Influence of Reinforcing Efficiency of Clay on the Mechanical Properties of Poly(butylene terephthalate) Nanocomposite

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

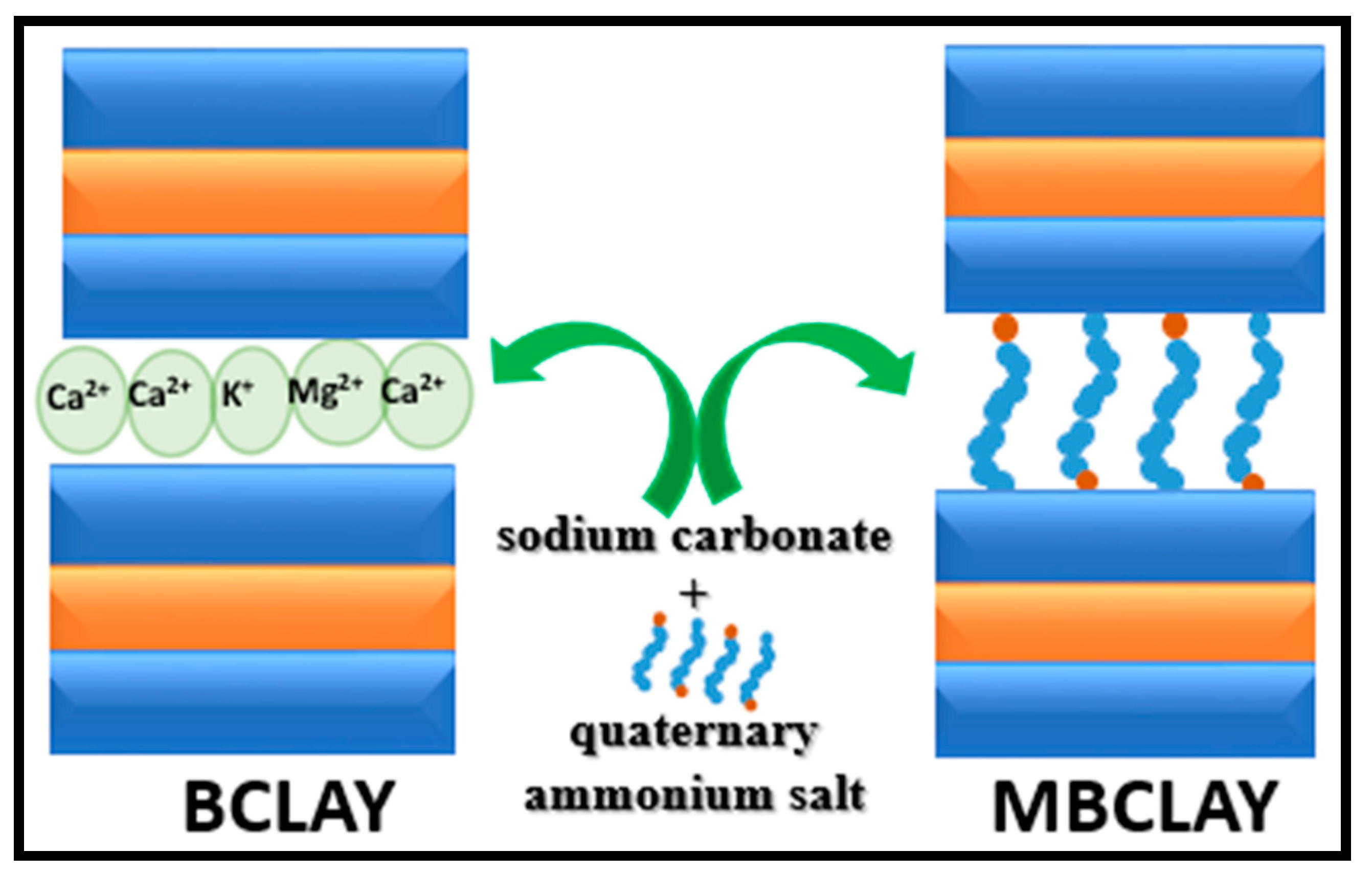

2.2. Clay Preparation

2.3. Moisture Content of Samples

2.4. Nanocomposite Preparation

2.5. Characterization of Brazilian Clay

2.5.1. Measured Clay Content

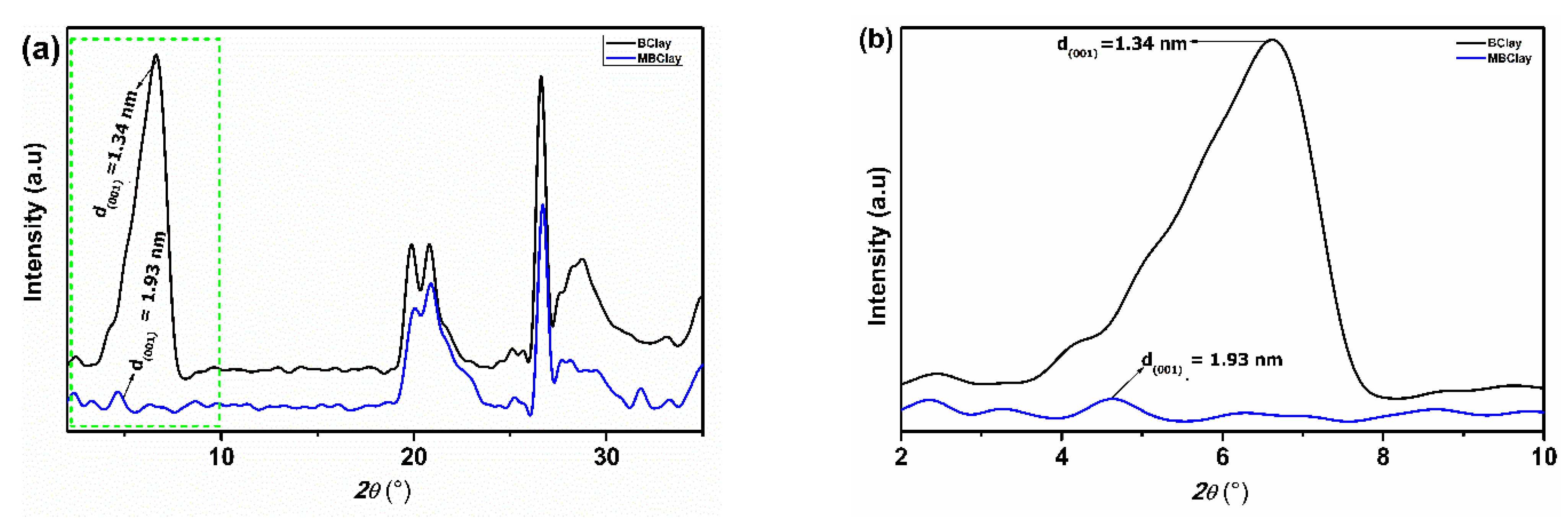

2.5.2. X-ray Diffraction (XRD) of Clay

2.5.3. Transmission Electron Microscopy (TEM)

2.6. Characterization of Neat PBT and PBT/MBClay Nanocomposites

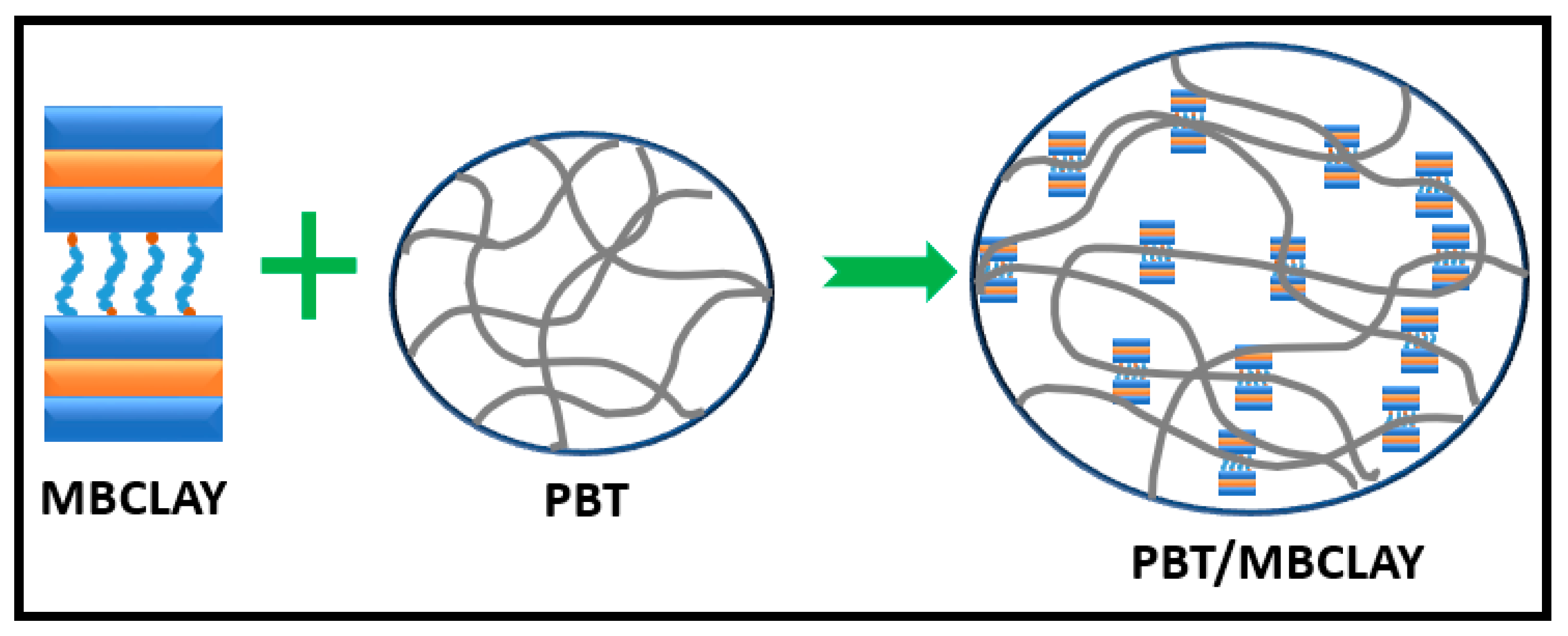

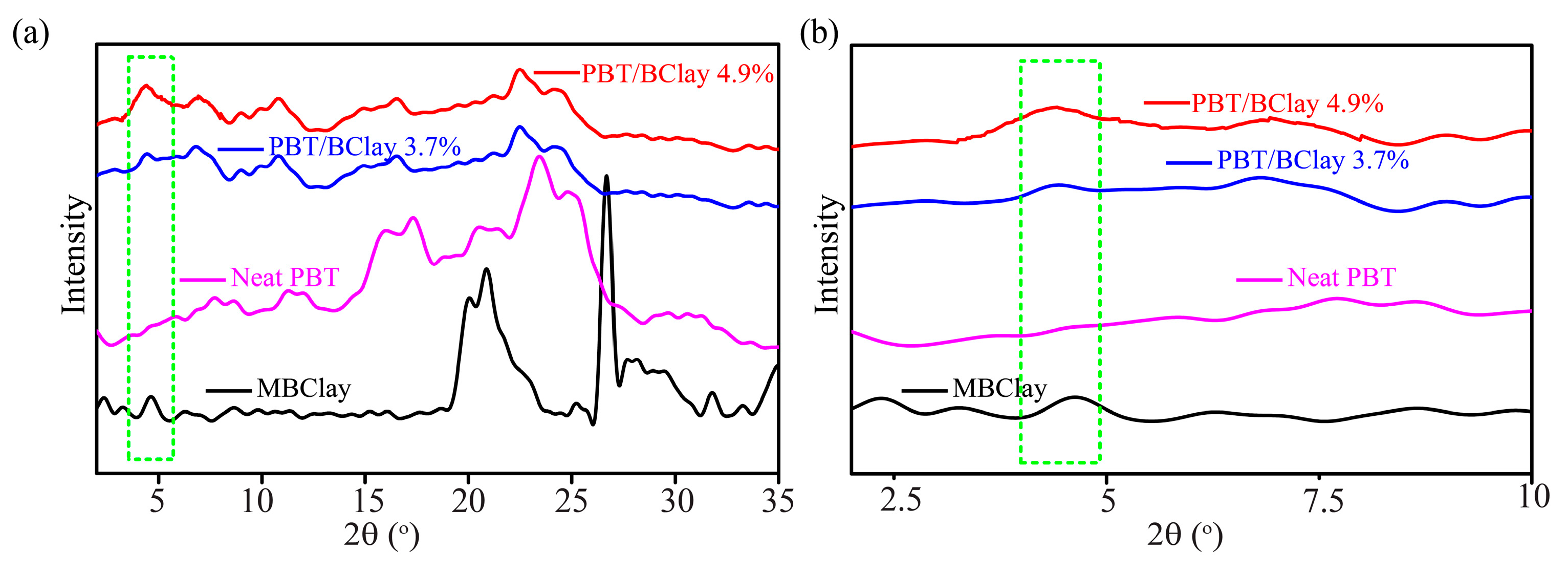

2.6.1. X-ray Diffraction (XRD) of Composites

2.6.2. Microscopy Analysis of Composites

2.6.3. Differential Scanning Calorimetry (DSC)

2.6.4. Thermogravimetric Analyses (TGA)

2.6.5. Tensile Tests

2.6.6. Flexure Tests

2.6.7. Izod Impact Tests

2.6.8. Heat Distortion Temperature Tests

2.6.9. Clay’s Reinforcing Efficiency

3. Results and Discussion

3.1. Brazilian Clay Characterization Results

3.1.1. Measured Clay Content

3.1.2. XRD Analysis

3.1.3. TEM Analysis

3.2. PBT/MBClay Nanocomposite Analysis

3.2.1. XRD Analysis of Composites

3.2.2. Surface Morphology of the Composites

3.2.3. Thermal Analysis

3.2.4. Tensile Test

3.2.5. Flexural Test

3.2.6. Izod Impact Test

3.2.7. Heat Distortion Temperature

3.2.8. MBClay’s Reinforcing Efficiency

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, F.; Aryana, S.; Han, Y.; Jiao, Y. A Review of the Synthesis and Applications of Polymer-Nanoclay Composites. Appl. Sci. 2018, 8, 1696. [Google Scholar] [CrossRef]

- Kotal, M.; Bhowmick, A.K. Polymer Nanocomposites from Modified Clays: Recent Advances and Challenges. Prog. Polym. Sci. 2015, 51, 127–187. [Google Scholar] [CrossRef]

- Ali, F.; Ullah, H.; Ali, Z.; Rahim, F.; Khan, F.; Rehman, Z.U. Polymer-Clay Nanocomposites, Preparations and Current Applications: A Review. Curr. Nanomater. 2016, 1, 83–95. [Google Scholar] [CrossRef]

- Xu, P.; Erdem, T.; Eiser, E. A Simple Approach to Prepare Self-Assembled, Nacre-Inspired Clay/Polymer Nanocomposites. Soft Matter 2020, 16, 5497–5505. [Google Scholar] [CrossRef] [PubMed]

- Ummartyotin, S.; Bunnak, N.; Manuspiya, H. A Comprehensive Review on Modified Clay Based Composite for Energy Based Materials. Renew. Sustain. Energy Rev. 2016, 61, 466–472. [Google Scholar] [CrossRef]

- Kodali, D.; Uddin, M.J.; Moura, E.A.B.; Rangari, V.K. Mechanical and Thermal Properties of Modified Georgian and Brazilian Clay Infused Biobased Epoxy Nanocomposites. Mater. Chem. Phys. 2021, 257, 123821. [Google Scholar] [CrossRef]

- Griffin, S.; Masood, M.I.; Nasim, M.J.; Sarfraz, M.; Ebokaiwe, A.P.; Schäfer, K.H.; Keck, C.M.; Jacob, C. Natural Nanoparticles: A Particular Matter Inspired by Nature. Antioxidants 2018, 7, 3. [Google Scholar] [CrossRef]

- Modi, V.K.; Shrives, Y.; Sharma, A.; Sen, P.K.; Bohidar, S. Review on Green Polymer Nanocomposite AndTheir Applications. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 17651–17656. [Google Scholar]

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Potential Natural Fiber Polymeric Nanobiocomposites: A Review. Polymers 2020, 12, 1072. [Google Scholar] [CrossRef]

- Ahmad, I.; Ali, F.; Rahim, F. Clay Based Nanocomposites and Their Environmental Applications. In Development and Prospective Applications of Nanoscience and Nanotechnology Nanomaterials for Environmental Applications and their Fascinating Attributes; Ahmad, I., Ali, F., Rahim, F., Eds.; Bentham Science Publisher: Sharjah, United Arab Emirates, 2018; pp. 166–190. [Google Scholar]

- Zazoum, B.; Triki, E.; Bachri, A. Modeling of Mechanical Properties of Clay-Reinforced Polymer Nanocomposites Using Deep Neural Network. Materials 2020, 13, 4266. [Google Scholar] [CrossRef]

- Zare, Y.; Fasihi, M.; Rhee, K.Y. Efficiency of Stress Transfer between Polymer Matrix and Nanoplatelets in Clay/Polymer Nanocomposites. Appl. Clay Sci. 2017, 143, 265–272. [Google Scholar] [CrossRef]

- Zare, Y. Estimation of Material and Interfacial/Interphase Properties in Clay/Polymer Nanocomposites by Yield Strength Data. Appl. Clay Sci. 2015, 115, 61–66. [Google Scholar] [CrossRef]

- Martino, L.; Guigo, N.; van Berkel, J.G.; Sbirrazzuoli, N. Influence of Organically Modified Montmorillonite and Sepiolite Clays on the Physical Properties of Bio-Based Poly(Ethylene 2, 5-Furandicarboxylate). Compos. Part B Eng. 2017, 110, 96–105. [Google Scholar] [CrossRef]

- Murugesan, S.; Scheibel, T. Copolymer/Clay Nanocomposites for Biomedical Applications. Adv. Funct. Mater. 2020, 30, 1908101. [Google Scholar] [CrossRef]

- Ray, S.S.; Okamoto, M. Polymer/Layered Silicate Nanocomposites: A Review from Preparation to Processing. Prog. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar] [CrossRef]

- Saleh, T.A.; Shetti, N.P.; Shanbhag, M.M.; Raghava Reddy, K.; Aminabhavi, T.M. Recent Trends in Functionalized Nanoparticles Loaded Polymeric Composites: An Energy Application. Mater. Sci. Energy Technol. 2020, 3, 515–525. [Google Scholar] [CrossRef]

- Qasim, U.; Osman, A.I.; Al-Muhtaseb, A.H.; Farrell, C.; Al-Abri, M.; Ali, M.; Vo, D.V.N.; Jamil, F.; Rooney, D.W. Renewable Cellulosic Nanocomposites for Food Packaging to Avoid Fossil Fuel Plastic Pollution: A Review. Environ. Chem. Lett. 2021, 19, 613–641. [Google Scholar] [CrossRef]

- Mohammed, Z.; Tcherbi-Narteh, A.; Jeelani, S. Effect of Graphene Nanoplatelets and Montmorillonite Nanoclay on Mechanical and Thermal Properties of Polymer Nanocomposites and Carbon Fiber Reinforced Composites. SN Appl. Sci. 2020, 2, 1959. [Google Scholar] [CrossRef]

- Pham, N.T.-H.; Nguyen, V.-T. Morphological and Mechanical Properties of Poly (Butylene Terephthalate)/High-Density Polyethylene Blends. Adv. Mater. Sci. Eng. 2020, 2020, 8890551. [Google Scholar] [CrossRef]

- Chisholm, B.J.; Moore, R.B.; Barber, G.; Khouri, F.; Hempstead, A.; Larsen, M.; Olson, E.; Kelley, J.; Balch, G.; Caraher, J. Nanocomposites Derived from Sulfonated Poly(Butylene Terephthalate). Macromolecules 2002, 35, 5508–5516. [Google Scholar] [CrossRef]

- Wu, D.; Zhou, C.; Hong, Z.; Mao, D.; Bian, Z. Study on Rheological Behaviour of Poly(Butylene Terephthalate)/ Montmorillonite Nanocomposites. Eur. Polym. J. 2005, 41, 2199–2207. [Google Scholar] [CrossRef]

- Saeed, K.; Khan, I. Characterization of Clay Filled Poly (Butylene Terephthalate) Nanocomposites Prepared by Solution Blending. Polimeros 2015, 25, 591–595. [Google Scholar] [CrossRef]

- Chow, W.S. Cyclic Extrusion of Poly(Butylene Terephthalate)/Organo-Montmorillonite Nanocomposites: Thermal and Mechanical Retention Properties. J. Appl. Polym. Sci. 2008, 110, 1642–1648. [Google Scholar] [CrossRef]

- Heidarzadeh, N.; Rafizadeh, M.; Taromi, F.A.; Bouhendi, H. Preparation of Poly(Butylene Terephthalate)/Modified Organoclay Nanocomposite via in-Situ Polymerization: Characterization, Thermal Properties and Flame Retardancy. High Perform. Polym. 2012, 24, 589–602. [Google Scholar] [CrossRef]

- Kalkar, A.K.; Deshpande, V.D.; Vatsaraj, B.S. Poly(Butylene Terephthalate)/Montmorillonite Nanocomposites: Effect of Montmorillonite on the Morphology, Crystalline Structure,Isothermal Crystallization Kinetics and Mechanical Properties. Thermochim. Acta 2013, 568, 74–94. [Google Scholar] [CrossRef]

- Yamamoto, B.E.; Trimble, A.Z.; Minei, B.; Ghasemi Nejhad, M.N. Development of Multifunctional Nanocomposites with 3-D Printing Additive Manufacturing and Low Graphene Loading. J. Thermoplast. Compos. Mater. 2019, 32, 383–408. [Google Scholar] [CrossRef]

- Russo, P.; Cimino, F.; Acierno, D.; Lupò, G.; Petrarca, C. Poly(Butylene Terephthalate) Based Composites Containing Alumina Whiskers: Influence of Filler Functionalization on Dielectric Properties. Int. J. Polym. Sci. 2014, 2014, 150589. [Google Scholar] [CrossRef]

- Gómez, C.; Mira, J.; Carrión-Vilches, F.J.; Cavas, F. Dynamic Moduli of Polybutylene Terephthalate Glass Fiber Reinforced in High-Temperature Environments. Materials 2021, 14, 483. [Google Scholar] [CrossRef]

- Cao, Y.; Xu, P.; Yang, W.; Zhu, X.; Dong, W.; Chen, M.; Du, M.; Liu, T.; Lemstra, P.J.; Ma, P. UV Resistant PBT Nanocomposites by Reactive Compatibilization and Selective Distribution of Tailor-Made Double-Shelled TiO2 Nanohybrids. Compos. Part B Eng. 2021, 205, 108510. [Google Scholar] [CrossRef]

- Wu, D.; Zhou, C.; Zhang, M. Effect of Clay on Immiscible Morphology of Poly(Butylene Terephthalate)/Polyethylene Blend Nanocomposites. J. Appl. Polym. Sci. 2006, 102, 3628–3633. [Google Scholar] [CrossRef]

- Yang, W.; Hu, Y.; Tai, Q.; Lu, H.; Song, L.; Yuen, R.K.K. Fire and Mechanical Performance of Nanoclay Reinforced Glass-Fiber/PBT Composites Containing Aluminum Hypophosphite Particles. Compos. Part A Appl. Sci. Manuf. 2011, 42, 794–800. [Google Scholar] [CrossRef]

- Khashkhozheva, R.R.; Zhansitov, A.A.; Khashirova, S.Y.; Mikitaev, A.K. The Development of Fireproof Composite Materials Based on Polybutylene Terephthalates. Int. Polym. Sci. Technol. 2016, 43, 47–52. [Google Scholar] [CrossRef]

- Tehran, A.C.; Shelesh-Nezhad, K.; Kalajahi, P.F.; Olad, A. A Study of the Effect of TPU and Clay Nanoparticles on the Mechanical Behavior of PBT-Based Nanocomposites. Mech. Adv. Compos. Struct. 2017, 4, 179–186. [Google Scholar] [CrossRef]

- Chang, J.H.; An, Y.U.; Kim, S.J.; Im, S. Poly(Butylene Terephthalate)/Organoclay Nanocomposites Prepared by in Situ Interlayer Polymerization and Its Fiber (II). Polymer 2003, 44, 5655–5661. [Google Scholar] [CrossRef]

- Oburoğlu, N.; Ercan, N.; Durmus, A.; Kaşgöz, A. Effects of Filler Type on the Nonisothermal Crystallization Kinetics of Poly(Butylene Terephthalate) (PBT) Composites. J. Appl. Polym. Sci. 2012, 123, 77–91. [Google Scholar] [CrossRef]

- Ślusarczyk, C.; Sieradzka, M.; Fabia, J.; Fryczkowski, R. Supermolecular Structure of Poly(Butylene Terephthalate) Fibers Formed with the Addition of Reduced Graphene Oxide. Polymers 2020, 12, 1456. [Google Scholar] [CrossRef]

- Wu, F.; Yang, G. Poly(Butylene Terephthalate)/Organoclay Nanocomposites Prepared by in-Situ Bulk Polymerization with Cyclic Poly(Butylene Terephthalate). Mater. Lett. 2009, 63, 1686–1688. [Google Scholar] [CrossRef]

- Hajibaba, A.; Masoomi, M.; Nazockdast, H. The Role of Hydrophilic Organoclay in Morphology Development of Poly(Butylene Terephthalate)/Polypropylene Blends. High Perform. Polym. 2016, 28, 85–95. [Google Scholar] [CrossRef]

- Xiao, J.; Hu, Y.; Wang, Z.; Tang, Y.; Chen, Z.; Fan, W. Preparation and Characterization of Poly(Butylene Terephthalate) Nanocomposites from Thermally Stable Organic-Modified Montmorillonite. Eur. Polym. J. 2005, 41, 1030–1035. [Google Scholar] [CrossRef]

- Soudmand, B.H.; Shelesh-Nezhad, K.; Hassanifard, S. Toughness Evaluation of Poly(Butylene Terephthalate) Nanocomposites. Theor. Appl. Fract. Mech. 2020, 108, 102662. [Google Scholar] [CrossRef]

- Delbem, M.F.; Valera, T.S.; Valenzuela-Diaz, F.R.; Demarquette, N.R. Modification of a Brazilian Smectite Clay with Different Quaternary Ammonium Salts. Quim. Nova 2010, 33, 309–315. [Google Scholar] [CrossRef]

- de Paiva, L.B.; Morales, A.R.; Valenzuela Díaz, F.R. Organoclays: Properties, Preparation and Applications. Appl. Clay Sci. 2008, 42, 8–24. [Google Scholar] [CrossRef]

- Celanese Celanex 1600a Datasheet. Available online: https://www.matweb.com/search/datasheet (accessed on 1 October 2021).

- Deshpande, R.; Naik, G.; Chopra, S.; Deshmukh, K.A.; Deshmukh, A.D.; Peshwe, D.R. A Study on Mechanical Properties of PBT Nano-Composites Reinforced with Microwave Functionalized MWCNTs. IOP Conf. Ser. Mater. Sci. Eng. 2018, 346, 012004. [Google Scholar] [CrossRef]

- Merah, N.; Mohamed, O. Nanoclay and Water Uptake Effects on Mechanical Properties of Unsaturated Polyester. J. Nanomater. 2019, 2019, 8130419. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and Thermal Properties of ABS/Montmorillonite Nanocomposites for Fused Deposition Modeling 3D Printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Baba-Ahmadi, S.B.; Hashemian, M.; Khosravi, M.; Khandan, A. An Experimental and Analytical Investigation of Novel Nanocomposite Reinforced with Nanoclay with Enhanced Properties for Low Velocity Impact Test. J. Nanostructures 2020, 10, 92–106. [Google Scholar] [CrossRef]

- Sun, Y.; Mei, J.; Hu, H.; Ying, J.; Zhou, W.; Zhao, X.; Peng, S. In-Situ Polymerization of Exfoliated Structure PA6/Organo-Clay Nanocomposites. Rev. Adv. Mater. Sci. 2020, 59, 434–440. [Google Scholar] [CrossRef]

- Pumchusak, J.; Thajina, N.; Keawsujai, W.; Chaiwan, P. Effect of Organo-Modified Montmorillonite Nanoclay on Mechanical, Thermo-Mechanical, and Thermal Properties of Carbon Fiber-Reinforced Phenolic Composites. Polymers 2021, 13, 754. [Google Scholar] [CrossRef]

- Nirukhe, A.B.; Shertukde, V.V. Preparation and Characterization of Poly(Butylene Terephthalate) Nanocomposites with Various Organoclays. J. Appl. Polym. Sci. 2009, 113, 585–592. [Google Scholar] [CrossRef]

- Zhang, Q.; Fu, Q.; Jiang, L.; Lei, Y. Preparation and Properties of Polypropylene/Montmorillonite Layered Nanocomposites. Polym. Int. 2000, 49, 1561–1564. [Google Scholar] [CrossRef]

| Samples | PBT (%wt) | MBClay (%wt) |

|---|---|---|

| Neat PBT | 100 | 0 |

| PBT/MBClay 3.0% | 97.0 | 3.0 |

| PBT/MBClay 5.0% | 95.0 | 5.0 |

| Samples | PBT (%wt) | MBClay (%wt) |

|---|---|---|

| Neat PBT | 100 | 0 |

| PBT/MBClay 3.7 wt% | 96.3 | 3.7 |

| PBT/MBClay 4.9 wt% | 95.1 | 4.9 |

| Materials | ΔHm (J/g) | χc (%) | Tm (°C) | Onset Temp (°C) | Total Weight Loss (%) |

|---|---|---|---|---|---|

| Neat PBT | 41.0 a | 29.2 a | 212.9 a | 332.5 a | 89.6 a |

| PBT/MBClay (3.7 wt%) | 45.6 b | 34.1 b | 213.7 b | 331.2 b | 83.6 b |

| PBT/MBClay (4.9 wt%) | 46.1 c | 34.6 c | 219.1 c | 337.2 c | 82.5 c |

| Tensile Parameters | Neat PBT | PBT/MBClay 3.7 wt% | PBT/MBClay 4.9 wt% |

|---|---|---|---|

| Tensile stress at yield (MPa) | 59.2 ± 4.1 a | 60.6 ± 1.5 b | 48.4 ± 1.8 c |

| Tensile strength at break (MPa) | 38.0 ± 3.4 a | 60.1 ± 1.9 b | 47.9 ± 1.6 c |

| Young’s modulus (GPa) | 2.5 ± 0.1 a | 2.7 ± 0.1 b | 2.6 ± 0.1 c |

| Elongation at break (%) | 161.6 ± 35 a | 21.1 ± 1.0 b | 20.5 ± 1.3 c |

| Tensile Parameters | Neat PBT | PBT/MBClay 3.7 wt% | PBT/MBClay 4.9 wt% |

|---|---|---|---|

| Flexural strength (MPa) | 74.2 ± 3.2 a | 91.7 ± 2.8 b | 78.7 ± 3.6 c |

| Flexural modulus (GPa) | 2.4 ± 0.2 a | 2.8 ± 0.1 b | 2.5 ± 0.7 c |

| Test | Neat PBT | PBT/MBClay 3.7 wt% | PBT/MBClay 4.9 wt% |

|---|---|---|---|

| Izod Impact (J/m) | 72.6 ±2.1 a | 47.2 ± 1.4 b | 37.4 ± 1.1 c |

| HDT (1.82 MPa) (°C) | 55.4 ± 3.2 a | 80.1 ± 6.2 b | 69.7 ± 5.3 c |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Colombo, M.A.S.; Díaz, F.R.V.; Kodali, D.; Rangari, V.; Güven, O.; Moura, E.A.B. Influence of Reinforcing Efficiency of Clay on the Mechanical Properties of Poly(butylene terephthalate) Nanocomposite. Ceramics 2023, 6, 58-73. https://doi.org/10.3390/ceramics6010005

Colombo MAS, Díaz FRV, Kodali D, Rangari V, Güven O, Moura EAB. Influence of Reinforcing Efficiency of Clay on the Mechanical Properties of Poly(butylene terephthalate) Nanocomposite. Ceramics. 2023; 6(1):58-73. https://doi.org/10.3390/ceramics6010005

Chicago/Turabian StyleColombo, Maria A. S., Francisco R. V. Díaz, Deepa Kodali, Vijaya Rangari, Olgun Güven, and Esperidiana A. B. Moura. 2023. "Influence of Reinforcing Efficiency of Clay on the Mechanical Properties of Poly(butylene terephthalate) Nanocomposite" Ceramics 6, no. 1: 58-73. https://doi.org/10.3390/ceramics6010005

APA StyleColombo, M. A. S., Díaz, F. R. V., Kodali, D., Rangari, V., Güven, O., & Moura, E. A. B. (2023). Influence of Reinforcing Efficiency of Clay on the Mechanical Properties of Poly(butylene terephthalate) Nanocomposite. Ceramics, 6(1), 58-73. https://doi.org/10.3390/ceramics6010005