Occupational Risk Assessment of Wind Turbines in Bangladesh

Abstract

:1. Introduction

- To identify the occupational risk of wind turbines during the transportation, construction, operation, and maintenance stages.

- To implement the Fine–Kinney, Fuzzy-AHP, and Fuzzy-TOPSIS methods for analyzing and ranking the hazards using occupational health and safety (OSH) expertise in judgment.

- To control and mitigate risks using the risk control framework.

2. Literature Review

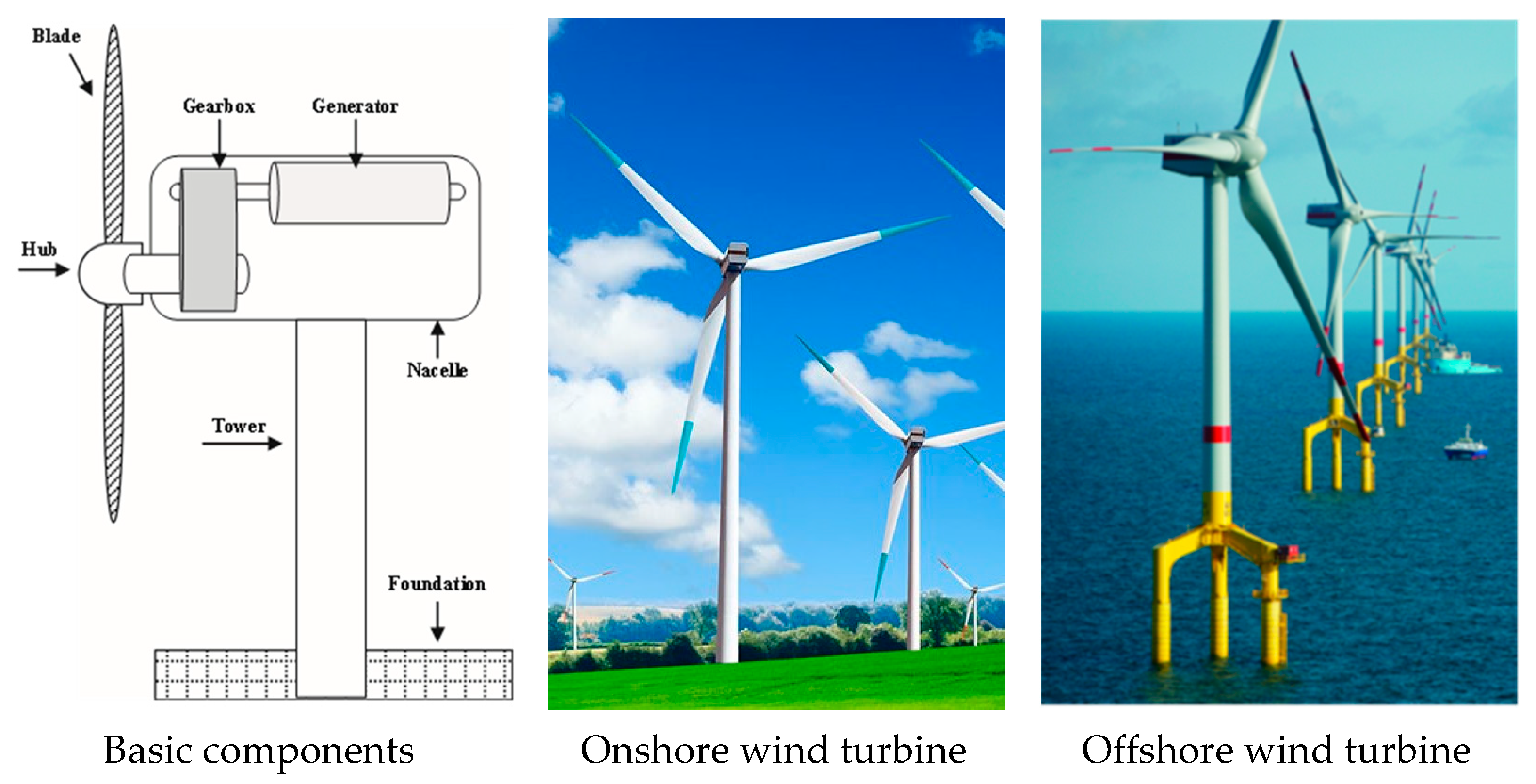

2.1. Wind Turbine and Occupational Risk

2.2. Occupational Risk Assessment Methods

2.3. Wind Turbines Occupational Risk Assessment

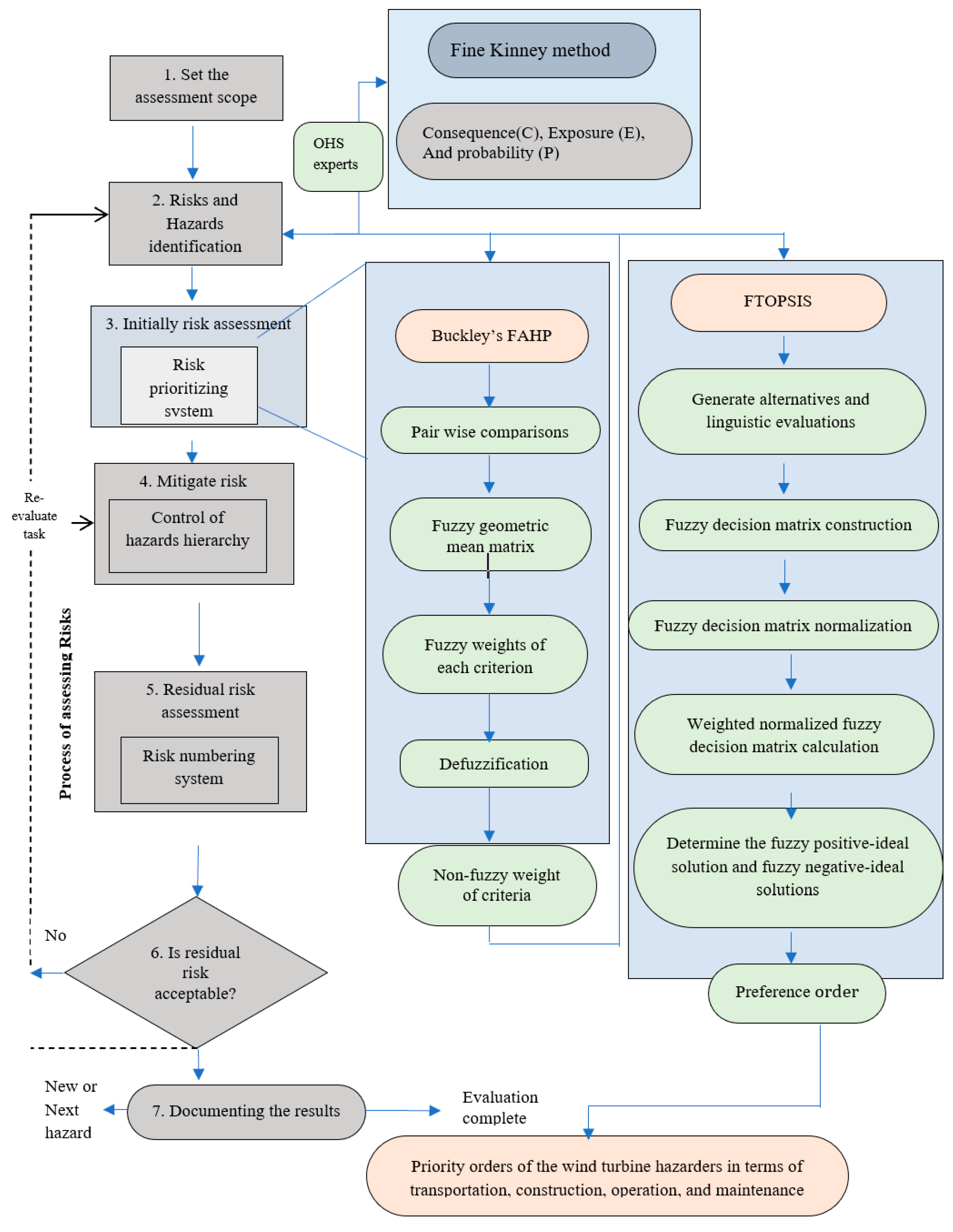

3. Proposed Framework

4. Research Methodology

4.1. Fine–Kinney Method

4.2. Buckley’s Fuzzy AHP Method

4.3. Fuzzy TOPSIS Method

5. Data Collection and Risk Initialization

6. Result and Discussions

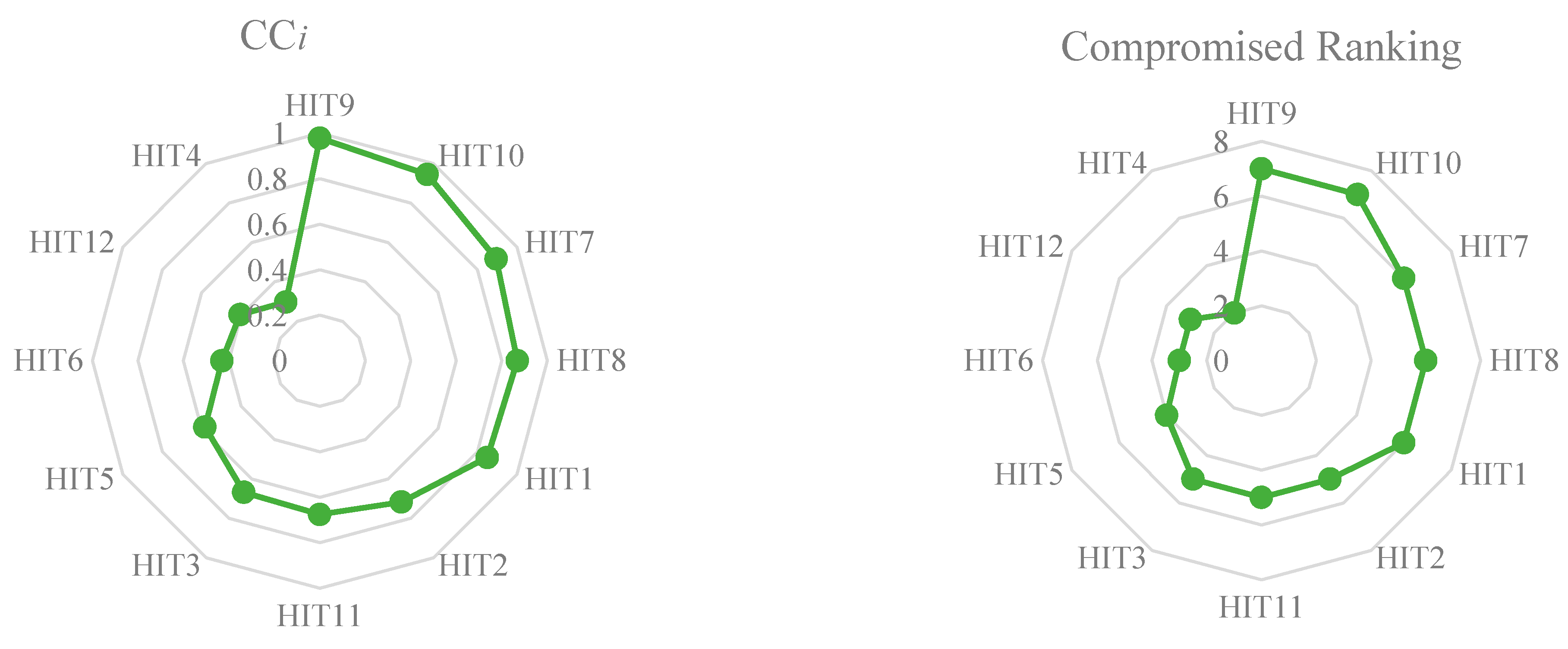

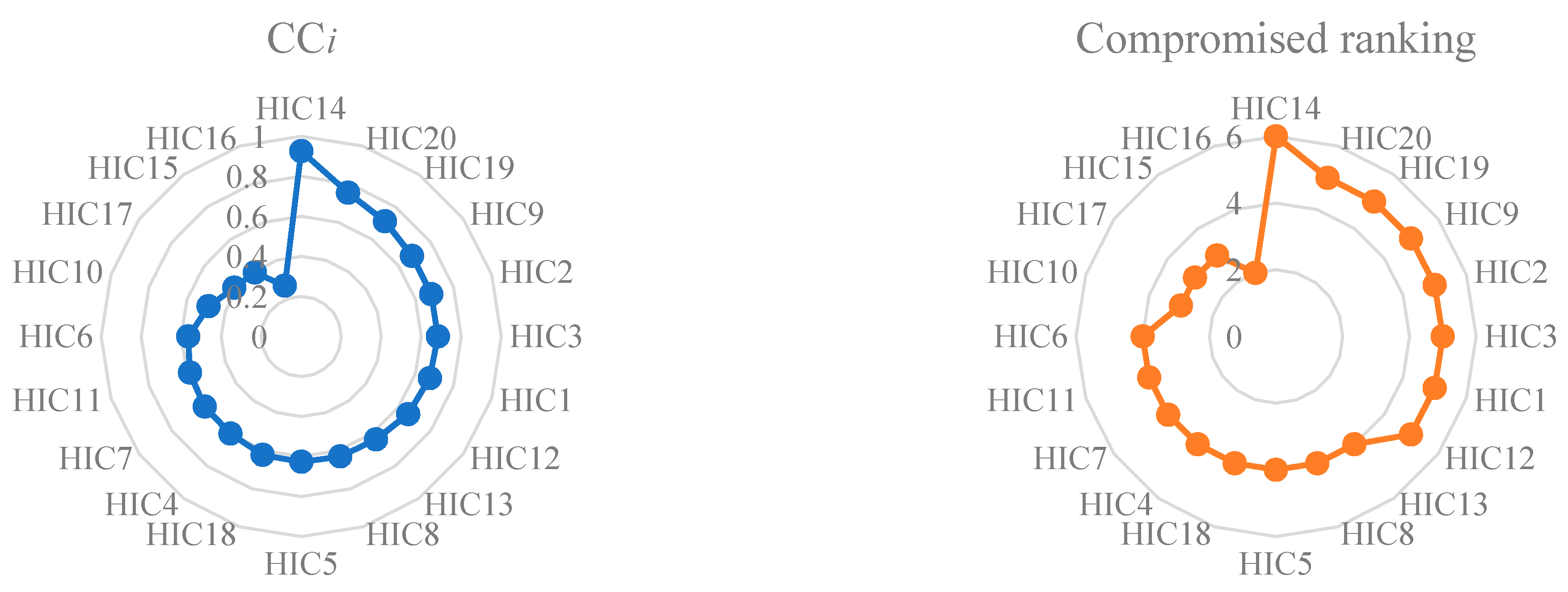

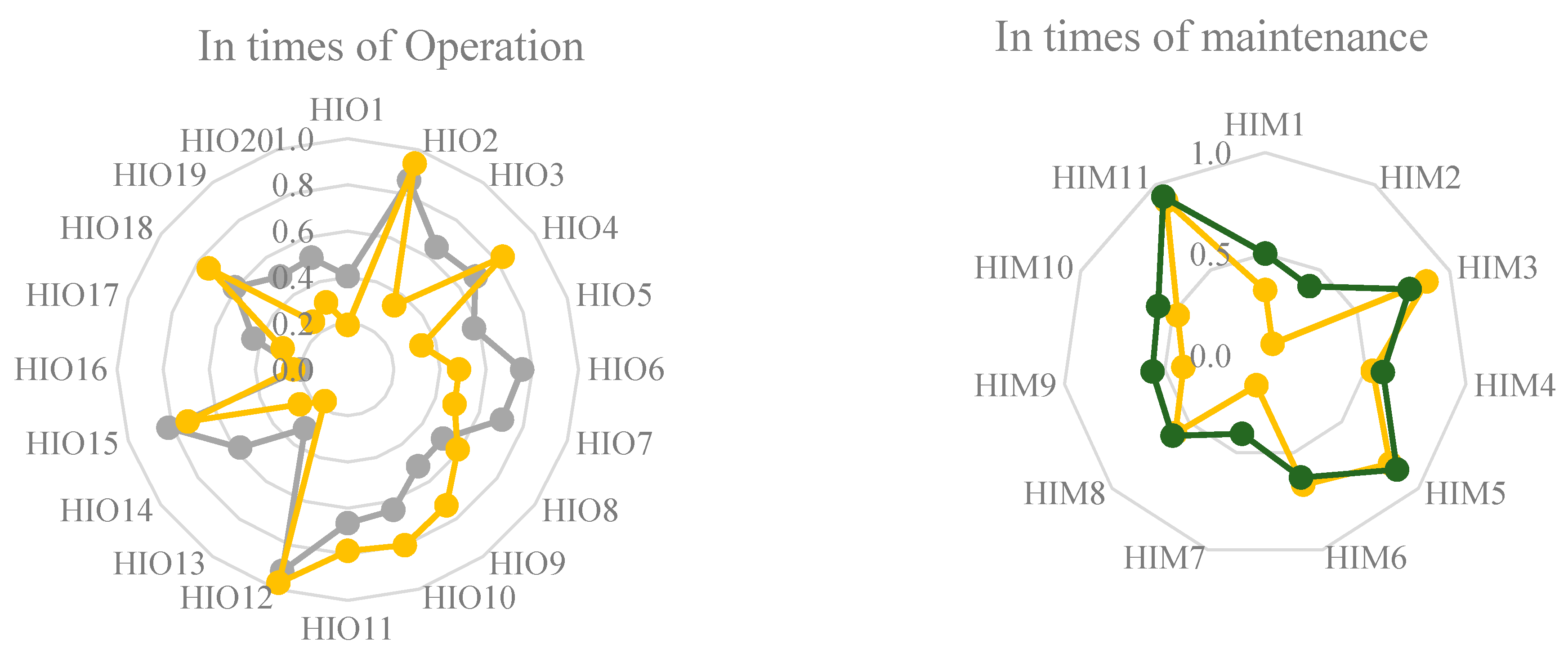

6.1. Risk Assessment and Risk Prioritizing

6.2. Model Comparison and Sensitivity Analysis

6.3. Risk Control Straregies

- Driving should be avoided during dark nights and periods of bad weather.

- Follow the traffic rules and do not exceed the speed limit to reduce traffic accidents.

- A special precaution should be taken during rain and windy weather.

- An operator should take extra precautions to operate the excavation truck.

- Always check the weather news update and take an extra security step to overcome unexpected weather conditions.

- For lightning risks, all manpower should leave the work area. All equipment must be placed on the ground and laid horizontally.

- For reducing the skidding risk, always keep the floor clean and dry.

- To reduce the risk of transformer explosion, cooling fans, securing isolation, tagging systems, and safe working methods can be implemented during the operation process in the wind turbine [37].

7. Conclusions

- Developed a systematic framework to assess the occupational risk of wind turbines for transportation, construction, operation, and maintenance stages from an emerging economy context.

- Integrated fuzzy-AHP and fuzzy-TOPSIS methods to generate effective results considering the uncertainty and vagueness of the decision-making.

- Established a benchmark for the assessment of the occupational risk of wind turbines in Bangladesh. The government and concerned authorities can utilize this information to develop an appropriate action plan to improve their occupational risk management practices.

- Offered policymakers, engineers, managers, supervisors, and researchers more realistic decision-making visions and demonstrated an effective way to evaluate occupational risks associated with wind turbines.

- Proposed analytical framework that is applicable for other renewable energies such as wind turbines, solar energy countries, and other emerging economies and low-income countries.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Exp | Q No | Parameter | HI | MI | I | SI | EA | SU | U | MU | HU | Parameter |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | C | √ | E | ||||||||

| 2 | C | √ | P | |||||||||

| 3 | E | √ | P | |||||||||

| 2 | 1 | C | √ | E | ||||||||

| 2 | C | √ | P | |||||||||

| 3 | E | √ | P | |||||||||

| 3 | 1 | C | √ | E | ||||||||

| 2 | C | √ | P | |||||||||

| 3 | E | √ | P |

| Weighted Normalized Decision Matrix and S+, S−, Ci | |||||||

|---|---|---|---|---|---|---|---|

| HITi | C | E | P | S+ | S− | Ci | Rank |

| HIT1 | 0.049 | 0.153 | 0.105 | 0.047 | 0.175 | 0.789 | 5 |

| HIT2 | 0.014 | 0.153 | 0.09 | 0.074 | 0.175 | 0.703 | 6 |

| HIT3 | 0.055 | 0.113 | 0.066 | 0.094 | 0.144 | 0.605 | 8 |

| HIT4 | 0.02 | 0.007 | 0.097 | 0.194 | 0.207 | 0.517 | 11 |

| HIT5 | 0.072 | 0.127 | 0.027 | 0.109 | 0.152 | 0.584 | 9 |

| HIT6 | 0.055 | 0.013 | 0.105 | 0.181 | 0.199 | 0.524 | 10 |

| HIT7 | 0.037 | 0.187 | 0.113 | 0.035 | 0.204 | 0.853 | 3 |

| HIT8 | 0.072 | 0.153 | 0.109 | 0.04 | 0.176 | 0.814 | 4 |

| HIT9 | 0.066 | 0.187 | 0.113 | 0.009 | 0.202 | 0.958 | 1 |

| HIT10 | 0.049 | 0.193 | 0.109 | 0.023 | 0.207 | 0.899 | 2 |

| HIT11 | 0.072 | 0.193 | 0.008 | 0.105 | 0.204 | 0.659 | 7 |

| HIT12 | 0.072 | 0.047 | 0.043 | 0.163 | 0.162 | 0.499 | 12 |

| X+ | 0.072 | 0.193 | 0.113 | ||||

| X− | 0.014 | 0.007 | 0.008 | ||||

| Weighted Normalized Decision Matrix and S+, S−, Ci | |||||||

|---|---|---|---|---|---|---|---|

| HICi | C | E | P | S+ | S− | Ci | Rank |

| HIC1 | 0.018 | 0.125 | 0.077 | 0.046 | 0.053 | 0.533 | 13 |

| HIC2 | 0.054 | 0.103 | 0.075 | 0.029 | 0.054 | 0.653 | 5 |

| HIC3 | 0.048 | 0.112 | 0.072 | 0.024 | 0.053 | 0.687 | 3 |

| HIC4 | 0.048 | 0.112 | 0.064 | 0.027 | 0.049 | 0.647 | 6 |

| HIC5 | 0.064 | 0.103 | 0.059 | 0.032 | 0.056 | 0.635 | 7 |

| HIC6 | 0.048 | 0.103 | 0.064 | 0.033 | 0.045 | 0.573 | 10 |

| HIC7 | 0.054 | 0.103 | 0.064 | 0.031 | 0.049 | 0.609 | 8 |

| HIC8 | 0.018 | 0.130 | 0.075 | 0.046 | 0.055 | 0.543 | 12 |

| HIC9 | 0.013 | 0.130 | 0.077 | 0.051 | 0.056 | 0.523 | 14 |

| HIC10 | 0.018 | 0.103 | 0.069 | 0.054 | 0.032 | 0.371 | 19 |

| HIC11 | 0.013 | 0.125 | 0.072 | 0.051 | 0.049 | 0.489 | 16 |

| HIC12 | 0.013 | 0.125 | 0.077 | 0.051 | 0.052 | 0.505 | 15 |

| HIC13 | 0.048 | 0.103 | 0.069 | 0.032 | 0.047 | 0.599 | 9 |

| HIC14 | 0.064 | 0.130 | 0.075 | 0.003 | 0.074 | 0.967 | 1 |

| HIC15 | 0.033 | 0.094 | 0.064 | 0.049 | 0.03 | 0.383 | 18 |

| HIC16 | 0.028 | 0.085 | 0.064 | 0.059 | 0.026 | 0.304 | 20 |

| HIC17 | 0.048 | 0.103 | 0.044 | 0.045 | 0.04 | 0.467 | 17 |

| HIC18 | 0.043 | 0.103 | 0.069 | 0.035 | 0.044 | 0.559 | 11 |

| HIC19 | 0.059 | 0.103 | 0.072 | 0.028 | 0.057 | 0.671 | 4 |

| HIC20 | 0.059 | 0.112 | 0.075 | 0.019 | 0.061 | 0.766 | 2 |

| X+ | 0.064 | 0.130 | 0.077 | ||||

| X− | 0.013 | 0.085 | 0.044 | ||||

| Weighted Normalized Decision Matrix and S+, S−, Ci | |||||||

|---|---|---|---|---|---|---|---|

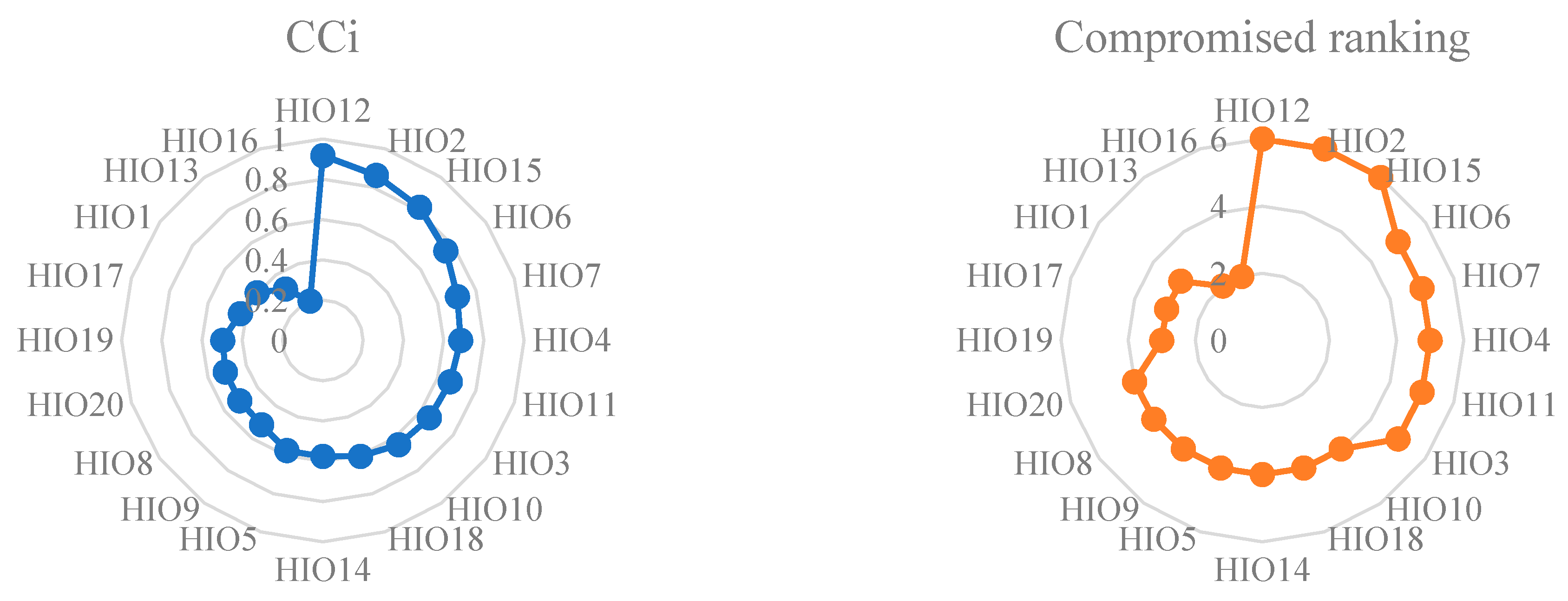

| HIOi | C | E | P | S+ | S− | Ci | Rank |

| HIO1 | 0.239 | 1.942 | 2.281 | 2.524 | 0.602 | 0.1925 | 19 |

| HIO2 | 2.743 | 2.098 | 2.205 | 0.173 | 2.598 | 0.9376 | 2 |

| HIO3 | 0.835 | 2.176 | 2.281 | 1.91 | 0.994 | 0.3424 | 12 |

| HIO4 | 2.743 | 1.787 | 2.053 | 0.519 | 2.528 | 0.8297 | 3 |

| HIO5 | 0.835 | 2.176 | 2.205 | 1.911 | 0.968 | 0.3362 | 13 |

| HIO6 | 1.312 | 2.176 | 2.281 | 1.433 | 1.336 | 0.4825 | 11 |

| HIO7 | 1.312 | 2.253 | 2.205 | 1.433 | 1.359 | 0.4868 | 10 |

| HIO8 | 1.789 | 1.787 | 1.976 | 1.105 | 1.583 | 0.589 | 9 |

| HIO9 | 2.266 | 1.787 | 1.900 | 0.768 | 2.051 | 0.7276 | 8 |

| HIO10 | 2.504 | 1.787 | 2.053 | 0.571 | 2.292 | 0.8005 | 4 |

| HIO11 | 2.266 | 1.942 | 2.205 | 0.574 | 2.102 | 0.7854 | 5 |

| HIO12 | 2.743 | 2.253 | 2.205 | 0.076 | 2.64 | 0.972 | 1 |

| HIO13 | 0.239 | 1.942 | 2.129 | 2.528 | 0.519 | 0.1703 | 20 |

| HIO14 | 0.239 | 2.253 | 2.281 | 2.504 | 0.865 | 0.2567 | 16 |

| HIO15 | 2.027 | 2.253 | 2.129 | 0.732 | 1.964 | 0.7286 | 7 |

| HIO16 | 0.835 | 1.476 | 2.129 | 2.066 | 0.638 | 0.2361 | 18 |

| HIO17 | 0.835 | 1.942 | 2.205 | 1.935 | 0.816 | 0.2966 | 15 |

| HIO18 | 2.266 | 1.787 | 2.053 | 0.705 | 2.057 | 0.7447 | 6 |

| HIO19 | 0.358 | 2.253 | 2.129 | 2.39 | 0.819 | 0.2551 | 17 |

| HIO20 | 0.835 | 1.942 | 2.281 | 1.933 | 0.847 | 0.3046 | 14 |

| X+ | 2.743 | 2.253 | 2.281 | ||||

| X− | 0.239 | 1.476 | 1.900 | ||||

| Weighted Normalized Decision Matrix and S+, S−, Ci | |||||||

|---|---|---|---|---|---|---|---|

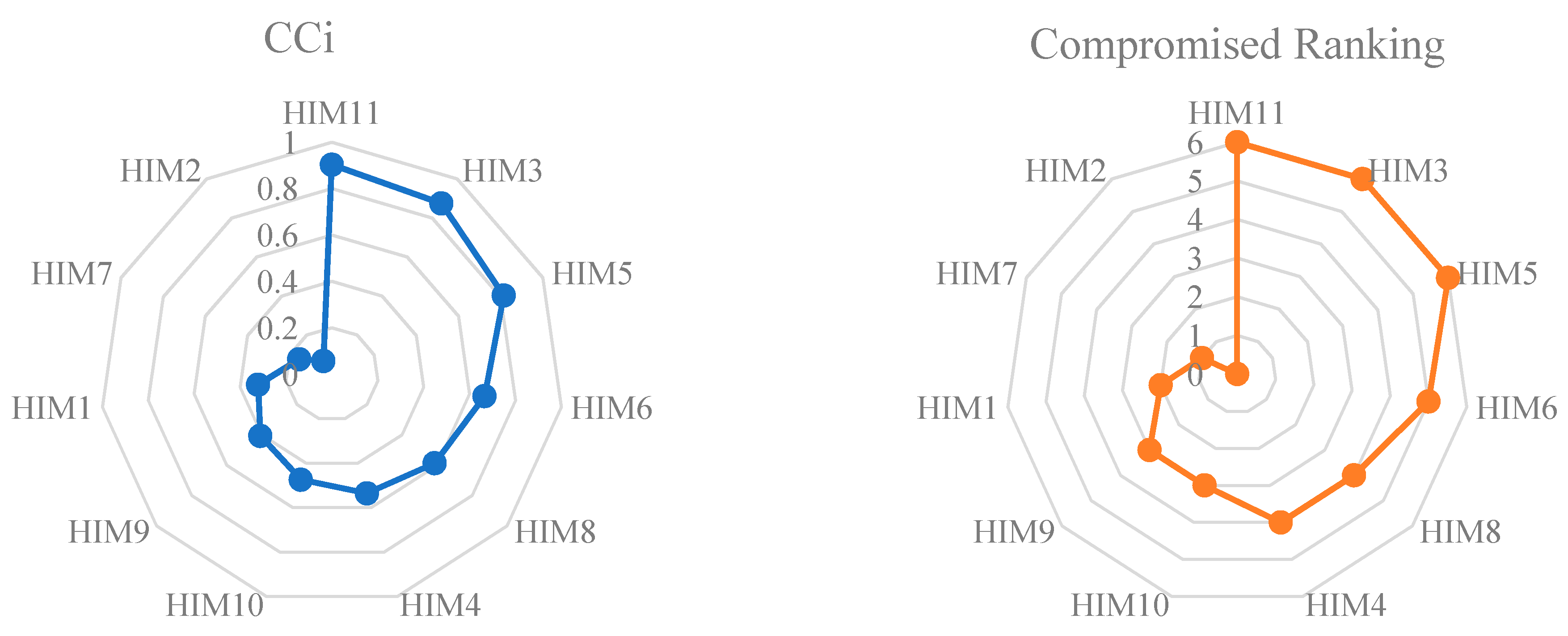

| HIMi | C | E | P | S+ | S− | Ci | Rank |

| HIM1 | 0.006 | 0.125 | 0.089 | 0.132 | 0.133 | 0.502 | 9 |

| HIM2 | 0.013 | 0.072 | 0.082 | 0.161 | 0.109 | 0.404 | 10 |

| HIM3 | 0.069 | 0.184 | 0.107 | 0.051 | 0.183 | 0.783 | 3 |

| HIM4 | 0.006 | 0.165 | 0.096 | 0.117 | 0.165 | 0.586 | 6 |

| HIM5 | 0.119 | 0.165 | 0.1 | 0.027 | 0.167 | 0.86 | 2 |

| HIM6 | 0.006 | 0.191 | 0.103 | 0.113 | 0.191 | 0.628 | 4 |

| HIM7 | 0.031 | 0.072 | 0.089 | 0.149 | 0.1 | 0.403 | 11 |

| HIM8 | 0.031 | 0.151 | 0.096 | 0.097 | 0.149 | 0.605 | 5 |

| HIM9 | 0.013 | 0.151 | 0.075 | 0.118 | 0.151 | 0.561 | 8 |

| HIM10 | 0.069 | 0.125 | 0.082 | 0.086 | 0.12 | 0.581 | 7 |

| HIM11 | 0.107 | 0.184 | 0.103 | 0.015 | 0.19 | 0.929 | 1 |

| X+ | 0.119 | 0.191 | 0.107 | ||||

| X− | 0.006 | 0.072 | 0.075 | ||||

References

- Siddique, A.H.; Tasnim, S.; Shahriyar, F.; Hasan, M.; Rashid, K. Renewable Energy Sector in Bangladesh: The Current Scenario, Challenges and the Role of IoT in Building a Smart Distribution Grid. Energies 2021, 14, 5083. [Google Scholar] [CrossRef]

- Karanikas, N.; Steele, S.; Bruschi, K.; Robertson, C.; Kass, J.; Popovich, A.; MacFadyen, C. Occupational health hazards and risks in the wind industry. Energy Rep. 2021, 7, 3750–3759. [Google Scholar] [CrossRef]

- Wandzich, D.E.; Płaza, G.A. New and Emerging Risks Associated With “Green” Workplaces. Work. Health Saf. 2017, 65, 493–500. [Google Scholar] [CrossRef]

- Madlool, N.A.; Hossain, M.S.; Alshukri, M.J.; Selvaraj, J.; Taher, A.A.; Das Gupta, V.; Mazumder, P.; Rahim, N.A. Investigation on wind energy for grid connection in Bangladesh: Case study. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1127, 012021. [Google Scholar] [CrossRef]

- Asian, S.; Ertek, G.; Haksoz, C.; Pakter, S.; Ulun, S. Wind Turbine Accidents: A Data Mining Study. IEEE Syst. J. 2017, 11, 1567–1578. [Google Scholar] [CrossRef] [Green Version]

- Gul, M.; Guneri, A.F.; Baskan, M. An occupational risk assessment approach for construction and operation period of wind turbines. Glob. J. Environ. Sci. Manag. 2018, 4, 281–298. [Google Scholar] [CrossRef]

- Al Zubayer, A.; Ali, S.M.; Kabir, G. Analysis of supply chain risk in the ceramic industry using the TOPSIS method under a fuzzy environment. J. Model. Manag. 2019, 14, 792–815. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. Renewable Capacity Statistics 2021. Statistiques De Capacité Renouvelable 2021. Estadísticas De Capacidad Renovable 2021. Available online: www.irena.org (accessed on 1 May 2021).

- Chaumel, J.; Ilinca, A.; Laurent, G. Wind Energy Sector Occupational Health and Safety Risks and Accident Prevention Strategies; The Institut de Recherche Robert-Sauvé En Santé et En Sécurité Du Travail (IRSST): Montreal, QC, Canada, 2015; pp. 1–50. Available online: www.csst.qc.ca/AbonnementPA (accessed on 1 May 2021).

- Aneziris, O.; Papazoglou, I.; Psinias, A. Occupational risk for an onshore wind farm. Saf. Sci. 2016, 88, 188–198. [Google Scholar] [CrossRef]

- Gang, C. Risk Analysis and Evaluation of Wind Electric Farm Construction. In Proceedings of the AASRI International Conference on Industrial Electronics and Applications 2015, London, UK, 27–28 June 2015; pp. 539–543. [Google Scholar] [CrossRef] [Green Version]

- Stikova, E.; Donev, D.; Kostova, N.; Jocic, N. Workplace Risk Assessment. In Methods and Tools in Public Health; Hans Jacobs Publishing Company: Lage, Germany, 2010; pp. 583–606. Available online: https://www.researchgate.net/publication/231315785_Workplace_Risk_Assessment (accessed on 1 May 2021).

- Gul, M.; Mete, S.; Serin, F.; Celik, E. Fine–Kinney-Based Fuzzy Multi-Criteria Occupational Risk Assessment, Approaches, Case Studies and Python Applications; Springer: Berlin/Heidelberg, Germany, 2021; Volume 398, Available online: http://link.springer.com/10.1007/978-3-030-52148-6 (accessed on 1 May 2021).

- Vishnyak, M.N.; A Mashenskaya, E.; Melbert, A.A. Occupational Risk Assessment Method for Food Industry. IOP Conf. Ser. Earth Environ. Sci. 2020, 459, 022038. [Google Scholar] [CrossRef]

- Karahan, V.; Akosman, C. Occupational Health Risk Analysis and Assessment in Cement Production Processes. Fırat Univ. Turk. J. Sci. Technol. 2018, 13, 29–37. [Google Scholar]

- Gul, M.; Guven, B.; Guneri, A.F. A new Fine-Kinney-based risk assessment framework using FAHP-FVIKOR incorporation. J. Loss Prev. Process Ind. 2018, 53, 3–16. [Google Scholar] [CrossRef]

- Mohsen, O.; Fereshteh, N. An extended VIKOR method based on entropy measure for the failure modes risk assessment—A case study of the geothermal power plant (GPP). Saf. Sci. 2017, 92, 160–172. [Google Scholar] [CrossRef]

- Mentes, A.; Akyildiz, H.; Yetkin, M.; Turkoglu, N. A FSA based fuzzy DEMATEL approach for risk assessment of cargo ships at coasts and open seas of Turkey. Saf. Sci. 2015, 79, 1–10. [Google Scholar] [CrossRef]

- Hatami-Marbini, A.; Tavana, M.; Moradi, M.; Kangi, F. A fuzzy group Electre method for safety and health assessment in hazardous waste recycling facilities. Saf. Sci. 2013, 51, 414–426. [Google Scholar] [CrossRef]

- Pinto, A.; Nunes, I.L.; Ribeiro, R. Occupational risk assessment in construction industry—Overview and reflection. Saf. Sci. 2011, 49, 616–624. [Google Scholar] [CrossRef]

- Grassi, A.; Gamberini, R.; Mora, C.; Rimini, B. A fuzzy multi-attribute model for risk evaluation in workplaces. Saf. Sci. 2009, 47, 707–716. [Google Scholar] [CrossRef]

- Katzner, T.; Bennett, V.; Miller, T.; Duerr, A.; Braham, M.; Hale, A. Wind energy development: Methods for assessing risks to birds and bats pre-construction. Hum.-Wildl. Interact. 2016, 10, 42–52. [Google Scholar] [CrossRef]

- Mustafa, A.M.; Al-Mahadin, A. Risk assessment of hazards due to the installation and maintenance of onshore wind turbines. In Proceedings of the 2018 Advances in Science and Engineering Technology International Conferences, ASET, Abu Dhabi, United Arab Emirates, 6 February–5 April 2018; pp. 1–7. [Google Scholar] [CrossRef] [Green Version]

- Prag, P. Wind Turbines. In Renewable Energy in the Countryside; Estates Gazette; 2012; pp. 33–59. Available online: https://www.taylorfrancis.com/chapters/mono/10.4324/9780203103289-9/wind-turbines-peter-prag (accessed on 1 May 2021).

- Ashrafi, M.; Davoudpour, H.; Khodakarami, V. Risk assessment of wind turbines: Transition from pure mechanistic paradigm to modern complexity paradigm. Renew. Sustain. Energy Rev. 2015, 51, 347–355. [Google Scholar] [CrossRef]

- Friedberg, A. The “Age of Windows”. In The Virtual Window: From Alberti to Microsoft; MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

- Fine, W.T. Mathematical Evaluations for Controlling Hazards. J. Saf. Res. 1971, 3, 157–166. Available online: https://apps.dtic.mil/sti/pdfs/AD0722011.pdf (accessed on 1 May 2021).

- Yang, C.-C.; Chen, B.-S. Key quality performance evaluation using fuzzy AHP. J. Chin. Inst. Ind. Eng. 2004, 21, 543–550. [Google Scholar] [CrossRef]

- Kabir, G.; Ahsan Akhtar Hasin, M. Comparative Analysis of Ahp and Fuzzy Ahp Models for Multicriteria Inventory Classification. Int. J. Fuzzy Log. Syst. 2011, 1, 1544–1551. [Google Scholar]

- Hsieh, T.-Y.; Lu, S.-T.; Tzeng, G.-H. Fuzzy MCDM approach for planning and design tenders selection in public office buildings. Int. J. Proj. Manag. 2004, 22, 573–584. [Google Scholar] [CrossRef]

- Cavallaro, F. Fuzzy TOPSIS approach for assessing thermal-energy storage in concentrated solar power (CSP) systems. Appl. Energy 2010, 87, 496–503. [Google Scholar] [CrossRef]

- Jahanshahloo, G.; Lotfi, F.H.; Izadikhah, M. Extension of the TOPSIS method for decision-making problems with fuzzy data. Appl. Math. Comput. 2006, 181, 1544–1551. [Google Scholar] [CrossRef]

- Sun, C.-C. A performance evaluation model by integrating fuzzy AHP and fuzzy TOPSIS methods. Expert Syst. Appl. 2010, 37, 7745–7754. [Google Scholar] [CrossRef]

- Mokhtarian, M. A note on “Extension of fuzzy TOPSIS method based on interval-valued fuzzy sets”. Appl. Soft Comput. 2015, 26, 513–514. [Google Scholar] [CrossRef]

- Yazdi, M. Risk assessment based on novel intuitionistic fuzzy-hybrid-modified TOPSIS approach. Saf. Sci. 2018, 110, 438–448. [Google Scholar] [CrossRef]

- Samuels, P.; Gilchrist, M. Pearson Correlation; Birmingham City University: Birmingham, UK, 2014; pp. 1–4. [Google Scholar]

- Safe Work Australia. Managing Electrical Code of Practice (Issue July). 2012. Available online: www.safeworkaustralia.gov.auWestern (accessed on 1 May 2021).

| Reference | Major Occupational Health and Safety (OHS) Hazards |

|---|---|

| [2] | Noise, vibration, electromagnetic fields, flickering shadows, materials and chemicals that are dangerous, material substance risks, environmental risks, biological hazards |

| [6] | Fire, safety signs, faulty Personal Protective Equipment (PPE), weather conditions, road signs, toxic wild animal, tree pruning, electricity, transformer explosion, lights (high or low) |

| [9] | Fall from heights, falling object, physical exertion, electric shock, crane fall or collapse, explosion, fire, moving parts, traffic, temperature, contamination, sea |

| [10] | Working condition, fire, electricity, working tools, hazardous chemicals, weather condition |

| [11] | Damaged equipment, improper location, lightning, flood, fire, earthquake, low or high temperature, the lack of equipment, occupational moral hazard |

| Reference | Methods | Application Area |

|---|---|---|

| [13] | Fine–Kinney-based FTOPSIS, FVIKOR | Gun factory |

| [14] | ORA | Food industry |

| [15] | ORA | Cement industry |

| [6] | FAHP, FVIKOR | Wind turbine |

| [16] | FAHP, FVIKOR | Arms industry |

| [17] | FVIKOR, FAHP, FMEA | Geothermal Power Plant (GPP) |

| [18] | FDEMATEL | Cargo ship industry |

| [19] | FELECTRE | Waste recycling industry |

| [20] | Fuzzy-ORA | Production industry |

| [21] | FTOPSIS | Food industry |

| Rank | Consequence (C) Description | Rank | Exposer (E) Description | Rank | Probability (P) Description |

|---|---|---|---|---|---|

| 100.0 | Catastrophic (many fatalities) | 10.0 | Continuous (multiple times per day) | 10.0 | To be expected |

| 40.0 | Disaster (few fatalities) | 6.0 | Recurring (everyday) | 6.0 | Feasible |

| 15.0 | Super serious (fatality) | 3.0 | Occasional (weekly) | 3.0 | Unusual but possible |

| 7.0 | Serious (serious injury) | 2.0 | Unusual (every month) | 1.0 | Unlikely, possible in the long term |

| 3.0 | Not serious (disability) | 1.0 | Moderately rare (approximately once per year) | 0.5 | Highly unlikely, but conceivable |

| 1.0 | Noticeable | 0.5 | Very rare (less than once per year) | 0.2 | Almost unimaginable |

| 0.1 | Almost impossible |

| Risk Score (R) | Risk Classification |

|---|---|

| Above 400 | Very high risk; immediately stop operations |

| In between 200 and 400 | High risk; take quick large corrective actions |

| In between 70 and 200 | More risk; take simple corrective actions |

| In between 20 and 70 | Low risk: attention required |

| Less than 20 | Very low risk; acceptable |

| Experts | Designation | Experience (Years) | Organization |

|---|---|---|---|

| Exp1 | General Manager (Production) | 20 | Bangladesh Power Development Board |

| Exp2 | Manager (Quality Control) | 14 | Bangladesh Power Development Board |

| Exp3 | Safety Supervisor (Wind Power) | 12 | Bangladesh Power Development Board |

| No | Hazards | Scope | Hazard Identification | Risk Identification |

|---|---|---|---|---|

| 1 | HIT1 | Transportation Security | Communication gap with the work site | Unable to assist in emergency cases in the work site |

| 2 | HIT2 | For Emergency | Undefined dangerous work sites | Trespassing of unauthorized people in the work area |

| 3 | HIT3 | Vehicle Use | Presence of workers in the back of the vehicle while transporting materials | Occupational accidents |

| 4 | HIT4 | Working Methods | Unsuitable slope in the excavation roads | Traffic accident because of the slope |

| 5 | HIT5 | Turbine Transportation | Insufficient road signs | Unable to be warned of road hazards |

| 6 | HIT6 | Turbine Transportation | Tree pruning | Injury from fall, injury from falling branches |

| 7 | HIT7 | Weather Condition | Rough weather conditions (windy, rainy) | Workers might get hit by flying objects; workers may slip due to wet surface |

| 8 | HIT8 | Trucks and Vehicles | Uncoordinated movement by heavy vehicles | Accidents might happen due to the lack of coordination |

| 9 | HIT9 | Wind Farm Vehicles | Dark conditions | Collision due to decreased vision |

| 10 | HIT10 | Shipping of Turbines | Turbines not secured properly | Turbines may become unsecured and hit other property or person |

| 11 | HIT11 | Security | Theft and robberies | Theft and robberies may occur and cause injury to staff |

| 12 | HIT12 | Use of Hytrol | Industrial fluid under high pressure and excessive noise | Loss of hearing and possibility of injury due to malfunction |

| No | Hazards | Scope | Hazard Identification | Risk Identification |

|---|---|---|---|---|

| 1 | HIC1 | Work With Electricity | Lack of safety signs for electrical panels | Electric shock and wrong response |

| 2 | HIC2 | Work in Adverse Weather Conditions | Unsuitable weather conditions | Improper working situations |

| 3 | HIC3 | Night Works | Insufficiency of lighting | Visual disturbances and undesirable behavior |

| 4 | HIC4 | Machine and Equipment | Lack of workers supervising and enforcing safety | Lapse of safety enforcement and increased chances of accidents |

| 5 | HIC5 | Unauthorized Personnel | Unwanted personnel entering the worksite | Accidents may occur due to the entry of the unauthorized person |

| 6 | HIC6 | Control | Quality of goods provided by suppliers | Lack of quality of material supplied may become a hazard |

| 7 | HIC7 | Construction Associated Works | Lack of seat belts or faulty seat belts | Injury from fall or collision |

| 8 | HIC8 | Construction Associated Works | Ignoring employment measures at a height | Fall from heights |

| 9 | HIC9 | Fire and Emergency Cases | No plans for emergency | Unable to act properly during an emergency, injuries may occur |

| 10 | HIC10 | Concrete Mixer | Making concrete and lacking signals for backing up | Collision with property and personnel |

| 11 | HIC11 | Concreting | Treating with concrete at height | Injury from fall |

| 12 | HIC12 | Accidents and Diseases | Unqualified workers being hired | Increase in risk of accident for a worker not qualified for the job |

| 13 | HIC13 | Weather Condition | Rough weather conditions (windy, rainy) | Workers might get hit by flying objects and slip due to wet surface |

| 14 | HIC14 | Working in Hot Temperature for Attaching Blades | Work in hot and humid conditions | Sunstroke and fall from height |

| 15 | HIC15 | After Assembly | Elevator going up and down | Injury from fall |

| 16 | HIC16 | Ladders | Using ladders to get to a height | Injury from fall |

| 17 | HIC17 | Use of Guidewire | Guidewire being pulled | Injury to the hand from using the guidewires |

| 18 | HIC18 | Use of PPE | PPE not used by staff | Injury or sickness from particles such as debris |

| 19 | HIC19 | Hazard Signs | Lack of hazard signs | Unable to warn about construction hazard, might cause injury |

| 20 | HIC20 | Personnel Equipment | Accidents from hand equipment use | Damage of tools and injury to staff |

| No | Hazards | Scope | Hazard Identification | Risk Identification |

|---|---|---|---|---|

| 1 | HIO1 | Administrative Building | Fire | Risk of fire |

| 2 | HIO2 | Administrative Building | Stairs | Wet and slippery floor, skidding risk |

| 3 | HIO3 | Administrative Building | Wind turbine transformer | Risk of explosion or failure of the transformer |

| 4 | HIO4 | Administrative Building | Unauthorized personnel | Loss/damage of equipment by that unauthorized person |

| 5 | HIO5 | Administrative Building | Pests and insects | Pest and insect bites |

| 6 | HIO6 | Security Duty | Possibility of electric shock | Injury to security personnel from electric shock |

| 7 | HIO7 | Dump Area | Possibility of contact with dangerous chemical | Staff may get sick from contact with the chemicals |

| 8 | HIO8 | Storage | Possibility of stored materials falling | Injury of workers from the fall of materials |

| 9 | HIO9 | Mixed-Use Land | Farmers farming near the wind farm | Possible damage to wind farm equipment |

| 10 | HIO10 | Cables | Cables running through a public area such as roads | Damage to cables during maintenance of public infrastructure |

| 11 | HIO11 | Cables | Cables being inspected | Possibility of workers getting an electric shock |

| 12 | HIO12 | Wind Turbine | Inclement weather | Damage to the blades or wind turbine |

| 13 | HIO13 | Turbine Area | Unauthorized personnel | An unauthorized person may suffer from electric shock |

| 14 | HIO14 | Transformer | Transformer breakdown | The breakdown from wear and tear |

| 15 | HIO15 | Transformer | Transformer explosion | Explosion from operation |

| 16 | HIO16 | Ring Main Unit Cell | Ring main unit setup | Possibility of being electrocuted |

| 17 | HIO17 | Ring Main Unit Cell | Ring main unit setup | Burns from explosion |

| 18 | HIO18 | Kiosks | Access by an unauthorized person | Loss of equipment |

| 19 | HIO19 | Kiosks | Short circuit | Equipment damage |

| 20 | HIO20 | Kiosks | Broken rectifiers | Possibility of electric shock |

| No | Hazards | Scope/Area | Hazard Identification | Risk Identification |

|---|---|---|---|---|

| 1 | HIM1 | Turbine Blade Maintenance | Using long ladder and failing to use PPE | Fall from heights |

| 2 | HIM2 | Turbine Blade Maintenance | Lack of safety signs for electrical panels | Electric shock by contacting the MV cables |

| 3 | HIM3 | Turbine Blade Maintenance | Fire due to the lack of heat control | Risk of fire |

| 4 | HIM4 | Transformer Maintenance | Lack of safety signs for electrical panels | Electric shock |

| 5 | HIM5 | Transformer Maintenance | Lack of material management | An accident resulting in material damage and spreading |

| 6 | HIM6 | Transformer Maintenance | Oil spill from an explosion | The explosion resulted in injured personnel |

| 7 | HIM7 | Ring Main Unit Maintenance | Lack of Maintenance skills safety | Explosion during the maintenance |

| 8 | HIM8 | Ring Main Unit Maintenance | Failure to use PPE | Shock from electricity |

| 9 | HIM9 | Concrete Kiosk Maintenance | Control panel short circuit | Damage as a result of fire |

| 10 | HIM10 | Concrete Kiosk Maintenance | Failure to use PPE | Electric shock |

| 11 | HIM11 | Wind Turbine Area | Entering of unauthorized persons | Theft |

| Linguistic Scale | Fuzzy Numbers | Triangular Fuzzy Scale |

|---|---|---|

| High Importance (HI) | (7, 9, 9) | |

| More Importance (MI) | (5, 7, 9) | |

| Importance (I) | (3, 5, 7) | |

| Slight Importance (LI) | (1, 3, 5) | |

| Equilibrium (EA) | (1, 1, 1) | |

| Slight Unimportance (LU) | (1/5, 1/3, 1) | |

| Unimportance (U) | (1/7, 1/5, 1/3) | |

| More Unimportance (MU) | (1/9, 1/7, 1/5) | |

| High Unimportance (HU) | (1/9, 1/9, 1/7) |

| Exp1 | Exp2 | Exp3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C | E | P | C | E | P | C | E | P | |

| C | |||||||||

| E | |||||||||

| P | |||||||||

| Linguistic Term | Fuzzy Number (Triangular) |

|---|---|

| Very poor (VP) | (0, 0, 1) |

| Poor (P) | (0, 1, 3) |

| Moderately poor (MP) | (1, 3, 5) |

| Fair (F) | (3, 5, 7) |

| Moderately good (MG) | (5, 7, 9) |

| Good (G) | (7, 9, 10) |

| Excellent (ET) | (9, 10, 10) |

| Transportation Hazards HITi | Expert Opinion | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Consequence (C) | Exposure (E) | Probability (P) | |||||||

| Exp1 | Exp2 | Exp3 | Exp1 | Exp2 | Exp3 | Exp1 | Exp2 | Exp3 | |

| HIT1 | F | MG | F | MG | G | MG | G | G | G |

| HIT2 | MP | P | P | MG | G | MG | MG | G | MG |

| HIT3 | F | MG | MG | F | F | MG | F | F | MG |

| HIT4 | PR | MP | MP | VP | VP | PR | G | G | MG |

| HIT5 | G | MG | G | MG | F | MG | MP | MP | PR |

| HIT6 | MG | F | MG | PR | PR | VP | G | G | G |

| HIT7 | F | MP | F | G | ET | G | ET | ET | G |

| HIT8 | MG | G | G | G | G | MG | G | G | ET |

| HIT9 | MG | G | MG | G | G | ET | ET | ET | G |

| HIT10 | F | MG | F | ET | ET | G | G | G | ET |

| HIT11 | G | G | MG | ET | ET | G | PR | PR | VP |

| HIT12 | G | G | MG | MP | PR | MP | MP | MP | F |

| Constructional Hazards HICi | Expert Opinion | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Consequence (C) | Exposure (E) | Probability (P) | |||||||

| Exp1 | Exp2 | Exp3 | Exp1 | Exp2 | Exp3 | Exp1 | Exp2 | Exp3 | |

| HIC1 | PR | MP | MP | G | ET | G | ET | ET | ET |

| HIC2 | F | MG | G | G | MG | MG | G | ET | ET |

| HIC3 | MG | F | MG | G | MG | G | G | ET | G |

| HIC4 | F | M G | MG | MG | G | G | G | MG | G |

| HIC5 | G | MG | G | G | MG | MG | MG | G | MG |

| HIC6 | F | MG | MG | MG | G | MG | G | G | MG |

| HIC7 | F | MG | G | G | MG | MG | MG | G | G |

| HIC8 | PR | MP | MP | G | ET | ET | G | ET | ET |

| HIC9 | MP | PR | PR | G | ET | ET | ET | ET | ET |

| HIC10 | F | PR | PR | G | MG | MG | G | G | G |

| HIC11 | PR | PR | MP | G | G | ET | G | G | ET |

| HIC12 | MP | PR | PR | G | ET | G | ET | ET | ET |

| HIC13 | F | MG | MG | MG | G | MG | G | G | G |

| HIC14 | MG | G | G | G | ET | ET | ET | ET | G |

| HIC15 | F | MP | F | MG | MG | MG | G | MG | G |

| HIC16 | MP | F | MP | F | MG | MG | MG | G | G |

| HIC17 | F | MG | MG | MG | G | MG | F | MG | F |

| HIC18 | F | F | MG | MG | MG | G | G | G | G |

| HIC19 | MG | MG | G | G | MG | MG | G | G | ET |

| HIC20 | G | MG | MG | MG | G | G | G | ET | ET |

| Operational Hazards HIOi | Expert Opinion | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Consequence (C) | Exposure (E) | Probability (P) | |||||||

| Exp1 | Exp2 | Exp3 | Exp1 | Exp2 | Exp3 | Exp1 | Exp2 | Exp3 | |

| HIO1 | PR | PR | VP | G | MG | G | ET | ET | ET |

| HIO2 | MG | G | MG | G | G | G | ET | G | ET |

| HIO3 | PR | MP | MP | G | G | ET | ET | ET | ET |

| HIO4 | G | MG | MG | G | MG | MG | G | G | G |

| HIO5 | MP | PR | MP | G | G | ET | ET | G | ET |

| HIO6 | F | MP | MP | G | G | ET | ET | ET | ET |

| HIO7 | F | MP | MP | G | ET | ET | ET | G | ET |

| HIO8 | MPF | MP | G | MG | G | MG | ET | MG | G |

| HIO9 | MG | F | MG | G | MG | MG | G | G | MG |

| HIO10 | F | MG | G | G | MG | MG | G | G | G |

| HIO11 | MG | MG | F | MG | G | G | G | ET | ET |

| HIO12 | MG | G | MG | G | ET | ET | ET | G | ET |

| HIO13 | PR | VP | PR | G | MG | G | G | ET | G |

| HIO14 | VP | PR | PR | G | ET | ET | ET | ET | ET |

| HIO15 | MG | F | F | G | ET | ET | ET | G | G |

| HIO16 | PR | MP | MP | F | G | F | G | ET | G |

| HIO17 | MP | MP | PR | G | G | MG | ET | ET | G |

| HIO18 | F | MG | MG | G | MG | MG | G | G | G |

| HIO19 | PR | PR | PR | G | ET | ET | ET | G | G |

| HIO20 | PR | MP | MP | G | MG | G | ET | ET | ET |

| Maintenance hazards HIMi | Expert Opinion | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Consequence (C) | Exposure (E) | Probability (P) | |||||||

| Exp1 | Exp2 | Exp3 | Exp1 | Exp2 | Exp3 | Exp1 | Exp2 | Exp3 | |

| HIM1 | VP | P | VP | F | MG | MG | MG | G | G |

| HIM2 | P | P | VP | MP | F | MP | MG | G | MG |

| HIM3 | MP | F | MP | G | ET | G | ET | ET | ET |

| HIM4 | VP | VP | P | G | MG | G | G | G | G |

| HIM5 | MG | F | MG | G | MG | G | G | ET | G |

| HIM6 | VP | P | VP | G | ET | ET | ET | G | ET |

| HIM7 | P | MP | P | F | MP | MP | MG | G | G |

| HIM8 | PR | PR | MP | MG | MG | G | G | G | G |

| HIM9 | P | VP | P | G | MG | MG | MG | MG | MG |

| HIM10 | MP | F | MP | MG | F | MG | G | MG | MG |

| HIM11 | FF | MG | F | G | ET | G | ET | ET | G |

| HITi | Consequence (C) | Exposure (E) | Probability (P) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| l | m | u | l | m | u | l | m | u | |

| HIT1 | 3.00 | 5.67 | 9.00 | 5.00 | 7.67 | 10.00 | 7.00 | 9.00 | 10.00 |

| HIT2 | 0.00 | 1.67 | 5.00 | 5.00 | 7.67 | 10.00 | 5.00 | 7.67 | 10.00 |

| HIT3 | 3.00 | 6.33 | 9.00 | 3.00 | 5.67 | 9.00 | 3.00 | 5.67 | 9.00 |

| HIT4 | 0.00 | 2.33 | 5.00 | 0.00 | 0.33 | 3.00 | 5.00 | 8.33 | 10.00 |

| HIT5 | 5.00 | 8.33 | 10.00 | 3.00 | 6.33 | 9.00 | 0.00 | 2.33 | 5.00 |

| HIT6 | 3.00 | 6.33 | 9.00 | 0.00 | 0.67 | 3.00 | 7.00 | 9.00 | 10.00 |

| HIT7 | 1.00 | 4.33 | 7.00 | 7.00 | 9.33 | 10.00 | 7.00 | 9.67 | 10.00 |

| HIT8 | 5.00 | 8.33 | 10.00 | 3.00 | 7.67 | 10.00 | 7.00 | 9.33 | 10.00 |

| HIT9 | 5.00 | 7.67 | 10.00 | 7.00 | 9.33 | 10.00 | 7.00 | 9.67 | 10.00 |

| HIT10 | 3.00 | 5.67 | 9.00 | 7.00 | 9.67 | 10.00 | 7.00 | 9.33 | 10.00 |

| HIT11 | 5.00 | 8.33 | 10.00 | 7.00 | 9.67 | 10.00 | 0.00 | 0.67 | 3.00 |

| HIT12 | 5.00 | 8.33 | 10.00 | 0.00 | 2.33 | 5.00 | 1.00 | 3.67 | 7.00 |

| 10.00 | 10.00 | 10.00 | |||||||

| HITi | Consequence (C) | Exposure (E) | Probability (P) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| l | m | u | l | m | u | l | m | u | |

| HIT1 | 0.043 | 0.107 | 0.239 | 0.182 | 0.385 | 0.671 | 0.160 | 0.277 | 0.423 |

| HIT2 | 0.000 | 0.032 | 0.133 | 0.182 | 0.385 | 0.671 | 0.114 | 0.236 | 0.423 |

| HIT3 | 0.043 | 0.120 | 0.239 | 0.109 | 0.284 | 0.604 | 0.068 | 0.175 | 0.381 |

| HIT4 | 0.000 | 0.044 | 0.133 | 0.000 | 0.017 | 0.201 | 0.114 | 0.257 | 0.423 |

| HIT5 | 0.072 | 0.158 | 0.266 | 0.109 | 0.318 | 0.604 | 0.000 | 0.072 | 0.212 |

| HIT6 | 0.043 | 0.120 | 0.239 | 0.000 | 0.033 | 0.201 | 0.160 | 0.277 | 0.423 |

| HIT7 | 0.014 | 0.082 | 0.186 | 0.254 | 0.469 | 0.671 | 0.160 | 0.298 | 0.423 |

| HIT8 | 0.072 | 0.158 | 0.266 | 0.109 | 0.385 | 0.671 | 0.160 | 0.287 | 0.423 |

| HIT9 | 0.072 | 0.145 | 0.266 | 0.254 | 0.469 | 0.671 | 0.160 | 0.298 | 0.423 |

| HIT10 | 0.043 | 0.107 | 0.239 | 0.254 | 0.485 | 0.671 | 0.160 | 0.287 | 0.423 |

| HIT11 | 0.072 | 0.158 | 0.266 | 0.254 | 0.485 | 0.671 | 0.000 | 0.021 | 0.127 |

| HIT12 | 0.072 | 0.158 | 0.266 | 0.000 | 0.117 | 0.336 | 0.023 | 0.113 | 0.296 |

| 0.072 | 0.158 | 0.266 | 0.254 | 0.485 | 0.671 | 0.160 | 0.298 | 0.423 | |

| 0 | 0.032 | 0.133 | 0 | 0.017 | 0.201 | 0 | 0.021 | 0.127 | |

| Hazard | Rank | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| HIT1 | 0.037 | 0.072 | 0.012 | 0.079 | 0.360 | 0.244 | 0.120 | 0.684 | 0.850 | 5 |

| HIT2 | 0.114 | 0.072 | 0.044 | 0.000 | 0.360 | 0.221 | 0.229 | 0.582 | 0.717 | 6 |

| HIT3 | 0.031 | 0.148 | 0.092 | 0.084 | 0.286 | 0.176 | 0.271 | 0.546 | 0.668 | 8 |

| HIT4 | 0.109 | 0.410 | 0.035 | 0.007 | 0.000 | 0.228 | 0.555 | 0.236 | 0.298 | 12 |

| HIT5 | 0.000 | 0.134 | 0.201 | 0.114 | 0.297 | 0.057 | 0.335 | 0.468 | 0.583 | 9 |

| HIT6 | 0.031 | 0.404 | 0.012 | 0.084 | 0.010 | 0.244 | 0.447 | 0.338 | 0.430 | 10 |

| HIT7 | 0.072 | 0.010 | 0.000 | 0.043 | 0.404 | 0.252 | 0.081 | 0.699 | 0.896 | 3 |

| HIT8 | 0.000 | 0.102 | 0.006 | 0.114 | 0.350 | 0.248 | 0.108 | 0.712 | 0.868 | 4 |

| HIT9 | 0.007 | 0.010 | 0.000 | 0.109 | 0.404 | 0.252 | 0.017 | 0.765 | 0.978 | 1 |

| HIT10 | 0.037 | 0.000 | 0.006 | 0.079 | 0.410 | 0.248 | 0.043 | 0.737 | 0.945 | 2 |

| HIT11 | 0.000 | 0.000 | 0.252 | 0.114 | 0.410 | 0.000 | 0.252 | 0.524 | 0.675 | 7 |

| HIT12 | 0.000 | 0.323 | 0.152 | 0.114 | 0.097 | 0.112 | 0.474 | 0.322 | 0.405 | 11 |

| Construction Hazard | Rank | Operation Hazard | Rank | Maintenance Hazard | Rank |

|---|---|---|---|---|---|

| HIC1 | 7 | HIO1 | 18 | HIM1 | 9 |

| HIC2 | 5 | HIO2 | 2 | HIM2 | 11 |

| HIC3 | 6 | HIO3 | 8 | HIM3 | 2 |

| HIC4 | 13 | HIO4 | 6 | HIM4 | 6 |

| HIC5 | 11 | HIO5 | 12 | HIM5 | 3 |

| HIC6 | 16 | HIO6 | 4 | HIM6 | 4 |

| HIC7 | 14 | HIO7 | 5 | HIM7 | 10 |

| HIC8 | 10 | HIO8 | 14 | HIM8 | 5 |

| HIC9 | 4 | HIO9 | 13 | HIM9 | 8 |

| HIC10 | 17 | HIO10 | 9 | HIM10 | 7 |

| HIC11 | 15 | HIO11 | 7 | HIM11 | 1 |

| HIC12 | 8 | HIO12 | 1 | ||

| HIC13 | 9 | HIO13 | 19 | ||

| HIC14 | 1 | HIO14 | 11 | ||

| HIC15 | 19 | HIO15 | 3 | ||

| HIC16 | 20 | HIO16 | 20 | ||

| HIC17 | 18 | HIO17 | 17 | ||

| HIC18 | 12 | HIO18 | 10 | ||

| HIC19 | 3 | HIO19 | 16 | ||

| HIC20 | 2 | HIO20 | 15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bepary, B.; Kabir, G. Occupational Risk Assessment of Wind Turbines in Bangladesh. Appl. Syst. Innov. 2022, 5, 34. https://doi.org/10.3390/asi5020034

Bepary B, Kabir G. Occupational Risk Assessment of Wind Turbines in Bangladesh. Applied System Innovation. 2022; 5(2):34. https://doi.org/10.3390/asi5020034

Chicago/Turabian StyleBepary, Bijoy, and Golam Kabir. 2022. "Occupational Risk Assessment of Wind Turbines in Bangladesh" Applied System Innovation 5, no. 2: 34. https://doi.org/10.3390/asi5020034

APA StyleBepary, B., & Kabir, G. (2022). Occupational Risk Assessment of Wind Turbines in Bangladesh. Applied System Innovation, 5(2), 34. https://doi.org/10.3390/asi5020034