Abstract

This manuscript presents the development and testing of a novel model designed to help organizations, particularly small and medium-sized enterprises (SMEs), address the challenges of integrating new technologies within the frameworks of Industry 4.0 and 5.0. The proposed model is a metamodel that evaluates organizational and contextual vulnerabilities concerning both existing technologies and potential external technologies under consideration for adoption. It synthesizes three foundational frameworks: the Viable System Model (VSM), the principles of viable and sustainable systems, and the Technology, Organization, and Environment (TOE) Model. The findings demonstrate the practical applicability of this model in an SME context, showcasing its ability to facilitate the gradual and sustainable adoption of new technologies. By aligning business needs with technological solutions and leveraging insights from computer science and organizational cybernetics, the model adapts to varying levels of technological adoption, integrating organizational dynamics and business evolution to support the implementation of emerging technologies.

1. Introduction

In the context of technological advancements associated with Industry 4.0 (I4.0) and Industry 5.0 (I5.0), organizations face a steep learning and adoption curve for emerging technologies rooted in computer science (CS) and cybernetics. These advancements encompass artificial intelligence (AI), the Internet of Things (IoT), and cyber–physical systems (CPSs) [1].

However, throughout the history of industrial revolutions, humanity has repeatedly faced management challenges in achieving seamless collaboration between machines and humans. These challenges extend beyond technological barriers to include broader issues such as sustainability [2,3].

For example, the challenge during the First Industrial Revolution (1IR) was determining how to mechanize production processes using steam engines and how this would push the industry, which originated in England and spread globally, primarily to the advantage of developed nations. At this time, the greatest challenge from the human perspective was the replacement of hand-made products by mass production and cheap labor, which provoked the abandonment of local products and the concentration of centralized mass products in industrialized cities. This resulted in the formation of the working class, which was marked by low wages and labor violations [4,5].

The Second Industrial Revolution (2IR) was defined by the widespread adoption of electricity and internal combustion engines, marking a transformative shift in energy usage from steam power to electric energy and the combustion of petroleum derivatives. During this period, the United States emerged as a dominant global force, leveraging these technological advances to drive industrial production. This era also saw the establishment of a management framework that continues to influence certain sectors of the manufacturing industry [6]. Known as classical or mechanistic management, this system conceptualized human labor as interchangeable parts of the industrial machine, often exacerbating stress levels during working hours [7].

Furthermore, this era witnessed an increase in the exploitation of natural resources, which initially manifested itself in substantial planetary contamination. Petroleum-derived products, especially plastics, have emerged as a global predicament, particularly affecting oceans and natural habitats and gradually diminishing the biodiversity of various species around the world [8,9,10].

The Third Industrial Revolution (3IR) was defined by the development of transformative technologies, including the internet, transistors, and the digitization of processes, which collectively gave rise to Information and Communication Technologies (ICTs) [11,12]. This transition period was marked by significant challenges, including information concentration and management, the implementation of remote control systems, the acceleration of globalization, and the safeguarding of information across national boundaries.

The application of novel technologies to regulate machines and control systems is theoretically framed within the field of cybernetics. This discipline reached its peak with the development of first-order cybernetics [13], which explored the interaction between humans and machines through feedback mechanisms. Its primary objective was to harness the benefits of automation and control, thereby enhancing human services and optimizing productive processes.

Subsequently, traditional management underwent transformations, incorporating novel approaches such as the implementation of just-in-time methodologies and the reorganization of hierarchical structures [14]. This argument is strengthened by the fact that, as previously mentioned, this dilemma regarding change endures despite advancements in technology. Despite the complex nature of the operational environment, it shows a lack of preparedness, an unwillingness to embrace new paradigms, and an insistence on governing organizations using obsolete procedures.

The Fourth Industrial Revolution, commonly referred to as Industry 4.0 (I4.0), integrates advanced computer science (CS) technologies such as artificial intelligence (AI), the Internet of Things (IoT), data mining, cloud computing, and cybersecurity [15]. Artificial intelligence, for example, has become a focal point in recent years, with the aim of developing machines and computers capable of emulating human behavior in service delivery and production processes [16,17]. In addition, I4.0 seeks to empower organizations by leveraging these transformative technologies, facing challenges similar to those encountered in previous industrial revolutions. These include limitations in disciplines, workforce competencies, organizational cultures, strategies, and structures [18].

Historically, humanity has struggled to fully comprehend the social repercussions of replacing human labor with “intelligent” machines. This challenge requires the integration of physical, cybernetic, and social systems, a contemporary framework referred to as cyber–physical–social systems (CPSSs) [19,20,21]. On a global scale, institutions and nations not only strive to identify the most effective strategies to adapt to emerging technologies but also ensure that these adaptations minimize negative impacts on the ecosystems in which organizations operate, regardless of their size [22,23]. Key considerations include environmental sustainability, human well-being, and the dynamics of human–machine interaction (cybernetics) [24]. Industry 5.0 (I5.0), a concept introduced in Europe in the early twentieth century [25], embodies these principles by emphasizing conservation, ethical production, and service practices that address both internal and external aspects of business operations. Although I4.0 continues to be a dominant trend in management, in the last few years, I5.0 has emerged as an alternative visionary management concept due to providing a different vision of the future of industry [26].

Throughout various revolutions, humanity has adapted in the most suitable way allowed by each corresponding management paradigm of the era, and I4.0 is no exception. However, at the beginning of 2020, the relevance of I5.0 prompted technology and organizations to look for sustainability. According to Verma et al. [27], I5.0 is value-based, and I4.0 is technology-based; the two complement each other, although the idea of I5.0 has not been widely adopted by researchers. Sustainability and human well-being are the primary goals of I5.0, which is a subset of Society 5.0. In this sense, I5.0 shows how industry migration impacts social needs and raises the standard of living with the future scope to make it more human-centric and sustainable [28].

The problem, when migrating to one or both, lies in the fact that managers and owners of organizations, from small to large companies, face the aforementioned challenges, as their current operational methods do not provide them with the ability to effectively execute an industry transformation. On the one hand, there is a dilemma with regard to knowledge of and adaptation to processes and infrastructure for I4.0 tools. On the other hand, I5.0 requires the construction of more inclusive jobs, resilient supply chains, and the adoption of more sustainable production methods accompanied by I4.0 technologies [29,30]. However, according to Soomro et al. [31], digital technologies influence SMEs to enhance the creation of economic and social value.

Reviewing the current state [32,33,34,35,36] reveals that the models that have been used for the adoption of technology are based on models used for the implementation of digital technologies such as TOE, TAM, etc.; that is, models that have been well accepted since the end and beginning of the twentieth century are used in use cases such as implementing computers in organizations, ERP software, social networks, applications, etc. But these are not enough to understand the complexity of AI in organizations. From a systemic approach, it is observed that there are internal and external considerations for making the decision of whether or not to use AI [37]; however, there is no tool for the abstraction and evaluation of the complexity that reflects the reality of the system under study in order to identify relevant systems (to weigh) before starting a management process. Only two studies present evaluation tools [38,39] that benefit management in measuring the progress of adoption. This highlights the need to conduct an evaluation of an organization’s capacity for the adoption of technology; the manager would have the appropriate worldview of the initial state and, therefore, the ability to define whether there has been progress in adoption and to know whether the objective has been reached. In addition, they lack an agile evolutionary process that keeps them constantly adapting to the outside and inside at the speed demanded by the market.

In addressing the presented challenge, the research question (RS) that guides this work is as follows: How can a systems science-based model guide SMEs in adopting new technologies in the context of Industry 4.0 and 5.0? To answer the RQ, the research performs a thorough analysis of the identified issues and proposes a solution employing a model rooted in the principles of organizational cybernetics. Despite the existence of theories, proposals, and practices within this management paradigm dating back to 3RI with the viability theory in systems [40,41], their widespread adoption remains limited. In light of the intricate landscape posed by technological advancements in the I4.0 and the ethical–environmental considerations of the I5.0, the resurgence of robust concepts like these attains heightened significance. Thus, there is a compelling need to revive both the theoretical and practical aspects of this knowledge to formulate a comprehensive solution adaptable to diverse systems based on their intrinsic characteristics.

This manuscript introduces a viable framework designed to provide guidance to enterprises, particularly those interested in adopting I4.0 technology, while also aligning with the goals of I5.0. This model is predominantly derived from Stafford Beer’s Viable System Model (VSM) [42] while also integrating the sustainability principles of the Viable and Sustainable Model [43]. These theories form the development of a sophisticated model that can effectively tackle the issues presented via the recent industrial revolutions. To improve the model, the ideas of the TOE model [44] were incorporated; these ideas are widely used for the assimilation of new technology in various organizations and business domains. The following sections explore the different models and theories that contribute to the metamodel known as the Viable and Sustainable Model for the Adoption of New Technology (VSM-ANT). To date, no other contributions with these characteristics have been recognized as addressing the challenges of Industry 4.0 and 5.0.

Finally, a practical demonstration of the proposed VSM-ANT model is presented, showcasing its real-world application. The study was carried out at a secondary-sector company that specializes in plastic pelletization for subsequent plastic packaging shaping and molding. The company’s identity will remain confidential in the model description. However, it should be noted that the company is classified among small and medium enterprises (SMEs) and is located in the Valley of Mexico, a significant economic region of the country. This organization enabled us to document, analyze, and guide an artificial intelligence adoption process.

2. New Technology Adoption

I4.0 gained momentum and was primarily utilized by companies as a result of its perceived advantages within the capitalist system. Consequently, the incorporation of computational fields, such as artificial intelligence, became increasingly significant until the early 2000s. To discern a subject of global significance, one only needs to examine many studies and implementations in the fields of education [45], business [46,47,48], and government [49,50].

Currently, we are in the middle of I4.0, where there is a significant transformation of industrial processes and daily life worldwide. However, this transformation is accompanied by various challenges that need to be addressed in order to adapt effectively. In addition to the factors mentioned in the first section, there are several others that should be considered. These include the efficient handling of multitasking by workers, the presence of experienced managers in the industry, employees who are more focused and purposeful, challenges in accurately determining investment returns, cyber security concerns, access to high-quality information, a reliable internet connection with good bandwidth, and a well-structured organizational setup [15,51]. However, it is also important to take into account the social implications if an ethical and socially responsible adoption is desired [52]. 1RI, 2RI, and 3RI have demonstrated a lack of responsible implementation. Now, the success of I4.0 depends not only on technological advances but also on creative collaboration and harmonious interaction between humans and machines to develop homeostatic systems [53].

Based on these assumptions, a novel study was conducted to examine the ways in which the business community has attempted to incorporate the new technologies of I4.0 [54]. Two goals guided this research: first, to identify the models; and second, to understand the challenges facing SMEs as a result of I4.0. Three primary models were identified as having the potential to enhance organizational management’s adoption of new technology.

- Business models: These models adjust the business model in order to incorporate training for new technologies as a critical component of their operational policies.

- Diagnostic models: These models generate a diagnostic of the organization’s condition and highlight the critical sections that need to be adhered to in order to achieve adoption.

- Process models: These suggest approaches to achieving adoption objectives, but they lack an initial diagnosis that would indicate the organization’s readiness to implement the strategies.

These three qualities of the models were discovered independently in different plans. They appear to stimulate the incorporation of new technologies, but they lack the viability and transdisciplinary integration needed to achieve the objective [55]. For example, the first type recognizes that it is impossible to change an organization’s business model without first comprehending its environment and self-assessing to determine what the first step should be. However, strategies with weaknesses in the business model cannot be launched since the strategy must be oriented toward the objectives that have a direct impact on the business model.

Upon transferring the three attributes of the general structures of organizations, it is clear that they can be distributed among different functions within a company. For example, establishing the pillar functions of an organization takes priority over developing a precisely delineated new business model. However, firms that prioritize strategy and process may lack clear foundations, and their business model fails to determine the direction of these activities.

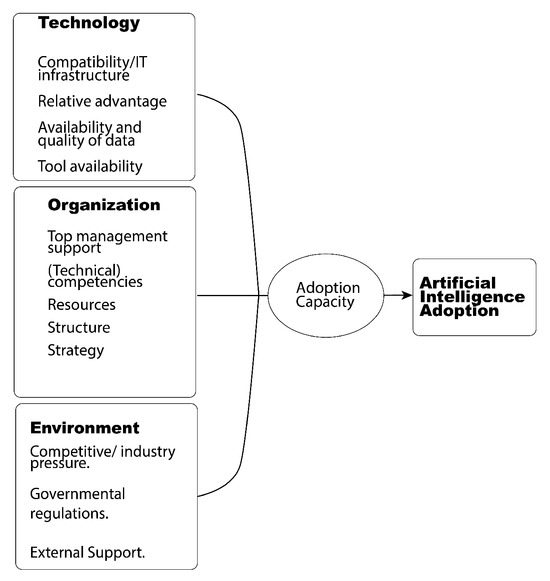

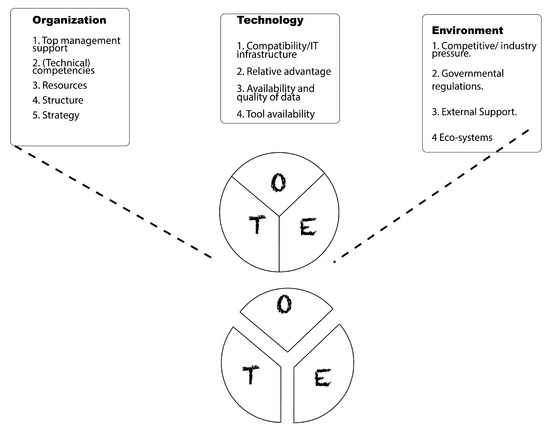

The readiness or diagnostic models designed for stakeholders were among the most relevant findings. These models comprise clearly defined criteria that allow organizations to self-evaluate and determine their readiness for the adoption process. Illustrative examples of such models include the Technology Organization Environment Model (TOE) and the Technology Acceptance Model (TAM), both of which have been implemented to evaluate the feasibility of adoption for various organizations, universities, and companies [54,56,57]. For this research, the TOE model was selected as a diagnostic tool to integrate with the Viable System Model (VSM). Its purpose is to assist with the initial diagnosis of the metamodel for the implementation of new technologies. The essential attributes that a business has to consider in order to prepare or launch an adoption process are taken into consideration. Figure 1, designed based on the elements of the TOE framework, illustrates the principal criteria that a company must consider for successful implementation. These elements have been thoroughly analyzed and expressed through extensive studies and questionnaires conducted with managers from various countries [54].

Figure 1.

TOE model adapted from the work of Tornatzky and Fleischer in [44].

These fundamental elements are used in the third section to explain the design of the VSM-ANT. The aim is to detail the key points that organizations need to innovate on through the proper use of VSM, creating a common and recognizable framework for organizational design. Each element grouped in Figure 1 represents activities that directors, managers, or strategists are accustomed to and handle daily.

3. Cybernetic Organizational

Cybernetics, as defined by Wiener, refers to the process of controlling and communicating between humans and machines by exchanging information in a continuous loop [58]. However, in contemporary times, the advantages of cybernetics extend beyond artificial systems and encompass natural systems, including organisms and societies. These systems are now examined through the lens of cybernetic control and communication. Beer, a prominent figure in the field of cybernetics, describes it as the study of efficient systems and their functioning [40]. Beer perceived cybernetics from a broader perspective and dedicated his research to constructing a highly resilient model that would guarantee the future viability of a system.

In summary, viability, according to Beer, refers to the maintenance of an organization’s identity through a comprehensive regulatory process that encompasses learning, adaptation, and evolution, thus allowing its survival. Viability is the function of achieving a suitable balance between the autonomy of subsystems and their integration within the system, or the balance between stability and adaptation. Although Beer aimed to conceptually convey the complexity of the term “viability”, he also developed a model that not only conceptualizes the value of viability but also proposes an organizational structure with various subsystems that collectively pursue a common objective [42].

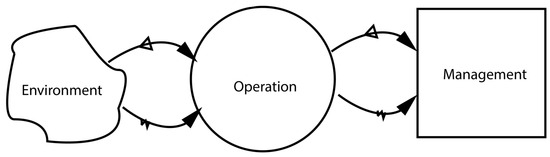

The Viable System Model (VSM), developed by Stafford Beer, encompass the essential features of viability. The model is grounded in three fundamental parts (Figure 2: The environment refers to the specific conditions and circumstances in which a system functions, and it determines and controls the system’s performance based on its goals and potential risks. Operation encompasses the framework and components that are responsible for performing the essential tasks involved in engaging with the environment. The management or meta-system is responsible for orchestrating the harmonious collaboration of the functioning subsystems in order to uphold the identity and goals of an organization). Beer adds two elements to the model, amplifiers, and attenuators: an attenuator (represented as a resistor), whose function is to reduce variety and share just important information with the system; and the amplifier (represented by a white arrow), whose function is to increase variety and transmit more information to the system.

Figure 2.

Basic elements for a self-organization based on the work of Beer [40].

Furthermore, the operation and management elements consist of five subsystems, as indicated in Table 1. These subsystems play a crucial role in achieving viability. The operation includes subsystems S1, whereas the remaining subsystems constitute management. Management plays a crucial role in coordinating and exerting control over the various S1s that may be present within an organization.

Table 1.

Subsystems.

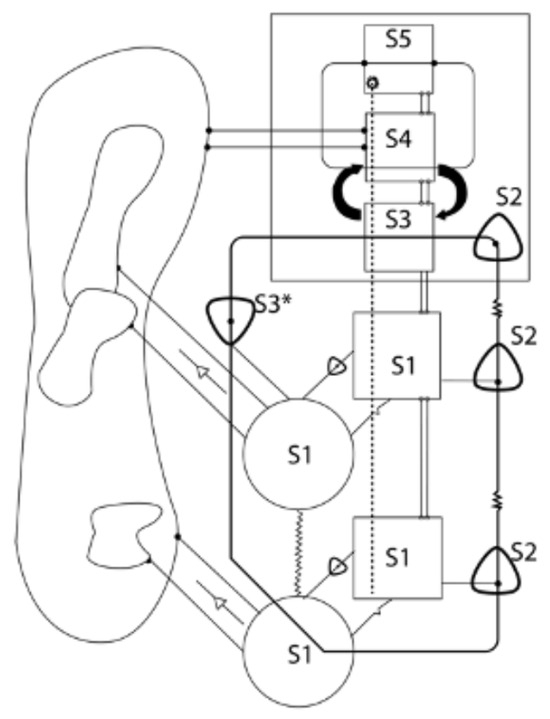

Ultimately, his research centers around the VSM, a framework that integrates cybernetics, complexity theory, and structural analysis. In addition to subsystems and the axioms delineated by Beer, these three components direct the development of viable systems. The template is depicted in Figure 3.

Figure 3.

Viable System Model [40].

Describing the VSM is essential since it is a highly effective tool for overcoming the challenges a company faces when integrating into I4.0 and 5.0. Nevertheless, this current project incorporates a proposition that is more suitable for computer science (CS) technologies and simultaneously aims to achieve sustainability from Espinosa’s viewpoints. This leads to a model that is more detailed and more aligned with the TOE requirements for an adopting corporation.

Viable and Sustainable

Stafford Beer introduced the notion of viability at organizations through his comprehensive collection of books and articles, in which he established the Viable System Model (VSM). More recently, systemic developers have focused on the study and development of viable and sustainable systems (V&S) [59,60,61]. The accurate diagnosis provided via these studies using the self-transformation method (STM) allows us to gain a thorough understanding of the challenges and impracticability facing a company. The research aims to comprehend accurate diagnostics and discover issues within the niche.

To integrate the basic concepts of system sustainability, we rely on the book The Viable System Model in Action [43]. Espinosa references us, and we address the definition of sustainable development as established by the World Commission on Environment and Development. Sustainable developments are defined as the type of development that meets the needs of the current generation without compromising the ability of future generations to meet their own needs.

An organization aiming at sustainability must break away from the existing economic model. If growth or stability is only determined by monetary factors, it can lead to the development of organizations that are financially viable but not sustainable long-term. Additional evaluation criteria should be present, including aspects such as social, environmental, and political concerns and well-being [62].

To consider a system a V&S, it must have the following attributes:

- Able to exist independently without separation from its niche or from future generations that will inhabit it.

- Its structural niche coupling may result (or may not) in access to vital resources and knowledge to effectively implement its identity.

- It can survive with the resources it has access to.

- Its products or services are welcomed and needed in its niche.

- It does not result in a separation from its social or ecological niche.

- It contributes to improving the quality of life of its affiliates and the communities with which it interacts.

- It preserves and/or improves the biodiversity and health of ecosystems in its niche.

The crux of comprehending V&S is in the concept of a niche. Espinosa consistently employs the term niche to refer to an entity that interacts directly with its environment. Specifically, the S1 subsystems, which Beer indicated as key components in establishing cyber organizations, are largely described as niches. All aspects are significant, but Espinosa’s study with V&S specifically focuses on implementing the self-governance of these specific areas, known as S1, in order to achieve more independence by delegating operational decision-making away from the other subsystems, S3–S5. Doing this demonstrated that the effectiveness of systems can be significantly enhanced.

4. Model Description

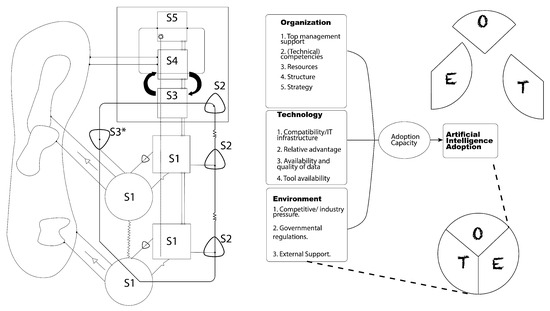

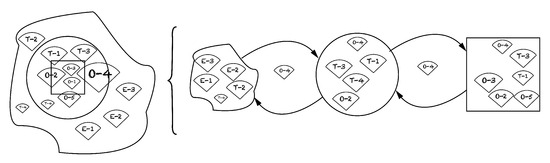

The previous models and approaches adequately serve the purpose of providing a guide and introduction to the metamodel proposal. In the field of organizational cybernetics, the Viable System Model (VSM) framework and the Technology–Organization–Environment (TOE) model serve as the necessary requirements for an organization to enhance its capacity to adopt new technologies (Figure 4). In addition, efforts are made to strengthen the implementation of the VSM, with a particular focus on sustainability [43,63,64].

Figure 4.

Models.

Both models have extensive utility in organizations and provide advantages in organizational diagnostics and the assessment of functional deficiencies, which could enhance the ability to embrace new technologies. Each has addressed the practicability of its implementation. However, both models offer inherent potential on the basis of their respective design methodologies. Moreover, the VSM represents the viewpoint of the organization, whereas TOE pertains to the process of adopting new technology.

Since the analysis conducted in the initial Section 1, the challenge of organizational management has persisted after the advent of Industry 4.0 (I4.0). Organizations often prefer straightforward models aligned with business strategies, such as the Technology–Organization–Environment (TOE) model, which can easily translate organizational goals into actionable strategies for owners and decision-makers. However, the complexities introduced via Industry 4.0 and 5.0 require a paradigm shift, rendering traditional approaches impractical. The key to the successful adoption of new technologies lies in effective organizational planning and readiness.

The application of both models is founded on systems science, namely the development of a model that can handle the necessary complexity to ensure organizational viability and sustainability within the context of I4.0 and I5.0. The metamodel is designed to facilitate the translation of commercial company requirements into organizational cyber-technologies’ needs.

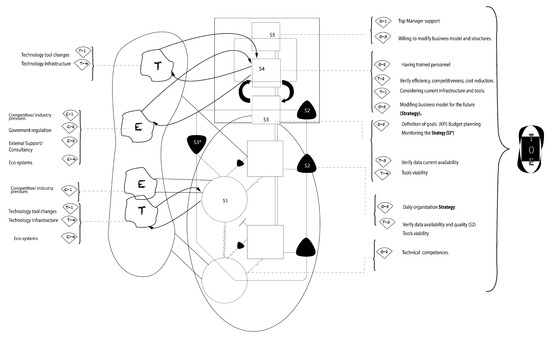

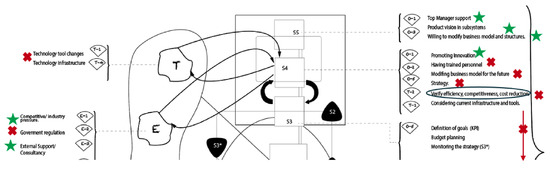

To effectively implement a relevant model, it is essential to perform an enterprise diagnosis using the TOE framework. Figure 5 and Figure 6 illustrate the allocation of key criteria related to the environment, meta-system, and operation of the VSM. The TOE criteria are as follows: The Organization subsystem is rated on a scale of 1 to 5, the Technology subsystem on a scale of 1 to 4, and the Environment subsystem on a scale of 1 to 4. These criteria are then distributed across the three core components of the VSM to determine the specific tasks required for each subsystem.

Figure 5.

TOE model.

Figure 6.

TOE distributed across VSM.

This distribution initiates the implementation of the VSM-ANT, where the subsystems are assigned TOE criteria to ensure that stakeholders understand the specific responsibilities of each subsystem in the context of adopting new technology. Moreover, while systems thinkers familiar with VSM excel in identifying issues and devising strategies to address cybernetic challenges, stakeholders operate differently. They focus on goals aligned with their business models, involving tasks such as validating information, understanding organizational infrastructure, and developing competitive strategies.

This structured approach facilitates the translation of business imperatives into systemic structures and processes. Therefore, the subsequent focus and primary guideline in employing our model’s proposition emphasize the critical importance of the 0–4 “organizational structure” criterion, which is essential for ensuring the model’s analytical feasibility.

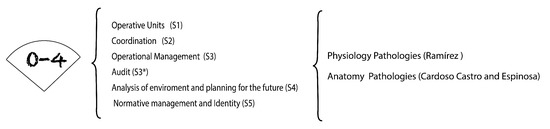

4.1. The Importance of the 0–4 Criterion

It is important to note that the “0–4” criterion, depicted in Figure 7, should be given priority when considering the most crucial factor for a successful adoption. 0–4 denotes the organizational structure, which is a fundamental element in the implementation of new technologies [65,66]. Therefore, it is necessary for the category “0–4” to include the five subsystems mentioned with reference to the VSM (Table 1). If it is not included in any new adoption procedure, it is unlikely to achieve success.

Figure 7.

“O–4”.

These subsystems play a crucial role in creating flexible and intelligent organizations that can adapt to rapid and uncertain changes in the present. In fact, current research continues to emphasize the importance of these five subsystems for organizational viability [67,68,69,70].

After evaluating the significance of the 0–4 criterion, it is feasible to proceed with the use of the workable model depicted in Figure 8 called VSM-ANT. The adopting organization will discover that the remaining TOE criteria, attached to the Stafford Beer model, serve as guidelines that subsystems must conform to.

Figure 8.

VSM-ANT.

Each criterion is a task that must be executed via each subsystem, using training, workshops, and the creation of action plans. It is advisable to include measurable key performance indicators (KPIs) to provide feedback on the progress made at each level of the comprehensive model. The TOE criteria depicted in Figure 8 must be met through the hermeneutic responsibility among VSM subsystems following the principles and process description described below.

4.2. Principles and Processes

The first principle for using the model at any organizational level should begin with the following:

- Recruit the five VSM subsystems to achieve viability and continue to adopt new technologies. This principle follows criterion 0–4.

Once the viable structure of the system has been completed or listed, the second principle of the use of VSM-ANT emerges. This principle is the trigger for any activity relevant to substantial changes in reality:

- To cover the TOE criteria or work on them, the model analysis must be top-down in order to assess which ones are covered and which ones need to be worked on.

For instance, criterion T-1, “changes in external technology”, must belong to the responsibilities of S4, which proposes its autopoeitic modifications. However, as observed, this criterion T-1 is shared with S1.

T-1 is shared by two important premises. First, returning to Espinosa’s niche principle [61], the analysis of tools and infrastructure must be carried out in the “niche” (S1), since it interacts with the interior and exterior of the system. S1 will use technology and transform energy, matter, or information for the benefit of its environment and the general system itself.

The second reason is that S4 seeks to generate a strategy; however, it must understand the behavior of S1 and how the adoption proposals will affect its performance.

Based on this example, the third principle for using the VSM-ANT is also emphasized.

- If the criterion is located within the responsibilities of more than two subsystems, the analysis must take into account the worldview of the subsystems in interaction.

This third principle mentions that the worldview of systems in direct interaction with the desired modification must be taken into account; however, it does not limit other systems’ interaction.

The last principle refers to the criteria that directly influence the S1 subsystems, as they are the “niche”.

- The TOE criteria interacting in S1’s must seek sustainability in their behavior.

As the model description advances, it becomes evident that the criteria are fulfilled. For example, functions O-1, 2, and 5 within S4 require collaborative evaluation by members of the organization. Although these functions fall under S4’s responsibility, the primary goal is to enhance relationships between subsystems, identify factors impacting operations, and effectively implement TOE criteria recommendations. The main objective of this part is to assess the viability of the proposed changes and determine whether the integration of new tools is necessary and beneficial to the system (T-2; T-1). Avoid pursuing solutions that are either more complex than necessary for the firm or not sufficiently complex to meet the demands of the environment, competition, and customers (E-1; E-3).

This is how the TOE criteria are understood in the Viable System Model (VSM). The combination proposal due to the Stafford Beer model is effective in managing communication between subsystems and complexity, while the TOE model is useful for evaluating, diagnosing, and implementing new technologies. By combining the strengths of each model, a reproducible functional structure can be created for every organization.

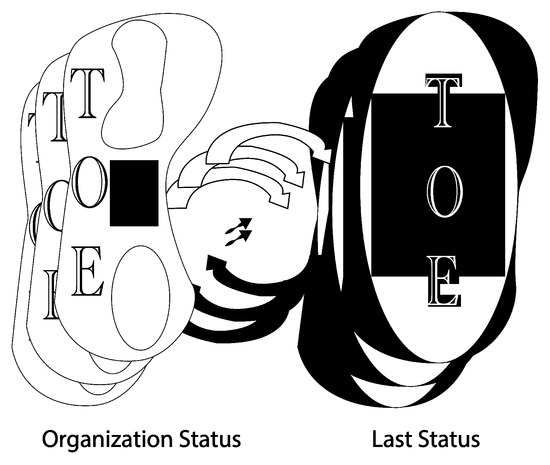

Finally, Figure 9 aims to describe the iteration at different organizational levels, fulfilling the TOE criteria since “organization status” until reaching the desired model, the “Last status”. As shown, no other work promotes the adoption of new technologies through holistic thinking and managerial thought applied by TOE. It should be noted that, while a work was found with holistic perspectives that promote business maturation, it does not present a viable structure and process [65]. Using the VSM-ANT model, an organization becomes “alive”, continuously seeking homeostasis and sustainability.

Figure 9.

VSM-ANT process.

In each iteration, the subsystems involved must decide on the best practices and criteria to fulfill in each iteration. To carry out the process, it is important to follow the four principles previously described and to adopt tools used in the three methodologies combined in a transdisciplinary manner, namely using the VSM, TOE, and V&S. Furthermore, it is essential to make it known to model practitioners that a system thinker is indispensable in teamwork, serving as a manager and designer of the tools used during the adoption of new technologies.

To exemplify everything described in this section, we explain in the following section the first implementation of the model.

5. Application

We worked with a medium company classified among small and medium companies, which was dedicated to plastic manufacturing and located in one of the most important economic areas of the country: the Valley of Mexico Zone. This region is a key hub for various companies at the national level, according to the National Statistics of Economic Units in 2022. Almost 20% of all companies in the country are located in this area.

This company, which we will call “Pelletizer” to maintain its anonymity, specializes in the development of plastic pelletization. Its main commercial objective is the production of raw materials for injection molding, profile extrusion, and color mixing for specific products.

The core mission of the company is to deliver exceptional-quality plastic pellets that meet specific customer requirements. To achieve this goal, Pelletizer is implementing an artificial intelligence system to streamline their quality control system for plastic pellet production. This innovative system aims to identify manufacturing defects promptly, eliminating reliance on the quality department’s judgment for every pellet. By automating defect detection, Pelletizer can ensure consistent quality and minimize customer returns due to products not meeting specified standards. This not only benefits their customers but also optimizes their internal processes.

Following the description of the model (Section 4), the first principle to be implemented is to ensure the readiness of the five subsystems of the Viable System Model (VSM): S1, S2, S3, S4, and S5.

To analyze the system and ensure the readiness of the five VSM subsystems, the team organized an in-person workshop with the participation of representatives of the Continuous Improvement Department, production line workers, and the security group. During the workshop, the three areas conducted guided tours of the plant to provide detailed explanations of how they carry out their processes. This enabled a comprehensive diagnosis of how they could adapt to the VSM and, additionally, helped identify, through the application of a questionnaire based on the work of Ramírez Gutiérrez et al. [54], the criteria within the TOE model where they experienced the greatest deficiencies. It is important to note that the TOE model evaluates organizations’ capacity to adopt new technologies.

This is the information that will come out after the workshop:

- S5: Regional coordination exists whereby the company’s policies and identity are aligned, and the implementation of artificial intelligence (AI) in the pelletization process is supported by the senior regional manager. This is encapsulated in four organization-wide pillars: People, Product, Operational Excellence, and Business Excellence. Operational Excellence is associated with each of the most essential values for the organization, in this instance, the adoption of AI.

- S4: The organization is committed to the ongoing development and modification of the system in response to its internal and external environment. “As the leader of continuous development, you must engage in ongoing planning and training to surpass the various operational and product excellence standards of international certifications”.

- S3: Management is the responsibility of a chief in each area; for instance, the chief of continuous improvement oversees the deployment of new processes to their respective operating areas with the support of an assistant, whose duties are more similar to those in subsystem 2.

- S3*: An internal audit is conducted under the supervision of quality and in accordance with methodologies such as Lean Six Sigma to ensure that positive and negative control outputs are maintained per area. In addition, it includes an exclusive quality section that conducts internal examinations of all product-related components.

- S2: A supervisor is assigned to each area; in the primary location where the adoption is being pursued, a production supervisor oversees the four lines that are operational.

- S1: This comprises the line workers who supervise, operate, sanitize, and mix, among other responsibilities.

Understanding the organization’s structure and alignment triggers the initiation of the second principle and its related process.

5.1. First Process

In interviews conducted with the continuous improvement manager and related areas, S1, it was determined that the organization is backed by management, which possesses a vision of transforming business models and structures while fostering innovation.

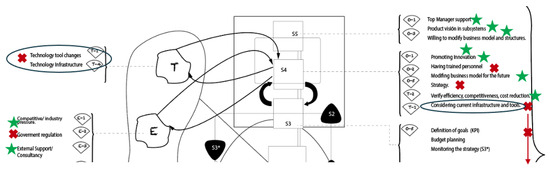

Following the second principle, from the top to the bottom, the missing criteria TOE in the first process are marked in Figure 10, with red for the missing criteria and green for the criteria fulfilled.

Figure 10.

First process. The red crosses refer to the missing criteria and the green stars for the criteria fulfilled.

Not all criteria are colored green; instead, the red ones indicate those that have yet to be developed and require a transition to the green state.

In S4, the E-3 criterion, with the contribution of computing specialists, determined that the initial version of the structure includes one or more missing criteria suggested by the model.

Likewise, the third principle must be applied at this point. The subsystems chose the best criterion to prioritize first. The important aspect is fulfilling one, two, or three criteria in sequence, and if working on one criterion helps fulfill others, it is advantageous.

In this first instance, the organization chooses T-2 to validate the viability of AI intervention and implement cost reductions.

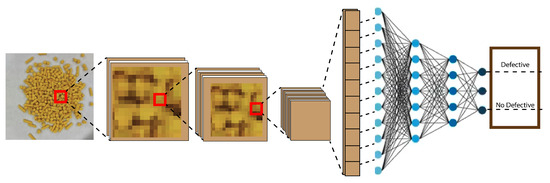

The challenge of identifying costs, benefits, and feasibility was addressed by incorporating a processing step into a minimum viable product (MVP). This step was performed offline before the production began to ensure that the information could be modified and adjusted effectively. As part of this process, the product images were integrated into an artificial intelligence system designed to distinguish between defective and non-defective surfaces. These images (Figure 11) were used throughout the training phase to ensure the accuracy and reliability of the system.

Figure 11.

Training images.

The photographs were taken over one week using product samples obtained from the quality control department. Due to restrictions in the department, photographs could not be captured on a designated table. Instead, a dual-lens smartphone camera was used, featuring a 12-megapixel primary sensor and an ultra-wide-angle lens. The camera setup was mounted on a fixed base, positioned 30 cm above plastic pellets, ensuring consistent framing and focus across all samples. To prepare the data for training, reprocessing of the captured images was necessary. A minimum of two thousand images of specific dimensions were taken and subsequently subdivided into nine groups, resulting in approximately 18,000 images. This extensive data set was used to effectively train the artificial intelligence model.

The images were then subjected to a second round of information preprocessing; they were converted to grayscale to identify physical deformations, such as those of longer or more porous surfaces, for which grayscale alone would have reduced the training time.

The architecture used for image classification is based on the VGG-13 architecture [71,72]. This provides a detailed example of its implementation, featuring sequential convolutional layers and grouping operations that establish a strong foundation for feature extraction and pattern recognition, which are both essential for identifying defective surfaces. However, this study focuses on demonstrating how artificial intelligence can be applied in a viable and practical manner, particularly in real-world manufacturing environments. The use of VGG-13 in these references serves as just one example of how this model can be used effectively.

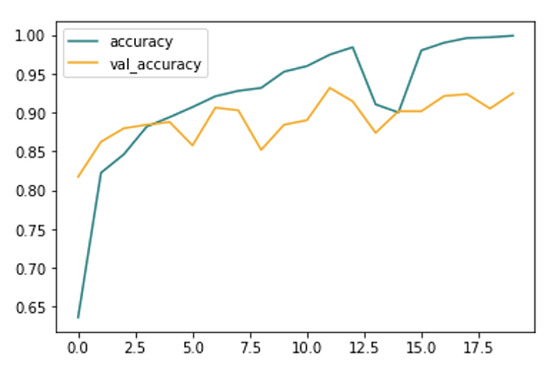

In evaluating the performance of the model, we used the accuracy metric. This choice was driven by the balanced nature of the dataset across all classes, where prioritizing overall classification performance was critical. Accuracy, as a measure of the proportion of correctly classified instances, aligns with the objective of minimizing errors in image classification. Figure 12 illustrates the nesting behavior of the data during training, highlighting the model’s ability to generalize effectively. The consistent performance across training and validation datasets further validates the selection of accuracy as the most appropriate metric for this context and demonstrates the robustness of the chosen approach.

Figure 12.

Accuracy.

The arrangement was constructed using a perceptron, a classifier, and three convolutional layers. As illustrated in Figure 13, the data pass through three convolutional operations before reaching the flatten layer, which connects to the perceptron. Ultimately, the classifier was developed to differentiate between defective and non-defective items. The training of the neural network resulted in satisfactory performance, achieving a precision of 93% (Figure 12). This value, determined through a computational metric that quantifies accuracy, highlights the effectiveness of the model in classifying the items correctly.

Figure 13.

Convolutional neural network.

After the process was successfully demonstrated, both managers and operators gave their full approval. When integrating a new tool, the T-2 procedure must be followed to understand to what extent the new technologies will affect the processes that need improvement. Using this approach, an organization can effectively facilitate the integration of new technologies and the execution of subsequent functions.

5.2. Second Process

A subsequent iteration of the model is executed under the assumption that the T-2 function reaches a valid conclusion. The subsequent Figure 14 illustrates the revised criteria that the organization assesses to promote the adoption of artificial intelligence, T-1 in S4 “Considering current infrastructure and tools”.

Figure 14.

Second process intervention. The red crosses refer to the missing criteria and the green stars for the criteria fulfilled.

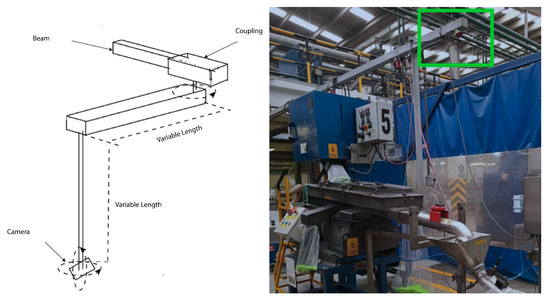

In this diagnostic, we collaborated with a different category of specialists who modify the production lines of other businesses; in this case, the required infrastructure, costs, and strategy for a new learning initiative were determined in conjunction with computing specialists.

The subsequent list will exclusively outline the prerequisites, machinery, and approach for the third iteration that the organization demanded to estimate the costs and milestones.

- Position a camera-loading limb that is also equipped with the necessary components to acquire the training information.

- Construct camera and control elements and modify the production line procedure.

- Load of information (videos) about the primary defects to be trained on.

- Develop a beta version of the initial three defects.

A potential solution was to incorporate it within the existing infrastructure, with the arm positioned at the location indicated in green (Figure 15).

Figure 15.

Robotic arm.

Upon the completion of this iteration, two additional criteria of the VSM-ANT were achieved to identify the strategy for incorporating this new tool (T-1) into the environment in order to complete a new phase of the model. However, the company decided to temporarily suspend the adoption project due to circumstances that were not related to the project.

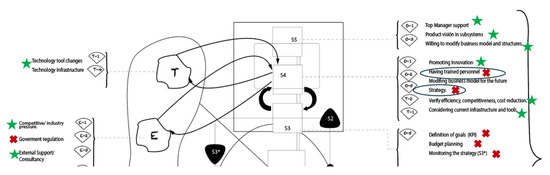

If the company had continued with the process, the VSM-ANT would now have the following appearance as a third iteration of the model (Figure 16).

Figure 16.

Third process intervention. The red crosses refer to the missing criteria and the green stars for the criteria fulfilled.

During a third working table with the innovation area, the manager stated that training personnel (0–2) on how to collaborate with AI and developing an integration strategy (0–5) to support the operational areas were the subsequent stages in implementing the intervention in the lines.

The meeting with the company came to an end, and the investigation will recommence once the organization makes a decision regarding the investment’s continuation.

6. Discussion

This research addresses the problem of integrating technological advancements in business organizations in an orderly and gradual way. Despite the existence of models designed to tackle this challenge, historical and theoretical analyses show that they lack holistic and sustainable approaches that are easy for system owners to interpret and apply.

Our research proposes the Viable Model for the Adoption of New Technologies, whose main contribution is the transdisciplinary integration of the managerial advantages of the TOE model, the viability of the VSM, and the sustainability of V&S. This model aims to address the contextual and historical issues discussed in the first two sections of the manuscript.

Our model is the main contribution of this research, as no other model combines these features. Although there are holistic works and contributions from the V&S approach, none provide tools that clearly define the criteria to be evaluated and transformed.

To validate this tool, we performed the first application of the model at a plastic pelletizing company. One of the most relevant actions was to assess the current state of the organization. Fortunately, the organization had a structure similar to the VSM with its five defined subsystems, facilitating the first principle of the model, which we named 0–4.

Subsequently, the model allowed for a technological validation of what was intended to be introduced into the production line, a criterion also covered by the TOE. This validation was carried out by the subsystems of the corresponding management area, coordinating communication with external consultants (environmental) and the operations system (production line).

This validation was performed as the first cycle of the model. First, a validation strategy was developed, a full technological process that included training a convolutional network and verifying its benefits. AI demonstrated its ability to detect production defects with 93% precision. This first cycle allowed decision-makers to approve the continuation of the process, seeing the opportunity to improve their quality system and potentially reduce operational costs by minimizing production waste in a process normally assisted only by humans.

The second cycle of the model provided an organized method for determining the infrastructure the company would need for a direct intervention on the production line. A tailored solution was designed, video recordings were made, and a new phase of neural network training was started. This second cycle, along with the third theoretical cycle, aimed to define human behavior processes once the AI detected defects. This phase would establish KPIs and training for worker interaction with AI, leading to the creation of a cyber–physical system.

Unfortunately, due to financial constraints and decisions by system owners, the third cycle of our model, which would define communication channels between the operating system, the environment, and management systems, was not implemented. This is our future recommendation for the company, as defining these processes would bring them closer to a viable objective. In addition, we recommend applying our model to other organizations in order to verify its general applicability. We understand that to consolidate the use of our model, more applications need to be documented, but the cycles applied to the organization demonstrate that the tool functions as a managerial support to adopt the principles of I4.0 and 5.0 in an orderly and gradual manner.

7. Conclusions

The study identified several challenges that organizations face when transitioning to Industry 4.0 and 5.0. These challenges often arise when organizational owners continue to employ traditional management strategies or when organizations achieve a satisfactory level of success but fail to meet the goals of Industry 5.0. The main problem lies in integrating technological advancements into business organizations in a viable, orderly, and gradual manner.

Current models, such as the TOE model, tend to focus on managerial evaluation to determine an organization’s adoption capabilities. However, these models only evaluate business characteristics and do not propose methodologies, structures, and processes from a viable and sustainable perspective. This prevents the creation of a holistic tool tailored to contemporary business demands.

The manuscript developed the necessary theories to construct the model, sharing the premise that the fundamentals of systems science are essential for transforming an organization. Subsequently, the main contribution and integration of the research was presented in the design of the Viable Model for the Adoption of New Technologies (VSM-ANT). Its design was described as a guide for developing diagnostics, strategies, and processes that support the managers of an organization step by step.

Furthermore, the VSM-ANT model, applied in a pellet company, demonstrates its effectiveness in identifying the fundamental criteria of the TOE and how the integration of the VSM and sustainability allows it to be used as the appropriate tool for viable diagnostics, structures, and processes in modern management demands. In addition, this model can be further defined in its evaluation frameworks, providing a more detailed explanation of how to adapt the TOE criteria to different organizations. This opens the possibility of perfecting our VSM-ANT model and allowing its use by other scientific collaborators.

However, in this manuscript, only the second iteration of the VSM-ANT model is reached, that is, the adaptation of the robotic arm to the production line and the accuracy in data collection. Therefore, in future work, the third phase remains to be carried out in order to establish the performance indicators or KPIs once it has been proven that the integration of artificial intelligence is viable.

Moreover, in the short term, it is not possible to implement the VSM-ANT model, for a robust validation of the same, at different companies because it is very difficult for companies to allow access to their facilities and provide very sensitive information pertaining to them.

In addition, to properly implement the VSM-ANT model, the end user must possess knowledge of systems science in order to carry out the activities proposed by the model. Additionally, support from a specialist in computer science is required to propose technological solutions, according to what the model suggests.

Finally, as part of future research, it will be crucial to define measurable sustainability outcomes and establish clear metrics to assess progress, encompassing environmental, economic, and social dimensions to ensure a comprehensive evaluation of the system’s impact. We believe starting with the implementation of the viable model opens the door to introducing sustainability, as both concepts complement each other. Dr. Espinoza [43] explains in detail how understanding the behavior of Subsystem S1 in relation to its environment (which she refers to as a “niche”) and its implications allows the definition of specific sustainability metrics for each system. In this sense, the model could be strengthened in this area by conducting a sustainability analysis based on the principles of viable and sustainable systems, providing a more robust framework aligned with sustainable development goals.

Author Contributions

Conceptualization, P.G.S., O.M.M. and A.G.R.-G.; methodology, O.M.M., A.L.C.P. and A.G.R.-G.; software, P.G.S.; validation, P.G.S., A.G.R.-G., A.L.C.P. and O.M.M.; formal analysis, P.G.S.; investigation, P.G.S. and A.G.R.-G.; resources, O.M.M. and A.G.R.-G.; data; writing—original draft preparation, P.G.S., A.G.R.-G., O.M.M. and A.L.C.P.; writing—review and editing, P.G.S., A.G.R.-G., O.M.M. and A.L.C.P.; visualization, P.G.S.; supervision, A.G.R.-G. and O.M.M.; project administration, A.G.R.-G., O.M.M. and A.L.C.P.; funding acquisition, P.G.S. All authors have read and agreed to the published version of the manuscript.

Funding

This article was supported by Universidad Panamericana, in addition to Instituto Poliécnico Nacional (IPN), 20241762 granted Secretería de Investigación y Posgrado, and the Consejo Nacional de Humanidades, Ciencias y Tecnologías (CONAHCyT) of Mexico.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

The research described in this work was carried out at the Superior School of Mechanical and Electrical Engineering (Escuela Superior de Ingeniería Mecánica y Eléctrica) of the Instituto Politécnico Nacional, Campus Zacatenco. It should be noted that this research is part of a doctoral thesis entitled Modelo Viable para la Migración Digital de PyME’s en México, supported by Pavel Solano García, with work directed by Oswaldo Morales Matamoros and Ana Gabriela Ramírez Gutiérrez.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bartodziej, C.J. The concept Industry 4.0. In The Concept Industry 4.0; Springer Fachmedien: Wiesbaden, Germany, 2016; pp. 27–50. [Google Scholar] [CrossRef]

- Khosravy, M.; Gupta, N.; Pasquali, A.; Dey, N.; Crespo, R.G.; Witkowski, O. Human-Collaborative Artificial Intelligence Along With Social Values in Industry 5.0: A Survey of the State-of-the-Art. IEEE Trans. Cogn. Dev. Syst. 2024, 16, 165–176. [Google Scholar] [CrossRef]

- Camarinha-Matos, L.M.; Rocha, A.D.; Graça, P. Collaborative approaches in sustainable and resilient manufacturing. J. Intell. Manuf. 2022, 35, 499–519. [Google Scholar] [CrossRef] [PubMed]

- de Pleijt, A.; Nuvolari, A.; Weisdorf, J. Human Capital Formation During the First Industrial Revolution: Evidence from the use of Steam Engines. J. Eur. Econ. Assoc. 2019, 18, 829–889. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, J. A History of Mechanical Engineering; Springer: Singapore, 2020. [Google Scholar]

- Barras, R. Industrial Revolution. In A Wealth of Buildings: Marking the Rhythm of English History; Palgrave Macmillan: London, UK, 2016; pp. 103–221. [Google Scholar] [CrossRef]

- Turner, P. Management During the First Industrial Revolution: European Pioneers—The Genesis of Modern Management; Springer International Publishing: Cham, Switzerland, 2021; pp. 33–63. [Google Scholar] [CrossRef]

- Haidar Torres, E.; Torres Estévez, G.C. La gestión mecanicista de las Instituciones de Educación Superior: Un estudio desde la modelación sistémica. Contad. Adm. 2015, 60, 796–816. [Google Scholar] [CrossRef]

- Agarwal, H.; Agarwal, R. First Industrial Revolution and Second Industrial Revolution: Technological differences and the differences in banking and financing of the firms. Saudi J. Humanit. Soc. Sci. 2017, 2, 1062–1066. [Google Scholar]

- Truesdell, C. History of classical mechanics: Part II, the 19th and 20th centuries. Die Naturwissenschaften 1976, 63, 119–130. [Google Scholar] [CrossRef]

- Bardeen, J.; Brattain, W.H. The transistor, a semi-conductor triode. Phys. Rev. 1948, 74, 230–231. [Google Scholar] [CrossRef]

- Bernhard, G.; Booth, C.R.; Ehramjian, J.C.; Stone, R.; Dutton, E.G. Ultraviolet and visible radiation at Barrow, Alaska: Climatology and influencing factors on the basis of version 2 National Science Foundation network data. J. Geophys. Res. Atmos. 2007, 112, D09101. [Google Scholar] [CrossRef]

- Galison, P. The Ontology of the Enemy: Norbert Wiener and the Cybernetic Vision. Crit. Inq. 1994, 21, 228–266. [Google Scholar] [CrossRef]

- Drucker, P. The Practice of Management; Routledge: London, UK, 2012. [Google Scholar] [CrossRef]

- Singh, M.; Goyat, R.; Panwar, R. Fundamental pillars for industry 4.0 development: Implementation framework and challenges in manufacturing environment. TQM J. 2023, 36, 288–309. [Google Scholar] [CrossRef]

- Gilchrist, A. Introducing Industry 4.0. In Industry 4.0; Apress: Berkeley, CA, USA, 2016; pp. 195–215. [Google Scholar] [CrossRef]

- Radanliev, P.; De Roure, D.; Van Kleek, M.; Santos, O.; Ani, U. Artificial intelligence in cyber physical systems. AI Soc. 2020, 36, 783–796. [Google Scholar] [CrossRef] [PubMed]

- Mittal, S.; Khan, M.A.; Romero, D.; Wuest, T. A critical review of smart manufacturing & Industry 4.0 maturity models: Implications for small and medium-sized enterprises (SMEs). J. Manuf. Syst. 2018, 49, 194–214. [Google Scholar] [CrossRef]

- Zhou, X.; Liang, W.; Ma, J.; Yan, Z.; Wang, K.I.K. 2D Federated Learning for Personalized Human Activity Recognition in Cyber-Physical-Social Systems. IEEE Trans. Netw. Sci. Eng. 2022, 9, 3934–3944. [Google Scholar] [CrossRef]

- Zeb, S.; Mahmood, A.; Khowaja, S.A.; Dev, K.; Hassan, S.A.; Gidlund, M.; Bellavista, P. Towards defining industry 5.0 vision with intelligent and softwarized wireless network architectures and services: A survey. J. Netw. Comput. Appl. 2024, 223, 103796. [Google Scholar] [CrossRef]

- Lou, S.; Hu, Z.; Zhang, Y.; Feng, Y.; Zhou, M.; Lv, C. Human-Cyber-Physical System for Industry 5.0: A Review From a Human-Centric Perspective. IEEE Trans. Autom. Sci. Eng. 2024, 1–18. [Google Scholar] [CrossRef]

- Almawishir, N.F.S.; Benlaria, H. Innovation and dimensions of sustainable development: Mediating role of ICTs. Cogent Bus. Manag. 2024, 11, 2336306. [Google Scholar] [CrossRef]

- Su, C.W.; Xie, Y.; Shahab, S.; Faisal, C.M.N.; Hafeez, M.; Qamri, G.M. Towards Achieving Sustainable Development: Role of Technology Innovation, Technology Adoption and CO2 Emission for BRICS. Int. J. Environ. Res. Public Health 2021, 18, 277. [Google Scholar] [CrossRef]

- Brundtland, G.H. Our Common Future World Commission on Environment and Developement; United Nations: New York, NY, USA, 1987. [Google Scholar]

- Directorate-General for Research and Innovation (European Commission); Breque, M.; De Nul, L.; Petridis, A. Industry 5.0—Towards a Sustainable, Human-Centric and Resilient European Industry; Publications Office of the European Union: Luxembourg, 2021. [Google Scholar] [CrossRef]

- Madsen, D.; Slåtten, K. Comparing the Evolutionary Trajectories of Industry 4.0 and 5.0: A Management Fashion Perspective. Appl. Syst. Innov. 2023, 6, 48. [Google Scholar] [CrossRef]

- Verma, S.K.; Verma, V.; Ansari, M.T.J. A transition from Industry 4.0 to Industry 5.0. In Computational Intelligence Applications in Cyber Security; CRC Press: London, UK, 2024; pp. 1–15. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-Oriented and Ethical Technology Engineering in Industry 5.0: A Human-Centric Perspective for the Design of the Factory of the Future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Baig, M.I.; Yadegaridehkordi, E. Industry 5.0 applications for sustainability: A systematic review and future research directions. Sustain. Dev. 2024, 32, 662–681. [Google Scholar] [CrossRef]

- Grosso, C.; Sazen, N.; Boselli, R. AI-implemented toolkit to assist users with career “configuration”: The case of create your own future. In Proceedings of the 26th ACM International Systems and Software Product Line Conference—Volume B (SPLC ’22), Graz, Austria, 12–16 September 2022; ACM: New York, NY, USA, 2022; pp. 158–165. [Google Scholar] [CrossRef]

- Soomro, R.B.; Memon, S.G.; Dahri, N.A.; Al-Rahmi, W.M.; Aldriwish, K.; Salameh, A.A.; Al-Adwan, A.S.; Saleem, A. The Adoption of Digital Technologies by Small and Medium-Sized Enterprises for Sustainability and Value Creation in Pakistan: The Application of a Two-Staged Hybrid SEM-ANN Approach. Sustainability 2024, 16, 7351. [Google Scholar] [CrossRef]

- Kerzel, U. Enterprise AI Canvas Integrating Artificial Intelligence into Business. Appl. Artif. Intell. 2020, 35, 1–12. [Google Scholar] [CrossRef]

- Hmoud, B. The adoption of artificial intelligence in human resource management and the role of human resources. Forum Sci. Oecon. 2021, 9, 105–118. [Google Scholar] [CrossRef]

- Chatterjee, S.; Rana, N.P.; Dwivedi, Y.K.; Baabdullah, A.M. Understanding AI adoption in manufacturing and production firms using an integrated TAM-TOE model. Technol. Forecast. Soc. Change 2021, 170, 120880. [Google Scholar] [CrossRef]

- Nortje, M.; Grobbelaar, S. A Framework for the Implementation of Artificial Intelligence in Business Enterprises: A Readiness Model. In Proceedings of the 2020 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC), Cardiff, UK, 15–17 June 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–10. [Google Scholar] [CrossRef]

- Behl, A.; Chavan, M.; Jain, K.; Sharma, I.; Pereira, V.E.; Zhang, J.Z. The role of organizational culture and voluntariness in the adoption of artificial intelligence for disaster relief operations. Int. J. Manpow. 2021, 43, 569–586. [Google Scholar] [CrossRef]

- Muto, V.; Luongo, S.; Percuoco, M.; Tani, M. Artificial Intelligence and the Great Reset: Impacts and Perspectives for Italian SMEs Business Model Innovation. Systems 2024, 12, 330. [Google Scholar] [CrossRef]

- Someh, I.; Wixom, B.; Zutavern, A. Overcoming Organizational Obstacles to Artificial Intelligence Value Creation: Propositions for Research. In Proceedings of the 53rd Hawaii International Conference on System Sciences, HICSS 2020, Maui, HI, USA, 7–10 January 2020. [Google Scholar] [CrossRef]

- Yams, N.B.; Richardson, V.; Shubina, G.E.; Albrecht, S.; Gillblad, D. Integrated AI and Innovation Management: The Beginning of a Beautiful Friendship. Technol. Innov. Manag. Rev. 2020, 10, 5–18. [Google Scholar] [CrossRef]

- Beer, S. Diagnosing the System for Organizations; Wiley: Chichester, UK, 1985. [Google Scholar]

- Schwaninger, M. Methodologies in conflict: Achieving synergies between system dynamics and organizational cybernetics. Syst. Res. Behav. Sci. 2004, 21, 411–431. [Google Scholar] [CrossRef]

- Beer, S. The viable system model: Its provenance, development, methodology and pathology. J. Oper. Res. Soc. 1984, 35, 7–25. [Google Scholar] [CrossRef]

- Espinosa, A. Sustainable Self-Governance in Businesses and Society: The Viable System Model in Action; Routledge: London, UK, 2022. [Google Scholar] [CrossRef]

- Tornatzky, L.G.; Fleischer, M.; Chakrabarti, A.K. Processes of Technological Innovation; Lexington Books: Lanham, MD, USA, 1990. [Google Scholar]

- Tyson, M.M.; Sauers, N.J. School leaders’ adoption and implementation of artificial intelligence. J. Educ. Adm. 2021, 59, 271–285. [Google Scholar] [CrossRef]

- Lui, A.K.H.; Lee, M.C.M.; Ngai, E.W.T. Impact of artificial intelligence investment on firm value. Ann. Oper. Res. 2021, 308, 373–388. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J.; Kim, Y.; Song, Y. A Study on Priorities for Utilization of AI Recruitment System. In Proceedings of the 2021 21st ACIS International Winter Conference on Software Engineering, Artificial Intelligence, Networking and Parallel/Distributed Computing (SNPD-Winter), Ho Chi Minh City, Vietnam, 28–30 January 2021; pp. 278–279. [Google Scholar] [CrossRef]

- Lahlali, M.; Berbiche, N.; Alami, J.E. How Enterprise must be Prepared to be “AI First”? Int. J. Adv. Comput. Sci. Appl. 2021, 12, 346–351. [Google Scholar] [CrossRef]

- Zhang, W.; Zuo, N.; He, W.; Li, S.; Yu, L. Factors influencing the use of artificial intelligence in government: Evidence from China. Technol. Soc. 2021, 66, 101675. [Google Scholar] [CrossRef]

- Al-Mushayt, O.S. Automating E-Government Services With Artificial Intelligence. IEEE Access 2019, 7, 146821–146829. [Google Scholar] [CrossRef]

- Samani, A.; Saghafi, F. A hybrid model of implementing a smart production factory within the Industry 4.0 framework. J. Model. Manag. 2023, 19, 215–239. [Google Scholar] [CrossRef]

- Zerfass, A.; Hagelstein, J.; Tench, R. Artificial intelligence in communication management: A cross-national study on adoption and knowledge, impact, challenges and risks. J. Commun. Manag. 2020, 24, 377–389. [Google Scholar] [CrossRef]

- Malyshkin, A.V. Integration of artificial intelligence into public life: Some ethical and legal problems. Vestn. St. Petersburg UL 2019, 10, 444–460. [Google Scholar] [CrossRef]

- Ramírez-Gutiérrez, A.G.; Solano García, P.; Morales Matamoros, O.; Moreno Escobar, J.J.; Tejeida-Padilla, R. Systems Approach for the Adoption of New Technologies in Enterprises. Systems 2023, 11, 494. [Google Scholar] [CrossRef]

- Satalkina, L.; Zenk, L.; Steiner, G. Transdisciplinary multistage system modeling: Migrant entrepreneurship in the digital economy. Kybernetes 2022, 51, 219–240. [Google Scholar] [CrossRef]

- Salimon, M.G.; Sanuri, S.M.M.; Aliyu, O.A.; Perumal, S.; Yusr, M.M. E-learning satisfaction and retention: A concurrent perspective of cognitive absorption, perceived social presence and technology acceptance model. J. Syst. Inf. Technol. 2021, 23, 109–129. [Google Scholar] [CrossRef]

- Ramanathan, L.; Krishnan, S. An empirical investigation into the adoption of open source software in Information Technology outsourcing organizations. J. Syst. Inf. Technol. 2015, 17, 167–192. [Google Scholar] [CrossRef]

- Wiener, N. Cybernetics. Bull. Am. Acad. Arts Sci. 1950, 3, 2–4. [Google Scholar] [CrossRef]

- Martinez-Lozada, A.C.; Espinosa, A. Corporate viability and sustainability: A case study in a Mexican corporation. Syst. Res. Behav. Sci. 2020, 39, 143–158. [Google Scholar] [CrossRef]

- Sydelko, P.; Espinosa, A.; Midgley, G. Designing interagency responses to wicked problems: A viable system model board game. Eur. J. Oper. Res. 2024, 312, 746–764. [Google Scholar] [CrossRef]

- Espinosa, A.M.; Walker, J.; Grover, K.; Vachkova, M.V. The viability and sustainability approach to support organisational resilience: Learning in a recent case study in the health sector. Syst. Res. Behav. Sci. 2023, 40, 689–700. [Google Scholar] [CrossRef]

- Alves, J.; Lima, T.M.; Gaspar, P.D. Is Industry 5.0 a Human-Centred Approach? A Systematic Review. Processes 2023, 11, 193. [Google Scholar] [CrossRef]

- Panagiotakopoulos, P.D.; Espinosa, A.; Walker, J. Sustainability management: Insights from the Viable System Model. J. Clean. Prod. 2016, 113, 792–806. [Google Scholar] [CrossRef]

- Espinosa, A.; Harnden, R.; Walker, J. A complexity approach to sustainability—Stafford Beer revisited. Eur. J. Oper. Res. 2008, 187, 636–651. [Google Scholar] [CrossRef]

- Gianluca, E.; Alessandro, M. A conceptual framework for the cognitive enterprise: Pillars, maturity, value drivers. Technol. Anal. Strateg. Manag. 2022, 34, 377–389. [Google Scholar] [CrossRef]

- Volberda, H.W.; Khanagha, S.; Baden-Fuller, C.; Mihalache, O.R.; Birkinshaw, J. Strategizing in a digital world: Overcoming cognitive barriers, reconfiguring routines and introducing new organizational forms. Long Range Plan. 2021, 54, 102110. [Google Scholar] [CrossRef]

- Cardoso Castro, P.P. The viable system model as a framework to guide organisational adaptive response in times of instability and change. Int. J. Organ. Anal. 2019, 27, 289–307. [Google Scholar] [CrossRef]

- Ganzert, C.; Martinelli, D.P.; Delai, I. Intelligence systems methodology: A systemic approach to the organizational intelligence function. Knowl. Manag. Res. Pract. 2012, 10, 141–152. [Google Scholar] [CrossRef]

- Huygh, T.; De Haes, S. Investigating IT Governance through the Viable System Model. Inf. Syst. Manag. 2019, 36, 168–192. [Google Scholar] [CrossRef]

- Ramírez-Gutiérrez, A.G.; Cardoso-Castro, P.P.; Tejeida-Padilla, R. A Methodological Proposal for the Complementarity of the SSM and the VSM for the Analysis of Viability in Organizations. Syst. Pract. Action Res. 2020, 34, 331–357. [Google Scholar] [CrossRef]

- Huang, Y.C.; Hung, K.C.; Lin, J.C. Automated Machine Learning System for Defect Detection on Cylindrical Metal Surfaces. Sensors 2022, 22, 9783. [Google Scholar] [CrossRef] [PubMed]

- Naqvi, M.; Gilani, S.Q.; Syed, T.; Marques, O.; Kim, H.C. Skin Cancer Detection Using Deep Learning—A Review. Diagnostics 2023, 13, 1911. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the International Institute of Knowledge Innovation and Invention. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).