Theoretical Analysis of a Biomass-Driven Single-Effect Absorption Heat Pump for Heating and Cooling Purposes

Abstract

1. Introduction

2. Material and Methods

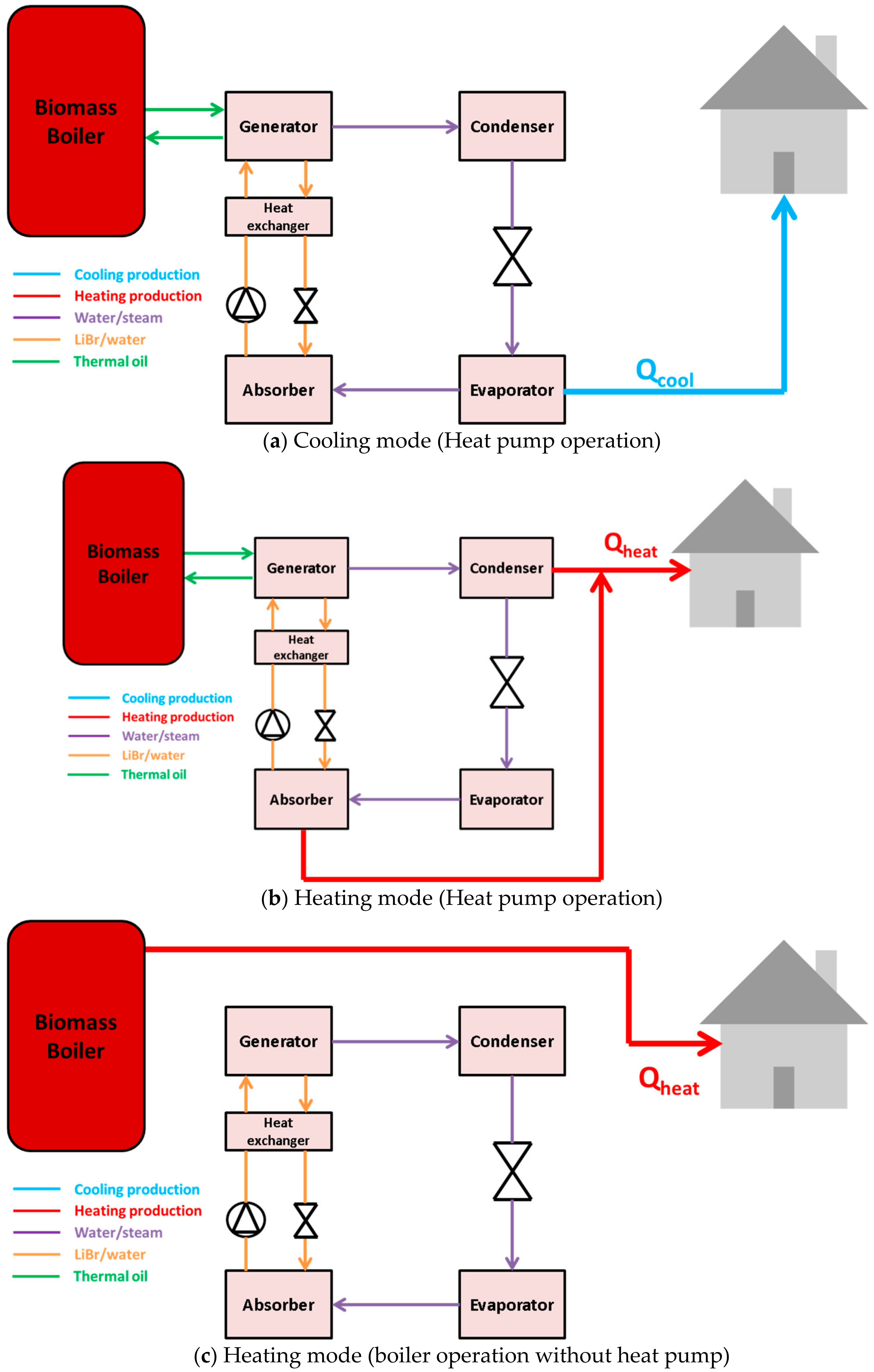

2.1. The Examined Heating/Cooling System

2.2. The Examined Building

2.3. Mathematical Formulation

2.3.1. General Equations for the Building and the Boiler

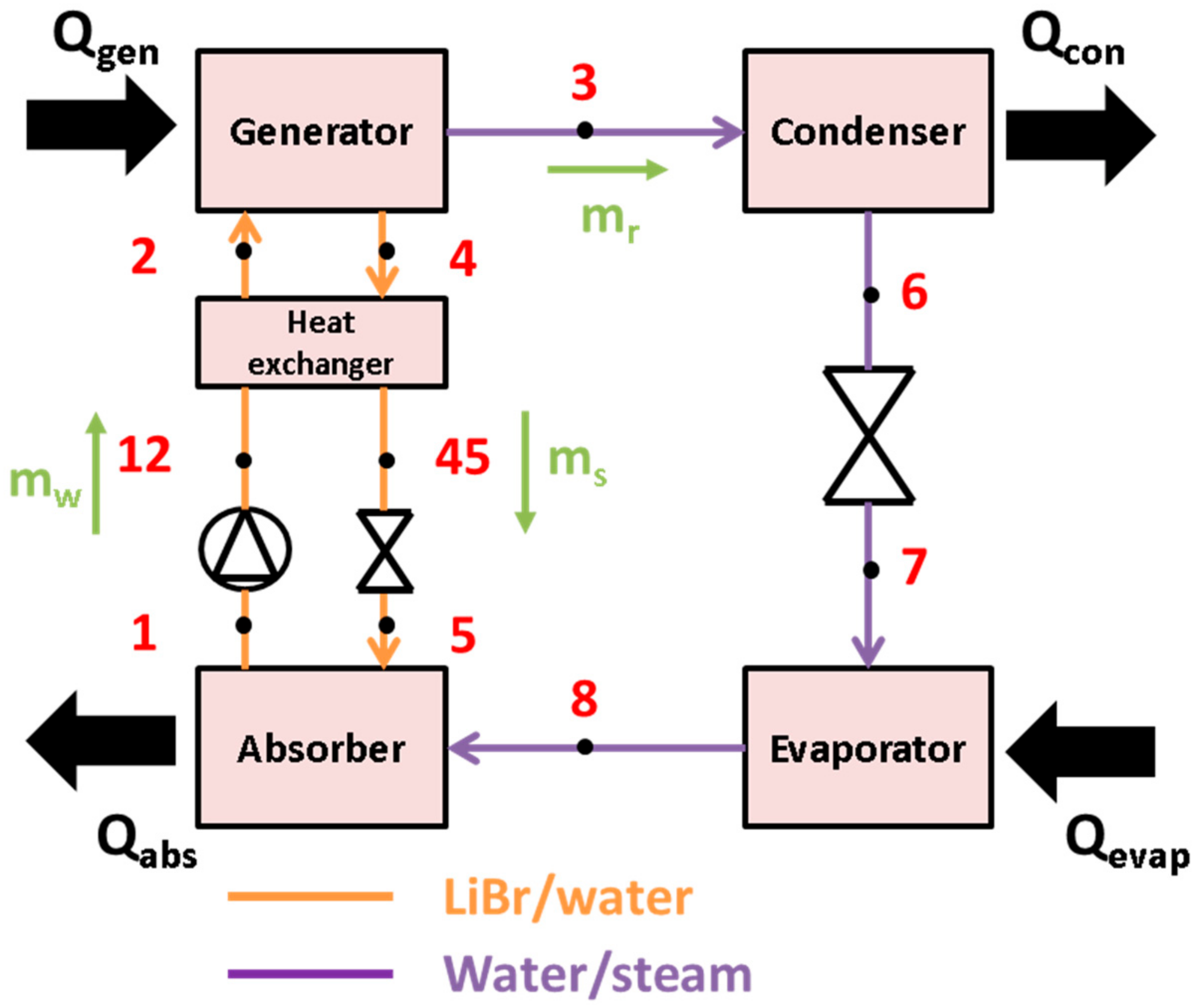

2.3.2. Equations for the Absorption Heat Pump

- -

- Every device is assumed to be in steady-state conditions in order to apply the energy balance.

- -

- There are no piping pressure losses, and the pressure level changes only in the pumps and in the valves.

- -

- The process in the throttling valves is ideal and so the enthalpy is preserved.

- -

- There is no LiBr in the condenser and in the evaporator devices.

- -

- There are no thermal losses from the system to the ambient.

- -

- The exits of the devices (evaporator, condenser, absorber and generator) are assumed to be saturated state points.

2.3.3. Evaluation Indexes

2.4. Followed Methodology

3. Results and Discussion

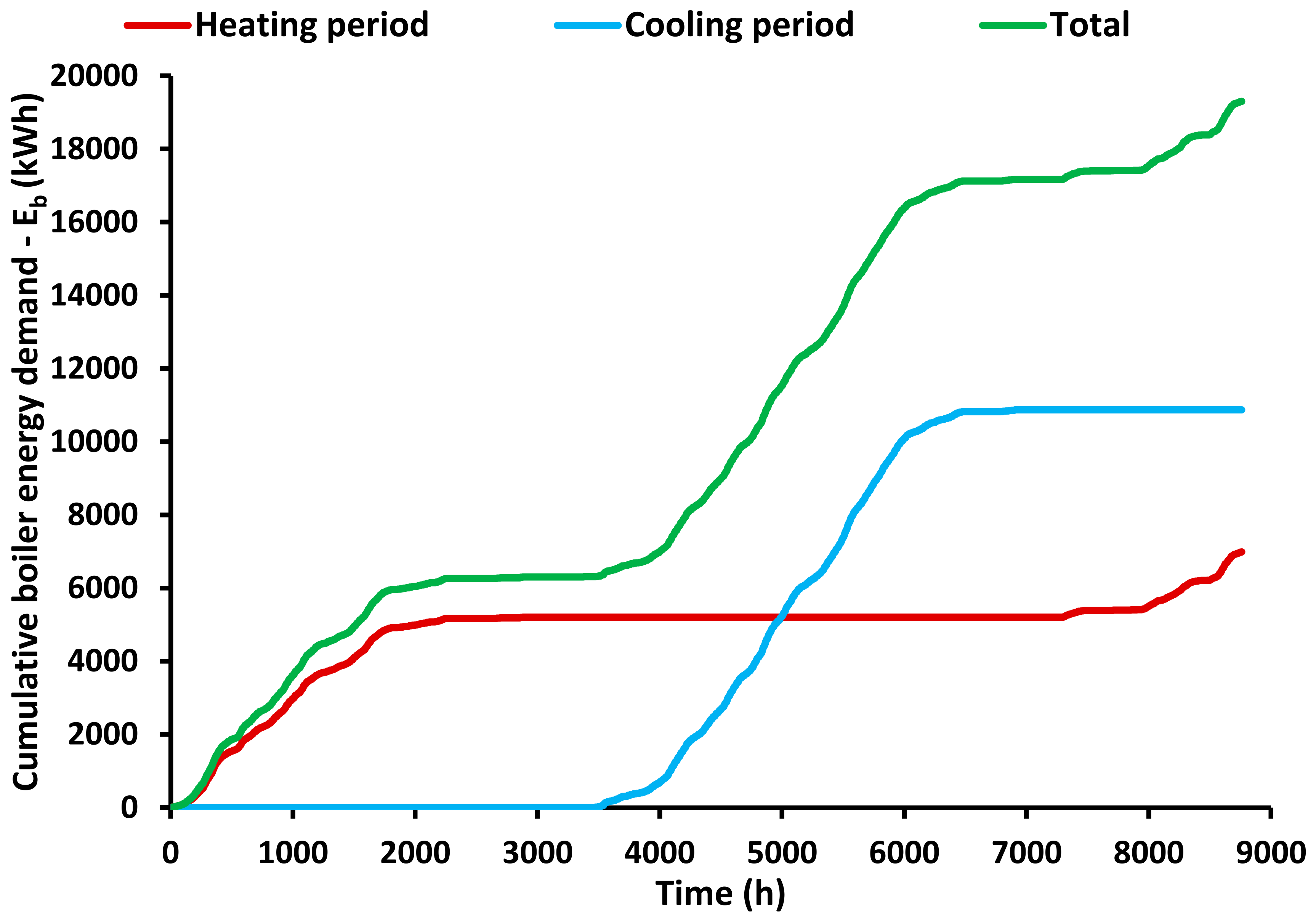

3.1. Thermal Loads of the Examined Buildings

3.2. System Results

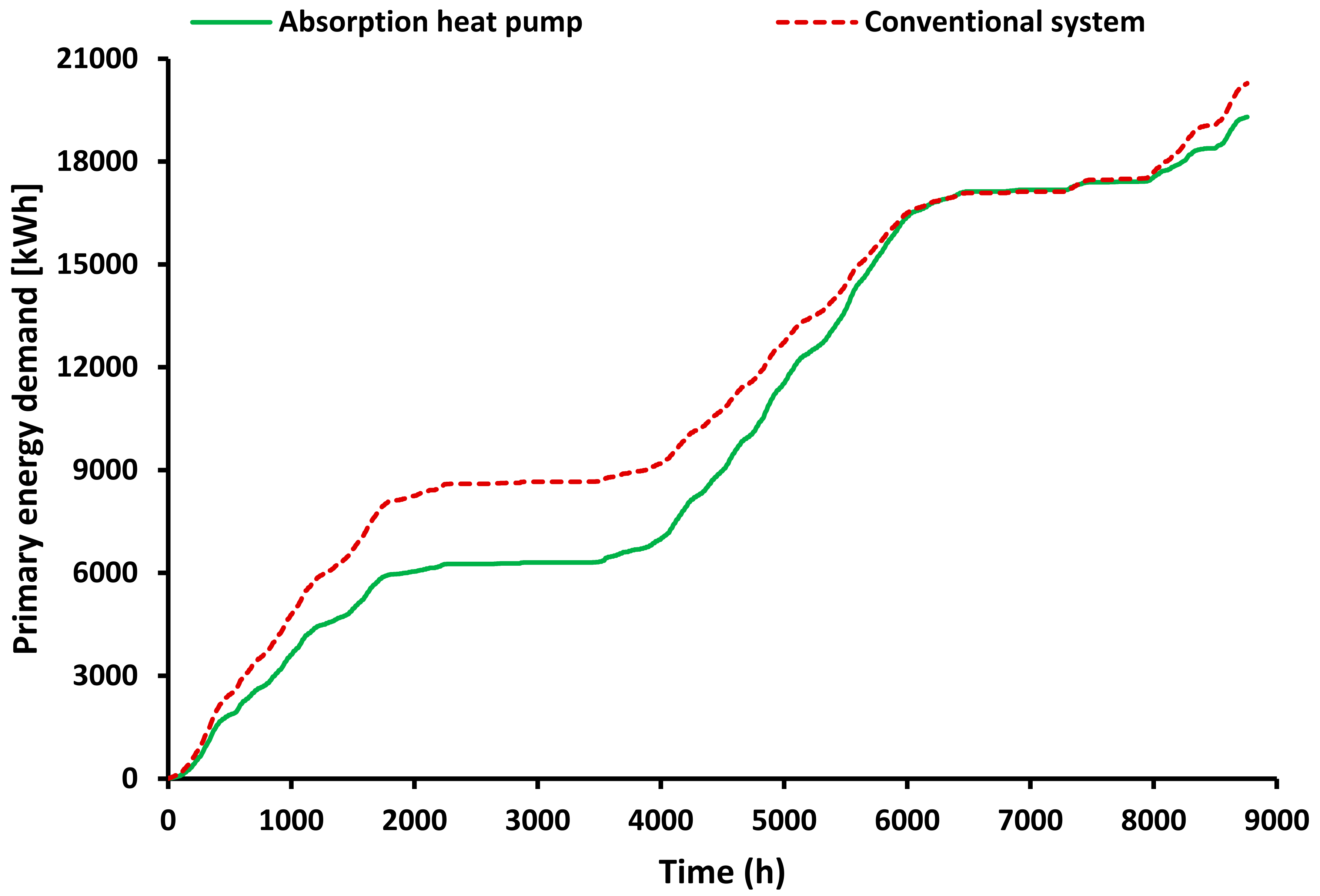

3.3. Comparison with a Conventional System

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | Area, m2 |

| cp | Specific heat capacity, J/kgK |

| COPcool | Cooling coefficient of performance |

| COPheat | Heating coefficient of performance |

| Exb | Exergy flow rate of the biomass heat rate, kW |

| h | Specific enthalpy, kJ/kg |

| hin | Indoor heat convection coefficient, W/m2K |

| hout | Outdoor heat convection coefficient, W/m2K |

| HHV | High heating value of the biomass, kJ/kg |

| k | Thermal conductivity, W/mK |

| L | Layer thickness, m |

| mb | Biomass mass flow rate, kg/s |

| mr | Refrigerant mass flow rate, kg/s |

| ms | Strong solution mass flow rate, kg/s |

| mw | Weak solution mass flow rate, kg/s |

| N | Number of the layers in the examined structural element |

| Q | Heat rate, kW |

| T | Temperature, °C or K |

| U | Thermal transmittance, W/m2K |

| Xs | Strong solution concentration in LiBr, % |

| Xw | Weak solution concentration in LiBr, % |

Greek Symbols

| ηboiler | Boiler efficiency |

| ηen,cool | Energy efficiency for cooling |

| ηen,heat | Energy efficiency for heating |

| ηex,cool | Exergy efficiency for cooling |

| ηex,heat | Exergy efficiency for heating |

| ηHEX | Effectiveness of the heat exchanger solution |

| ρ | Density, kg/m3 |

Subscripts

| abs | absorber |

| am | ambient |

| am,cr | ambient critical |

| b | biomass |

| con | condenser |

| cool | cooling |

| evap | evaporator |

| fram | frame |

| gen | generator |

| glaz | glazing |

| heat | heating |

| u | useful |

| wind | window |

Abbreviation

| PCM | Phase Change Materials |

References

- Seferlis, P.; Varbanov, P.S.; Papadopoulos, A.I.; Chin, H.H.; Klemeš, J.J. Sustainable design, integration, and operation for energy high-performance process systems. Energy 2021, 224, 120158. [Google Scholar] [CrossRef]

- European Commission. A Renovation Wave for Europe—Greening Our Buildings, Creating Jobs, Improving Lives; European Commission: Brusseles, Belgium, 2020. [Google Scholar]

- Frangou, M.; Aryblia, M.; Tournaki, S.; Tsoutsos, T. Renewable energy performance contracting in the tertiary sector Standardization to overcome barriers in Greece. Renew. Energy 2018, 125, 829–839. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, L.; Xu, P.; Liu, B.; Shuai, Y.; Li, B. Hydrogen production through biomass gasification in supercritical water: A review from exergy aspect. Int. J. Hydrog. Energy 2019, 44, 15727–15736. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, P.; Liang, S.; Liu, B.; Shuai, Y.; Li, B. Exergy analysis of hydrogen production from steam gasification of biomass: A review. Int. J. Hydrog. Energy 2019, 44, 14290–14302. [Google Scholar] [CrossRef]

- Demirci, A.; Akar, O.; Ozturk, Z. Technical-environmental-economic evaluation of biomass-based hybrid power system with energy storage for rural electrification. Renew. Energy 2022, 195, 1202–1217. [Google Scholar] [CrossRef]

- Soltero, V.M.; Quirosa, G.; Peralta, M.E.; Chacartegui, R.; Torres, M. A biomass universal district heating model for sustainability evaluation for geographical areas with early experience. Energy 2022, 242, 122954. [Google Scholar] [CrossRef]

- Chen, Y.; Standl, P.; Weiker, S.; Gaderer, M. A general approach to integrating compression heat pumps into biomass heating networks for heat recovery. Appl. Energy 2022, 130, 118559. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, J.; Fan, Y.; Zhao, X.; Yan, R.; Zhao, J.; Myers, S. Experimental and analytic study of a hybrid solar/biomass rural heating system. Energy 2020, 190, 116392. [Google Scholar] [CrossRef]

- Nami, H.; Anvari-Moghaddam, A.; Nemati, A. Modeling and analysis of a solar boosted biomass-driven combined cooling, heating and power plant for domestic applications. Sustain. Energy Technol. Assess. 2021, 47, 101326. [Google Scholar] [CrossRef]

- Bellos, E.; Vellios, L.; Theodosiou, I.-C.; Tzivanidis, C. Investigation of a solar-biomass polygeneration system. Energy Convers. Manag. 2018, 173, 283–295. [Google Scholar] [CrossRef]

- Tsimpoukis, D.; Syngounas, E.; Bellos, E.; Koukou, M.; Tzivanidis, C.; Anagnostatos, S.; Vrachopoulos, M.G. Investigation of energy and financial performance of a novel CO2 supercritical solar-biomass trigeneration system for operation in the climate of Athens. Energy Convers. Manag. 2021, 245, 114583. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Parametric Analysis of a Polygeneration System with CO2 Working Fluid. Appl. Sci. 2021, 11, 3215. [Google Scholar] [CrossRef]

- Xing, L.; Li, J. Proposal of biomass/geothermal hybrid driven poly-generation plant centering cooling, heating, power, and hydrogen production with CO2 capturing: Design and 3E evaluation. Fuel 2022, 330, 125593. [Google Scholar] [CrossRef]

- Rezaei, M.; Sameti, M.; Nasiri, F. An enviro-economic optimization of a hybrid energy system from biomass and geothermal resources for low-enthalpy areas. Energy Clim. Chang. 2021, 2, 100040. [Google Scholar] [CrossRef]

- Guo, J.; Liu, Z.; Yang, B.; Yang, X.; Yan, J. Melting assessment on the angled fin design for a novel latent heat thermal energy storage tube. Renew. Energy 2022, 183, 406–422. [Google Scholar] [CrossRef]

- Guo, J.; Wang, X.; Yang, B.; Yang, X.; Li, M.-J. Thermal assessment on solid-liquid energy storage tube packed with non-uniform angled fins. Sol. Energy Mater. Sol. Cells 2022, 236, 111526. [Google Scholar] [CrossRef]

- Mao, Q.; Hu, X.; Zhu, Y. Numerical Investigation of Heat Transfer Performance and Structural Optimization of Fan-Shaped Finned Tube Heat Exchanger. Energies 2022, 15, 5682. [Google Scholar] [CrossRef]

- Mo, C.; Zhang, G.; Yang, X.; Wu, X.; Li, X. A Battery Thermal Management System Coupling High-Stable Phase Change Material Module with Internal Liquid Cooling. Energies 2022, 15, 5863. [Google Scholar] [CrossRef]

- Borri, E.; Hua, N.; Sciacovelli, A.; Wu, D.; Ding, Y.; Li, Y.; Brancato, V.; Zhang, Y.; Frazzica, A.; Li, W.; et al. Phase Change Slurries for Cooling and Storage: An Overview of Research Trends and Gaps. Energies 2022, 15, 6873. [Google Scholar] [CrossRef]

- Available online: https://www.trnsys.com/ (accessed on 11 September 2022).

- F-Chart Software. Engineering Equation Solver (EES). 2015. Available online: https://www.fchart.com/ees (accessed on 11 September 2022).

- Bellos, E.; Tzivanidis, C. Performance analysis and optimization of an absorption chiller driven by nanofluid based solar flat plate collector. J. Clean. Prod. 2018, 174, 256–272. [Google Scholar] [CrossRef]

- Friedl, A.; Padouvas, E.; Rotter, H.; Varmuza, K. Prediction of heating values of biomass fuel from elemental composition. Anal. Chim. Acta 2005, 544, 191–198. [Google Scholar] [CrossRef]

- ΤOΤΕΕ 20701-1; Technical Guidelines on Buildings’ Energy Performance. Greek Technical Chamber: Athens, Greece, 2017.

- ISO 7730:2005; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. ISO: Geneva, Switzerland, 2005.

- Mitsopoulos, G.; Bellos, E.; Tzivanidis, C. Financial and Energetic Optimization of Greek Buildings Insulation. Designs 2018, 2, 34. [Google Scholar] [CrossRef]

- Gogoi, T.K.; Konwar, D. Exergy analysis of a H2O–LiCl absorption refrigeration system with operating temperatures estimated through inverse analysis. Energy Convers. Manag. 2016, 110, 436–447. [Google Scholar] [CrossRef]

- Compton, M.; Rezaie, B.; Rosen, M.A. Exergy approach for advancing sustainability of a biomass boiler. Int. J. Exergy 2018, 27, 62–80. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Tsifis, G. Energetic, Exergetic, Economic and Environmental (4E) analysis of a solar assisted refrigeration system for various operating scenarios. Energy Convers. Manag. 2017, 148, 1055–1069. [Google Scholar] [CrossRef]

- Available online: https://trnsys.de/en/resources/faq/validation (accessed on 11 September 2022).

- Plytaria, M.T.; Bellos, E.; Tzivanidis, C.; Antonopoulos, K.A. Numerical simulation of a solar cooling system with and without phase change materials in radiant walls of a building. Energy Convers. Manag. 2019, 188, 40–53. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Energetic and financial analysis of solar cooling systems with single effect absorption chiller in various climates. Appl. Therm. Eng. 2017, 126, 809–821. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Energetic and financial sustainability of solar assisted heat pump heating systems in Europe. Sustain. Cities Soc. 2017, 33, 70–84. [Google Scholar] [CrossRef]

- Tzivanidis, C.; Bellos, E.; Mitsopoulos, G.; Antonopoulos, K.A.; Delis, A. Energetic and financial evaluation of a solar assisted heat pump heating system with other usual heating systems in Athens. Appl. Therm. Eng. 2016, 106, 87–97. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C.; Kouvari, A.; Antonopoulos, K.A. Comparison of Heating and Cooling Loads of a Typical Building with TRNSYS and eQUEST, Energy, Transportation and Global Warming; Springer: New York, NY, USA, 2016; pp. 327–338. [Google Scholar]

- Available online: https://www.dapeep.gr/ (accessed on 11 September 2022).

| Parameter | Value |

|---|---|

| Evaporator temperature in cooling mode | 5 °C |

| Condenser/absorber temperature in heating mode | 50 °C |

| Generator temperature | 110 °C |

| Solution heat exchanger effectiveness | 70% |

| Temperature pinch point in the evaporator | 5 K |

| Temperature pinch point in the absorber/condenser | 10 K |

| Boiler nominal efficiency | 90% [11] |

| Higher heating value of the biomass | 18467 kJ/kg [24] |

| Structural Component | Materials | Thickness (cm) | k (W/mK) | ρ (kg/m3) | cp (J/kgK) |

|---|---|---|---|---|---|

| Roof | Concrete | 25 | 2.1 | 2400 | 800 |

| Insulation | 10 | 0.035 | 40 | 800 | |

| Ground | Floor | 1 | 0.07 | 800 | 1000 |

| Concrete | 25 | 2.1 | 2400 | 800 | |

| Insulation | 10 | 0.035 | 40 | 800 | |

| Wall | Plaster | 1 | 1.389 | 2000 | 1000 |

| Brick | 12 | 0.889 | 1800 | 1000 | |

| Insulation | 8 | 0.035 | 40 | 800 | |

| Brick | 12 | 0.889 | 1800 | 1000 | |

| Plaster | 1 | 1.389 | 2000 | 1000 |

| Parameter | Value |

|---|---|

| Heating set point | 20 °C |

| Cooling set point | 26 °C |

| Floor area | 400 m2 |

| Length | 20 m |

| Width | 20 m |

| Height | 3 m |

| South window total area | 10 m2 |

| Infiltration and natural ventilation | 1 air change per hour |

| Appliances and lighting specific gain | 7 W/m2 |

| Occupants | 7 persons sited in rest |

| Specific load per occupant | 100 W/occupant (ISO 7730) [26] |

| U-values of the ground | 0.304 W/m2K |

| U-value of the roof | 0.318 W/m2K |

| U-value of the external walls | 0.365 W/m2K |

| U-value of the glazing (85% of the window) | 2.80 W/m2K |

| U-value of the frame (15% of the window) | 2.27 W/m2K |

| U-value of the window | 2.72 W/m2K |

| g-value of the window | 0.755 |

| Month | Heating (kWh) | Cooling (kWh) |

|---|---|---|

| January | 2712 | 0 |

| February | 2193 | 0 |

| March | 1597 | 0 |

| April | 186 | 0 |

| May | 5 | 151 |

| June | 0 | 1412 |

| July | 0 | 2751 |

| August | 0 | 2669 |

| September | 0 | 1148 |

| October | 0 | 37 |

| November | 487 | 0 |

| December | 1956 | 0 |

| Year | 9136 | 8168 |

| Parameter | Value |

|---|---|

| Cooling load | 8168 kWh |

| Heating load | 9136 kWh |

| Biomass demand for cooling | 10870 kWh |

| Biomass demand for heating | 6989 kWh |

| Total biomass demand | 17859 kWh |

| Mass of the consumed biomass for cooling | 2119 kg |

| Mass of the consumed biomass for heating | 1644 kg |

| The total mass the consumed biomass | 3763 kg |

| Yearly system cooling energy performance | 0.751 |

| Yearly system heating energy performance | 1.307 |

| Yearly exergy efficiency for cooling | 6.31% |

| Yearly exergy efficiency for heating | 14.48% |

| Cooling period | 2627 h |

| Heating period | 3041 h |

| Heating period without heat pump operation | 1126 h |

| Heating period with heat pump operation | 1915 h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bellos, E.; Lykas, P.; Tzivanidis, C. Theoretical Analysis of a Biomass-Driven Single-Effect Absorption Heat Pump for Heating and Cooling Purposes. Appl. Syst. Innov. 2022, 5, 99. https://doi.org/10.3390/asi5050099

Bellos E, Lykas P, Tzivanidis C. Theoretical Analysis of a Biomass-Driven Single-Effect Absorption Heat Pump for Heating and Cooling Purposes. Applied System Innovation. 2022; 5(5):99. https://doi.org/10.3390/asi5050099

Chicago/Turabian StyleBellos, Evangelos, Panagiotis Lykas, and Christos Tzivanidis. 2022. "Theoretical Analysis of a Biomass-Driven Single-Effect Absorption Heat Pump for Heating and Cooling Purposes" Applied System Innovation 5, no. 5: 99. https://doi.org/10.3390/asi5050099

APA StyleBellos, E., Lykas, P., & Tzivanidis, C. (2022). Theoretical Analysis of a Biomass-Driven Single-Effect Absorption Heat Pump for Heating and Cooling Purposes. Applied System Innovation, 5(5), 99. https://doi.org/10.3390/asi5050099