Enhancing Efficiency and Creativity in Mechanical Drafting: A Comparative Study of General-Purpose CAD Versus Specialized Toolsets

Abstract

1. Introduction

2. Materials and Methods

2.1. Evaluation of the Efficiency of AutoCAD and AutoCAD Mechanical

2.1.1. Predefined Drawing Tasks

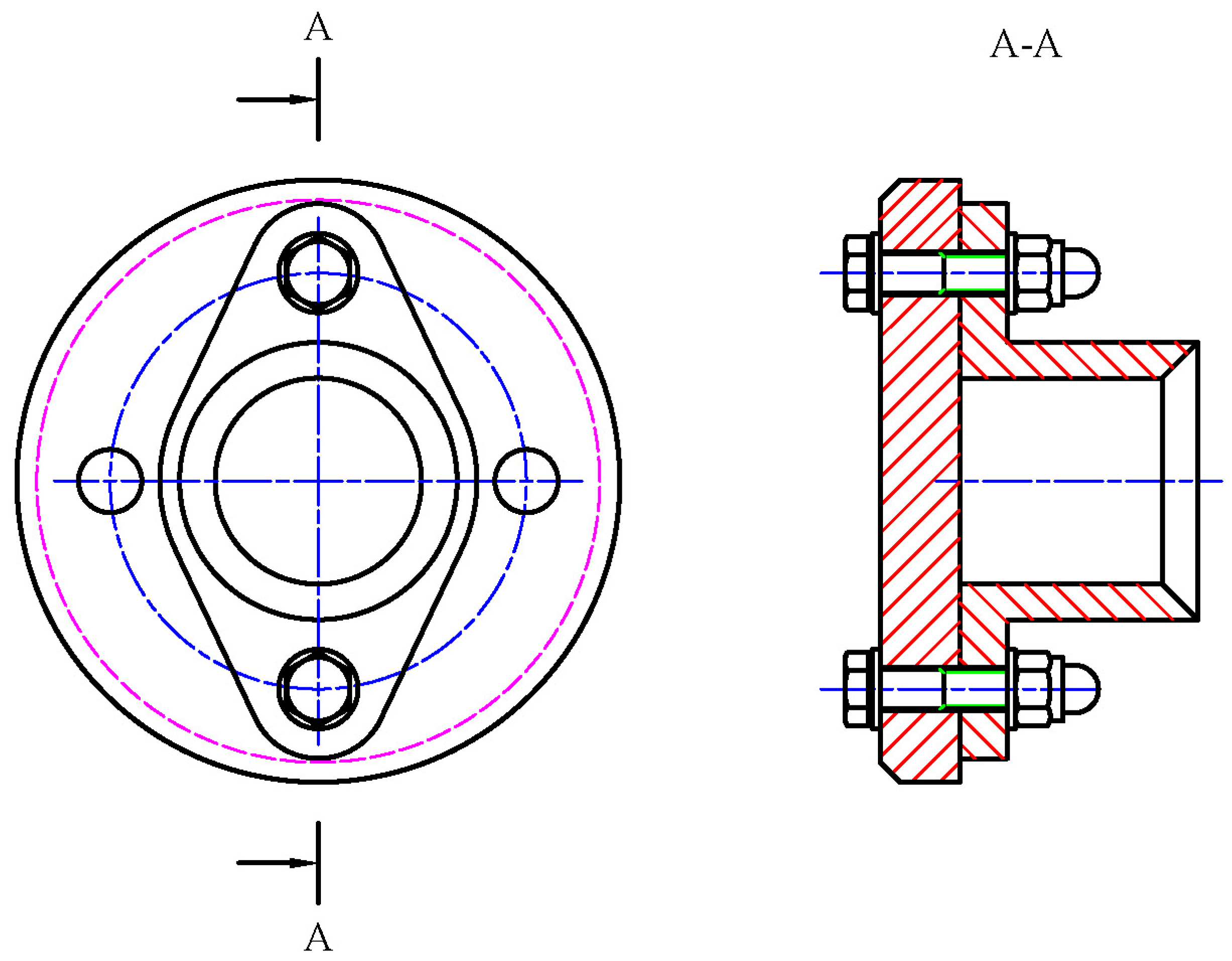

- Screw connection.

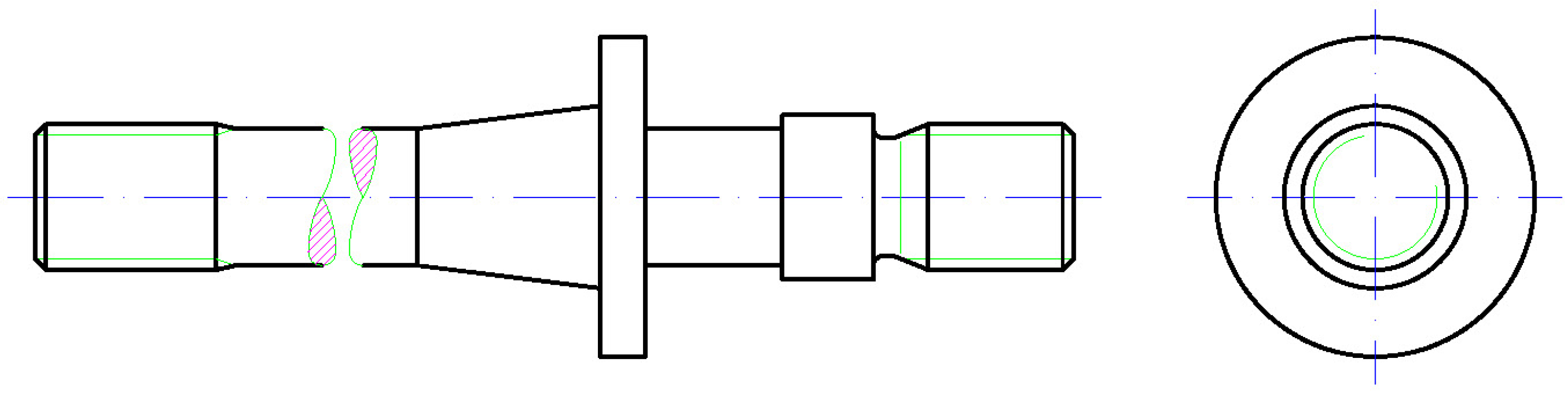

- Shaft assembly.

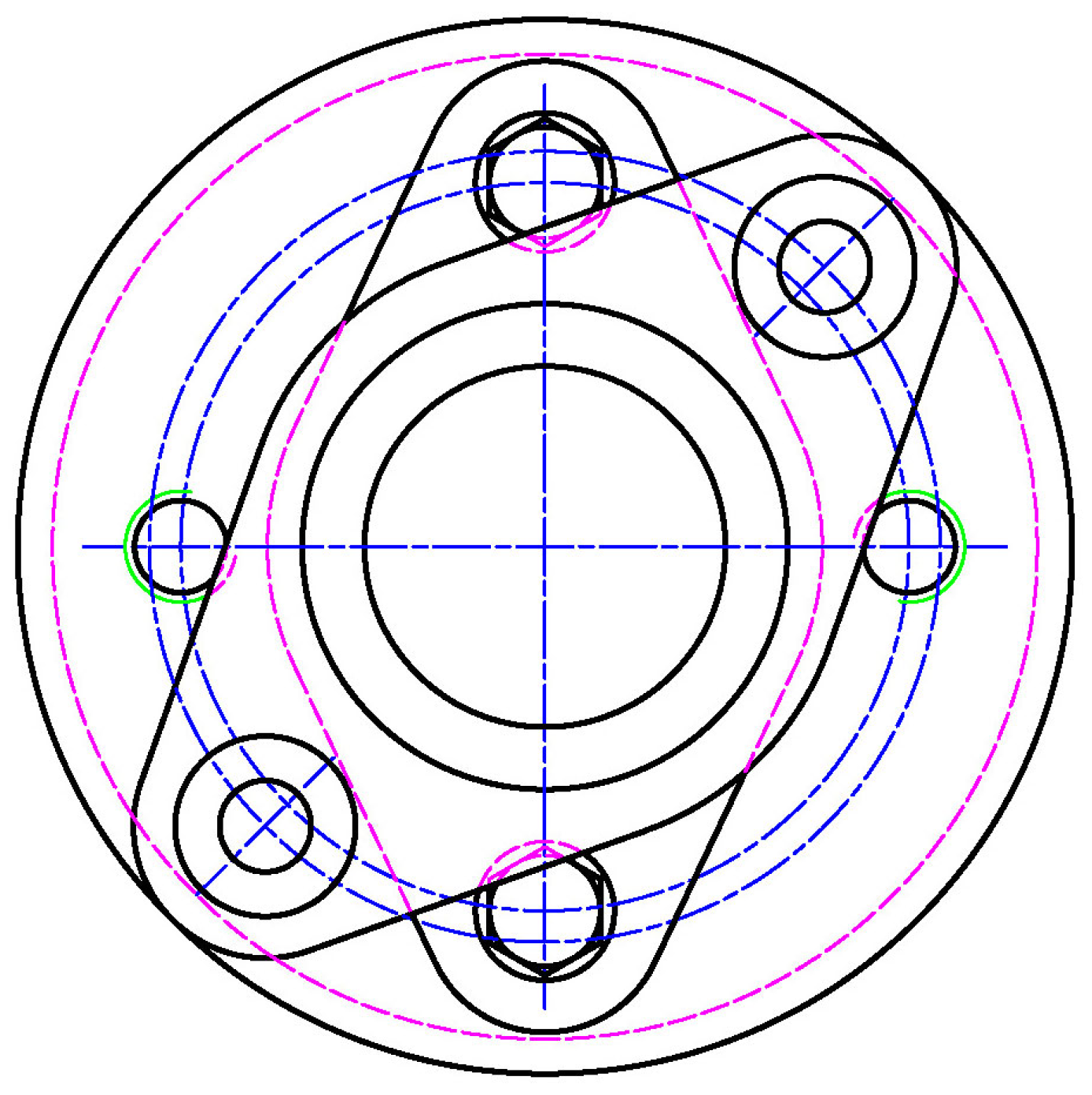

- Hidden geometry.

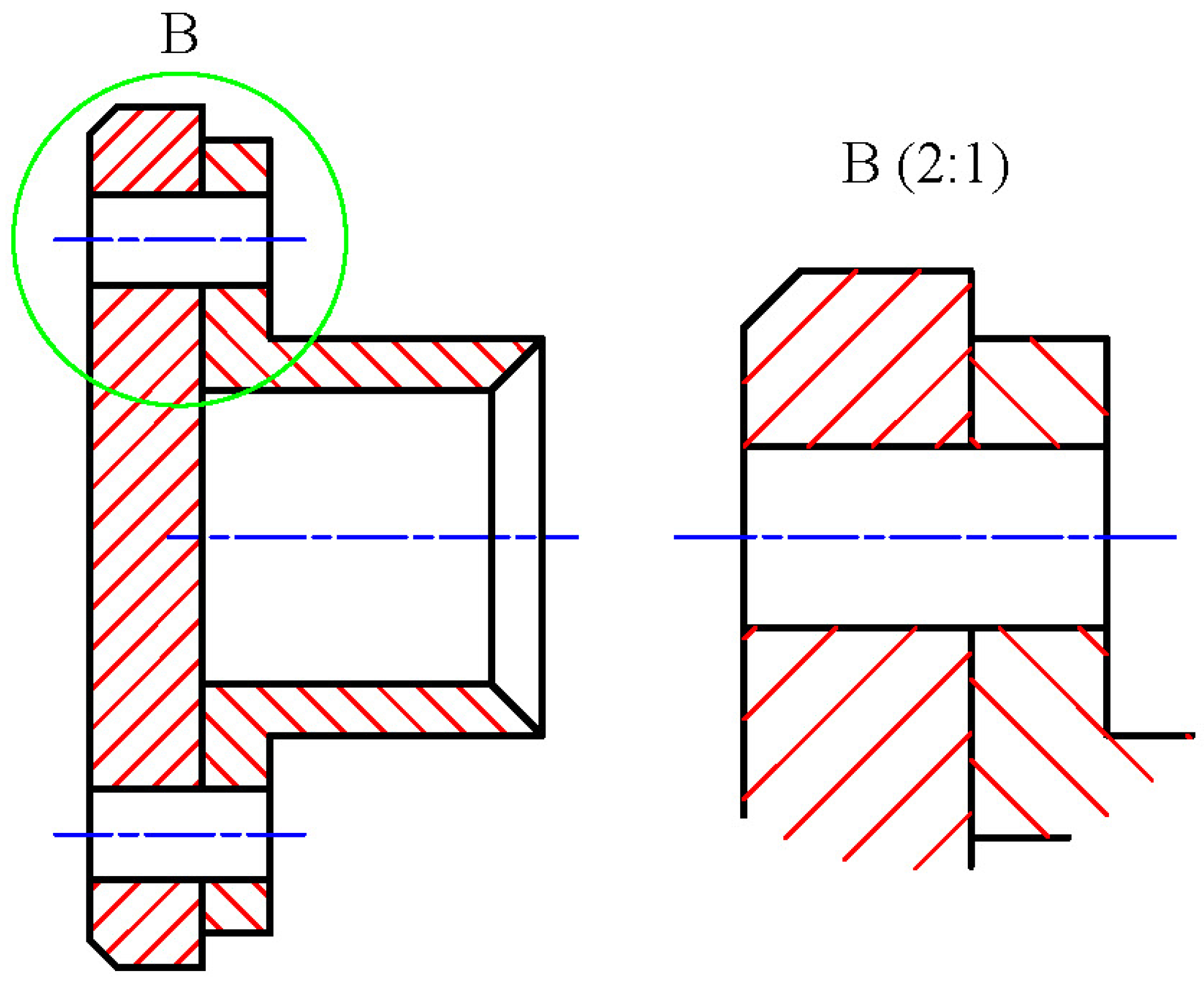

- Enlarged view.

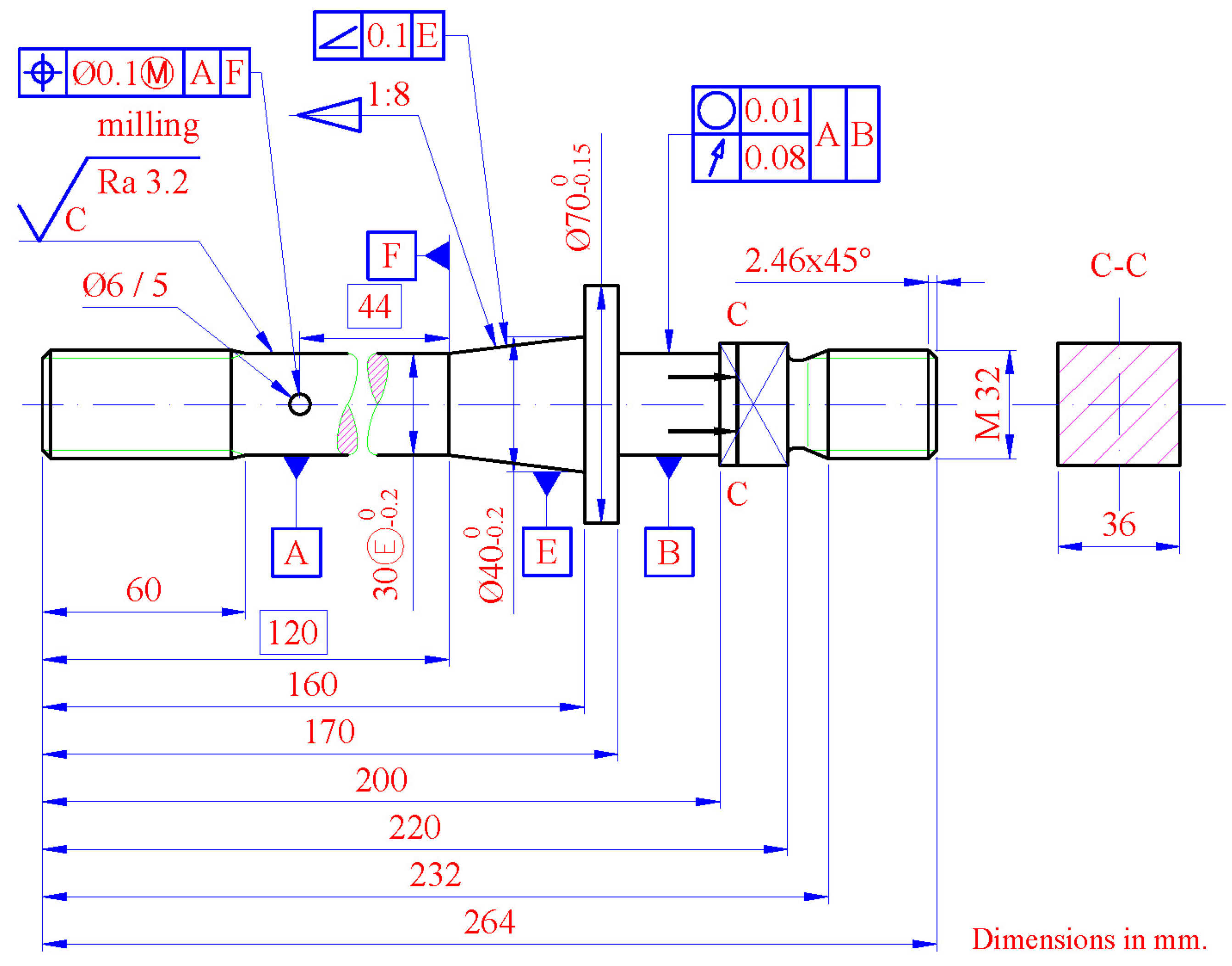

- Dimensioned and annotated machined shaft.

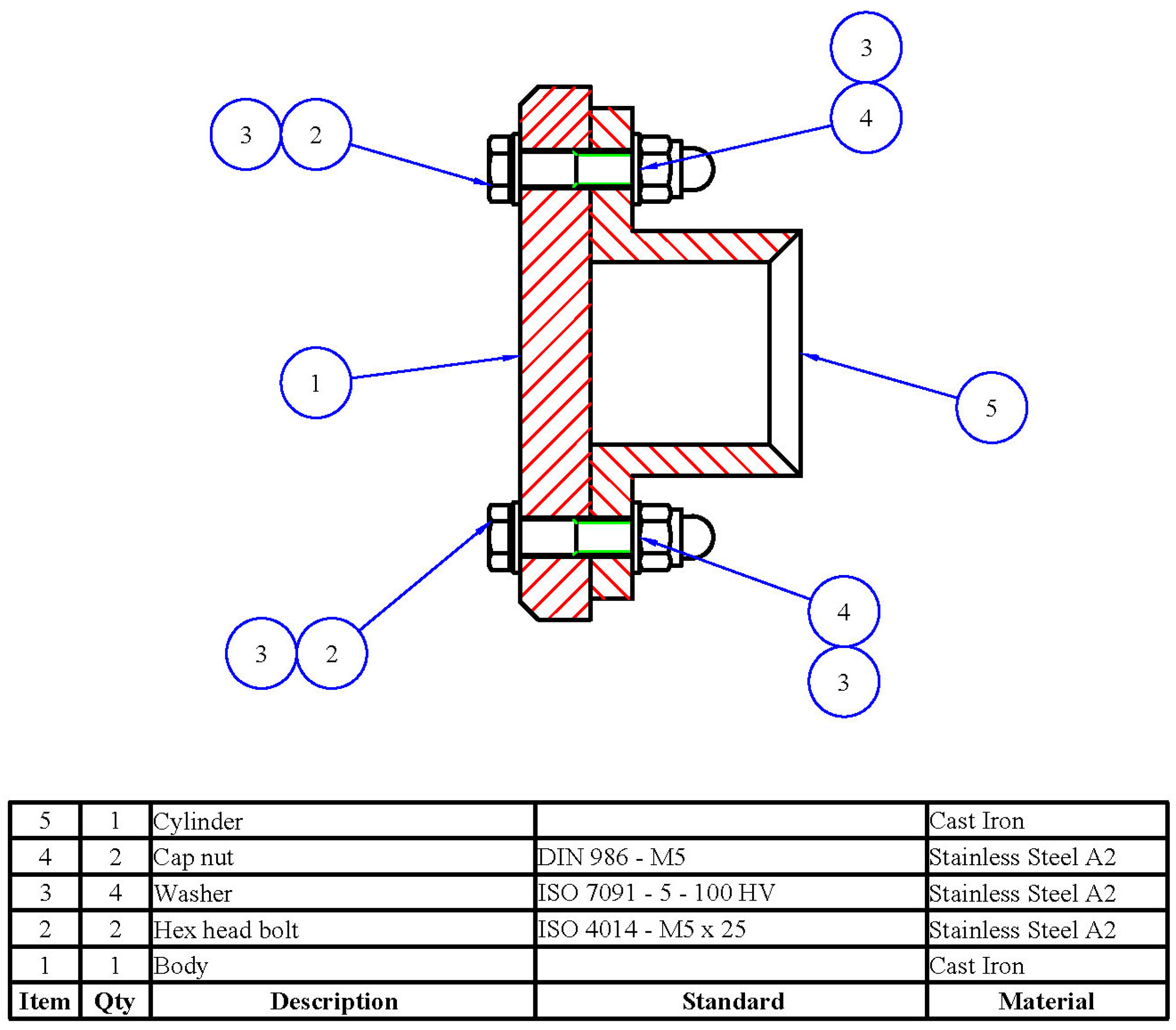

- Adding balloons and parts list.

2.1.2. Analyzing Command Usage, Access Frequency, and Task Completion Time

2.2. Evaluating Potential Creativity Improvement When Using AutoCAD Mechanical

3. Results

3.1. AutoCAD vs. AutoCAD Mechanical Efficiency

3.2. Impact of Using AutoCAD and AutoCAD Mechanical on Creativity

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vrolijk, A.P.; Olechowski, A. Computer-aided design as a research instrument for engineering design: Supporting multiple methods by observing artifacts, actors, and actions. J. Eng. Des. 2024, 1–32. [Google Scholar] [CrossRef]

- Yin, G.; Xiao, X.; Cirak, F. Topologically robust CAD model generation for structural optimization. Comput. Meth. Appl. Mech. Eng. 2020, 369, 113102. [Google Scholar] [CrossRef]

- Camba, J.D.; Company, P.; Contero, M. Parametric CAD modeling: An analysis of strategies for design reusability. Comput.-Aided Des. 2016, 74, 18–31. [Google Scholar] [CrossRef]

- Zou, Q.; Wu, Y.; Liu, Z.; Xu, W.; Gao, S. Intelligent CAD 2.0. Vis. Inform. 2024, 8, 1–12. [Google Scholar] [CrossRef]

- Deng, H.; Khan, S.; Erkoyuncu, J.A. An investigation on utilizing large language model for industrial computer-aided design automation. Procedia CIRP 2024, 128, 221–226. [Google Scholar] [CrossRef]

- Chandrasegaran, S.K.; Ramani, K.; Sriram, R.D.; Horváth, I.; Bernard, A.; Harik, R.F.; Gao, W. The evolution, challenges, and future of knowledge representation in product design systems. Comput.-Aided Des. 2013, 45, 204–228. [Google Scholar] [CrossRef]

- Vuletic, T.; Duffy, A.; Hay, L.; McTeague, C.; Pidgeon, L.; Grealy, M. The challenges in computer-supported conceptual engineering design. Comput. Ind. 2018, 95, 22–37. [Google Scholar] [CrossRef]

- Tekmen-Araci, Y.; Mann, L. Instructor approaches to creativity in engineering design education. J. Mech. Eng. Sci. 2019, 233, 395–402. [Google Scholar] [CrossRef]

- Felder, R.M.; Brent, R. Teaching and Learning STEM: A Practical Guide, 1st ed.; Jossey-Bass Inc. Pub: San Francisco, CA, USA, 2016. [Google Scholar]

- Robertson, B.F.; Radcliffe, D.F. Impact of CAD tools on creative problem-solving in engineering design. Comput.-Aided Des. 2009, 41, 136–146. [Google Scholar] [CrossRef]

- Dym, C.L.; Agogino, A.M.; Eris, O.; Frey, D.D.; Leifer, L.J. Engineering design thinking, teaching, and learning. J. Eng. Educ. 2005, 94, 103–120. [Google Scholar] [CrossRef]

- Martin-Doñate, C.; Lucena-Muñoz, F.; Garcia-Cabrera, L.; Mesa-Villar, A. Application of promotional marketing activities to industrial drawing courses in Engineering Graphics. In Proceedings of the 11th International Conference on Education and New Learning Technologies, Palma, Spain, 1–3 July 2019; pp. 4473–4481. [Google Scholar] [CrossRef]

- Carbonell-Carrera, C.; Saorin, J.L.; Melian-Diaz, D.; de la Torre-Cantero, J. Enhancing creative thinking in STEM with 3D CAD Modelling. Sustainability 2019, 11, 6036. [Google Scholar] [CrossRef]

- Das, M.; Huang, M.; Yang, M.C. Paper or tablet? The impact of digital tools on sketching during engineering design concept generation. ASME. J. Mech. Des. 2024, 146, 111401. [Google Scholar] [CrossRef]

- Booth, J.W.; Taborda, E.A.; Ramani, K.; Reid, T. Interventions for teaching sketching skills and reducing inhibition for novice engineering designers. Des. Stud. 2016, 43, 1–23. [Google Scholar] [CrossRef]

- Morin, S.; Robert, J.M.; Gabora, L. How to train future engineers to be more creative? Think. Skills Creat. 2018, 28, 150–166. [Google Scholar] [CrossRef]

- Ozturk, E.; Johnson, M.D.; Yalvac, B.; Peng, X. Development of adaptive expertise in engineering undergraduates through contextual computer aided design modeling activities. Int. J. Eng. Educ. 2023, 39, 685–702. [Google Scholar]

- Sancibrian, R.; Gonzalez Sarabia, E.; Llata, J.R.; San-José, J.T.; Torre-Ferrero, C.; Blanco, J.M. A method for assessing creativity and innovation of industrial products by engineering students. In Proceedings of the 9th International Conference on Education and New Learning Technologies, Barcelona, Spain, 3–5 July 2017; pp. 3038–3045. [Google Scholar] [CrossRef]

- Taleyarkhan, M.; Dasgupta, C.; Mendoza Garcia, J.; Magana, A.J. Investigating the impact of using a CAD simulation tool on students’ learning of design thinking. J. Sci. Educ. Technol. 2018, 27, 334–347. [Google Scholar] [CrossRef]

- Fleury, S.; Blanchard, P.; Richir, S. A study of the effects of a natural virtual environment on creativity during a product design activity. Think. Skills Creat. 2021, 40, 100828. [Google Scholar] [CrossRef]

- Brink, H.; Kilbrink, N.; Gericke, N. Teach to use CAD or through using CAD: An interview study with technology teachers. Int. J. Technol. Des. Educ. 2023, 33, 957–979. [Google Scholar] [CrossRef]

- Gutiérrez de Ravé, E.; Jiménez-Hornero, F.J. A 3D Descriptive Geometry Problem-Solving Methodology Using CAD. Symmetry 2024, 16, 476. [Google Scholar] [CrossRef]

- Dagman, A.; Wärmefjord, K. An evidence-based study on teaching Computer-Aided Design in higher education during the COVID-19 pandemic. Educ. Sci. 2022, 12, 29. [Google Scholar] [CrossRef]

- Company, P.; Contero, M.; Otey, J.; Plumed, R. Approach for developing coordinated rubrics to convey quality criteria in MCAD training. Comput.-Aided Des. 2015, 63, 101–117. [Google Scholar] [CrossRef]

- Sakunkawinkorn, K.; Rugsaj, R.; Kamrueng, C.; Kongthon, J. Development of an engineering drawing course structure with CAD software integration using multi-level rubric assessment. In Proceedings of the 9th International STEM Education Conference (iSTEM-Ed), Cha-am, Hua Hin, Thailand, 31 July–2 August 2024; pp. 1–6. [Google Scholar] [CrossRef]

| Criteria | 1—Poor | 2—Fair | 3—Satisfactory | 4—Good | 5—Excellent |

|---|---|---|---|---|---|

| Originality (degree of innovation) | The design lacks creativity, showing a direct replication of the reference without any modifications. No new features are introduced. | Minimal innovation is present. Some minor modifications or additional elements are included but do not contribute significantly to improvement. | A moderate level of creativity is demonstrated. The design includes new features, but they are not fully integrated into a unique or innovative solution. | The design shows a strong level of innovation, introducing original modifications that enhance functionality or aesthetics. | Highly creative and innovative design that introduces entirely new elements, optimizes material usage, and enhances functionality beyond conventional expectations. |

| Functionality (feasibility and appropriateness for manufacturing) | The design is impractical for manufacturing. It contains errors in dimensions, tolerances, or assembly features that prevent real-world application. | Some aspects of the design are functional, but there are major manufacturability concerns, such as incorrect tolerances or missing critical details. | The design is generally manufacturable, but minor issues (e.g., suboptimal material selection, excessive complexity) reduce its efficiency. | The design is well-structured for manufacturing with only minor refinements needed. It considers realistic tolerances and assembly constraints. | The design is highly optimized for manufacturability, incorporating appropriate tolerances, material efficiency, ease of assembly, and industry-standard best practices. |

| Efficient use of CAD tools (proficiency in AutoCAD/AutoCAD Mechanical commands) | The design was created inefficiently with excessive manual operations, improper use of tools, and lack of automation. Frequent errors requiring correction. | Basic CAD tools are used, but there is minimal understanding of advanced features. The workflow is slow and inefficient. | The design demonstrates moderate proficiency with CAD tools, making use of fundamental commands but with room for optimization. | CAD commands and features are used efficiently. Parametric tools, constraints, and standard libraries are properly integrated for a streamlined workflow. | Highly proficient use of AutoCAD/AutoCAD Mechanical tools. The designer effectively uses automation, constraints, standard libraries, and advanced features to maximize efficiency. |

| Graphical quality (clarity, precision, and completeness of technical drawings) | The drawing is unclear, lacks dimensions, and contains inconsistencies in views and projections. The layout is disorganized. | The drawing includes basic dimensions but has errors in scaling, projection alignment, or clarity. Annotation placement is poor. | The drawing is mostly clear with accurate projections and proper annotations but lacks refinement in line weights, hatching, or notation consistency. | The drawing is precise, well-organized, and correctly dimensioned. Proper use of line weights, section views, and annotations enhances readability. | The drawing is of professional quality, adhering to all drafting standards with perfect clarity, precise dimensions, appropriate annotations, and highly detailed visualization of features. |

| Criteria | Weight (%) | Rationale for Weighting |

|---|---|---|

| Originality | 20% | While creativity is important, it must be balanced with functionality. In mechanical design, excessive innovation without feasibility can lead to impractical solutions. Thus, originality is valued but not prioritized over functionality. |

| Functionality | 35% | Functionality is the most critical factor in mechanical design because even the most innovative and visually appealing design is useless if it cannot be manufactured or assembled correctly. It must adhere to realistic tolerances, material considerations, and practical engineering constraints. |

| Efficient use of CAD tools | 30% | CAD proficiency is essential for an efficient workflow. Mastery of automation tools, parametric design, and feature libraries directly impacts productivity and quality. Using CAD tools effectively minimizes design errors and accelerates modifications. |

| Graphical quality | 15% | While essential, graphical quality has less impact than functionality or efficient CAD use. Aesthetics and drawing clarity enhance communication but do not directly affect manufacturability. A design can be functional even if the drawing is slightly imperfect, if it is interpretable. |

| AutoCAD | AutoCAD Mechanical | |||||||

|---|---|---|---|---|---|---|---|---|

| Task | Avg. Commands Used | Std. Dev. (Commands) | Avg. Command Access | Std. Dev. (Access) | Avg. Commands Used | Std. Dev. (Commands) | Avg. Command Access | Std. Dev. (Access) |

| Screw connection | 18 | 2 | 42 | 5 | 9 | 2 | 20 | 2 |

| Shaft assembly | 22 | 3 | 55 | 7 | 11 | 2 | 25 | 3 |

| Hidden geometry | 19 | 2 | 38 | 5 | 8 | 2 | 18 | 2 |

| Enlarged view | 21 | 3 | 50 | 6 | 12 | 2 | 27 | 3 |

| Dimensioned and annotated shaft | 23 | 3 | 58 | 7 | 13 | 3 | 28 | 3 |

| Balloons and parts list | 20 | 3 | 53 | 6 | 11 | 2 | 24 | 3 |

| AutoCAD | AutoCAD Mechanical | |||||

|---|---|---|---|---|---|---|

| Task | Avg. Time (min) | Std. Dev. (min) | Avg. Time (min) | Std. Dev. (min) | Time Reduction (%) | p-Value (t-test) |

| Screw connection | 15.20 | 2.45 | 7.40 | 1.85 | 51.32 | 0.0001 |

| Shaft assembly | 16.00 | 2.90 | 8.00 | 2.10 | 50.00 | 0.0002 |

| Hidden geometry | 13.50 | 2.20 | 6.30 | 1.75 | 53.33 | 0.0001 |

| Enlarged view | 14.60 | 2.55 | 7.10 | 1.90 | 51.37 | 0.0003 |

| Dimensioned and annotated shaft | 17.00 | 3.00 | 8.50 | 2.30 | 52.32 | 0.0003 |

| Balloons and parts list | 16.50 | 2.85 | 8.30 | 2.10 | 49.70 | 0.0004 |

| AutoCAD | AutoCAD Mechanical | ||||

|---|---|---|---|---|---|

| Criteria | Average | Std. Dev. | Average | Std. Dev. | p-Value (t-test) |

| Originality | 2.93 | 0.88 | 3.80 | 0.77 | 0.0080 |

| Functionality | 3.00 | 0.93 | 4.20 | 0.86 | 0.0010 |

| Efficient CAD use | 3.27 | 0.70 | 4.07 | 0.88 | 0.0107 |

| Graphical quality | 3.20 | 0.86 | 3.67 | 0.62 | 0.1004 |

| Average weighted creativity score | 12.56 | 3.41 | 16.24 | 2.89 | 0.0007 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gutiérrez de Ravé, S.; Gutiérrez de Ravé, E.; Jiménez-Hornero, F.J. Enhancing Efficiency and Creativity in Mechanical Drafting: A Comparative Study of General-Purpose CAD Versus Specialized Toolsets. Appl. Syst. Innov. 2025, 8, 74. https://doi.org/10.3390/asi8030074

Gutiérrez de Ravé S, Gutiérrez de Ravé E, Jiménez-Hornero FJ. Enhancing Efficiency and Creativity in Mechanical Drafting: A Comparative Study of General-Purpose CAD Versus Specialized Toolsets. Applied System Innovation. 2025; 8(3):74. https://doi.org/10.3390/asi8030074

Chicago/Turabian StyleGutiérrez de Ravé, Simón, Eduardo Gutiérrez de Ravé, and Francisco J. Jiménez-Hornero. 2025. "Enhancing Efficiency and Creativity in Mechanical Drafting: A Comparative Study of General-Purpose CAD Versus Specialized Toolsets" Applied System Innovation 8, no. 3: 74. https://doi.org/10.3390/asi8030074

APA StyleGutiérrez de Ravé, S., Gutiérrez de Ravé, E., & Jiménez-Hornero, F. J. (2025). Enhancing Efficiency and Creativity in Mechanical Drafting: A Comparative Study of General-Purpose CAD Versus Specialized Toolsets. Applied System Innovation, 8(3), 74. https://doi.org/10.3390/asi8030074