The Effect of Adding Banana Fibers on the Physical and Mechanical Properties of Mortar for Paving Block Applications

Abstract

1. Introduction

2. Materials and Methods

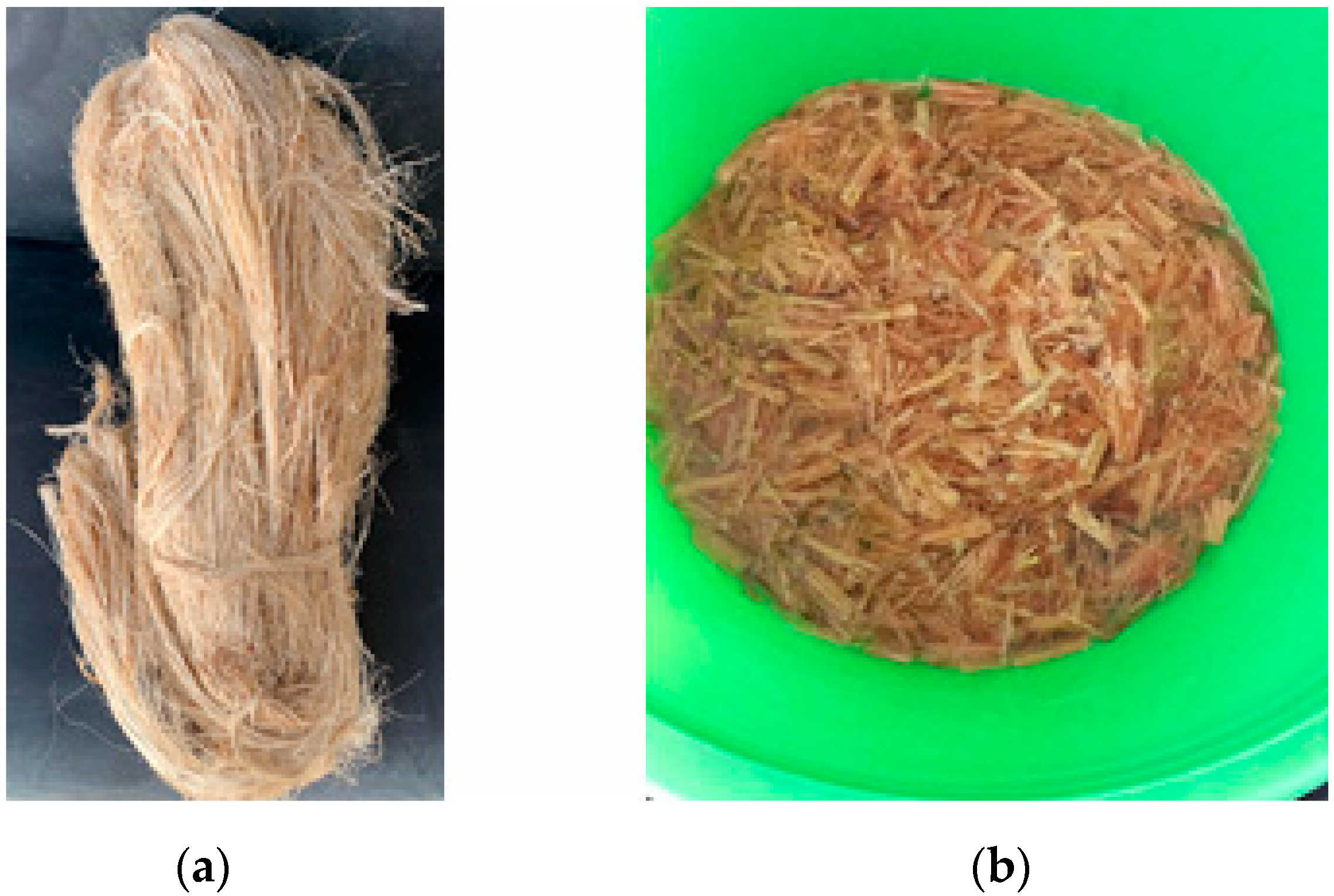

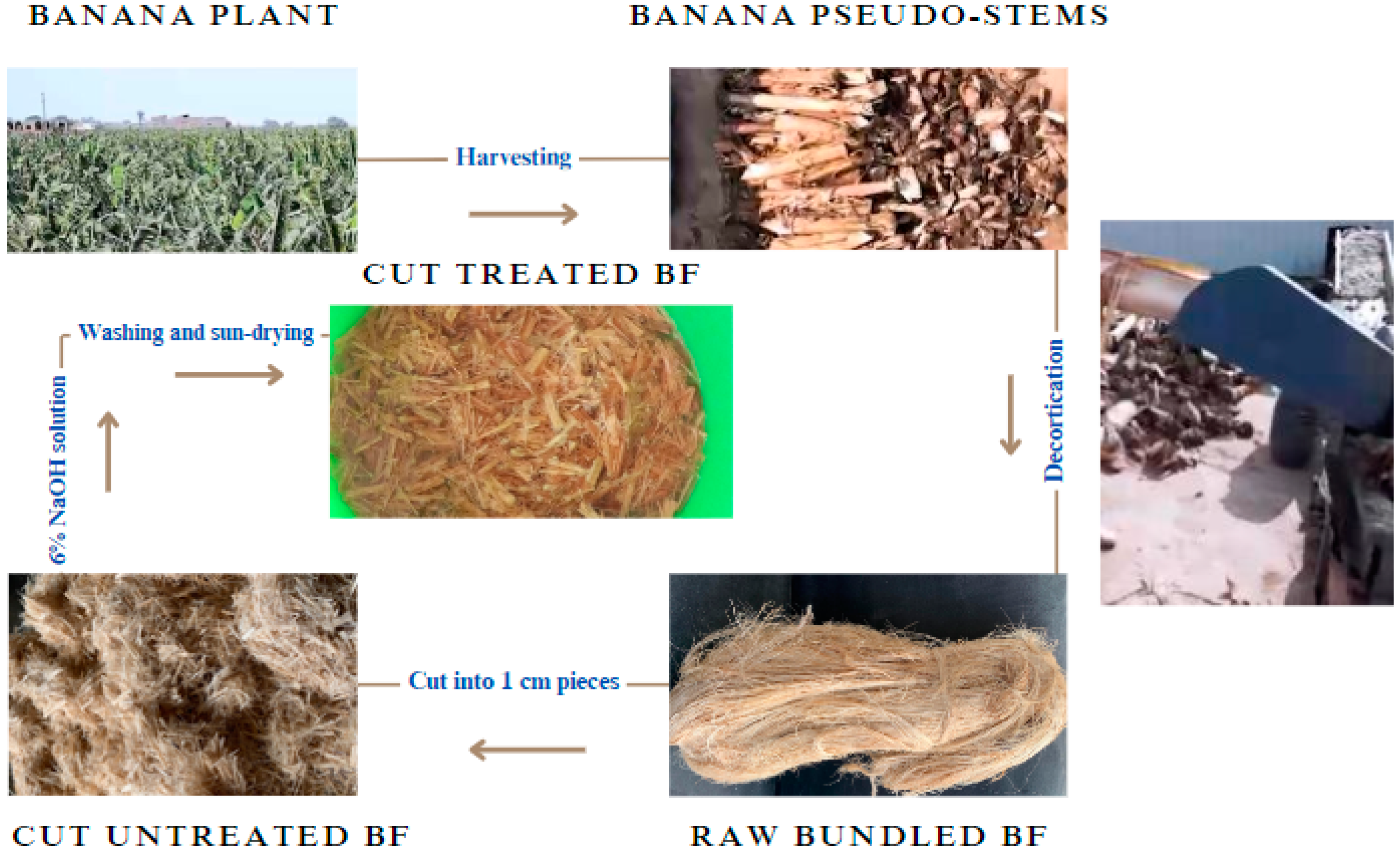

2.1. Materials

2.2. Mix Proportions

2.3. Experimental Methodology

2.3.1. Mortar Sample Preparation

2.3.2. Ultrasonic-Pulse Velocity (UPV)

2.3.3. Compressive Strength

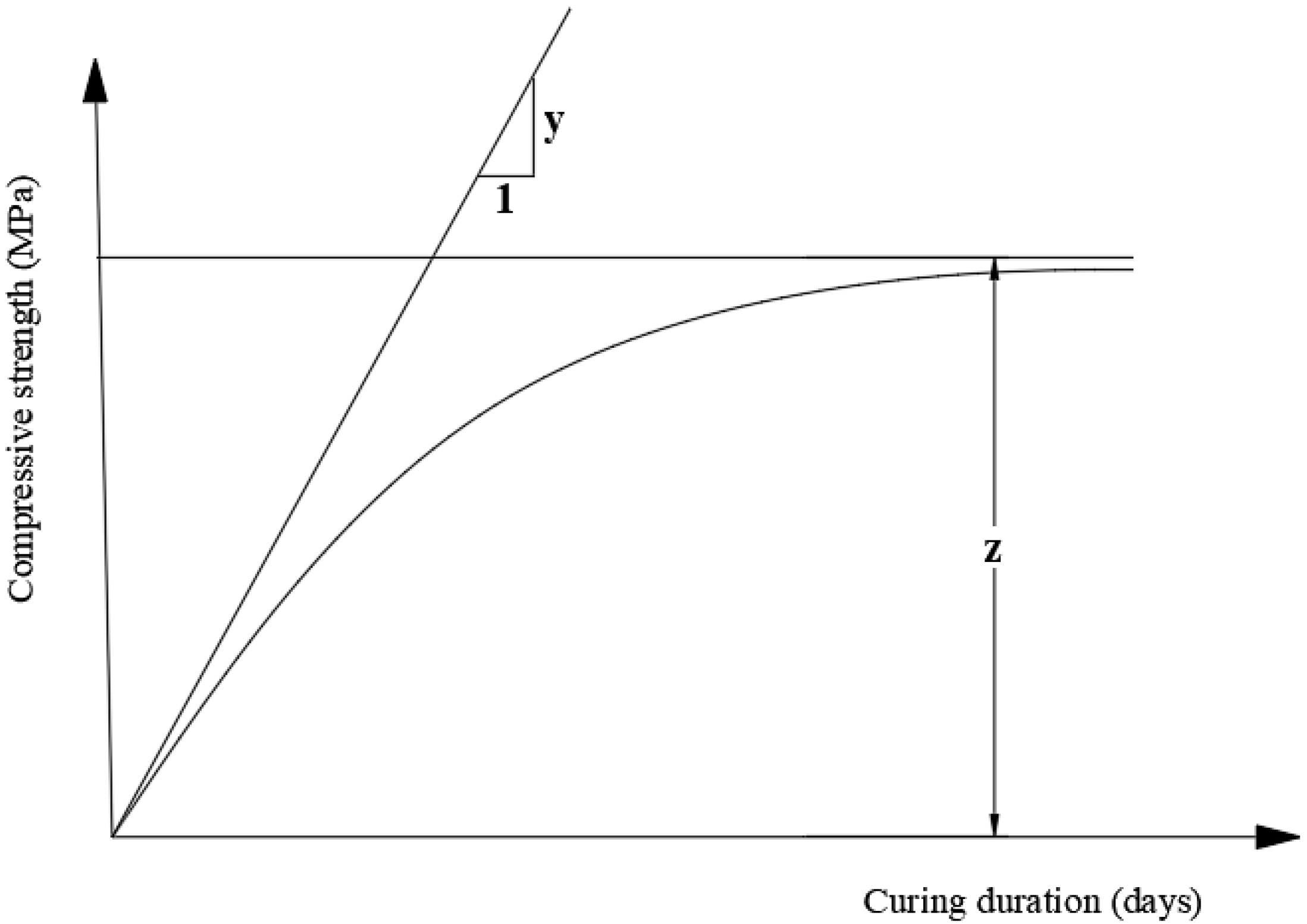

2.3.4. Compressive Strength Modeling

| C | = | modeled compressive strength; |

| x | = | curing period (days); |

| y | = | initial rate of compressive strength (IRC); |

| z | = | ultimate compressive strength (UC). |

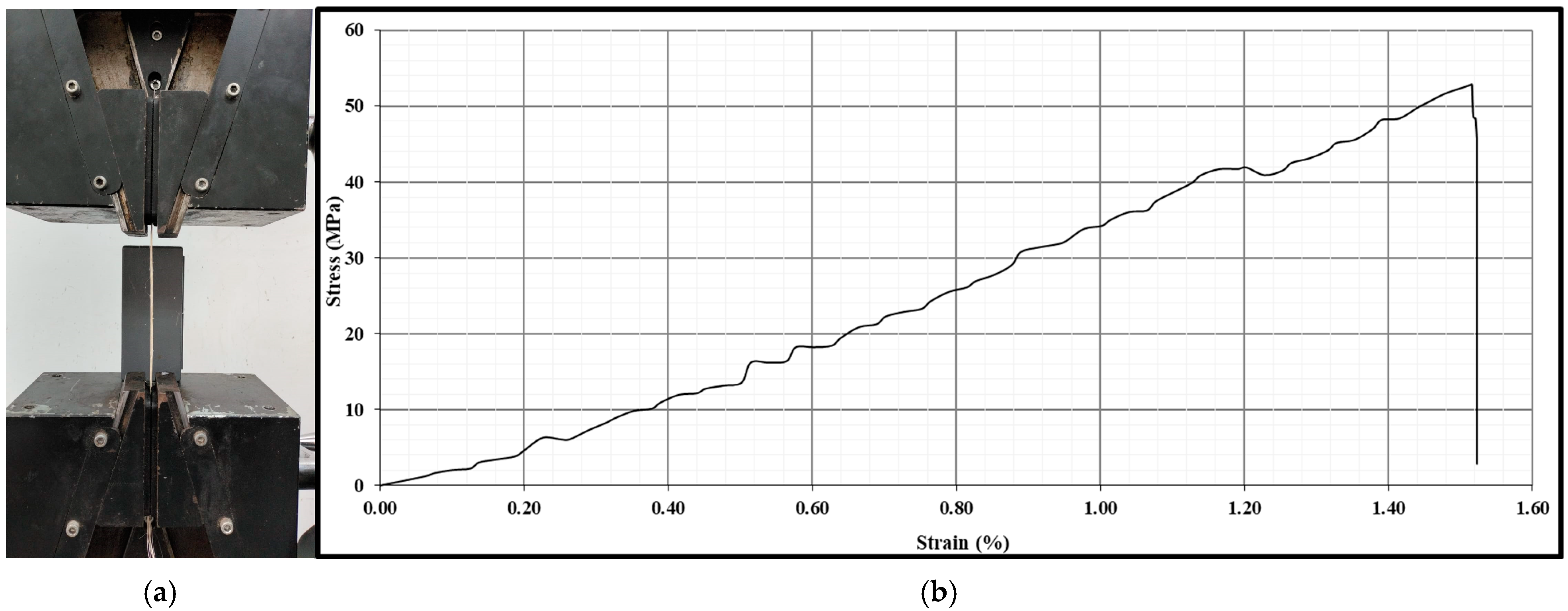

2.3.5. Flexural Strength

2.3.6. Total Water Absorption (TWA)

2.3.7. Capillary Water Absorption (CWA)

2.3.8. Capillary-Diffusive Model

| M/A | = | weight of water absorbed per unit of area (kg/m2); |

| C | = | constant associated with the distance from the concrete surface where capillary pores regulate the initial sorption; |

| ρ | = | density of the water (kg/m3); |

| S | = | sorptivity coefficient (kg/m2·s1/2); |

| t | = | time (s); |

| CO | = | invariance of water concentration (kg/m2); |

| L | = | depth of the sample = 0.1 m; |

| D | = | diffusion coefficient (m2/s). |

3. Results and Discussion

3.1. Ultrasonic-Pulse Velocity (UPV)

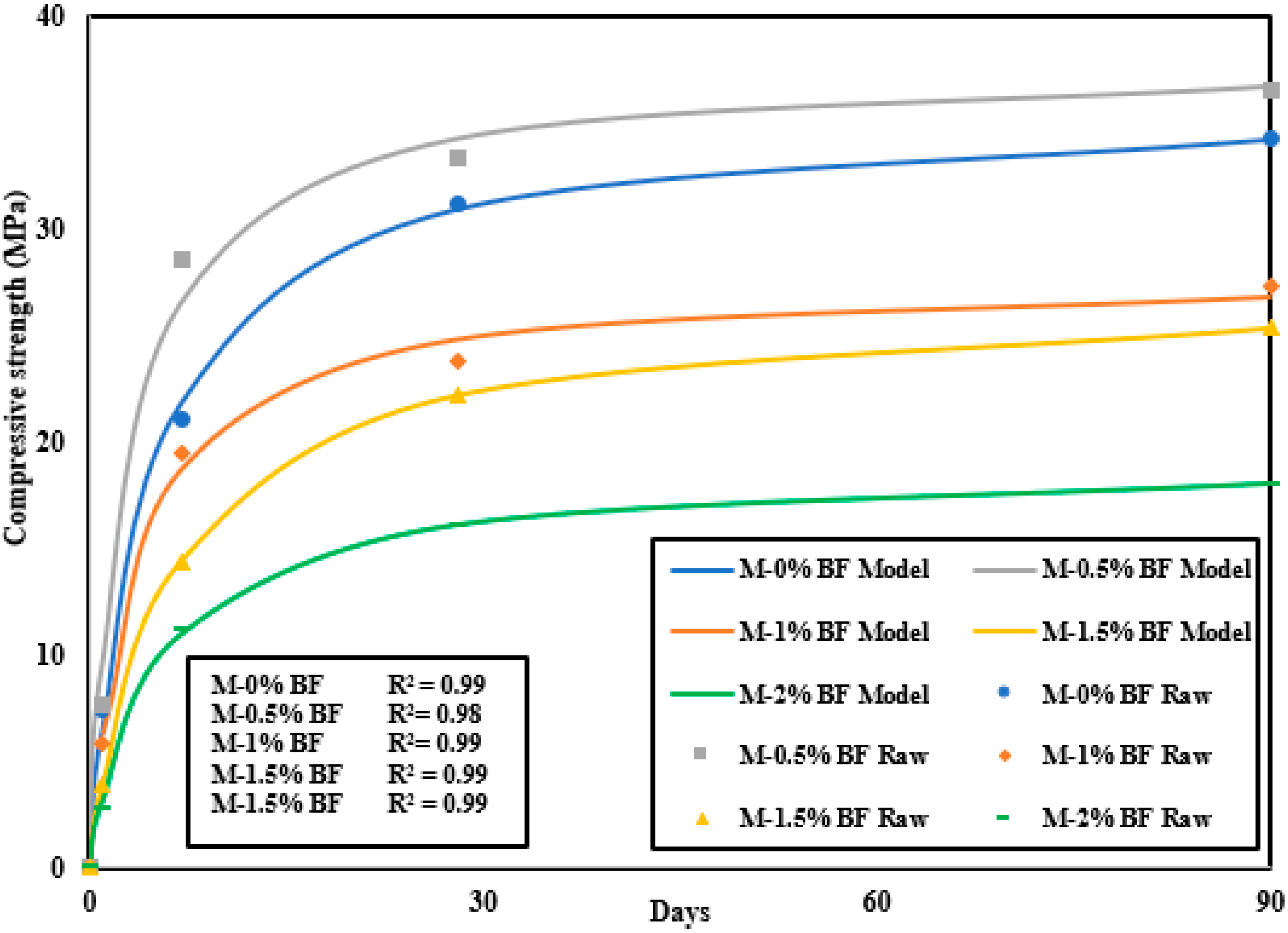

3.2. Compressive Strength

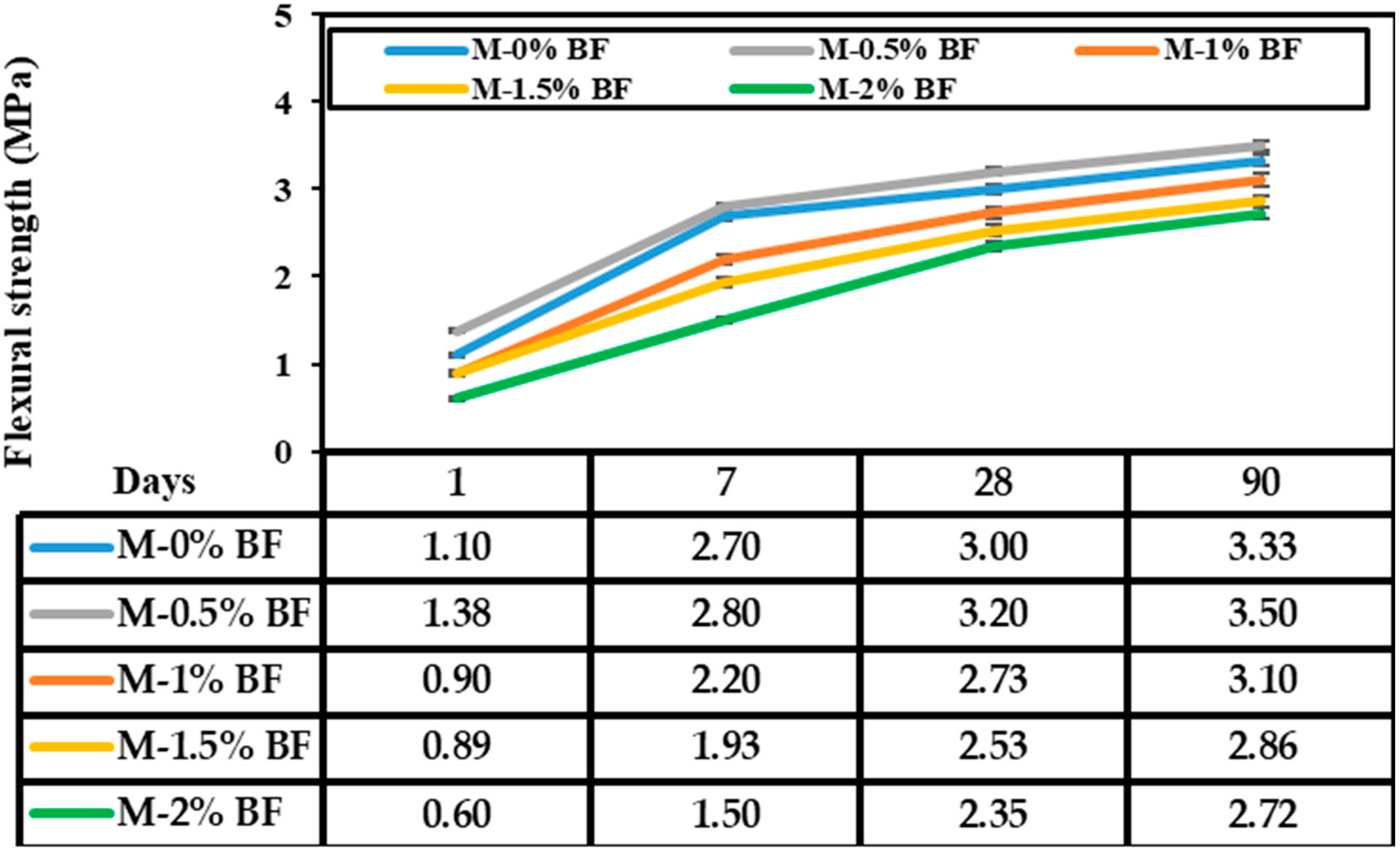

3.3. Flexural Strength

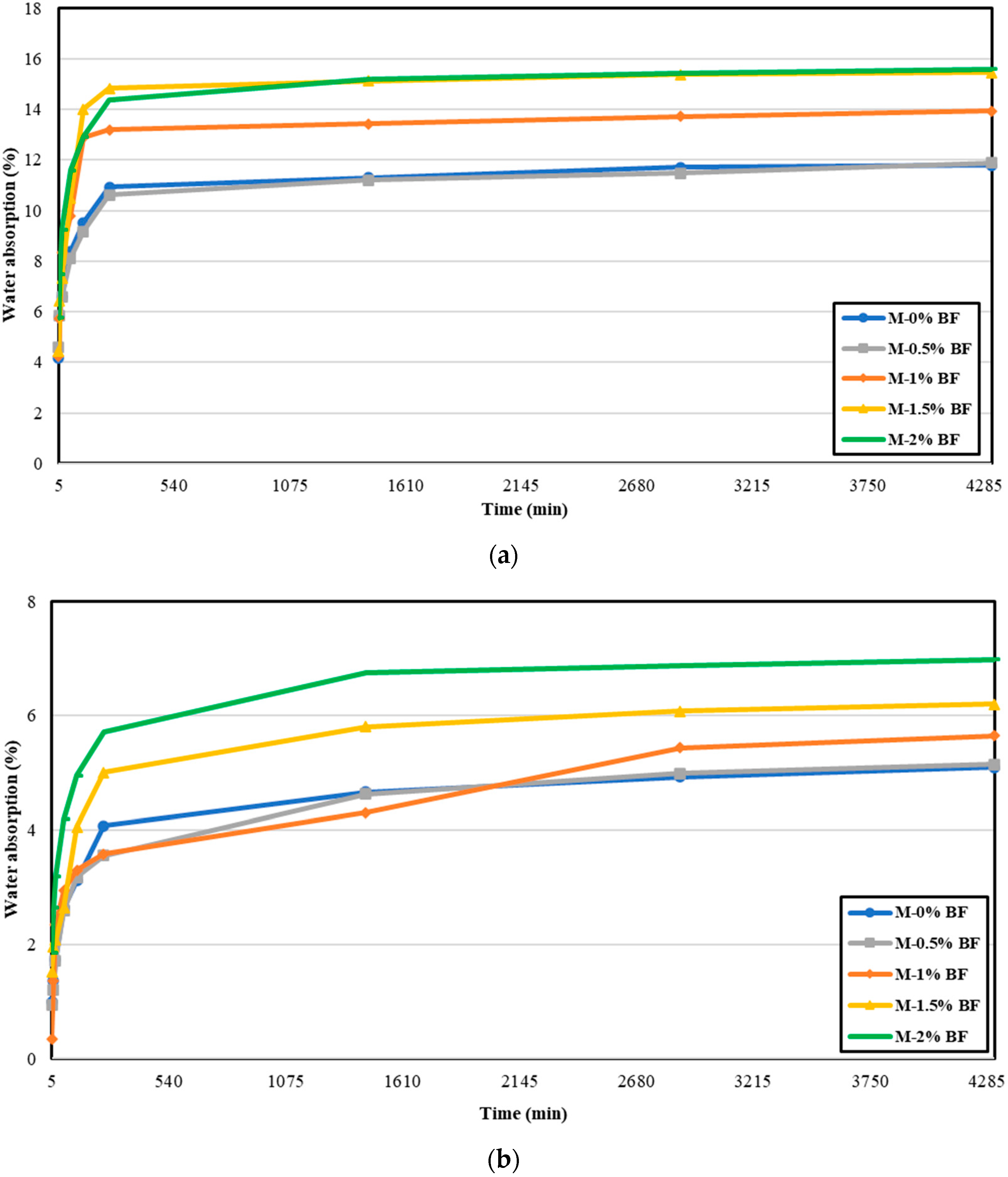

3.4. Total Water Absorption (TWA)

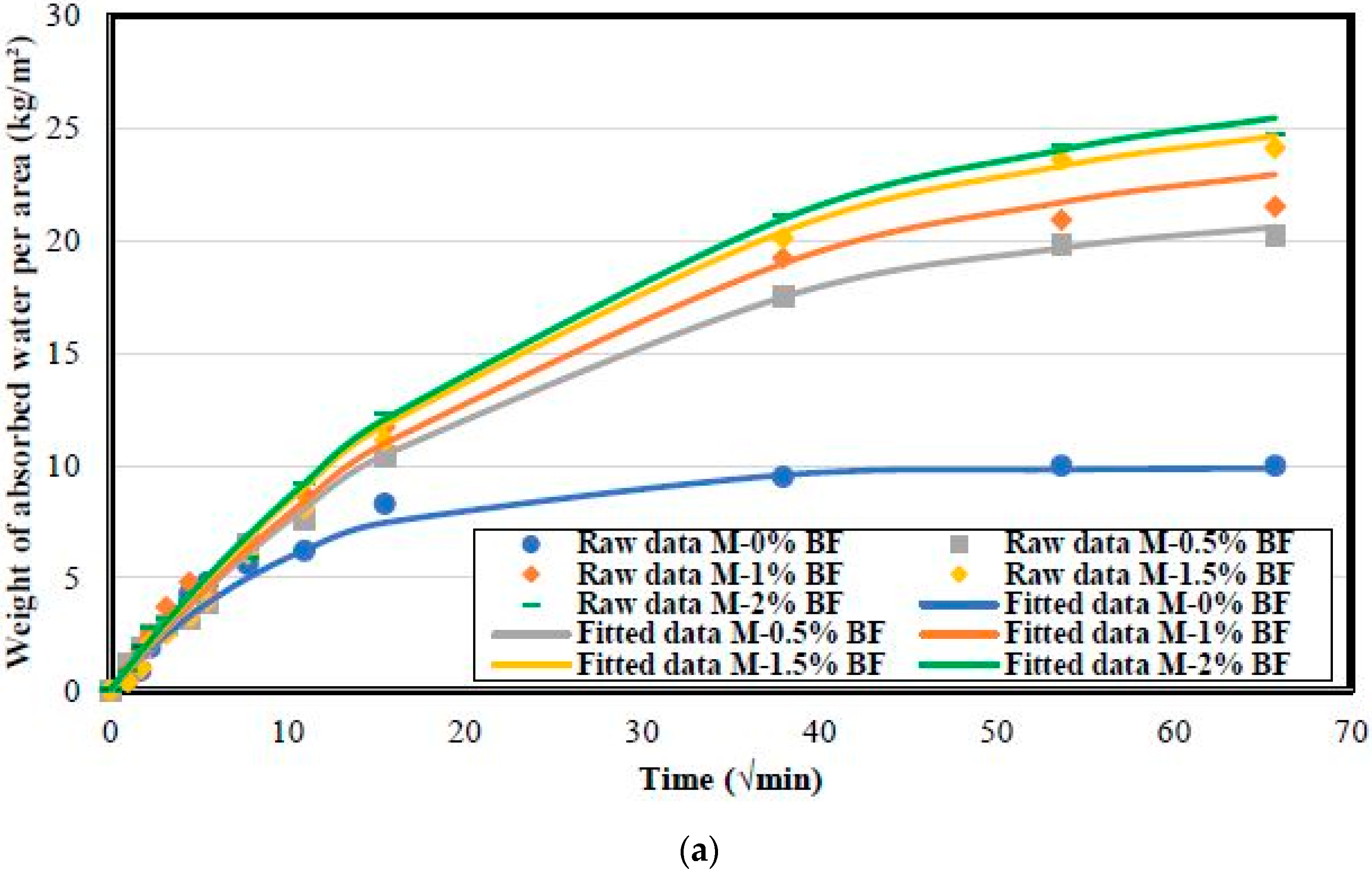

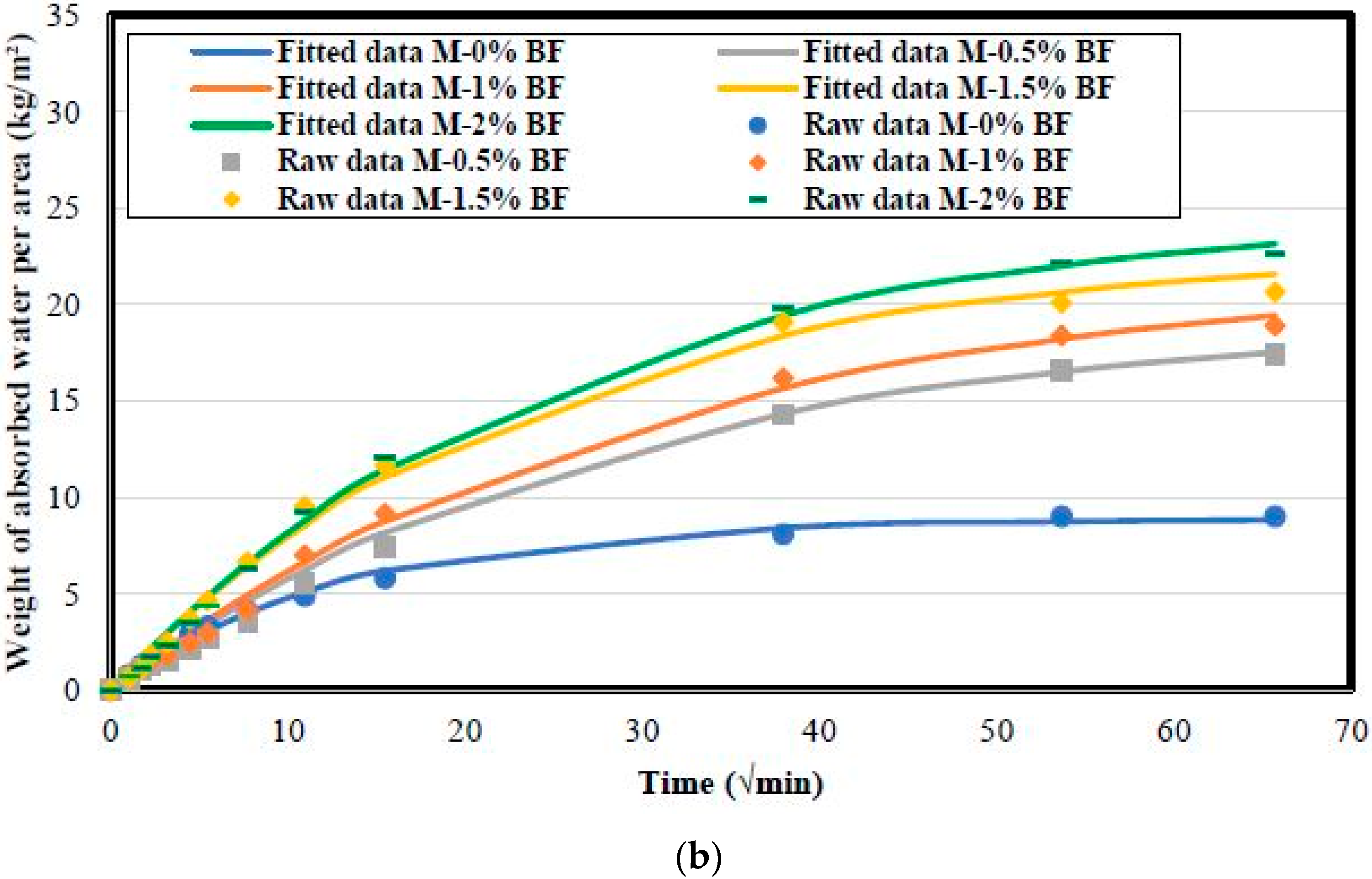

3.5. Capillary-Diffusive Process

3.6. Relationships between Various Properties

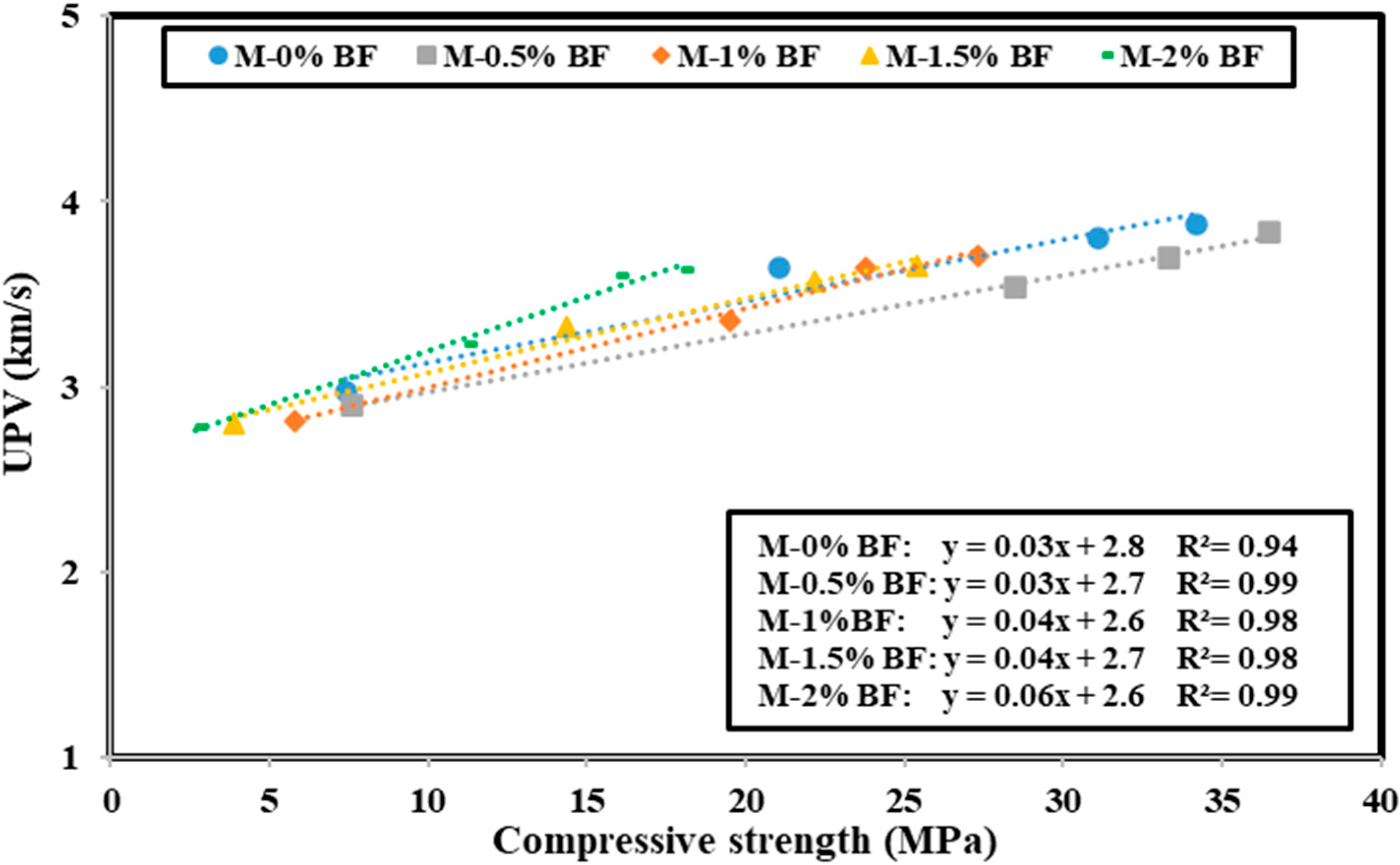

3.6.1. Compressive Strength-UPV Relationship

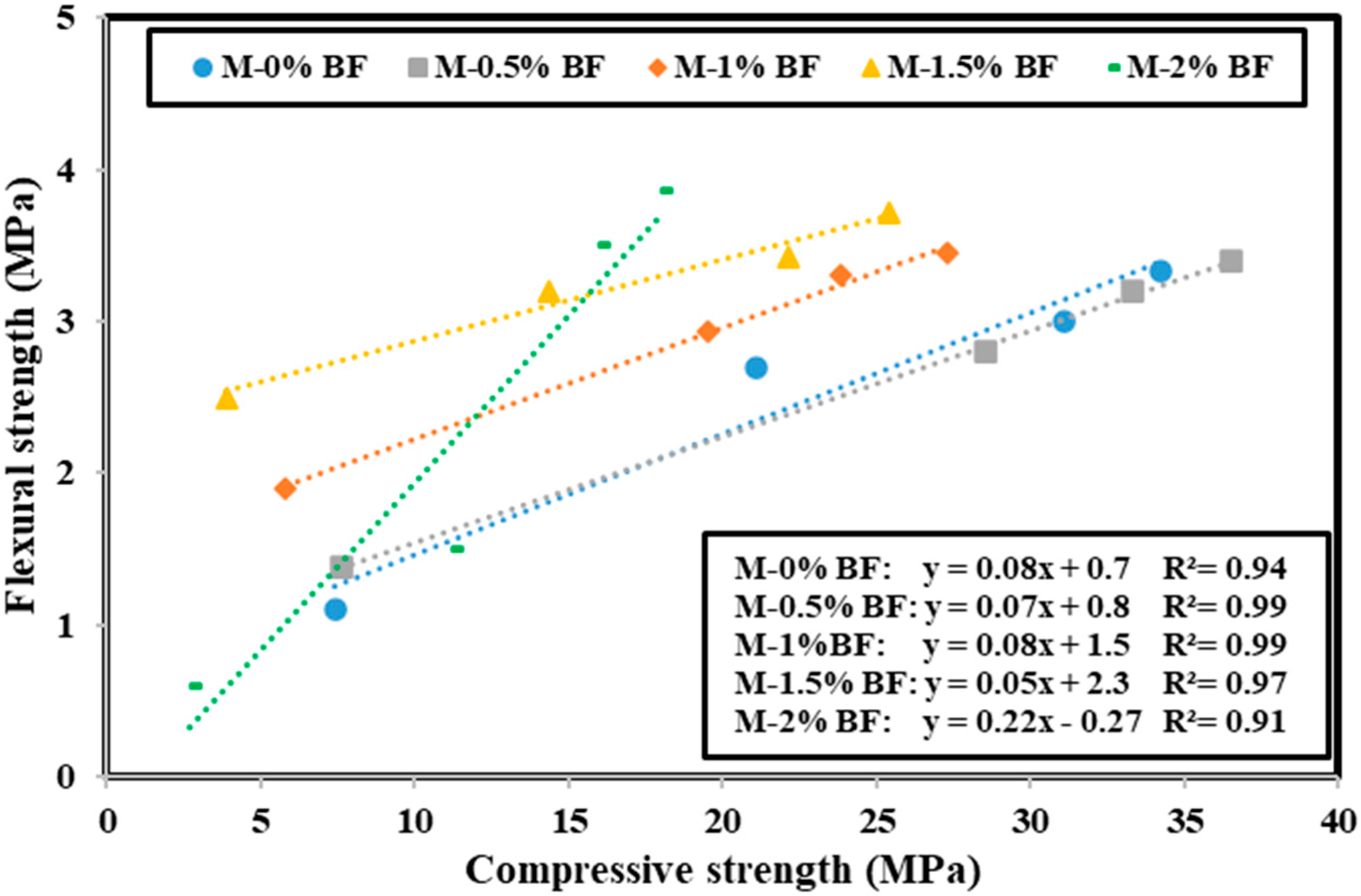

3.6.2. Compressive Strength–Flexural Strength Relationship

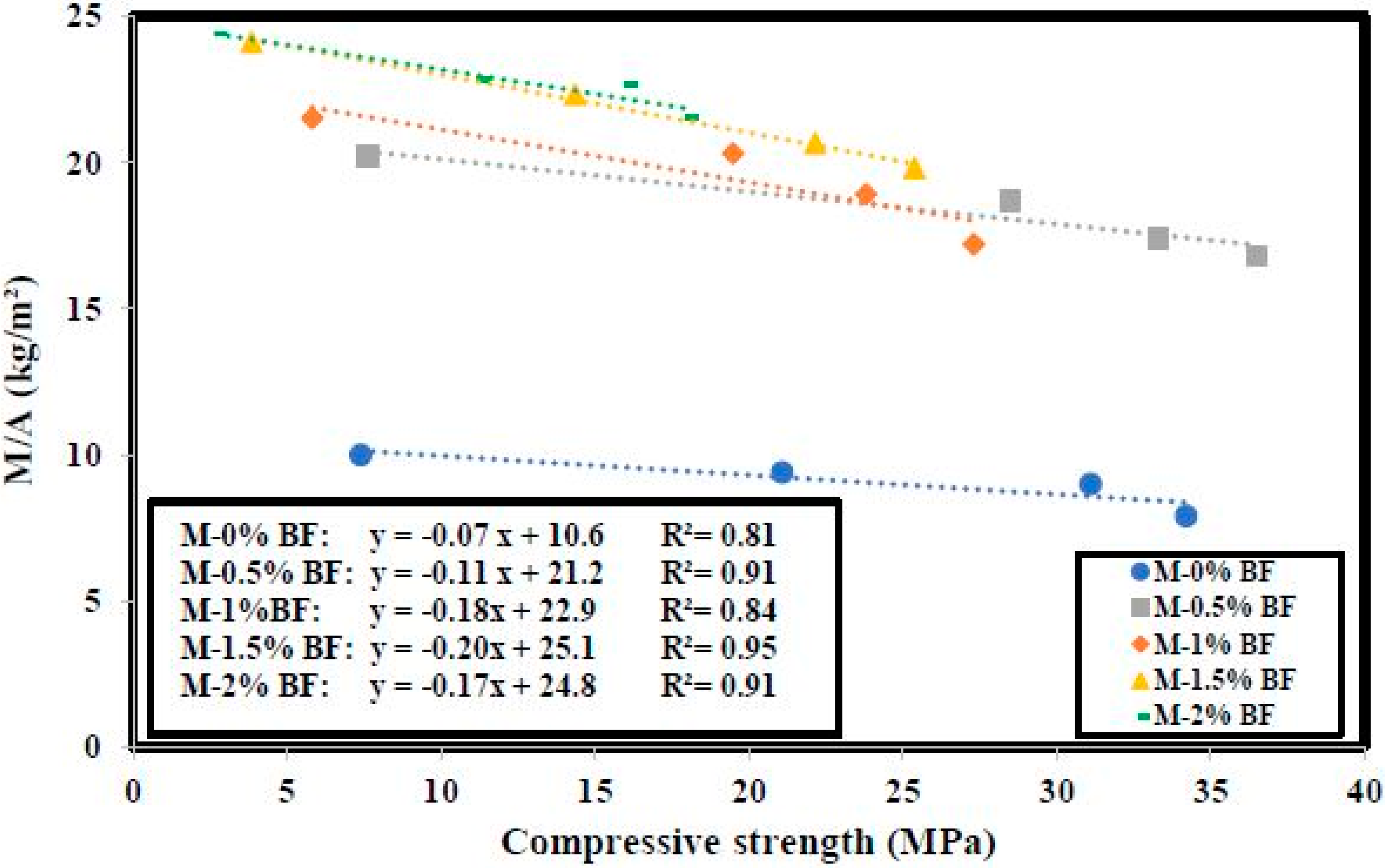

3.6.3. Compressive Strength-(M/A) Relationship

4. Conclusions

- The addition of 0.5% BF resulted in either similar or slightly higher compressive and flexural strength compared to the control. Beyond 0.5%, there is a consistent reduction in mechanical properties.

- A correlation coefficient of R2 ~ 0.9 indicates that the hyperbolic model was effective in predicting the compressive strength over a 90-day period. Both the initial length change and the ultimate length change parameters peaked at 0.5% BF addition and subsequently steadily declined with increasing BF%.

- As the amount of BF added to mortar mixes rises, the TWA increases. With reference to the control, the TWA is increased by 1, 11, 21.8, and 37.1% for mixes containing 0.5%, 1%, 1.5%, and 2% BF, respectively, at 28 days.

- The weight of water absorbed per area increases with the addition of BF to the mortar mixture. M/A is increased by 93, 110, 130, and 152% at 28 days for mixes containing 0.5, 1, 1.5, and 2% BF, respectively, compared to the control mix.

- With a correlation coefficient of R2 > 0.99, the capillary-diffusive model successfully predicted the capillary-diffusive phenomenon as a function of time. The sorptivity and diffusion coefficients exhibited a progressive increase when BF is added and a reduction as the curation period progresses.

- UPV and flexural strength show a strong positive association with compressive strength with high coefficients of correlation (R2 ≥ 0.9). On the other hand, M/A is negatively correlated to compressive strength.

- According to this study, BF content of 0.5% in the matrix yields the best mechanical and physical properties, providing appropriate mechanical and durability performance. Future research should consider adding less than 0.5% BF.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Obi, F.O.; Ugwuishiwu, B.O.; Nwakaire, J.N. Agricultural waste concept, generation, utilization and management. Niger. J. Technol. 2016, 35, 957–964. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Okonkwo, C.E.; Alhassan, E.A.; Ajiboye, M. Durability and strength properties of particle boards from polystyrene–wood wastes. J. Mater. Cycles Waste Manag. 2019, 21, 1541–1549. [Google Scholar] [CrossRef]

- Tolêdo Filho, R.D.; Ghavami, K.; England, G.L.; Scrivener, K. Development of vegetable fibre–mortar composites of improved durability. Cem. Concr. Compos. 2003, 25, 185–196. [Google Scholar] [CrossRef]

- Al-Massri, G.; Ghanem, H.; Khatib, J.; Kırgız, M.S.; Elkordi, A. Chemical shrinkage, autogenous shrinkage, drying shrinkage, and expansion stability of interfacial transition zone material using alkali-treated banana fiber for concrete. J. Struct. Integr. Maint. 2024, 9, 2390650. [Google Scholar] [CrossRef]

- De Andrade Silva, F.; Mobasher, B.; Toledo Filho, R.D. Cracking mechanisms in durable sisal fiber reinforced cement composites. Cem. Concr. Compos. 2009, 31, 721–730. [Google Scholar] [CrossRef]

- Shah, I.; Li, J.; Yang, S.; Zhang, Y.; Anwar, A. Experimental investigation on the mechanical properties of natural fiber reinforced concrete. J. Renew. Mater. 2022, 10, 1307. [Google Scholar] [CrossRef]

- Khan, M.B.; Shafiq, N.; Waqar, A.; Radu, D.; Cismaș, C.; Imran, M.; Almujibah, H.; Benjeddou, O. Effects of jute fiber on fresh and hardened characteristics of concrete with environmental assessment. Buildings 2023, 13, 1691. [Google Scholar] [CrossRef]

- Prafulla, K.; Nagaraju, A. An experimental study on coir fiber reinforced concrete with ground granulated blast furnace slag and dolomite powder as partial replacement of cement. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022; Volume 1086, p. 012052. [Google Scholar] [CrossRef]

- Machaka, M.; Khatib, J.; Baydoun, S.; Elkordi, A.; Assaad, J.J. The Effect of Adding Phragmites australis Fibers on the Properties of Concrete. Buildings 2022, 12, 278. [Google Scholar] [CrossRef]

- Zouaoui, Y.; Benmahiddine, F.; Yahia, A.; Belarbi, R. Hygrothermal and mechanical behaviors of fiber mortar: Comparative study between palm and hemp fibers. Energies 2021, 14, 7110. [Google Scholar] [CrossRef]

- Li, Q.; Ibrahim, L.; Zhou, W.; Zhang, M.; Yuan, Z. Treatment methods for plant fibers for use as reinforcement in cement-based materials. Cellulose 2021, 28, 5257–5268. [Google Scholar] [CrossRef]

- Mohammed-Ziegler, I.; Oszlánczi, Á.; Somfai, B.; Hórvölgyi, Z.; Pászli, I.; Holmgren, A.; Forsling, W. Surface free energy of natural and surface-modified tropical and European wood species. J. Adhes. Sci. Technol. 2004, 18, 687–713. [Google Scholar] [CrossRef]

- Mohammed-Ziegler, I.; Tánczos, I.; Hórvölgyi, Z.; Agoston, B. Water-repellent acylated and silylated wood samples and their surface analytical characterization. Colloids Surf. A Physicochem. Eng. Asp. 2008, 319, 204–212. [Google Scholar] [CrossRef]

- Arias, P. The World Banana Economy 2003, 1985–2002 (No. 1). Food & Agriculture Org. Available online: https://www.fao.org/3/y5102e/y5102e04.htm (accessed on 15 September 2024).

- Ali, B.; Azab, M.; Ahmed, H.; Kurda, R.; El Ouni, M.H.; Elhag, A.B. Investigation of physical, strength, and ductility characteristics of concrete reinforced with banana (Musaceae) stem fiber. J. Build. Eng. 2022, 61, 105024. [Google Scholar] [CrossRef]

- Logeshwar, A.B.; Bhuvaneshpandi, M.; Harishkanna, V.; Midhunkumar, R.; Praveenkumar, S. Effect of Banana Fibre on Strength Properties of Bagasse ash & Rice Husk ash blended high performance concrete composite. In Proceedings of the ASPS Conference Proceedings, Rajasthan, India, 19–22 December 2022; Volume 1, pp. 201–206. [Google Scholar] [CrossRef]

- Pathan, T.A.; Jhumarwala, R.A. Evaluation of mechanical properties of high strength banana fibre concrete (HSBFC) incorporating fly ash and silica fume. Int. J. Res. Appl. Sci. Eng. Technol. 2022, 10, 780–785. [Google Scholar] [CrossRef]

- Lamichhane, N.; Lamichhane, A.; Gyawali, T.R. Enhancing mechanical properties of mortar with short and thin banana fibers: A sustainable alternative to synthetic fibers. Heliyon 2024, 10, e30652. [Google Scholar] [CrossRef]

- Thanushan, K.; Sathiparan, N. Mechanical performance and durability of banana fibre and coconut coir reinforced cement stabilized soil blocks. Materialia 2022, 21, 101309. [Google Scholar] [CrossRef]

- ASTM C1437-15 2015; Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C 597; Standard Test Method for Pulse Velocity through Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- Ghanem, H.; Khatib, J.; Elkordi, A. Effect of partial replacement of sand by mswi-ba on the properties of mortar. BAU J. Sci. Technol. 2020, 1, 4. [Google Scholar] [CrossRef]

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens. ASTM International: West Conshohocken, PA, USA, 2016.

- Ghanem, H.; Ramadan, R.; Khatib, J.; Elkordi, A. A Review on Chemical and Autogenous Shrinkage of Cementitious Systems. Materials 2024, 17, 283. [Google Scholar] [CrossRef]

- ASTM C348; Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. American Society for Testing and Materials International: West Conshohocken, PA, USA, 2008.

- ASTM C1585; Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes. ASTM International: West Conshohocken, PA, USA, 2004.

- Martys, N.S.; Ferraris, C.F. Capillary transport in mortars and concrete. Cem. Concr. Res. 1997, 27, 747–760. [Google Scholar] [CrossRef]

- Villar-Cocina, E.; Valencia-Morales, E.; Vega-Leyva, J.; Munoz, J.A. Kinetics of the water absorption in GGBS-concretes: A capillary-diffusive model. Comput. Concr. Int. J. 2005, 2, 19–30. [Google Scholar] [CrossRef]

- Wongsa, A.; Kunthawatwong, R.; Naenudon, S.; Sata, V.; Chindaprasirt, P. Natural fiber reinforced high calcium fly ash geopolymer mortar. Constr. Build. Mater. 2020, 241, 118143. [Google Scholar] [CrossRef]

- Mathavan, M.; Sakthieswaran, N.; Babu, O.G. Experimental investigation on strength and properties of natural fibre reinforced cement. Mater. Today Proc. 2021, 37, 1066–1070. [Google Scholar] [CrossRef]

- Alatshan, F.; Altlomate, A.M.; Mashiri, F.; Alamin, W. Effect of date palm fibers on the mechanical properties of concrete. Int. J. Sustain. Build. Technol. Urban Dev. 2017, 8, 68–80. [Google Scholar] [CrossRef]

- Khatib, J.M.; Ramadan, R.; Ghanem, H.; Elkordi, A.; Baalbaki, O.; Kırgız, M. Chemical shrinkage of paste and mortar containing limestone fines. Mater. Today Proc. 2022, 61, 530–536. [Google Scholar] [CrossRef]

- De La Grée, G.D.; Yu, Q.L.; Brouwers, H.J.H. Assessing the effect of CaSO4 content on the hydration kinetics, microstructure and mechanical properties of cements containing sugars. Constr. Build. Mater. 2017, 143, 48–60. [Google Scholar] [CrossRef]

- Bilba, K.; Arsène, M.A.; Ouensanga, A. Sugar cane bagasse fibre reinforced cement composites. Part I. Influence of the botanical components of bagasse on the setting of bagasse/cement composite. Cem. Concr. Compos. 2003, 25, 91–96. [Google Scholar] [CrossRef]

- Tolêdo Filho, R.D.; Scrivener, K.; England, G.L.; Ghavami, K. Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Araya-Letelier, G.; Antico, F.C.; Carrasco, M.; Rojas, P.; García-Herrera, C.M. Effectiveness of new natural fibers on damage-mechanical performance of mortar. Constr. Build. Mater. 2017, 152, 672–682. [Google Scholar] [CrossRef]

- Choi, J.I.; Jang, S.Y.; Kwon, S.J.; Lee, B.Y. Tensile behavior and cracking pattern of an ultra-high-performance mortar reinforced by polyethylene fiber. Adv. Mater. Sci. Eng. 2017, 2017, 5383982. [Google Scholar] [CrossRef]

- Aslon MW, B.; Lakawa, I.; Sulaiman, S.; Hawa, S. Testing the Compressive Strength of Concrete With the Utilization of Rice Husk Ash and Palm Fiber. Sultra Civ. Eng. J. 2023, 4, 11–19. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, J.; Wang, J. Flexural performance of recycled concrete beam reinforced with modified basalt fiber and nano-silica. Case Stud. Constr. Mater. 2023, 18, e02022. [Google Scholar] [CrossRef]

- Hannawi, K.; Bian, H.; Prince-Agbodjan, W.; Raghavan, B. Effect of different types of fibers on the microstructure and the mechanical behavior of ultra-high performance fiber-reinforced concretes. Compos. Part B Eng. 2016, 86, 214–220. [Google Scholar] [CrossRef]

- Arshad, S.; Sharif, M.B.; Irfan-ul-Hassan, M.; Khan, M.; Zhang, J.L. Efficiency of supplementary cementitious materials and natural fiber on mechanical performance of concrete. Arab. J. Sci. Eng. 2020, 45, 8577–8589. [Google Scholar] [CrossRef]

- Mounanga, P.; Khelidj, A.; Loukili, A.; Baroghel-Bouny, V. Predicting Ca (OH) 2 content and chemical shrinkage of hydrating cement pastes using analytical approach. Cem. Concr. Res. 2004, 34, 255–265. [Google Scholar] [CrossRef]

- Kouta, N.; Saliba, J.; Saiyouri, N. Effect of flax fibers on early age shrinkage and cracking of earth concrete. Constr. Build. Mater. 2020, 254, 119315. [Google Scholar] [CrossRef]

- Alzebdeh, K.I.; Nassar, M.M.; Arunachalam, R. Effect of fabrication parameters on strength of natural fiber polypropylene composites: Statistical assessment. Measurement 2019, 146, 195–207. [Google Scholar] [CrossRef]

- Ji, Y.; Ji, W.; Zhang, Z.; Wang, R. Road performance investigation on fiber-reinforced recycled cement base material. Polymers 2022, 14, 4102. [Google Scholar] [CrossRef]

- Ghanem, H.; Machaka, M.; Khatib, J.; Elkordi, A.; Baalbaki, O. Effect of partial replacement of cement by MSWIBA on the properties of mortar. Acad. J. Civ. Eng. 2019, 37, 82–89. [Google Scholar] [CrossRef]

- Khatib, J.; Ramadan, R.; Ghanem, H.; ElKordi, A. Effect of using limestone fines on the chemical shrinkage of pastes and mortars. Environ. Sci. Pollut. Res. 2023, 30, 25287–25298. [Google Scholar] [CrossRef]

- Ren, F.; Zhou, C.; Zeng, Q.; Ding, Z.; Xing, F.; Wang, W. The dependence of capillary sorptivity and gas permeability on initial water content for unsaturated cement mortars. Cem. Concr. Compos. 2019, 104, 103356. [Google Scholar] [CrossRef]

- Khatib, J.; Ramadan, R.; Ghanem, H.; Elkordi, A. Volume stability of cement paste containing limestone fines. Buildings 2021, 11, 366. [Google Scholar] [CrossRef]

- Pipilikaki, P.; Katsioti, M. Study of the hydration process of quaternary blended cements and durability of the produced mortars and concretes. Constr. Build. Mater. 2009, 23, 2246–2250. [Google Scholar] [CrossRef]

| Quantity (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|

| Mortar Code | Cement | Water | Sand | BF | BF (% by vol) | w/c | c/s |

| M-0% BF | 657 | 295.6 | 1314 | 0 | 0 | 0.45 | 0.5 |

| M-0.5% BF | 657 | 295.6 | 1314 | 6.75 | 0.5 | 0.45 | 0.5 |

| M-1% BF | 657 | 295.6 | 1314 | 13.5 | 1 | 0.45 | 0.5 |

| M-1.5% BF | 657 | 295.6 | 1314 | 20.25 | 1.5 | 0.45 | 0.5 |

| M-2% BF | 657 | 295.6 | 1314 | 27 | 2 | 0.45 | 0.5 |

| Quality of Concrete | Excellent | Good | Doubtful | Poor | Very poor |

| UPV (km/s) | >4.5 | 3.5-4.5 | 3.0-3.5 | 2.0-3.0 | <2.0 |

| Mortar Code | Curing Period (Days) | S (kg/m2·s1/2) | D (m2/s) | R2 |

|---|---|---|---|---|

| M-0% BF | 1 | 1.15 × 10−2 | 8.03 × 10−5 | 0.983 |

| 28 | 8.78 × 10−2 | 8.05 × 10−8 | 0.995 | |

| M-0.5% BF | 1 | 1.18 × 10−1 | 9.98 × 10−3 | 0.997 |

| 28 | 8.81 × 10−2 | 5.61 × 10−7 | 0.997 | |

| M-1% BF | 1 | 1.20 × 10−1 | 5.60 × 10−2 | 0.995 |

| 28 | 9.31 × 10−2 | 6.72 × 10−7 | 0.996 | |

| M-1.5% BF | 1 | 1.29 × 10−1 | 7.81 × 10−2 | 0.998 |

| 28 | 1.25 × 10−1 | 2.76 × 10−4 | 0.995 | |

| M-2% BF | 1 | 1.31 × 10−1 | 8.24 × 10−2 | 0.998 |

| 28 | 1.27 × 10−1 | 2.07 × 10−3 | 0.998 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Massri, G.; Ghanem, H.; Khatib, J.; El-Zahab, S.; Elkordi, A. The Effect of Adding Banana Fibers on the Physical and Mechanical Properties of Mortar for Paving Block Applications. Ceramics 2024, 7, 1533-1553. https://doi.org/10.3390/ceramics7040099

Al-Massri G, Ghanem H, Khatib J, El-Zahab S, Elkordi A. The Effect of Adding Banana Fibers on the Physical and Mechanical Properties of Mortar for Paving Block Applications. Ceramics. 2024; 7(4):1533-1553. https://doi.org/10.3390/ceramics7040099

Chicago/Turabian StyleAl-Massri, Ginan, Hassan Ghanem, Jamal Khatib, Samer El-Zahab, and Adel Elkordi. 2024. "The Effect of Adding Banana Fibers on the Physical and Mechanical Properties of Mortar for Paving Block Applications" Ceramics 7, no. 4: 1533-1553. https://doi.org/10.3390/ceramics7040099

APA StyleAl-Massri, G., Ghanem, H., Khatib, J., El-Zahab, S., & Elkordi, A. (2024). The Effect of Adding Banana Fibers on the Physical and Mechanical Properties of Mortar for Paving Block Applications. Ceramics, 7(4), 1533-1553. https://doi.org/10.3390/ceramics7040099