Holistic Characterization of MgO-Al2O3, MgO-CaZrO3, and Y2O3-ZrO2 Ceramic Composites for Aerospace Propulsion Systems

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Manufacturing

2.2. Sample Analysis

3. Results and Discussion

3.1. Particle Size Distribution and Microstructure

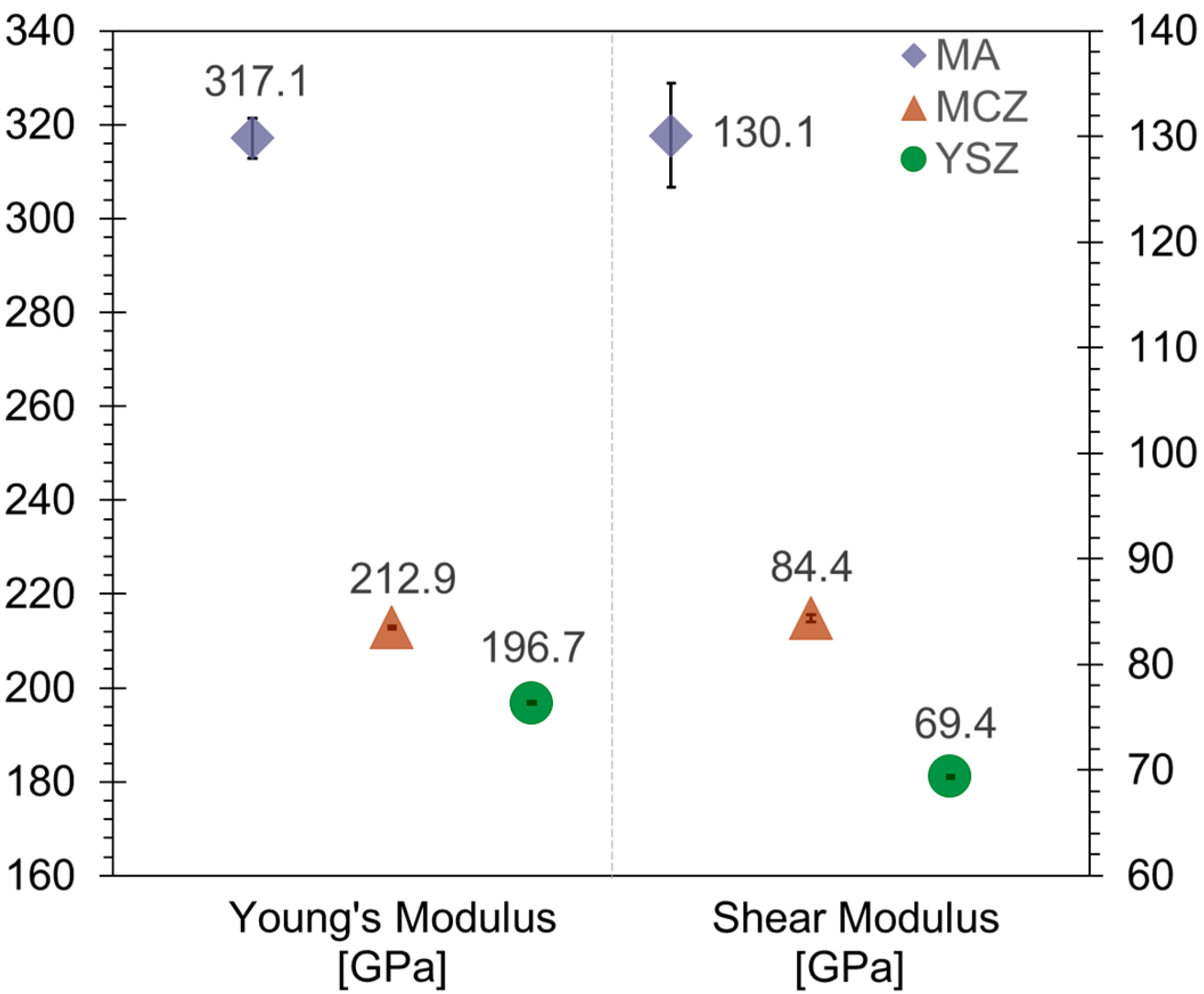

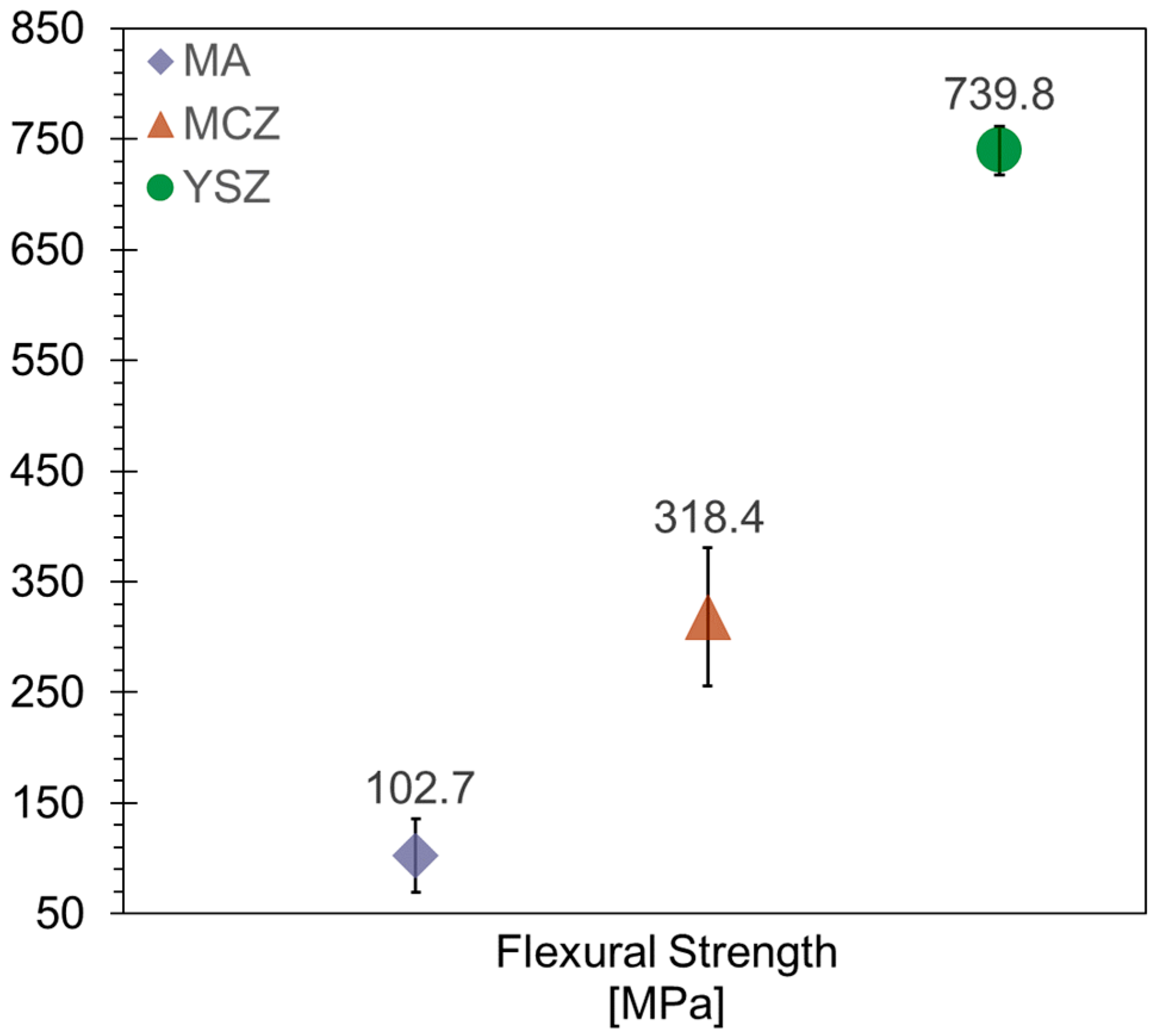

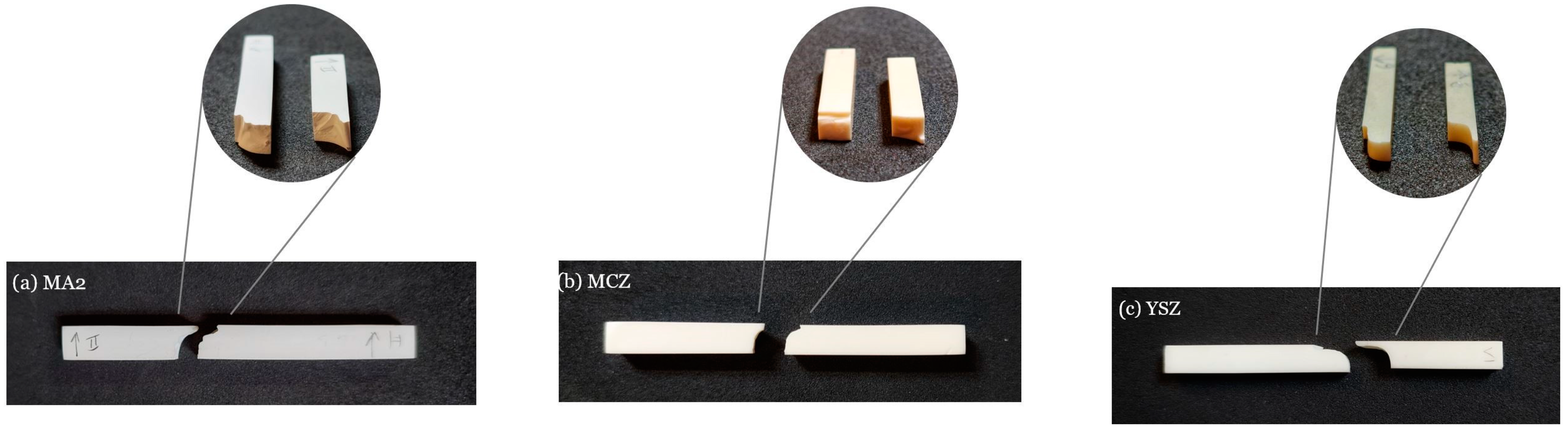

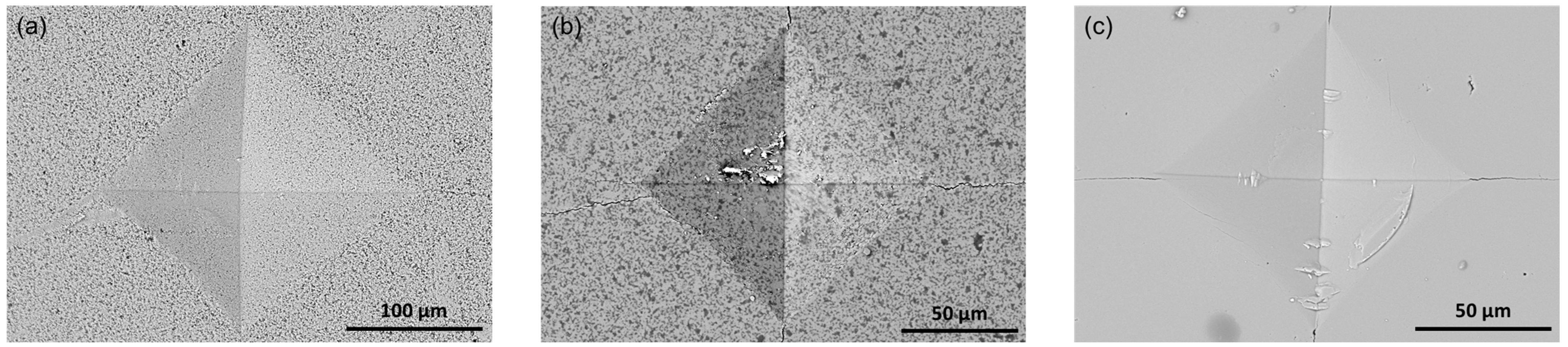

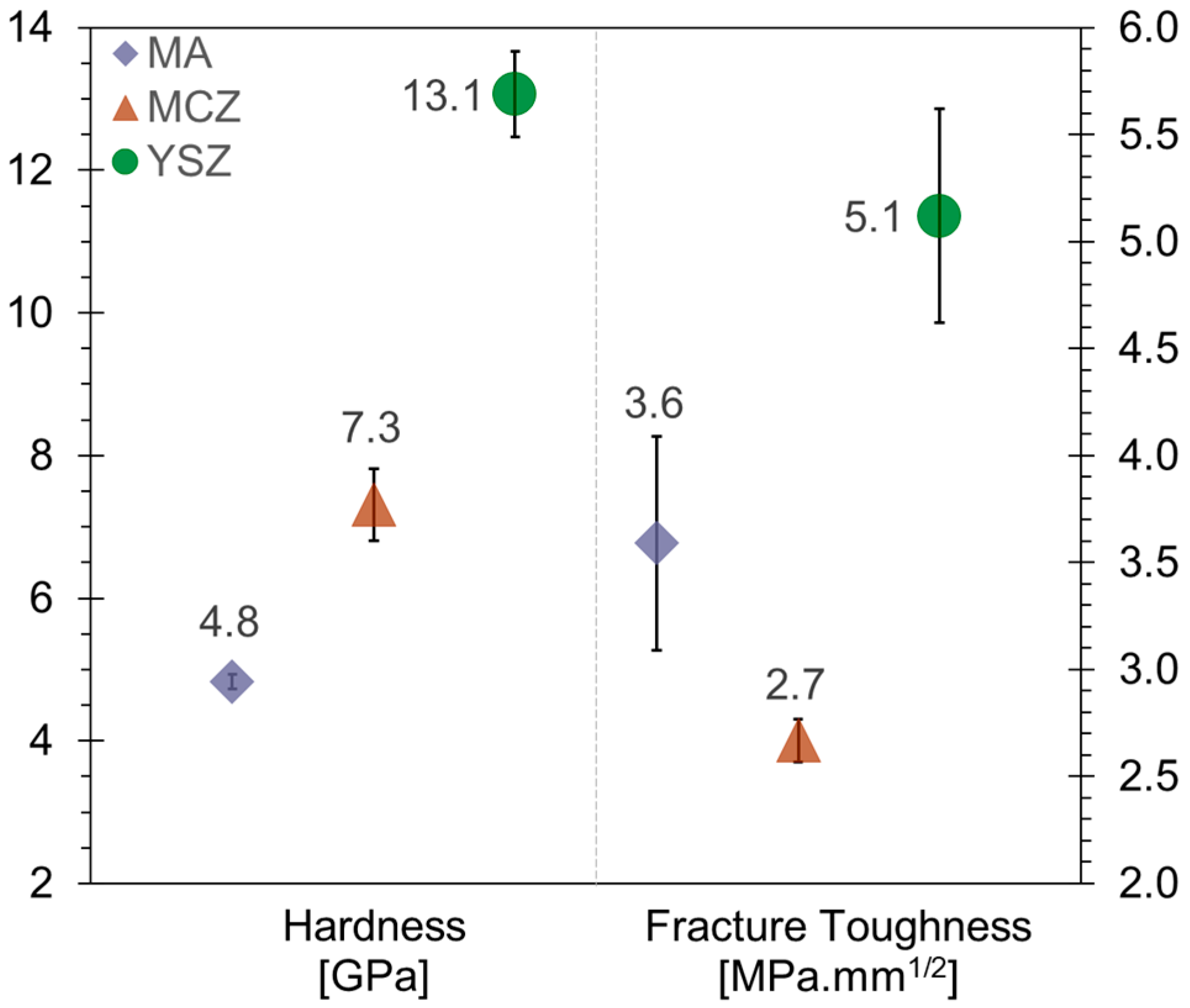

3.2. Mechanical Properties

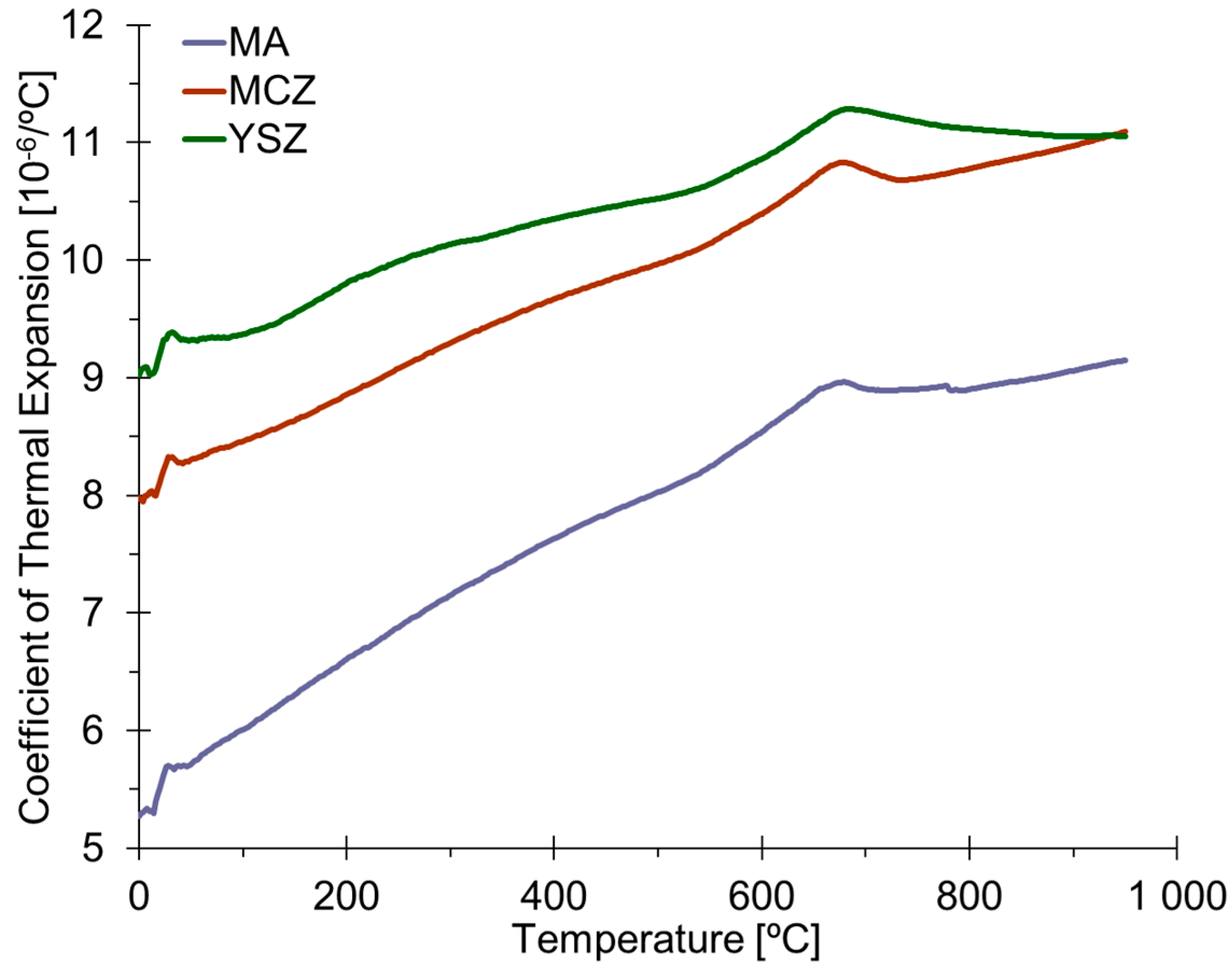

3.3. Thermal Properties

3.4. Dielectric Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shvydyuk, K.O.; Nunes-Pereira, J.; Rodrigues, F.F.; Silva, A.P. Review of Ceramic Composites in Aeronautics and Aerospace: A Multifunctional Approach for TPS, TBC and DBD Applications. Ceramics 2023, 6, 195–230. [Google Scholar] [CrossRef]

- Otitoju, T.A.; Okoye, P.U.; Chen, G.; Li, Y.; Okoye, M.O.; Li, S. Advanced ceramic components: Materials, fabrication, and applications. J. Ind. Eng. Chem. 2020, 85, 34–65. [Google Scholar] [CrossRef]

- Rödel, J.; Kounga, A.B.; Weissenberger-Eibl, M.; Koch, D.; Bierwisch, A.; Rossner, W.; Hoffmann, M.J.; Danzer, R.; Schneider, G. Development of a roadmap for advanced ceramics: 2010–2025. J. Eur. Ceram. Soc. 2009, 29, 1549–1560. [Google Scholar] [CrossRef]

- Advanced Ceramics Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023–2028. Research and Markets. 2023. Available online: https://www.researchandmarkets.com/reports/5742831/advanced-ceramics-market-global-industry (accessed on 28 August 2022).

- Subbarao, E.C. Advanced ceramics—An overview. Sādhanā 1988, 13, 1–11. [Google Scholar] [CrossRef]

- Petzow, G.; Telle, R.; Danzer, R. Microstructural defects and mechanical properties of high-performance ceramics. Mater. Charact. 1991, 26, 289–302. [Google Scholar] [CrossRef]

- Padture, N.P. Advanced structural ceramics in aerospace propulsion. Nat. Mater. 2016, 15, 804–809. [Google Scholar] [CrossRef]

- Yang, Q.; Gao, B.; Xu, Z.; Xie, W.; Meng, S. Topology optimisations for integrated thermal protection systems considering thermo-mechanical constraints. Appl. Therm. Eng. 2019, 150, 995–1001. [Google Scholar] [CrossRef]

- Triantou, K.; Mergia, K.; Perez, B.; Florez, S.; Stefan, A.; Ban, C.; Pelin, G.; Ionescu, G.; Zuber, C.; Fischer, W.; et al. Thermal shock performance of carbon-bonded carbon fiber composite and ceramic matrix composite joints for thermal protection re-entry applications. Compos. Part B Eng. 2017, 111, 270–278. [Google Scholar] [CrossRef]

- Bakan, E.; Vaßen, R. Ceramic top coats of plasma-sprayed thermal barrier coatings: Materials, processes, and properties. J. Therm. Spray Technol. 2017, 26, 992–1010. [Google Scholar] [CrossRef]

- Venkadesan, G.; Muthusamy, J. Experimental investigation of Al2O3/8YSZ and CeO2/8YSZ plasma sprayed thermal barrier coating on diesel engine. Ceram. Int. 2019, 45, 3166–3176. [Google Scholar] [CrossRef]

- Ejaz, N.; Ali, L.; Ahmad, A.; Mansoor, M.; Asim, M.M.; Rauf, A.; Mehmood, K. Thermo-physical properties measurement of advanced TBC materials with pyrochlore and perovskite structures. Key Eng. Mater. 2018, 778, 236–244. [Google Scholar] [CrossRef]

- Xu, J.; Sarin, V.; Dixit, S.; Basu, S. Stability of interfaces in hybrid EBC/TBC coatings for Si-based ceramics in corrosive environments. Int. J. Refract. Met. Hard Mater. 2015, 49, 339–349. [Google Scholar] [CrossRef]

- Shvydyuk, K.O.; Nunes-Pereira, J.; Rodrigues, F.F.; Páscoa, J.; Lanceros-Mendez, S.; Silva, A.P. Long-lasting ceramic composites for surface dielectric barrier discharge plasma actuators. J. Eur. Ceram. Soc. 2023, 43, 6112–6121. [Google Scholar] [CrossRef]

- Khasare, S.; Bagherighajari, F.; Dolati, F.; Mahmoudimehr, J.; Pascoa, J.; Abdollahzadeh, M. Control of the flame and flow characteristics of a non-premixed bluff body burner using dielectric barrier discharge plasma actuators. Appl. Therm. Eng. 2023, 235, 121432. [Google Scholar] [CrossRef]

- Abdollahzadeh, M.; Rodrigues, F.; Nunes-Pereira, J.; Pascoa, J.; Pires, L. Parametric optimization of surface dielectric barrier discharge actuators for ice sensing application. Sens. Actuators A Phys. 2022, 335, 113391. [Google Scholar] [CrossRef]

- Rodrigues, F.F.; Pascoa, J.C. Implementation of Stair-Shaped Dielectric Layers in Micro- and Macroplasma Actuators for Increased Efficiency and Lifetime. J. Fluids Eng. 2020, 142, 104502. [Google Scholar] [CrossRef]

- Nunes-Pereira, J.; Rodrigues, F.F.; Abdollahzadehsangroudi, M.; Páscoa, J.C.; Lanceros-Mendez, S. Improved performance of polyimide Cirlex-based dielectric barrier discharge plasma actuators for flow control. Polym. Adv. Technol. 2021, 33, 1278–1290. [Google Scholar] [CrossRef]

- ASTM C20-00; Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2022; p. 3.

- ASTM C1054–03; Standard Test Method for Drying and Firing Linear Change of Refractory Plastic and Ramming Mix Specimens. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2019; p. 3.

- ASTM C119–20; Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio for Advanced Ceramics by Sonic Resonance. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2020; p. 12.

- ASTM C1161–18; Standard Test Method for Flexural Strength of Advanced Ceramics at Ambient Temperature. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2019; p. 19.

- ASTM C1327; Standard Test Method for Vickers Indentation Hardness of Advanced Ceramics. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2019; p. 10.

- ASTM E1461-07; Standard Test Method for Thermal Diffusivity by the Flash Method. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2022; p. 11.

- ASTM E228-17; Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis. ASTM—American Society for Testing and Materials: West Conshohocken, PA, USA, 2012; p. 5.

- Somton, K.; Dateraksa, K.; Laoratanakul, P.; McCuiston, R. Shrinkage and Properties of Die Pressed Alumina Produced from Different Granule Sources. AIP Conf. Proc. 2020, 2279, 060003. [Google Scholar] [CrossRef]

- Shui, A.; Uchida, N.; Uematsu, K. Origin of Shrinkage Anisotropy During Sintering for Uniaxially Pressed Alumina Compacts. Powder Technol. 2002, 127, 9–18. [Google Scholar] [CrossRef]

- Szczerba, J.; Pdzich, Z.; Madej, D. Synthesis of Spinel-Calcium Zirconate Materials. Mater. Ceram. 2011, 63, 27–33. Available online: https://www.researchgate.net/profile/Zbigniew-Pedzich/publication/285158717_Synthesis_of_spinel-calcium_zirconate_materials_materialy_ceramiczne/links/5662adc108ae4931cd5ea54b/Synthesis-of-spinel-calcium-zirconate-materials-materialy-ceramiczne.pdf (accessed on 28 August 2022).

- Hu, L.; Wang, C.A. Effect of Sintering Temperature on Compressive Strength of Porous Yttria-Stabilized Zirconia Ceramics. Ceram. Int. 2010, 36, 1697–1701. [Google Scholar] [CrossRef]

- Ren, F.; Case, E.D.; Morrison, A.; Tafesse, M.; Baumann, M.J. Resonant ultrasound spectroscopy measurement of Young’s modulus, shear modulus and Poisson’s ratio as a function of porosity for alumina and hydroxyapatite. Philos. Mag. 2009, 89, 1163–1182. [Google Scholar] [CrossRef]

- Rice, R.W. The porosity dependence of physical properties of materials: A summary review. Key Eng. Mater. 1996, 115, 1–20. [Google Scholar] [CrossRef]

- Pabst, W.; Gregorová, E.; Tichá, G. Elasticity of porous ceramics—A critical study of modulus—porosity relations. J. Eur. Ceram. Soc. 2006, 26, 1085–1097. [Google Scholar] [CrossRef]

- Munro, M. Evaluated material properties for a sintered α-alumina. J. Am. Ceram. Soc. 1997, 80, 1919–1928. [Google Scholar] [CrossRef]

- Phani, K.K.; Sanyal, D. The relations between the shear modulus, the bulk modulus and Young’s modulus for porous isotropic ceramic materials. Mater. Sci. Eng. A 2008, 490, 305–312. [Google Scholar] [CrossRef]

- Heimann, R.B. Classic and Advanced Ceramics: From Fundamentals to Applications; Wiley & Sons: Hoboken, NJ, USA, 2010; Chapter 7; p. 176. [Google Scholar]

- High Purity Alumina (99.5%, 99.8%, 99.96%). STC Material Solutions, Ceramic Materials Solutions. Available online: https://www.ceramics.net/ceramic-materials-solutions/aluminas/high-purity (accessed on 28 August 2022).

- Heimann, R.B. Classic and Advanced Ceramics: From Fundamentals to Applications; Wiley & Sons: Hoboken, NJ, USA, 2010; Chapter 10; p. 361. [Google Scholar]

- Auerkari, P. Mechanical and Physical Properties of Engineering Alumina Ceramics. VTT Manufacturing Technology, ESPOO: Technical Research Centre of Finland. 1996. Available online: https://www.vttresearch.com/sites/default/files/pdf/tiedotteet/1996/T1792.pdf (accessed on 28 August 2022).

- Cabral, A.R.S. Melhoria da Resistência Mecânica do Compósito Cerâmico CaZrO3-MgO com a Adição de 3YSZ e 8YSZ. 2021. Available online: https://ubibliorum.ubi.pt/handle/10400.6/11881 (accessed on 28 August 2022).

- Mamede, J.; Macedo, D.F.; Maceiras, A.; Silva, A.P. Reinforcement of the Ceramic Matrix of CaO-ZrO2-MgO with Al2O3 Coarse Particles. Ceramics 2022, 5, 148–160. [Google Scholar] [CrossRef]

- Lang, J.F.; You, J.G.; Zhang, X.F.; Luo, X.D.; Zheng, S.Y. Effect of MgO on thermal shock resistance of CaZrO3 ceramic. Ceram. Int. 2018, 44, 22176–22180. [Google Scholar] [CrossRef]

- Zirconia Brochure. TOSOH Corporation. Available online: https://www.rbhltd.com/wp-content/uploads/2019/05/Tosoh-Zirconia-Brochure.pdf (accessed on 28 August 2022).

- Amarante, J.E.V.; Pereira, M.V.S.; Souza, G.M.; Alves, M.F.R.P.; Simba, B.G.; Santos, C. Roughness and its effects on flexural strength of dental yttria-stabilized zirconia ceramics. Mater. Sci. Eng. A 2019, 739, 149–157. [Google Scholar] [CrossRef]

- White, S.N.; Miklus, V.G.; McLaren, E.A.; Lang, L.A.; Caputo, A.A. Flexural strength of a layered zirconia and porcelain dental all-ceramic system. J. Prosthet. Dent. 2005, 94, 125–131. [Google Scholar] [CrossRef]

- Teng, X.; Liu, H.; Huang, C. Effect of Al2O3 particle size on the mechanical properties of alumina-based ceramics. Mater. Sci. Eng. A 2007, 452, 545–551. [Google Scholar] [CrossRef]

- Piconi, C.; Maccauro, G. Zirconia as a ceramic biomaterial. Biomaterials 1999, 20, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Ceramic Materia Comparison Chart. Precision Ceramics USA. 28 August 2022. Available online: https://precision-ceramics.com/materials/properties/hardness/ (accessed on 28 August 2022).

- Extreme Hardness Surpassing that of Metals. Fine Ceramic World. Available online: https://global.kyocera.com/fcworld/charact/strong/hardness.html (accessed on 28 August 2022).

- Nunes-Pereira, J.; Carneiro, P.M.; Maceiras, A.; Baudín, C.; Silva, A.P. Modelling of elastic modulus of CaZrO3-MgO composites using isotropic elastic and anisotropic models. J. Eur. Ceram. Soc. 2020, 40, 5882–5890. [Google Scholar] [CrossRef]

- Ternero, F.; Rosa, L.G.; Urban, P.; Montes, J.M.; Cuevas, F.G. Influence of the total porosity on the properties of sintered materials—A review. Metals 2021, 11, 730. [Google Scholar] [CrossRef]

- Balça, F. Otimização de Compósitos Multifásicos de Zircónia para Aplicações Termomecânicas Aeronáuticas. 2022. Available online: https://ubibliorum.ubi.pt/handle/10400.6/13019 (accessed on 28 August 2022).

- Rösler, J.; Harders, H.; Bäker, M. Mechanical Behaviour of Engineering Materials: Metals, Ceramics, Polymers, and Composites; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Wellman, R.G.; Dyer, A.; Nicholls, J.R. Nano and Micro indentation studies of bulk zirconia and EB PVD TBCs. Surf. Coat. Technol. 2004, 176, 253–260. [Google Scholar] [CrossRef]

- Ragurajan, D.; Golieskardi, M.; Satgunam, M.; Hoque, M.E.; Ng, A.M.H.; Ghazali, M.J.; Ariffin, A.K. Advanced 3Y-TZP bioceramic doped with Al2O3 and MnO2 particles potentially for biomedical applications: Study on mechanical and degradation properties. J. Mater. Res. Technol. 2018, 7, 432–442. [Google Scholar] [CrossRef]

- Silva, A.P.; Booth, F.; Garrido, L.; Aglietti, E.; Pena, P.; Baudín, C. Young’s modulus and hardness of multiphase CaZrO3-MgO ceramics by micro and nanoindentation. J. Eur. Ceram. Soc. 2018, 38, 2194–2201. [Google Scholar] [CrossRef]

- Cutler, R.A.; Reynolds, J.R.; Jones, A. Sintering and characterization of polycrystalline monoclinic, tetragonal, and cubic zirconia. J. Am. Ceram. Soc. 1992, 75, 2173–2183. [Google Scholar] [CrossRef]

- Glymond, D.; Vick, M.J.; Giuliani, F.; Vandeperre, L.J. High-temperature fracture toughness of mullite with monoclinic zirconia. J. Am. Ceram. Soc. 2017, 100, 1570–1577. [Google Scholar] [CrossRef]

- Rhee, S.K. Porosity—Thermal conductivity correlations for ceramic materials. Mater. Sci. Eng. 1975, 20, 89–93. [Google Scholar] [CrossRef]

- Sun, J.; Hu, Z.; Zhou, J.; Wang, X.; Sun, C. Thermal Properties of Highly Porous Fibrous Ceramics. In Proceedings of the 5th International Conference on Porous Media and Its Applications in Science and Engineering, Kona, Hawaii, 22–27 June 2014. [Google Scholar]

- Živcová, Z.; Gregorová, E.; Pabst, W.; Smith, D.S.; Michot, A.; Poulier, C. Thermal conductivity of porous alumina ceramics prepared using starch as a pore-forming agent. J. Eur. Ceram. Soc. 2009, 29, 347–353. [Google Scholar] [CrossRef]

- Carneiro, P.M.; Maceiras, A.; Nunes-Pereira, J.; Silva, P.D.; Silva, A.P.; Baudín, C. Property characterization and numerical modelling of the thermal conductivity of CaZrO3-MgO ceramic composites. J. Eur. Ceram. Soc. 2021, 41, 7241–7252. [Google Scholar] [CrossRef]

- Cao, X.; Vassen, R.; Stoever, D. Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 2004, 24, 1–10. [Google Scholar] [CrossRef]

- Thermal Conductivity Easily Transmits Heat. Fine Ceramics World. Available online: https://global.kyocera.com/fcworld/charact/heat/thermalcond.html?_sm_au_=iVVVM32RrVnNH5f6f7CV7K0qc3s8c (accessed on 28 August 2022).

- Zhao, H.; Yu, F.; Bennett, T.D.; Wadley, H.N. Morphology and thermal conductivity of yttria-stabilized zirconia coatings. Acta Mater. 2006, 54, 5195–5207. [Google Scholar] [CrossRef]

- Schlichting, K.W.; Padture, N.P.; Klemens, P.G. Thermal conductivity of dense and porous yttria-stabilized zirconia. J. Mater. Sci. 2001, 36, 3003–3010. [Google Scholar] [CrossRef]

- Schafföner, S.; Fruhstorfer, J.; Faßauer, C.; Freitag, L.; Jahn, C.; Aneziris, C.G. Influence of in situ phase formation on properties of calcium zirconate refractories. J. Eur. Ceram. Soc. 2017, 37, 305–313. [Google Scholar] [CrossRef]

- Schafföner, S.; Aneziris, C.G.; Berek, H.; Hubálková, J.; Priese, A. Fused calcium zirconate for refractory applications. J. Eur. Ceram. Soc. 2013, 33, 3411–3418. [Google Scholar] [CrossRef]

- Hou, Z.F. Ab initio calculations of elastic modulus and electronic structures of cubic CaZrO3. Phys. B Condens. Matter 2008, 403, 2624–2628. [Google Scholar] [CrossRef]

- Aksel, C.; Rand, B.; Riley, F.L.; Warren, P.D. Thermal shock behaviour of magnesia–spinel composites. J. Eur. Ceram. Soc. 2004, 24, 2839–2845. [Google Scholar] [CrossRef]

- Compare by Thermal Expansion Coefficient. Nishimura Advanced Ceramics. Available online: https://nishimuraac.com/propertie/compare-by-thermal-expansion-coefficient/ (accessed on 28 August 2022).

- Zirconia Ceramics. STC Material Solutions. Available online: https://ceramics.net/wp-content/uploads/stc-material-brochure-zirconia-ceramic-web-NEW-LOGO.pdf (accessed on 28 August 2022).

- Wintersgill, M.; Fontanella, J.; Andeen, C.; Schuele, D. The temperature variation of the dielectric constant of ‘‘pure’’ CaF2, SrF2, BaF2, and MgO. J. Appl. Phys. 1979, 50, 8259–8261. [Google Scholar] [CrossRef]

- Fontanella, J.; Andeen, C.; Schuele, D. Low-frequency dielectric constants of α-quartz, sapphire, MgF2, and MgO. J. Appl. Phys. 1974, 45, 2852–2854. [Google Scholar] [CrossRef]

- Bartels, R.; Smith, P. Pressure and temperature dependence of the static dielectric constants of KCl, NaCl, LiF, and MgO. Phys. Rev. B 1973, 7, 3885–3892. [Google Scholar] [CrossRef]

- Subramanian, M.; Shannon, R.; Chai, B.; Abraham, M.; Wintersgill, M. Dielectric constants of BeO, MgO, and CaO using the two-terminal method. Phys. Chem. Miner. 1989, 16, 741–746. [Google Scholar] [CrossRef]

- Birey, H. Thickness dependence of the dielectric constant and resistance of Al2O3 films. J. Appl. Phys. 1977, 48, 5209–5212. [Google Scholar] [CrossRef]

- Xing, C.; Wang, J.; Li, J.; Shi, F. Precise prediction of dielectric property for CaZrO3 ceramic. J. Adv. Dielectr. 2018, 8, 1850029. [Google Scholar] [CrossRef]

- Prasanth, C.; Kumar, H.; Pazhani, R.; Solomon, S.; Thomas, J. Synthesis, characterization and microwave dielectric properties of nanocrystalline CaZrO3 ceramics. J. Alloys Compd. 2008, 464, 306–309. [Google Scholar] [CrossRef]

- Lee, W.; Su, C.; Lee, Y.; Lin, S.; Yang, T. Effects of dopant on the dielectric properties of CaZrO3 ceramic sintered in a reducing atmosphere. Jpn. J. Appl. Phys. 2006, 45, 5853–5858. [Google Scholar] [CrossRef]

- Thorp, J.; Buckley, H. The dielectric constants of current-blackened single crystral yttria-stabilized zirconia. J. Mater. Sci. 1973, 8, 1401–1408. [Google Scholar] [CrossRef]

- Subramanian, M.; Shannon, R. Dielectric constant of Y-stabilized zirconia, the polarizability of zirconia and the oxide additivity rule. Mater. Res. Bull. 1989, 24, 1477–1483. [Google Scholar] [CrossRef]

- Lanagan, M.; Yamamoto, J.; Bhalla, A.; Sankar, S. The dielectric properties of yttria-stabilized zirconia. Mater. Lett. 1989, 7, 437–440. [Google Scholar] [CrossRef]

- Liang, G.; Bi, J.; Sun, G.; Wang, W.; Wang, L. Effect of boron nitride nanosheets addition on the mechanical and dielectric properties of magnesium oxide ceramics. Ceram. Int. 2020, 46, 23669–23676. [Google Scholar] [CrossRef]

- Rajab, K.; Naftaly, M.; Linfield, E.; Nino, J.; Arenas, D.; Tanner, D.; Mittra, R.; Lanagan, M. Broadband dielectric characterization of aluminum oxide (Al2O3). J. Microelectron. Electron. Packag. 2008, 5, 2–7. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, P.; Mondal, D. Advanced Ceramics for Versatile Interdisciplinary Applications; Elsevier: Amsterdam, The Netherlands, 2022; pp. 89–109. [Google Scholar]

- Jebli, M.; Rayssi, C.; Dhahri, J.; Henda, M.; Belmabrouk, H.; Bajahzar, A. Structural and morphological studies, and temperature/frequency dependence of electrical conductivity of Ba0.97La0.02Ti1−xNb4x/5O3 perovskite ceramics. RSC Adv. 2021, 11, 23664–23678. [Google Scholar] [CrossRef] [PubMed]

| Ceramic Composite | Sintering Temperature [°C] | |

|---|---|---|

| MA | 13.0 ± 0.2 | 1600 |

| MCZ | 24.0 ± 0.1 | 1450 |

| YSZ | 27.4 ± 0.3 | 1450 |

| Ceramic Composite | Thermal Conductivity [W/(mK)] | |

|---|---|---|

| Room Temperature (30 °C) | High Temperature (700 °C) | |

| MA | 5.61 | 2.95 |

| MCZ | 6.95 | 3.59 |

| YSZ | 2.87 | 1.91 |

| Ceramic Composite | Material CTE [10−6/°C] | |

|---|---|---|

| Room Temperature [20; 30] | High Temperature [800; 950] | |

| MA | 5.6 | 9.0 |

| MCZ | 8.2 | 10.9 |

| YSZ | 9.3 | 11.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shvydyuk, K.O.; Nunes-Pereira, J.; Rodrigues, F.F.; Páscoa, J.C.; Lanceros-Mendez, S.; Silva, A.P. Holistic Characterization of MgO-Al2O3, MgO-CaZrO3, and Y2O3-ZrO2 Ceramic Composites for Aerospace Propulsion Systems. Ceramics 2024, 7, 364-384. https://doi.org/10.3390/ceramics7010023

Shvydyuk KO, Nunes-Pereira J, Rodrigues FF, Páscoa JC, Lanceros-Mendez S, Silva AP. Holistic Characterization of MgO-Al2O3, MgO-CaZrO3, and Y2O3-ZrO2 Ceramic Composites for Aerospace Propulsion Systems. Ceramics. 2024; 7(1):364-384. https://doi.org/10.3390/ceramics7010023

Chicago/Turabian StyleShvydyuk, Kateryna O., João Nunes-Pereira, Frederico F. Rodrigues, José C. Páscoa, Senentxu Lanceros-Mendez, and Abílio P. Silva. 2024. "Holistic Characterization of MgO-Al2O3, MgO-CaZrO3, and Y2O3-ZrO2 Ceramic Composites for Aerospace Propulsion Systems" Ceramics 7, no. 1: 364-384. https://doi.org/10.3390/ceramics7010023

APA StyleShvydyuk, K. O., Nunes-Pereira, J., Rodrigues, F. F., Páscoa, J. C., Lanceros-Mendez, S., & Silva, A. P. (2024). Holistic Characterization of MgO-Al2O3, MgO-CaZrO3, and Y2O3-ZrO2 Ceramic Composites for Aerospace Propulsion Systems. Ceramics, 7(1), 364-384. https://doi.org/10.3390/ceramics7010023