Frequency Characteristics of High Strain Rate Compressions of Cf-MWCNTs/SiC Composites

Abstract

:1. Introduction

2. Materials and Methods

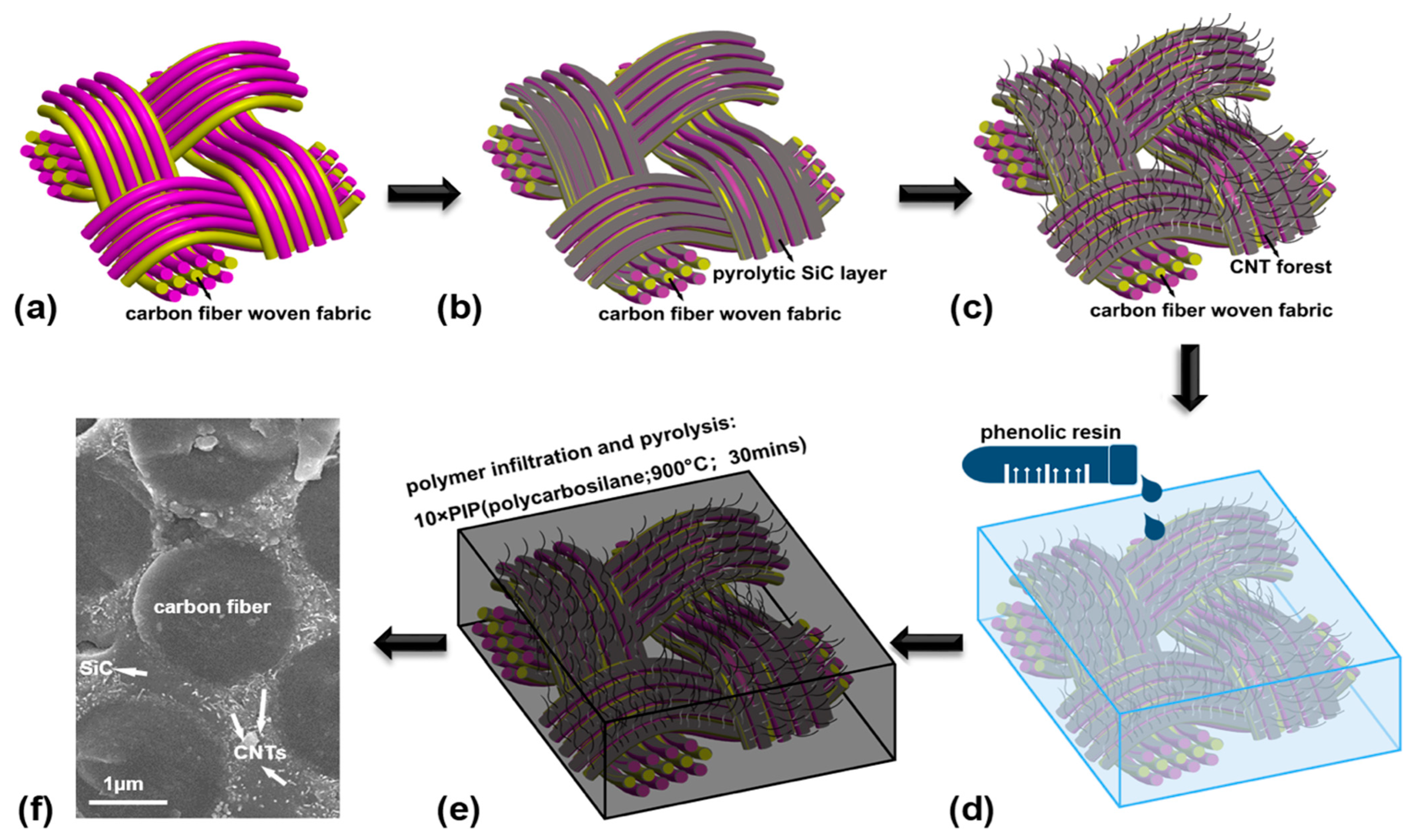

2.1. Cf-MWCNT/SiC Composites

- Coating carbon woven fabrics with SiC precursor and then pyrolyzing it (Figure 1a,b).

- Synthesizing multiwall carbon nanotube forest on the surface of carbon woven fabrics (Figure 1c).

- The combination of fabric reinforcement with matrix using the PIP process (Figure 1d,e).

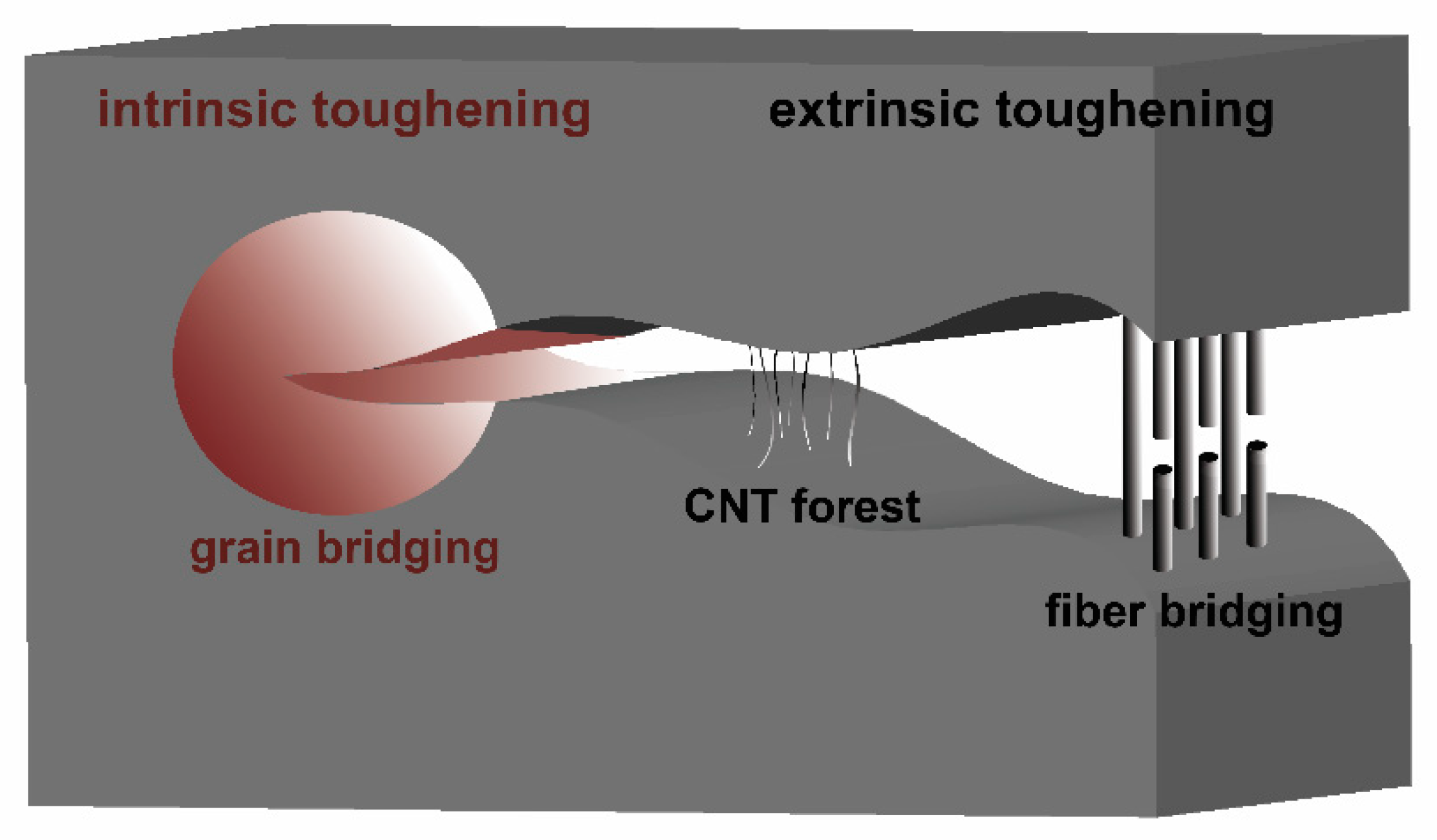

2.2. Toughening Mechanism of Using MWCNTs Coated Carbon Fabric as Reinforcement

2.3. Methods

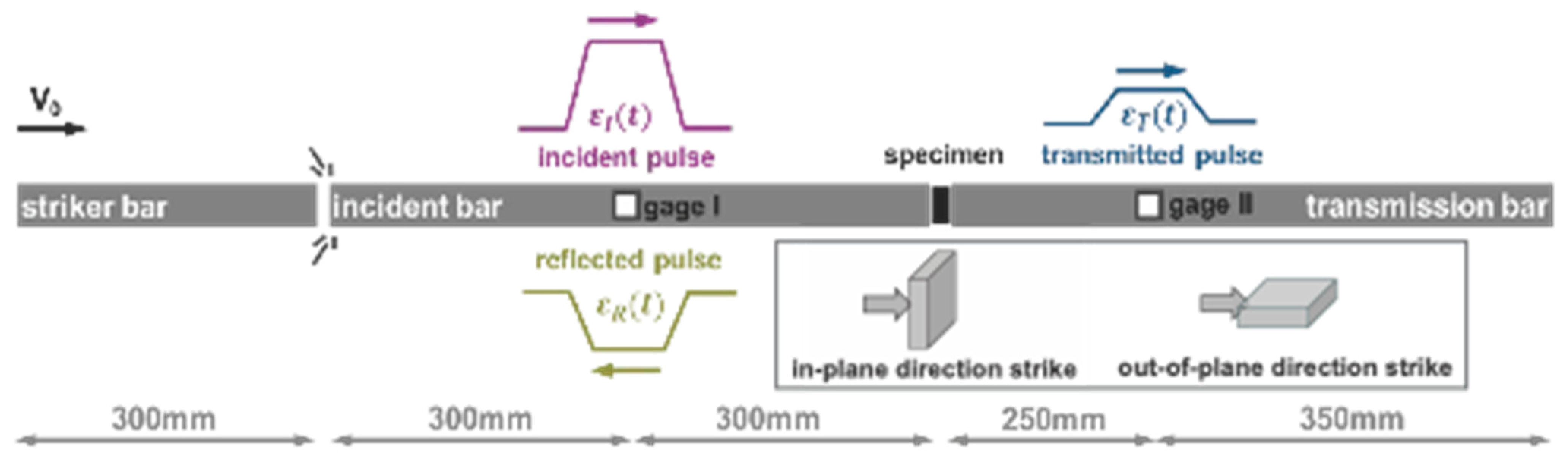

2.3.1. Characterizations of High Strain Rate and Quasi-Static Compressions Properties

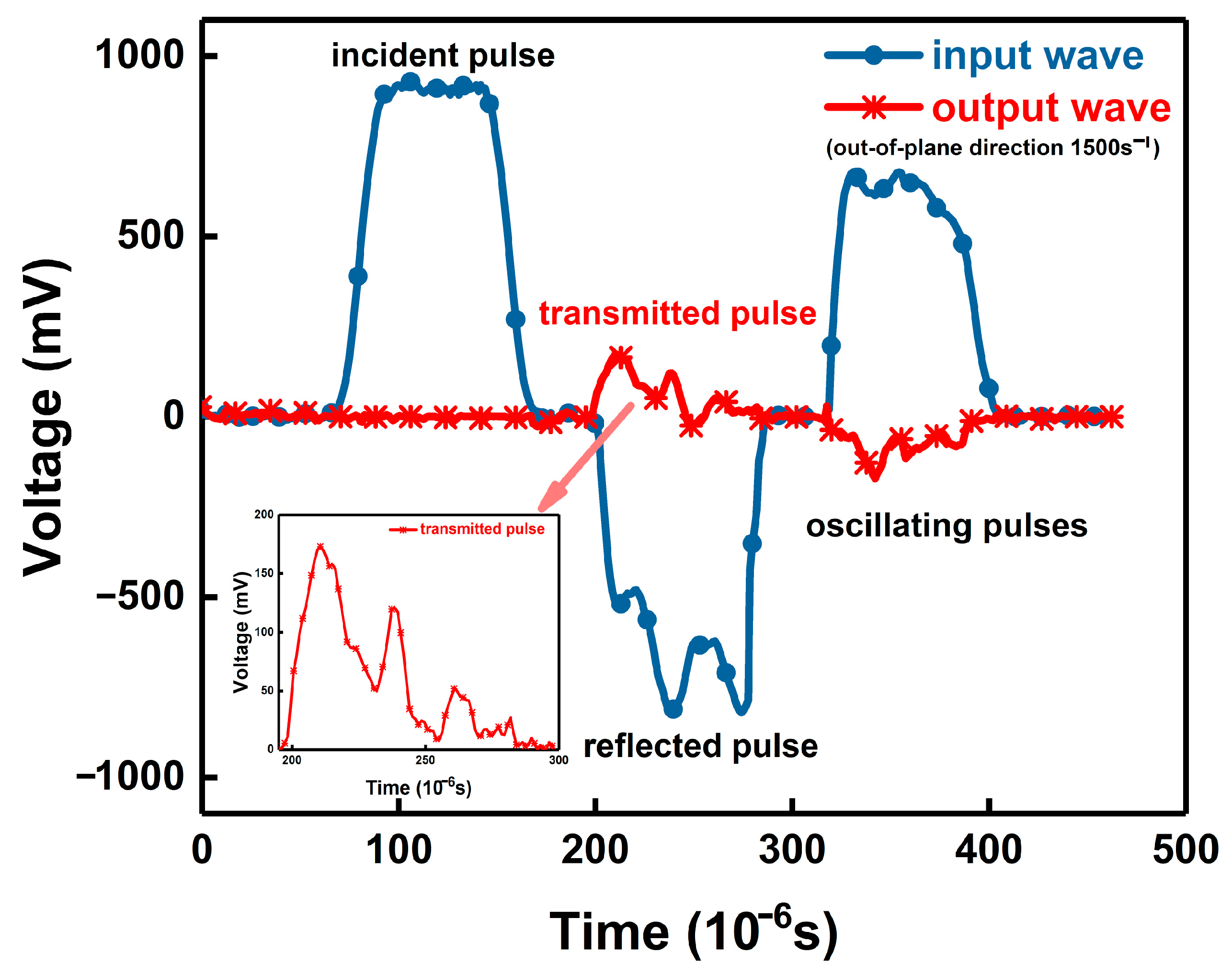

2.3.2. Typical SHPB Signals of Cf-MWCNT/SiC Composites

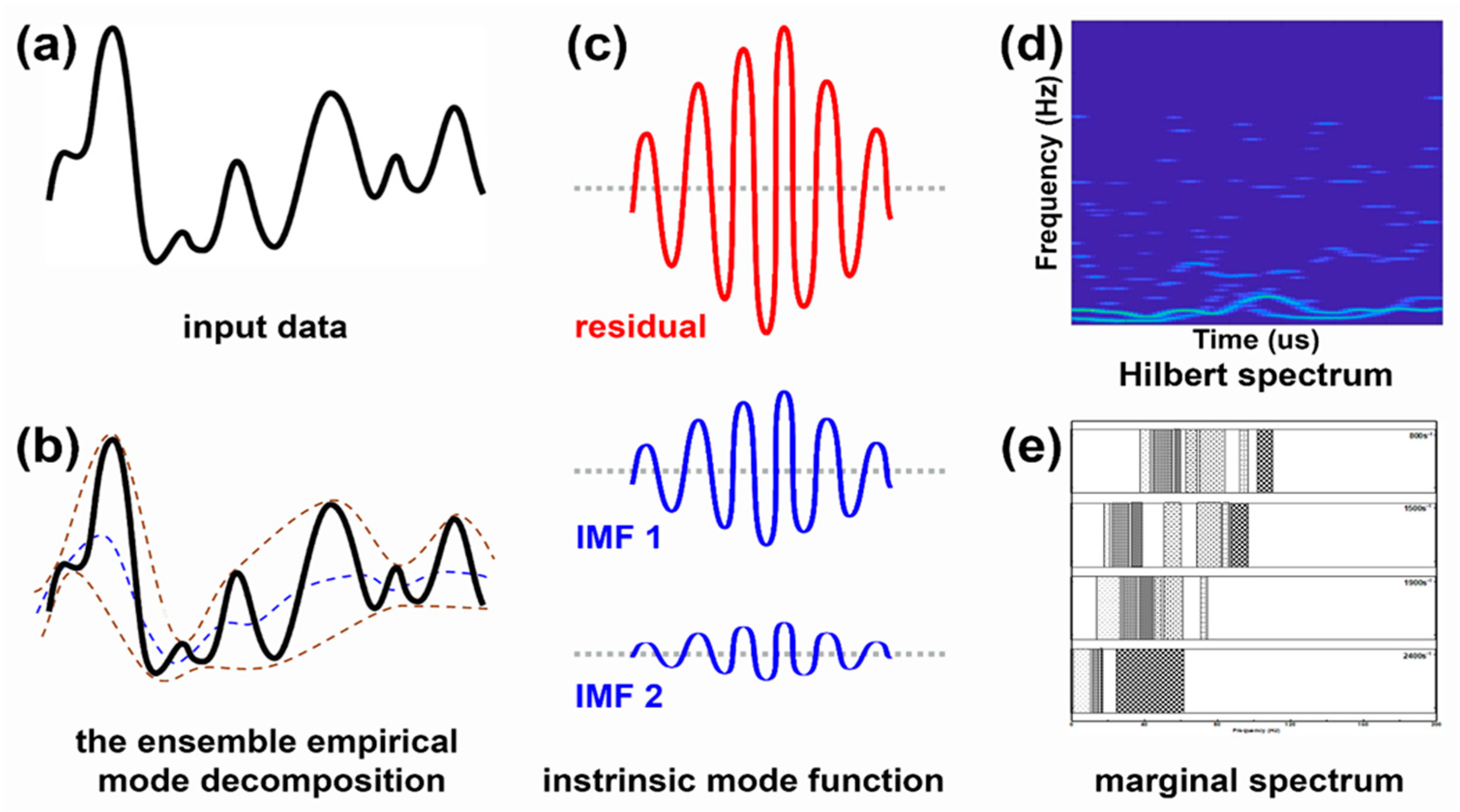

2.3.3. Hilbert–Huang Transform

- Produce a noise-added signal to the input data y(t) using Equation (4),where is Gaussian white noise.

- Decompose yi(t) into IMFs and one residue using Equation (5),where is residue.

- Repeat steps 1 and 2 with by using as new signal data.

- Take the average of all IMFs and prepare for the Hilbert transform.

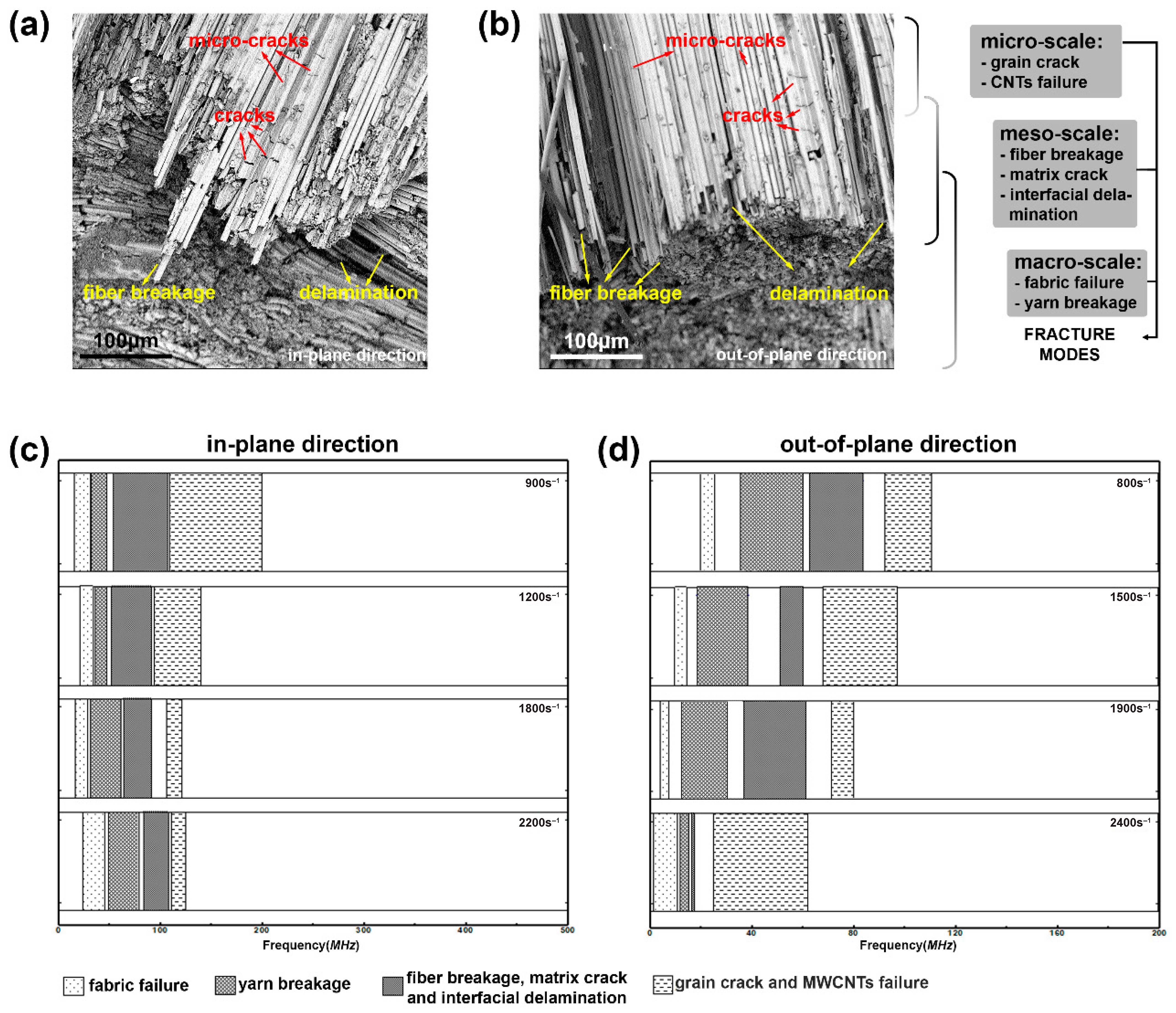

2.3.4. Fracture Identification

3. Results

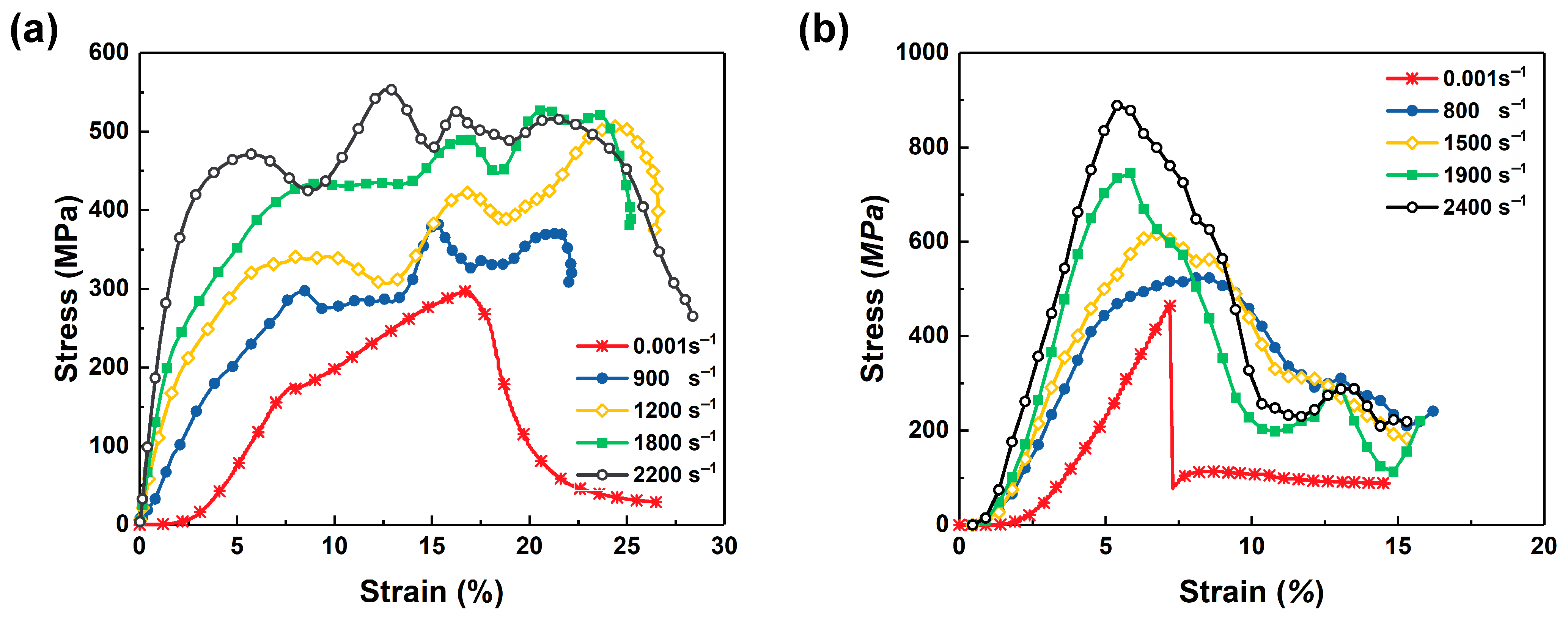

3.1. Stress–Strain Curves of Cf-MWCNT/SiC Composites under High Strain Rate Impact

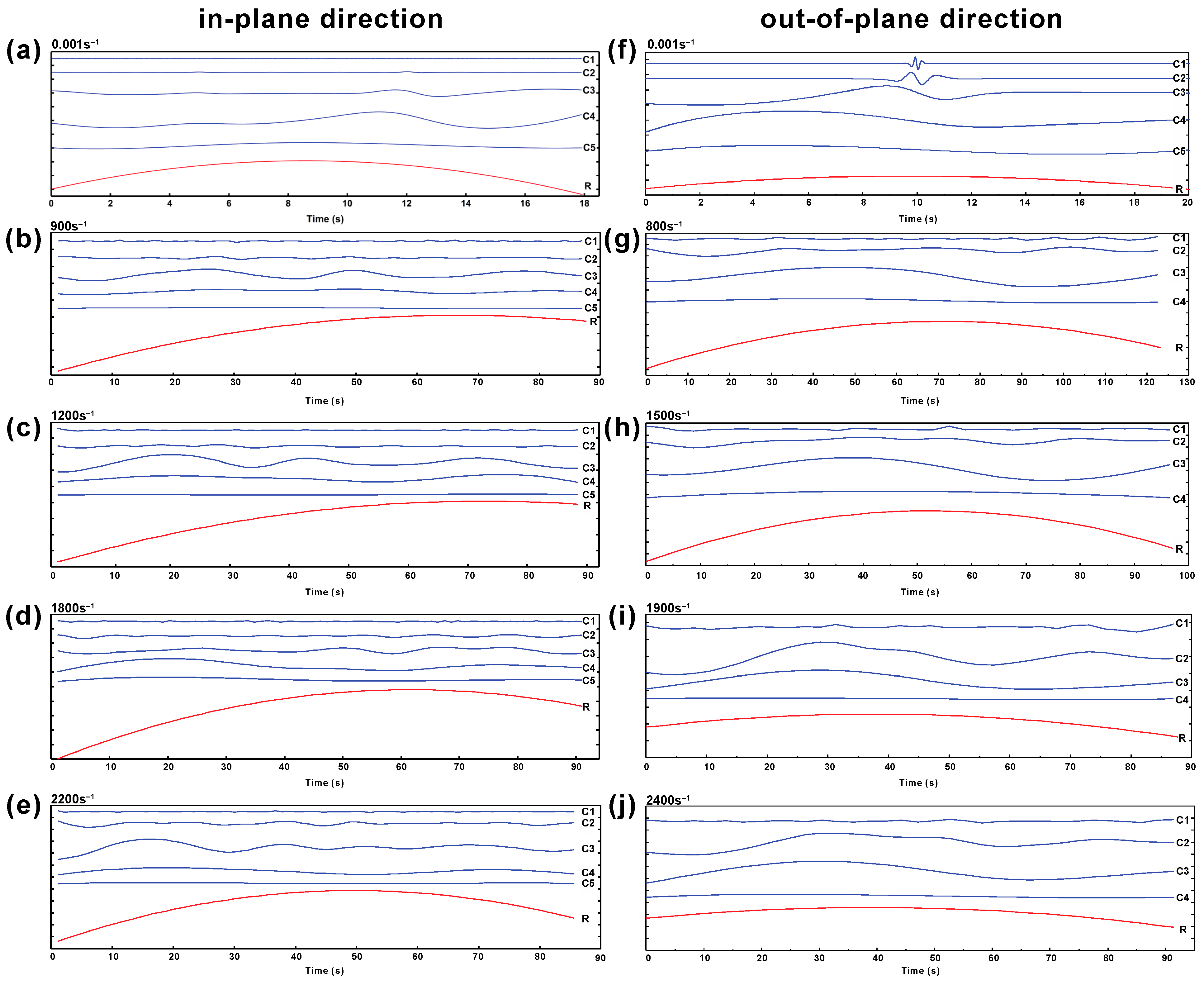

3.2. HHT: EEMD Decomposition

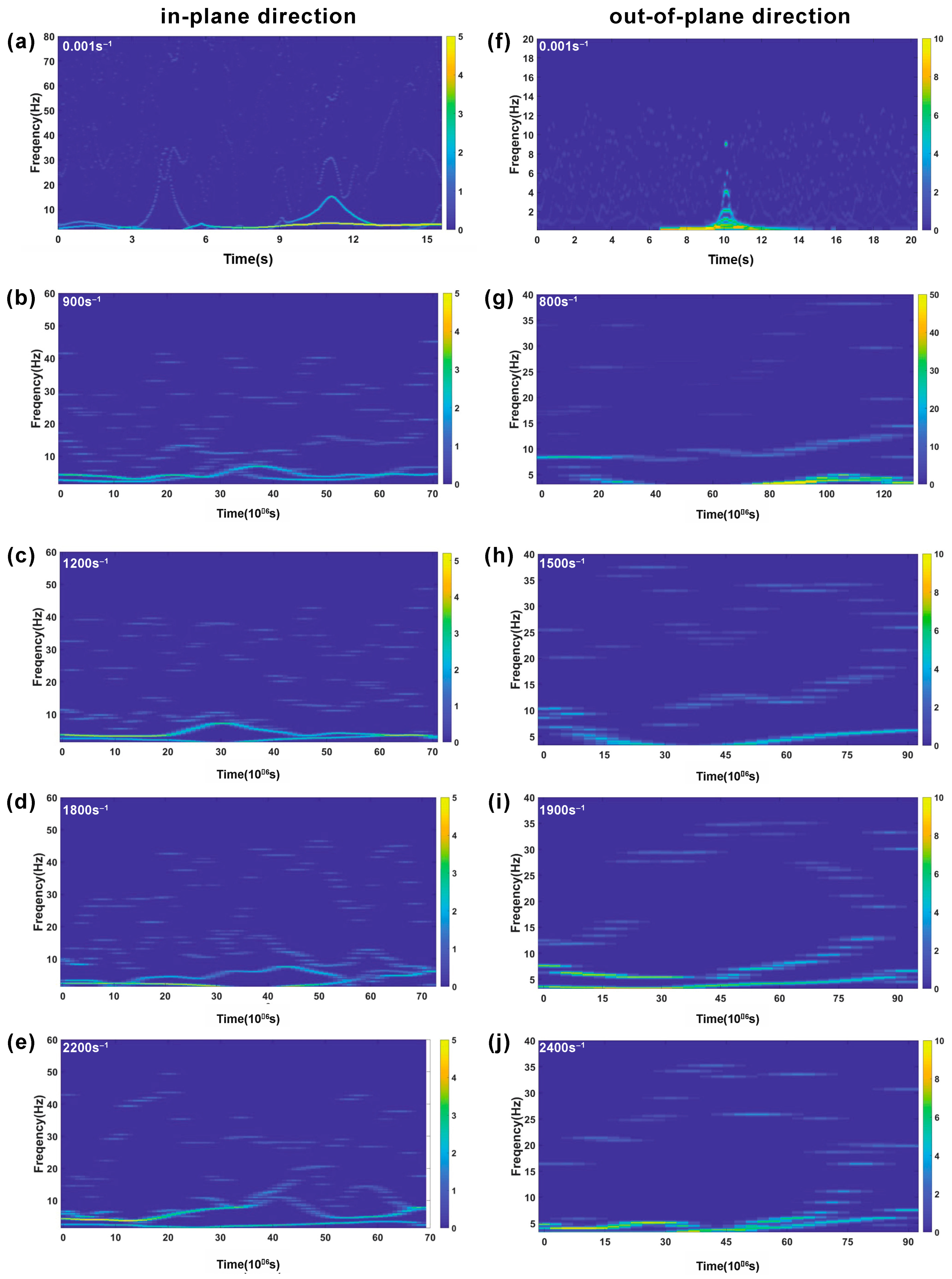

3.3. HHT: Frequency–Time Spectrum

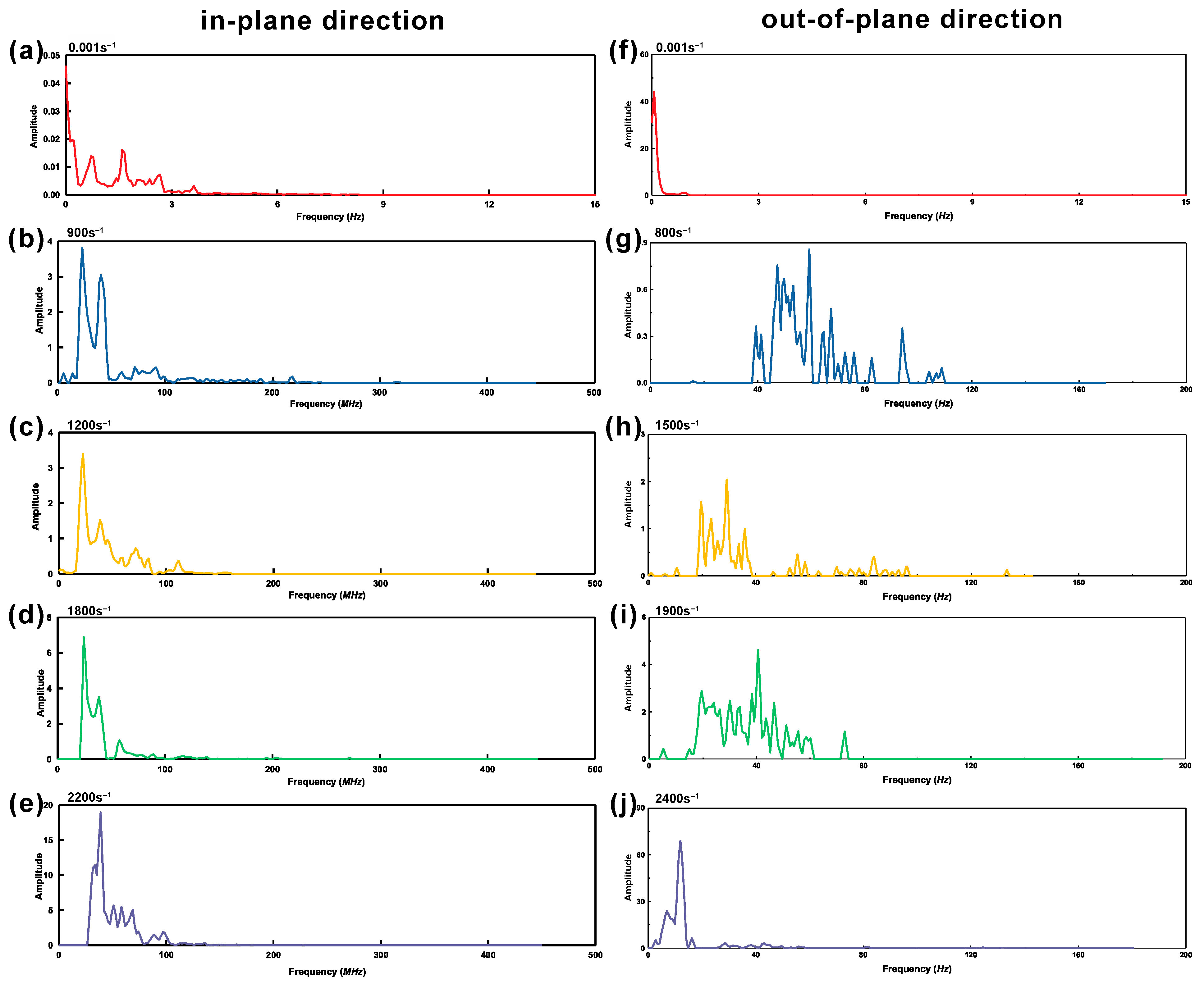

3.4. HHT: Marginal Hilbert Spectrum

3.5. Correlation between Sample Fractures and Frequency Analysis Results

4. Discussion

4.1. Influence of Strain Rate on Mechanical Response of Cf-MWCNT/SiC Composites

4.2. Anisotropic Mechanical Properties

4.3. Correlation between Frequency–Time Analysis and Fractures

5. Conclusions

- The Cf-MWCNT/SiC composites performed differently under the quasi-static and high-strain rate compression. The ultimate stress of the materials increases when testing strain rates increase.

- The Cf-MWCNT/SiC composites show anisotropic mechanical properties, which stem from the yarn arrangement in the woven fabrics. Therefore, the stress, toughness, and failure behavior are different between samples tested in the in-plane direction and out-of-plane direction.

- The testing results of Cf-MWCNT/SiC composites compressed at quasi-static and high strain rates can be converted into a frequency–time spectrum and marginal Hilbert spectrum via HHT. These spectrum results can effectively identify composite material’s dynamic fracture behavior, offering information related to the fraction evolution over time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ge, X.; Liu, X.; Hou, C.; Lu, H.; Tang, F.; Meng, X.; Xu, W.; Song, X. Distinguishing contributions of ceramic matrix and binder metal to the plasticity of nanocrystalline cermets. IUCrJ 2020, 7, 42–48. [Google Scholar] [CrossRef]

- Luan, K.; Gu, B. Energy absorption of three-dimensional angle-interlock woven composite under ballistic penetration based on a multi-scale finite element model. Int. J. Damage Mech. 2015, 24, 3–20. [Google Scholar] [CrossRef]

- Luan, K.; Sun, B.; Gu, B. Ballistic impact damages of 3-D angle-interlock woven composites based on high strain rate constitutive equation of fiber tows. Int. J. Impact Eng. 2013, 57, 145–158. [Google Scholar] [CrossRef]

- Ming, C.; Yang, T.; Luan, K.; Chen, L.; Wang, L.; Zeng, J.; Li, Y.; Zhang, W.; Chen, L.-Q. Microstructural effects on effective piezoelectric responses of textured PMN-PT ceramics. Acta Mater. 2018, 145, 62–70. [Google Scholar] [CrossRef]

- Sun, J.; Yu, S.; Wade-Zhu, J.; Chen, X.; Binner, J.; Bai, J. 3D printing of layered ceramic/carbon fiber composite with improved toughness. Addit. Manuf. 2022, 50, 102543. [Google Scholar] [CrossRef]

- Clegg, W.J. Controlling Cracks in Ceramics. Science 1999, 286, 1097–1099. [Google Scholar] [CrossRef]

- Tredway, W.K. Toughened Ceramics. Science 1998, 282, 1275. [Google Scholar] [CrossRef]

- Taya, M.; Hayashi, S.; Kobayashi, A.S.; Yoon, H.S. Toughening of a Particulate-Reinforced Ceramic-Matrix Composite by Thermal Residual Stress. J. Am. Ceram. Soc. 1990, 73, 1382–1391. [Google Scholar] [CrossRef]

- Song, Y.; Liu, D.; Hu, S.; Song, X.; Cao, J. Graphene nanoplatelets reinforced AgCuTi composite filler for brazing SiC ceramic. J. Eur. Ceram. Soc. 2019, 39, 696–704. [Google Scholar] [CrossRef]

- Ritchie, R.O. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef]

- Cheng, T.; Wang, X.; Zhang, R.; Pei, Y.; Ai, S.; He, R.; Fang, D.; Yang, Y. Tensile properties of two-dimensional carbon fiber reinforced silicon carbide composites at temperatures up to 2300 °C. J. Eur. Ceram. Soc. 2020, 40, 630–635. [Google Scholar] [CrossRef]

- Giugliano, D.; Barbera, D.; Chen, H. Effect of fiber cross section geometry on cyclic plastic behavior of continuous fiber reinforced aluminum matrix composites. Eur. J. Mech.—A/Solids 2017, 61, 35–46. [Google Scholar] [CrossRef]

- Bekyarova, E.; Thostenson, E.T.; Yu, A.; Kim, H.; Gao, J.; Tang, J.; Hahn, H.T.; Chou, T.W.; Itkis, M.E.; Haddon, R.C. Multiscale Carbon Nanotube−Carbon Fiber Reinforcement for Advanced Epoxy Composites. Langmuir 2007, 23, 3970–3974. [Google Scholar] [CrossRef]

- Chou, T.-W.; Gao, L.; Thostenson, E.T.; Zhang, Z.; Byun, J.-H. An assessment of the science and technology of carbon nanotube-based fibers and composites. Compos. Sci. Technol. 2010, 70, 1–19. [Google Scholar] [CrossRef]

- Veedu, V.P.; Cao, A.; Li, X.; Ma, K.; Soldano, C.; Kar, S.; Ajayan, P.M.; Ghasemi-Nejhad, M.N. Multifunctional composites using reinforced laminae with carbon-nanotube forests. Nat. Mater. 2006, 5, 457–462. [Google Scholar] [CrossRef] [PubMed]

- Garcia, E.J.; Wardle, B.L.; John Hart, A. Joining prepreg composite interfaces with aligned carbon nanotubes. Compos. Part A: Appl. Sci. Manuf. 2008, 39, 1065–1070. [Google Scholar] [CrossRef]

- Kumar, R.S. Crack-growth resistance behavior of mode-I delamination in ceramic matrix composites. Acta Mater. 2017, 131, 511–522. [Google Scholar] [CrossRef]

- Papon, E.A.; Haque, A.; Mulani, S.B. Process optimization and stochastic modeling of void contents and mechanical properties in additively manufactured composites. Compos. Part B: Eng. 2019, 177, 107325. [Google Scholar] [CrossRef]

- Luan, K.; Liu, J.; Sun, B.; Zhang, W.; Hu, J.; Fang, X.; Ming, C.; Song, E. High strain rate compressive response of the Cf/SiC composite. Ceram. Int. 2019, 45, 6812–6818. [Google Scholar] [CrossRef]

- Gholizadeh, S. A review of non-destructive testing methods of composite materials. Procedia Struct. Integr. 2016, 1, 50–57. [Google Scholar] [CrossRef]

- Morscher, G.N.; Maxwell, R. Monitoring tensile fatigue crack growth and fiber failure around a notch in laminate SIC/SIC composites utilizing acoustic emission, electrical resistance, and digital image correlation. J. Eur. Ceram. Soc. 2019, 39, 229–239. [Google Scholar] [CrossRef]

- El Yagoubi, J.; Lamon, J.; Batsale, J.-C.; Le Flem, M. Experimental assessment of damage-thermal diffusivity relationship in unidirectional fibre-reinforced composite under axial tensile test. Acta Mater. 2019, 173, 302–312. [Google Scholar] [CrossRef]

- Sikorska, J.Z.; Mba, D. Challenges and obstacles in the application of acoustic emission to process machinery. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2008, 222, 1–19. [Google Scholar] [CrossRef]

- Wu, Q.; Xu, W.; Zhang, L. Microstructure-based modelling of fracture of particulate reinforced metal matrix composites. Compos. Part B: Eng. 2019, 163, 384–392. [Google Scholar] [CrossRef]

- Dey, S.; Naskar, S.; Mukhopadhyay, T.; Gohs, U.; Spickenheuer, A.; Bittrich, L.; Sriramula, S.; Adhikari, S.; Heinrich, G. Uncertain natural frequency analysis of composite plates including effect of noise—A polynomial neural network approach. Compos. Struct. 2016, 143, 130–142. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, B.; Wang, T.; Hao, W.; Luo, Y. Detection and monitoring of delamination in composite laminates using ultrasonic guided wave. Compos. Struct. 2019, 225, 111161. [Google Scholar] [CrossRef]

- Huang, N.E.; Wu, Z. A review on Hilbert-Huang transform: Method and its applications to geophysical studies. Rev. Geophys. 2008, 46, 2007RG000228RG2006. [Google Scholar] [CrossRef]

- Huang, N.E. Hilbert-Huang Transform and Its Applications; World Scientific: Singapore, 2014; Volume 16. [Google Scholar]

- Siracusano, G.; Lamonaca, F.; Tomasello, R.; Garescì, F.; Corte, A.L.; Carnì, D.L.; Carpentieri, M.; Grimaldi, D.; Finocchio, G. A framework for the damage evaluation of acoustic emission signals through Hilbert-Huang transform. Mech. Syst. Signal Process. 2016, 75, 109–122. [Google Scholar] [CrossRef]

- Merainani, B.; Benazzouz, D.; Rahmoune, C. Early detection of tooth crack damage in gearbox using empirical wavelet transform combined by Hilbert transform. J. Vib. Control. 2017, 23, 1623–1634. [Google Scholar] [CrossRef]

- Hu, J.; Dong, S.; Wu, B.; Zhang, X.; Zhou, H.; Wang, Z.; Kan, Y. Tailoring Carbon Fiber/Carbon Nanotubes Interface to Optimize Mechanical Properties of Cf-CNTs/SiC Composites. Int. J. Appl. Ceram. Technol. 2014, 11, 207–217. [Google Scholar] [CrossRef]

- Ravichandran, G.; Subhash, G. Critical Appraisal of Limiting Strain Rates for Compression Testing of Ceramics in a Split Hopkinson Pressure Bar. J. Am. Ceram. Soc. 1994, 77, 263–267. [Google Scholar] [CrossRef]

- Miao, Y.G. On loading ceramic-like materials using split Hopkinson pressure bar. Acta Mech. 2018, 229, 3437–3452. [Google Scholar] [CrossRef]

- Frew, D.J.; Forrestal, M.J.; Chen, W. Pulse shaping techniques for testing brittle materials with a split hopkinson pressure bar. Exp. Mech. 2002, 42, 93–106. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, M.; Yu, Q.; Zhang, H. Comparing the applications of EMD and EEMD on time–frequency analysis of seismic signal. J. Appl. Geophys. 2012, 83, 29–34. [Google Scholar] [CrossRef]

- Zhang, J. Investigation of Relation between Fracture Scale and Acoustic Emission Time-Frequency Parameters in Rocks. Shock. Vib. 2018, 2018, 3057628. [Google Scholar] [CrossRef]

- de Groot, P.J.; Wijnen, P.A.M.; Janssen, R.B.F. Real-time frequency determination of acoustic emission for different fracture mechanisms in carbon/epoxy composites. Compos. Sci. Technol. 1995, 55, 405–412. [Google Scholar] [CrossRef]

- Du, K.; Li, X.; Tao, M.; Wang, S. Experimental study on acoustic emission (AE) characteristics and crack classification during rock fracture in several basic lab tests. Int. J. Rock Mech. Min. Sci. 2020, 133, 104411. [Google Scholar] [CrossRef]

- Hamdi, S.E.; Le Duff, A.; Simon, L.; Plantier, G.; Sourice, A.; Feuilloy, M. Acoustic emission pattern recognition approach based on Hilbert–Huang transform for structural health monitoring in polymer-composite materials. Appl. Acoust. 2013, 74, 746–757. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luan, K.; Ming, C.; Fang, X.; Liu, J. Frequency Characteristics of High Strain Rate Compressions of Cf-MWCNTs/SiC Composites. Ceramics 2023, 6, 1991-2007. https://doi.org/10.3390/ceramics6040122

Luan K, Ming C, Fang X, Liu J. Frequency Characteristics of High Strain Rate Compressions of Cf-MWCNTs/SiC Composites. Ceramics. 2023; 6(4):1991-2007. https://doi.org/10.3390/ceramics6040122

Chicago/Turabian StyleLuan, Kun, Chen Ming, Xiaomeng Fang, and Jianjun Liu. 2023. "Frequency Characteristics of High Strain Rate Compressions of Cf-MWCNTs/SiC Composites" Ceramics 6, no. 4: 1991-2007. https://doi.org/10.3390/ceramics6040122

APA StyleLuan, K., Ming, C., Fang, X., & Liu, J. (2023). Frequency Characteristics of High Strain Rate Compressions of Cf-MWCNTs/SiC Composites. Ceramics, 6(4), 1991-2007. https://doi.org/10.3390/ceramics6040122