Hydroxyapatite-Resin Composites Produced by Vat Photopolymerization and Post-Processing via In Situ Hydrolysis of Alpha Tricalcium Phosphate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Feedstock Materials

2.2. Vat Photopolymerization

2.3. Hydrothermal Treatments

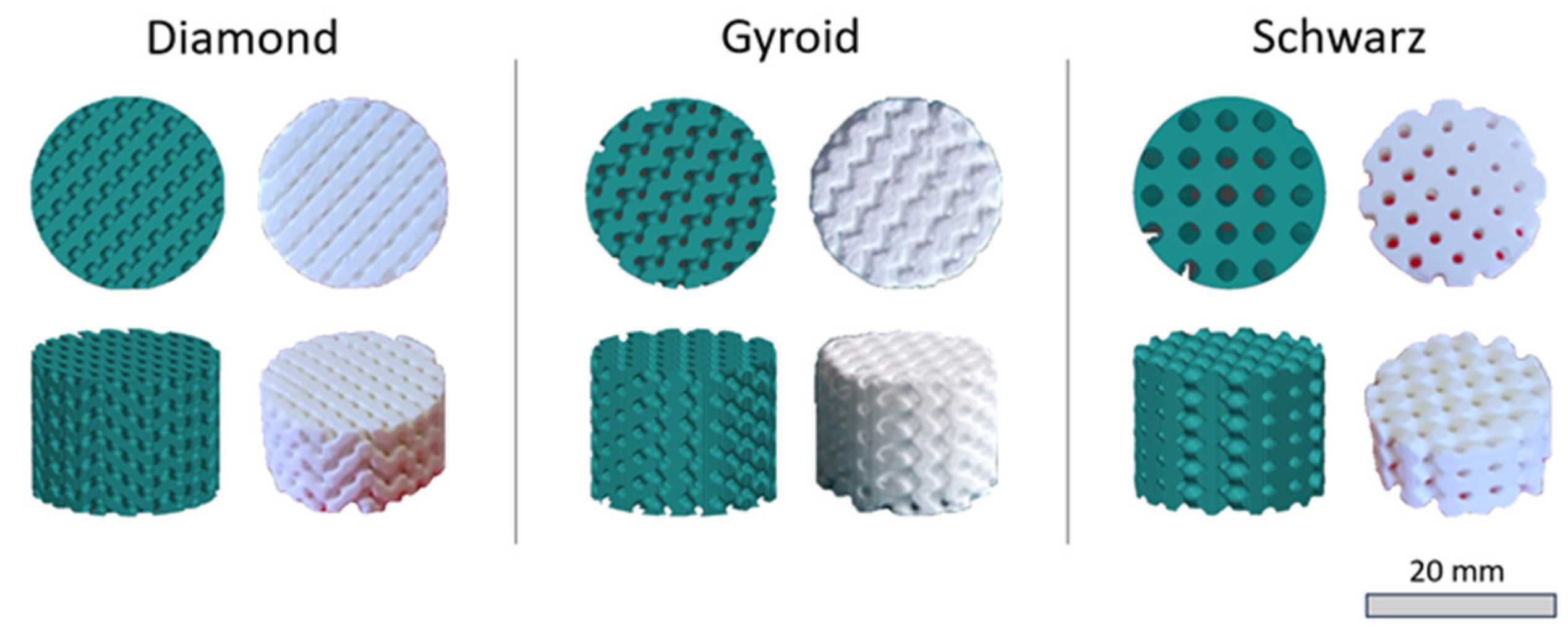

2.4. Fabrication of Porous Structures

2.5. Physicochemical and Structural Characterization

3. Results

3.1. Polymerization Process and as Printed Structures

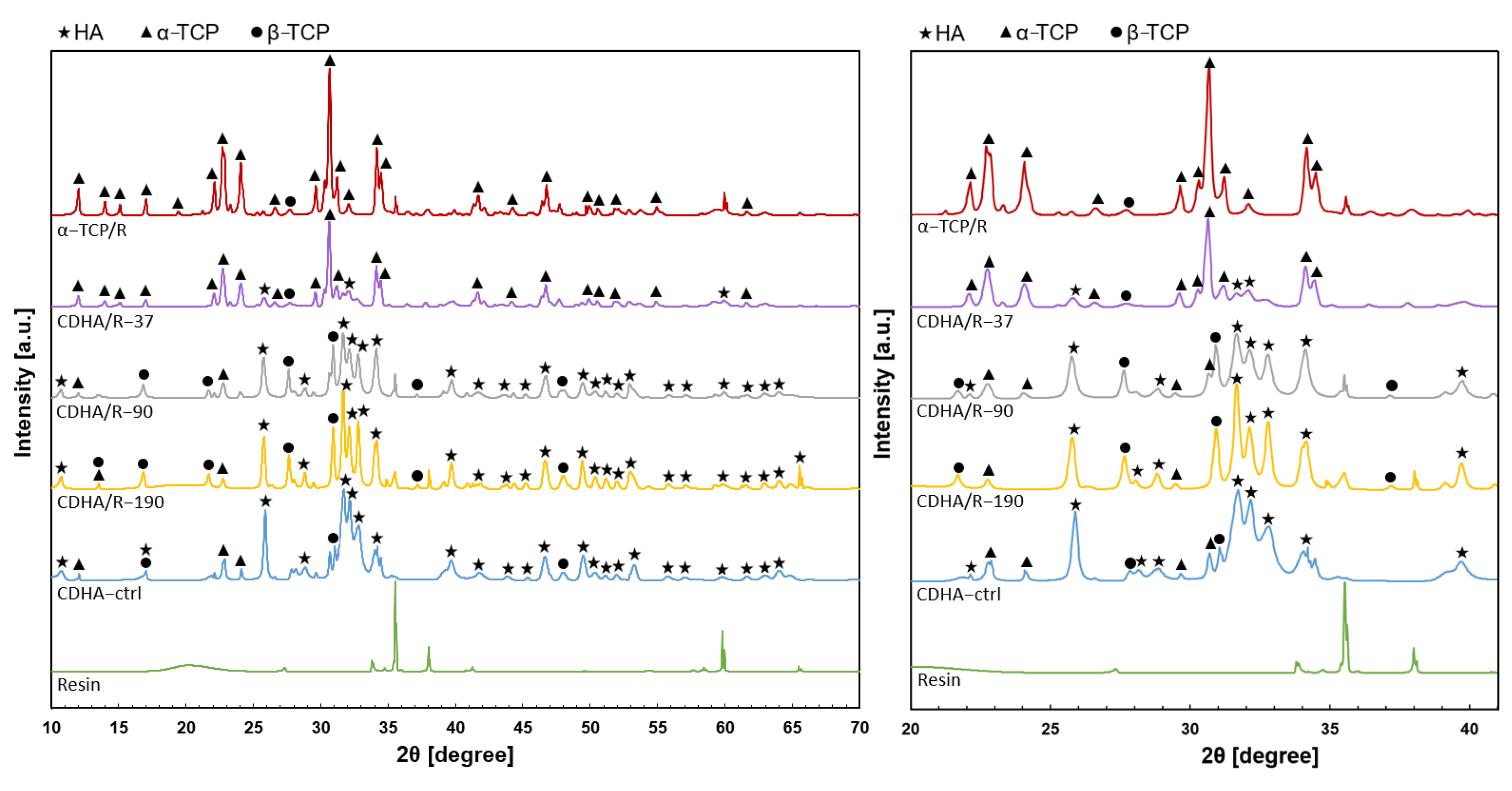

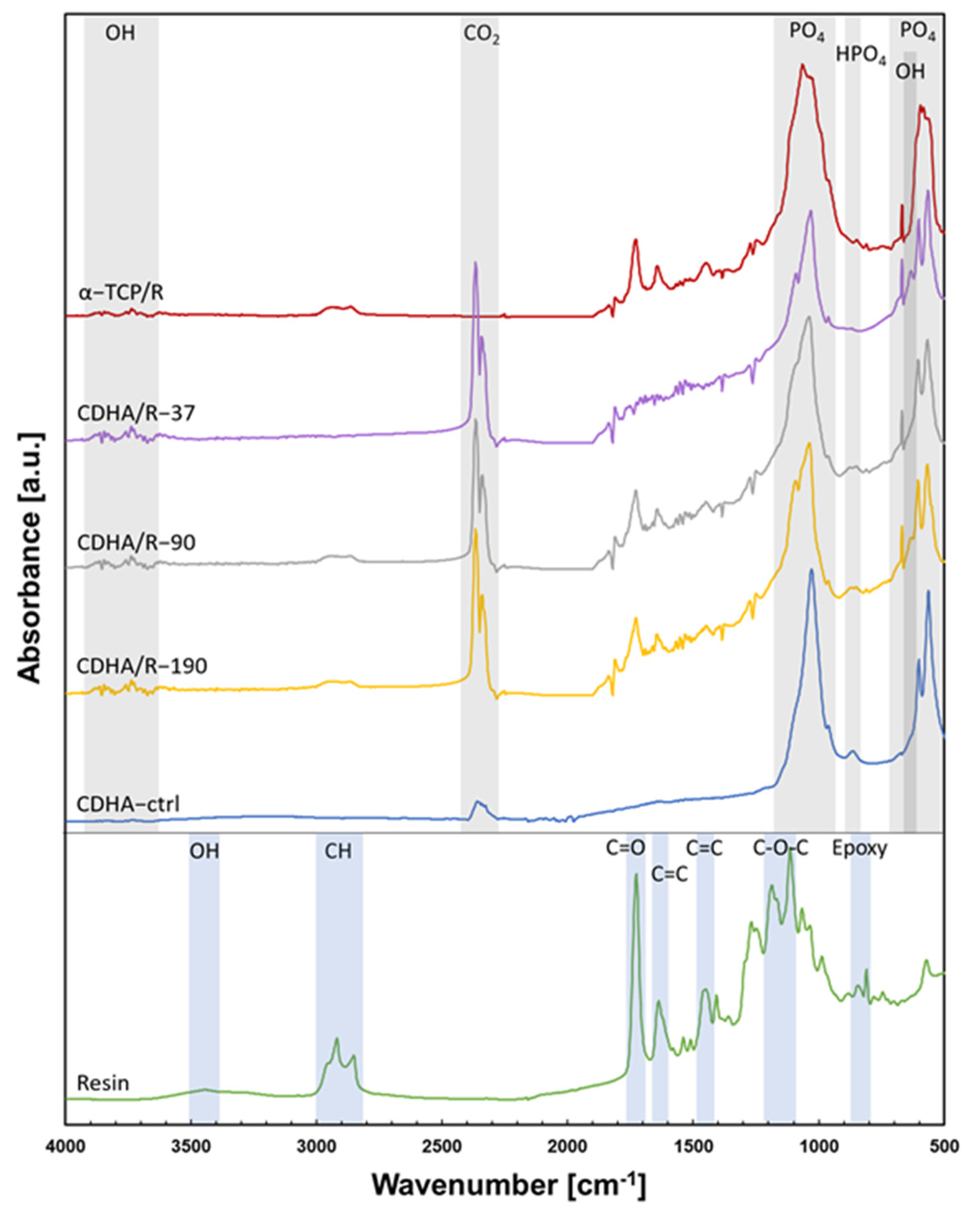

3.2. Hydrothermal Treatment

3.3. Mechanical Characterization

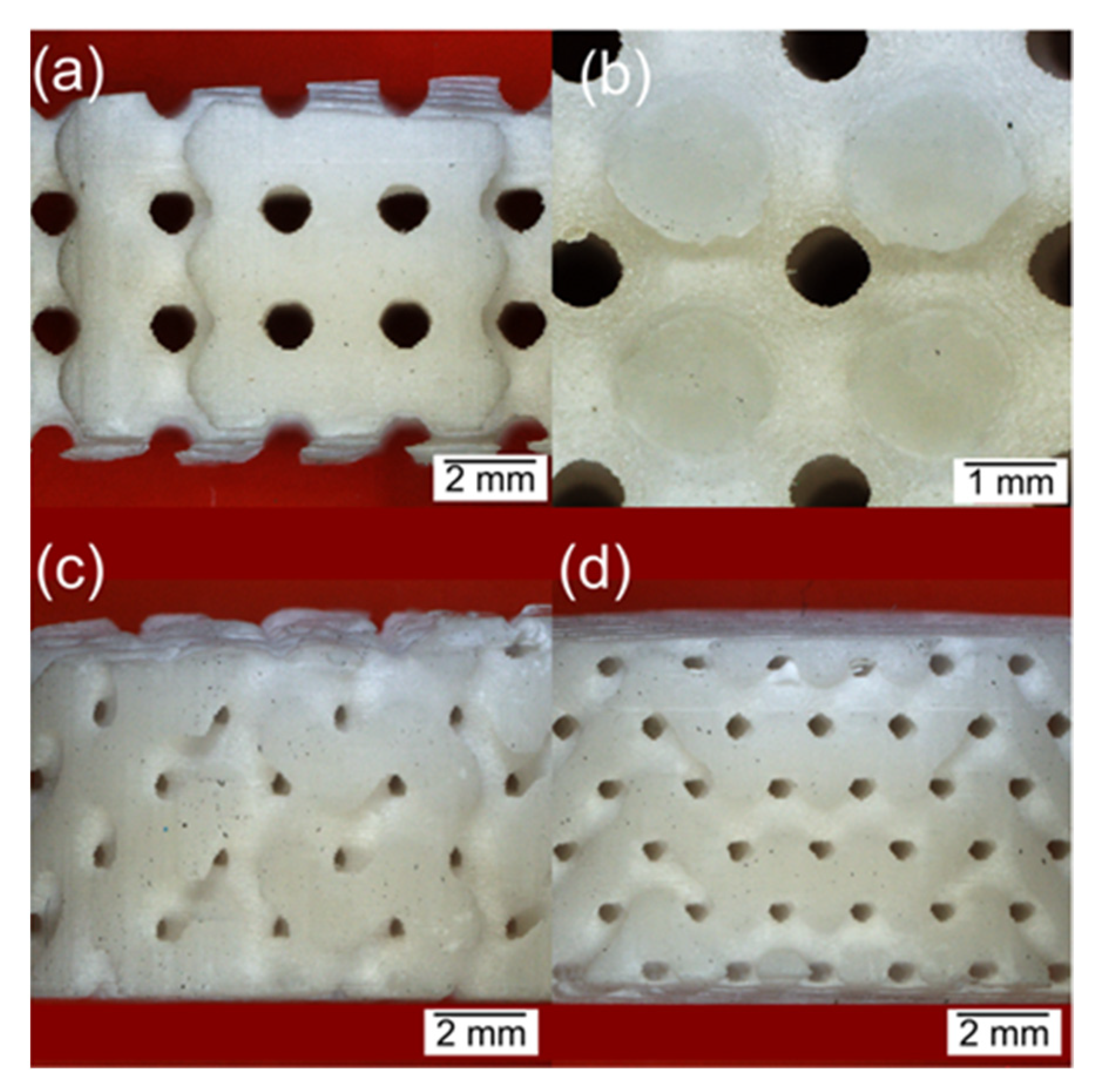

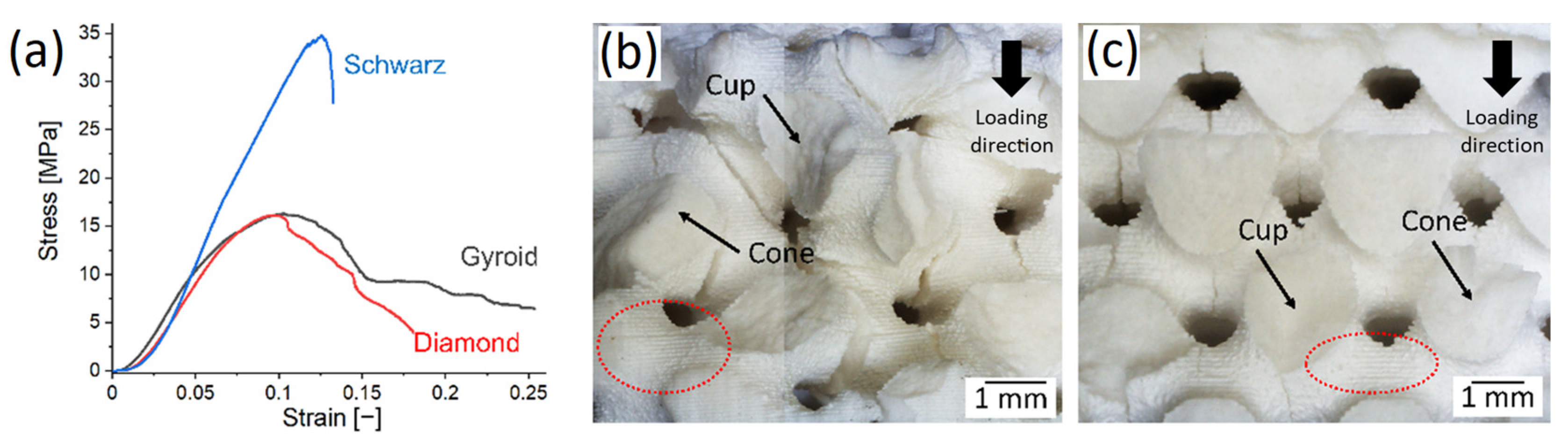

3.4. TPMS Porous Composite Structures

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Paral, S.K.; Lin, D.Z.; Cheng, Y.L.; Lin, S.C.; Jeng, J.Y. A Review of Critical Issues in High-Speed Vat Photopolymerization. Polymers 2023, 15, 2716. [Google Scholar] [CrossRef] [PubMed]

- Medellin, A.; Du, W.; Miao, G.; Zou, J.; Pei, Z.; Ma, C. Vat Photopolymerization 3d Printing of Nanocomposites: A Literature Review. J. Micro Nano-Manuf. 2019, 7, 031006. [Google Scholar] [CrossRef]

- Zakeri, S.; Vippola, M.; Levänen, E. A Comprehensive Review of the Photopolymerization of Ceramic Resins Used in Stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Papadakis, V.M.; Mountakis, N. Multifunctional Medical Grade Resin with Enhanced Mechanical and Antibacterial Properties: The Effect of Copper Nano-Inclusions in Vat Polymerization (VPP) Additive Manufacturing. J. Funct. Biomater. 2022, 13, 258. [Google Scholar] [CrossRef] [PubMed]

- Lala, S.D.; Deoghare, A.B.; Chatterjee, S. Effect of Reinforcements on Polymer Matrix Bio-Composites—An Overview. IEEE J. Sel. Top. Quantum Electron. 2018, 25, 1039–1058. [Google Scholar] [CrossRef]

- Li, Y.; Wang, W.; Wu, F.; Kankala, R.K. Vat Polymerization-Based 3D Printing of Nanocomposites: A Mini Review. Front. Mater. 2023, 9, 1118943. [Google Scholar] [CrossRef]

- Chiappone, A.; Fantino, E.; Roppolo, I.; Lorusso, M.; Manfredi, D.; Fino, P.; Pirri, C.F.; Calignano, F. 3D Printed PEG-Based Hybrid Nanocomposites Obtained by Sol-Gel Technique. ACS Appl. Mater. Interfaces 2016, 8, 5627–5633. [Google Scholar] [CrossRef]

- Fantino, E.; Chiappone, A.; Calignano, F.; Fontana, M.; Pirri, F.; Roppolo, I. In Situ Thermal Generation of Silver Nanoparticles in 3D Printed Polymeric Structures. Materials 2016, 9, 589. [Google Scholar] [CrossRef]

- Tronco, M.C.; Cassel, J.B.; dos Santos, L.A. α-TCP-Based Calcium Phosphate Cements: A Critical Review. Acta Biomater. 2022, 151, 70–87. [Google Scholar] [CrossRef]

- Ginebra, M.P.; Fernández, E.; De Maeyer, E.A.P.; Verbeeck, R.M.H.; Boltong, M.G.; Ginebra, J.; Driessens, F.C.M.; Planell, J.A. Setting Reaction and Hardening of an Apatitic Calcium Phosphate Cement. J. Dent. Res. 1997, 76, 905–912. [Google Scholar] [CrossRef]

- Paredes, C.; Martínez-Vázquez, F.J.; Elsayed, H.; Colombo, P.; Pajares, A.; Miranda, P. Evaluation of Direct Light Processing for the Fabrication of Bioactive Ceramic Scaffolds: Effect of Pore/Strut Size on Manufacturability and Mechanical Performance. J. Eur. Ceram. Soc. 2021, 41, 892–900. [Google Scholar] [CrossRef]

- Scalera, F.; Esposito Corcione, C.; Montagna, F.; Sannino, A.; Maffezzoli, A. Development and Characterization of UV Curable Epoxy/Hydroxyapatite Suspensions for Stereolithography Applied to Bone Tissue Engineering. Ceram. Int. 2014, 40, 15455–15462. [Google Scholar] [CrossRef]

- Lee, Y.H.; Lee, J.B.; Maeng, W.Y.; Koh, Y.H.; Kim, H.E. Photocurable Ceramic Slurry Using Solid Camphor as Novel Diluent for Conventional Digital Light Processing (DLP) Process. J. Eur. Ceram. Soc. 2019, 39, 4358–4365. [Google Scholar] [CrossRef]

- Goutagny, C.; Hocquet, S.; Hautcoeur, D.; Lasgorceix, M.; Somers, N.; Leriche, A. Development of Calcium Phosphate Suspensions Suitable for the Stereolithography Process. Open Ceram. 2021, 7, 100167. [Google Scholar] [CrossRef]

- Liu, Z.; Liang, H.; Shi, T.; Xie, D.; Chen, R.; Han, X.; Shen, L.; Wang, C.; Tian, Z. Additive Manufacturing of Hydroxyapatite Bone Scaffolds via Digital Light Processing and in Vitro Compatibility. Ceram. Int. 2019, 45, 11079–11086. [Google Scholar] [CrossRef]

- Lasgorceix, M.; Champion, E.; Chartier, T. Shaping by Microstereolithography and Sintering of Macro-Micro-Porous Silicon Substituted Hydroxyapatite. J. Eur. Ceram. Soc. 2016, 36, 1091–1101. [Google Scholar] [CrossRef]

- Mohammadi, M.; Coppola, B.; Montanaro, L.; Palmero, P. Digital Light Processing of High-Strength Hydroxyapatite Ceramics: Role of Particle Size and Printing Parameters on Microstructural Defects and Mechanical Properties. J. Eur. Ceram. Soc. 2023, 43, 2761–2772. [Google Scholar] [CrossRef]

- Poralan, G.M.; Gambe, J.E.; Alcantara, E.M.; Vequizo, R.M. X-Ray Diffraction and Infrared Spectroscopy Analyses on the Crystallinity of Engineered Biological Hydroxyapatite for Medical Application. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2015; Volume 79. [Google Scholar]

- Galea, L.; Alexeev, D.; Bohner, M.; Doebelin, N.; Studart, A.R.; Aneziris, C.G.; Graule, T. Textured and Hierarchically Structured Calcium Phosphate Ceramic Blocks through Hydrothermal Treatment. Biomaterials 2015, 67, 93–103. [Google Scholar] [CrossRef]

- Raymond, S.; Maazouz, Y.; Montufar, E.B.; Perez, R.A.; González, B.; Konka, J.; Kaiser, J.; Ginebra, M.P. Accelerated Hardening of Nanotextured 3D-Plotted Self-Setting Calcium Phosphate Inks. Acta Biomater. 2018, 75, 451–462. [Google Scholar] [CrossRef]

- Wang, B.; Li, D.; Xian, G.; Li, C. Effect of Immersion in Water or Alkali Solution on the Structures and Properties of Epoxy Resin. Polymers 2021, 13, 1902. [Google Scholar] [CrossRef]

- Kashimbetova, A.; Slámečka, K.; Casas-Luna, M.; Oliver-Urrutia, C.; Ravaszová, S.; Dvořák, K.; Čelko, L.; Montufar, E.B. Implications of Unconventional Setting Conditions on the Mechanical Strength of Synthetic Bone Grafts Produced with Self-Hardening Calcium Phosphate Pastes. Ceram. Int. 2022, 48, 6225–6235. [Google Scholar] [CrossRef]

- Golhin, A.P.; Tonello, R.; Frisvad, J.R.; Grammatikos, S.; Strandlie, A. Surface Roughness of As-Printed Polymers: A Comprehensive Review. Int. J. Adv. Manuf. Technol. 2023, 127, 987–1043. [Google Scholar] [CrossRef]

- Rodriguez, E.L. Cup-and-Cone Fracture Surfaces in Polyvinyl Chloride Due to Tensile Fatigue. J. Mater. Sci. Lett. 1995, 14, 1230–1233. [Google Scholar] [CrossRef]

- Weng, Z.; Zhou, Y.; Lin, W.; Senthil, T.; Wu, L. Structure-Property Relationship of Nano Enhanced Stereolithography Resin for Desktop SLA 3D Printer. Compos. Part A Appl. Sci. Manuf. 2016, 88, 234–242. [Google Scholar] [CrossRef]

- Corcione, C.E.; Cataldi, A.; Frigione, M. Measurements of Size Distribution Nanoparticles in Ultraviolet-Curable Methacrylate-Based Boehmite Nanocomposites. J. Appl. Polym. Sci. 2013, 128, 4102–4109. [Google Scholar] [CrossRef]

- Kumar, S.; Hofmann, M.; Steinmann, B.; Foster, E.J.; Weder, C. Reinforcement of Stereolithographic Resins for Rapid Prototyping with Cellulose Nanocrystals. ACS Appl. Mater. Interfaces 2012, 4, 5399–5407. [Google Scholar] [CrossRef]

- Chong, Y.T.; Tan, C.S.H.; Liu, L.Y.; Liu, J.; Teng, C.P.; Wang, F.K. Enhanced Dispersion of Hydroxyapatite Whisker in Orthopedics 3D Printing Resin with Improved Mechanical Performance. J. Appl. Polym. Sci. 2021, 138, 50811. [Google Scholar] [CrossRef]

- Makvandi, P.; Esposito Corcione, C.; Paladini, F.; Gallo, A.L.; Montagna, F.; Jamaledin, R.; Pollini, M.; Maffezzoli, A. Antimicrobial Modified Hydroxyapatite Composite Dental Bite by Stereolithography. Polym. Adv. Technol. 2018, 29, 364–371. [Google Scholar] [CrossRef]

- Friedman, C.D.; Costantino, P.D.; Takagi, S.; Chow, L.C. Bonesource(TM) Hydroxyapatite Cement: A Novel Biomaterial for Craniofacial Skeletal Tissue Engineering and Reconstruction. J. Biomed. Mater. Res. 1998, 43, 428–432. [Google Scholar] [CrossRef]

- Yunus, D.E.; Shi, W.; Sohrabi, S.; Liu, Y. Shear Induced Alignment of Short Nanofibers in 3D Printed Polymer Composites. Nanotechnology 2016, 27, 495302. [Google Scholar] [CrossRef]

- Manapat, J.Z.; Mangadlao, J.D.; Tiu, B.D.B.; Tritchler, G.C.; Advincula, R.C. High-Strength Stereolithographic 3D Printed Nanocomposites: Graphene Oxide Metastability. ACS Appl. Mater. Interfaces 2017, 9, 10085–10093. [Google Scholar] [CrossRef]

- Gonzalez, G.; Chiappone, A.; Roppolo, I.; Fantino, E.; Bertana, V.; Perrucci, F.; Scaltrito, L.; Pirri, F.; Sangermano, M. Development of 3D Printable Formulations Containing CNT with Enhanced Electrical Properties. Polymer 2017, 109, 246–253. [Google Scholar] [CrossRef]

- Dall’Oca, C.; Maluta, T.; Cavani, F.; Morbioli, G.P.; Bernardi, P.; Sbarbati, A.; Degl’Innocenti, D.; Magnan, B. The Biocompatibility of Porous vs Non-Porous Bone Cements: A New Methodological Approach. Eur. J. Histochem. 2014, 58, 2255. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, K.; Zhang, S.; Fan, J.; Guo, X.; Dong, W.; Wang, S.; Chen, Y.; Yu, B. Preparation of Calcium Phosphate Cement and Polymethyl Methacrylate for Biological Composite Bone Cements. Med. Sci. Monit. 2015, 21, 1162. [Google Scholar] [CrossRef] [PubMed]

- Beruto, D.T.; Mezzasalma, S.A.; Capurro, M.; Botter, R.; Cirillo, P. Use of α-Tricalcium Phosphate (TCP) as Powders and as an Aqueous Dispersion to Modify Processing, Microstructure, and Mechanical Properties of Polymethylmethacrylate (PMMA) Bone Cements and to Produce Bone-Substitute Compounds. J. Biomed. Mater. Res. 2000, 49, 498–505. [Google Scholar] [CrossRef]

- Gao, S.; Lv, Y.; Yuan, L.; Ren, H.; Wu, T.; Liu, B.; Zhang, Y.; Zhou, R.; Li, A.; Zhou, F. Improved Bone Ingrowth of Tricalcium Phosphate Filled Poly(Methyl Methacrylate) (PMMA) Bone Cements In Vivo. Polym. Test. 2019, 76, 513–521. [Google Scholar] [CrossRef]

- Sugawara, A.; Antonucci, J.M.; Takagi, S.; Chow, L.C.; Ohashi, M. Formation of Hydroxyapatite in Hydrogels from Tetracalcium Phosphate/Dicalcium Phosphate Mixtures. J. Nihon Univ. Sch. Dent. 1989, 31, 372–381. [Google Scholar] [CrossRef] [PubMed]

- Gbureck, U.; Spatz, K.; Thull, R.; Barralet, J.E. Rheological Enhancement of Mechanically Activated α-Tricalcium Phosphate Cements. J. Biomed. Mater. Res.—Part B Appl. Biomater. 2005, 73, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Mickiewicz, R.A.; Mayes, A.M.; Knaack, D. Polymer-Calcium Phosphate Cement Composites for Bone Substitutes. J. Biomed. Mater. Res. 2002, 61, 581–592. [Google Scholar] [CrossRef]

- Xu, H.H.K.; Burguera, E.F.; Carey, L.E. Strong, Macroporous, and in Situ-Setting Calcium Phosphate Cement-Layered Structures. Biomaterials 2007, 28, 3786–3796. [Google Scholar] [CrossRef]

- Chen, W.C.; Ju, C.P.; Wang, J.C.; Hung, C.C.; Chern Lin, J.H. Brittle and Ductile Adjustable Cement Derived from Calcium Phosphate Cement/Polyacrylic Acid Composites. Dent. Mater. 2008, 24, 1616–1622. [Google Scholar] [CrossRef] [PubMed]

- Matsuya, Y.; Antonucci, J.M.; Matsuya, S.; Takagi, S.; Chow, L.C. Polymeric Calcium Phosphate Cements Derived from Poly(Methyl Vinyl Ether-Maleic Acid). Dent. Mater. 1996, 12, 2–7. [Google Scholar] [CrossRef] [PubMed]

- Keshavarzan, M.; Kadkhodaei, M.; Badrossamay, M.; Karamooz Ravari, M.R. Investigation on the Failure Mechanism of Triply Periodic Minimal Surface Cellular Structures Fabricated by Vat Photopolymerization Additive Manufacturing under Compressive Loadings. Mech. Mater. 2020, 140, 103150. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliver-Urrutia, C.; Drotárová, L.; Gascón-Pérez, S.; Slámečka, K.; Ravaszová, S.; Čelko, L.; Montufar, E.B. Hydroxyapatite-Resin Composites Produced by Vat Photopolymerization and Post-Processing via In Situ Hydrolysis of Alpha Tricalcium Phosphate. Ceramics 2023, 6, 2282-2294. https://doi.org/10.3390/ceramics6040139

Oliver-Urrutia C, Drotárová L, Gascón-Pérez S, Slámečka K, Ravaszová S, Čelko L, Montufar EB. Hydroxyapatite-Resin Composites Produced by Vat Photopolymerization and Post-Processing via In Situ Hydrolysis of Alpha Tricalcium Phosphate. Ceramics. 2023; 6(4):2282-2294. https://doi.org/10.3390/ceramics6040139

Chicago/Turabian StyleOliver-Urrutia, Carolina, Lenka Drotárová, Sebastián Gascón-Pérez, Karel Slámečka, Simona Ravaszová, Ladislav Čelko, and Edgar B. Montufar. 2023. "Hydroxyapatite-Resin Composites Produced by Vat Photopolymerization and Post-Processing via In Situ Hydrolysis of Alpha Tricalcium Phosphate" Ceramics 6, no. 4: 2282-2294. https://doi.org/10.3390/ceramics6040139

APA StyleOliver-Urrutia, C., Drotárová, L., Gascón-Pérez, S., Slámečka, K., Ravaszová, S., Čelko, L., & Montufar, E. B. (2023). Hydroxyapatite-Resin Composites Produced by Vat Photopolymerization and Post-Processing via In Situ Hydrolysis of Alpha Tricalcium Phosphate. Ceramics, 6(4), 2282-2294. https://doi.org/10.3390/ceramics6040139