1. Introduction

Consumer behavior is changing with time and now consumers are getting in details of the packaging. It is not just enough to buy and consume any product; customers need to know the source of raw material, its processing, and its effects on the environment [

1]. Considering the United Nations sustainable packaging goals, sustainability has shifted from being a non-factor for package producers and customers to becoming a driving force. United Nations 193 members created new global objectives for sustainable development during UN-Sustainable development summit in 2015 [

2]. The objectives created a roadmap for every industry to strive toward sustainability. The proposed Sustainable Development Goals (SDGs), which are being established by the international community under the charter of the United Nations, set targets for eliminating poverty, safeguarding the climate, and empowering individuals and organizations.

The packaging sector is among the most applicable industry that, quite rightfully, receives a lot of attention. As per UN-sustainable development goals, by 2030 all materials used will be environmentally friendly, with the goal of completely implementing packaging that does not need the usage of additional coal and oil [

2]. Polyethylene terephthalate material utilization per bottle should also be decreased by 35% by 2030 [

3]. From manufacturing to logistics and from warehousing to end consumer packaging industry plays a crucial role in each transition. Making sustainable packaging and implementing it in mass industrialization can be a tough task due to supply-chain challenges that are further studied in the article. The key focus of the study is to analyze through the perspective of supply-chain professional, the importance of sustainable supply chain in packaging industry. Since packaging has an impact on overall supply chain, from material producers to product manufacturers and retailers than trash collection organizations then it is back to the recyclable facility.

Unsustainable packaging practices have become a threat for sustainable development and ultimately to the development of a circular economy [

4]. The packaging industry plays an important role in world economy [

5]. Packaging is not only about a simple carton or a box or a plastic wrap, but it is a process that ensures safe, cost effective, and efficient storage, delivery, and handling of the products from point of production till the point of consumption [

6]. Although packaging is an important aspect of supply chain and the economy, there is still lack of proper implementation of policies with respect to packaging; many local companies continue to rely on environmentally degrading options for packaging, such as single-use plastics and multi-layered packaging, where unsustainable consumption and dumping of packaging by end consumers creates ecological complications [

7]. This growing concerns for the climate and for the world of tomorrow have made companies to think out of the box in order to achieve competitive advantage by taking the sustainability aspect into consideration in terms of a better management of their processes, mainly those to do with packaging in supply chain [

8].

With the world moving rapidly toward sustainability by adapting sustainable practices in their processes, it is important for our local supply chain management to adapt sustainability in their operational aspects and logistics processes and their strategic decisions in order to stay competitive with the global shift toward sustainable development. Sustainable packaging has become a vital force in shifting packaging industry toward recyclable materials [

9]. In Pakistan, the shift is negligible [

10]; however, according to the Europe’s Circular Economy policy, the countries that have trade with Europe, must make their process aligned with the circular economy policy by 2030. As nearly 60% exports are done with Europe in Pakistan, therefore moving toward sustainability has become vital for Pakistan as a faster pace. The causes and effects will be studied in this case study.

This study emphasizes on the significance of sustainable packaging in today’s world from a supply chain perspective by studying the current process of three departments of Midas Safety (i.e., Supply Chain Department, Sustainability and Compliance, and Packaging Department) and then, carrying out a gap analysis in order to come up with the future state in which all those gaps are fulfilled.

- 1.

To identify the obstructions of current sustainable packaging practices with a supply chain perspective.

- 2.

To suggest a sustainable packaging option that would cut down the environmental impact from supply chain operations.

- 3.

To comprehend how logistic system is involved in sustainable packaging development and the significance of improved packaging designs.

2. Literature Review

Packaging performs diverse and complex functions in the supply chain as it is the most important aspect for any product; a well packed product can assure protection to the consumer [

11]. Packaging is not only about a simple carton or a box or a plastic wrap, but it is a process that ensures safe, cost effective, and efficient storage, delivery, and handling of the products [

6]. However, there are various studies among developing and developed economies that highlight the emission of greenhouse gases (GHG) due to packaging production. Duan et al. (2019) identified approximately 7.80 mmt of packaging disposal were dumped every year in China due to e-commerce activity [

12]. Similarly, Orzan et al. (2018) evaluated that approximately 1.5 mt was an outcome from online food delivery service (OFDS) which includes consumption of fuels, paper, and plastics utensils [

13].

Huge quantities of natural resources such as raw materials and natural energy are consumed in order to manufacture packaging, the large quantity consumption of energy and raw materials causes a strain in the environment due to the depletion of resources and emission of greenhouse gases [

14]. As packaging largely consumed multiple resources (for instance consumption of energy based on multiple sources) [

15,

16,

17]. The utilization of multiple energy sources leads to a burden on the environment through the consumption of multiple natural resources allowing manufacturing companies to emit harmful greenhouse gas (GHG). Impaired packaging and dispatch can also steer to discharge a variety of harmful impurities in the shape of natural and synthetic contamination into the ecosystem [

18]. However, according to International organization for standardization (ISO), life cycle assessment (LCA) can be applied to gauge the environmental impact related with packaging production. This perspective quantify the comprehensive environmental aspect of product flow occurring during entire product life cycle starting from unfinished product to its final dispatch. According to Yi et al. (2017), in 2015 alone the production and packaging contribute up to 1.2 Mt of CO

2 emission from China [

17].

Plastic packaging is one of the most used ways of packaging around the world. Though plastic is known for its longer lifespan and toughness, it is frequently used for single-use applications. Plastics output has been steadily increasing for more than half-century, peaking at 299 million metric tons in 2013 [

19]. A growing utilization of plastic packing due to its economical production cost and permanence is considered a specific area of interest among many firms, as pollution due to massive involvement of plastic has surfaced as potential threat to the ecosystem in recent time [

20]. Despite of its characteristics, plastic roots ecological complications at the disposal stage, such as impacting human life, environment, and ocean life; around 5000 million tons of plastic has accumulated in the natural environment and landfills and is predicted to be increased by 12,000 million tons by the mid-century [

21]. Single-use plastic must be reduced, and this implies that people play a critical part in this effort.

In 2021, European Union has imposed restrictions on several single-use plastic products which enters the marine environment every year. As single-use plastics refer to disposable plastic that can only be used once before they are thrown away; however, the ban imposed by the European Union has decreased the use of single-use plastic by 10–20% (Herberz, Barlow, & Finkbeiner, 2020) [

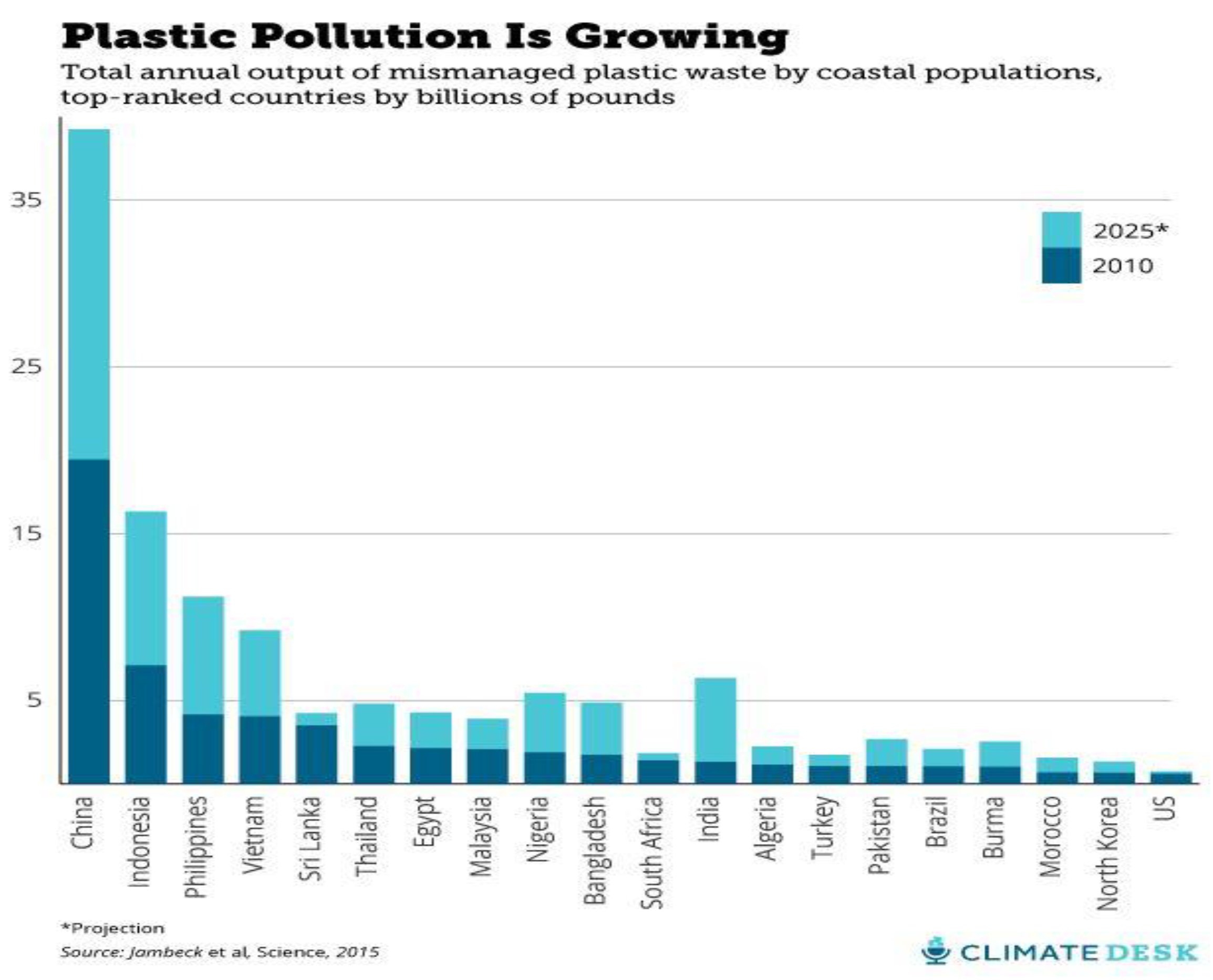

22]. How much plastic waste has been generated till 2010 and what will be the world’s situation by the end of 2025, and where being on number one in production of plastic waste as shown in

Figure 1.

In case of Pakistan, things are getting even worse in term of utilization of single layer plastic. Due to its characteristics such as longevity, water-resistance, and low cost, the use of single-use plastic has become very common in Pakistanis’ everyday life. Pakistan produces 50,438 tons of Municipal Solid Waste per day out of which 18% is generated through plastic, and out of all types of plastics the ratio of single-use plastic is the highest which is non-recyclable and is alarming for the environment [

23]. Even though these single-use PET bottles and other plastic components that have higher economic value gets collected, the single-use plastic ultimately ends in landfills, garbage sinks, or municipal sewers, blocking the sewage system in Pakistan [

24]. However, Pakistan is gradually moving toward implementing the UN’s Sustainable Development Goals (SDGs) by 2030, where there is a need to invest in infrastructure to develop its PET waste collection, recycling capacity, and developing a strategy for assessing different options based on environmental, economic, and social impacts [

23].

Similarly, multi-layered packaging is made up of two or more distinct materials that are very closely laminated to form flexible packaging [

25]. According to a study conducted in 2021, multi-layered packaging is the most used type of packaging in fast-moving consumer goods industry, as multi-layered packaging has enhanced the properties such as the shelf life of a product [

26]. However, on the other hand, Lahtela et al. (2020) contradicts that even though multi-layered has its own benefits, but the recycling of multi-layer product is itself a complex and multi-step process which starts from collection and sorting of materials, identifying the composition of those materials, as the materials are very closely laminated, it becomes extremely difficult to separate them from one another [

27].

According to the rules of Plastic Waste (Management and Handling) Rules, 2016, multi-layered packaging shall be eliminated within the period of two years, issued by the Union Ministry of Environment, Forests and Climate Change [

28].

According to a recent study conducted in Pakistan, even though multi-layered packaging has helped companies to deliver their products to the customers with the quality like never before as it is light weighted and protect the goods for a longer time, it has also challenged them in terms of disposal [

29]. Multi-layered packaging consists of layers of different polymers designed to achieve penetration and oxygen barrier properties; the polymer used in multi-layered packaging are polyethylene, polyethylene terephthalate, nylon, and aluminum [

29]. Ahamed et al. (2021) investigated the environmental consequences caused by the populated cities of Pakistan, which alone produces around 2,420,680 tons of plastic waste per year [

30]. With regard to multi-layer packaging waste, it is concluded that the avoidance of multi-layered material packaging is one of the policy initiatives that would significantly increase the flexible packaging’s recyclability. Hence changing to polyolefin could be the first step in the ladder to success in combating plastic waste.

As per the Pakistan Environmental Agency, Pakistan is one of the fastest developing countries of Asia, but the solid waste management system of Pakistan is still not as effective to dispose of and recycle the waste generated through these packaging materials [

31].

Similarly, greenhouse gas (GHG) emission during production processes also poses a radical impact on the environment; for example during the cultivation processes as compared to small-scale individual farming, large-scale rice production emits approximately 1178 kg CO

2 eq ha

−1 year

−1 greenhouse gas (GHG) which is equivalent to 11% lesser than small-scale individual production [

32]. In contrast, greenhouse gas (GHG) emission for per yield of paddy rice at commercial farming level is approximately 2.19 kg CO

2 eq kg

−1 as compared to individual small-scale farming which contributes similarly to 2.19 kg CO

2 eq kg

−1 per yield [

32]. Since the difference was not statistically significant among both categories of farming. On the other hand, (GHG) emission for per kg yield of white milled rice for large-scale commercial farming purposes is 2.60 kg CO

2 eq kg

−1 compared to small-scale farming which produces 2.99 kg CO

2 kg

−1 per plastic bag, in this case it is statistically significant (

p < 0.05) [

9]. Therefore, at aggregated level, large-scale farming contributes less GHG emission than small-scale individual farming [

32].

2.1. Sustainable Packaging and Green Packaging with a Global Perspective

In today’s world, the concept of sustainability has become the limelight of almost every industry. The change in trends in human lifestyle, practices and technology have reformed the industries, communities, and overall, the world has moved toward suitability [

33].

According to the new guidelines for environmental protection, role of packaging is not only limited to the protection of the product, but also it must be environmentally friendly; it must meet both its objectives i.e., product requirements as well as the specific environmental objectives [

13]. Therefore, the packaging that is made up of reusable or biodegradable material is becoming popular; scientist think that this type of eco-packaging is the future. As consumers are now becoming more aware of the environmental changes and the impact of their consumption behavior on the environment, therefore they have started to give priority to ecological packaging in order to protect the environment and quality of life [

34].

Similarly, Yi et al. (2017) estimate environmental consequences such as climate change, oxidation due to photochemical pollutants, acidification, anthropogenic activities increase power consumption [

17]. They explore the potential cause due to massive production and utilization of packaging life cycle (PLC), which subscribe as potential threat to the entire eco-system shared approximately 79% of its life cycle based on extensive utilization of power sources. Emissions due to express delivery packaging are from 0.3 million tones (Mt) in year 2007 to 13.2 million tones (Mt) in year 2018. Jia et al. (2018) investigated that 1.6 Mt of packaging disposal requires 58.90 GWh of power for processing and discharges 73.90 Giga tones of carbon dioxide (CO

2), which is equivalent (CO

2e) [

35].

Sundqvist-Andberg et al. (2021) investigates the reasons for the challenges in governing the sustainability of plastic food packaging and sheds light on the contestations between different sustainability goals and interests that relate to food packaging by integrating the results from various disciplinary fields [

36]. This ranges from material sciences to behavioral and social sciences, and it shows that there are trade-offs between them [

36]. The article identifies how attempts to govern individual sustainability problems as part of circular economy policies create tensions with other sustainability issues through an in-depth analysis of the sustainability challenges related to different stages of the life cycle of plastic food packages [

36]. While the circular economy covers the entire life cycle of a food package, the analysis shows that the beginning and end of the life cycle have gotten the most attention, with only a few policy measures focusing on the consumption phase [

36]. Finally, we argue that the various functions of plastic food packaging should be better recognized in environmental policy design.

The concept of green packaging has been introduced in the recent years in order to lessen the effect of waste and pollution and promote sustainable development [

37]. The purpose of green packaging or also known as sustainable packaging, recyclable packaging, or eco-friendly packaging is to use ecological friendly materials in packaging, keeping in mind the safety of human life and environment [

38].

Companies are encouraged to incorporate strategies for green packaging in their process mainly due to either customer demands or regulations imposed by authorities such as European Union demands that the member must introduce legislations to take steps in order to introduce packaging waste management systems [

39]. Another example is a regulatory authority in Japan, Container and Packaging Recycling Law of Japan, which institutes that every city must gather and store the containers and packaging separated from the solid wastes [

40]. However, a gap between the consumer’s expectation and the company’s perspective still exists. On the one hand the consumers demand green packaging in order to eliminate the negative impact of packaging on the environment, while on the other hand, companies face packaging-related issues in different dimensions such as technological, organizational, and human skills in order to implement green packaging strategies [

41].

2.2. Sustainable Packaging & Green Packaging Practices in Pakistan

In Pakistan, nearly 30 million tons of solid waste is produced every year, 9% of which are plastics, and around 55 billion single used, non-biodegradable plastic bags are produced which end up being in the garbage dump, landfill sites, or municipal sewers thus choking the sewage disposal system; however, in order to address the pollution created by plastic, Pakistan has adopted oxo-biodegradable technology in 2017, which biodegrades plastic into the environment without harming or polluting the air once the useful life of plastic expires [

42].

According to Nestle Pakistan (Sustainable Packaging, 2020), none of their packaging material goes to landfill, not even their plastic; Nestle has developed a strategy to move toward sustainable packaging transformation which will help them to achieve 100% recyclable or reusable packaging by 2025, by eliminating the use of oxo-degradable plastics, PVC, PVDC, PS, or Expanded PS and encouraging the use of bio-based and recycled packaging, lighter pigments and inks, eliminating litter prone materials [

43].

A study conducted in Pakistan by Kashif et al. (2021) investigated the consumer behavior regarding green and sustainable packaging with respect to a clothing brand Sapphire, which started “Go-Green” packaging concept that came with eco-friendly seed-infused shopping bags; these bags were made-up of seeds which can later be planted by burying them into the soil [

44]. It was observed that the consumers, mostly the young generation, were encouraged to move toward green packaging and were willing to pay little more in order to move toward sustainable environment [

44].

Roshan Packages Limited, one of the top leading packaging companies in Pakistan, provides sustainable packaging solution, and the latest technologies are adopted in order to develop sustainable packaging options such as corrugated boxes, carton boxes, stock boxes, die cuts, pads and partition sheets, and custom boxes; these boxes are not only eco-friendly but are sustainable as well, as they are made up of recycled paper, recycled cardboard, and by recycling their own waste [

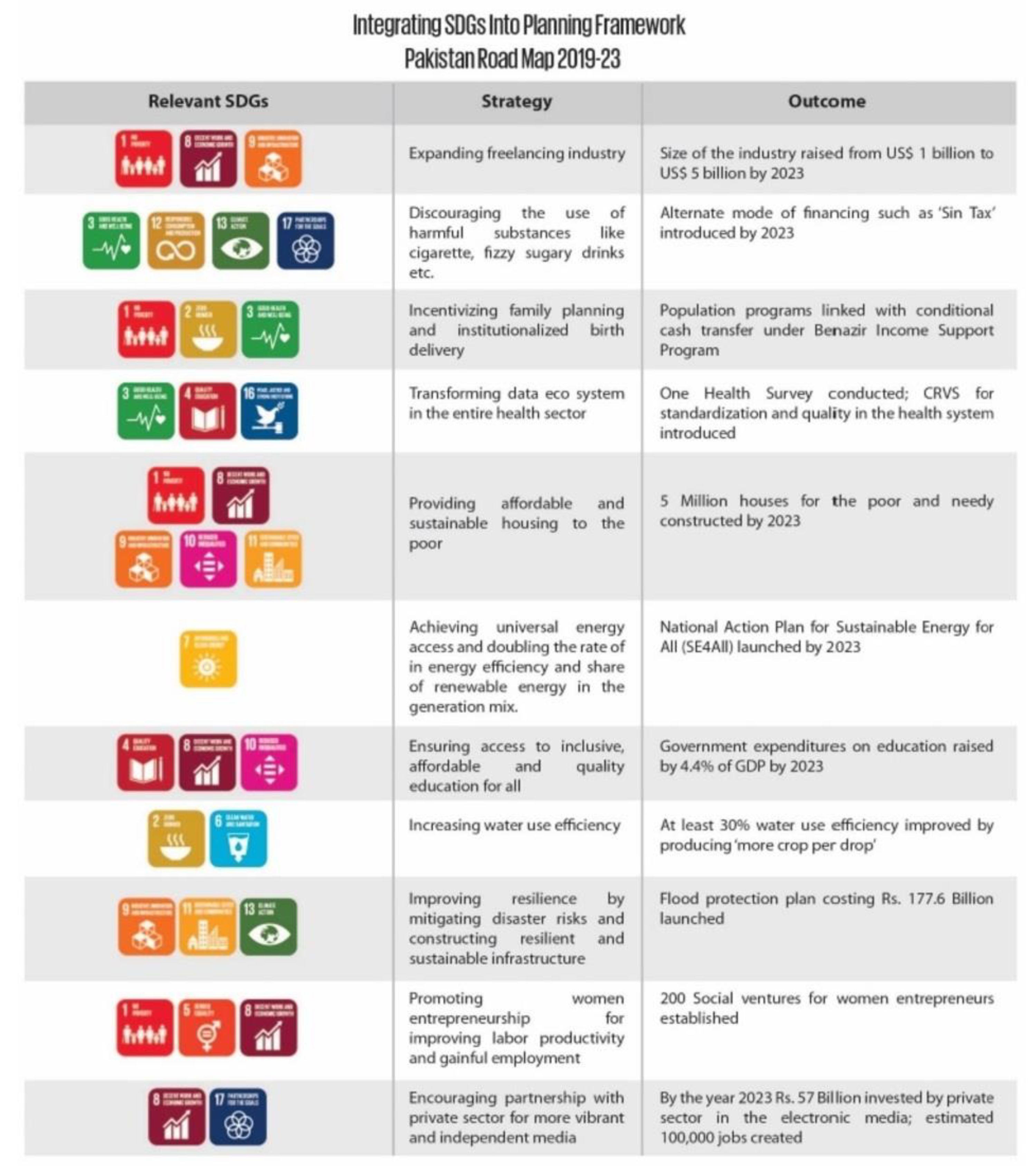

45]. Below is the sustainable development goal framework for Pakistan as show in

Figure 2 [

46].

2.3. Sustainable and Green Supply Chain Management

Supply chain industry is now evolving into Sustainable Supply Chain Management SSCM with the concept of eco-friendly environment that has already been adopted by many manufacturing industries; but with adopting such concepts comes obstacles which affect the efficiency of sustainable supply chain management SSCM [

47]. According to Shalke et al. (2017), the factors such as supplier’s eco-practices, cost, and lack of available sustainable options in manufacturing and packaging process, raising awareness about sustainable products and its recycling process are a few barriers that create obstacles in the implementation of SSCM (sustainable supply chain management) [

48].

SSCM is an advanced concept which has already been implemented in developed countries, and now these countries are moving toward implementing green supply chain management GSCM; GSCM has changed the objective viewpoint of the organization which not only helps in achieving the profit and market share (by attracting customer from sustainable initiative) but also helps ecologically [

49].

Supply chain network involves all stakeholder in the business cycle from farms to retail stores, therefore everyone has to share their part for ecological packaging. The green packaging’s multipurpose character necessitates the fulfilment of business requirements (capacity to make a product stand out), logistics (by making purchasing, packaging, processing, warehousing, and transportation more efficient), and eco-friendly or reverse logistics (exploring the adoption of waste, recycling, and recovery strategies), all elements that have a significant impact on the profitability of an organization [

50].

Interest in green packaging has been formed due to global distress on petrochemical-based plastic materials such as polyethylene terephthalat, polyvinyl chloride, and poly-styrene and packaging automation. Recycling consumes energy therefore, composability is a critically important factor in green packaging as it enables the packages to be disposed of in the soil by converting them into water, CO

2, and inorganic chemicals [

51]. For making green packaging commercially viable, it is important that the packaging should have barrier properties; it should not allow smell, moisture, and light to transfer [

52]. PLA (poly lactide) has grown in popularity as a food packaging material over the past decade due to its ease of production from renewable resources [

53]. Despite PLA production expenses are higher than traditional polymers, this is expected to alter over time as capacity utilization and consumption both rise [

28]. PLA is making steps toward being a “green” packaging solution. Vilarinho et al. (2017) concluded that bio nanomaterials are a feasible option polymer in industrial applications, notably those produced from oil [

54]. Nevertheless, the materials’ weak mechanical and moisture barrier characteristics prevent them from being widely used in food packaging. Nano cellulose materials have outstanding characteristics; therefore, they might be termed green packaging materials because they are neutral, ecological, biodegradable, and non-hazardous.

Companies are now looking forward to adopting green and lean supply chain and production methods in their operations for better environment management [

55]. The lean supply chain is an approach that focuses on the cost reduction by elimination of the non-value-added activities, which ultimately result in waste reduction by helping companies to cut down on the activities that do not add any value by reducing the redundant use of time, labor, inventories, equipment across the supply chain. On the other hand, green supply chain refers to the efforts in order to reduce the negative environmental effect of businesses and their supply networks and focuses on the analysis of internal processed and operations in terms of the environmental consideration in development of a product and product’s life cycles. However, there is still a gap between lean and green supply chain, as the lean strategies refer to the approaches such as just in time delivery, which requires increased transportation and packaging which may challenge the concept of green supply chain, that mainly focuses on dealing with suppliers and customers, analyzing internal operations and process and product development while keeping the environmental aspects in consideration [

56].

In order to reduce plastic waste currently researchers are focusing on utilizing biopolymers derived from renewable resources to develop green packaging. These components can be carbohydrates such as starch and chitosan, as well as enzymes such as casein, fibro, gluten, and milk solid, which are produced from cellulose or derivatives [

57].

2.4. Waste Management and Reusable Packaging

Single-use packaging for reverse logistic is a common practice in the supply chain industry. The paper packaging is not reliable as is not strong enough and the chances of product damage are higher with the paper packaging; cloth and jute packaging are quite expensive therefore, finding alternatives for plastic packaging has become a hurdle, as there is an immediate need to reduce the cost of packaging with the increase in demands of global consumers for products from various industries and at the same time, it is necessary to keep the sustainability factor in consideration while looking for cost-effective packaging solutions. Therefore, there is a need for reusable packaging for reverse logistic which is both sustainable and cost effective [

58].

Plastic packaging is the most suitable option for reusable packaging as it ensures safe product flow from raw material to a finished product and is used for storing, moving, and distributing products across the entire supply chain. Reusable packaging has its importance in wide range of industrial sectors such as textile, chemical, pharmaceutical, food and beverages, apparel, printing, automotive, and electrical [

58].

SWM (solid waste management) is a foremost issue in major cities around the world and is considered as an essential element of sustainable supply chain management which appears to be a realistic method for integrating social, environmental, and economic goals as pillars for an organization’s and supply chain’s long-standing development. In order to address environmental issues related to SWM, basic social issues such as education, security, and infrastructure must be addressed, with the participation and support of government, the local community, and industry. In addition to the industrial focus, the government and community perspectives, and points to practical actions based on SSCM enablers, reinforcing a holistic and multi-perspective view, and understanding the need for cohesive management for better solid waste management in the developing countries. Because this is a first step in this direction, more research in similar settings is needed to refine the analysis and make it more generalizable [

59].

2.5. Theoretical Framework

Mostly the products are packed from final part of the production until they are unpacked by the end users for consumption, which interconnects the lifecycle of a product and its packaging. Therefore, the environmental impact on supply chain is not only influenced by the product design but it is also equally influenced by the packaging design [

60].

In order to cut down the negative environmental impact of packaging, companies and legislatures have now started to focus on the direct environmental impact of packaging which is related to packaging’s life cycle [

61]. In recent years, research have been conducted to inspect the influence of packaging on environment along with the SC of the packed product, results of which have shown that packaging designs such as multi-layered and single-use plastics have significance impact on the environment [

62].

Our theoretical framework that has been derived from the literature intends to capture the sustainable packaging with a supply chain perspective, the goal of which is to understand the obstructions of sustainable packaging practices.

The literature shows that the previous studies have been conducted globally and within Pakistan related to sustainable packaging, where use of single-use plastic and multi-layered packaging has been strictly banned by the authorities. Even though plastic packaging is one of the most used ways of packaging used around the world. Though plastic is known for its longer lifespan and toughness, it is frequently used for single-use applications. Plastics output has been steadily increasing for more than half-century, peaking at 299 million metric tons in 2013 [

63]. Multi-layered packaging has properties such as the increased shelf life of a product, higher protection [

27]; the use of single-use plastics and multi-layered packaging has been banned in many countries. According to the new guidelines for environmental protection, role of packaging is not only limited to the protection of the product, but also it must be environmentally friendly [

13].

In Pakistan, evidence has been found where the use of multi-layered packaging and single-use plastics have been discouraged. Ahamed et al. (2021) investigated the environmental consequences due to multilayer packaging waste and concluded that the avoidance of multi-layered material packaging is one of the policy initiatives that would significantly increase the flexible packaging’s recyclability [

31]. Companies have started to move towards sustainable packaging, such as Sapphire that came out with a concept of eco-friendly seed-infused shopping bags [

44]. Currently, Midas Safety is also planning to move toward sustainability, on which our research is based on, and the below framework has been developed with the help of the literature.

The above theoretical framework conceived from the current literature, develops a relationship between three sustainability pillars i.e., economic, social, and environment with supply chain perspective and packaging sustainability in order to find out the obstructions or barriers that our local packaging industry faces while connecting sustainable packaging with supply chain as shown in

Figure 3 adopted from [

64].

5. Discussion

The unstructured interview started with Head of Sustainability and Compliance at Midas Safety. The discussion started by understanding the current packaging practices at Midas, where he mentioned, that the use of composite materials is strictly avoided at Midas Safety, because in packaging if composite material such as multi-layered packaging is used, it becomes extremely difficult to detach the layers as they are closely laminated, for example, if low density polyethylene (LDP) is used in packaging, then the recycled content of LDP can easily be added; however, this would not have been possible if multi-layered packaging was being used. Further he added that the plastic cannot be eliminated completely from their packaging practices; however they have reduced the use of plastic, especially in terms of gauge as the finer the gauge the lesser the waste is produced.

Even though Midas have moved toward recyclable plastic, it still has drawbacks such as the recycled plastic cannot be very transparent, only a certain percentage of recycled packaging can be mixed into the current existing plastic packaging. Transparency cannot be achieved completely in recycled plastic, as the color difference will always exist. Then, other than the recyclable plastic, recyclable paper is also being used at Midas. The first strategy is to reduce weight or minimize the use of paper and cardboard so that the less waste is produced. The goal is to reduce GSM of the paper and use recycled paper instead of the virgin paper.

Further, he also mentioned that the corroded carton packaging made up of kraft paper is also used at Midas Safety of which 80% content is recyclable in Karachi region and 100% content is recyclable for Faisalabad region and for international regions such as Srilanka, 60% content is recyclable and 40% content is recyclable for Bangladesh. Further, the carton that is imported from Dubai is made up of 80% recycled material and 20% virgin material; where the outer layer of the carton is made up of the virgin paper, and the inner layer is made up of recycled paper.

Moreover, the shining coating lacer that is used to bring the shine on cartons is considered as recycle friendly, because it is easily dissolvable in the water. UV coating is also another sustainable option as it is emulsion and can be dissolved once put for processing. Further the kraft paper that is used is 100% recyclable. Moreover, TAC pins are used to pack pairs of gloves for bulk packaging and for, sample packaging, Jute Thread was being used which they later switched to cotton yarn bags.

Midas Safety have now started to move toward biodegradable packaging that can be degraded into the environment within a span of a few months such as 6–12 months. There are different types of biodegradable packaging options available, which are triggered by different factors such as heat and light, known as ortho-biodegradable materials. Packaging materials that consist of components of ortho-biodegradable materials are harmful and not eco-friendly as it is converted to micro-plastics that goes inside the human body, consumed by animals, and other living organisms through air and water, so is the case with recycle polyester as it sheds micro plastics and ultimately pollutes the environment. Since, the main product of Midas Safety is gloves, which can be kept for sale for longer period of time and can also be exposed to heat and light, heat or light will not affect the product itself, packaging made up of ortho-biodegradable materials would not be suitable for their product. Therefore, the biodegradable option that they are moving toward is where the biodegradability is not triggered by the light of heath but is triggered when the packaging is dumped into the landfills.

Further, FSC cartons are also used, that are derived from renewable material. According to Head of Sustainability and Compliance, renewable material means that resources of future generation are not at stake, for example, paper is derived from the trees, and the trees will always grow back in the forest.

While discussing the SOPs that need to be followed while packing the products, it was informed that at Midas Safety, the important guidelines that needs to be kept in consideration for the packaging of products are:

- 1.

Packaging must be light in weight.

- 2.

Must be able to make the life of a product last longer, i.e., must keep the product in its original form for a longer time.

- 3.

Must be made up of sustainable and renewable (such as cotton, silk, paper) materials.

- 4.

Must be made of recyclable materials (such as plastics, paper).

Next, the related environmental impact of current packaging practices was discussed, where Head of Sustainability and Compliance mentioned that the packaging used will always ultimately go to dump; for example, if packaging consists of six components, then those components will require different plants for recycling respectively. At Midas Safety, gloves are exported to different parts of the world; here the recyclability of those components cannot be assured as we are not sure that if the country where they are exported to has the facility to recycle those components which ultimately lead to waste and then ends up in the landfills or the waste is incinerated, hence impacting the environment. Therefore, in most cases the countries that do not have recycling facility of a particular material usually reject the packaging that consist of that material, and instead, decomposable packaging materials are used for such countries at Midas. The recyclable packaging materials are only used where the countries have recyclable facility of that materials such as Europe, where they have proper recycling laws, recyclable material is properly separated from the waste and proper waste management is conducted.

On the other hand, waste dumping activity of leftover packaging materials at Midas Safety is divided into two areas i.e., Zone Areas and Tariff Area. Under the Zone Area, all the waste that is generated is handed over to the zone authorities, which is later sold to a bidder by the zone which is later recycled by the concerned authority against which a certificate is issued to Midas where it is stated that the waste will be recycled and not thrown away. Hence the waste under zone is not thrown away and is recycled. On the other hand, in Tariff Area the waste is dumped according to the characteristic of a material; for example, plastic dumping material will have its own dumping box, paper waste will have its own dumping box, which later is also sold.

Next, question related to the current packaging material was asked, if the materials used in current packaging are recyclable or reusable, where it was stated by the Head of Sustainability and Compliance that only pouch PLA used in bundle and pair packaging is reusable, and the rest of the material used is recyclable i.e., plastic, carton, and paper/kraft paper.

First, while expressing his level of satisfaction with the current packaging practices at Midas Safety, Head of Sustainability and Compliance mentioned that the pace of moving toward sustainability is slow but the direction is correct. The reason that the pace is slow is that the local suppliers are not geared up or prepared for the change which is mainly because of obstacles such as supply barriers, material options are not locally and easily available, and materials are costly, import barriers, and lack of awareness.

Second, he mentioned that the current packaging also has its limitations such as single-use plastic packaging materials are banned in Europe, Italy, and laws related to packaging are implemented that whatever packaging material is used while exporting the products, it must have codes and if multi-layered packaging materials are used then all the layers should be made up of the same components. According to the laws of UK, the packaging must consists of 30% recycled material. Circular economy policy has also set directions for European Union countries for packaging around the world which is now slowly being implemented and adapted by the countries. Further, testing of every packaging is conducted before its proper implementation. A scenario was discussed, where the products that were being exported to Sri Lanka had moisture in their packaging as the paper or carton packaging does not completely seal the product, which was damaging the product. The material that was producing the moisture in the packaging was immediately removed.

The current packaging process at Midas Safety have started taking the environmental aspects into consideration while packaging their products as the company now have pre-defined targets for waste. Now the packaging material is only ordered as required i.e., if there are 1000 units that needs to be packed then the packaging material limited to that only will be ordered, nothing more, and nothing less. It has been instructed by authorities at Midas Safety to reduce the waste by 20–40% every year, therefore limited packaging materials are ordered as more packaging material will only result in more waste.

Moving towards Sustainability

As the Head of Sustainability and Compliance at Midas Safety mentioned that sustainability is not only related to the environmental aspect only, but it also means that the material that has been already used and brought into the environment should be reused by recycling it and not depleting the remaining resources of the world. Further, the recycling technology that is adopted must have less carbon footprint in comparison to manufacturing the original material.

According to the Marketing Manager, in order to move toward sustainability goals, Midas have increased labor accuracy by giving necessary training to the labor involved in processes such as packaging, usage of reusable materials such as fabric packaging instead of the use of plastic packaging material and the use of laminated packaging, single-use packaging, and multi-layered packaging has been banned at Midas completely. Further, palletizing is also banned by Midas Safety, bulk packaging is being promoted with an approach to reduce packaging waste, since the nature of product is not fragile, therefore removing or eliminate palletizing will not have any impact on the product, resulting in eliminating the excess use of wood.

Midas Safety is currently following Global Reporting System (GRI) guidelines in order to move adopt sustainability in their packaging operations. The guidelines that needed to be followed have been discussed above such as order material when needed and how much is needed, using recyclable and reusable material.

Midas Safety can move toward standardization in packaging. As discussed above, Midas Safety packs the products as per the customer’s demand and all the customers provide different layouts for their packaging, which ultimately goes to waste if all the “customized packaging material” is not utilized. Here bringing customers on one page for packaging by adopting standardization would not only help in generating less waste but will also cut down the cost. Further, Midas own carton printing facility will help cut down the waste production, for example, if minimum order quantity (MOQ) is 100 pieces of already printed carton out of which only 90 are being used for fulfilling the order requirement then the remaining 10 will ultimately goes to the waste, in order to avoid this situation Midas Safety can install printing facility and print their own cartons as per the requirement.

Material used in the packaging is imported and procured from different parts of the world; however, if Midas Safety start developing local vendors their packaging material from local vendors instead of international vendors it will cut down the environmental aspect and less carbon footprint will be generated. Not only this, MOQ of international vendors is higher; however, the local vendors do not have higher MOQ.

Change in packaging design may also help in reduction of use of raw material and transportation of the products. Cartons can be designed in such a way that they are less in weight and occupy little space in the vessel so that bulk quantities can be transported in one go. The more the packaging is compact, the less space will be occupied, hence helping in cutting down the transportation. This will not only create less carbon footprint but will also help in reducing costs of transpiration. Similarly, butter paper can be used instead of the plastic, as butter paper is recyclable.

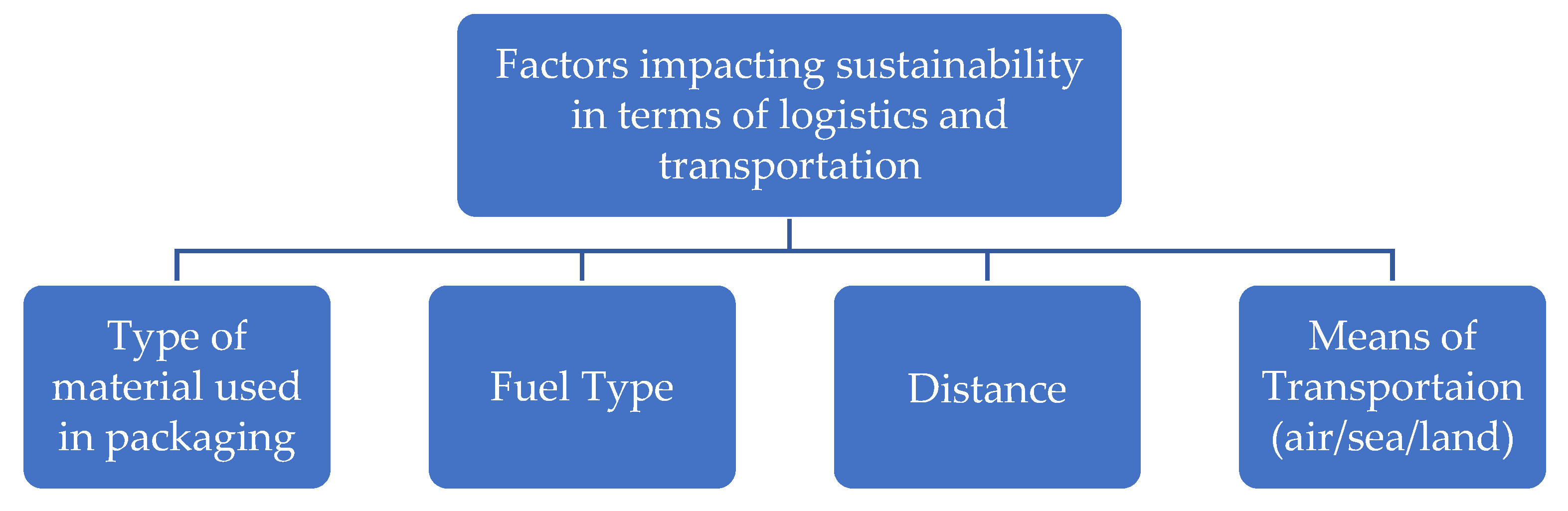

Logistics play an important role in order to move toward sustainability, as it needs to be decided from where the material can be ordered, considering three pillars of sustainability i.e., social, economic, and environment. It will include the cost of raw material, how much carbon footprint is being generated while ordering the material; both the type of material and the route of material are kept in consideration. In order to reduce this impact, Midas should develop local supplier of the sustainable factors that influence logistics and transportation as show in

Figure 4.

Air shipments can be narrowed down as the fuel burned in air shipment is very high specially when the airplane takes off and lands; however, in comparison sea shipment is eco-friendlier and generates less carbon footprint. Further, the incoterms are set up in such a way that the responsibility of carbon footprint is transmitted to the buyer such as FOB.

- 1.

Type of Material: As already discussed, if packaging is made of materials that are light in weight and designed in a compact way, it will help in transporting bulk quantities in one go.

- 2.

Fuel Type: Type and quality of fuel plays an important role in supply chain sustainability, as a bad quality fuel will lead to sulfur emission in the environment. Further, diesel is hazardous for the environment.

- 3.

Distance: As discussed earlier, if Midas Safety develop local suppliers, the carbon footprint generated and would result in low transportation cost.

- 4.

Means of Transportation: Choosing the mode of transportation have significant impact on sustainability. As discussed earlier, sea transportation is more sustainable compared to air and land transportation and creates less carbon footprint.