Comparative Study on the Scratch and Wear Resistance of Diamond-like Carbon (DLC) Coatings Deposited on X42Cr13 Steel of Different Surface Conditions

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Coating Thickness and Structure

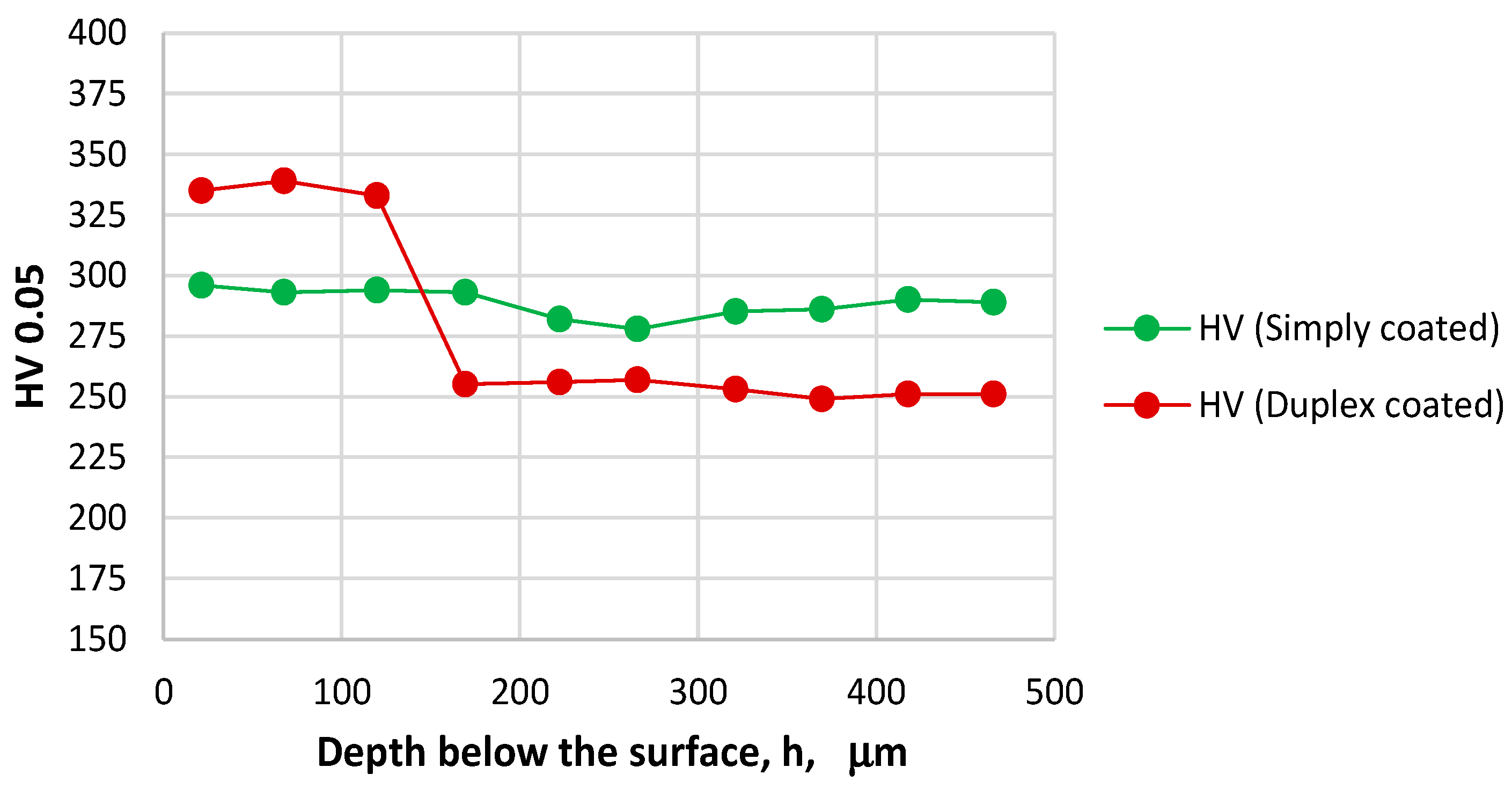

3.2. Microhardness

3.3. Microstructure Characterisation

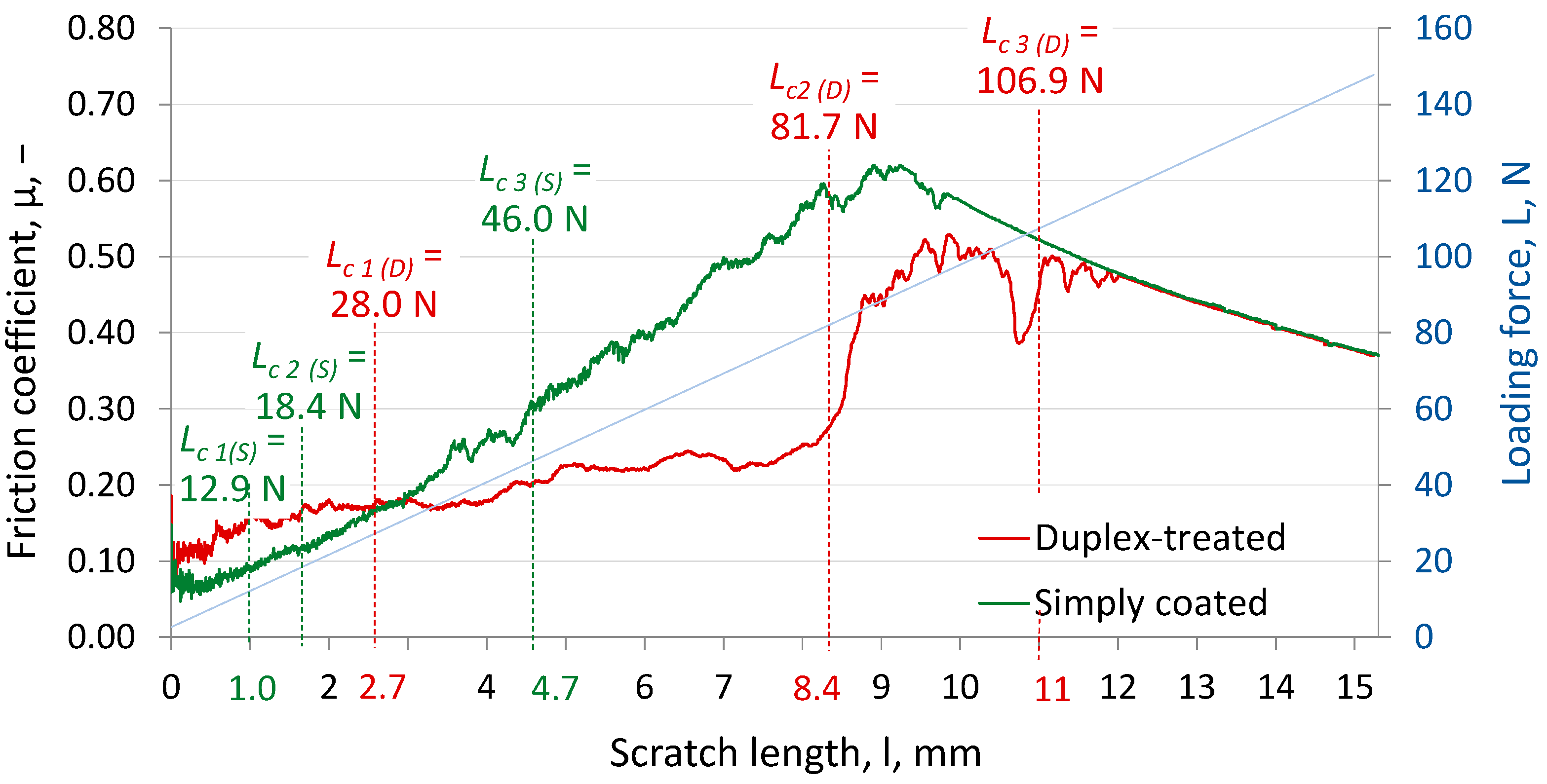

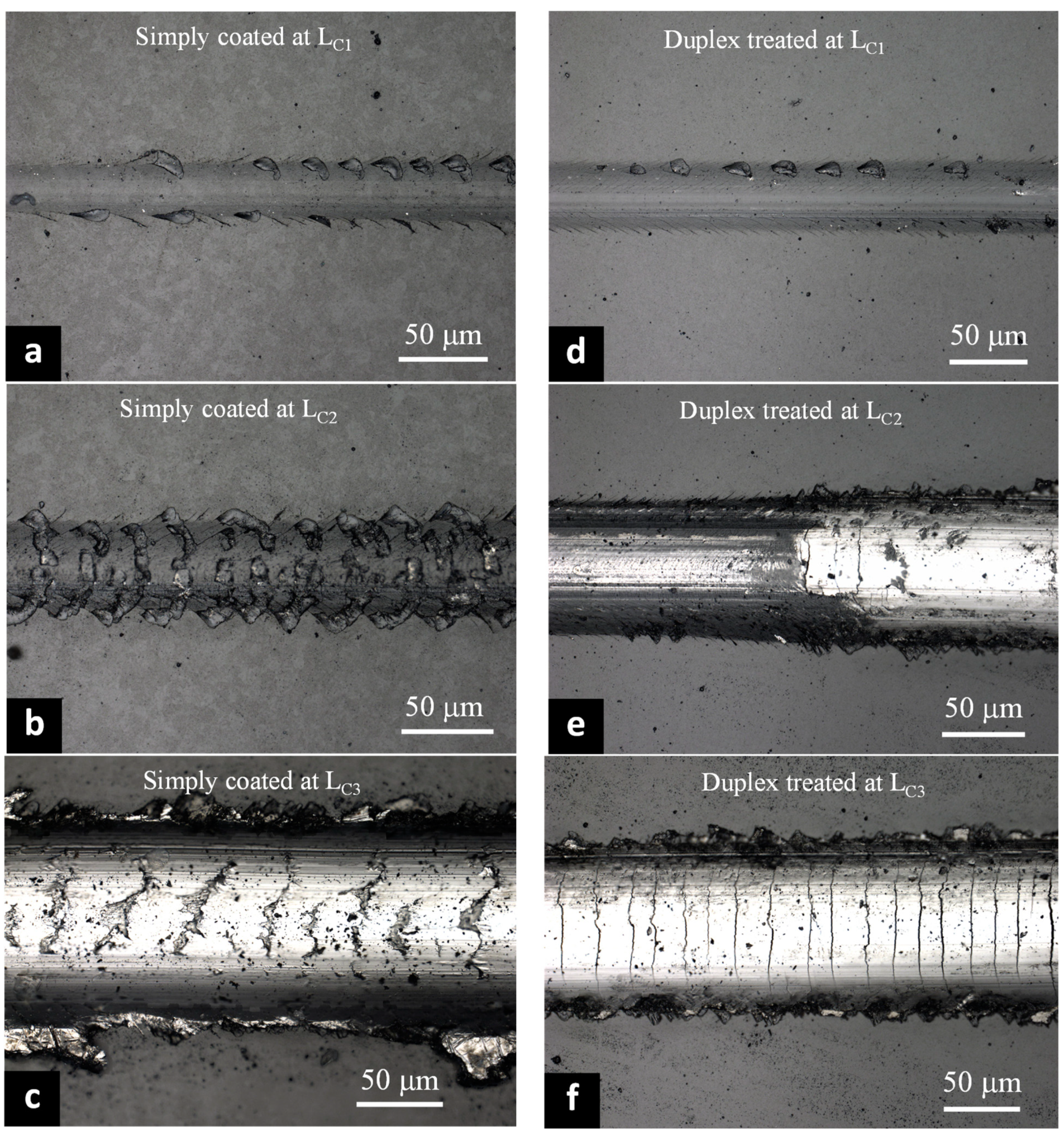

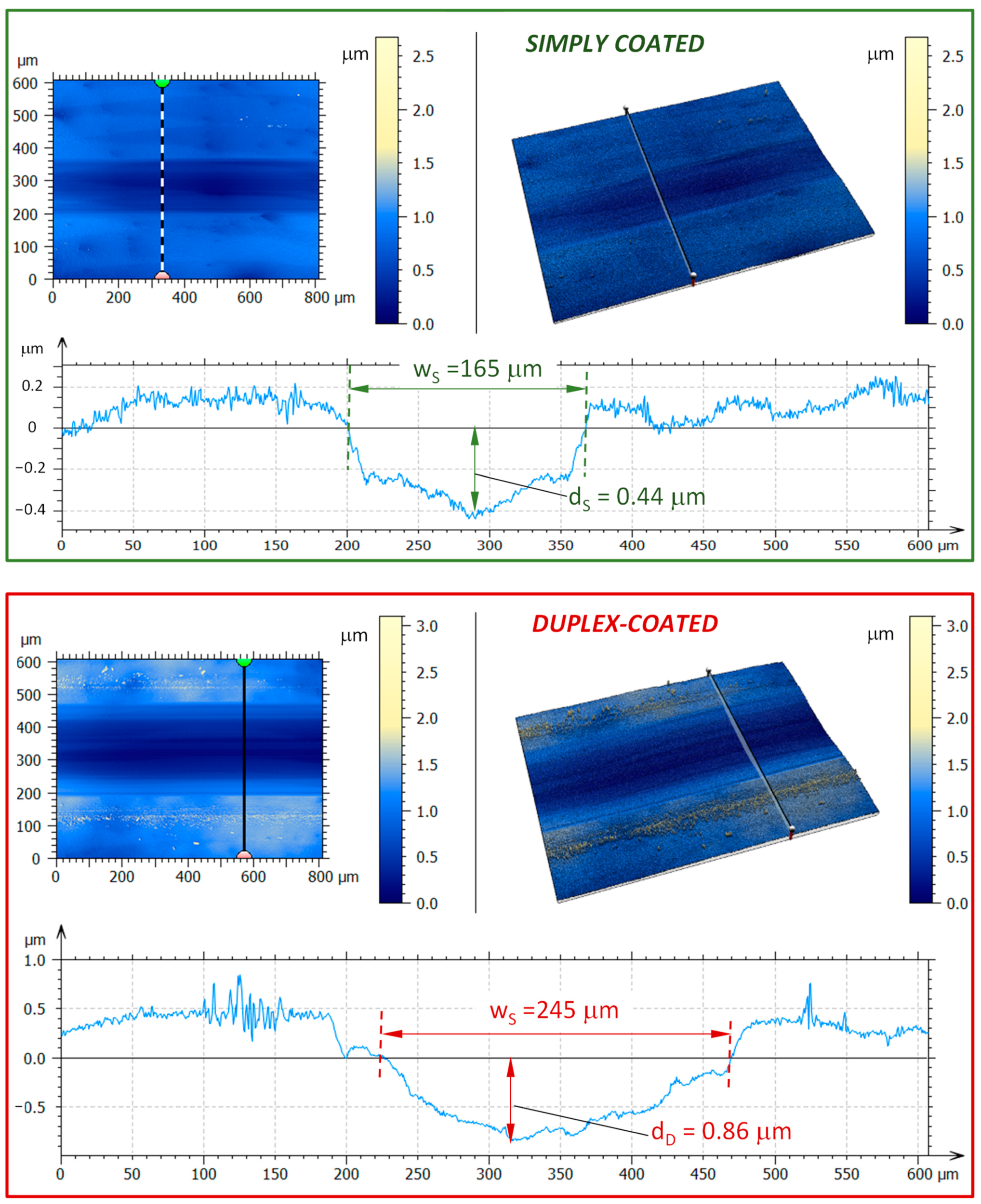

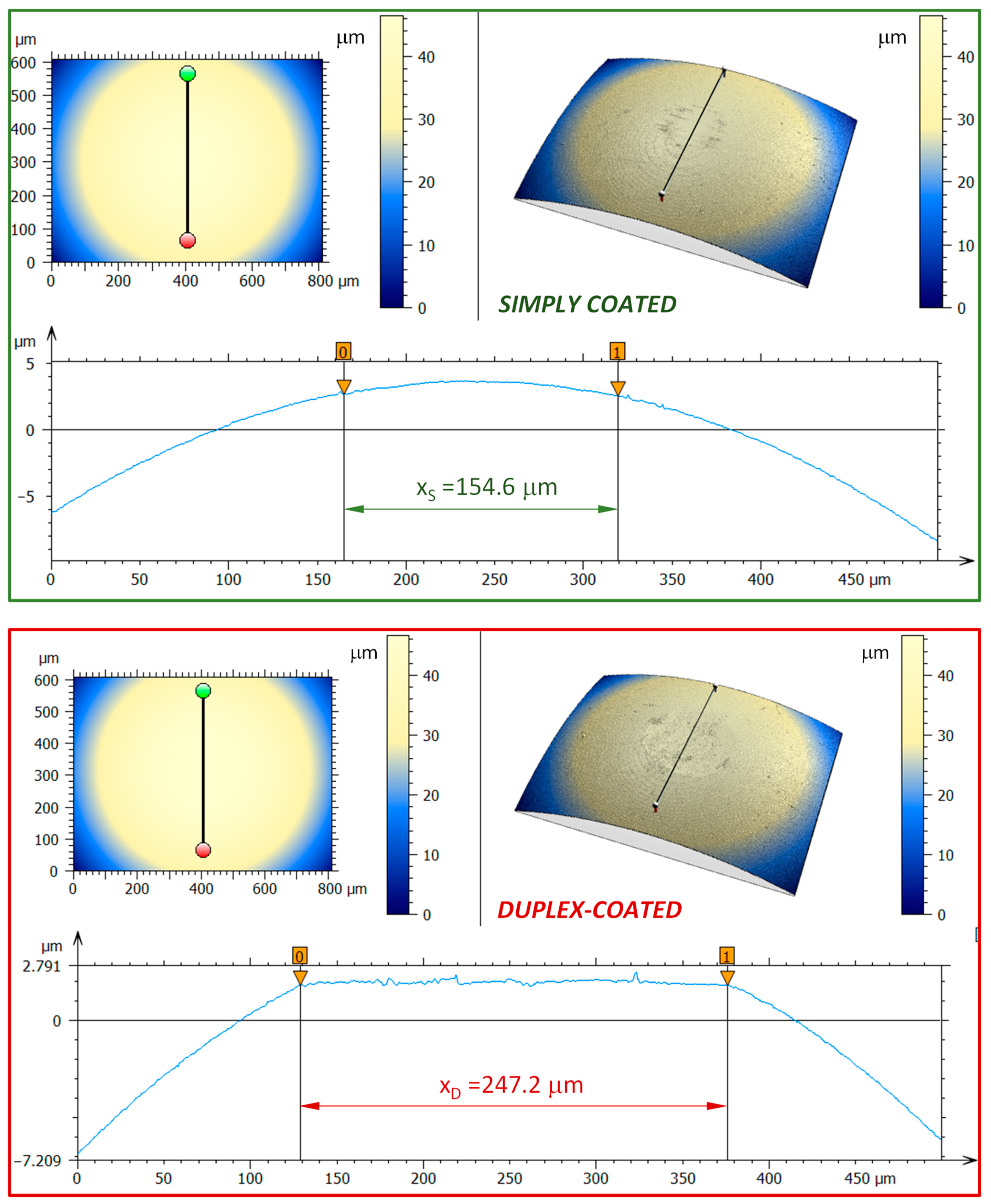

3.4. Scratch Resistance

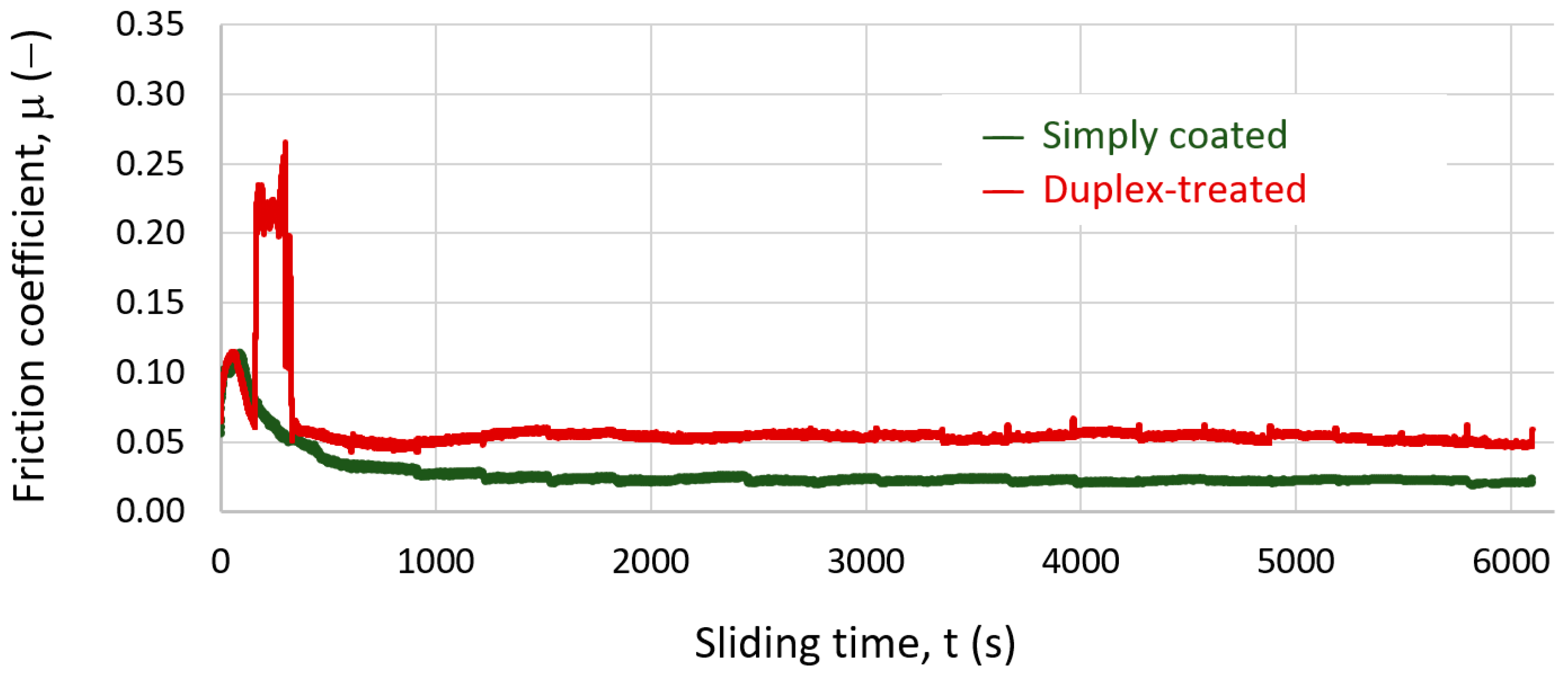

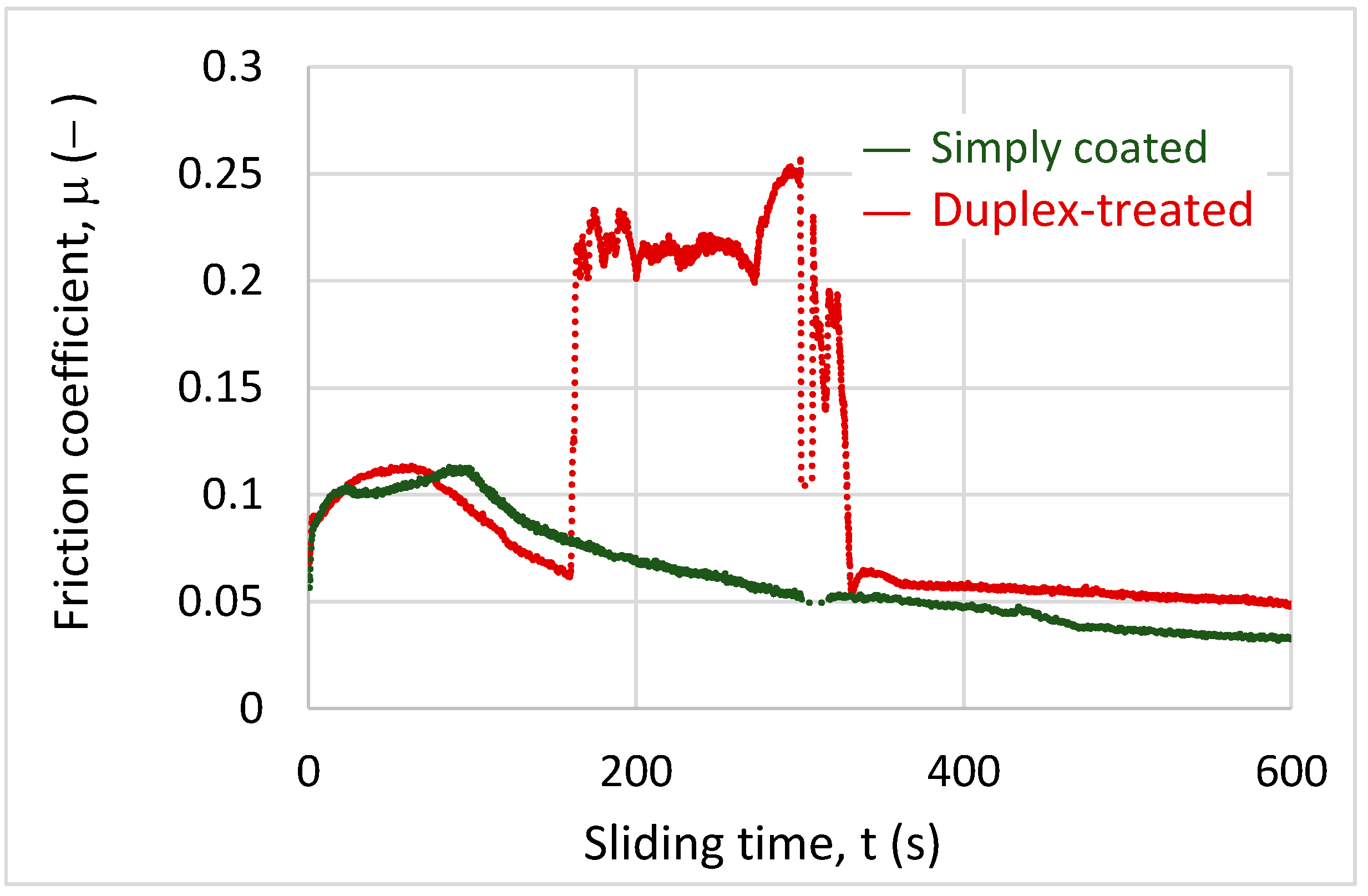

3.5. Wear Resistance of the Simple and Duplex-Treated Coatings

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bell, T.; Dong, H.; Sun, Y. Realising the potential of duplex surface engineering. Tribol. Int. 1998, 31, 127–137. [Google Scholar] [CrossRef]

- Hakami, F.; Pramanik, A.; Basak, A. Duplex surface treatment of steels by nitriding and chromizing. Aust. J. Mech. Eng. 2015, 15, 55–72. [Google Scholar] [CrossRef]

- Lin, N.; Liu, Q.; Zou, J.; Guo, J.; Li, D.; Yuan, S.; Ma, Y.; Wang, Z.; Wang, Z.; Tang, B. Surface Texturing-Plasma Nitriding Duplex Treatment for Improving Tribological Performance of AISI 316 Stainless Steel. Materials 2016, 9, 875. [Google Scholar] [CrossRef]

- Haftlang, F.; Habibolahzadeh, A. Influence of Treatment Sequence on Tribological Performance of Duplex Surface-Treated AISI 1045 Steel. Acta Met. Sin. (Engl. Lett.) 2019, 32, 1227–1236. [Google Scholar] [CrossRef]

- Das, K.; Alphonsa, J.; Ghosh, M.; Ghanshyam, J.; Rane, R.; Mukherjee, S. Influence of pretreatment on surface behavior of duplex plasma treated AISI H13 tool steel. Surf. Interfaces 2017, 8, 206–213. [Google Scholar] [CrossRef]

- Sun, Y.; Bell, T. Combined Plasma Nitriding and PVD Treatments. Trans. IMF 1992, 70, 38–44. [Google Scholar] [CrossRef]

- Dalibon, E.L.; Trava-Airoldi, V.; Pereira, L.A.; Cabo, A.; Brühl, S.P. Wear resistance of nitrided and DLC coated PH stainless steel. Surf. Coat. Technol. 2014, 255, 22–27. [Google Scholar] [CrossRef]

- Dalibon, E.L.; Escalada, L.; Simison, S.; Forsich, C.; Heim, D.; Brühl, S.P. Mechanical and corrosion behavior of thick and soft DLC coatings. Surf. Coat. Technol. 2017, 312, 101–109. [Google Scholar] [CrossRef]

- Holmberg, K.; Ronkainen, H.; Matthews, A. Tribology of thin coatings. Ceram. Int. 2000, 26, 787–795. [Google Scholar] [CrossRef]

- Wood, R.J.; Neville, A. Second International Conference on Erosive and Abrasive Wear (ICEAW II). Wear 2005, 258, 1. [Google Scholar] [CrossRef]

- Chung, K.H.; Lee, Y.H.; Kim, Y.T.; Kim, D.E.; Yoo, J.; Hong, S. Nano-tribological characteristics of PZT thin film investigated by atomic force microscopy. Surf. Coat. Technol. 2007, 201, 7983–7991. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef]

- Chung, K.H.; Kim, D.E. Wear characteristics of diamond-coated atomic force microscope probe. Ultramicroscopy 2007, 108, 1–10. [Google Scholar] [CrossRef]

- Wilson, G.M.; Sullivan, J.L. An investigation into the effect of film thickness on nanowear with amorphous carbon-based coatings. Wear 2009, 266, 1039–1043. [Google Scholar] [CrossRef]

- Hainsworth, S.V.; Uhure, N.J. Diamond like carbon coatings for tribology: Production techniques, characterisation methods and applications. Int. Mater. Rev. 2007, 52, 153–174. [Google Scholar] [CrossRef]

- Casiraghi, C.; Piazza, F.; Ferrari, A.C.; Grambole, D.; Robertson, J. Bonding in hydrogenated diamond-like carbon by Raman spectroscopy. Diam. Relat. Mater. 2005, 14, 1098–1102. [Google Scholar] [CrossRef]

- Hauert, R. An overview on the tribological behavior of diamond-like carbon in technical and medical applications. Tribol. Int. 2004, 37, 991–1003. [Google Scholar] [CrossRef]

- Wang, C.T.; Escudeiro, A.; Polcar, T.; Cavaleiro, A.; Wood, R.J.; Gao, N.; Langdon, T.G. Indentation and scratch testing of DLC-Zr coatings on ultrafine-grained titanium processed by high-pressure torsion. Wear 2013, 306, 304–310. [Google Scholar] [CrossRef]

- Tiainen, V.M. Amorphous carbon as a bio-mechanical coating—Mechanical properties and biological applications. In Proceedings of the 3rd Specialist Meeting on Amorphous Carbon, Mondovi, Italy, 31 August–1 September 2000; Volume 10, pp. 153–160. [Google Scholar]

- Treutler, C.P.O. Industrial use of plasma-deposited coatings for components of automotive fuel injection systems. In Proceedings of the 32nd International Conference on Metallurgical Coatings and Thin Film, San Diego, CA, USA, 2–6 May 2005; Volume 200, pp. 1969–1975. [Google Scholar]

- Joyce, T.J. Examination of failed ex vivo metal-on-metal metatarsophalangeal prosthesis and comparison with theoretically determined lubrication regimes. In Proceedings of the 16th International Conference on Wear of Materials, Montreal, QC, Canada, 15–17 April 2007; Volume 263, pp. 1050–1054. [Google Scholar]

- Falub, C.V.; Müller, U.; Thorwarth, G.; Parlinska-Wojtan, M.; Voisard, C.; Hauert, R. In vitro studies of the adhesion of diamond-like carbon thin films on CoCrMo biomedical implant alloy. Acta Mater. 2011, 59, 4678–4689. [Google Scholar] [CrossRef]

- Hauert, R.; Thorwarth, G.; Müller, U.; Stiefel, M.; Falub, C.V.; Thorwarth, K.; Joyce, T.J. Analysis of the in-vivo failure of the adhesive interlayer for a DLC coated articulating metatarsophalangeal joint. Diam. Relat. Mater. 2012, 25, 34–39. [Google Scholar] [CrossRef]

- Navabpour, P.; Teer, D.; Hitt, D.; Gilbert, M. Evaluation of non-stick properties of magnetron-sputtered coatings for moulds used for the processing of polymers. Surf. Coat. Technol. 2006, 201, 3802–3809. [Google Scholar] [CrossRef]

- Delaney, K.D.; Bissacco, G.; Kennedy, D. A structured review and classification of demolding issues and proven solutions. Int. Polym. Process. 2012, 27, 77–90. [Google Scholar] [CrossRef]

- Sasaki, T.; Koga, N.; Shirai, K.; Kobayashi, Y.; Toyoshima, A. An experimental study on ejection forces of injection molding. Precis. Eng. 2000, 24, 270–273. [Google Scholar] [CrossRef]

- Martins, L.C.; Ferreira, S.C.; Martins, C.I.; Pontes, A.J. Study of ejection forces in injection moulding of thin-walled tubular mouldings. In Proceedings of the PMI 2014 International Conference on Polymers and Moulds Innovations, Guimarães, Portugal, 10–12 September 2014; pp. 281–286. [Google Scholar]

- Sorgato, M.; Masato, D.; Lucchetta, G. Tribological effects of mold surface coatings during ejection in micro injection molding. J. Manuf. Process. 2018, 36, 51–59. [Google Scholar] [CrossRef]

- Lucchetta, G.; Masato, D.; Sorgato, M.; Crema, L.; Savio, E. Effects of different mould coatings on polymer filling flow in thin-wall injection moulding. CIRP Ann. 2016, 65, 537–540. [Google Scholar] [CrossRef]

- Liu, J.; Li, L.; Wei, B.; Wen, F.; Cao, H.; Pei, Y. Effect of sputtering pressure on the surface topography, structure, wettability and tribological performance of DLC films coated on rubber by magnetron sputtering. Surf. Coat. Technol. 2019, 365, 33–40. [Google Scholar] [CrossRef]

- Ye, Y.; Wang, Y.; Ma, X.; Zhang, D.; Wang, L.; Li, X. Tribocorrosion behaviors of multilayer PVD DLC coated 304L stainless steel in seawater. Diam. Relat. Mater. 2017, 79, 70–78. [Google Scholar] [CrossRef]

- Santiago, J.; Fernández-Martínez, I.; Sánchez-López, J.; Rojas, T.; Wennberg, A.; Bellido-González, V.; Molina-Aldareguia, J.; Monclús, M.; González-Arrabal, R. Tribomechanical properties of hard Cr-doped DLC coatings deposited by low-frequency HiPIMS. Surf. Coat. Technol. 2019, 382, 124899. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.; Wang, X. Structure characterization and antibacterial properties of Ag-DLC films fabricated by dual-targets HiPIMS. Surf. Coat. Technol. 2021, 410, 126967. [Google Scholar] [CrossRef]

- Bouabibsa, I.; Lamri, S.; Alhussein, A.; Minea, T.; Sanchette, F. Plasma investigations and deposition of Me-DLC (Me = Al, Ti or Nb) obtained by a magnetron sputtering-RFPECVD hybrid process. Surf. Coat. Technol. 2018, 354, 351–359. [Google Scholar] [CrossRef]

- Bouabibsa, I.; Lamri, S.; Sanchette, F. Structure, mechanical and tribological properties of Me-doped diamond-like carbon (DLC)(Me= Al, Ti, or Nb) hydrogenated amorphous carbon coatings. Coatings 2018, 8, 370. [Google Scholar] [CrossRef]

- Lugo, D.; Silva, P.; Ramirez, M.; Pillaca, E.; Rodrigues, C.; Fukumasu, N.; Corat, E.; Tabacniks, M.; Trava-Airoldi, V. Characterization and tribologic study in high vacuum of hydrogenated DLC films deposited using pulsed DC PECVD system for space applications. Surf. Coat. Technol. 2017, 332, 135–141. [Google Scholar] [CrossRef]

- Capote, G.; Ramírez, M.; da Silva, P.; Lugo, D.; Trava-Airoldi, V. Improvement of the properties and the adherence of DLC coatings deposited using a modified pulsed-DC PECVD technique and an additional cathode. Surf. Coat. Technol. 2016, 308, 70–79. [Google Scholar] [CrossRef]

- Chang, S.H.; Tang, T.C.; Huang, K.T.; Liu, C.M. Investigation of the characteristics of DLC films on oxynitriding-treated ASP23 high speed steel by DC-pulsed PECVD process. Surf. Coat. Technol. 2015, 261, 331–336. [Google Scholar] [CrossRef]

- Sanchette, F.; El Garah, M.; Achache, S.; Schuster, F.; Chouquet, C.; Ducros, C.; Billard, A. DLC-Based Coatings Obtained by Low-Frequency Plasma-Enhanced Chemical Vapor Deposition (LFPECVD) in Cyclohexane, Principle and Examples. Coatings 2021, 11, 1225. [Google Scholar] [CrossRef]

- Kovacı, H.; Baran, Ö.; Yetim, A.F.; Bozkurt, Y.B.; Kara, L.; Çelik, A. The friction and wear performance of DLC coatings deposited on plasma nitrided AISI 4140 steel by magnetron sputtering under air and vacuum conditions. Surf. Coat. Technol. 2018, 349, 969–979. [Google Scholar] [CrossRef]

- Ghiotti, A.; Bruschi, S. Tribological behaviour of DLC coatings for sheet metal forming tools. Wear 2011, 271, 2454–2458. [Google Scholar] [CrossRef]

- Toboła, D.; Kania, B. Phase composition and stress state in the surface layers of burnished and gas nitrided Sverker 21 and Vanadis 6 tool steels. Surf. Coat. Technol. 2018, 353, 105–115. [Google Scholar] [CrossRef]

- Tillmann, W.; Dias, N.F.L.; Stangier, D. Influence of plasma nitriding pretreatments on the tribo-mechanical properties of DLC coatings sputtered on AISI H11. Surf. Coat. Technol. 2018, 357, 1027–1036. [Google Scholar] [CrossRef]

- Podgornik, B.; Hogmark, S.; Sandberg, O.; Leskovsek, V. Wear resistance and anti-sticking properties of duplex treated forming tool steel. Wear 2003, 254, 1113–1121. [Google Scholar] [CrossRef]

- Czyzniewski, A. Optimising deposition parameters of W-DLC coatings for tool materials of high speed steel and cemented carbide. Vacuum 2012, 86, 2140–2147. [Google Scholar] [CrossRef]

- Claver, A.; Jiménez-Piqué, E.; Palacio, J.F.; Almandoz, E.; Fernández de Ara, J.F.; Fernández, I.; Santiago, J.A.; Barba, E.; García, J.A. Comparative Study of Tribomechanical Properties of HiPIMS with Positive Pulses DLC Coatings on Different Tools Steels. Coatings 2021, 11, 28. [Google Scholar] [CrossRef]

- Moreno-Bárcenas, A.; Alvarado-Orozco, J.M.; Carmona, J.M.G.; Mondragón-Rodríguez, G.C.; González-Hernández, J.; García-García, A. Synergistic effect of plasma nitriding and bias voltage on the adhesion of diamond-like carbon coatings on M2 steel by PECVD. Surf. Coat. Technol. 2019, 374, 327–337. [Google Scholar] [CrossRef]

- An, X.; Wu, Z.; Liu, L.; Shao, T.; Xiao, S.; Cui, S.; Lin, H.; Fu, R.K.; Tian, X.; Chu, P.K.; et al. High-ion-energy and low-temperature deposition of diamond-like carbon (DLC) coatings with pulsed kV bias. Surf. Coat. Technol. 2018, 365, 152–157. [Google Scholar] [CrossRef]

- Sheeja, D.; Tay, B.K.; Lau, S.P.; Shi, X. Tribological properties and adhesive strength of DLC coatings prepared under different substrate bias voltages. Wear 2001, 249, 433–439. [Google Scholar] [CrossRef]

- Sun, Y.; Bloyce, A.; Bell, T. Finite element analysis of plastic deformation of various TiN coating/ substrate systems under normal contact with a rigid sphere. Thin Solid Film. 1995, 271, 122–131. [Google Scholar] [CrossRef]

- Łępicka, M.; Grądzka-Dahlke, M.; Pieniak, D.; Pasierbiewicz, K.; Niewczas, A. Effect of mechanical properties of substrate and coating on wear performance of TiN- or DLC-coated 316LVM stainless steel. Wear 2017, 382–383, 62–70. [Google Scholar] [CrossRef]

- Li, Z.; Guan, X.; Wang, Y.; Li, J.; Cheng, X.; Lu, X.; Wang, L.; Xue, Q. Comparative study on the load carrying capacities of DLC, GLC and CrN coatings under sliding-friction condition in different environments. Surf. Coat. Technol. 2017, 321, 350–357. [Google Scholar] [CrossRef]

- Kovacı, H.; Yetim, A.F.; Baran, Ö.; Çelik, A. Tribological behavior of DLC films and duplex ceramic coatings under different sliding conditions. Ceram. Int. 2018, 44, 7151–7158. [Google Scholar] [CrossRef]

- Zawischa, M.; Supian, M.M.A.B.M.; Makowski, S.; Schaller, F.; Weihnacht, V. Generalized approach of scratch adhesion testing and failure classification for hard coatings using the concept of relative area of delamination and properly scaled indenters. Surf. Coat. Technol. 2021, 415, 127118. [Google Scholar] [CrossRef]

- Arnell, D. Mechanisms and laws of friction and wear. In Tribology Dynamic Engine Powertrain Fundamentals, Applications and Future Trends; Elsevier Ltd.: Amsterdam, The Netherlands, 2010; pp. 41–72. ISBN 9781845693619. [Google Scholar]

- Williams, J. Engineering Tribology; Cambridge University Press: Cambridge, UK, 2005; ISBN 9780511805905. [Google Scholar]

- Hutchings, I.M. Tribology: Friction and Wear of Engineering Materials; Edward Arnold A Division of Hodder & Stoughton: London, UK, 1992; pp. 77–78. ISBN 0-340-56184-x. [Google Scholar]

- Balla, V.K.; Das, M. Advances in Wear and Tribocorrosion Testing of Artificial Implants and Materials: A Review. Trends Biomater. Artif. Organs 2017, 31, 150–163. [Google Scholar]

- Pinedo, C.E.; Monteiro, W.A. Surface hardening by plasma nitriding on high chromium alloy steel. J. Mater. Sci. Lett. 2001, 20, 147–150. [Google Scholar] [CrossRef]

- Brühl, S.P.; Charadia, R.; Sanchez, C.; Staia, M.H. Wear behavior of plasma nitrided AISI 420 stainless steel. Int. J. Mater. Res. 2008, 99, 779–786. [Google Scholar] [CrossRef]

- Dalibon, E.; Charadia, R.; Cabo, A.; Brühl, S.P. Short Time Ion Nitriding of AISI 420 Martensitic Stainless Steel to Improve Wear and Corrosion Resistance. Mater. Res. 2019, 22. [Google Scholar] [CrossRef]

- Czél, G.; Baán, M.; Makk, P.; Raffay, C.; Fancsali, J.; Janovszky, D. Research Scene to Examine Mechanical Strength of Coatings on Metallic Substrate. In Proceedings of the Fourth International Symposium on Measurement Technology and Intelligent Instruments, ISMT II ’98, ISMTII 1998, Miskolc-Lillafured, Hungary, 2–4 September 1998; Dudás, I., Ed.; Springer: Budapest, Hungary, 1998; pp. 335–338, ISBN 963-8455-578. [Google Scholar]

- ASTM C1624-22; Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing. ASTM International: West Conshohocken, PA, USA, 2022.

- EN ISO 26423:2016; Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Coating Thickness by Crater-Grinding Method. International Organisation for Standardization: Geneva, Switzerland, 2016.

- Kocsisné Baán, M.; Marosné, B.M.; Szilágyiné, B.A. (Szerk): Nitridálás-Korszerű Eljárások és Vizsgálati Módszerek; Miskolci Egyetem: Miskolc, Hungary, 2015; p. 296. ISBN 978-963-3580-806. [Google Scholar]

- Riazi, H.; Ashrafizadeh, F.; Hosseini, S.R.; Ghomashchi, R.; Liu, R. Characterization of simultaneous aged and plasma nitrided 17-4 PH stainless steel. Mater. Charact. 2017, 133, 33–43. [Google Scholar] [CrossRef]

- Siddiqui, S.A.; Favaro, G.; Berkes Maros, M. Investigation of the Damage Mechanism of CrN and Diamond-Like Carbon Coatings on Precipitation-Hardened and Duplex-Treated X42Cr13/W Tool Steel by 3D Scratch Testing. J. Mater. Eng. Perform. 2022, 31, 7830–7842. [Google Scholar] [CrossRef]

- Ellermann, A.; Scholtes, B. The Bauschinger Effect in Different Heat Treatment Conditions of 42CrMo4. Int. J. Struct. Changes Solids-Mech. Appl. 2011, 3, 1–13. [Google Scholar]

- Queyreau, S.; Devincre, B. Bauschinger effect in precipitation-strengthened materials: A dislocation dynamics investigation. Philos. Mag. Lett. 2009, 89, 419–430. [Google Scholar] [CrossRef]

- Kostryzhev, A.G.; Strangwood, M.; Davis, C.L. Bauschinger effect in Nb and V alloyed line-pipe steels. Ironmak. Steelmak. 2009, 36, 186–192. [Google Scholar] [CrossRef]

- Roostaei, A.A.; Jahed, H. (Eds.) Cyclic Plasticity of Metals; Elsevier Inc.: Amsterdam, The Netherlands, 2022; ISBN 978-0-12-819293-1. [Google Scholar] [CrossRef]

- Bell, T.; Sun, Y. Load bearing capacity of plasma nitrided steel under rolling–sliding contact. Surf. Eng. 1990, 6, 133–139. [Google Scholar] [CrossRef]

- Mussa, A.; Krakhmalev, P.; Bergström, J. Sliding wear and fatigue cracking damage mechanisms in reciprocal and unidirectional sliding of high-strength steels in dry contact. Wear 2019, 444–445, 203119. [Google Scholar] [CrossRef]

- Siddiqui, S.A. Enhancing the Tribological Performance of X42cr13 Steel by Simple and Duplex Treated CrN and DLC Coating. Ph.D. Thesis, University of Miskolc, Miskolc, Hungary, 2022; pp. 1–117. Available online: http://193.6.1.94:9080/JaDoX_Portlets/documents/document_40884_section_38533.pdf (accessed on 3 December 2022).

| Sample | Substrate Condition | Coating | |||||

|---|---|---|---|---|---|---|---|

| Thickness, μm | Hardness, HV0.05 | ||||||

| Nomi-Nation | Type | DLC Coating | Nitrided Layer | DLC Coating * | Substrate Surface | Substrate Core | |

| S | simple-coated | un-nitrided | 3.4 | – | 1386 | 295 | 290 |

| D | duplex-treated | nitrided | 3.6 | 140 | 2077 | 335 | 250 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siddiqui, S.A.; Maros, M.B. Comparative Study on the Scratch and Wear Resistance of Diamond-like Carbon (DLC) Coatings Deposited on X42Cr13 Steel of Different Surface Conditions. Ceramics 2022, 5, 1207-1224. https://doi.org/10.3390/ceramics5040086

Siddiqui SA, Maros MB. Comparative Study on the Scratch and Wear Resistance of Diamond-like Carbon (DLC) Coatings Deposited on X42Cr13 Steel of Different Surface Conditions. Ceramics. 2022; 5(4):1207-1224. https://doi.org/10.3390/ceramics5040086

Chicago/Turabian StyleSiddiqui, Shiraz Ahmed, and Maria Berkes Maros. 2022. "Comparative Study on the Scratch and Wear Resistance of Diamond-like Carbon (DLC) Coatings Deposited on X42Cr13 Steel of Different Surface Conditions" Ceramics 5, no. 4: 1207-1224. https://doi.org/10.3390/ceramics5040086

APA StyleSiddiqui, S. A., & Maros, M. B. (2022). Comparative Study on the Scratch and Wear Resistance of Diamond-like Carbon (DLC) Coatings Deposited on X42Cr13 Steel of Different Surface Conditions. Ceramics, 5(4), 1207-1224. https://doi.org/10.3390/ceramics5040086