Potentials of Numerical Methods for Increasing the Productivity of Additive Manufacturing Processes

Abstract

1. Introduction

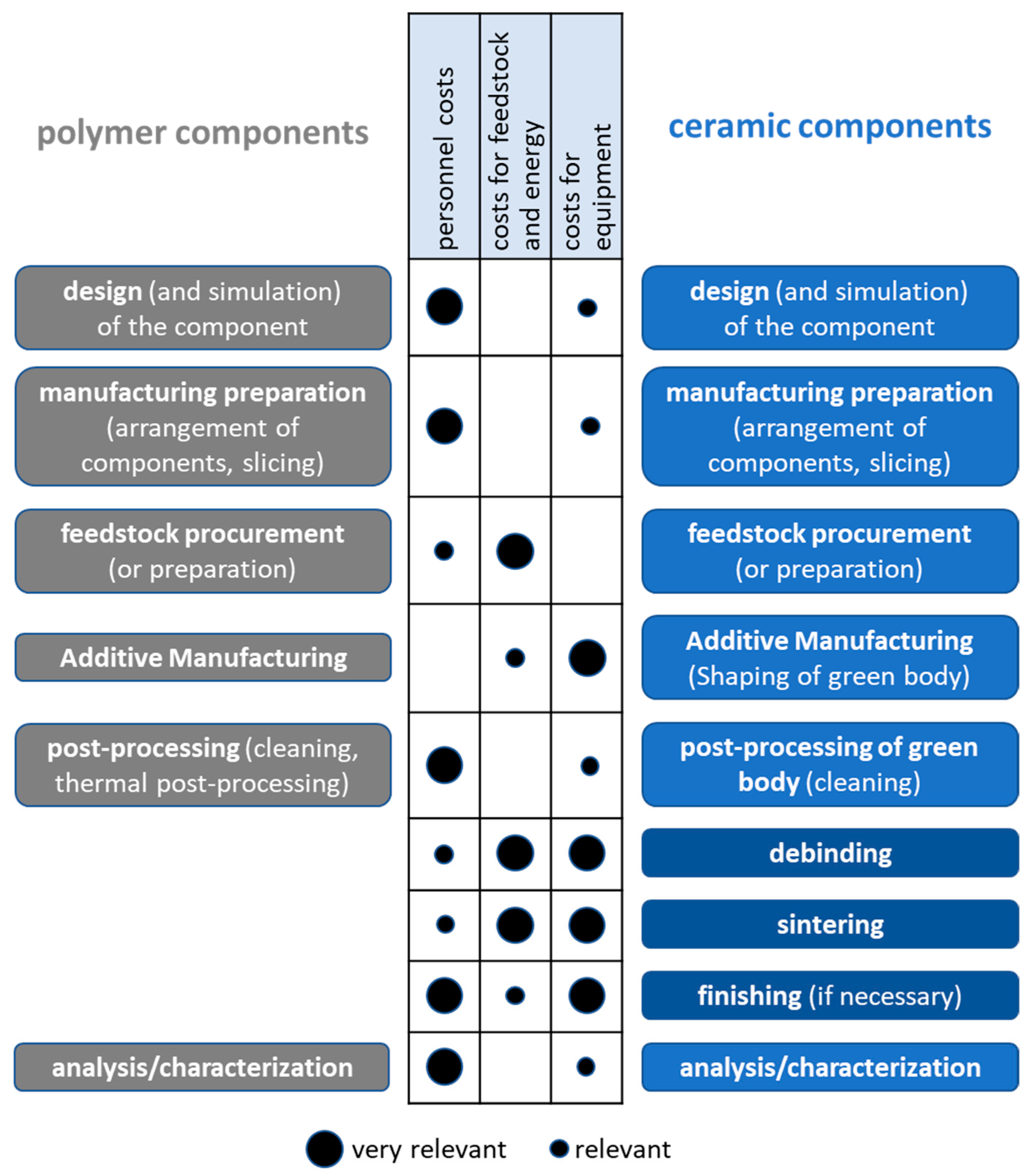

2. Manufacturing Costs for AM Components

2.1. General Considerations

2.2. Cost Structure for Indirect and Direct AM Technologies

2.3. State-of-the-Art concerning the Component Arrangement

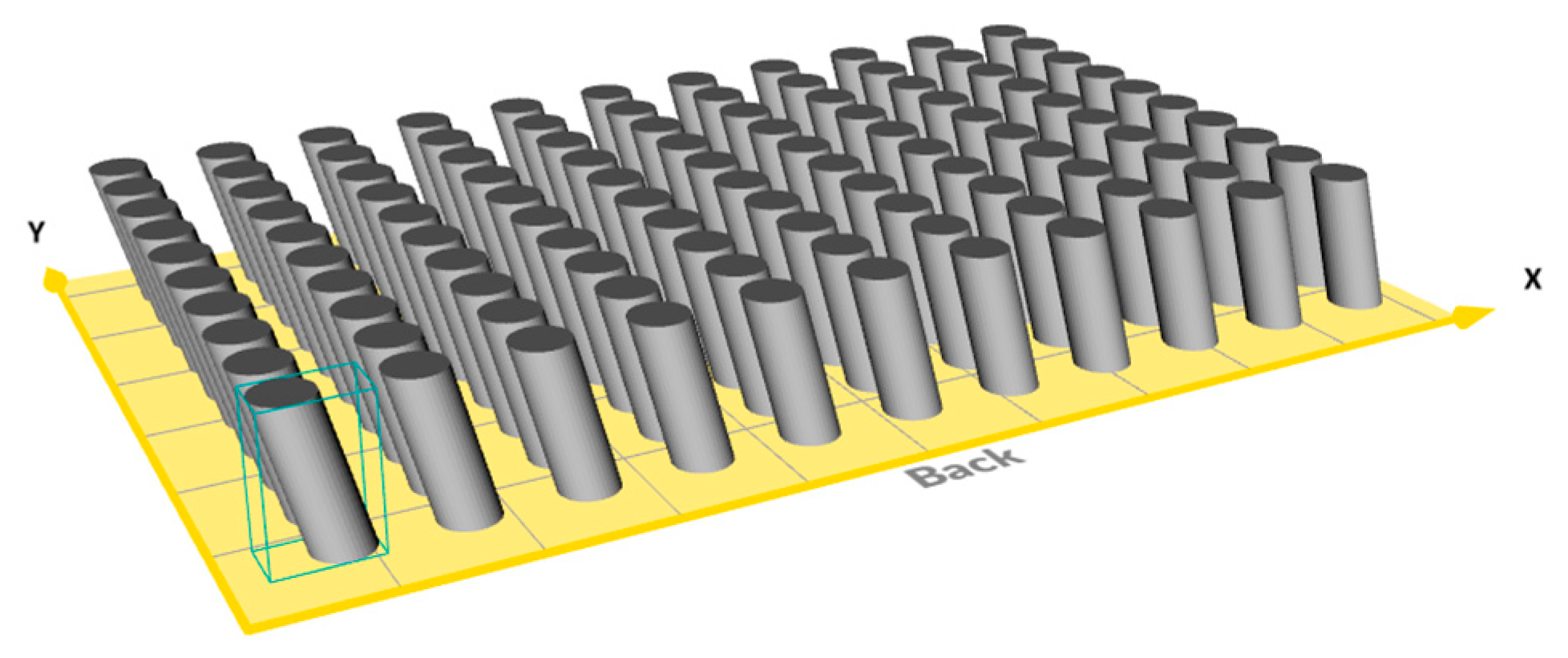

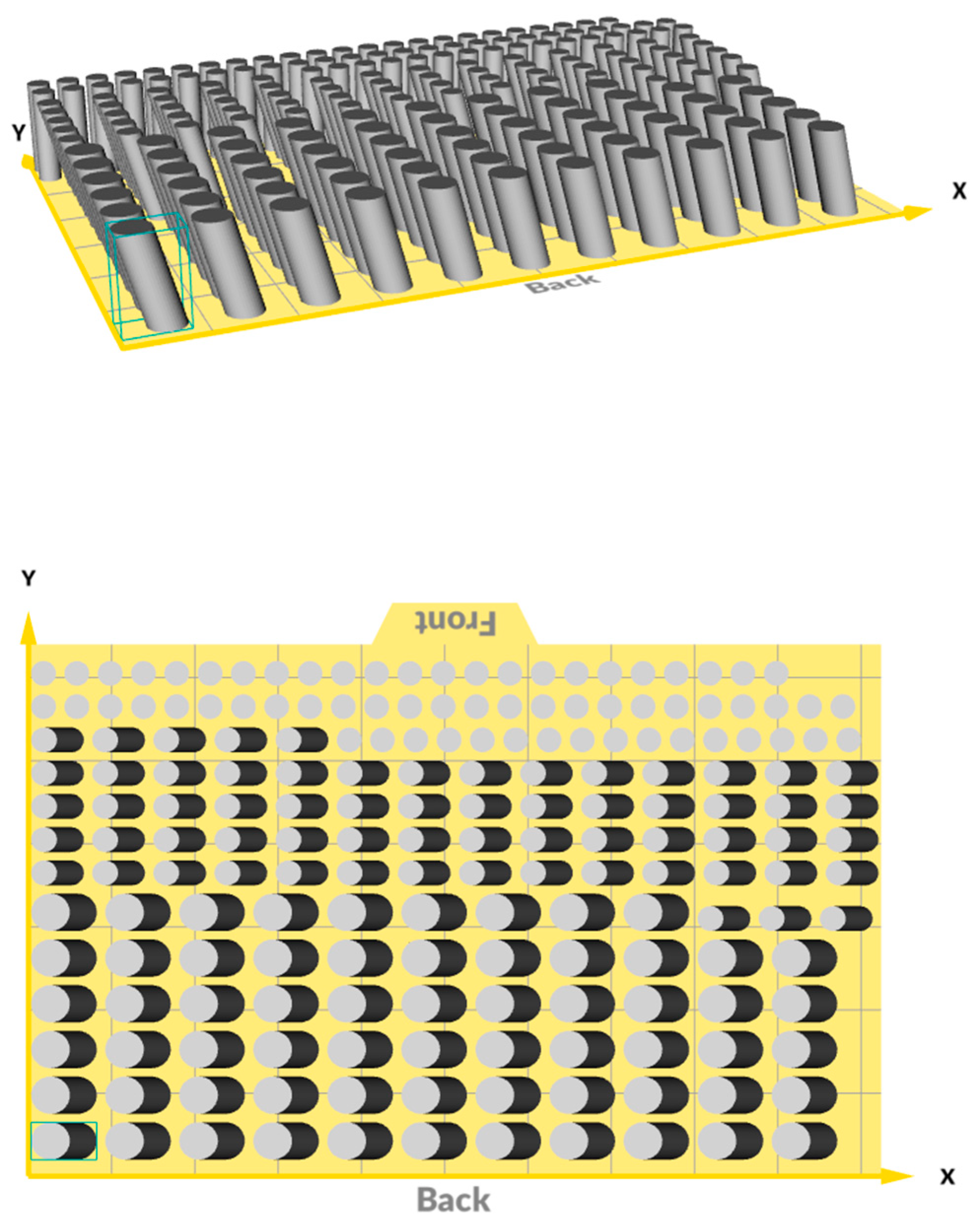

3. Optimization of Component Arrangement

3.1. Relations to Existing Packing Problems

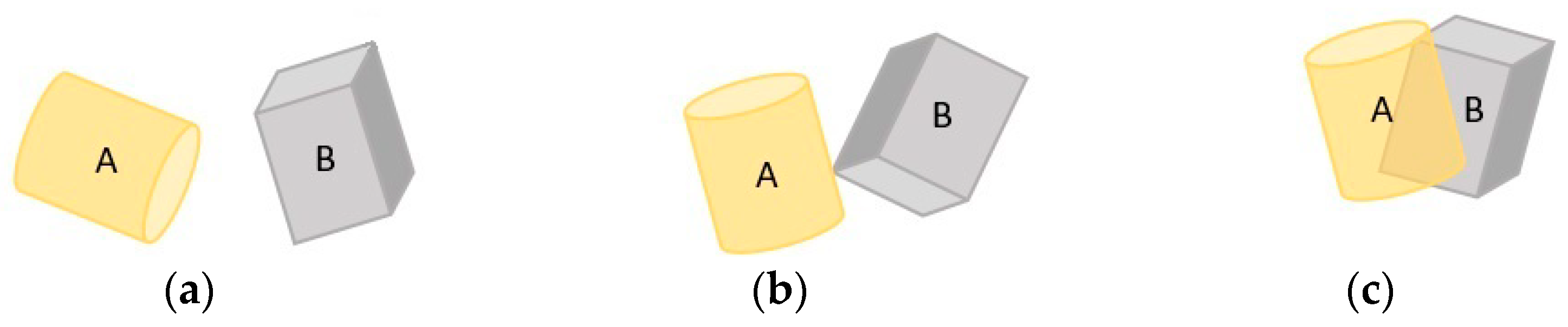

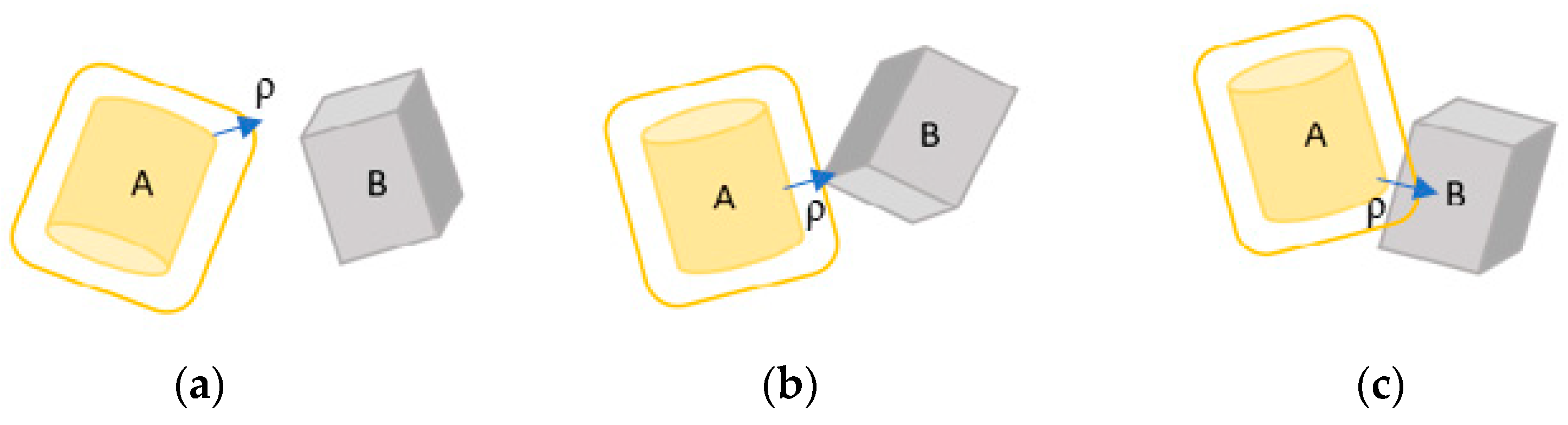

3.2. Three Different Arrangement Cases

- Case 1. Individual packing: a small number of components with the same or different geometries are needed, arrangement in one building space, manufacturing in one printing job possible.

- Case 2. Packing for small-scale (small batch) production: many components with the same geometries (hundreds or thousands of each type of geometry) are needed, manufacturing in more than one printing job.

- Case 3. Packing for bulk (mass) production: with an almost unlimited number of elements of each type, considering the specified percentage for different types of components.

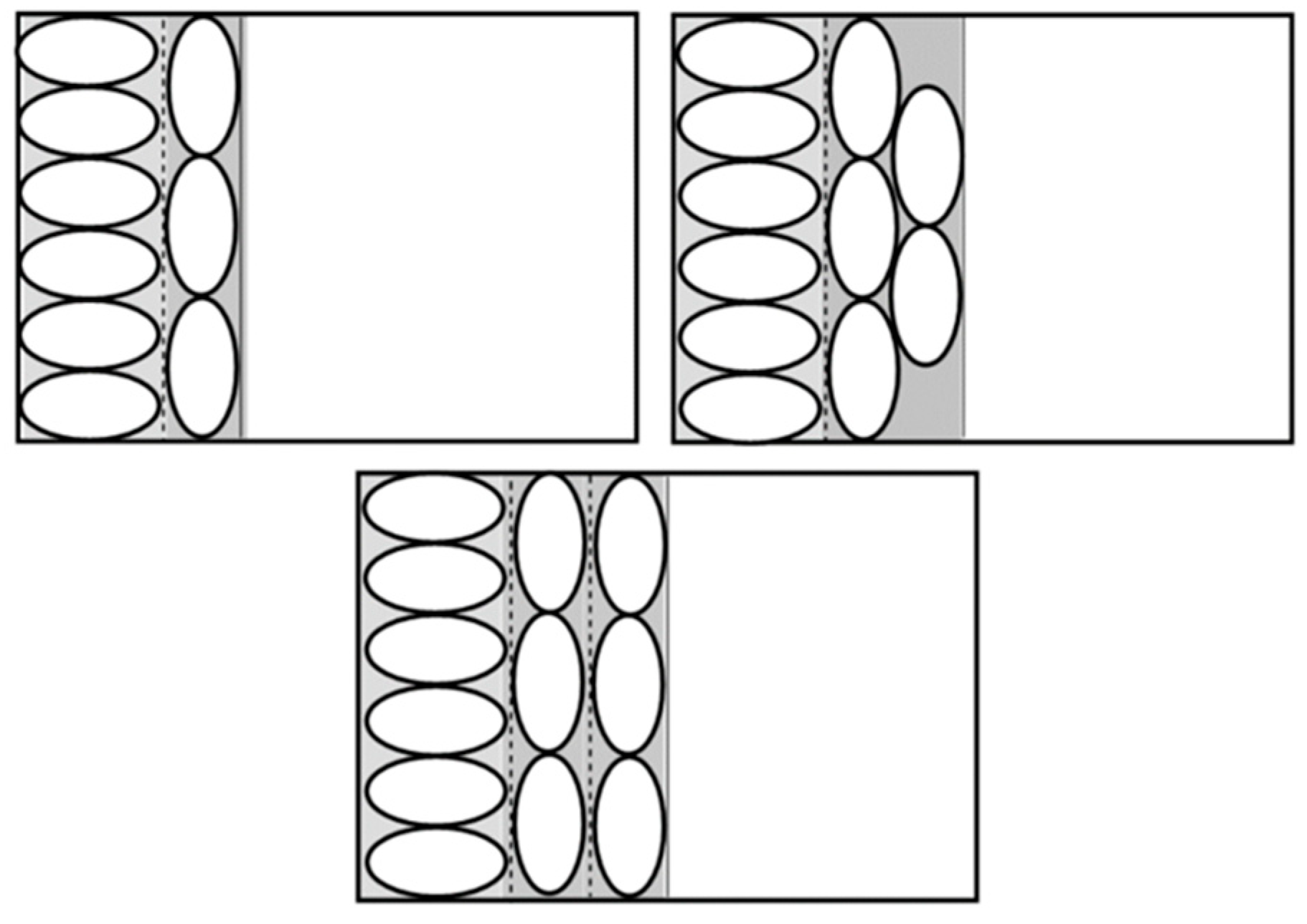

3.3. Boundary Conditions and an Exemplary Task for Demonstration

- non-overlapping of components taking into account minimal allowable distances between each pair of components;

- containment of components in the cuboidal container.

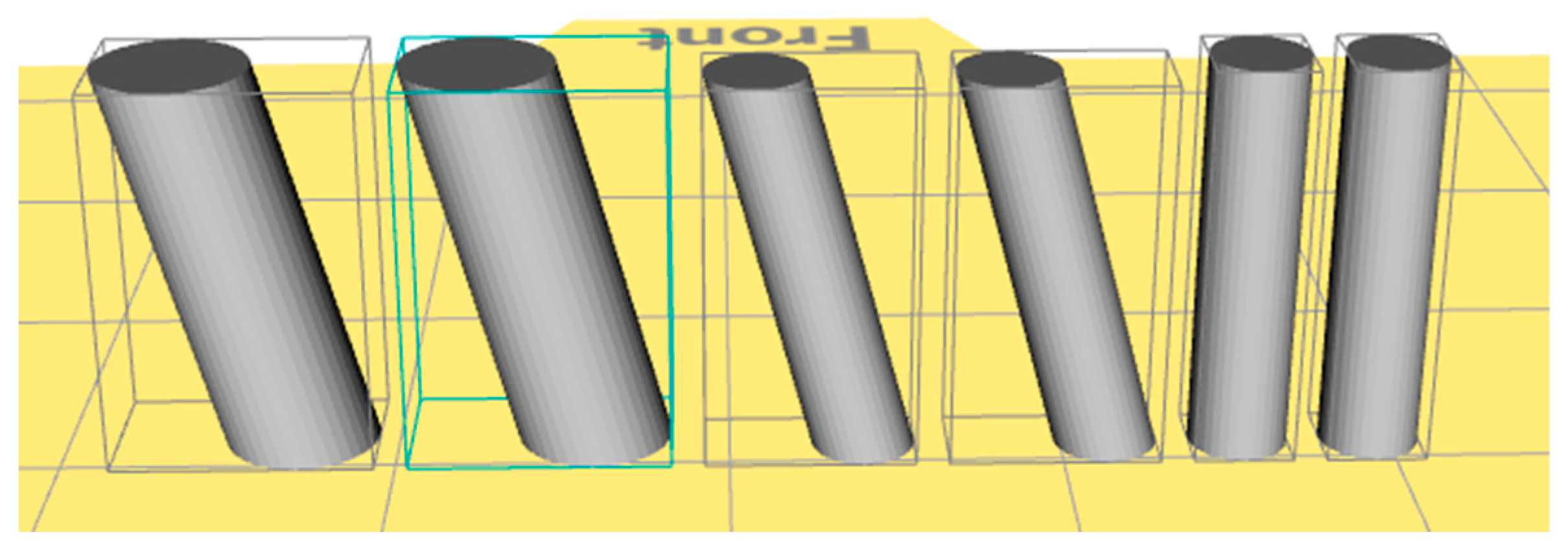

4. New Approach: Regular-Sectional Arrangement

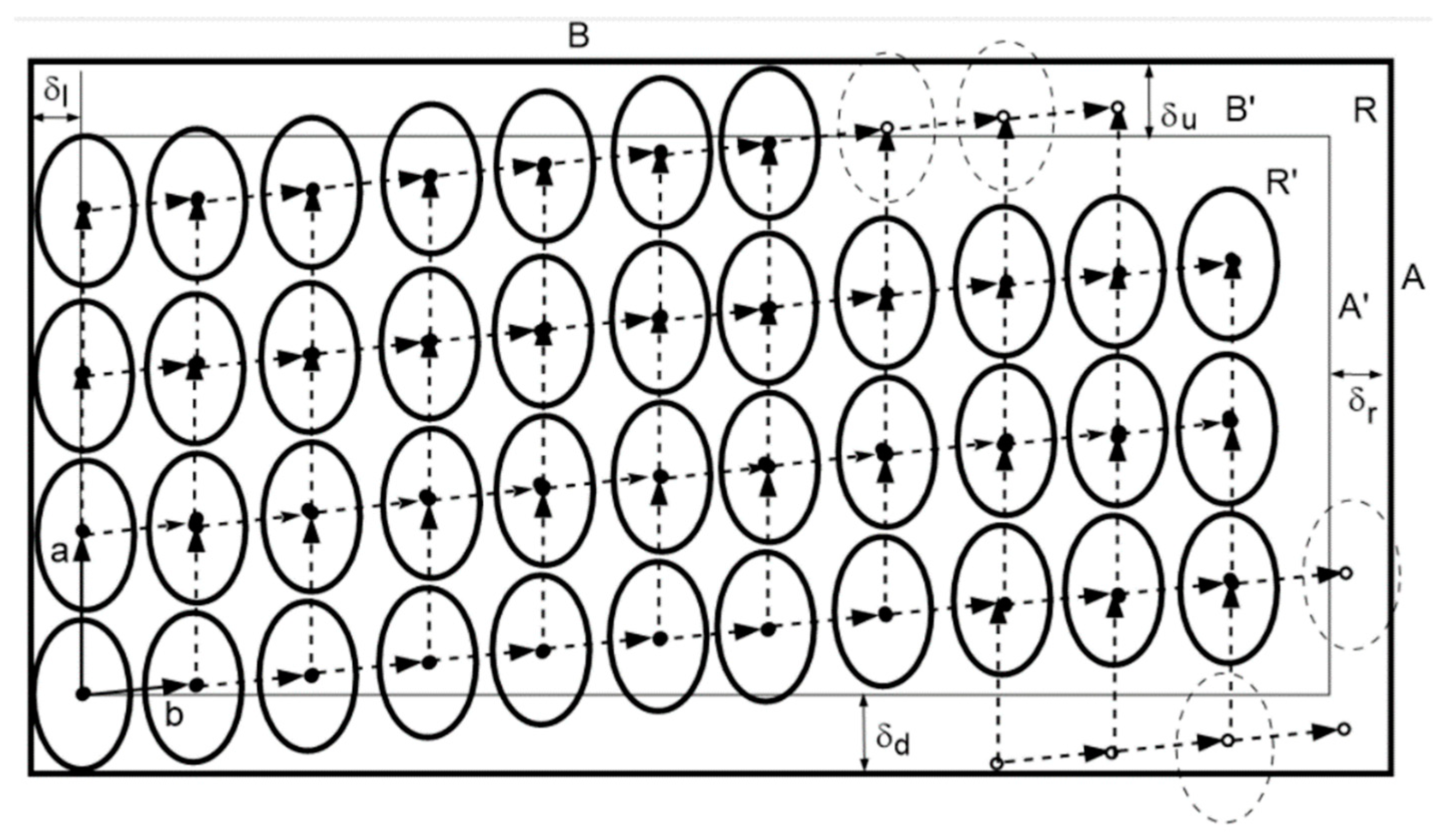

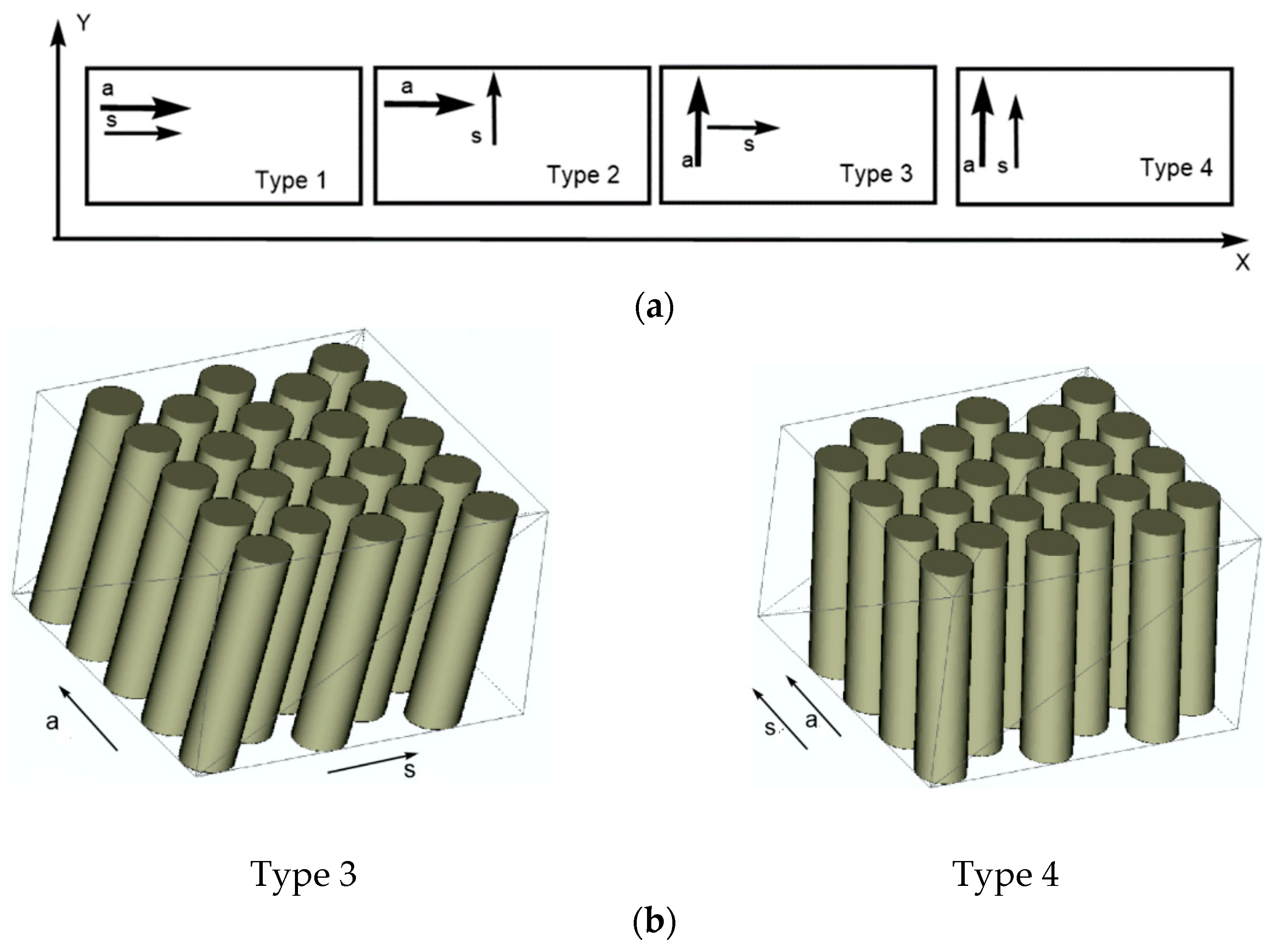

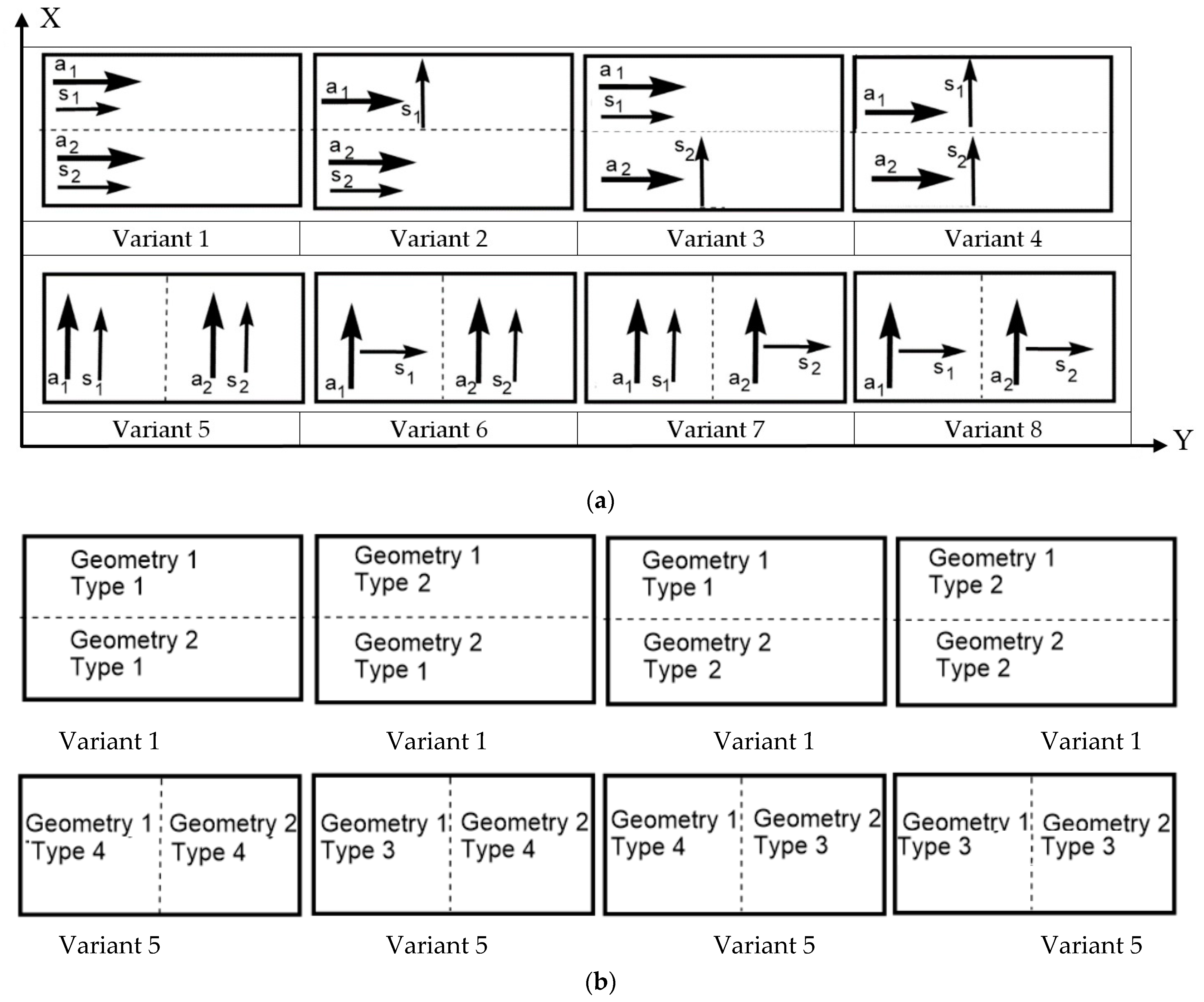

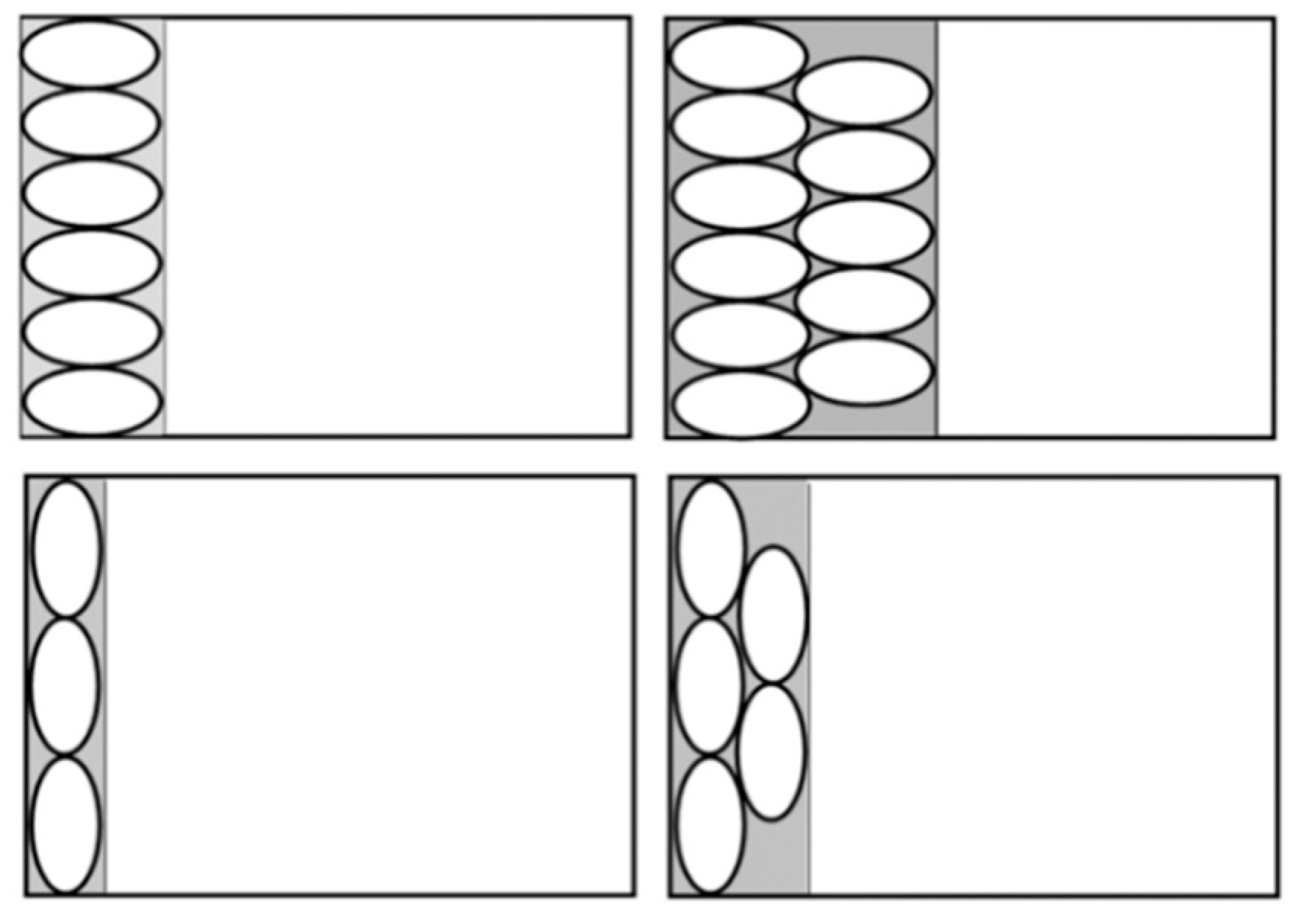

4.1. Main Scenario and Techniques

4.2. Solution Algorithm

5. Results and Discussion

6. Conclusions

- Preparation-analysis and abstraction of the component geometry:

- an assessment of the manufacturability of the component as a function of the orientation on the build platform (manufacturability/probability of defect/…) is made in order to limit the number of possibilities for positioning the components during optimization of the feasible variants;

- an abstraction of the outer geometry of the components by simple three-dimensional geometries (sphere, cylinder, cuboid, tetrahedron, …) is carried out in order to reduce the computational effort.

- Optimization of the component arrangement:

- the arrangement of the (abstracted) components is optimized, whereby the (abstracted) components can be rotated around all three spatial axes;

- the specification of boundary conditions for the optimization takes place (e.g., (minimum) distance of the components to each other, desired number (interval), desired construction height/production time, …);

- a weighting of the boundary conditions can be carried out;

- optimization can be carried out according to several target variables/(weighted) boundary conditions.

- Generation of the CAM data:

- reconversion of the abstracted geometries into the original geometries;

- machine data are generated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Modeling of Basis Geometric Constraints in Packing Problems

- non-overlapping condition: and do not intersect, but can touch each other, i.e., ;

- containment condition: is arranged fully inside the container , i.e., ;

- distance condition: the distance between objects and is grater than or equal to , i.e.,where , , stands for the Euclidean distance between two points .

Appendix A.2. Basic Definitions of the phi-Function Technique

Appendix A.3. Adjusted phi-Function

Appendix A.4. Phi-Function for Irregular Objects Composed by a Union of Basic Shapes

References

- Gries, S.; Meyer, G.; Wonisch, A.; Jakobi, R.; Mittelstedt, C. Towards Enhancing the Potential of Injection Molding Tools through Optimized Close-Contour Cooling and Additive Manufacturing. Materials 2021, 14, 3434. [Google Scholar] [CrossRef] [PubMed]

- Hybrid Metal 3D Printer Redefines Mold Component Production. Available online: https://www.moldmakingtechnology.com/products/hybrid-metal-3d-printer-redefines-mold-component-production (accessed on 29 January 2023).

- Achinas, S.; Heins, J.I.; Krooneman, J.; Euverink, G.J.W. Miniaturization and 3D Printing of Bioreactors: A Technological Mini Review. Micromachines 2020, 11, 853. [Google Scholar] [CrossRef]

- Fujimoto, K.T.; Hone, L.A.; Manning, K.D.; Seifert, R.D.; Davis, K.L.; Milloway, J.N.; Skifton, R.S.; Wu, Y.; Wilding, M.; Estrada, D. Additive Manufacturing of Miniaturized Peak Temperature Monitors for In-Pile Applications. Sensors 2021, 21, 7688. [Google Scholar] [CrossRef]

- Realizing the Benefits of Miniaturization of Electronic Components with 3D Printing. Available online: https://www.nano-di.com/resources/blog/2020-realizing-the-benefits-of-miniaturization-of-electronic-components-with-3d-printing (accessed on 29 January 2023).

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive manufacturing of ceramics: Issues, potentialities, and opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive Manufacturing of ceramic-based material. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Tan, C.K.L.; Goh, Z.H.; De Chua, K.W.; Kamath, S.; Chung, C.K.R.; Teo, W.B.Y.; Martinez, J.C.; Dritsas, S.; Simpson, R.E. An improved hearing aid fitting journey; the role of 3D scanning, additive manufacturing, and sustainable practices. Mater. Today Proc. 2022, 70, 504–511. [Google Scholar] [CrossRef]

- How Personalization Has Changed the Hearing Aid Industry for the Better. Available online: https://www.materialise.com/en/inspiration/cases/phonak-3d-printed-hearing-aid (accessed on 29 January 2023).

- Top Seven Industries for Additive Manufacturing Applications. Available online: https://luxcreo.com/top-seven-industries-for-additive-manufacturing-applications/ (accessed on 29 January 2023).

- Additive Manufacturing: Applications by Sector. Available online: https://www.3dnatives.com/en/applications-by-sector/# (accessed on 29 January 2023).

- Hopkinson, N.; Dicknes, P. Analysis of rapid manufacturing—Using layer manufacturing processes for production. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2003, 217, 31–39. [Google Scholar] [CrossRef]

- 3D Printing Manufacturing Costs. Available online: https://multec.de/en/3d-printing-technology/production-costs-of-3d-printed-parts (accessed on 8 December 2022).

- Ruffo, M.; Tuck, C.; Hague, R.J.M. Cost estimation for rapid manufacturing—Laser sintering production for low to medium volumes. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2006, 220, 1417–1427. [Google Scholar] [CrossRef]

- Thomas, D.; Gilbert, S. Costs and Cost Effectiveness of Additive Manufacturing; Special Publication (NIST SP), National Institute of Standards and Technology: Gaithersburg, MD, USA, 2014. [CrossRef]

- Thomas, D. Costs, benefits, and adoption of additive manufacturing: A supply chain perspective. Int. J. Adv. Manuf. Technol. 2016, 85, 1857–1876. [Google Scholar] [CrossRef]

- Homa, J. Rapid prototyping of high-performance ceramics opens new opportunities for the CIM industry. Powder Inject. Mould. Int. 2012, 6, 65–68. [Google Scholar]

- Schwentenwein, M.; Homa, J. Additive manufacturing of dense alumina ceramics. Int. J. Appl. Cer. Technol. 2015, 12, 1–7. [Google Scholar] [CrossRef]

- Halloran, J.W. Ceramic stereolithography: Additive manufacturing for ceramics by photopolymerization. Annu. Rev. Mater. Res. 2016, 46, 19–40. [Google Scholar] [CrossRef]

- Griffith, M.L.; Halloran, J.W. Freeform fabrication of ceramics via stereolithography. J. Am. Ceram. Soc. 1996, 79, 2601–2608. [Google Scholar] [CrossRef]

- Abel, J.; Scheithauer, U.; Janics, T.; Hampel, S.; Cano, S.; Müller-Köhn, A.; Günther, A.; Kukla, C.; Moritz, T. Fused Filament Fabrication (FFF) of Metal-Ceramic Components. J. Vis. Exp. 2018, 143, e57693. [Google Scholar]

- Weingarten, S.; Scheithauer, U.; Johne, R.; Abel, J.; Schwarzer, E.; Moritz, T.; Michaelis, A. Multi-material Ceramic-Based Components—Additive Manufacturing of Black-and-white Zirconia Components by Thermoplastic 3D-Printing (CerAM-T3DP). J. Vis. Exp. 2019, 143, e57538. [Google Scholar] [CrossRef]

- Michaelis, A.; Scheithauer, U.; Moritz, T.; Weingarten, S.; Abel, J.; Schwarzer, E.; Kunz, W. Advanced Manufacturing for Advanced Ceramics. Procedia CIRP 2020, 95, 18–22. [Google Scholar] [CrossRef]

- Terno, J.; Lindemann, R.; Scheithauer, G. Zuschnittprobleme und Ihre Praktische Lösung. Mathematische Modelle von Layout-Problemen, 1st ed.; Harri Deutsch: Frankfurt/Main, Germany, 1987. [Google Scholar]

- Scheithauer, G. Algorithms for the Container Loading Problem. In Operations Research Proceedings; Gaul, W., Bachem, A., Habenicht, W., Runge, W., Stahl, W.W., Eds.; Springer: Berlin/Heidelberg, Germany, 1991; pp. 445–452. [Google Scholar] [CrossRef]

- Fischer, A.; Scheithauer, G. Cutting and Packing Problems with Placement Constraints. In Optimized Packings with Applications; Fasano, G., Pinter, J.D., Eds.; Springer: Cham, Switzerland, 2015; pp. 119–156. [Google Scholar]

- Chernov, N.; Stoyan, Y.; Romanova, T. Mathematical model and efficient algorithms for object packing problem. Comput. Geom. Theory Appl. 2010, 43, 535–553. [Google Scholar] [CrossRef]

- Burke, E.K.; Hellier, R.S.R.; Kendall, G.; Whitwell, G. A New Bottom-Left-Fill Heuristic Algorithm for the Two-Dimensional Irregular Packing Problem. Oper. Res. 2006, 54, 587–601. [Google Scholar] [CrossRef]

- Stannarius, R.; Schulze, J. On regular and random two-dimensional packing of crosses. Granul. Matter 2022, 24, 25. [Google Scholar] [CrossRef]

- Kallus, Y.; Kusner, W. The Local Optimality of the Double Lattice Packing. Discret. Comput. Geom. 2016, 56, 449–471. [Google Scholar] [CrossRef]

- Milenkovic, V.J. Densest translational lattice packing of non-convex polygons. Comput. Geom. Theory Appl. 2002, 22, 205–222. [Google Scholar] [CrossRef]

- Chazelle, B.; Edelsbrunner, H.; Guibas, L.J. The complexity of cutting complexes. Discret. Comput. Geom. 1989, 4, 139–181. [Google Scholar] [CrossRef]

- Leao, A.S.; Toledo, F.M.B.; Oliveira, J.F.; Carravilla, M.A.; Alvarez-Valdés, R. Irregular packing problems: A review of mathematical models. Eur. J. Oper. Res. 2020, 282, 803–822. [Google Scholar] [CrossRef]

- Stoyan, Y.; Pankratov, A.; Romanova, T. Quasi-phi-functions and optimal packing of ellipses. J. Glob. Optim. 2016, 65, 283–307. [Google Scholar] [CrossRef]

- Kallrath, J. Business Optimisation Using Mathematical Programming. In Cutting & Packing beyond and within Mathematical Programming, 2nd ed.; Springer: Cham, Switzerland, 2021; Chapter 15; pp. 495–526. [Google Scholar]

- Romanova, T.; Stoyan, Y.; Pankratov, A.; Litvinchev, I.; Plankovskyy, S.; Tsegelnyk, Y.; Shypul, O. Sparsest balanced packing of irregular 3D objects in a cylindrical container. Eur. J. Oper. Res. 2021, 291, 84–100. [Google Scholar] [CrossRef]

- Romanova, T.; Stoyan, Y.; Pankratov, A.; Litvinchev, I.; Avramov, K.; Chernobryvko, M.; Yanchevskyi, I.; Mozgova, I.; Bennell, J. Optimal layout of ellipses and its application for additive manufacturing. Int. J. Prod. Res. 2021, 59, 560–575. [Google Scholar] [CrossRef]

- Duriagina, Z.; Lemishka, I.; Litvinchev, I.; Marmolejo, J.; Pankratov, A.; Romanova, T.; Yaskov, G. Optimized filling a given cuboid with spherical powders for additive manufacturing. J. Oper. Res. Soc. China 2021, 9, 853–868. [Google Scholar] [CrossRef]

- Pankratov, A.; Romanova, T.; Litvinchev, I. Packing oblique 3D objects. Mathematics 2020, 8, 1130. [Google Scholar] [CrossRef]

- Stoyan, Y.; Pankratov, A.; Romanova, T. Placement Problems for Irregular Objects: Mathematical Modeling, Optimization and Applications. In Optimization Methods and Applications; Butenko, S., Pardalos, P., Shylo, V., Eds.; Springer: Cham, Switzerland, 2017; Volume 130, pp. 521–559. [Google Scholar]

- Pankratov, A.; Romanova, T.; Litvinchev, I. Packing ellipses in an optimized rectangular container16. Wirel. Netw. 2020, 26, 4869–4879. [Google Scholar] [CrossRef]

- Romanova, T.; Pankratov, A.; Litvinchev, I.; Dubinskyi, V.; Infante, L. Sparse layout of irregular 3D clusters. J. Oper. Res. Soc. 2022, 74, 351–361. [Google Scholar] [CrossRef]

- Romanova, T.; Litvinchev, I.; Pankratov, A. Packing ellipsoids in an optimized cylinder. Eur. J. Oper. Res. 2020, 285, 429–443. [Google Scholar] [CrossRef]

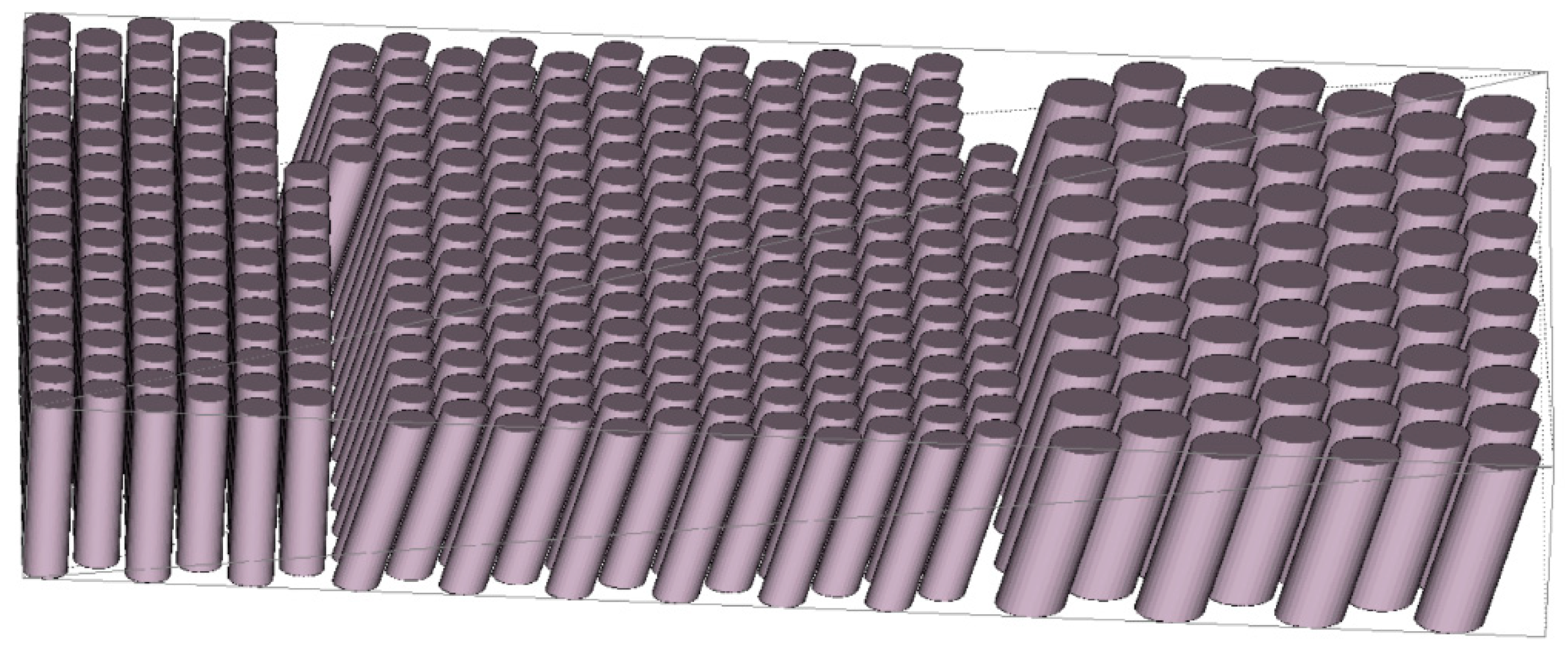

| Cylinder Geometry (CGx) | CG1 | CG2 | CG3 | |

|---|---|---|---|---|

| length | [mm] | 12.5 | 12.5 | 12.5 |

| diameter | [mm] | 3 | 3 | 4.5 |

| inclination | [°] | 0 | 15 | 15 |

| numbers needed (approx.) | [1] | 1000 | 1000 | 1000 |

| Numbers of CGx per Building Platform | Number of Building Platforms Needed for approx. 1000 Components per Type | |||

|---|---|---|---|---|

| Kind of Building Platform | CG1 | CG2 | CG3 | |

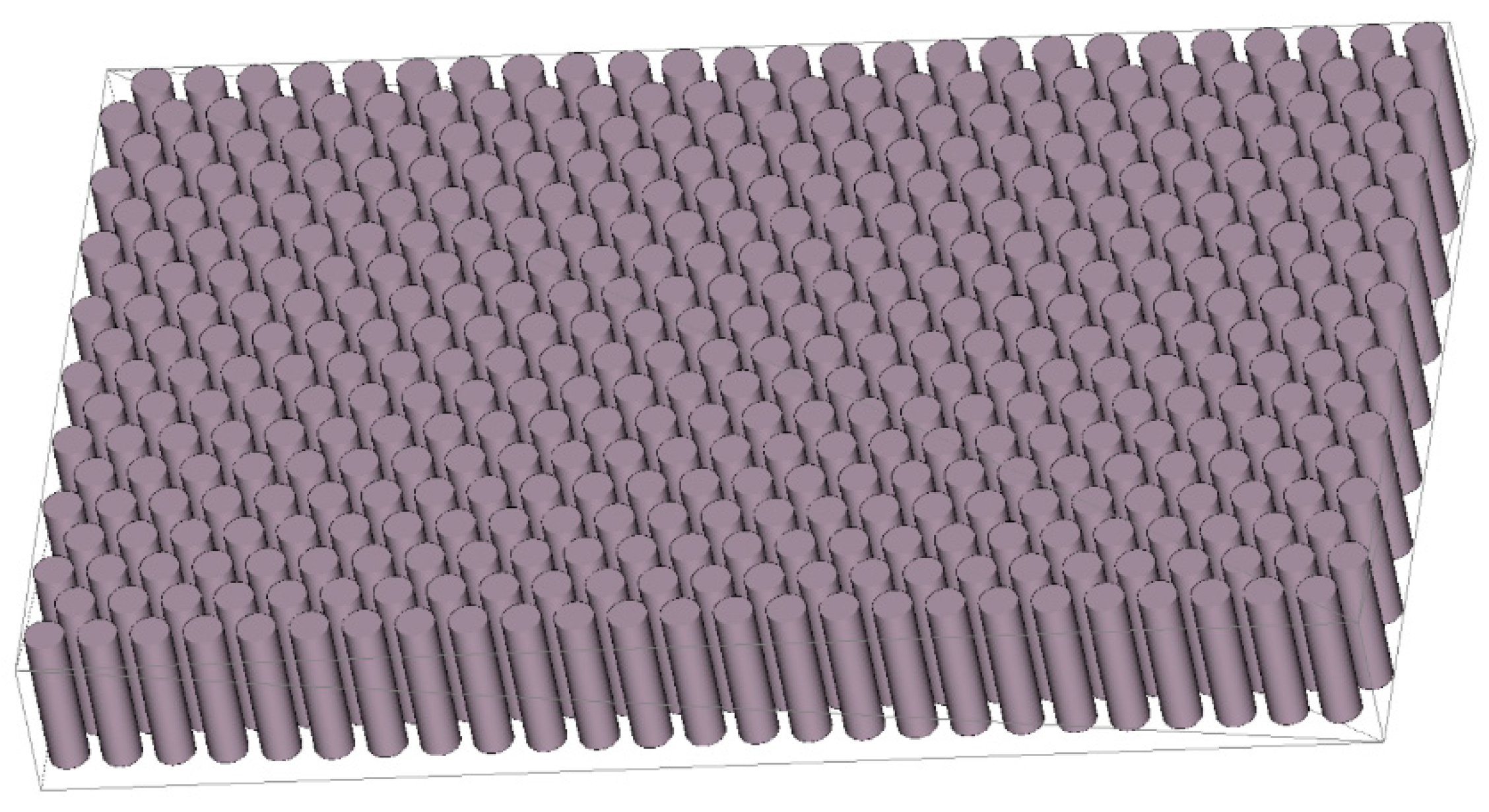

| Max_CG1 (Figure E1) | 375 | 3|1125 | ||

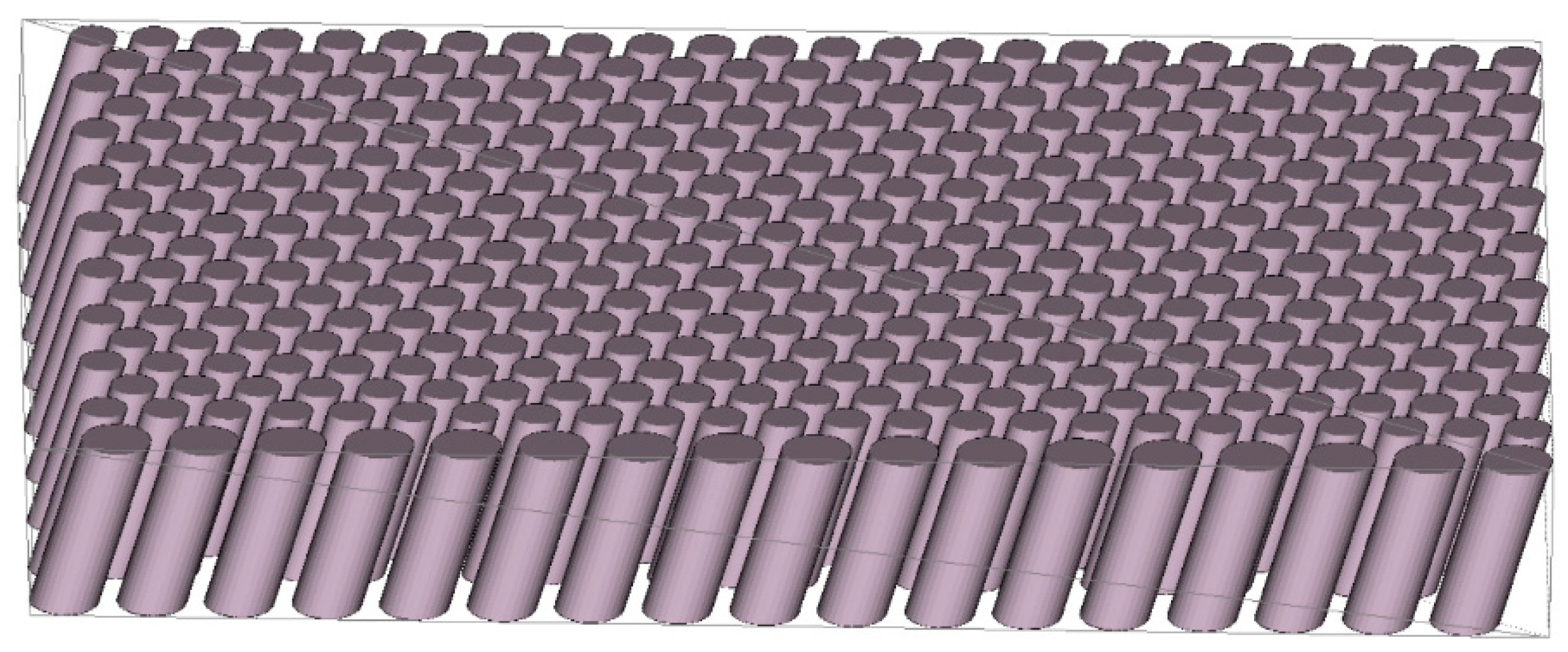

| Max_CG2 (Figure E2) | 196 | 5|980 | ||

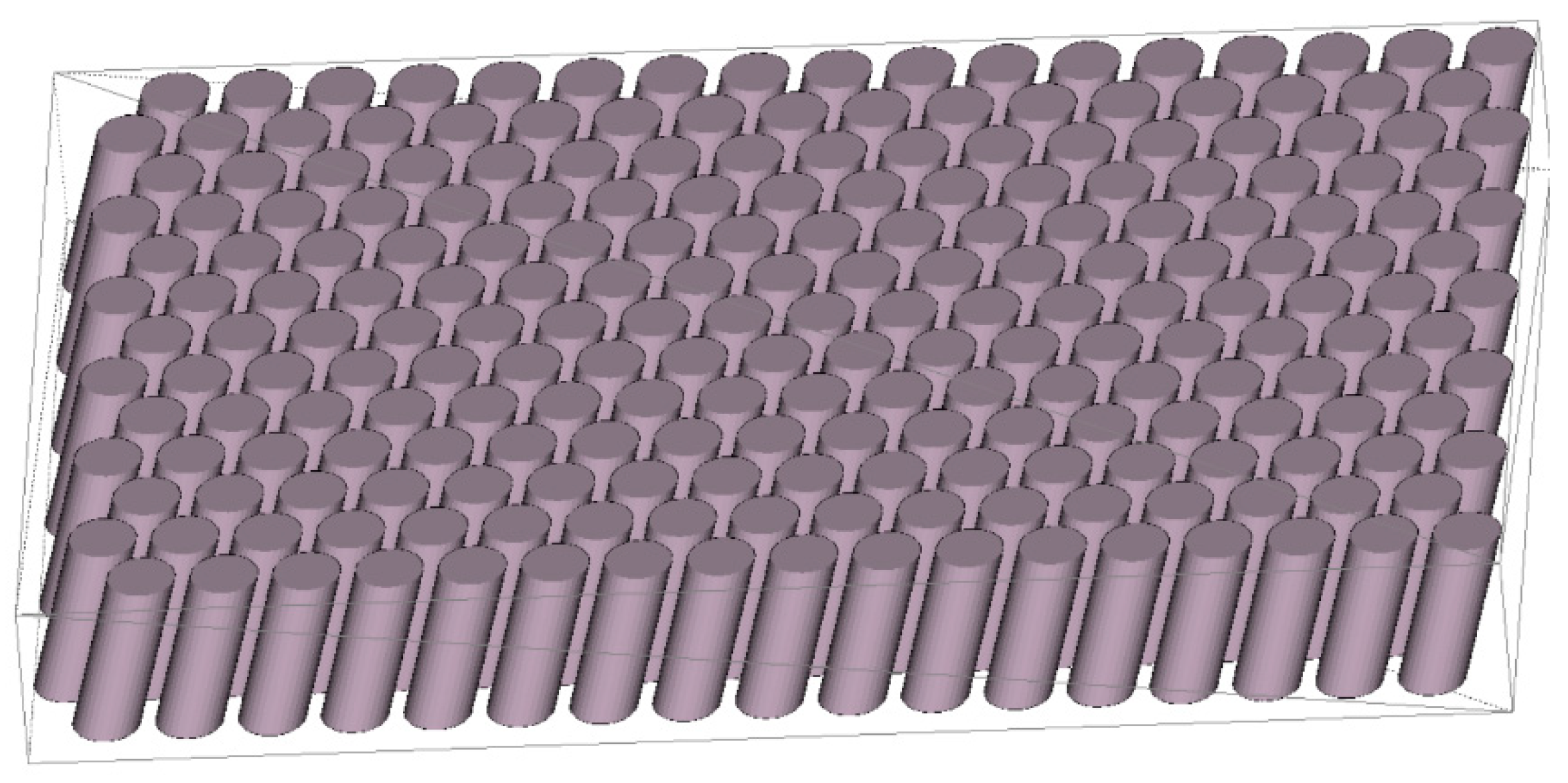

| Max_CG3 (Figure E3) | 110 | 9|990 | ||

| sum | 17|1125 + 980 + 990 | |||

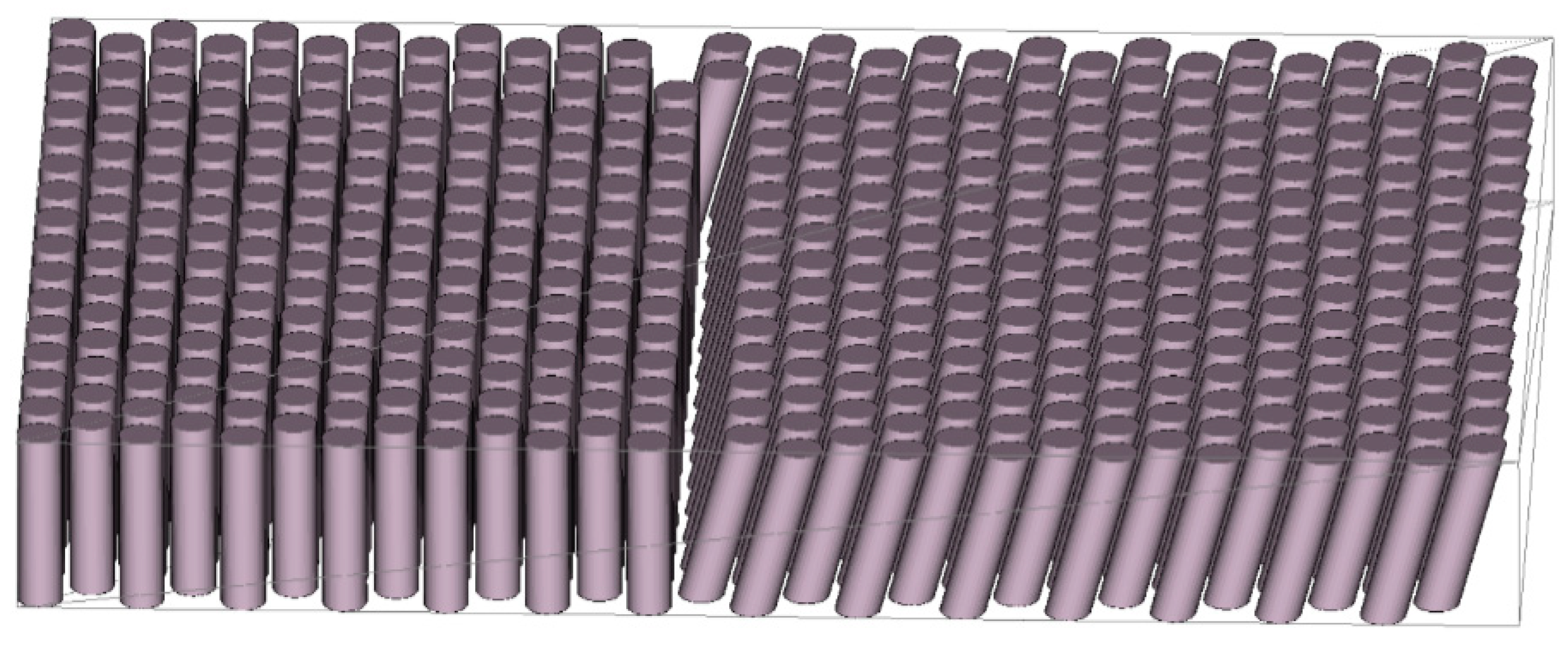

| Equal_CGx (Figure E4) | 64 | 64 | 64 | 16|1024 |

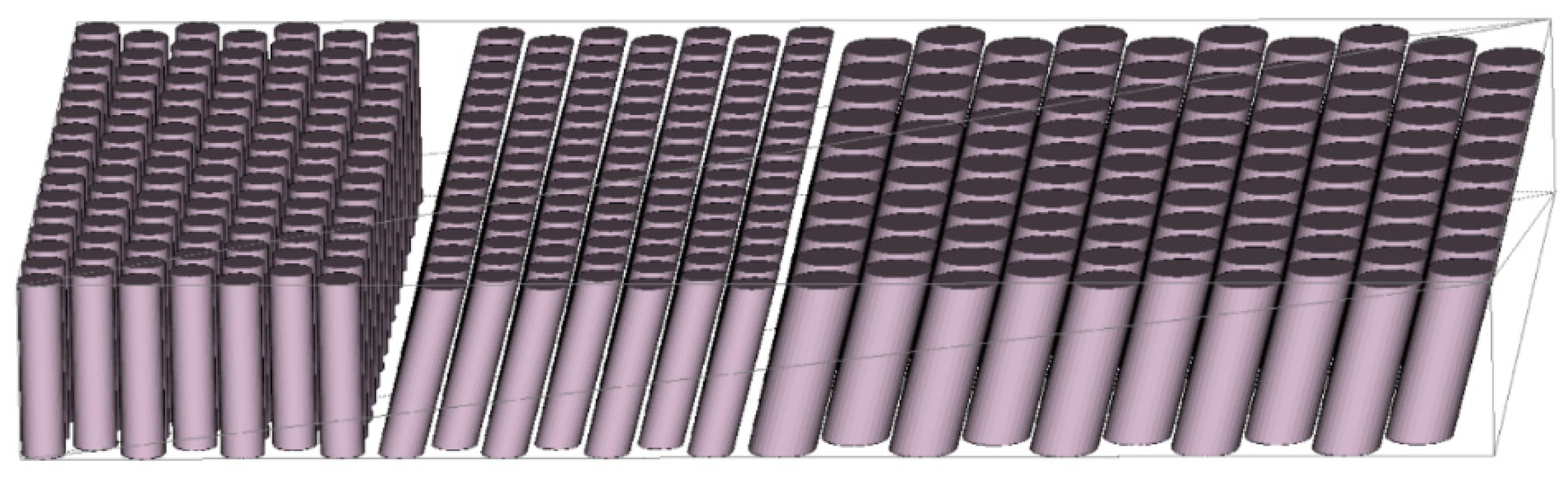

| Number of Building Platforms | Numbers of CGx per Building Platform | Total Number of CGx | |||||

|---|---|---|---|---|---|---|---|

| Kind of Building Platform | CG1 | CG2 | CG3 | CG1 | CG2 | CG3 | |

| BP_1_1-1 | 9 | 109 | 109 | 109 | 981 | 981 | 981 |

| 10 | 109 | 109 | 109 | 1090 | 1090 | 1090 | |

| Number of Building Platforms | Numbers of CGx per Building Platform | Total Number of CGx | |||||

|---|---|---|---|---|---|---|---|

| Kind of Building Platform | CG1 | CG2 | CG3 | CG1 | CG2 | CG3 | |

| BP_1_2-1 | 2 | 450 | 0 | 0 | 900 | 0 | 0 |

| BP_1_2-2 | 2 | 0 | 400 | 17 | 0 | 800 | 34 |

| BP_1_2-3 | 4 | 0 | 0 | 221 | 0 | 0 | 884 |

| BP_1_2-4 | 1 | 88 | 188 | 70 | 88 | 188 | 70 |

| sum | 9 | 988 | 988 | 988 | |||

| Number of Building Platforms | Numbers of CGx per Building Platform | Total Number of CGx | |||||

|---|---|---|---|---|---|---|---|

| Kind of Building Platform | CG1 | CG2 | CG3 | CG1 | CG2 | CG3 | |

| BP_1_3-1 | 2 | 450 | 0 | 0 | 900 | 0 | 0 |

| BP_1_3-2 | 2 | 0 | 400 | 17 | 0 | 800 | 34 |

| BP_1_3-3 | 4 | 0 | 0 | 221 | 0 | 0 | 884 |

| BP_1_3-4 | 1 | 200 | 234 | 0 | 200 | 234 | 0 |

| BP_1_3-5 | 1 | 0 | 66 | 182 | 0 | 66 | 182 |

| sum | 10 | 1100 | 1100 | 1100 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scheithauer, U.; Romanova, T.; Pankratov, O.; Schwarzer-Fischer, E.; Schwentenwein, M.; Ertl, F.; Fischer, A. Potentials of Numerical Methods for Increasing the Productivity of Additive Manufacturing Processes. Ceramics 2023, 6, 630-650. https://doi.org/10.3390/ceramics6010038

Scheithauer U, Romanova T, Pankratov O, Schwarzer-Fischer E, Schwentenwein M, Ertl F, Fischer A. Potentials of Numerical Methods for Increasing the Productivity of Additive Manufacturing Processes. Ceramics. 2023; 6(1):630-650. https://doi.org/10.3390/ceramics6010038

Chicago/Turabian StyleScheithauer, Uwe, Tetyana Romanova, Oleksandr Pankratov, Eric Schwarzer-Fischer, Martin Schwentenwein, Florian Ertl, and Andreas Fischer. 2023. "Potentials of Numerical Methods for Increasing the Productivity of Additive Manufacturing Processes" Ceramics 6, no. 1: 630-650. https://doi.org/10.3390/ceramics6010038

APA StyleScheithauer, U., Romanova, T., Pankratov, O., Schwarzer-Fischer, E., Schwentenwein, M., Ertl, F., & Fischer, A. (2023). Potentials of Numerical Methods for Increasing the Productivity of Additive Manufacturing Processes. Ceramics, 6(1), 630-650. https://doi.org/10.3390/ceramics6010038