3D Printing of Ceramic Elements with Q-Surface Geometry for the Fabrication of Protective Barrier

Abstract

1. Introduction

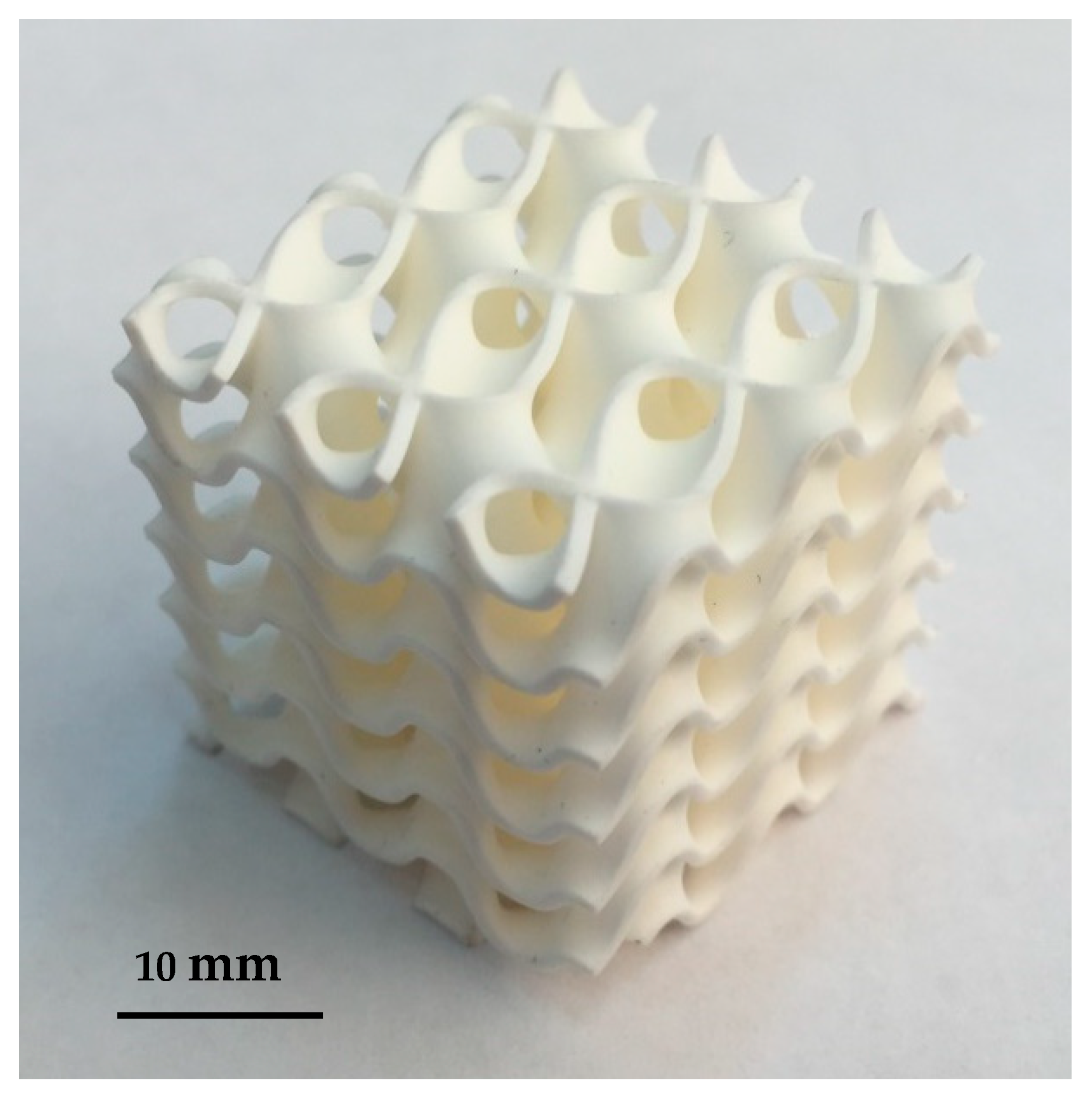

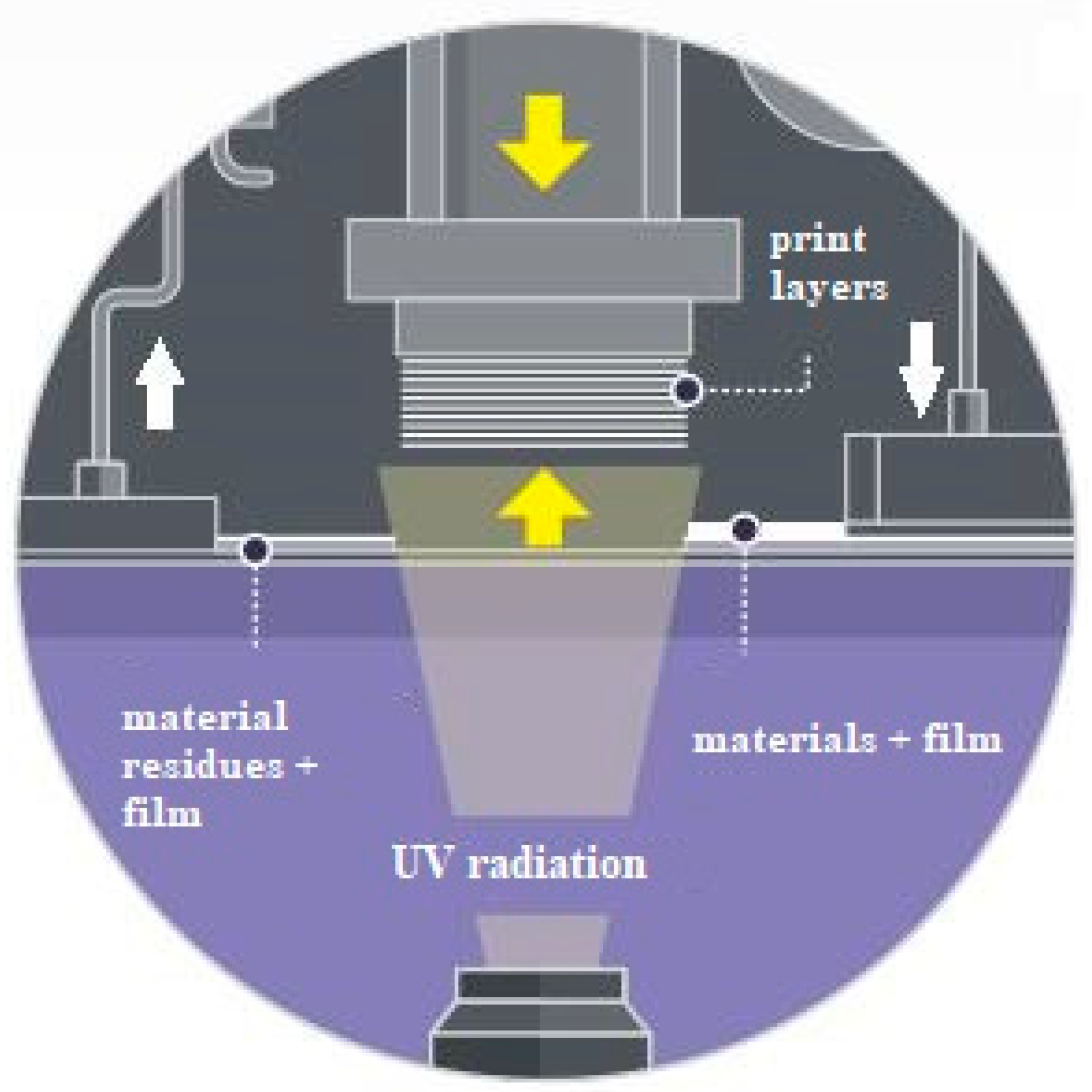

2. Production Technology

3. Research Method

4. Discussion of Results

5. Scope of Application

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lord, E.A.; Mackay, A.L.; Ranganathan, S. New Geometries for New Materials; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- Hasegawa, H.; Tanaka, H.; Yamasaki, K.; Hashimoto, T. Bicontinuous microdomain morphology of block copolymers. I. Tetrapod-network structure of polystyrene-polyisoprene diblock polymers. Macromolecules 1987, 20, 1651–1662. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids Structure and Properties, 2nd ed.; Energy Absorption in Cellular Material; Chapter 8; Cambridge University Press: Cambridge, UK, 1997; pp. 309–344. [Google Scholar] [CrossRef]

- Păcurar, R.; Păcurar, A.; Petrilak, N.B. Finite element analysis to predict the mechanical behavior of lattice structures made by selective laser melting technology. In Applied Mechanics and Materials; Trans Tech Publications: Bäch, Switzerland, 2014; pp. 231–235. [Google Scholar]

- McKown, S.; Shen, Y.; Brookes, W.K.; Sutcliffe, C.J.; Cantwell, W.J.; Langdon, G.S.; Nurick, G.N.; Theobald, M.D. The quasi-static and blast loading response of lattice structures. Int. J. Impact Eng. 2008, 35, 795–810. [Google Scholar] [CrossRef]

- Chu, C.; Graf, G.; Rosen, D.W. Design for additive manufacturing of cellular structures. Comput. Aided Des. Appl. 2008, 5, 686–696. [Google Scholar] [CrossRef]

- Rosen, D.W. Computer-aided design for additive manufacturing of cellular structures. Comput. Aided Des. Appl. 2007, 4, 585–594. [Google Scholar] [CrossRef]

- Meza, L.R.; Das, S.; Greer, J.R. Strong, lightweight, recoverable three-dimensional ceramic nanolattices. Science 2014, 345, 1322–1326. [Google Scholar] [CrossRef]

- Santorinaios, M.; Brooks, W.; Sutcliffe, C.; Mines, R. Crush behaviour of open cellular lattice structures manufactured using selective laser melting. WIT Trans. Built Environ. 2006, 85, 481–490. [Google Scholar]

- Ravari, M.K.; Kadkhodaei, M.; Badrossamay, M.; Rezaei, R. Numerical investigation on mechanical properties of cellular lattice structures fabricated by fused deposition modeling. Int. J. Mech. Sci. 2014, 88, 154–161. [Google Scholar] [CrossRef]

- Ponche, R.; Hasco, J.-Y.; Kerbrat, O.; Mognol, P. A new global approach to design for additive manufacturing. In Additive Manufacturing Handbook; CRC Press: Boca Raton, FL, USA, 2017; pp. 169–180. [Google Scholar]

- Tancogne-Dejean, T.; Spierings, A.B.; Mohr, D. Additively-manufactured metallic micro-lattice materials for high specific energy absorption under static and dynamic loading. Acta Mater. 2016, 116, 14–28. [Google Scholar] [CrossRef]

- Schaedler, T.A.; Jacobsen, A.J.; Torrents, A.; Sorensen, A.E.; Lian, J.; Greer, J.R.; Valdevit, L.; Carter, W.B. Ultralight metallic microlattices. Science 2011, 334, 962–965. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A.; Ashby, M.F. Effective properties of the octet-truss lattice material. J. Mech. Phys. Solids 2001, 49, 1747–1769. [Google Scholar] [CrossRef]

- Grigoryan, V.A.; Kobylkin, I.F.; Marinin, V.M.; Chistaykov, E.N. Materials and Protective Structures for Local and Individual Booking; Radio Software: Moscow, Russia, 2008; 406p. [Google Scholar]

- GOST 34286-2017; Armored Clothing. Classification and General Technical Requirements. Rosstandart: Moscow, Russia, 2019.

- Garshin, A.P.; Gropyanov, V.M.; Zaitsev, G.P.; Semenov, S.S. Ceramics in Mechanical Engineering; JSC Nauchtekhlitizdat Publishing House: Moscow, Russian, 2003; 384p. [Google Scholar]

- Kobylkin, I.F.; Selivanov, V.V. Materials and Structures of Light Armor Protection; Textbook; MSTU im. N. E. Bauman: Moscow, Russia, 2014; 191p. [Google Scholar]

- Ignatova, A.M.; Artemov, A.O.; Zignatov, M.N.; Sokovikov, M.A. Methods for studying the dissipative properties of synthetic mineral alloys during high-speed penetration. Fundam. Res. Tech. Sci. 2012, 145–150. [Google Scholar]

- Crouch, J.G. Introduction to armor materials. Sci. Armor Mater. 2017, 1, 33. [Google Scholar]

- Neshpor, V.C.; Zaitsev, G.P.; Dovgal, E.J. Armour ceramics ballistic efficiency evaluation. In Ceramics: Charting the Future, Proceedings of the 8th. CIMTEC, Florence, Italy, 28 June–4 July 1994; Vincenzini, P., Ed.; Techna S.R.L.: Milano, Italy, 1995; pp. 2395–2401. [Google Scholar]

- Quinn, J.B.; Quinn, G.D. On the Hardness and Brittleness of Ceramics. Key Eng. Mater. 1997, 132–136, 460–463. [Google Scholar] [CrossRef]

- Shevchenko, V.Y.; Oryshchenko, A.S.; Perevislov, S.N.; Sil’nikov, M.V. Sound Waves Could be the Secret to Better Armour; Springer Nature: Berlin, Germany, 2021. [Google Scholar]

- Shevchenko, V.Y.; Oryshchenko, A.S.; Perevislov, S.N.; Sil’nikov, M.V. About the Criteria for the Choice of Materials to Protect Against the Mechanical Dynamic Loading. Glass Phys. Chem. 2021, 47, 281–288. [Google Scholar] [CrossRef]

- Rogov, V.A.; Solovyov, V.V.; Kopylov, V.V. New Materials in Mechanical Engineering; Textbook; RUDN: Moscow, Russia, 2008; 324p. [Google Scholar]

- Karandikar, P.G.; Evans, G.; Wong, S.; Aghajanian, M.K.; Sennett, M. A review of ceramics for armor applications. Adv. Ceram. Armor IV 2009, 29, 163–175. [Google Scholar]

- Woodward, R.L.; Gooch, W.A.; O’Donnell, R.G.; Perciballi, W.J.; Baxter, B.J.; Pattie, S.D. A study of fragmentation in the ballistic impact of ceramics. Int. J. Impact Eng. 1994, 15, 605–618. [Google Scholar] [CrossRef]

- Gooch, W.A. Overview of the development of ceramic armor technology: Past, present and the future. Adv. Ceram. Armor VII Ceram. Eng. Sci. Proc. 2011, 32, 193–213. [Google Scholar]

- Van Es, M.; Beugels, J.; van Dingenen, J. Development of Dyneema/ceramic hybrids for SAPI inserts. In Proceedings of the Personal Armour Systems Symposium 2002—PASS 2020, The Hague, The Netherlands, 18–22 November 2002; pp. 163–168. [Google Scholar]

- Gahr, M.; Heidenreich, B. Biomorphe SiSiC-Keramiken fur den Einsatz im Ballistischen Schutz; DKG; Deutsches Zentrum fur Luftund Raumfahrt: Stuttgart, Germany, 2005; Volume 82, pp. 125–129. [Google Scholar]

- Kamenskikh A., S.; Kormushin, V.A.; Kalgin, A.N.; Bogdanov, V.V.; Zyryanov, K.A.; Medvedko, V.S.; Medvedko, O.V.; Days, H.A.; Mukhin, V.V.; Markov, V.N. Ceramic Armour Element and Composite Armour on Its Basis. RU2459174C1, 20 August 2012. [Google Scholar]

- Shevchenko, V.Y.; Sychev, M.M.; Lapshin, A.E.; Lebedev, L.A. Ceramic materials with the triply periodic minimal surface for constructions functioning under conditions of extreme loads. Glass Phys. Chem. 2017, 43, 605–607. [Google Scholar] [CrossRef]

- Diachenko, S.V.; Lebedev, L.A.; Sychov, M.M.; Nefedova, L.A. Physicomechanical Properties of a Model Material in the Form of a Cube with the Topology of Triply Periodic Minimal Surfaces of the Gyroid Type. Technical physics. Russ. J. Appl. Phys. 2018, 63, 984–987. [Google Scholar] [CrossRef]

- Balabanov, S.V.; Makogon, A.I.; Sychev, M.M.; Evstratov, A.A.B.; Regazzi, A.; Lopez-Cuesta, J.M. 3D Printing and Mechanical Properties of Polyamide Products with Schwartz Primitive Topology. Technical physics. Russ. J. Appl. Phys. 2020, 65, 211–215. [Google Scholar]

- Sychov, M.M.; Lebedev, L.A.; Diachenko, S.V.; Nefedova, L.A. Mechanical properties of energy-absorbing structures with triply periodic minimal surface topology. Acta Astronaut. 2018, 150, 81–84. [Google Scholar] [CrossRef]

- Schnering, H.G.; von Nesper, R. Nodal surfaces of Fourier series: Fundamental invariants of structured matter. Z. Phys. B Condens. Matter. 1991, 83, 407–412. [Google Scholar] [CrossRef]

- Available online: https://admateceurope.com/admaflex-technology (accessed on 22 February 2022).

- Samsonov, G.V.; Borisova, A.L.; Zhidkova, T.G. Physico-Chemical Properties of Oxides: Handbook; Metallurgizdat: Moscow, Russia, 1978; 471p. [Google Scholar]

- Kharchenko, E.F.; Composite, E.A.F. Textile and Combined Armor Materials; JSC TSNIISM: Moscow, Russia, 2013; 294p. [Google Scholar]

- Afanasiev, V.V.; Dolgina, T.M.; Bespalova, N.B. Dicyclopentadiene Metathesis Polymerisation Catalyst, Prepartion Method Thereof and Polymerisation Method. RU2008148502/04A, 10 December 2008. [Google Scholar]

| Material | ρ, g/cm3 | HK, GPa | E, GPa | M, EPa2·m3/kg (EN/s2) | K |

|---|---|---|---|---|---|

| Boron carbide hot pressed B4C | 2.55 | 30.0 | 450 | 5.30 | 0.77 |

| Titanate diboride hot pressed TiB2 | 4.50 | 33.0 | 570 | 4.18 | 0.72 |

| Silicon carbide SiC | 3.10 | 21.0 | 410 | 2.78 | 0.80 |

| Aluminium oxide sintered Al2O3 | 3.99 | 18.0 | 404 | 1.82 | 0.83 |

| Armor steel | 7.81 | 3.5 | 210 | 0.094 | 1.00 |

| Element | Al | O | Fe | Si | Na |

|---|---|---|---|---|---|

| Content, % w. | 57.7 | 38.8 | 2.2 | 0.8 | 0.5 |

| TPMS | ρap, g/cm3 | * ρ, g/cm3 | Popn, % | Pt, % | W, % |

|---|---|---|---|---|---|

| Q—surface | 3.60 | 3.99 | 8.53 | 9.77 | 2.37 |

| Fabricator | ρap, g/cm3 | l, μm | Pt, % | Hμ, GPa | Vs, m/s | E, GPa | M, EPa2·m3/kg (EN/s2) | K |

|---|---|---|---|---|---|---|---|---|

| Prodways | 3.76 | 83 | 5.76 | 12.2 | 9500 | 339 | 1.10 | 0.85 |

| 3D CERAM | 3.79 | 83 | 5.12 | 8.8 | 9950 | 375 | 1.42 | 0.82 |

| Lithoz | 3.90 | 40 | 2.26 | 17.7 | 10,450 | 425 | 1.84 | 0.80 |

| Admatec | 3.60 | 20 | 9.77 | 15.3 | 10,600 | 405 | 1.72 | 0.80 |

| Corundum [38] | 3.99 | - | - | ≥20 | - | 404 | 2.03 | 0.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diachenko, S.V.; Dolgin, A.S.; Khristyuk, N.A.; Lebedev, L.A.; Nefedova, L.A.; Pavlov, S.B.; Merenkov, K.F.; Ivkov, V.I.; Dmitrieva, A.N. 3D Printing of Ceramic Elements with Q-Surface Geometry for the Fabrication of Protective Barrier. Ceramics 2023, 6, 912-921. https://doi.org/10.3390/ceramics6020053

Diachenko SV, Dolgin AS, Khristyuk NA, Lebedev LA, Nefedova LA, Pavlov SB, Merenkov KF, Ivkov VI, Dmitrieva AN. 3D Printing of Ceramic Elements with Q-Surface Geometry for the Fabrication of Protective Barrier. Ceramics. 2023; 6(2):912-921. https://doi.org/10.3390/ceramics6020053

Chicago/Turabian StyleDiachenko, Semen V., Andrey S. Dolgin, Nikolai A. Khristyuk, Lev A. Lebedev, Lubov A. Nefedova, Sergey B. Pavlov, Kirill F. Merenkov, Vladimir I. Ivkov, and Alla N. Dmitrieva. 2023. "3D Printing of Ceramic Elements with Q-Surface Geometry for the Fabrication of Protective Barrier" Ceramics 6, no. 2: 912-921. https://doi.org/10.3390/ceramics6020053

APA StyleDiachenko, S. V., Dolgin, A. S., Khristyuk, N. A., Lebedev, L. A., Nefedova, L. A., Pavlov, S. B., Merenkov, K. F., Ivkov, V. I., & Dmitrieva, A. N. (2023). 3D Printing of Ceramic Elements with Q-Surface Geometry for the Fabrication of Protective Barrier. Ceramics, 6(2), 912-921. https://doi.org/10.3390/ceramics6020053