Abstract

The automotive industry is at a critical juncture, facing increasing pressure from stringent environmental regulations, resource scarcity, and global supply chain disruptions. This study aims to identify, model, and prioritize the key factors influencing the adoption of circular economy principles in the automotive sector. The Decision-Making Trial and Evaluation Laboratory method was applied to analyze the interdependencies among ten critical factors. Based on a contribution from a panel of six experts from a European automotive distributor with its main operating points in France and Romania, the study reveals a clear cause-and-effect relationship among the factors. Causal factors such as organizational culture, internal integration, regulatory policies, circular business models, and R&D capacity were identified as key drivers. Conversely, factors like top management commitment, stakeholder engagement, technological capability, sustainable materials management, and ecodesign were classified as effect factors, meaning they are influenced by other variables. The key practical contribution of this research is a strategic prioritization framework for decision-makers, offering guidance on how to effectively boost key factors, either directly or indirectly, to achieve a more efficient alignment with circular economy principles. By strategically leveraging these interdependencies, organizations can trigger a positive chain reaction, leading to improved performance in the dependent effect factors and ultimately accelerating the transition to a circular economy.

1. Introduction

The automotive industry is currently experiencing a significant period of transition, caused by both complex obstacles and significant external demands. Such pressures include rigorous environmental regulations, depleting natural resources, and a critical need for operational and technological restructuring. Global disruptions affected the effectiveness and reliability of existing supply chains. Such risk factors, including abrupt supply chain disturbances, erratic demand variations, persistent logistical bottlenecks, and ambitious carbon reduction objectives, have consistently undermined the performance and dependability of existing supply networks. This widespread volatility clearly highlights the urgent need for sustainable and reliable solutions. In this context, embracing the fundamental principles of the circular economy is no longer just a strategic option, but has emerged as a necessity. This model provides a solid framework for decoupling economic growth from the consumption of primary resources, in this way strengthening the long-term resilience and enhancing the competitive advantage of the entire automotive industry.

The effective implementation of circular economy principles in the automotive industry is a complex initiative that depends on several interrelated factors. These factors include strong strategic management commitment [1], continuous technological innovation [2], and rigorous legislative frameworks [1]. A complete understanding of these complex relations proves to be essential for both the development and the execution of successful transition strategies. Identified barriers, such as operational disruptions, limited transparency across the value chain, and fragmented internal coordination, can negatively affect the implementation schedule, as well as the cost and the environmental impact. The existing academic literature on responsible management and supply chains repeatedly highlights the inherent limitations of isolated improvement initiatives, emphasizing instead the particular importance of adopting a systemic approach to managing such complex transitions [3,4]. Despite a clear increase in academic interest, there is still no clear consensus on the optimal methods for intelligently integrating strategic, technological, and organizational elements to truly improve the sustainability performance of value chains in the automotive industry [3]. Furthermore, conventional assessment models, which are often built upon linear or additive assumptions, frequently fall short in adequately capturing the multifaceted and interactive nature of transformation processes [5,6].

In this context, multi-attribute decision-making (MADMs) methods have gained recognition for their ability to simultaneously evaluate multiple interdependent variables [5,7]. However, many commonly employed MADM approaches, such as the Analytic Hierarchy Process (AHP) or the Best–Worst Method (BWM), tend to focus primarily on static rankings or binary selections [5]. This intrinsic limitation significantly restricts their ability to provide a truly thorough understanding of the structural interactions that decisively influence decision-making processes.

To overcome these analytical limitations and strengthen the methodological contribution of this paper, the present study employs the Decision-Making Trial and Evaluation Laboratory (DEMATEL) method. Unlike AHP or BWM, which focus on ordering or ranking factors based on importance weights, DEMATEL provides a rigorous framework for modeling causal relationships and accurately quantifying the paths of influence between variables in a complex system [5,6]. Developed by the Battelle Geneva Foundation, this method allowed us to clearly identify the most influential causal factors and dependent variables by constructing a detailed, structured map of their interactions [7]. The choice of DEMATEL is justified by our study’s primary objective: to establish a hierarchy of critical factors for the circular economy in the automotive industry and to understand and model the complex interdependencies between them. This is particularly vital in non-linear systems characterized by complex feedback loops [4]. Thus, the proposed methodological framework contributes to advancing decision-support tools for the complex systems within the automotive industry, which is undergoing a sustainability-oriented reconfiguration. Specifically, the theoretical innovation of this study lies in using this method to identify organizational culture and internal integration as key causal factors, providing insights into the foundational elements required for successful circular economy transitions that are often overlooked in macro-level analyses. This offers a more detailed understanding of their influence within this complex system, demonstrating that these often-qualitative internal elements are not merely supportive but act as the active engine for the adoption and success of circular economy practices.

Figure 1 graphically illustrates the important issues and key factors that are significantly influencing the automotive industry’s progression toward a circular economy. The red boxes on the left side of the diagram clearly represent the main obstacles preventing this transformation. In contrast, the green arrows on the right symbolize the strong momentum for change, which is driven by three determining factors presented in the green boxes. The cyclical green arrows highlight the highly interconnected and dynamic nature of these elements, emphasizing how their collective interaction drives fundamental change towards circularity, effectively overcoming the obstacles identified above.

Figure 1.

Barriers and enablers in the automotive industry’s transition to a circular economy.

The primary aim of this research is to model the structural interdependencies between critical transformation factors and to develop a prioritization framework to support the implementation of the circular economy in the automotive industry. By applying the DEMATEL method concept, the study aims to support strategic planning processes by distinguishing between influential (causal) and receptive (effect) variables and facilitating targeted interventions based on systemic levers [4]. The main goal of this study is to address a gap in the literature regarding a lack of in-depth analysis of the structural relationships and causal interdependencies between critical factors for the circular economy in the automotive sector. This work seeks to provide a quantitative analysis that moves beyond descriptive studies, thereby offering a clearer, data-driven framework for strategic decision-making. Based on this, the central research question addressed in this paper is the following: What are the causal and effect relationships between the critical factors influencing the automotive industry’s transition to a circular economy, and how can these relationships be leveraged to develop effective implementation strategies? The proposed methodological framework contributes to the promotion of decision-support tools for complex systems in the automotive industry, undergoing a sustainability-oriented reconfiguration.

More specifically, this study offers a new contribution by identifying organizational culture and internal integration [8,9] as key causal factors [6], providing information on the fundamental elements necessary for successful transitions to the circular economy [10,11,12], which are often overlooked in macro-level analyses. Although the importance of organizational culture and internal integration for strategic initiatives is well established, the novelty of this study lies in identifying them as causal factors in the transition to the circular economy of the automotive industry, using the DEMATEL method. This provides a more detailed understanding of their influence within this complex system, demonstrating that these internal elements, which are often qualitative, are not only supportive but actively drive the adoption and success of circular economy practices.

This paper is structured as follows: Section 2 provides a theoretical framework detailing the ten key factors relevant to the circular economy in the automotive industry, which are evaluated in this study. Section 3 presents the DEMATEL conceptual methodology. Section 4 presents the simulated results, and Section 5 discusses them in the context of the existing literature. Section 6 concludes the study by summarizing the conclusions and highlighting the contributions of the research.

2. Theoretical Framework

The automotive industry is under increasing pressure to adopt more sustainable production and consumption models. This is driven by strict emissions regulations, volatile raw material prices, and consumer demand for environmentally friendly solutions. The circular economy in this sector involves redesigning vehicles and components to be more durable, repairable, reusable, and recyclable, and developing business models that prioritize sharing, usage, and services over traditional ownership. It also involves optimizing material and energy life cycles, converting waste into resources, and reducing the sector’s overall environmental footprint. In order to understand the complexity of implementing this transformative paradigm, we have conducted an in-depth analysis of the literature and identified ten key factors. These factors are essential for fully mapping the complex dynamics of the automotive industry’s transition to circularity and identifying strategic intervention points. Table 1 presents the factors included in the analysis.

Table 1.

Factors included in the DEMATEL analysis.

One of the most important factors is the commitment of top management [13]. This represents the extent to which an organization’s top management prioritizes, supports, and integrates circular economy principles into the company’s strategy and operations [10]. In the automotive industry, this commitment is particularly important because the transition to circularity often requires paradigm shifts in production processes, supply chains, and business models. Strategic decisions and high-level resource allocation are essential for initiating and sustaining circularity initiatives [6], including investments in new technologies [1] and the development of a sustainability-oriented organizational culture [10,13]. Without explicit support from executives, circularity initiatives risk becoming fragmented [14] and underfunded, failing to reach their full potential [6].

Stakeholder engagement is also a key factor, referring to an automotive company’s ability to collaborate effectively with a wide range of stakeholders, such as suppliers, customers, regulators, competitors, non-governmental organizations (NGOs), and local communities [12,15]. In the circular economy, collaboration across the entire value chain is essential. For instance, adopting circular principles frequently necessitates forming partnerships with suppliers to source innovative materials and with recycling companies to efficiently recover resources at the end of the product’s life cycle [11,16]. Proactive stakeholder engagement helps co-create solutions, overcome barriers, and ensure acceptance of initiatives, while also managing potential conflicts of interest [17]. It is therefore a pillar of successful sustainable transformation [6].

Another vital element is regulatory alignment and policies. This refers to the extent to which a car company’s strategies and operations comply with, and more importantly, utilize existing national and international legislative frameworks and environmental policies [18]. Specialized studies emphasize the importance of sustainable policies and EU regulations, such as the End-of-Life Vehicles (ELV) Directive and Extended Producer Responsibility (EPR) schemes [19,21]. These regulations stimulate innovation and investment in clean technologies, as well as the adoption of circular practices. The ability to anticipate and influence these regulations can provide a significant competitive advantage [20].

Technological capability refers to an organization’s readiness and ability to acquire, implement, and utilize advanced technologies that support circularity objectives [22] within the automotive industry. This includes a wide range of innovations, from advanced manufacturing processes [23,35] such as 3D printing for rapid prototyping and on-demand manufacturing of spare parts, to the development of smart materials with self-repairing or improved recycling properties. Digital technologies such as the Internet of Things (IoT), virtual sensors, digital twins, and artificial intelligence (AI) are also important for monitoring product lifecycles, optimizing material flows, and facilitating usage-based services [24]. These capabilities enable increased transparency and traceability, which are essential for efficient closed-loop resource management.

The success of implementing a circular economy also depends on internal integration. This describes the extent to which different functional units and departments (e.g., research and development, design, production, procurement, reverse logistics, and after-sales) coordinate and collaborate within an organization [26]. Strong internal integration is vital for effectively and coherently implementing circular economy practices in the automotive industry. For instance, effective ecodesign necessitates close collaboration between the design, production, and recycling teams. Integration reduces organizational ‘silos’ that can hinder information flow [6], lead to suboptimal decisions, and create misalignment between operational activities [25] and strategic sustainability objectives.

A key factor is sustainable materials and recycling management, which focuses on strategies for selecting, using, and recovering materials in the context of automotive circularity [27]. This includes adopting biomaterials, recycled materials, and materials with a low carbon footprint, as well as developing robust systems for efficiently collecting, sorting, processing, and recycling ELVs and their components [28]. The effective management of sustainable materials and recycling is central to the circular economy, transforming waste into valuable resources and reducing dependence on virgin raw materials [19].

Another important aspect is the ecodesign and product sustainability conception [30,31]. This is a fundamental factor in the circular economy and refers to the application of design principles that aim to minimize the ecological impact of products throughout their entire life cycle, from initial design to end of life [30]. In the automotive industry, for example, ecodesign involves creating vehicles and components that are easier to disassemble, repair, reuse, and recycle. Literature highlights the basic principles of circular product design and its importance in facilitating value recovery and closing material loops [29].

Organizational culture and awareness can have a significant influence on the success of circular initiatives [31]. This refers to the values, beliefs, and norms shared within an organization that influence how employees perceive and respond to such initiatives. A culture that supports innovation, environmental responsibility, and continuous learning is essential for the circular transition to succeed [32]. When employees are aware of the benefits of the circular economy and their individual role in its implementation, this can lead to grassroots initiatives and ensure the widespread adoption of new practices.

Circular business models and value strategies are transformative factors that involve developing and implementing new business approaches [33]. These approaches generate value from the extended use of products and the recovery of resources, which is detrimental to the traditional linear model [33]. In the automotive industry, this could mean offering usage-based mobility services instead of ownership, providing extended leasing programs, remanufacturing components, offering repair and upgrade services, and setting up end-of-life vehicle take-back schemes to recover materials. These models transform how automotive companies create, deliver, and capture value, thereby contributing directly to the goals of the circular economy [34].

Finally, a company’s capacity for innovation and research and development (R&D) is critical, referring to its ability to generate and implement innovations (technological, process-related, organizational, and in terms of business models) specific to the circular economy [1,6]. The concept of ‘eco-innovation’ is important in the automotive industry’s transition to the circular economy. This involves investing in research into new recyclable or renewable materials, developing advanced recycling and remanufacturing technologies, and exploring new manufacturing processes that reduce resource consumption and generate less waste [21,30]. Strong R&D capacity is essential for overcoming technical barriers and unlocking new opportunities in the circular economy.

3. Methodology

The research employs a mixed-method design, leveraging the DEMATEL method, which is inherently both qualitative and quantitative. The qualitative component involves the deliberate selection of a small, expert panel to provide in-depth insights into the interdependencies of factors. The quantitative component utilizes a structured questionnaire to collect data and mathematical modeling to analyze the relationships between these factors. This approach is essential for integrating a deep, qualitative understanding of the subject matter from professionals with direct managerial experience, thereby strengthening the empirical foundation of the quantitative analysis.

Respondents were selected based on their managerial roles in the logistics, operations, or sustainability departments of industrial organizations in the EU automotive sector, as well as on the basis of a minimum of two years’ experience in supply chain management and/or sustainability projects. Their contribution was instrumental in assessing the interactions between the critical factors involved in the sustainable transition of value chains towards the circular economy. Specifically, the expert panel was composed of professionals from various large industrial organizations in the European Union, ensuring a diverse but relevant perspective on the challenges of value chain management and the implementation of circularity.

The DEMATEL methodology, a well-established technique in multi-criteria decision analysis, was applied to identify and measure the mutual influence between key variables. According to recommendations in the literature [5,8], this approach requires a small panel of experts. In this study, six professionals from a European automotive distributor with main operating points in France and Romania were interviewed to participate in the evaluation. This number is considered robust for this type of research, as it is consistent with or exceeds the number of experts in many similar DEMATEL studies reviewed in the literature [4,5,7]. The panel of experts was selected based on their in-depth managerial experience and specific relevance to industrial supply chains and sustainability projects within the automotive sector. This specific case study approach, focusing on a company with operations in both a Western and an Eastern European country, provides valuable insights into the dynamics of the EU automotive sector, reflecting the different market conditions and regulatory environments that influence the transition to a circular economy.

Data collection was planned for July 2025, using a structured questionnaire in the form of a matrix of direct relationships containing 10 factors. Each respondent would have been asked to assess the degree of influence between all pairs of factors (a total of 100 pair assessments) using a five-point scale:

- 0—no influence;

- 1—low influence;

- 2—moderate influence;

- 3—strong influence;

- 4—very strong influence.

These assessments were used as input for the DEMATEL analysis, which identifies the cause-and-effect relationships that are critical for strategic decision-making. In the initial stage, the influence matrix was derived from matrix , which contains the average influence score assigned by each respondent. The relationship between the matrices is expressed as follows:

The variable represents the initial direct-relation matrix (Appendix A), which aggregates the average scores given by the expert panel. The variable is a normalization factor used to scale the matrix elements between 0 and 1. This step is essential for ensuring that the total influence of each factor does not exceed 1, which is a fundamental requirement for subsequent matrix calculations in the DEMATEL method.

A critical consideration was the consistency of expert responses. The DEMATEL methodology addresses this through its mathematical processes, which involve matrix normalization and the calculation of a total influence matrix. These steps guarantee that the final outcomes are a stable and consistent reflection of the collective expert consensus. To ensure the study’s transparency and reproducibility, the direct relationships matrix is provided in Appendix A.

Here, ‘’ signifies the total count of factors under investigation. Once ‘’ (set at 10) is established and the normalized direct-relation matrix is acquired, the subsequent phase involves computing the total influence matrix . This matrix comprehensively encapsulates both the direct and indirect impacts each factor has on the others.

The normalization factor is calculated by finding the maximum row sum of the initial direct-relation matrix . This ensures that the elements of the normalized matrix are all within a range of [0, 1], which is a prerequisite for the next computational step. This normalization procedure is a standard practice in the DEMATEL method to make the matrix compatible with the mathematical operations that follow.

Once (set at 10) is established and the normalized direct-relation matrix is acquired, the subsequent phase involves computing the total influence matrix . This matrix comprehensively encapsulates both the direct and indirect impacts each factor has on the others.

To calculate the matrix, first find the inverse of the difference matrix between the identity matrix and the matrix. This operation is expressed by the following formula:

Here, is the identity matrix, and is the normalized direct-relation matrix. The subtraction represents the relative influence of factors on each other, while the inversion of this matrix, , is a critical step in DEMATEL that allows for the capture of both direct and indirect influences. This is a key feature of the method, as it accounts for the complex feedback loops and chains of influence within the system.

Therefore, the matrix is obtained by multiplying the matrix by its inverse.

This final calculation combines the direct influence scores from matrix with the indirect influences captured in the inverse matrix, resulting in the total influence matrix . The elements of this matrix, , represent the total (direct and indirect) influence that factor exerts on factor . The resulting matrix consolidates both direct and indirect influences among the factors, offering a holistic view of the interdependencies within the system.

Selecting the -threshold is a pivotal step in the DEMATEL methodology, as it is what separates meaningful causal links from those that are negligible. In this study, we determined the threshold value by calculating the arithmetic mean of all elements in the total influence matrix (). This approach is a widely accepted standard in the field, as it acts as an objective filter to ensure that only influences exceeding the average total effect are retained for analysis. Consequently, any relationship with a value in the matrix greater than the -threshold is considered a significant causal or effect factor. By filtering out weaker relationships that might otherwise introduce ‘noise’ into the analysis, this method strengthens the validity and clarity of the causal map, enabling us to focus on the most essential interdependencies within the system. To determine a significance threshold () for interpreting these influences, the following formula is employed:

where ; this represents the total number of possible relationships between the factors in the matrix .

Here, denotes the cumulative number of factors, and refers to an individual entry within the matrix. Subsequent to computing the total influence matrix , two key metrics are ascertained for every factor: the impact score (), which quantifies the cumulative influence a factor ‘’ exerts on all others, and the causality score (), which indicates the total influence a factor ‘’ receives from the remaining factors.

is the total number of relationships or elements in the influence matrix, where .

This threshold value is derived from the average of all the elements in the total influence matrix, providing a data-driven benchmark to identify the most significant relationships. The value of 0.577 is the calculated average of the total influence matrix elements for this specific study, making it a relevant and applicable threshold for a clear visual representation of the most impactful connections.

The impact score for each factor is calculated as the sum of its influence on all other factors:

where . This formula sums the elements in each row of the total influence matrix . A higher value indicates that the factor has a greater total influence on the other factors in the system.

The causal score for each factor is calculated as the sum of the influence of the factors on it:

where . This formula sums the elements in each column of the total influence matrix . A higher value indicates that the factor is more influenced by the other factors in the system.

4. Results

The DEMATEL method was used to analyze the critical factors influencing the automotive industry’s transition to a circular economy. Six professionals with extensive experience in the automotive industry participated in this qualitative study, contributing 2, 4, 10, 15, and 20 years of experience. Their collective expertise was crucial in evaluating the interactions between the critical factors involved in the sustainable transformation of value chains to a circular economy. The results obtained detail the normalized matrix of direct relationships, the total influence matrix, and the assessment of the influence and causality of each factor.

The initial stage of the DEMATEL analysis involved constructing a normalized matrix of direct relationships, capturing the average influence scores assigned by the experts to each pair of factors. This matrix, presented in Table 2, is fundamental to understanding the direct relationships between the ten critical factors.

Table 2.

Normalized direct relations matrix.

The next step was to calculate the total influence matrix (), which summarizes the direct and indirect influences between factors (Table 3). This matrix provides a comprehensive overview of the system’s interdependencies, enabling the identification of factors that significantly impact others.

Table 3.

Total influence matrix highlighting (*) factors with significant influence (.

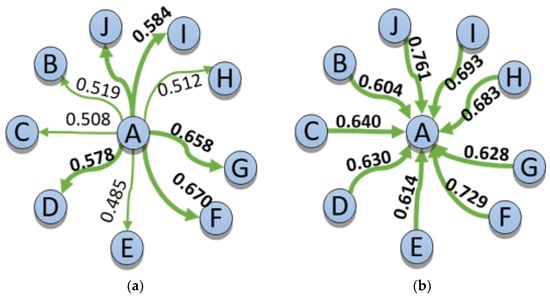

Figure 2 offers a lucid depiction of the interplay among the various factors, detailing both the impacts each factor has on others and the influences it receives. To facilitate a clearer comprehension by focusing on individual elements, the lines connecting these factors have been re-scaled. A bolder line indicates where the influence score meets or surpasses the predetermined threshold of 0.577, thereby drawing attention to the more significant connections within the network.

Figure 2.

Influence relationships of factor A: (a) Network of influence from factor A to the other factors; (b) Network of influence on factor A from the other factors, where A Top management commitment, B Stakeholder engagement, C Regulatory alignment and policies, D Technological capability, E Internal integration, F Sustainable material and recycling management, G Ecodesign and product sustainability conception, H Organizational culture and awareness, I Circular business models and value strategy, and J Innovation and research and development capacity.

After calculating the total influence matrix , two key scores were determined for each factor: the impact score and the causality score , which quantifies the cumulative influence that factor exerts on all the others, and the causality score , which indicates the total influence that factor ‘’ receives from the others. These scores, together with the dominant characteristic of each factor (cause or effect), are presented in Table 4.

Table 4.

Assessment of the influence and causality of factors.

Table 3 shows that the () scores indicate the total importance of each factor in the system, while the () scores show whether a factor predominantly causes or is caused by other variables.

Those with a positive () value are considered causal factors, exerting a greater direct and indirect influence on other factors than they receive. According to Table 3, these factors are the following:

- C (Alignment and regulatory policies): With a score of 0.483, this factor indicates that regulations and policies are an important driver for the implementation of the circular economy in the automotive industry.

- E (Internal integration): With a score of 0.777, internal integration is a strong causal factor, highlighting the importance of coordination and collaboration between departments for effectively implementing circular economy practices.

- H (Organizational culture and awareness): With a score of 0.800, organizational culture emerges as the strongest causal factor, underscoring the importance of fostering an environment that supports innovation, environmental responsibility, and continuous learning for the successful transition to a circular economy.

- I (Circular business models and value strategy): A score of 0.330 indicates that developing and implementing new business approaches that generate value from extended product use and resource recovery is a key driver.

- J (Innovation and R&D capacity): With a score of 0.217, innovation and R&D capacity are also causal factors, highlighting their critical role in generating and implementing innovations specific to the circular economy.

Conversely, factors with a negative value are considered to be effect factors, being more influenced by other factors than influencing them. These are:

- A (top management commitment): With a score of −0.825, top management commitment is strongly influenced by other factors. This suggests that, although it is crucial, managerial support is less influential.

- B (Stakeholder engagement): With a score of −0.206, stakeholder engagement is an effect too, suggesting that collaborative efforts depend on various internal and external factors.

- D (Technological capacity): With a score of −0.175, this factor shows that the ability to acquire and utilize advanced technologies is influenced by other elements within the system.

- F (Sustainable materials management and recycling): This factor has the lowest score of −1.253, indicating that the effectiveness of materials management and recycling depends significantly on the influence of other causal factors in the system.

- G (Ecodesign and product sustainability design): With a score of −0.148, ecodesign is also an effect, suggesting that sustainable design principles result from the implementation of other key factors.

The D + R scores provide insight into the prominence or importance of each factor in the system. Factor J (Innovation and R&D capacity) has the highest () score of 13.040, closely followed by Factor G (Ecodesign and product sustainability design) with 12.996. Despite being an effect factor, these values indicate that both are extremely important elements in the context of the transition to a circular economy, as they have the highest degree of interaction with other factors in the system. In contrast, factor E (internal integration), although a causal factor, has the lowest () score of 10.129, suggesting that its overall importance in the system is relatively low, despite being a driver of change.

These results highlight the complex interdependencies between key factors, providing a solid basis for intervention strategies and enabling decision-makers to focus on causal factors to generate a positive systemic impact on the implementation of the circular economy in the automotive industry.

To provide an in-depth analysis of how key causal factors affect effect factors, as suggested by the reviewers, an examination of the relationships revealed in the total influence matrix is necessary. For example, the effectiveness of sustainable materials and recycling management (F), the strongest effect factor, is highly dependent on other causal factors. The highest influence on factor F is exerted by factor J (innovation and R&D capacity) with a score of 0.768, followed by H (organizational culture and awareness) with 0.707 and I (circular business models and value strategy) with 0.688. This suggests that to improve sustainable material management, managers should first focus on fostering a culture of environmental responsibility and awareness (H) and investing in R&D (J) to develop new recycling technologies, which in turn will enable more effective business models (I) that support resource recovery. Similarly, top management commitment (A), another strong effect factor, is most influenced by J (Innovation and R&D capacity) with a score of 0.761, I (circular business models and value strategy) with 0.693, and H (Organizational culture and awareness) with 0.683. This indicates that a strong and visible commitment from top management is likely to emerge as a result of a robust organizational culture and awareness (H), and after the successful implementation of innovative R&D (J) and circular business models (I), rather than being an initial driver itself. This detailed analysis of interdependencies provides specific, actionable guidance for practitioners, enabling them to target upstream causal factors to achieve systemic improvements.

5. Discussion

The present study, which investigated and ranked the critical factors influencing the automotive industry’s transition to a circular economy using the DEMATEL methodology, reveals both significant convergences and divergences with recent literature. This section comparatively analyzes our findings with research published in the last five years, offering a scientific contextualization of the present contribution and addressing potential limitations identified by critical reviewers.

A key reference point is the study by Badhotiya et al. [36]. Although this study focuses on barriers in manufacturing SMEs, it offers relevant insights. Badhotiya et al. identify ‘lack of top management commitment’ as a major barrier. This finding is consistent with our result that A (top management commitment) is an effect factor, as evidenced by a score () of −0.825. This suggests that, while top-level commitment is indispensable for the success of the transition, it is not an independent causal variable, but rather a consequence of pre-existing conditions or favorable strategies. It is important to note that the DEMATEL method identifies the dominant cause-and-effect relationships within the current system, providing an overview of the influences at play. Although top management commitment is undoubtedly essential for initiating change, classifying it as an ‘effect’ factor suggests that, in this model, it is strongly influenced by other foundational elements, such as a receptive organizational culture, supportive policies, and visible innovation capacity, which create an environment conducive to such commitment. This emphasizes the cyclical and dynamic nature of these interactions, whereby long-term commitment may arise in response to positive feedback loops initiated by other causal factors. Similarly, ‘lack of knowledge and awareness’ is a barrier cited by Badhotiya et al., which validates the fundamental importance of our causal factor H (organizational culture and awareness). With a score of 0.8, this factor was identified as the strongest causal factor in our study. This emphasizes that a conducive organizational culture and a high level of awareness are critical prerequisites for overcoming obstacles and cultivating the necessary commitment in the context of circularity.

Another relevant study for comparison is that conducted by Amit Patel and Sumer Singh [37]. This study is directly relevant given its methodological (use of DEMATEL) and sectoral (automotive industry) alignment. Amit Patel and Sumer Singh emphasize the importance of ‘government support and policy’ as a causal factor. This conclusion aligns with our finding that C (alignment and regulatory policies) is a significant causal factor, with a score of 0.483. Both studies converge on the decisive role of the regulatory framework and institutional support in facilitating the implementation of the circular economy. Furthermore, Amit Patel and Sumer Singh mention ‘technology and innovation’ as a high-impact factor, which aligns with our identification of J (innovation and R&D capacity) as a causal factor ( score: 0.217) and the factor with the highest global prominence in the system ( score: 13,040). This convergence indicates an academic consensus on the transformative role of technological innovation in the transition to circularity.

However, a notable distinction can be observed in the classification of certain factors. While the study by Amit Patel and Sumer Singh [37] may emphasize external supply chain aspects, our study identified E (internal integration) as a strong causal factor ( score: 0.777). This classification highlights the primary role of intra-organizational cohesion and collaboration as intrinsic drivers of circular transformation. It suggests that the effectiveness of circular economy strategies depends on a solid internal foundation.

In addition, Amit Patel and Sumer Singh [37] address ‘supply chain collaboration’ as a key factor. By contrast, in our study, stakeholder engagement (B) is categorized as an effect factor ( score: −0.206). This difference suggests a nuance in the perception of causality: while some researchers may consider collaboration to be a prerequisite, our results suggest that effective stakeholder engagement is instead a consequence of fundamental causal factors such as policies, organizational culture, and innovation capacity. This difference suggests a nuance in the perception of causality: while some researchers may consider collaboration to be a prerequisite, our results suggest that effective stakeholder engagement is instead a consequence of fundamental causal factors such as policies, organizational culture, and innovation capacity.

Furthermore, factor F (sustainable materials and recycling management) was identified as the strongest effect factor in our study ( score: −1.253). This implies that although implementing effective resource management and recycling practices is a pillar of the circular economy, the success of these practices depends significantly on the presence and maturity of strategic and cultural causal factors. This perspective reconfirms the hypothesis that the operational and technical aspects of circularity are facilitated and conditioned by a well-defined strategic and organizational framework.

A third relevant study for comparison is that by Singh et al. [11]. This research focuses on assessing the impact of digital transformation on green supply chains for achieving carbon neutrality and accelerating circular economy initiatives. While their study broadly covers the impact of digital transformation, it implicitly highlights the importance of factors such as technological capability and innovation, which are central to our analysis.

Specifically, Singh et al. [11] emphasize the role of digital technologies in enabling green supply chains. This resonates with our factor D (technological capability) and J (innovation and R&D capacity). While our study categorizes technological capability (D) as an effect factor ( score: −0.175), suggesting it is influenced by other elements, and Innovation and R&D capacity (J) as a causal factor ( score: 0.217) with high prominence ( score: 13.040), Singh et al. [11] underscore the overarching impact of digital transformation. This convergence indicates that advanced technologies and continuous innovation are universally recognized as crucial for circular economy transitions, whether as drivers or as outcomes influenced by strategic frameworks.

A point of divergence lies in the emphasis on specific aspects. While Singh et al. [11] delve into the broader implications of digital transformation for carbon neutrality and green supply chains, our study, within the automotive sector, provides a more granular view of internal factors. For instance, our strong causal factors like E (internal integration) and H (organizational culture and awareness) are not explicitly foregrounded as causal in the same way within the scope of digital transformation studies like Singh et al. [11]. This suggests that while technological advancements are undoubtedly enablers, the internal readiness and cultural alignment of an organization are equally, if not more, fundamental for effectively integrating these technologies and realizing circular economy goals within a specific industry context like automotive.

The distinctive contribution of our study to the existing DEMATEL literature in the automotive and manufacturing sectors lies in its clear identification of intrinsic, foundational causal factors [38]. Specifically, the results position organizational culture and internal integration not merely as supporting elements, but as powerful causal factors that directly influence the success of other circular economy initiatives. This contrasts with many existing studies that tend to emphasize external factors, such as supply chain collaboration or regulatory policies, as the primary antecedents of change [39]. These results offer a more nuanced perspective, suggesting that an organization must first cultivate a robust internal environment before it can effectively leverage external opportunities and overcome barriers [40]. Based on this identification of causal factors, the following concrete and actionable recommendations are provided for managers and decision-makers in the automotive industry.

To leverage causal factor H (organizational culture), the strongest identified in the study, managers should prioritize the development of a strong circular economy culture [41]. This can be achieved through dedicated training programs that raise awareness and educate employees at all levels of the organization [42]. Similarly, the creation of reward systems and the establishment of performance indicators that incentivize employee contributions to circularity goals are essential for sustaining the new value system [43]. Another effective approach is to implement cross-functional teams and internal collaboration programs to ensure knowledge and resource sharing [44].

To address factor E (internal integration), companies must eliminate departmental silos [45]. An effective strategy is to form cross-functional teams that include members from research and development, production, and marketing to ensure that circularity principles are integrated from the product conception phase [46]. Investments in unified digital platforms that provide real-time data on material and waste flows are crucial to facilitate collaboration and provide a single source of truth for all departments [47].

Factor C (regulatory policies and alignment) suggests that, while policies are an external driver, companies can be proactive [48]. This can be achieved through active involvement in lobbying efforts and collaboration with industry associations to influence the development of favorable regulations [49]. Such involvement transforms compliance from a mere obligation into a strategic advantage, allowing companies to anticipate and adapt quickly to new requirements [50].

Finally, to capitalize on J (innovation and research and development capacity), it is recommended to direct research and development efforts towards designing new components and vehicles for durability and recyclability [51]. This includes investigating sustainable materials and advanced recycling technologies [52]. Companies are also encouraged to experiment with new circular business models, such as “product-as-a-service” or vehicle take-back programs at the end of their life cycle, which can generate new revenue streams and reduce resource consumption [53].

The study identified ‘organizational culture and awareness’ (H), ‘internal integration’ (E), ‘regulatory alignment and policies’ (C), ‘circular business models’ (I), and ‘innovation and R&D capacity’ (J) as causal factors, meaning they exert a greater direct and indirect influence on other factors than they receive. Specifically, ‘organizational culture and awareness’ (H) was identified as the strongest causal factor, emphasizing the importance of fostering an environment that supports innovation, environmental responsibility, and continuous learning for a successful transition to a circular economy. ‘Internal integration’ (E) was found to be a strong causal factor, emphasizing the crucial role of coordination and collaboration between departments in the effective implementation of circular economy practices. ‘Regulatory alignment and policies’ (C) is an important driver, indicating the significant role of legislative frameworks and environmental policies. ‘Circular business models and value strategy’ (I) and ‘innovation and R&D capacity’ (J) were also identified as key drivers in generating value through extended product use, resource recovery, and the implementation of innovations specific to the circular economy.

Conversely, ‘top management commitment’ (A), ‘stakeholder engagement’ (B), ‘technological capability’ (D), ‘sustainable materials and recycling management’ (F), and ‘ecodesign and product sustainability conception’ (G) were identified as effect factors that are more influenced by other factors in the system. ‘Sustainable materials and recycling management’ (F) had the lowest score, indicating its high dependence on other causal factors for effective implementation. Although ‘top management commitment’ (A) is important, it was found to be strongly influenced by other factors, suggesting that it is a consequence of existing conditions or favorable strategies rather than an independent causal variable. ‘Innovation and R&D capacity’ (J) and ‘ecodesign and product sustainability design’ (G) exhibited the highest scores, indicating their significant overall importance and degree of interaction within the system, despite ecodesign being an effect factor.

Overall, our study validates the importance of macro-strategic factors such as government regulations and innovation capacity—a conclusion that aligns with existing literature. The distinctive contribution of our research lies in identifying and prioritizing intrinsic causal factors.

6. Conclusions

This study used the DEMATEL methodology to analyze and rank the critical factors influencing the automotive industry’s transition to a circular economy. This approach offered valuable insights into the factors’ interdependencies and provided a framework for effective transition strategies. Ten critical factors were identified through a theoretical analysis of the literature and expert knowledge in the field. The DEMATEL analysis, conducted with input from six EU automotive sector professionals, revealed key interdependencies among these factors.

In summary, this study provides actionable, practical, and applicable conclusions for decision-makers. By identifying the causal and effect factors, an explicit strategic framework emerges: to improve an effect factor, such as sustainable materials and recycling management (F), managers should direct their efforts toward strengthening the causal factors that determine it. This practical guidance on targeted interventions is an essential utility of this research. The proposed methodological framework promotes decision-support tools for complex systems undergoing sustainability-oriented reconfiguration. The original contribution of this research lies in identifying organizational culture and internal integration as the main causal factors, which are often overlooked in macro-level analyses. This provides insights into the necessary building blocks for successful transitions to the circular economy. The findings corroborate the existing literature on the significance of macro-strategic factors, such as government regulations and innovation capacity. This study confirms that ‘government support and policy’ and ‘technology and innovation’ are high-impact causal factors, consistent with similar research.

However, one clear distinction is the classification of ‘internal integration’ as a strong causal factor, highlighting the decisive role of intra-organizational cohesion. Furthermore, while some studies consider ‘supply chain collaboration’ to be a prior condition, this research suggests that ‘stakeholder engagement’ is an effect factor influenced by more relevant causal factors such as policies, organizational culture, and innovation capacity. Identifying ‘sustainable materials and recycling management’ as the strongest effect factor further confirms that the operational and technical aspects of circularity are facilitated and conditioned by a well-defined strategic and organizational framework.

This study is based on the expertise of a group of voluntarily selected professionals rather than on a large panel for statistical generalization. Although the panel of six experts provides sufficient qualitative information from a methodological point of view, it is recognized that this inherently limits the direct generalizability of the conclusions to the EU automotive sector as a whole. The selection process for the participants focused on their managerial experience and the relevance of their work to industrial supply chains and sustainability projects within the automotive industry. The goal was to obtain expert insights in line with the procedures of the DEMATEL method. The results of this study reflect the expert opinions of these specialists, while future research would be needed to verify if these results are confirmed by a larger and more varied group of experts or through empirical studies to make the findings more widely applicable.

It can also be noted that the results of the five-point influence scale used in the DEMATEL method depend on the experts’ personal perception and evaluation, which can differ. Calculating the average scores within the expert panel aims to mitigate individual biases and achieve a collective understanding of influence. Although this process normalizes subjective assessments, the DEMATEL method lies in its ability to uncover structural relationships and dominant influences within a complex system, even with subjective inputs. The consistency in the identified causal and effect factors identified in the multiple contributions of experts enhances the consistency of the derived interdependencies, providing a structured map of influence pathways that is useful for strategic decision-making, despite individual perceptual differences.

This study primarily employs a qualitative and theoretical approach to the DEMATEL method, with a focus on establishing a prioritization framework based on interdependencies driven by expert opinion. We acknowledge the absence of quantitative validation or empirical data from real-world automotive companies as a limitation of this study. The ‘Results’ Section presents the calculated matrices and scores based on expert assessments. These reveal the theoretical relationships between the factors. Another important step for future research is to validate these connections and strategies using empirical studies, such as case studies or pilot projects within automotive organizations. These will demonstrate if the results obtained can be applied to practice and how useful they are in real-world scenarios.

In conclusion, by determining which variables are independent and which are dependent, this study supports strategic planning and taking focused action. This can result in a stronger and more competitive automotive sector, as it moves towards the circular economy.

To increase the potential of this research for future endeavors, the following recommendations for future research are suggested: conducting empirical studies, potentially through large-scale surveys or longitudinal case studies within diverse automotive companies, to quantitatively validate the identified causal relationships and their practical impact on the implementation of the circular economy. Additionally, exploring the application of dynamic systems models could simulate the evolution of these interdependencies over time by accounting for feedback loops and non-linear effects. This would provide a clearer understanding of how factors influence each other in an ongoing operational context. A major distinction can be noted in the classification of certain factors. While some studies may emphasize external aspects of the supply chain, the present study identified internal integration (E) as a strong causal factor ( score: 0.777). These rankings highlight the primary role of intra-organizational cohesion and collaboration as intrinsic drivers of circular transformation. This is a significant contribution because it reveals that the internal organizational readiness is a key requirement for a successful change towards the circular economy. Furthermore, a major benefit of this study is that it helps develop focused actions. When it is difficult to directly influence certain effect factors, such as ‘sustainable materials and recycling management’ (F), the framework demonstrates how other related causal factors, such as ‘organizational culture and awareness’ (H) or ‘regulatory alignment and policies’ (C), can be used strategically. Using these connections offers decision-makers a more effective and systemic way to achieve the desired outcomes.

In addition, inviting more relevant stakeholders to the expert panel, such as policymakers, technology developers, and representatives from different levels of the automotive supply chain, can provide a wider range of perspectives. Applying the DEMATEL method to other industries going through similar challenges could also help to identify shared characteristics and unique factors, which would enrich the overall knowledge base on the circular economy. Finally, integrating these identified cause-and-effect factors into a framework that supports the development of specific, measurable, achievable, relevant, and time-bound performance indicators would enable organizations to track their progress towards a circular model and assess the effectiveness of their interventions based on these findings.

Author Contributions

Conceptualization, R.-M.N., D.-C.D., S.-E.I. and V.-D.B.; methodology, R.-M.N., D.-C.D., S.-E.I. and V.-D.B.; validation, R.-M.N. and S.-E.I.; formal analysis, R.-M.N., S.-E.I. and V.-D.B.; investigation, S.-E.I. and V.-D.B.; resources, R.-M.N., D.-C.D., S.-E.I. and V.-D.B.; data curation, S.-E.I. and V.-D.B.; writing—original draft preparation, R.-M.N., S.-E.I. and V.-D.B.; writing—review and editing, R.-M.N., D.-C.D., S.-E.I. and V.-D.B.; visualization, R.-M.N., S.-E.I. and V.-D.B.; supervision, D.-C.D. and S.-E.I.; project administration, S.-E.I.; funding acquisition, D.-C.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research and the APC was funded by the National University of Science and Technology “Politehnica”—Bucharest through the PubArt program.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

This work has been supported by: (1) Research Program Nucleu within the National Research Development and Innovation Plan 2022–2027, carried out with the support of MCID, project no. PN 23 43 04 01, PN 23 43 05 03 and PN 23 43 05 02; (2) Support Center for Inte rnational RDI Projects in Mechatronics and Cyber-Mix-Mechatronics, Contract no. 323/22.09.2020, project co-financed by the European Regional Development Fund through the Competitiveness Operational Program (POC) and the national budget.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix A

The direct relation matrix (Table A1) is included in the Appendix to provide transparent documentation of the study’s qualitative inputs. As this matrix contains the arithmetic means of the questionnaire responses, it provides readers and other researchers with the raw data used for the DEMATEL analysis. This approach enhances the reproducibility of the study and allows for independent verification of our results, thereby strengthening the validity of our conclusions.

Table A1.

Direct-relation matrix.

Table A1.

Direct-relation matrix.

| Factor | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| A | 0.000 | 1.667 | 2.833 | 3.000 | 2.667 | 3.333 | 3.000 | 2.167 | 3.167 | 3.000 |

| B | 3.000 | 0.000 | 2.000 | 2.000 | 2.200 | 2.600 | 2.600 | 2.200 | 3.000 | 2.800 |

| C | 3.400 | 3.200 | 0.000 | 2.400 | 1.800 | 2.600 | 2.600 | 2.400 | 2.200 | 3.000 |

| D | 3.000 | 2.800 | 2.400 | 0.000 | 2.000 | 3.200 | 3.400 | 1.800 | 2.000 | 3.000 |

| E | 3.000 | 2.400 | 2.600 | 2.800 | 0.000 | 3.000 | 3.000 | 2.600 | 1.800 | 2.400 |

| F | 2.800 | 2.000 | 3.000 | 2.200 | 1.800 | 0.000 | 3.200 | 2.200 | 2.800 | 3.000 |

| G | 3.200 | 3.200 | 2.400 | 3.200 | 2.600 | 3.600 | 0.000 | 3.000 | 3.200 | 3.800 |

| H | 3.200 | 2.200 | 2.600 | 2.600 | 2.000 | 3.800 | 3.600 | 0.000 | 2.400 | 3.400 |

| I | 3.400 | 2.600 | 2.600 | 3.000 | 2.000 | 3.000 | 3.200 | 2.600 | 0.000 | 3.400 |

| J | 3.600 | 3.200 | 2.800 | 3.000 | 2.600 | 3.600 | 4.000 | 3.000 | 3.400 | 0.000 |

Where A Top management commitment, B Stakeholder engagement, C Regulatory alignment and policies, D Technological capability, E Internal integration, F Sustainable material and recycling management, G Ecodesign and product sustainability conception, H Organizational culture and awareness, I Circular business models and value strategy, and J Innovation and research and development capacity.

References

- Nechita, R.-M.; Ulerich, O.; Radoi, E.-A. Risk Management in Research Projects. FAIMA Bus. Manag. J. 2024, 12, 15–23. [Google Scholar]

- Roșu, O.B.; Voicu, G.; Coman, G.; Constantin, G.-A.; Paula, T. Research on the Hardness and Metallographic Structure of Steel for the Furrow Openers from Cereal Seeders. Bul. Stiintific-Univ. Politeh. Din Bucur. 2025, 87, 257–268. [Google Scholar]

- Bechtsis, D.; Tsolakis, N.; Vlachos, D.; Srai, J.S. Intelligent Autonomous Vehicles in Digital Supply Chains: A Framework for Integrating Innovations towards Sustainable Value Networks. J. Clean. Prod. 2018, 181, 60–71. [Google Scholar] [CrossRef]

- Agi, M.A.N. Understanding the Enablers of Blockchain Technology Adoption in Sustainable Supply Chains: A DEMATEL-Based Analysis. IFAC-PapersOnLine 2022, 55, 1962–1967. [Google Scholar] [CrossRef]

- Estiri, M.; Dahooie, J.H.; Vanaki, A.S.; Banaitis, A.; Binkytė-Vėlienė, A. A Multi-Attribute Framework for the Selection of High-Performance Work Systems: The Hybrid DEMATEL-MABAC Model. Econ. Res.-Ekon. Istraž. 2021, 34, 970–997. [Google Scholar] [CrossRef]

- Grecu, I.; Nechita, R.-M.; Ulerich, O.; Dumitrescu, C.-I. Multi-Attribute Decision-Making for Intelligent Allocation of Human Resources in Industrial Projects. Adm. Sci. 2025, 15, 181. [Google Scholar] [CrossRef]

- Sun, C.-C. An Intuitionistic Linguistic DEMATEL-Based Network Model for Effective National Defense and Force Innovative Project Planning. IEEE Access 2021, 9, 130141–130153. [Google Scholar] [CrossRef]

- Coker, K.K.; Flight, R.L.; Valle, K.N. Social Entrepreneurship: The Role of National Leadership Culture. J. Res. Mark. Entrep. 2017, 19, 125–139. [Google Scholar] [CrossRef]

- Dalton, K.; Kennedy, L. Management Culture in Romania: Patterns of Change and Resistance. JEEMS J. East Eur. Manag. Stud. 2007, 12, 232–259. [Google Scholar] [CrossRef]

- Akash, M.H.; Aziz, R.A.; Karmaker, C.L.; Bari, A.B.M.M.; Kabir, K.M.A.; Islam, A.R.M.T. Investigating the Attributes for Implementing Circular Economy in the Textile Manufacturing Supply Chain: Implications for the Triple Bottom Line of Sustainability. Sustain. Horiz. 2025, 14, 100129. [Google Scholar] [CrossRef]

- Singh, K.; Chaudhuri, R.; Chatterjee, S. Assessing the Impact of Digital Transformation on Green Supply Chain for Achieving Carbon Neutrality and Accelerating Circular Economy Initiatives. Comput. Ind. Eng. 2025, 201, 110943. [Google Scholar] [CrossRef]

- Provensi, T.; Marcon, M.L.; Sehnem, S.; Campos, L.M.S.; de Queiroz, A.F.S.L. Exploring ESG and Circular Economy in Brazilian Companies: The Role of Stakeholder Engagement. Benchmarking Int. J. 2025; ahead-of-print. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Appolloni, A.; Liu, J. Linking Top Management Commitment and Circular Practice Through Human Resource Perspective: Do Diversity, Equity, and Inclusion (DEI) Make a Difference in Sustainability? Corp. Soc. Responsib. Environ. Manag. 2025, 32, 2746–2768. [Google Scholar] [CrossRef]

- Grecu, I.; Belu, N.; Rachieru, N. Risk Measurement and Prioritization Using Fuzzy FMEA Approach—A Study of Processes in the Automotive Industry. In Proceedings of the International Conference on Management and Industrial Engineering; Niculescu Publishing House: Bucharest, Romania, 2019; pp. 325–335. [Google Scholar]

- Onukwulu, E.C.; Dienagha, I.N.; Digitemie, W.N.; Egbumokei, P.I.; Oladipo, O.T. Enhancing Sustainability through Stakeholder Engagement: Strategies for Effective Circular Economy Practices. South Asian J. Soc. Stud. Econ. 2025, 22, 135–150. [Google Scholar] [CrossRef]

- Tabas, A.M.; Rehman, M.A.; Khitous, F.; Urbinati, A. Stakeholder and Customer Engagement in Circular Economy Ecosystems: A Systematic Literature Review and Research Agenda. Bus. Strategy Environ. 2025, 34, 402–416. [Google Scholar] [CrossRef]

- Dong, X.; Qiu, W. A Method for Managing Scientific Research Project Resource Conflicts and Predicting Risks Using BP Neural Networks. Sci. Rep. 2024, 14, 9238. [Google Scholar] [CrossRef]

- Boakye, P.B.; Akparep, J.Y.; Salakpi, A. Enhancing Environmental Quality through Board Dynamics: The Role of Environmental Regulations in Advancing Circular Economy in the SSA Region. Circ. Econ. Sust. 2025, 5, 1757–1783. [Google Scholar] [CrossRef]

- Bajenaru, V.-D.; Istriteanu, S.-E. Waste from Dismantling of End-of-Life Vehicles. In Proceedings of the International Conference on Reliable Systems Engineering (ICoRSE)-2024; Cioboată, D.D., Ed.; Springer Nature: Cham, Switzerland, 2024; pp. 152–164. [Google Scholar]

- Alexe, C.M. Designing Knowledge Bases for Industrial Products; Printech: Bucharest, Romania, 2019; ISBN 978-606-23-0954-1. [Google Scholar]

- Istriteanu, S.; Bajenaru, V.; Badea, D.-M. Aspects Regarding Eco-Innovation Practice and Trends for a Sustainable Automotive Industry. Int. J. Mechatron. Appl. Mech. 2022, 1, 5. [Google Scholar] [CrossRef]

- Neri, A.; Cagno, E.; Susur, E.; Urueña, A.; Nuur, C.; Kumar, V.; Franchi, S.; Sorrentino, C. The Relationship between Digital Technologies and the Circular Economy: A Systematic Literature Review and a Research Agenda. R&D Manag. 2025, 55, 617–713. [Google Scholar] [CrossRef]

- Fusillo, F.; Quatraro, F.; Santhià, C. Leveraging on Circular Economy Technologies for Recombinant Dynamics: Do Localised Knowledge and Digital Complementarities Matter? Reg. Stud. 2025, 59, 2329255. [Google Scholar] [CrossRef]

- Crasoveanu, F.-C.; Deselnicu, D.-C.; Dumitrescu, C.L.; Dobrescu, R.; Stanciu, D.R. The Impact of Artificial Intelligence on Sustainable IT Asset Lifecycle Management. FAIMA Bus. Manag. J. 2024, 12, 69–75. [Google Scholar]

- You, P.-S.; Hsieh, Y.-C. Dynamic Allocation Strategy for the Car Rental Industry with Multiple Rental Channels. Available online: https://openurl.ebsco.com/contentitem/doi:10.46604%2Fijeti.2024.13827?sid=ebsco:plink:crawler&id=ebsco:doi:10.46604%2Fijeti.2024.13827 (accessed on 2 July 2025).

- Chernev, A. Strategic Brand Management, 4th ed.; Cerebellum Press: Stockholm, Sweden, 2025. [Google Scholar]

- Purushothaman, R.; Alamelu, R.; Selvabaskar, S.; Sudha, M. Theories, Techniques and Strategies of Sustainable Circular Economy: A Systematic Literature Review. Discov. Sustain. 2025, 6, 297. [Google Scholar] [CrossRef]

- Radu, I.-C.; Vadureanu, A.-M.; Cozorici, D.-E.; Blanzeanu, E.; Zaharia, C. Advancing Sustainability in Modern Polymer Processing: Strategies for Waste Resource Recovery and Circular Economy Integration. Polymers 2025, 17, 522. [Google Scholar] [CrossRef] [PubMed]

- Klose, S.A.; Fröhling, M. A New Circular Economy Conception for Sustainable Product Design. J. Ind. Ecol. 2025, 29, 546–560. [Google Scholar] [CrossRef]

- Istriteanu, S.; Badea, F.; Bajenaru, V. Eco-Innovation and Eco-Design in the Current Automotive Industry. Int. J. Mechatron. Appl. Mech. 2024, 15, 135–145. [Google Scholar] [CrossRef]

- Mishra, S.; Sahoo, D.; Mohapatra, S. Circular Economy Adoption in MSMEs: Unveiling Enablers and Barriers. Int. J. Dev. Issues 2024, 24, 237–263. [Google Scholar] [CrossRef]

- Gallego-Schmid, A.; Vásquez-Ibarra, L.; Guerrero, A.B.; Henninger, C.E.; Rebolledo-Leiva, R. Circular Economy in a Recently Transitioned High-Income Country in Latin America and the Caribbean: Barriers, Drivers, Strengths, Opportunities, Key Stakeholders and Priorities in Chile. J. Clean. Prod. 2025, 486, 144429. [Google Scholar] [CrossRef]

- Alcayaga, A.; Hansen, E.G. Smart Circular Economy as a Service Business Model: An Activity System Framework and Research Agenda. R&D Manag. 2025, 55, 508–530. [Google Scholar] [CrossRef]

- Zils, M.; Howard, M.; Hopkinson, P. Circular Economy Implementation in Operations & Supply Chain Management: Building a Pathway to Business Transformation. Prod. Plan. Control. 2025, 36, 501–520. [Google Scholar] [CrossRef]

- Stochioiu, F.; Stochioiu, C. Thermal Influence on Positioning Error and Position Repeatability of Machining Center Axes. UPB Sci. Bull. Ser. D Mech. Eng. 2021, 83, 181–188. [Google Scholar]

- Badhotiya, G.K.; Avikal, S.; Soni, G.; Sengar, N. Analyzing Barriers for the Adoption of Circular Economy in the Manufacturing Sector. Int. J. Product. Perform. Manag. 2021, 71, 912–931. [Google Scholar] [CrossRef]

- Patel, A.; Singh, S. Implementing Circular Economy Strategies in the Automobile Industry—A Step toward Creating Sustainable Automobiles. Benchmarking Int. J. 2022, 30, 2225–2233. [Google Scholar] [CrossRef]

- Cioca, L.-I.; Ivascu, L.; Turi, A.; Artene, A.; Găman, G.A. Sustainable Development Model for the Automotive Industry. Sustainability 2019, 11, 6447. [Google Scholar] [CrossRef]

- Molla, A.H.; Shams, H.; Harun, Z.; Ab Rahman, M.N.; Hishamuddin, H. An Assessment of Drivers and Barriers to Implementation of Circular Economy in the End-of-Life Vehicle Recycling Sector in India. Sustainability 2022, 14, 13084. [Google Scholar] [CrossRef]

- Bhanot, N.; Qaiser, F.H.; Alkahtani, M.; Rehman, A.U. An Integrated Decision-Making Approach for Cause-And-Effect Analysis of Sustainable Manufacturing Indicators. Sustainability 2020, 12, 1517. [Google Scholar] [CrossRef]

- Wurster, S. Creating a Circular Economy in the Automotive Industry: The Contribution of Combining Crowdsourcing and Delphi Research. Sustainability 2021, 13, 6762. [Google Scholar] [CrossRef]

- Chen, W.-K.; Nalluri, V.; Hung, H.-C.; Chang, M.-C.; Lin, C.-T. Apply DEMATEL to Analyzing Key Barriers to Implementing the Circular Economy: An Application for the Textile Sector. Appl. Sci. 2021, 11, 3335. [Google Scholar] [CrossRef]

- Chishty, S.K. Economic and Environmental Efficiencies of Organizations: Role of Technological Advancements and Circular Economy Practices. Sustainability 2023, 15, 15935. [Google Scholar] [CrossRef]

- Ndanguza, I.; Patience, A. Managerial Competence in Integrating Industry 4.0 with Corporate Social Responsibility for Enhanced Safety Culture in Manufacturing. Sustainability 2025, 17, 4678. [Google Scholar] [CrossRef]

- Al-Quradaghi, S.; Zheng, Q.P.; Betancourt-Torcat, A.; Elkamel, A. Optimization Model for Sustainable End-of-Life Vehicle Processing and Recycling. Sustainability 2022, 14, 3551. [Google Scholar] [CrossRef]

- Hsieh, T.-M.; Chen, K.-Y. Developmental Trajectories of Electric Vehicle Research in a Circular Economy: Main Path Analysis. Sustainability 2024, 16, 8162. [Google Scholar] [CrossRef]

- Vogiantzi, C.; Tserpes, K. On the Definition, Assessment, and Enhancement of Circular Economy across Various Industrial Sectors: A Literature Review and Recent Findings. Sustainability 2023, 15, 16532. [Google Scholar] [CrossRef]

- Ojeda, J.C.O.; de Moraes, J.G.B.; Filho, C.V.d.S.; Pereira, M.d.S.; Pereira, J.V.d.Q.; Dias, I.C.P.; da Silva, E.C.M.; Peixoto, M.G.M.; Gonçalves, M.C. Application of a Predictive Model to Reduce Unplanned Downtime in Automotive Industry Production Processes: A Sustainability Perspective. Sustainability 2025, 17, 3926. [Google Scholar] [CrossRef]

- Martusewicz, J.; Suchorski, K.; Chomiak-Orsa, I.; Usyk, J.; Bednarowicz, Ł.; Łukaszewicz, M. From Organizational Readiness to Industry 5.0: An EFQM Model Pathway to Net Zero. Energies 2025, 18, 2722. [Google Scholar] [CrossRef]

- Tighnavard Balasbaneh, A.; Aldrovandi, S.; Sher, W. A Systematic Review of Implementing Multi-Criteria Decision-Making (MCDM) Approaches for the Circular Economy and Cost Assessment. Sustainability 2025, 17, 5007. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.-H.; Chen, C.-W.; Huang, Y.-F.; Lin, C.-T. Apply Fuzzy DEMATEL to Explore the Decisive Factors of the Auto Lighting Aftermarket Industry in Taiwan. Mathematics 2020, 8, 1187. [Google Scholar] [CrossRef]

- Wicaksono, P.A.; Naufal, T.R.; Saptadi, S.; Susanty, A. Assessing Enablers to a Circular Economy in Indonesian Furniture Industry Using Fuzzy-DEMATel. IOP Conf. Ser. Earth Environ. Sci. 2021, 896, 012051. [Google Scholar] [CrossRef]

- Singh, P.K.; Sarkar, P. A Framework Based on Fuzzy Delphi and DEMATEL for Sustainable Product Development: A Case of Indian Automotive Industry. J. Clean. Prod. 2020, 246, 118991. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).