Advanced Vehicle Electrical System Modelling for Software Solutions on Manufacturing Plants: Proposal and Applications

Abstract

1. Introduction

1.1. From End-of-Line Checks to On-Process Validation

- Wiring data are scattered across multiple supplier documents, often in incompatible formats;

- Harness options are encoded through Boolean rules that must be evaluated for each serial number;

- Existing CAD formats are too heavy for shop floor software that must answer queries in milliseconds.

1.2. Digitalisation Challenges in Modern Manufacturing

1.3. Contribution of This Work

- Process-ready representation. The two-level graph model is designed not only for archival purposes but also for direct consumption by shop-floor devices and on-process validation stations, enabling real-time querying and decision making.

- Foundation for future tools. By exposing a clean API over a standard data structure, the model accelerates the development of new diagnostic algorithms, complexity metrics, path-finding routines and other software components required by next-generation validation processes.

- Standard display format. The graph provides a consistent view of every harness variant, simplifying human-centred visualisation and interactive debugging across engineering and maintenance teams.

- Digitalisation requirements for suppliers. The proposed format acts as a de facto specification that suppliers can target, ensuring that incoming documentation is machine-readable and immediately integrable into the plant’s information systems.

1.4. Objectives

- 1.

- Faithful representation through complex systems theory. Apply concepts and formalisms from complex systems and network science to model the vehicle wiring harness with a level of granularity and accuracy that mirrors physical reality.

- 2.

- Multilayer extensibility. Design the wiring layer so that it can seamlessly link to future models describing higher-level vehicle communication networks (e.g., CAN, LIN, Automotive Ethernet), ultimately enabling an integrated, multi-layer digital twin.

- 3.

- Stable and scalable data standard. Provide a technology-agnostic, vendor-independent format that is reusable across different vehicle platforms and model years, facilitating supplier compliance and long-term maintainability.

- 4.

- Graph-based analytics. Leverage characteristic graph functions, such as path-finding, centrality, community detection and redundancy analysis, to solve practical problems in validation, diagnostics and optimisation.

1.5. State-of-the-Art

2. Materials and Methods

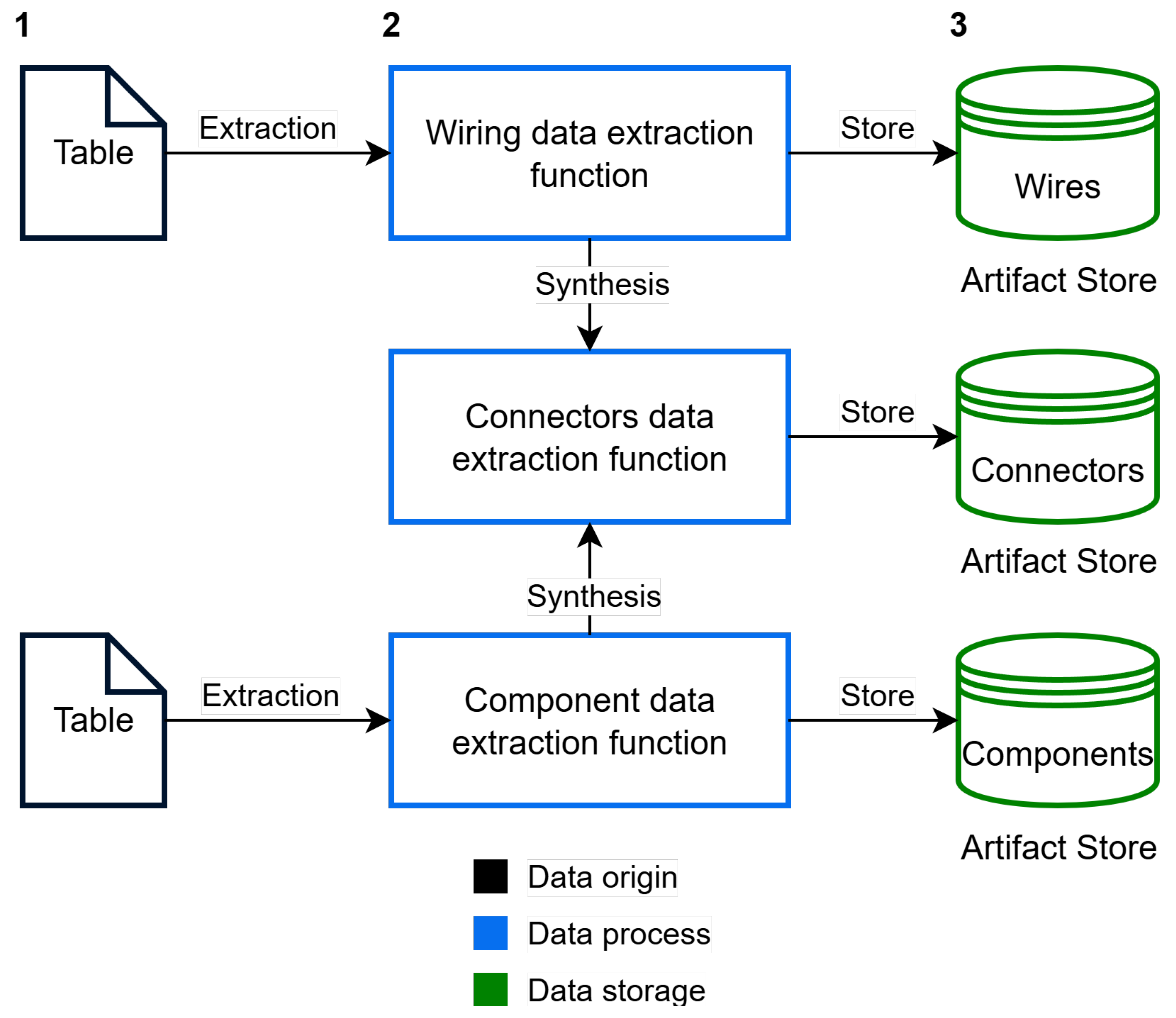

2.1. Data Sources and Acquisition

- “wires” table that lists every individual conductor together with its start and end destinations;

- “components and pin-outs” table that enumerates each harness component (ECUs, Grounds, shields) and the logical pins it exposes.

- No duplication: Normalised stores keyed by “id” prevent inconsistent copies of the same entity.

- Open-closed: New extractors or storage back-ends can be introduced without altering existing code.

- DRY and high cohesion: Validation rules live next to the extractor that generates the data they verify.

2.2. Domain-Driven Modelling

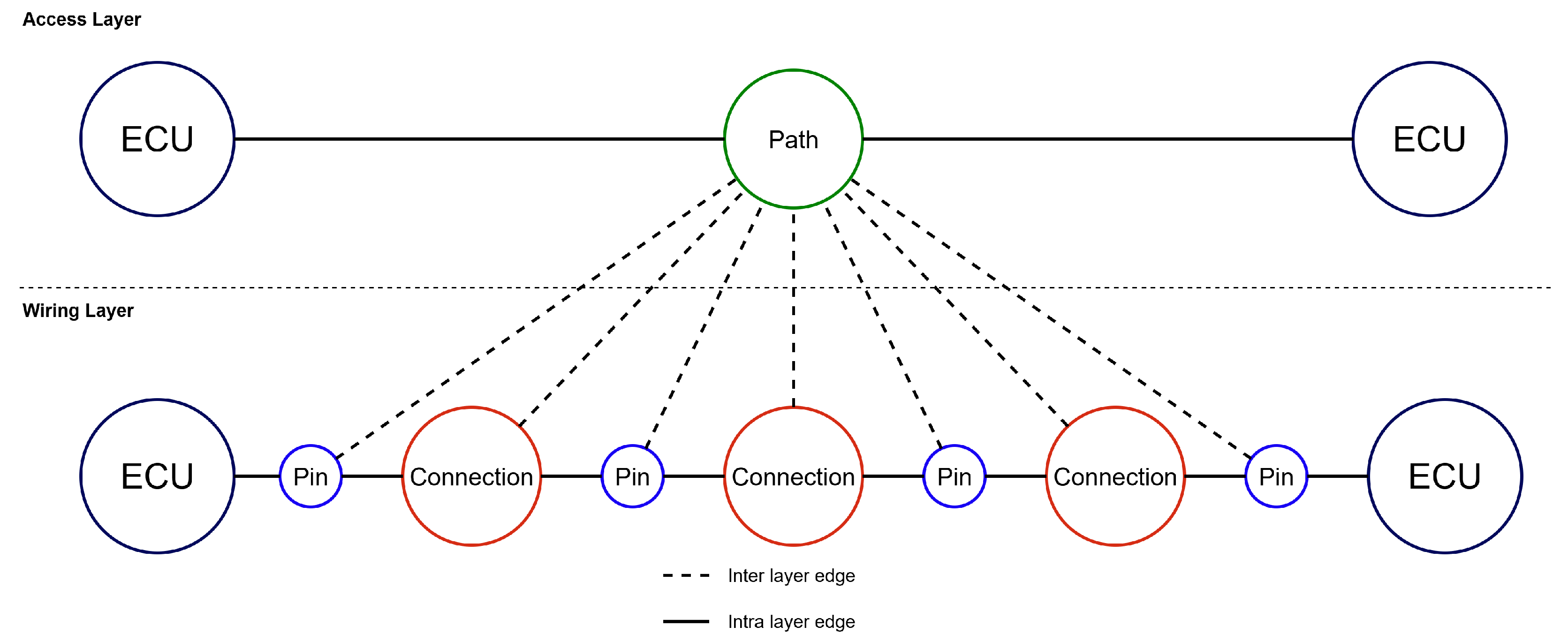

2.2.1. Graph Architecture

- Wiring layer: The shadow of an ECU at this tier is the set of its physical terminations: pins, splices, … Conductive elements themselves are also nodes: each Wire node is linked by plain connect edges to the two Pin nodes it terminates on (or to a Pin and a Splice node, and so forth). This yields an accurate representation of the harness while preserving a one-type-of-edge policy.

- Access layer: The same ECU casts a coarser shadow: a single Component node. Functional bundles are represented explicitly as Path and Circuit nodes; they connect to Component nodes via simple connect edges as well. Thus, a Path node can fan out to several Component nodes without overloading the edge semantics.

2.2.2. Domain Objects Definition

- Component.

- Wire.

- Endpoint.

- Splice: The junction where three or more wires meet;

- ConnectorPin: The terminal located in a cavity of a plug or inline connector;

- Shield: The single lug that grounds a cable braid.

- ComponentPin.

- Connection.

- Circuit.

- Path.

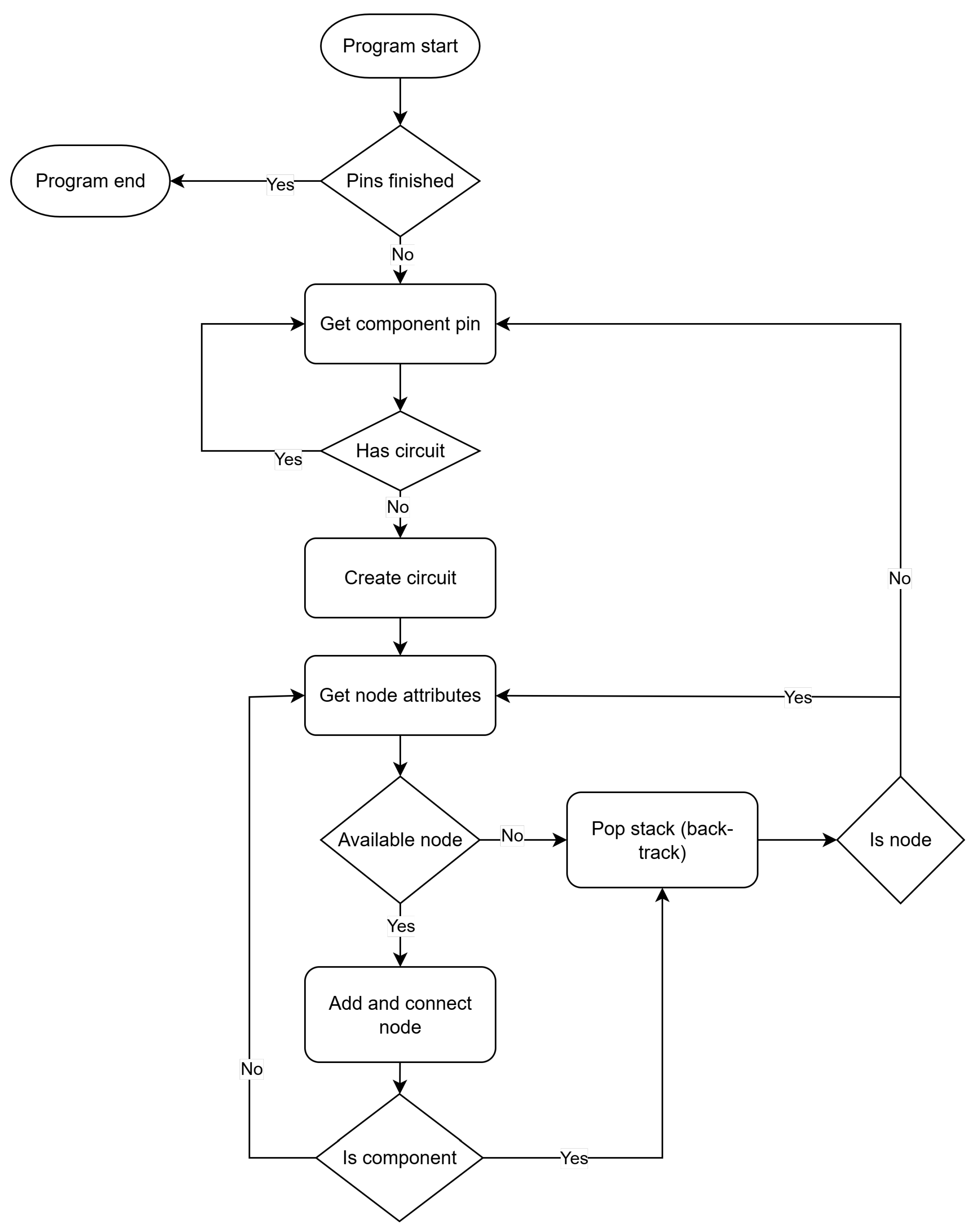

2.3. Graph Construction

2.3.1. Seed Selection

2.3.2. Guided Exploration

2.3.3. Component Encounter and Path Bookkeeping

2.3.4. Back-Tracking and Completion

2.3.5. On-the-Fly Synthesis of Connection Nodes

2.4. Per-Vehicle Filtering

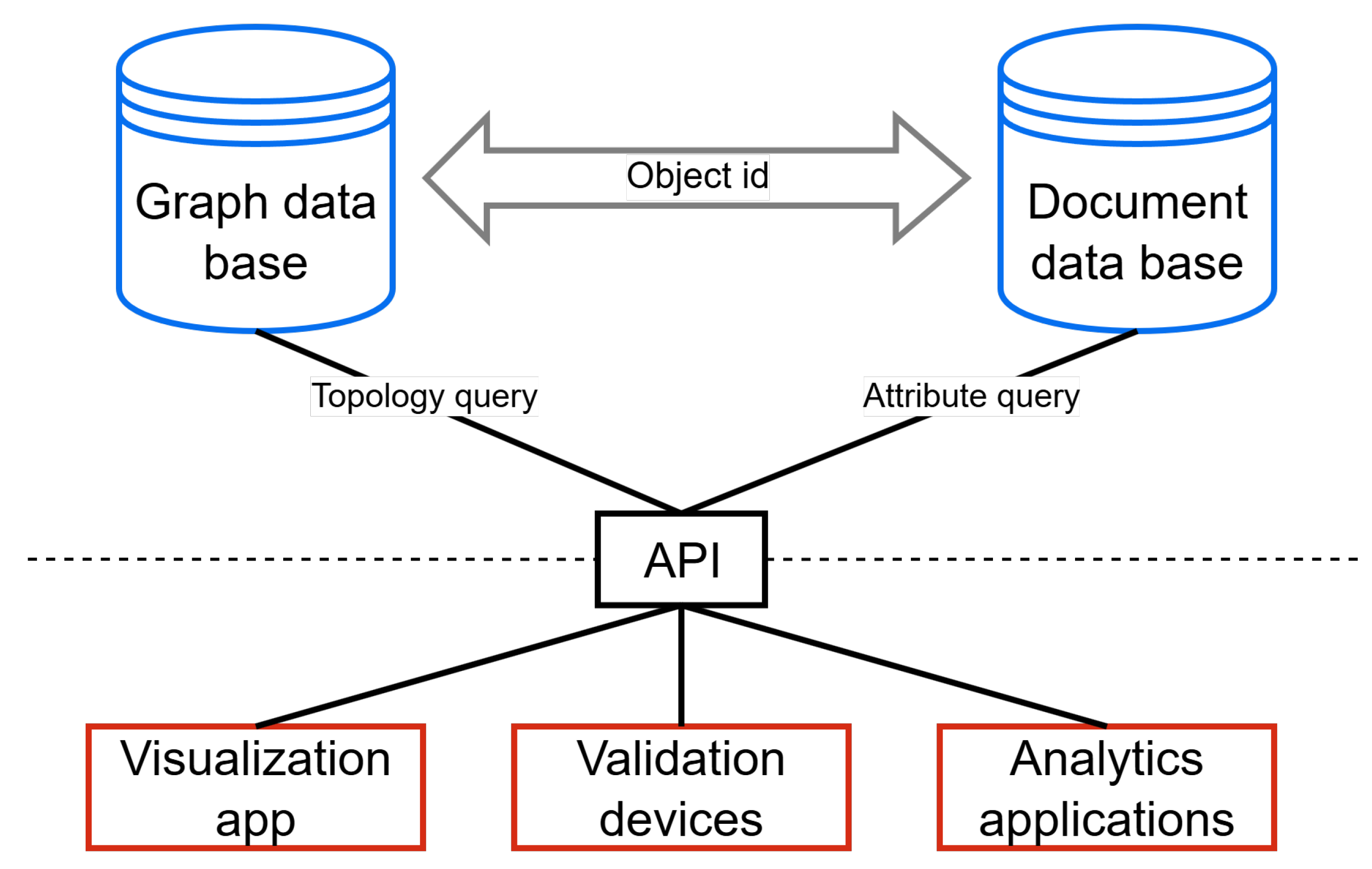

2.5. Persistence Strategy

2.5.1. Document Store

2.5.2. Graph Store

2.5.3. Multi-Layer Workaround

2.5.4. Durability and Exchange

2.5.5. Granularity per Vehicle Model and Release

2.5.6. Access and Version Control

2.6. Validation

2.6.1. Object-Local Checks (Inside the Artefact Store)

- Wire documents verify it has an attribute name and points to two valid endpoints.

- ConnectorPin documents confirm that cavitynumber is unique within a connector family.

- Component documents check that every exported pin appears in the pin list.

2.6.2. Contextual Checks on Circuit Objects

- Platform graph (all buildable variants). A circuit may contain multiple alternative paths between the same pair of components provided that each path belongs to a different build configuration. No restriction is placed on the degree of a ComponentPin; forks for optional equipment are legal.

- Single-vehicle graph (concrete VIN). The rules tighten considerably:

- (a)

- each ComponentPin and ConnectorPinmust terminate in exactly one Connection or wire

- (b)

- at most one Path may link any two components within the same circuit;

- (c)

- no dangling wires are allowed

3. Results

3.1. Model Build Time

3.2. Validation Outcome

3.3. Path-Finding Accuracy

3.4. Summary

4. Discussion

4.1. Rejected Design Alternatives

- (a)

- Connector-level graph. Treating the entire connector as a single node forced the path-finding algorithms to route current through connectors that were electrically valid but topologically impossible when analysed at pin resolution. Moreover, a connector is merely a mechanical envelope; the electric component is the individual pin. Therefore, a pin-level graph preserves the real degrees of freedom without overloading the physical abstraction.

- (b)

- Edges for wires and connections. Modelling wires and crimped connections as edges would be semantically correct—each wire links exactly two pins—but it prevents the graph from expressing higher-layer dependencies. By promoting wires and connections to first-class nodes, their state can be referenced by superordinate objects (sub-circuits, production tasks), allowing a fault in a single wire to cascade automatically to every component that relies on it.

4.2. Role of the Connection Object

4.3. Comparison with Related Work

- Dual-store persistence (graph + document) A single JSON definition of each component is referenced from multiple wiring graphs, so the system captures several vehicle-specific topologies while still honouring the “single-source-of-truth” principle no attribute duplication, yet full configurability across programmes.

- Fine-grained data model Pin-, path- and circuit-level entities are addressable through an open REST schema, making it straightforward to add future layers of complexity such as in-vehicle information networks, diagnostic flows or logistics routes.

- Native graph representation Because the wiring lives in a property graph, the full ecosystem of graph algorithms becomes directly available (e.g., path-finding, centrality, community detection). These capabilities support diverse production tasks ranging from connector heat-map analysis to automated change-impact assessment.

- Deployment neutrality Running on standard open-source stacks (document store + graph library + REST gateway) removes dependence on vendor runtimes, proprietary plug-ins or per seat licences, facilitating integration into existing MES and IIoT platforms.

4.4. Future Work

5. Conclusions

5.1. Achievements

5.2. Limitations and Improvement Opportunities

- Implementation language. The end-to-end toolchain is written in Python for maximum development velocity, but compute-intensive parts (graph traversal, validation scans) could achieve lower latency and a smaller memory footprint if ported to C++ or Rust.

- Persistence strategy complexity. The dual-store architecture (shared document DB + per-model graph files) adds operational complexity compared with a single monolithic database. However, its isolation of topology from attributes proved crucial for supporting dozens of car lines without data duplication; alternative stores may offer higher raw throughput but at the cost of flexibility.

- Quantitative impact data. Although the model has been used in production, quantitative metrics—cycle-time reduction, first-time-through gains—were not available at the time of writing. Qualitative feedback nonetheless confirms its value in launch activities.

5.3. Industrial Relevance

5.4. Future Work

- (a)

- Embed real-time validators on the assembly line so that each harness is checked against the graph as it is built, enabling immediate defect detection;

- (b)

- Couple the validator with guided repair logic that identifies the exact pin, wire or connection node that violates the model and prescribes the corrective action to operators or robots;

- (c)

- Stream validation events back into the graph as live attributes, closing the loop between digital twin and physical product and allowing the system to learn from recurring fault patterns; and

- (d)

- Integrate the wiring graph with higher-level IoT frameworks, so that plant MES and predictive-maintenance modules become context-aware and can schedule repairs or rebalance workloads autonomously.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bordel, B.; Alcarria, R.; de la Cal Hacar, G.; Valladares, T.R. Efficient and Accountable Industry 5.0 Production Scheduling Mechanism for Mass Customization Scenarios. In Proceedings of the 15th International Conference on Ubiquitous Computing & Ambient Intelligence (UCAmI 2023), Riviera Maya, Mexico, 28–30 November 2023; Bravo, J., Urzáiz, G., Eds.; Springer: Cham, Switzerland, 2023; pp. 44–56. [Google Scholar]

- Pizoń, J.; Gola, A. The Meaning and Directions of Development of Personalized Production in the Era of Industry 4.0 and Industry 5.0. In Innovations in Industrial Engineering II; Machado, J., Soares, F., Trojanowska, J., Ivanov, V., Antosz, K., Ren, Y., Manupati, V.K., Pereira, A., Eds.; Springer: Cham, Switzerland, 2023; pp. 1–13. [Google Scholar]

- Maddikunta, P.K.R.; Pham, Q.V.; Prabadevi, B.; Deepa, N.; Dev, K.; Gadekallu, T.R.; Ruby, R.; Liyanage, M. Industry 5.0: A survey on enabling technologies and potential applications. J. Ind. Inf. Integr. 2022, 26, 100257. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, conception and perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Akundi, A.; Euresti, D.; Luna, S.; Ankobiah, W.; Lopes, A.; Edinbarough, I. State of Industry 5.0—Analysis and identification of current research trends. Appl. Syst. Innov. 2022, 5, 27. [Google Scholar] [CrossRef]

- Bründl, P.; Stoidner, M.; Nguyen, H.G.; Baechler, A.; Franke, J. Challenges and Opportunities of Software-Based Production Planning and Control for Engineer-to-Order Manufacturing. In Advances in Production Management Systems. Production Management Systems for Responsible Manufacturing, Service, and Logistics Futures; Alfnes, E., Romsdal, A., Strandhagen, J.O., von Cieminski, G., Romero, D., Eds.; Springer: Cham, Switzerland, 2023; pp. 67–79. [Google Scholar]

- Feichtinger, K.; Meixner, K.; Rinker, F.; Koren, I.; Eichelberger, H.; Heinemann, T.; Holtmann, J.; Konersmann, M.; Michael, J.; Neumann, E.M.; et al. Industry Voices on Software Engineering Challenges in Cyber-Physical Production Systems Engineering. In Proceedings of the 2022 IEEE 27th International Conference on Emerging Technologies and Factory Automation (ETFA), Stuttgart, Germany, 6–9 September 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Strogatz, S.H. Exploring complex networks. Nature 2001, 410, 268–276. [Google Scholar] [CrossRef]

- Pagani, G.A.; Aiello, M. The Power Grid as a complex network: A survey. Phys. A Stat. Mech. Its Appl. 2013, 392, 2688–2700. [Google Scholar] [CrossRef]

- Cuadra, L.; Salcedo-Sanz, S.; Del Ser, J.; Jiménez-Fernández, S.; Geem, Z.W. A critical review of robustness in power grids using complex networks concepts. Energies 2015, 8, 9211–9265. [Google Scholar] [CrossRef]

- Pagani, G.A.; Aiello, M. Power grid complex network evolutions for the smart grid. Phys. A Stat. Mech. Its Appl. 2014, 396, 248–266. [Google Scholar] [CrossRef]

- Chu, C.C.; Iu, H.H.C. Complex networks theory for modern smart grid applications: A survey. IEEE J. Emerg. Sel. Top. Circuits Syst. 2017, 7, 177–191. [Google Scholar] [CrossRef]

- Arianos, S.; Bompard, E.; Carbone, A.; Xue, F. Power grid vulnerability: A complex network approach. Chaos Interdiscip. J. Nonlinear Sci. 2009, 19, 013119. [Google Scholar] [CrossRef] [PubMed]

- Pokorádi, L. Methodolody of Advanced Graph Model-based Vehicle Systems’ Analysis. In Proceedings of the 2018 IEEE 18th International Symposium on Computational Intelligence and Informatics (CINTI), Budapest, Hungary, 21–22 November 2018; pp. 000325–000328. [Google Scholar] [CrossRef]

- Weise, J.; Benkhardt, S.; Mostaghim, S. Graph-based multi-objective generation of customised wiring harnesses. In Proceedings of the Genetic and Evolutionary Computation Conference Companion, GECCO ’19, Prague, Czech Republic, 13–17 July 2019; pp. 407–408. [Google Scholar] [CrossRef]

- Wu, Z.; Pan, S.; Chen, F.; Long, G.; Zhang, C.; Philip, S.Y. A comprehensive survey on graph neural networks. IEEE Trans. Neural Netw. Learn. Syst. 2020, 32, 4–24. [Google Scholar] [CrossRef] [PubMed]

- Liao, W.; Bak-Jensen, B.; Pillai, J.R.; Wang, Y.; Wang, Y. A review of graph neural networks and their applications in power systems. J. Mod. Power Syst. Clean Energy 2021, 10, 345–360. [Google Scholar] [CrossRef]

- Owerko, D.; Gama, F.; Ribeiro, A. Optimal power flow using graph neural networks. In Proceedings of the ICASSP 2020—2020 IEEE International Conference on Acoustics, Speech and Signal Processing (ICASSP), Barcelona, Spain, 4–8 May 2020; pp. 5930–5934. [Google Scholar]

- Basic, F.; Gaertner, M.; Steger, C. Towards Trustworthy NFC-based Sensor Readout for Battery Packs in Battery Management Systems. In Proceedings of the 2021 IEEE International Conference on RFID Technology and Applications (RFID-TA), Delhi, India, 6–8 October 2021; pp. 285–288. [Google Scholar] [CrossRef]

- Wang, Q.A.; Zhang, C.; Ma, Z.G.; Jiao, G.Y.; Jiang, X.W.; Ni, Y.Q.; Wang, Y.C.; Du, Y.T.; Qu, G.B.; Huang, J. Towards long-transmission-distance and semi-active wireless strain sensing enabled by dual-interrogation-mode RFID technology. Struct. Control Health Monit. 2022, 29, e3069. [Google Scholar] [CrossRef]

- Ran, S.C.; Wang, Q.A.; Wang, J.F.; Ni, Y.Q.; Guo, Z.X.; Luo, Y. A Concise State-of-the-Art Review of Crack Monitoring Enabled by RFID Technology. Appl. Sci. 2024, 14, 3213. [Google Scholar] [CrossRef]

- Kaur, G.; Kamboj, G. RFID based Intelligent Transport System with RSU Communication for Emergency Vehicles in Urbanization. In Proceedings of the 2022 4th International Conference on Inventive Research in Computing Applications (ICIRCA), Coimbatore, India, 21–23 September 2022; pp. 333–338. [Google Scholar] [CrossRef]

- Le, V.V.; Be, N.T.; Dang, D.H. On Automatic Generation of Executable Domain Models for Domain-Driven Design. In Proceedings of the 2023 15th International Conference on Knowledge and Systems Engineering (KSE), Ha Noi, Vietnam, 18–20 October 2023; pp. 1–6. [Google Scholar]

- Cao, H.; Li, J. Design and implementation of design platform for automatic generated micro-application system based on domain model. In Proceedings of the Sixth International Conference on Computer Information Science and Application Technology (CISAT 2023), Hangzhou, China, 26–28 May 2023; Volume 12800, pp. 1593–1599. [Google Scholar]

- Tharma, R.; Winter, R.; Eigner, M. An approach for the implementation of the digital twin in the automotive wiring harness field. In Proceedings of the DS 92: Proceedings of the DESIGN 2018 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; pp. 3023–3032. [Google Scholar]

- Modarresi, A.; Symons, J. Modeling technological interdependency in IoT-A multidimensional and multilayer network model for smart environments. In Proceedings of the 2019 11th International Workshop on Resilient Networks Design and Modeling (RNDM), Nicosia, Cyprus, 14–16 October 2019; pp. 1–7. [Google Scholar]

- Wu, X.; Wang, J.; Li, P.; Luo, X.; Yang, Y. Internet of things as complex networks. IEEE Netw. 2021, 35, 238–245. [Google Scholar] [CrossRef]

| Domain-Rule Violations | Circuit Errors | Build Status | |

|---|---|---|---|

| Iteration 1 | 8 | 52 | failed |

| Iteration 3 | 0 | 0 | passed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bosch Serra, A.; Blanes Noguera, J.F.; Ruiz Matallana, L.; Álvarez Baldo, C.; Porcar Rodado, J. Advanced Vehicle Electrical System Modelling for Software Solutions on Manufacturing Plants: Proposal and Applications. Appl. Syst. Innov. 2025, 8, 134. https://doi.org/10.3390/asi8050134

Bosch Serra A, Blanes Noguera JF, Ruiz Matallana L, Álvarez Baldo C, Porcar Rodado J. Advanced Vehicle Electrical System Modelling for Software Solutions on Manufacturing Plants: Proposal and Applications. Applied System Innovation. 2025; 8(5):134. https://doi.org/10.3390/asi8050134

Chicago/Turabian StyleBosch Serra, Adrià, Juan Francisco Blanes Noguera, Luis Ruiz Matallana, Carlos Álvarez Baldo, and Joan Porcar Rodado. 2025. "Advanced Vehicle Electrical System Modelling for Software Solutions on Manufacturing Plants: Proposal and Applications" Applied System Innovation 8, no. 5: 134. https://doi.org/10.3390/asi8050134

APA StyleBosch Serra, A., Blanes Noguera, J. F., Ruiz Matallana, L., Álvarez Baldo, C., & Porcar Rodado, J. (2025). Advanced Vehicle Electrical System Modelling for Software Solutions on Manufacturing Plants: Proposal and Applications. Applied System Innovation, 8(5), 134. https://doi.org/10.3390/asi8050134