Tensile Adhesion Strength of Atmospheric Plasma Sprayed MgAl2O4, Al2O3 Coatings

Abstract

1. Introduction

2. Experimental Procedures

2.1. Plasma Spraying Conditions

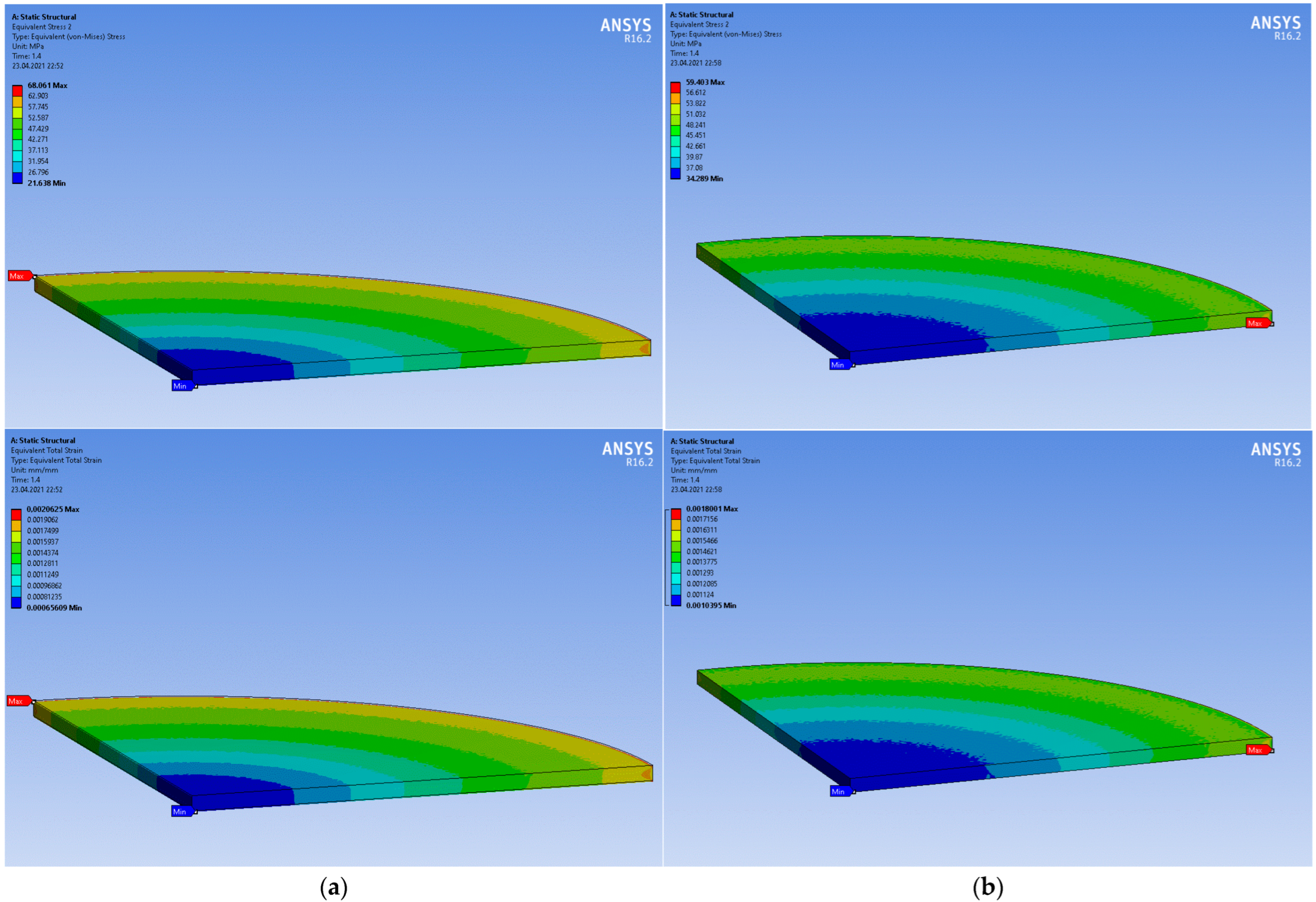

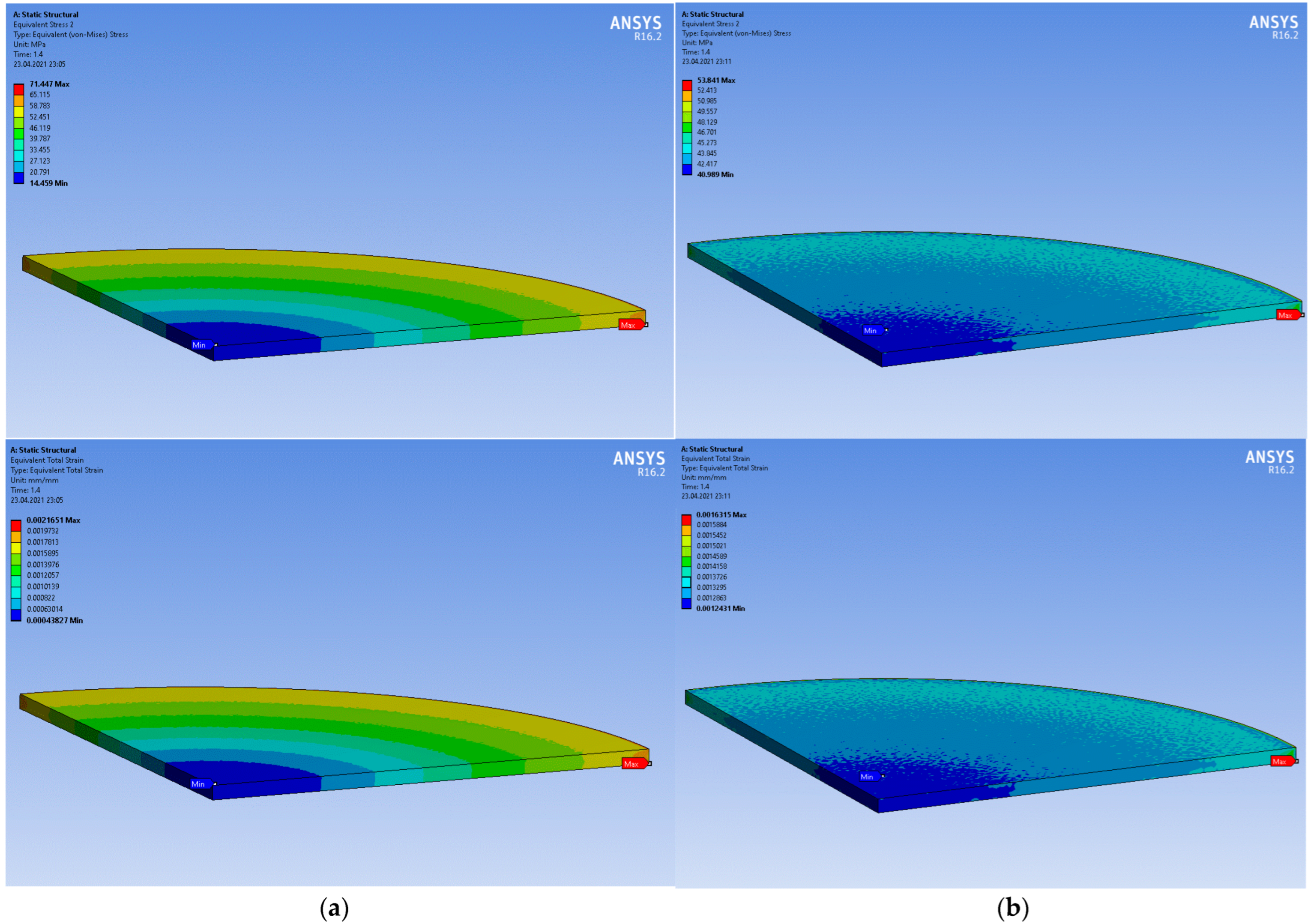

2.2. Finite Element Analysis, Boundary Conditions

- The contact between the substrate and coating was assumed as a rigid connection with a restriction on all degrees of freedom

- Axial symmetry was provided by a cyclic region in the form of a 1/4 model by imposing boundary conditions to the symmetry regions along the XOY and YOZ planes

- The material of the substrate and oxide coating possessed only elastic strain.

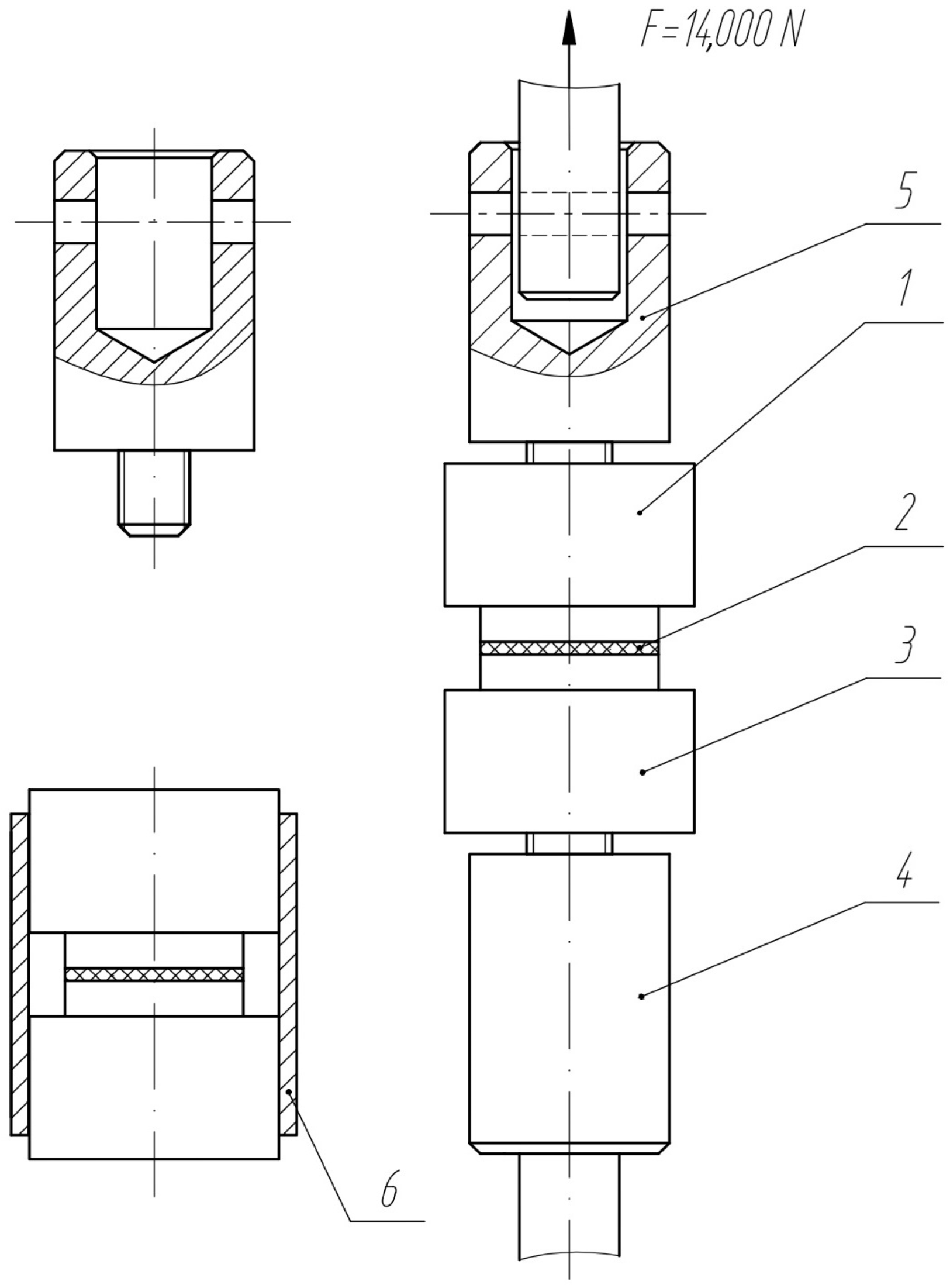

2.3. Tensile Adhesion Strength Testing

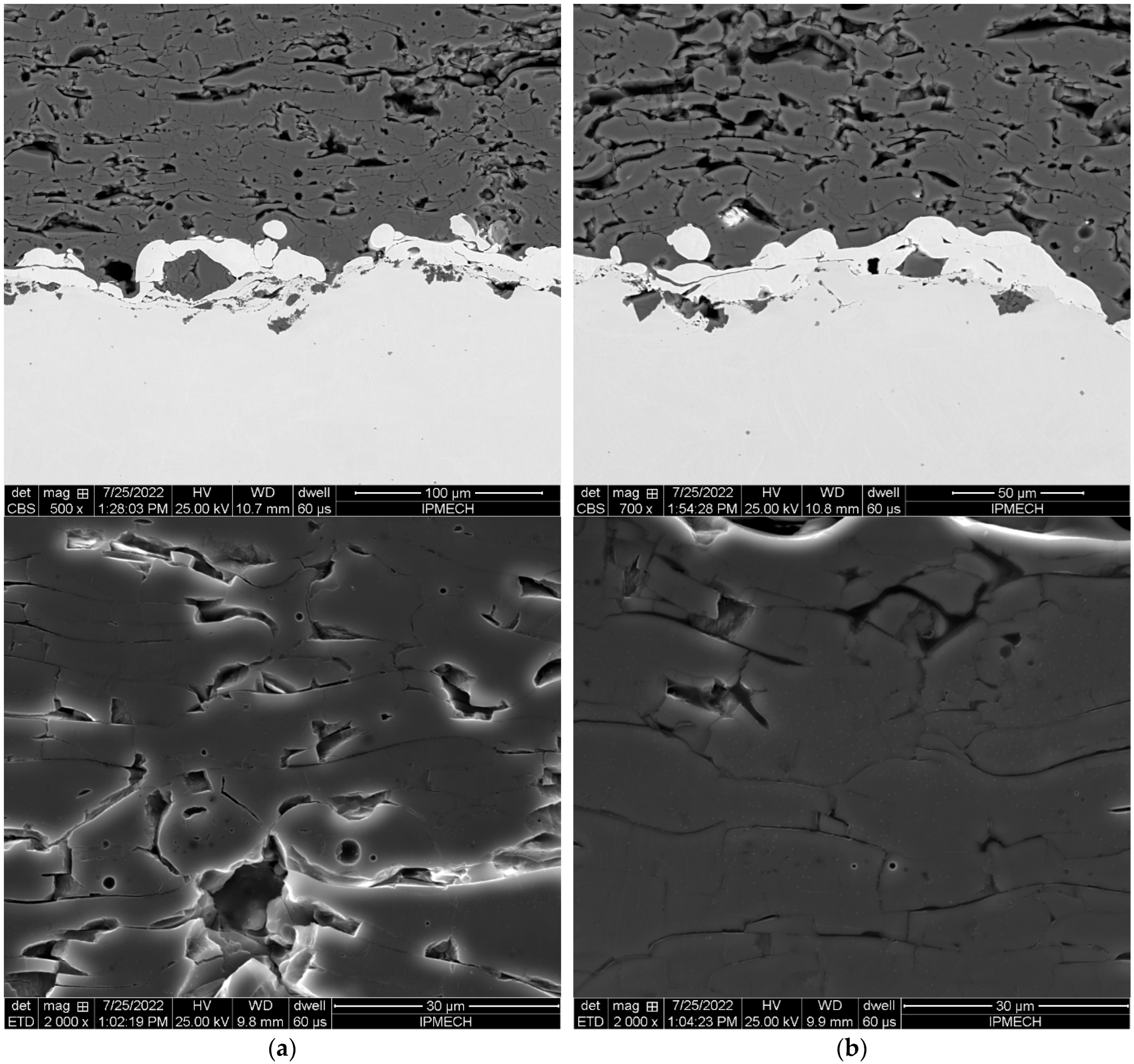

3. Results and Discussion

3.1. Results of Tensile Bond Strength of Standard and Elongated Specimens

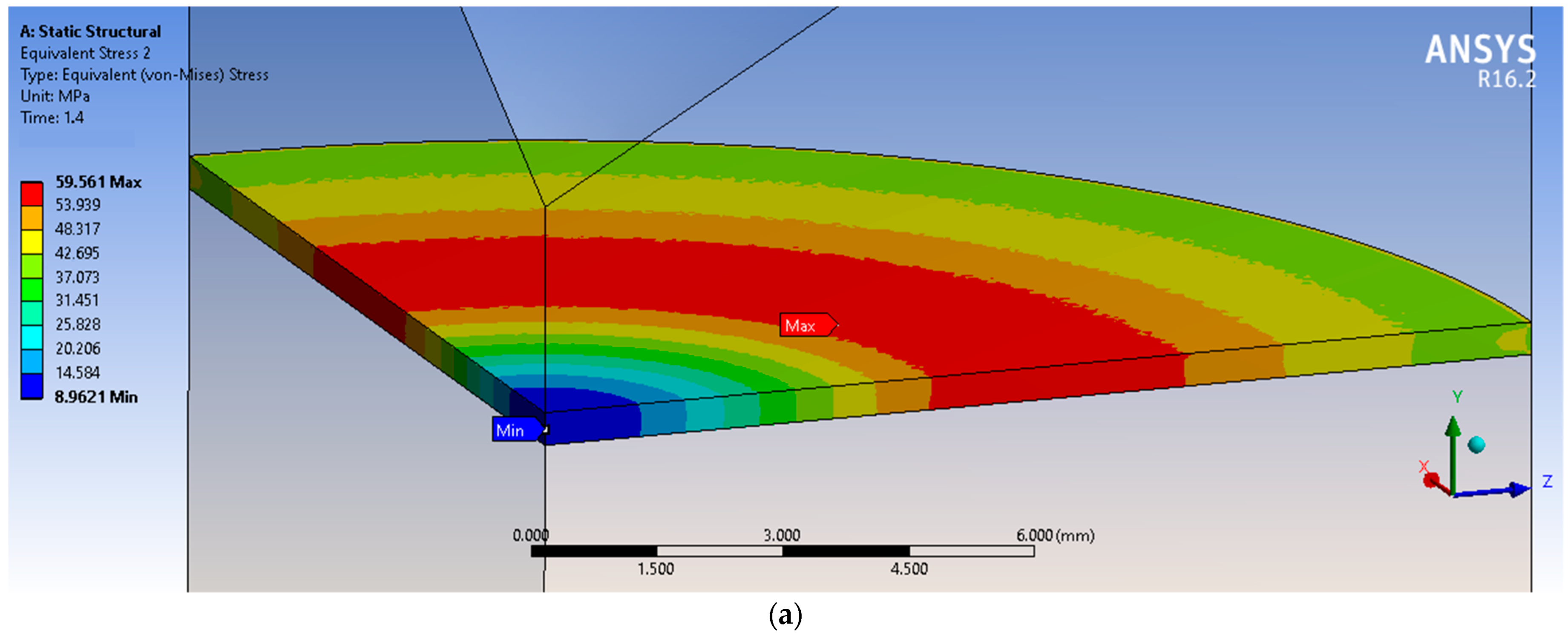

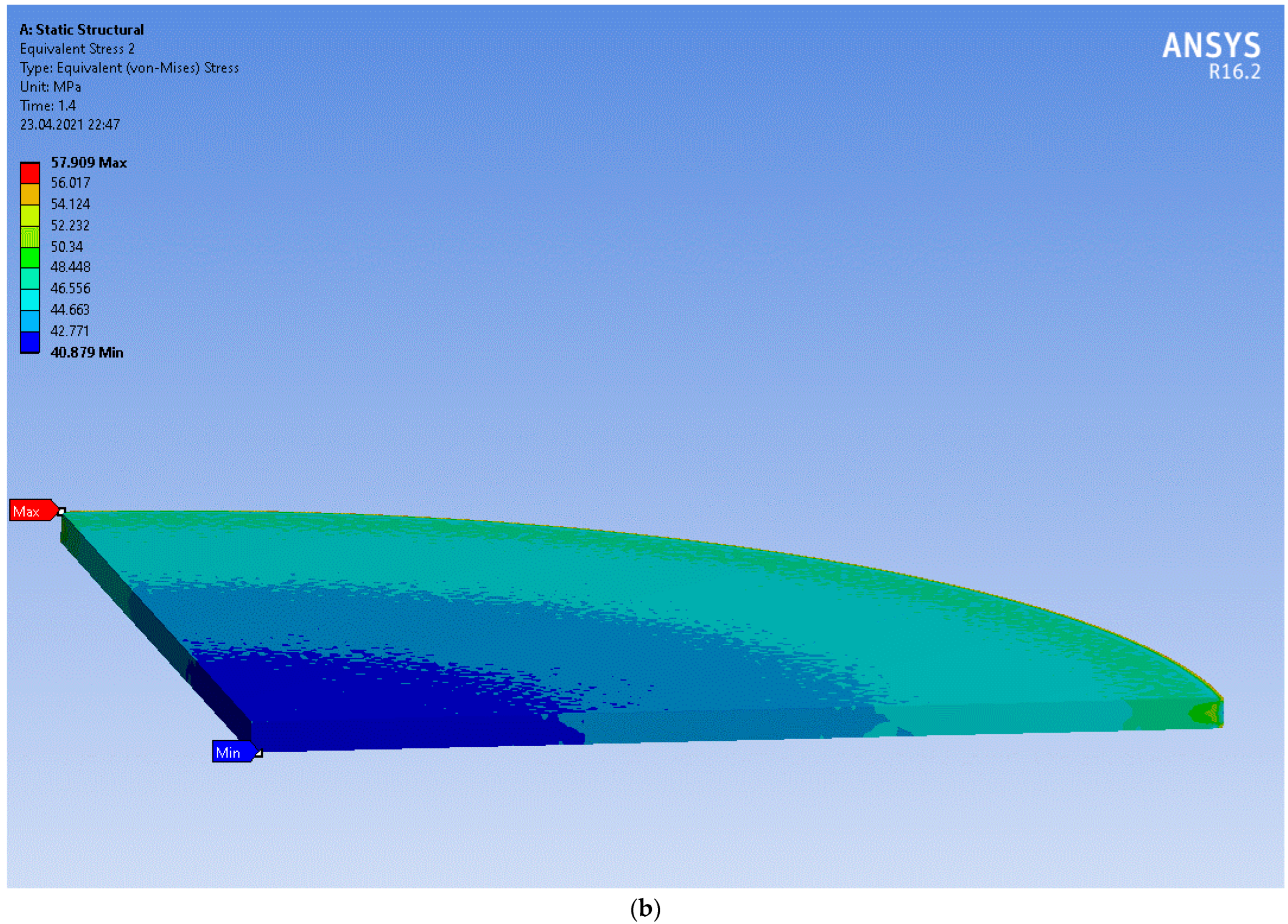

3.2. Assessment of Stress Distribution during Tensile Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Niemi, K.; Hakalahti, J.; Hyvärinen, L.; Laurila, J.; Vuoristo, P.; Berger, L.-M.; Toma, F.-L.; Shakhverdova, I. Influence of chromia alloying on the characteristics of APS and HVOF sprayed alumina coatings. In Proceedings of The ITSC 2011, International Thermal Spray Conference & Exposition, Düsseldorf, Germany, 27−29 September 2011; Volume 276. [Google Scholar]

- Sang, P.; Chen, L.-Y.; Zhao, C.; Wang, Z.-X.; Wang, H.; Lu, S.; Song, D.; Xu, J.-H.; Zhang, L.-C. Particle size-dependent microstructure, hardness and electrochemical corrosion behavior of atmospheric plasma sprayed NiCrBSi coatings. Metals 2019, 9, 1342. [Google Scholar] [CrossRef]

- Junge, P.; Rupprecht, C.; Greinacher, M.; Kober, D.; Stargardt, P. Thermally Sprayed Al2O3 Ceramic Coatin–s for Electrical Insulation Applications. In Proceedings of The ITSC, International Thermal Spray Conference, Vienna, Austria, 4−6 May 2022; pp. 72–81. [Google Scholar]

- Popov, A.I.; Lushchik, A.; Shablonin, E.; Vasil’chenko, E.; Kotomin, E.A.; Moskina, A.M.; Kuzovkov, V.N. Comparison of the F-type center thermal annealing in heavy-ion and neutron irradiated Al2O3 single crystals. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2018, 433, 93–97. [Google Scholar] [CrossRef]

- Lushchik, A.; Feldbach, E.; Kotomin, E.A.; Kudryavtseva, I.; Kuzovkov, V.N.; Popov, A.I.; Seeman, V.; Shablonin, E. Distinctive features of diffusion-controlled radiation defect recombination in stoichiometric magnesium aluminate spinel single crystals and transparent polycrystalline ceramics. Sci. Rep. 2020, 10, 7810. [Google Scholar] [CrossRef]

- ASTM C633-13; Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings. ASTM International: West Conshohocken, PA, USA, 2021. Available online: https://www.astm.org/c0633-13r21.html (accessed on 7 November 2022).

- EN ISO 14916; Thermal spraying—Determination of Tensile Adhesive Strength. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/60995.html (accessed on 7 November 2022).

- JIS H 8666; Test Methods for Ceramic Sprayed Coatings. Japanese Standards Association: Tokyo, Japan, 1994. Available online: https://jis.eomec.com/abolished/jish86661994?abolishedid=10886661994#gsc.tab=0 (accessed on 7 November 2022).

- GOST 9.304-87; Unified System of Corrosion and Ageing Protection. Thermal Sprayed Coatings. General Requirements and Methods of Control. GOST—USSR Ministry of Chemical and Petroleum Engineering: Moscow, Russia, 1987. Available online: https://docs.cntd.ru/document/1200014731 (accessed on 7 November 2022).

- Hadad, M.; Marot, G.; Démarécaux, P.; Chicot, D.; Lesage, J.; Rohr, L.; Siegmann, S. Adhesion tests for thermal spray coatings: Correlation of bond strength and interfacial toughness. J. Surf. Eng. 2007, 23, 279–283. [Google Scholar] [CrossRef]

- Vencl, A.; Arostegui, S.; Favaro, G.; Zivic, F.; Mrdak, M.; Mitrović, S.; Popovic, V. Evaluation of adhesion/cohesion bond strength of the thick plasma spray coatings by scratch testing on coatings cross-sections. Tribol. Int. 2011, 44, 1281–1288. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, K.; Lu, X.; Yee, C.L. A review of the mechanical methods for evaluating coating adhesion. Acta Mech. 2014, 255, 431–452. [Google Scholar] [CrossRef]

- Lorenzo-Bañuelos, M.; Díaz, A.; Rodríguez, D.; Cuesta, I.I.; Fernández, A.; Alegre, J.M. Influence of Atmospheric Plasma Spray Parameters (APS) on the Mechanical Properties of Ni-Al Coatings on Aluminum Alloy Substrate. Metals 2021, 11, 612. [Google Scholar] [CrossRef]

- Han, W.; Rybicki, E.F.; Shadley, J.R. An improved specimen geometry for ASTM C633-79 to estimate bond strengths of thermal spray coatings. J. Therm. Spray Technol. 1993, 2, 145–150. [Google Scholar] [CrossRef]

- Lindner, T.; Saborowski, E.; Scholze, M.; Zillmann, B.; Lampke, T. Thermal Spray Coatings as an Adhesion Promoter in Metal/FRP Joints. Metals 2018, 8, 769. [Google Scholar] [CrossRef]

- Lyphout, C.; Nylen, P.; Östergren, L.G. Adhesion Strength of HVOF Sprayed IN718 Coatings. J. Therm. Spray Technol. 2011, 21, 145–150. [Google Scholar] [CrossRef]

- Stokes, J.; Looney, L. FEA of residual stress during HVOF thermal spraying. J. Mat. Eng. Perf. 2009, 18, 21–25. [Google Scholar] [CrossRef]

- Boruah, D.; Robinson, B.; London, T.; Wu, H.; de Villiers-Lovelock, H.; McNutt, P.; Doré, M.; Zhang, X. Experimental evaluation of interfacial adhesion strength of cold sprayed Ti-6Al-4V thick coatings using an adhesive-free test method. Surf. Coat. Technol. 2020, 381, 125–130. [Google Scholar] [CrossRef]

- Marot, G.; Démarécaux, P.; Lesage, J.; Hadad, M.; Siegmann, S.T.; Staia, M.H. The interfacial indentation test to determine adhesion and residual stresses in NiCr VPS coatings. Surf. Coat. Technol. 2018, 202, 4411–4416. [Google Scholar] [CrossRef]

- Ang, A.S.M.; Sanpo, N.; Sesso, L.; Kim, S.Y.; Berndt, C.C. Thermal Spray Maps: Material Genomics of Processing Technologies. J. Therm. Spray Technol. 2013, 22, 1170–1183. [Google Scholar] [CrossRef]

- Kiilakoski, J.; Trache, R.; Björklund, S.; Joshi, S.; Vuoristo, P. Process parameter impact on suspension-HVOF-sprayed Cr2O3 coatings. J. Therm. Spray Technol. 2019, 28, 1933–1944. [Google Scholar] [CrossRef]

- Yilmaz, Ş. An evaluation of plasma-sprayed coatings based on Al2O3 and Al2O3–13 wt.% TiO2 with bond coat on pure titanium substrate. J. Therm. Spray Technol. 2009, 35, 2017–2022. [Google Scholar]

- Winnicki, M. Advanced functional metal-ceramic and ceramic coatings deposited by low-pressure cold spraying: A review. Coatings 2021, 11, 1044. [Google Scholar] [CrossRef]

- Toma, F.-L.; Berger, L.-M.; Scheitz, S.; Langner, S.; Rödel, C.; Potthoff, A.; Sauchuk, V.; Kusnezoff, M. Comparison of the microstructural characteristics and electrical properties of thermally sprayed Al2O3 coatings from aqueous suspensions and feedstock powders. J. Therm. Spray Technol. 2012, 21, 480–488. [Google Scholar] [CrossRef]

- Hadad, M.; Marot, G.; Démarécaux, P.; Lesage, J.; Michler, J.; Siegmann, S.T. Adhesion tests tor thermal spray coatings: Application range of tensile, shear and interfacial indentation methods. In Proceedings of The ITSC 2005: Thermal Spray Connects: Explore Its Surfacing Potential (DVS-ASM), Basel, Switzerland, 2–4 May 2005; pp. 759–764. [Google Scholar]

- Yamazaki, Y.; Arai, M.; Miyashita, Y.; Waki, H.; Suzuki, M. Determination of interfacial fracture toughness of thermal spray coatings by indentation. J. Therm. Spray Technol. 2013, 22, 1358–1365. [Google Scholar] [CrossRef]

- Mueller, E. Stress peening—A sophisticated way of normal shot peening. J. Mater. Sci. Eng. 2019, A9, 56–63. [Google Scholar]

- Liu, Y.; Fu, S.; Wang, Z.; Yan, X.; Xi, N.; Wu, Y.; Chen, H. Tensile properties, shear strength calculation and cracking behavior of bulk composite comprised of thick HVOF sprayed coating and steel substrate. Surface and Coating Technol. 2019, 374, 807–814. [Google Scholar] [CrossRef]

- Public Joint Stock Company. Electromekhanika. Available online: http://www.el-mech.ru/products/pokryt/pokryt_67.html (accessed on 7 November 2022).

- Zaytsev, A.N.; Yagopol’skiy, A.G.; Aleksandrova, Y.P. Assessing the impact of the structure and chemical composition of plasma-sprayed coatings on their adhesion and tribological properties. BMSTU J. Mech. Eng. 2018, 5, 48–59. [Google Scholar]

- Toma, F.-L.; Scheitz, S.; Berger, L.-M.; Sauchuk, V.; Kusnezoff, M.; Thiele, S.V. Comparative study of the electrical properties and characteristics of thermally sprayed alumina and spinel coatings. J. Therm. Spray Technol. 2011, 20, 195–204. [Google Scholar] [CrossRef]

- Zaytzev, A.N.; Lukianova, A.N.; Demoretsky, D.A. Assessment of Shear Bond Strength of Thermal Spray Coatings by Applying Prismatic Samples. Solid State Phenom. 2022, 337, 35–41. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Tyurin, Y.N. Modification of material properties and coating deposition using plasma jets. UFN 2005, 175, 515–544. [Google Scholar] [CrossRef]

- Public Joint Stock Company. Tochpribor. Available online: https://www.tochpribor-kb.ru (accessed on 7 November 2022).

- Siao, M.A.A.; Berndt, C.C. A review of testing methods for thermal spray coatings. Int. Mat. Rev. 2014, 59, 179–223. [Google Scholar]

| Parameters | MgAl2O4, Coating | Al2O3, Coating | NiAl, Bond Coat |

|---|---|---|---|

| Current (A) × voltage [V] = power [kW] | 330 × 50 = 16.50 | 320 × 50 = 16.00 | 330 × 48 = 15.84 |

| Spray distance, [mm] | 105 | 90 | |

| Feed powder, [g/min] | 15–18 | 30 | |

| Velocity of travel plasma torch, [s/min] | 2800 | 1600 | |

| Carrier gas type and flow rates, [L/min] | Ar: 25–30; N2: 2.0–2.4 | Ar: 20–25; N2: 1.5–2.0 | |

| Transporting gas type and flow rate, [L/min] | Ar: 2.5−3.0 | ||

| Number of passes | 9–10 | 1–2 | |

| Type of Specimen/Test Method | Type of Coating | Thickness [μm] | Roughness [μm] | Tensile Bond Strength [MPa] | Relative Error of Tensile Bond Strength [%] | Finite Element Average Equivalent Stress [MPa] | |

|---|---|---|---|---|---|---|---|

| Type 1, standard/GOST 9.304-87 [9] | Al2O3_APS | 420 ± 35 | 38 ± 10 | 30.1 ± 1.6 | 5 | 60 | 6.7 |

| MgAl2O4_APS | 406 ± 27 | 33 ± 6 | 28.8 ± 1.9 | 7 | - | - | |

| Type 4, elongated/GOST 9.304-87 [9] | Al2O3_APS | 484 ± 21 | 29 ± 4 | 25.0 ± 2.6 | 10 | 45 | 1.4 |

| MgAl2O4_APS | 446 ± 45 | 48 ± 5 | 22.0 ± 4.3 | 19 | - | - | |

| Type 2, modified/an in-house test method | Al2O3_APS | 424 ± 38 | 33 ± 8 | 23.2 ± 3.2 | 14 | 45 | 3.1 |

| MgAl2O4_APS | 484 ± 18 | 31 ± 4 | 26.4 ± 1.6 | 6 | - | - | |

| Type 5, elongated/an in-house test method | Al2O3_APS | 426 ± 36 | 31 ± 6 | 19.4 ± 0.5 | 2 | 44 | 1.8 |

| MgAl2O4_APS | 440 ± 29 | 30 ± 2 | 20.8 ± 2.0 | 10 | - | - | |

| Type 3, standard/ASTM C633-13 (2021) [6] | Al2O3_APS | 460 ± 32 | 37 ± 8 | 27.8 ± 0.6 | 2 | 43 | 4.9 |

| MgAl2O4_APS | 430 ± 30 | 38 ± 4 | 25.1 ± 3.2 | 13 | - | - | |

| Type 6, elongated/ASTM C633-13 (2021) [6] | Al2O3_APS | 472 ± 12 | 33 ± 3 | 20.7 ± 1.7 | 8 | 44 | 1.7 |

| MgAl2O4_APS | 450 ± 31 | 37 ± 3 | 18.4 ± 1.5 | 8 | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zayatzev, A.; Lukianova, A.; Demoretsky, D.; Alexandrova, Y. Tensile Adhesion Strength of Atmospheric Plasma Sprayed MgAl2O4, Al2O3 Coatings. Ceramics 2022, 5, 1242-1254. https://doi.org/10.3390/ceramics5040088

Zayatzev A, Lukianova A, Demoretsky D, Alexandrova Y. Tensile Adhesion Strength of Atmospheric Plasma Sprayed MgAl2O4, Al2O3 Coatings. Ceramics. 2022; 5(4):1242-1254. https://doi.org/10.3390/ceramics5040088

Chicago/Turabian StyleZayatzev, Andrey, Albina Lukianova, Dmitry Demoretsky, and Yulia Alexandrova. 2022. "Tensile Adhesion Strength of Atmospheric Plasma Sprayed MgAl2O4, Al2O3 Coatings" Ceramics 5, no. 4: 1242-1254. https://doi.org/10.3390/ceramics5040088

APA StyleZayatzev, A., Lukianova, A., Demoretsky, D., & Alexandrova, Y. (2022). Tensile Adhesion Strength of Atmospheric Plasma Sprayed MgAl2O4, Al2O3 Coatings. Ceramics, 5(4), 1242-1254. https://doi.org/10.3390/ceramics5040088