Fiber–Cement Composites: A Response Surface Methodology Study. C 2024, 10, 41. [Google Scholar] [CrossRef]

- Hamdaoui, O.; Limam, O.; Ibos, L.; Mazioud, A. Thermal and Mechanical Properties of Hardened Cement Paste Reinforced with Posidonia-Oceanica Natural Fibers. Constr. Build. Mater. 2021, 269, 121–339. [Google Scholar] [CrossRef]

- Santana, H.A.; Amorim, N.S.; Ribeiro, D.V.; Cilla, M.S.; Dias, C.M.R. Vegetable Fibers Behavior in Geopolymers and Alkali-Activated Cement Based Matrices: A Review. J. Build. Eng. 2021, 44, 103291. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A Review of Recent Developments in Natural Fibre Composites and Their Mechanical Performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- da Silva, E.J.; Marques, M.L.; Velasco, F.G.; Fornari, C., Jr.; Luzardo, F.M.; Tashima, M.M. A New Treatment for Coconut Fibers to Improve the Properties of Cement-Based Composites—Combined Effect of Natural Latex/Pozzolanic Materials. Sustain. Mater. Technol. 2017, 12, 44–51. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation Mechanisms of Natural Fiber in the Matrix of Cement Composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Characteristics of Hemp Fabric Reinforced Nanoclay-Cement Nanocomposites. Cem. Concr. Compos. 2014, 50, 27–35. [Google Scholar] [CrossRef]

- von Ameln Luzzardi, F.J.; Bosel Wally, G.; Costa Magalhães, F.; Behenck Aramburu, A.; Alves da Silveira, T.; de Avila Delucis, R. Lightweight Concrete Containing Rigid Polyurethane Foam and Three Different Ashes: Assessing Mechanical and Physical Properties. Aust. J. Civ. Eng. 2025, 1–12. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.; Low, I.M. Microstructures and Mechanical Properties of Hemp Fabric Reinforced Organoclay-Cement Nanocomposites. Constr. Build. Mater. 2013, 49, 298–307. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Sisal Fiber-Reinforced Cement Composite with Portland Cement Substitution by a Combination of Metakaolin and Nanoclay. J. Mater. Sci. 2014, 49, 7604–7619. [Google Scholar] [CrossRef]

- Delucis, R.d.A.; Almeida, J.H.S., Jr. Influence of Chemical Treatments on the Thermal Properties of Natural Fiber-Reinforced Hybrid Composites (NFRHC). In Natural Fiber-Reinforced Composites; Wiley: Hoboken, NJ, USA, 2022; pp. 291–307. [Google Scholar]

- Ajouguim, S.; Page, J.; Djelal, C.; Saâdi, L. Effect of Treated Alfa Fibers on Hydration Kinetics, Mechanical, and Adhesion Properties of Fiber Cement Composite. J. Build. Eng. 2023, 71, 106558. [Google Scholar] [CrossRef]

- Biskri, Y.; Babouri, L.; Boukhelf, F.; Charradi, K.; Annaba, K.; El Mendili, Y. On the Physical-Mechanical Behavior of Fiber Cement Composite: Effect of Chemical Treatment of Sisal Fibers. J. Build. Eng. 2025, 101, 111978. [Google Scholar] [CrossRef]

- Fonseca, C.S.; Scatolino, M.V.; Silva, L.E.; Martins, M.A.; Guimarães Júnior, M.; Tonoli, G.H.D. Valorization of Jute Biomass: Performance of Fiber–Cement Composites Extruded with Hybrid Reinforcement (Fibers and Nanofibrils). Waste Biomass Valoriz. 2021, 12, 5743–5761. [Google Scholar] [CrossRef]

- Aramburu, A.B.; Rossetto, H.L.; Magalhães, W.L.E.; Trindade, G.H.; de Avila Delucis, R. Cement Matrix Reinforced with Microfibrillated Cellulose Treated with Furfuryl Alcohol. Cellulose 2023, 30, 10297–10312. [Google Scholar] [CrossRef]

- Mejia-Ballesteros, J.E.; Rodier, L.; Filomeno, R.; Savastano, H.; Fiorelli, J.; Rojas, M.F. Influence of the Fiber Treatment and Matrix Modification on the Durability of Eucalyptus Fiber Reinforced Composites. Cem. Concr. Compos. 2021, 124, 104280. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Thermal and Mechanical Properties of NaOH Treated Hemp Fabric and Calcined Nanoclay-Reinforced Cement Nanocomposites. Mater. Des. 2015, 80, 70–81. [Google Scholar] [CrossRef]

- Thepruttana, S.; Patthanavarit, J.; Hankoy, M.; Kitiwan, M.; Keawprak, N.; Tunthawiroon, P. Enhancement of Flexural Strength in Fiber–Cement Composites through Modification of Sisal Fiber with Natural Rubber Latex and Expanded Perlite. Buildings 2024, 14, 1067. [Google Scholar] [CrossRef]

- Tonoli, G.H.D.; Rodrigues Filho, U.P.; Savastano, H.; Bras, J.; Belgacem, M.N.; Rocco Lahr, F.A. Cellulose Modified Fibres in Cement Based Composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2046–2053. [Google Scholar] [CrossRef]

- ASTM C187; Standard Test Method for Amount of Water Required for Normal Consistency of Hydraulic Cement Paste. ASTM International: Washington, DC, USA, 2016; pp. 1–3. [CrossRef]

- ASTM C191; Standart Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle. ASTM International: Washington, DC, USA, 2021. [CrossRef]

- ASTM C230; Standard Specification for Flow Table for Use in Tests of Hydraulic Cement. ASTM International: Washington, DC, USA, 2020. [CrossRef]

- ASTM C948; Standart Test Method for Dry and Wet Bulk Density, Water Absorption, and Apparent Porosity of Thin Sections of Glass-Fiber Reinforced Concrete. ASTM International: Washington, DC, USA, 2023. [CrossRef]

- Gutiérrez, M.A.U.; da Silveira, T.A.; Ribeiro, F.V.; Aramburu, A.B.; Gomes, C.C.; Gonçalves, M.R.F.; Delucis, R.A. Thermally Treated Granite Slurry Waste as a Mitigating Agent for Sisal Fiber Mineralization in Fiber-cement Composites. Int. J. Appl. Ceram. Technol. 2025, e15157. [Google Scholar] [CrossRef]

- ASTM C348; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: Washington, DC, USA, 2014; pp. 1–6. [CrossRef]

- ISO 12135:2021; Metallic Materials—Unified Method of Test for the Determination of Quasistatic Fracture Toughness. International Organization for Standardization: Geneva, Switzerland, 2021; p. 100.

- Ghafari, S.; Nejad Moghadas, F. R-Curve Behavior and Crack Propagation Properties of Asphalt Concrete at Low Temperatures. J. Civ. Eng. Manag. 2015, 21, 559–570. [Google Scholar] [CrossRef]

- Luo, R.; Liu, H.; Duan, P.; Ye, J.; Chen, W.; Zhang, Z.; Wang, A. Sulfate Resistance and Microstructure of Metakaolin Geopolymer Reinforced by Cellulose Nanofiber and Wollastonite. J. Build. Eng. 2023, 64, 105580. [Google Scholar] [CrossRef]

- Coldebella, R.; Gentil, M.; Berger, C.; Costa, H.W.D.; Pedrazzi, C.; Labidi, J.; Delucis, R.A.; Missio, A.L. Nanofibrillated Cellulose-Based Aerogels Functionalized with Tajuva (Maclura Tinctoria) Heartwood Extract. Polymers 2021, 13, 908. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A Comprehensive Review of Natural Fibers and Their Composites: An Eco-Friendly Alternative to Conventional Materials. Results Eng. 2023, 19, 101–271. [Google Scholar] [CrossRef]

- Tawfik, A.; Abd-El-Razik, R.A. Design, Fabrication, and Characterization of Distinguished Lightweight and Sustainable Building Materials. J. Build. Eng. 2022, 46, 103–712. [Google Scholar] [CrossRef]

- Motaung, T.E.; Mngomezulu, M.E.; Hato, M.J. Effects of Alkali Treatment on the Poly(Furfuryl) Alcohol—Flax Fibre Composites. J. Thermoplast. Compos. Mater. 2016, 48–60. [Google Scholar] [CrossRef]

- Pranger, L.A.; Nunnery, G.A.; Tannenbaum, R. Mechanism of the Nanoparticle-Catalyzed Polymerization of Furfuryl Alcohol and the Thermal and Mechanical Properties of the Resulting Nanocomposites. Compos. Part B 2012, 43, 1139–1146. [Google Scholar] [CrossRef]

- Motaung, T.E.; Linganiso, L.Z.; Kumar, R.; Anandjiwala, R.D. Agave and Sisal Fibre-Reinforced Polyfurfuryl Alcohol Composites. J. Thermoplast. Compos. Mater. 2017, 30, 1323–1343. [Google Scholar] [CrossRef]

- Jia, Y.; Fiedler, B. Influence of Furfuryl Alcohol Fiber Pre-Treatment on the Moisture Absorption and Mechanical Properties of Flax Fiber Composites. Fibers 2018, 6, 59. [Google Scholar] [CrossRef]

- Saw, S.; Sarkhel, G.; Arup, C. Surface Modification of Coir Fibre Involving Oxidation of Lignins Followed by Reaction with Furfuryl Alcohol: Characterization and Stability. Appl. Surf. Sci. 2011, 257, 3763–3769. [Google Scholar] [CrossRef]

- Bekele, A.E.; Lemu, H.G.; Jiru, M.G. Experimental Study of Physical, Chemical and Mechanical Properties of Enset and Sisal Fibers. Polym. Test. 2022, 106, 107453. [Google Scholar] [CrossRef]

- Hisseine, O.A.; Omran, A.F.; Tagnit-Hamou, A. Influence of Cellulose Filaments on Cement Paste and Concrete. J. Mater. Civ. Eng. 2018, 30, 04018109. [Google Scholar] [CrossRef]

- Kunchariyakun, K.; Sinyoung, S.; Kajitvichyanukul, P. Comparative Microstructures and Mechanical Properties of Mortar Incorporating Wood Fiber Waste from Various Curing Conditions. Case Stud. Constr. Mater. 2022, 16, e00855. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Panesar, D.K.; Sain, M. Properties of Nanofibre Reinforced Cement Composites. Constr. Build. Mater. 2014, 63, 119–124. [Google Scholar] [CrossRef]

- Jiao, L.; Su, M.; Chen, L.; Wang, Y.; Zhu, H.; Dai, H. Natural Cellulose Nanofibers As Sustainable Enhancers in Construction Cement. PLoS ONE 2016, 11, e0168422. [Google Scholar] [CrossRef]

- Morton, J.H.; Cooke, T.; Akers, S.A.S. Performance of Slash Pine Fibers in Fiber Cement Products. Constr. Build. Mater. 2010, 24, 165–170. [Google Scholar] [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Lignocellulosic Fiber Cement Compatibility: A State of the Art Review Lignocellulosic Fiber Cement Compatibility: A State of the Art Review. J. Nat. Fibers 2022, 19, 5409–5434. [Google Scholar] [CrossRef]

- Claramunt, J.; Fernández-carrasco, L.J.; Ventura, H.; Ardanuy, M. Natural Fiber Nonwoven Reinforced Cement Composites as Sustainable Materials for Building Envelopes. Constr. Build. Mater. 2016, 115, 230–239. [Google Scholar] [CrossRef]

- Lima, P.R.L.; Santos, H.M.; Camilloto, G.P.; Cruz, R.S. Effect of Surface Biopolymeric Treatment on Sisal Fiber Properties and Fiber-Cement Bond. J. Eng. Fiber. Fabr. 2017, 12, 59–71. [Google Scholar] [CrossRef]

- Pereira, M.V.; Fujiyama, R.; Darwish, F.; Alves, G.T. On the Strengthening of Cement Mortar by Natural Fibers. Mater. Res. 2015, 18, 177–183. [Google Scholar] [CrossRef]

- Filho, J.D.A.M.; Silva, F.D.A.; Toledo Filho, R.D. Degradation Kinetics and Aging Mechanisms on Sisal Fiber Cement Composite Systems. Cem. Concr. Compos. 2013, 40, 30–39. [Google Scholar] [CrossRef]

- Krishna, N.K.; Prasanth, M.; Gowtham, R.; Karthic, S.; Mini, K.M. ScienceDirect Enhancement of Properties of Concrete Using Natural Fibers. Mater. Today Proc. 2018, 5, 23816–23823. [Google Scholar] [CrossRef]

- Choi, H.; Choi, Y.C. Setting Characteristics of Natural Cellulose Fiber Reinforced Cement Composite. Constr. Build. Mater. 2021, 271, 121910. [Google Scholar] [CrossRef]

| Nomenclature | Cement (wt.%) | Limestone (wt.%) | Sisal (wt.%) | Water (wt.%) | Nanoclay (wt.%) | FAL (wt.%) | MA (wt.%) |

|---|---|---|---|---|---|---|---|

| CON | 62.91 | 10.43 | 1.5 | 25.16 | 0.0 | 0.0 | 0.0 |

| NC1 | 62.52 | 10.37 | 1.49 | 25.01 | 0.63 | 0.0 | 0.0 |

| NC5 | 60.99 | 10.11 | 1.45 | 24.4 | 3.05 | 0.0 | 0.0 |

| FAL50 | 62.42 | 10.35 | 1.49 | 24.97 | 0.0 | 0.74 | 0.04 |

| NC1FAL50 | 62.03 | 10.28 | 1.48 | 24.81 | 0.62 | 0.74 | 0.04 |

| NC1FAL50P | 62.03 | 10.28 | 1.48 | 24.81 | 0.62 | 0.74 | 0.04 |

| NC5FAL50 | 60.53 | 10.04 | 1.44 | 24.21 | 3.03 | 0.72 | 0.04 |

| FNC1FAL50 | 62.03 | 10.28 | 1.48 | 24.81 | 0.62 | 0.74 | 0.04 |

| Density (g/cm3) | Main Compounds | Size | Function in Composite | |

|---|---|---|---|---|

| Cement | ~3.15 | Ca, Si, Al and Fe | D50 ≈ 13 µm | Main binder and source of C–S–H |

| Limestone | ~2.70 | CaCO3 with high Ca content | D50 ≈ 25 µm | Filler that reduces cement use and overall cost |

| Hydrophilic nanoclay | ≤2.60 | Montmorillonite | ≤25 µm | Pozzolanic additive |

| Functionalized nanoclay | ≤2.60 | Montmorillonite + OA/APTES | ≤20 µm | Pozzolanic additive |

| Untreated sisal fiber | ~1.45 | Cellulose, hemicelluloses, and lignin | 2 cm length and 100–300 µm diameter | Reinforcement |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

da Silveira, T.A.; Ribeiro, F.V.; Gomes, C.C.; Aramburu, A.B.; Amico, S.C.; Missio, A.L.; Delucis, R.d.A. Synergistic Effects of Furfurylated Natural Fibers and Nanoclays on the Properties of Fiber–Cement Composites. Ceramics 2025, 8, 68. https://doi.org/10.3390/ceramics8020068

da Silveira TA, Ribeiro FV, Gomes CC, Aramburu AB, Amico SC, Missio AL, Delucis RdA. Synergistic Effects of Furfurylated Natural Fibers and Nanoclays on the Properties of Fiber–Cement Composites. Ceramics. 2025; 8(2):68. https://doi.org/10.3390/ceramics8020068

Chicago/Turabian Styleda Silveira, Thamires Alves, Felipe Vahl Ribeiro, Cristian Conceição Gomes, Arthur Behenck Aramburu, Sandro Campos Amico, André Luiz Missio, and Rafael de Avila Delucis. 2025. "Synergistic Effects of Furfurylated Natural Fibers and Nanoclays on the Properties of Fiber–Cement Composites" Ceramics 8, no. 2: 68. https://doi.org/10.3390/ceramics8020068

APA Styleda Silveira, T. A., Ribeiro, F. V., Gomes, C. C., Aramburu, A. B., Amico, S. C., Missio, A. L., & Delucis, R. d. A. (2025). Synergistic Effects of Furfurylated Natural Fibers and Nanoclays on the Properties of Fiber–Cement Composites. Ceramics, 8(2), 68. https://doi.org/10.3390/ceramics8020068