Abstract

Bucchero is a well-known class of Etruscan ceramics, characterized by being entirely black both on the surface and in the body. In the present investigation, a representative set of bucchero sherds from the excavations of the Etruscan town of Tarquinia (Viterbo, Italy) was analyzed through flame atomic absorption spectroscopy (FAAS), Fourier-transform infrared spectroscopy (FTIR) and near-infrared (NIR) reflection spectroscopy. Both elemental and mineralogical composition data were treated with methods of multivariate analysis. It was thus possible to discriminate between local and imported production, to estimate the firing temperature and to verify the origin of the grey-black color in this peculiar ceramic class. Furthermore, a virtual reconstruction of a bucchero vase starting from fragments was also attempted on the basis of chemical analysis data.

1. Introduction

Bucchero is a typical class of Etruscan pottery, the production of which started at the beginning of the 7th century B.C. and continued until the 5th century B.C. and beyond. The term bucchero came into use during the 18th century as an Italian version of the Spanish word búcaro or the Portuguese pocaro, indicating a dark or reddish scented clay that was used to produce containers capable of keeping water fresh and slightly perfumed. The word was then applied to the containers themselves, which were also exported to Italy, and to those vases which began to be excavated from Etruscan necropolises and were similar in color and brightness [1].

The distinctive feature of bucchero is its color, which is homogeneous both on the surface and inside the ceramic paste, ranging from predominantly black to light grey. Purified clay was commonly used to obtain this peculiar pottery, with small-sized inclusions and a polished surface. In terms of the origin of the color, much debate has taken place, but recently, thanks to experimental tests, it has been mostly associated with a firing process carried out in a reducing atmosphere at a maximum temperature of 750–800 °C [2,3]. Indeed, in modern firing experiments, temperatures as high as 900 °C appear to produce uneven coloring [3]. The development of the black color has been ascribed to the formation of iron(II)-containing oxides such as Fe3O4 [4]. However, based on the near-infrared (NIR) reflectance spectra of the ceramic paste, it has already been suggested by Bruni [5] that the observed hue is mainly due to the contribution of amorphous carbon. The intentional addition of charcoal powder to clay bodies prior to firing has been considered an expedient limited to the cases of iron-poor clays [3], but the hypothesis that finely pulverized amorphous carbon, formed by heating fuel in the absence of oxygen, is deposited inside the ceramic pores has been advanced at least to justify the appearance of the ceramic surface.

Traditionally, the earliest evidence of this production is attributed to the sites of Cerveteri and Veio, and Cerveteri is the place where the most technologically advanced and refined vessels first appeared [2]. However, this primacy has been revised in the light of more recent archaeological findings in Tarquinia. Here, we have evidence of the development of bucchero production from the technology and types of the so-called impasto (coarse ware) pottery, in the first half of the 7th century B.C. [6,7].

By the end of the 7th century B.C., the production of bucchero had extended to most of the main Etruscan cities. Many early vessels (from 680 to 630 B.C.) have very thin walls, ranging in thickness from 1 to 2 mm (bucchero sottile), and are characterized by a jet black color, high technical quality and fine decoration, suggesting that they were intended for use by elite households. During the 7th century B.C., the standardization and diffusion of production led to intermediate fabrics with a thickness from 2 to 4 mm and a less intensely black color. Finally, in the 6th century B.C., bucchero began to be exported throughout the Mediterranean basin and at the same time, less refined vases were produced with thicker walls (above 4 mm) and a black-grey color (bucchero pesante) [2].

As the past Etruscan studies mainly concentrated on excavations in necropolises, most bucchero vessels were found in tombs, and for this reason it has been thought that this ceramic class was intended for funerary use; however, more recent excavations in inhabited areas have demonstrated that it was also commonly used to serve and consume food and drink.

It is worth underlining that the distinction of bucchero produced in different places has relied primarily on the shape and decoration of the vessels in addition to the geographical find spots [2]. Scientific analyses are a powerful tool to investigate bucchero samples, as they can provide useful information on the nature of the raw materials used to create such artefacts, as well as the manufacturing technology. In the first case, the chemical composition is strictly connected to the nature of the clay used, which, in turn, can be referred to the composition of the soil and therefore to the production site of the pottery. In the second case, the mineralogical phases in the samples, in addition to the water content, are linked to the firing temperature, allowing one to determine the technological knowledge of a specific society [8].

In this context, the use of different analytical methods has been reported. X-ray diffraction (XRD) and/or polarized-light microscopy observation of thin sections have been widely exploited to study the mineralogical composition of bucchero samples from different geographical areas and dating back to different centuries (from the 7th to the 5th centuries B.C.) [9,10,11,12], while X-ray fluorescence (XRF) has provided their elemental composition [9,10,11,13]. The results of these techniques are crucial in provenance studies and are often interpreted in combination with multivariate analysis methods, such as cluster observation and principal component analysis (PCA) [11,13]. Moreover, the combined use of petrographic examination and XRF analysis has been the basis of the extensive work by K. Burkhardt that compares the characteristics of bucchero samples from several Etruscan sites in the Italian peninsula [14]. On the other hand, thermal analyses (TG and DTG) [9], as well as near-infrared (NIR) [5] and Mossbauer [15,16] spectroscopies, have been applied to assess the firing conditions or to clarify the process that leads to the typical black color of bucchero.

In the present work, 33 bucchero samples from La Civita di Tarquinia (central Italy, Figure 1) were examined to determine if they were manufactured locally or imported from other Etruscan sites and to elucidate the firing conditions with which they were obtained. It is worth remembering that Etruscan Tarquinia includes different archaeological sites, in particular the necropolis with the famous painted tombs (a UNESCO site) and the Civita plateau. This is the site of the ancient Etruscan city (Tarchna) where the Ara della Regina sanctuary, known for a valuable terracotta frieze of winged horses, and the ‘monumental complex’, one of the most ancient Etruscan sacred areas, stand. The peculiarity of the bucchero sherds examined here is their provenance from the excavations of the ancient city, whilst most of the bucchero pottery mentioned above come from funerary contexts. Therefore, one of the objectives of the present study was also to verify whether the different contexts of use could have impacted on differences in the characteristics of the ceramic material.

Figure 1.

Localization of Tarquinia in the map of Central Italy.

The provenance of the bucchero samples was investigated using a protocol based on the analysis of both elemental and mineralogical composition by flame atomic absorption (FAAS) and emission spectroscopy (AES) and FTIR spectroscopy, respectively, combined with multivariate data analysis using PCA and cluster observation. The NIR and again FTIR spectroscopic data then allowed us to formulate hypotheses on the firing process. The effectiveness of the approach based on vibrational spectroscopy to studying the mineralogical composition of archaeological pottery and correlating it with differences in raw material and firing conditions has been established in the literature from a general point of view [17,18,19,20], and also specifically for the Etruscan pottery of Tarquinia in previous works [5,21]. To further underline the strength of this approach, XRD data were also acquired in the present work for some of the samples examined, demonstrating the consistency of the information provided by the FTIR analysis. To conclude, a demonstration was given of how scientifical analyses can be a fundamental starting point for the virtual reconstruction of ancient pottery.

2. Materials and Methods

2.1. Archaeological Bucchero Samples from Tarquinia

Table 1 lists the bucchero samples examined in the present work. For each sample, the visual and tactile characteristics of the ceramic paste are indicated by a number, conventionally assigned by the archaeologists, as detailed in Table 2. Some of the samples are shown in Figure 2.

Table 1.

Bucchero samples from the excavation of La Civita di Tarquinia. For each sample, the inventory number, the codex of the ceramic paste (see Table 2) and the chronology are reported. Legend: n.d. = not determined.

Table 2.

Visual and tactile characteristics corresponding to each ceramic paste recognized for the bucchero from La Civita di Tarquinia.

Figure 2.

Examples of bucchero fragments from the excavation of La Civita di Tarquinia. Refer to Table 1 for the inventory numbers.

The bucchero ceramics were compared from the point of view of elemental composition with samples of fine ware whose local provenance had been ascertained in a previous study [22], based on multivariate analysis of the elemental composition for minor and trace elements and the abundance criterion [23], according to which the ceramic whose composition is strongly represented in a site is presumed to be of local manufacture. In the study described in [22], the compositional fingerprint of Tarquinia fine pottery production was established by examining a large series of samples dated from the 8th to the 6th century B.C. and representative of different decorative styles. In particular, the samples chosen as references in the present work belong to the classes of Etruscan-geometric pottery, datable to the 8th–7th century B.C., and Etruscan–Corinthian pottery, datable to the 7th–6th or first half of the 6th century B.C.

2.2. FAAS and AES

The weight percentages of 9 elements (Ca, Fe, Mg, K, Na, Cu, Cr, Mn and Ni) were determined by the FAAS and AES techniques. The latter technique was used to analyze the content of Na.

After removing the surface layers of all 33 samples with a diamond tip, about 50 mg of powder was taken from each of them and placed in a PTFE beaker. A total of 0.5 mL HCl 37%, 0.5 mL HF 47–51% and 2.5 mL HNO3 65% were added to the powder and heated at 70 °C until the mixture was dry. To the residue, 0.5 mL HCl and 0.5 mL HF were again added and again dried by heating at 70 °C. To the dried residue, 0.5 mL HCl and 0.5 mL ultrapure water were then added. The obtained solution was diluted to 25 mL with ultrapure water in a polypropylene volumetric flask. This solution was used as obtained for the quantitative determination of Ni, Cu and Cr and was further diluted 1:10 for the determination of Fe and Mn and 1:100 for the determination of Ca, Mg, Na and K.

The measurements were performed using a Perkin Elmer 3100 atomic absorption spectrometer (Waltham, MA, USA) (in emission mode for the analysis of Na) and an air/acetylene flame. Commercial standards (Sigma Aldrich, Milano, Italy) were used for the construction of calibration curves.

The weight percentages of the elements were then expressed under the form of the corresponding oxides for the more abundant ones, and as such for the trace elements.

2.3. FTIR and NIR Spectroscopy

Transmission FTIR spectra were acquired on KBr pellets of the 33 powdered samples using a Jasco FT/IR 470plus spectrometer (Jasco Europe, Cremella, LC, Italy). The spectra were recorded as the sum of 16 accumulations in the range 4000–400 cm−1, with a resolution of 4 cm−1.

NIR reflectance spectra were recorded on the powdered samples using a Jasco V-570 UV-visible-NIR spectrophotometer (Jasco Europe, Cremella, LC, Italy), equipped with an integrating sphere coated internally with BaSO4.

2.4. XRD

To support the conclusions deduced from the FTIR spectra, XRD patterns of some of the bucchero samples were acquired using a Philips PW 1820 diffractometer (Philips, Malvern, UK) with vertical scan, equipped with collimator plates (Soller’s slits), a single crystal graphite monochromator and a Na(TI)I scintillation counter with impulse height amplification. The Cu Kα line (1.5418 Å) (settings HV: 40 kV and 40 mA) was used as incident radiation, and the acquisition was run at room temperature from 10° to 65°, in the θ–2θ mode with a step size of 0.02° and a time of 3 s per step.

The qualitative identification of the mineralogical phases was performed by means of the software EVA V8.0 (Bruker AXS GmbH, Karlsruhe, Germany).

2.5. Multivariate Analysis of Data

PCA and cluster analysis were applied to both elemental composition data and FTIR spectra of the bucchero samples, using the Minitab ver. 13 software (Minitab Ltd., Coventry, UK).

The sum of the elemental composition data, expressed as percent by weight, was normalized to 100% before multivariate analysis [24]. For PCA, the correlation matrix was used. For cluster analysis the data were standardized, and Euclidean distance and complete linkage were used.

The FTIR spectra were normalized between 0 and 1 and transformed into their second derivatives using the software GRAMS (Thermo Scientific, Waltham, MA, USA) and in particular the “gap” algorithm (gap = 20 cm−1). It was decided to use the second derivatives of the spectra for multivariate analysis to eliminate the slope of the baseline and emphasize the less evident peaks. The covariance matrix was used for the PCA analysis. Euclidean distance and complete linkage were used for cluster analysis as above.

3. Results and Discussion

3.1. Provenance of the Bucchero Samples

As now well-established in the investigation of archaeological ceramics [23,25], also in the present work the discrimination between locally produced and imported materials has been based on their elemental composition, referring to minor elements such as Ca, Fe, Mg, Na and K, and in traces, such as Cr, Cu, Ni and Mn. In fact, more abundant elements characteristic of ceramics, such as Si and Al, can be influenced by multiple sources of variation, including the sieving of the clay [26], and by the overlapping of their concentration ranges in clays of different origins [23]. In this approach to provenance studies, statistical analysis of the weight percentages determined for the different elements in each sample is then mandatory [23,27], and in the investigation here reported, two methods of multivariate data analysis, i.e., PCA and cluster analysis, were applied.

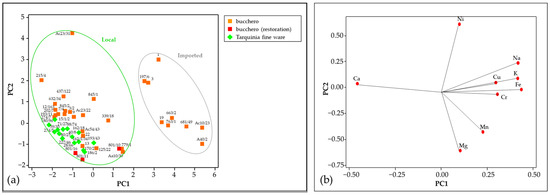

Figure 3 shows the score plot of the first two principal components of the elemental composition (Table S1) of the bucchero samples from the excavation of La Civita di Tarquinia. In the same plot, these materials are compared with fine ware samples belonging to other ceramic classes (Section 2.1) that are considered to be locally produced based on a previous study of their elemental composition [22]. It should be noted that, in the case of the investigation of archaeological ceramics, a procedure based on the comparison between the composition of the samples and that of clays of different origins is complicated by the fact that this type of raw material is widespread, and it would be at least very difficult to sample all possible sources. For this reason, comparison with materials of known provenance is usually preferred [27].

Figure 3.

(a) Score plot of the first two principal components of the elemental composition of bucchero pottery (orange and red squares) from the excavation of La Civita di Tarquinia, compared with the locally produced fine pottery (green squares); the red squares indicate the bucchero samples examined in view of a virtual reconstruction (see text, Section 3.3); (b) loading plot of the principal components as in (a).

In the score plot obtained in the present case (Figure 3a), two groups are clearly distinguished, the larger of which also includes the reference ceramic samples from Tarquinia and can therefore be associated with locally produced bucchero. The corresponding loading plot (Figure 3b) evidently shows an anti-correlation between the weight percentage of Ca and those of Na, K, Fe, Cu and Cr, which are instead correlated with each other. In fact, the higher amount of Ca in the locally produced materials is consistent with the geological characteristics of La Civita site (Figure S1, [28]). In fact, the hill on top of which La Civita is located is made up of “macco”, formed by fossiliferous calcarenite and cemented bioclastic sands. Consequently, the clay at this site was typically calcareous. The smaller group in the score plot, corresponding to samples very poor in Ca and richer in K, therefore contains imported materials.

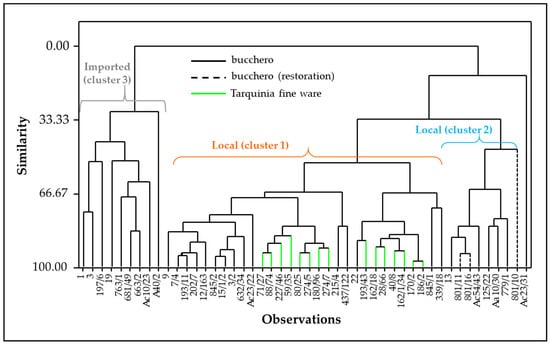

The dendrogram resulting from cluster analysis (Figure 4) confirms this subdivision of the bucchero samples examined and furthermore makes it possible to distinguish two different groups (cluster 1 and cluster 2) within the cluster of local materials. The smallest one (cluster 2 in Figure 4) includes samples always derived from a calcareous clay, but with a lower amount of calcium in comparison with the main set of local bucchero, as is also demonstrated by the mineralogical analysis based on FTIR spectroscopy (see below). Sample Ac23/31 is interesting, as it is still similar to the clusters containing locally produced bucchero but with a rather low similarity value.

Figure 4.

Dendrogram obtained from the cluster analysis of the elemental composition of bucchero pottery (black lines) from the excavation of La Civita di Tarquinia, compared with the locally produced fine pottery (green lines). The black dashed lines indicate the bucchero samples considered in view of a virtual reconstruction (see text, Section 3.3).

Of particular interest is the correspondence between these results obtained by chemical analysis for the bucchero from the city of Tarquinia with those deduced from petrographic and geochemical analysis by K. Burkhardt for ceramics of the same class found in tombs of the necropolises of Tarquinia [14]. In fact, this author too has distinguished three groups of bucchero samples, two of which he believes to be locally produced and one most likely imported from Cerveteri. Additionally, in the case of the materials from funerary contexts, of the two groups of ceramics produced in Tarquinia, one appeared to contain a lower quantity of calcium carbonate and a slightly higher quantity of feldspars than the other, leading Burkardt to hypothesize a provenance of the raw material from the volcanic outcrops west of Tarquinia or from the sediments of the nearby Marta river ([28]).

3.2. The Firing Conditions

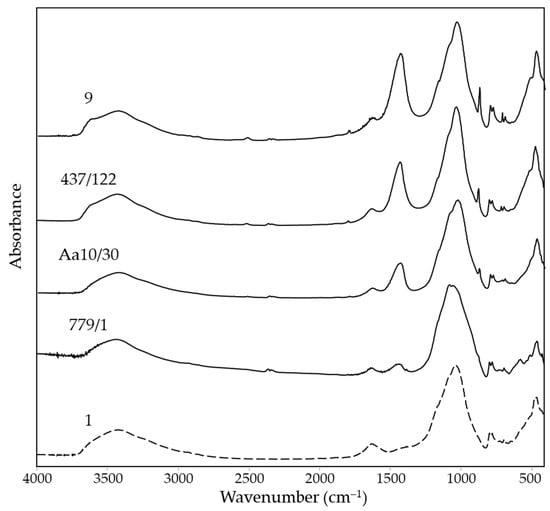

The mineralogical composition of the bucchero samples from the excavation of La Civita was investigated by means of FTIR spectroscopy. Some examples of the spectra obtained are shown in Figure 5.

Figure 5.

FTIR spectra acquired on KBr pellets of powders from some samples of bucchero from the excavation of La Civita di Tarquinia. The inventory numbers of the samples are indicated in the figure.

The main bands observed in the FTIR spectra can be assigned to the following components of the ceramic materials [19,29]:

| 3630 cm−1 | illite or smectite (see below) |

| 3430, 1630 cm−1 | absorbed water |

| 1430, 875, 714 cm−1 | calcite CaCO3 |

| 1085, 798, 780, 690 cm−1 | quartz SiO2 |

| 1030, 514, 470 cm−1 | silicate matrix |

It is worth noting that the 3630-cm−1 band can also be ascribed to reformed, i.e., rehydroxylated, clay [20]. Indeed, as reported by S. Shoval in reference [20], a slow process of rehydroxylation and recovery of the structural hydroxyl groups can occur within the fired clay.

PCA and cluster analysis were applied to the second derivatives of the FTIR spectra to obtain an easier comparison among them.

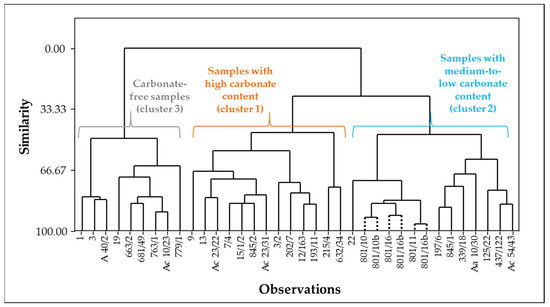

The score plot of the first two principal components obtained from PCA is reported in Figure S2 (Supplementary Material), while the dendrogram resulting from the cluster analysis is shown in Figure 6.

Figure 6.

Dendrogram obtained from the cluster analysis of the second derivatives of FTIR spectra acquired for bucchero sherds from the excavation of La Civita di Tarquinia. The black dashed lines indicate the bucchero samples considered in view of a virtual reconstruction.

Three clusters can be recognized in the dendrogram. The main difference between them is related to the presence or absence of calcium carbonate (as calcite) in the ceramic material, which distinguish cluster 3, containing samples without calcite, from clusters 1 and 2, formed of samples with high (cluster 1) or medium-to-low carbonate content (cluster 2). As an example of the FTIR spectra of samples belonging to cluster 1, Figure 5 shows the spectrum of sample 9, for which the aforementioned bands due to calcite are particularly intense. The same Figure 5 also shows the spectra of samples 437/122 and Aa10/30, belonging instead to cluster 2, for which the CaCO3 bands are observed again but with weaker intensity. Finally, the FTIR spectrum of sample 1, belonging to cluster 3, is also reported in Figure 5 and, as expected, does not show the signals due to the carbonate component. The XRD patterns acquired on samples representative of all three clusters are reported with the corresponding assignments in Figure S3 and Table S2.

A remarkable correspondence between the groups distinguishable on the basis of the FTIR spectra (Figure 6) and those identified on the basis of the elemental composition (Figure 4), is evident. In particular, all bucchero samples in cluster 3 also belong to the group of materials considered to be imported due to their elemental composition, with the exception of sample 779/1. Instead, all samples in cluster 1 and 2 are included in one of the groups of bucchero considered to be locally produced, with the exception of sample 197/6. This result is consistent with what has been observed above regarding the clay composition in the Tarquinia area.

At this point, it should be remembered that the mineralogical composition of a ceramic is related to the composition of the raw material (and its possible pre-treatment) as well as to the firing conditions, as described by R. Heimann for archaeological pottery [30]. The fact that, in the present study, samples of similar provenance also appear similar in mineralogical composition, as shown by FTIR spectra, strongly suggest that they were fired to at least a comparable temperature.

In the case of those pottery sherds obtained from calcareous clay, an estimate of the firing temperature can also be obtained based on the mineralogical phases. Indeed, by heating this raw material, dehydroxylation and then decomposition of the clay minerals, together with decarbonation of calcite, take place upon reaching a temperature of 700–800 °C, and the resulting oxides then recombine to give new silicate phases, such as gehlenite Ca2Al2SiO7 and diopside CaMgSi2O6, at temperatures around 850–950 °C, and then anorthite CaAl2Si2O8 at higher temperatures [30,31].

In the present study, for the bucchero samples of local production and therefore obtained from a calcareous clay, the presence in the ceramic paste of more or less high quantities of calcium carbonate, and also in some cases of small quantities of not completely dehydroxylated clay minerals (as suggested by the shoulder at about 3630 cm−1 due to OH groups), indicate that the corresponding vessels were most likely fired at temperatures not higher than 750–800 °C.

It is interesting to note that bucchero 779/1, produced in Tarquinia according to its elemental composition, belongs instead to the cluster of samples without calcium carbonate in the dendrogram obtained from the FTIR spectra. By observing its spectrum in Figure 5, it can be easily concluded that this is indeed a local material, but fired at a temperature higher than the other samples here examined. In fact, the typical bands of calcite are very weak, which is why this sample is not part of the cluster where all the local bucchero can be found, but the band due to Si-O stretching modes of the silicate matrix is larger on the side of the lower frequencies and its maximum is shifted from around 1030 to 1050 cm−1. Moreover, new bands are observed at ca. 580 and 535 cm−1. These observations suggest that a firing temperature higher than 950 °C was reached for this material, causing the formation of the aforementioned silicate phases, such as anorthite, to which the broadening of the silicate stretching band and the new signals between 600 and 500 cm−1 can be attributed [32,33]. XRD analysis was also applied to bucchero 779/1, and the diffraction pattern obtained (Figure S3, Supplementary Material) supported the conclusions reached based on the FTIR spectrum. It should be noted that the shift to higher wavenumbers of the IR silicate band at around 1000 cm−1 is also consistent with the fact that this sample was fired at higher temperatures than the others [19].

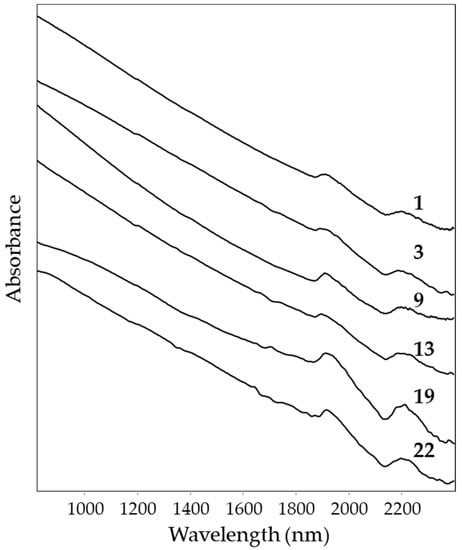

As demonstrated in [5], an independent estimation of the firing temperature of ancient pottery can be obtained from NIR reflectance spectra of the materials, based on the intensity of the overtone and combination bands due to absorbed water and, possibly, hydroxyl groups at about 1900 and 2200 nm [34,35,36]. However, in the same reference, it has also been shown that for black- or grey-paste ceramics, color-associated absorptions are also observed in this spectral region. In particular, when the color is mainly due to oxides containing Fe(II), characteristic bands appear around 1000 and 1800 nm, while, when elemental carbon is mainly responsible for the black or grey color, continuous absorption is observed throughout the spectral range.

In the present case, the NIR reflectance spectra of all samples showed the pattern expected for the presence of carbon (Figure 7), similar to that reported in [5] for another bucchero fragment compared with grey pottery. As regards the bands due to absorbed water, they can be observed at 1910 and 2210 nm, again suggesting a firing temperature lower than 800 °C, as proposed in [5] through a comparison with NIR reflectance spectra obtained for a clay heated at different temperatures. Of course, the absolute intensity of these bands for black or grey bucchero appears lower than in the case of conventional fine ware fired at the same temperature, due to the superimposition of the absorption due to elemental carbon. However, it is very interesting that, for bucchero samples of local or external production with a similar color, the NIR bands due to water are comparable in intensity and position, as shown in Figure 7 for samples 1, 3 and 19, which are considered to be imported from outside Tarquinia, and samples 9, 13 and 22, which can be considered local on the basis of the above. This fact suggests that also the firing temperature, which was already estimated from the mineralogical composition for the bucchero obtained with the calcareous clay of Tarquinia, was most likely similar also for the imported bucchero.

Figure 7.

NIR reflectance spectra obtained on powders of some bucchero samples, identified as locally produced (9, 13, 22) or imported (1, 3, 19) on the basis of elemental analysis, from the excavation of La Civita di Tarquinia.

3.3. The Virtual Reconstruction of a Bucchero Vase

In the scope of the present investigation, it was also evaluated if chemical analysis could be of help in assigning ceramic fragments, apparently referring to the same type of vase shape, to a single vase, which could therefore be reconstructed at least virtually.

The bucchero fragments examined (inventory numbers 801/10, 801/11 and 801/16) were referred to the vase shape known as “kyathos”, a vase with a tall, round cup and a single flat, curved handle, and were found in the same stratigraphic unit [37].

It has been hypothesized that these fragments (shown in Figure 8 and having a very similar ceramic paste) could represent, respectively, parts of the cup, the rim and the handle of the same “kyathos”. As can be seen in the dendrogram of Figure 4, two of them (namely 801/11 and 801/16) have a high similarity to each other, while the third one (801/ 10) has a lower similarity even if it is part of the same cluster. However, the observation of the data of elemental composition (Table S1) shows that sample 801/10 has a particularly high percentage of copper, possibly related to a contamination in the burial environment. This possibility is supported by the fact that, if the percentage of copper is not considered in the cluster analysis, the distance between 801/10 and the other two fragments (having a relative distance of 0.41) decreases from 5.01 and 5.02 to 0.76 and 0.88, respectively. At the same time, in the dendrogram of Figure 6, obtained from the FTIR spectra, the three fragments (for each one of which two replicate measurements were made) form a single cluster with a high degree of similarity. Therefore, the analytical data as a whole suggest that the three fragments really belonged to the same vase, which could thus be virtually reconstructed as shown in Figure 8.

Figure 8.

Bucchero fragments (801/10, 801/11, 801/16) from the excavation of La Civita di Tarquinia, belonging to the same “kyathos” (see text), and the virtual reconstruction of the vase.

4. Conclusions

A representative set of bucchero fragments from the excavation of the Etruscan site of La Civita di Tarquinia (Italy) has been investigated from the point of view of provenance and firing conditions using a protocol based on chemical analytical methods.

As regards provenance, elemental composition in terms of nine minor and trace elements was determined by optical atomic spectroscopy and examined with the aid of PCA and cluster analysis. It was therefore possible to distinguish two main groups of samples, one of which showed the greatest similarity with reference samples of fine ware produced in Tarquinia, while the other could be related to imported materials. The group of bucchero samples produced in Tarquinia was the largest one and could be further divided into two clusters based on the differences in Ca content. Similar groups were also recognized for the mineralogical composition from the statistical analysis of FTIR spectra.

These results are consistent with those reported in the literature [14] for the provenance of bucchero found in the tombs of the necropolises of Tarquinia, thus suggesting that the different context of use did not affect the typology of the ceramic materials. The similarity between bucchero samples from the town and from the necropolises also regards the chronological distribution of local and imported materials. In both cases, in fact, the bucchero pottery not produced in Tarquinia can all be dated to the second half of the 7th—first half of the 6th century (except for sample 13 in the present study, for which a generic dating to the 6th century was indicated), suggesting that after that period local production became predominant. From a methodological point of view, the comparable results of the two studies, in which different analytical methodologies were used, also confirm the effectiveness of the protocol based on chemical analysis methods, in particular optical atomic spectroscopy and FTIR spectroscopy, for the investigation of pottery obtained from purified clay as in the case of bucchero.

As regards the firing conditions, the use of FTIR spectroscopy, together with NIR reflectance spectroscopy, led us to hypothesize that the firing temperature of the examined ceramics was never higher than 800 °C. This could be clearly demonstrated for bucchero of local production both thanks to the presence of typical calcite bands in the FTIR spectra and the position of water and hydroxyl bands in the NIR spectra. Even if imported bucchero materials do not contain calcite as they do not derive from a calcareous clay, they exhibited NIR water bands similar to the local samples in intensity and position; thus, the same consideration regarding the firing temperature could also apply to them. This result is consistent with the firing experiments reported in the literature [3] and described in the Introduction, which demonstrated that a homogenous black or black-grey color similar to that of bucchero could be obtained in a reducing atmosphere only at temperatures not higher than 750–800 °C.

On the basis of the NIR spectra, it was also possible to establish that for all the bucchero samples examined, the black or grey color was mainly due to elemental carbon. Of course, due to the reducing atmosphere needed to produce this peculiar class of pottery, the iron initially contained in the clay was at least partially reduced, but it does not appear to be primarily responsible for the observed color, unlike the case of the so-called grey pottery [5].

Finally, the data from chemical analysis were also of use in supporting the virtual reconstruction of a vase starting from fragments found in the same stratigraphic unit, for which the close similarity of elemental and mineralogical composition could be demonstrated.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/ceramics6010035/s1, Figure S1: Detail of the geological map of the area of Tarquinia; Figure S2: Score plot of the first two principal components of the second-derivative FTIR spectra of bucchero pottery from La Civita di Tarquinia; Figure S3: XRD patterns of bucchero samples from the excavation of La Civita di Tarquinia; Table S1: Elemental composition data for the bucchero samples from La Civita di Tarquinia; Table S2: Positions and relative intensities of XRD peaks for bucchero samples from the excavation of La Civita di Tarquinia, with the mineralogical phases identified.

Author Contributions

Conceptualization, S.B. and G.B.G.; methodology, S.B.; formal analysis, M.L., N.C., S.B., M.M., D.T. and V.D.; investigation, N.C. and V.D.; resources: G.B.G. and S.B.; data curation, M.L., N.C., M.M., D.T. and V.D.; writing—original draft preparation, S.B., M.L., V.D. and D.T.; writing—review and editing, S.B., G.B.G. and M.L.; visualization, M.L., S.B. and V.D.; supervision, S.B. and G.B.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The dataset used for the PCA and cluster analysis of the elemental composition of the bucchero samples is reported in the Supplementary Material.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nogara, B. Bucchero. In Enciclopedia Italiana. Treccani.it, L’Enciclopedia Italiana 1930. Available online: https://www.treccani.it/enciclopedia/bucchero_%28Enciclopedia-Italiana%29/ (accessed on 3 December 2022). (In Italian).

- Perkins, P. Bucchero in context. In A Companion to the Etruscans; Bell, S., Carpino, A.A., Eds.; Wiley-Blackwell: Chichester, UK, 2016; pp. 224–236. [Google Scholar]

- Deriu, R. From Bucchero to grey ware in the Po valley: Experimenting with the importance of firing. EuroREA 2009, 6, 39–44. [Google Scholar]

- Cuomo Di Caprio, N. Ceramica in Archeologia, Antiche Tecniche di Lavorazione e Moderni Metodi D’Indagine; L’Erma Di Bretschneider: Rome, Italy, 2007; Volume II, pp. 437–438. (In Italian) [Google Scholar]

- Bruni, S. Etruscan Fine Ware Pottery: Near-Infrared (NIR) Spectroscopy as a Tool for the Investigation of Clay Firing Temperature and Atmosphere. Minerals 2022, 12, 412. [Google Scholar] [CrossRef]

- Locatelli, D. Tarquinia. In Appunti sul Bucchero, Atti Delle Giornate di Studio; Naso, A., Ed.; Comune di Blera: Blera, Italy, 2004; pp. 49–89. (In Italian) [Google Scholar]

- Bonghi Jovino, M. Spunti per una riflessione sul bucchero tarquiniese. In Etruria e Italia Preromana. Studi in Onore di Giovannangelo Camporeale (Studia Erudita 4); Bruni, S., Ed.; Fabrizio Serra: Pisa, Italy, 2009; pp. 45–56. (In Italian) [Google Scholar]

- Tite, M.S. Ceramic production, provenance and use—A review. Archaeometry 2008, 50, 216–231. [Google Scholar] [CrossRef]

- Francaviglia, V. Comparative study of various samples of Etruscan bucchero by X-ray diffraction, X-ray spectrometry, and thermoanalysis. Archaeometry 1975, 17, 223–231. [Google Scholar] [CrossRef]

- Naso, A. Funde aus Milet XXII. Etruscan Bucchero from Miletus: Preliminary Report with a contribution by Giorgio Trojsi. Archäologischer Anz. 2009, 1, 135–150. [Google Scholar]

- Ceccarelli, L. Analisi archeometriche e statistiche per la caratterizzazione di produzioni di bucchero. Archeol. Calc. 2019, 30, 387–404. (In Italian) [Google Scholar]

- Medeghini, L.; Mignardi, S.; Di Fusco, G.; Botticelli, M.; Coletti, F.; De Vito, C. How Microanalysis Can Be Discriminant on Black Pompeian Wares. Crystals 2020, 10, 879. [Google Scholar] [CrossRef]

- Gran-Aymerich, J.; Lahanier, C.; Gauthier, J.; Duval, A.; Malfoy, J.M.; Boyer, C. Sur deux groupes de bucchero examinés au Louvre. Mélanges de l’École française de Rome Antiquité 1985, 97, 611–638. [Google Scholar] [CrossRef]

- Burkhardt, K. Petrographische und geochemische Untersuchungen an etruskischer Bucchero-Keramik von den Fundorten Chiusi, Orvieto, Vulci, Tarquinia, Allumiere, Tolfa, Cerveteri, Ceri, Veji und Rom, Münchner geologische Hefte 5; Ludwig-Maximilians-Universität München/Institut für Allgemeine und Angewandte Geologie: München, Germany, 1991. (In German) [Google Scholar]

- Maglietta, M.; Pallecchi, P.; Spina, G. Mossbauer and XPS investigation of Etruscan ceramics. Sci. Technol. Cult. Herit. 1999, 8, 7–10. [Google Scholar]

- Nodari, L.; Maritan, L.; Mazzoli, C.; Russo, U. Sandwich structures in the Etruscan-Padan type pottery. Appl. Clay Sci. 2004, 27, 119–128. [Google Scholar] [CrossRef]

- Shoval, S.; Gaft, M.; Beck, P.; Kirsh, Y. Thermal behaviour of limestone and monocrystalline calcite tempers during firing and their use in ancient vessels. J. Therm. Anal. 1993, 40, 263–273. [Google Scholar] [CrossRef]

- De Benedetto, G.E.; Laviano, R.; Sabbatini, L.; Zambonin, P.G. Infrared spectroscopy in the mineralogical characterization of ancient pottery. J. Cult. Herit. 2002, 3, 177–186. [Google Scholar] [CrossRef]

- Shoval, S. Using FT-IR spectroscopy for study of calcareous ancient ceramics. Opt. Mater. 2003, 24, 117–122. [Google Scholar] [CrossRef]

- Shoval, S. Fourier transform infrared spectroscopy in archaeological ceramic analysis. In The Oxford Handbook of Archaeological Ceramic Analysis; Hunt, A.M.W., Ed.; Oxford University Press: Oxford, UK, 2017; pp. 509–530. [Google Scholar]

- Bruni, S.; Cariati, F.; Bagnasco Gianni, G.; Bonghi Jovino, M.; Artioli, G.; Russo, U. Spectroscopic characterization of Etruscan depurata and impasto pottery from the excavation at Pian di Civita in Tarquinia (Italy): A comparison with local clay. In Archaeology and Clays; BAR International Series 942; Druc, I.C., Ed.; John and Erica Hedges Ltd. Publisher: Oxford, UK, 2001; pp. 27–38. [Google Scholar]

- Cariati, F.; Bruni, S.; Fermo, P. Indagini chimico-fisiche sulla ceramica depurata e di impasto. In Tarquinia. Scavi sistematici nell’abitato. Campagne 1982–1988. I materiali 2; Bonghi Jovino, M., Ed.; L’Erma di Bretschneider: Roma, Italy, 2001; pp. 525–536. (In Italian) [Google Scholar]

- Bishop, R.L.; Rands, R.L.; Holley, G.R. Ceramic Compositional Analysis in Archaeological Perspective. In Advances in Archaeological Methods and Theory; Schiffer, M.B., Ed.; Academic Press: New York, USA, 1982; Volume 5, pp. 225–230. [Google Scholar]

- Aruga, R. Closure of analytical chemical data and multivariate classification. Talanta 1998, 47, 1053–1061. [Google Scholar] [CrossRef] [PubMed]

- Hunt, A.M.W. (Ed.) The Oxford Handbook of Archaeological Ceramic Analysis; Oxford University Press: Oxford, UK, 2017. [Google Scholar]

- Beltrame, M.; Sitzia, F.; Arruda, A.M.; Barrulas, P.; Barata, F.T.; Mirão, J. The Islamic Ceramic of the Santarém Alcaçova: Raw Materials, Technology, and Trade. Archaeometry 2021, 63, 1157–1177. [Google Scholar] [CrossRef]

- Glascock, M.D.; Neff, H.; Vaughn, K.J. Instrumental neutron activation analysis and multivariate statistics for pottery provenance. Hyperfine Interact. 2004, 154, 95–105. [Google Scholar] [CrossRef]

- Ispra: Carta Geologica d’Italia 1:50000-354 Tarquinia. Available online: https://www.isprambiente.gov.it/Media/carg/354_TARQUINIA/Foglio.html (accessed on 3 December 2022).

- Farmer, V.C. The Infrared Spectra of Minerals; Mineralogical Society of Great Britain and Ireland: London, UK, 1974. [Google Scholar]

- Heimann, R.B. Assessing the technology of ancient pottery: The use of ceramic phase diagrams. Archeomaterials 1989, 3, 123–148. [Google Scholar]

- Heimann, R.B.; Maggetti, M. Experiments on simulated burial of calcareous terra sigillata (mineralogical change). Preliminary results. Br. Mus. Occas. Pap. 1981, 19, 163–177. [Google Scholar]

- van der Marel, H.W.; Beutelspacher, H. Atlas of Infrared Spectroscopy of Clay Minerals and Their Admixtures; Elsevier: Amsterdam, The Netherlands, 1976. [Google Scholar]

- Gasden, J.A. Infrared Spectra of Minerals and Related Inorganic Compounds; Butterworths: London, UK, 1975. [Google Scholar]

- Chanéac, C.; Tronc, E.; Jolivet, J.P. Magnetic iron oxide–silica nanocomposites. Synthesis and characterization. J. Mater. Chem. 1996, 6, 1905–1911. [Google Scholar] [CrossRef]

- Cariati, F.; Erre, L.; Micera, G.; Piu, P.; Gessa, C. Water molecules and hydroxyl groups in montmorillonites as studied by near infrared spectroscopy. Clays Clay Miner. 1981, 29, 157–159. [Google Scholar] [CrossRef]

- Cariati, F.; Erre, L.; Micera, G.; Piu, P.; Gessa, C. Effects of layer charge on the near-infrared spectra of water molecules in smectites and vermiculites. Clays Clay Miner. 1983, 31, 447–449. [Google Scholar] [CrossRef]

- Duranti, V.; Tarquinia, A.S. “Complesso monumentale”: Bucchero. Boll. Archeol. Online 2010, 17–19. (In Italian) [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).