Ion Flotation of La3+, Cd2+, and Cs+ using Monorhamnolipid Collector

Abstract

1. Introduction

2. Materials and Methods

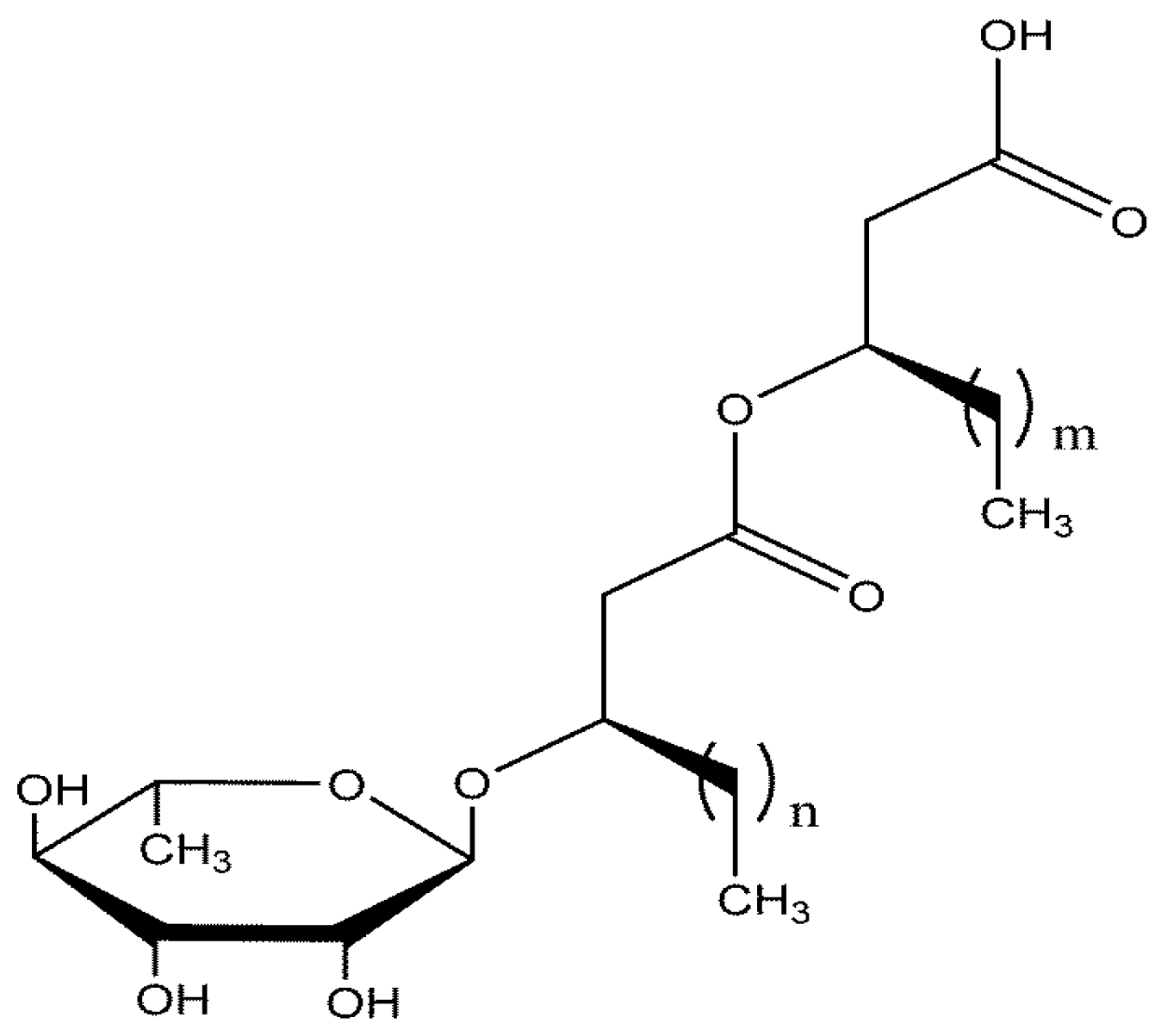

2.1. Monorhamnolipids

2.2. Chemicals

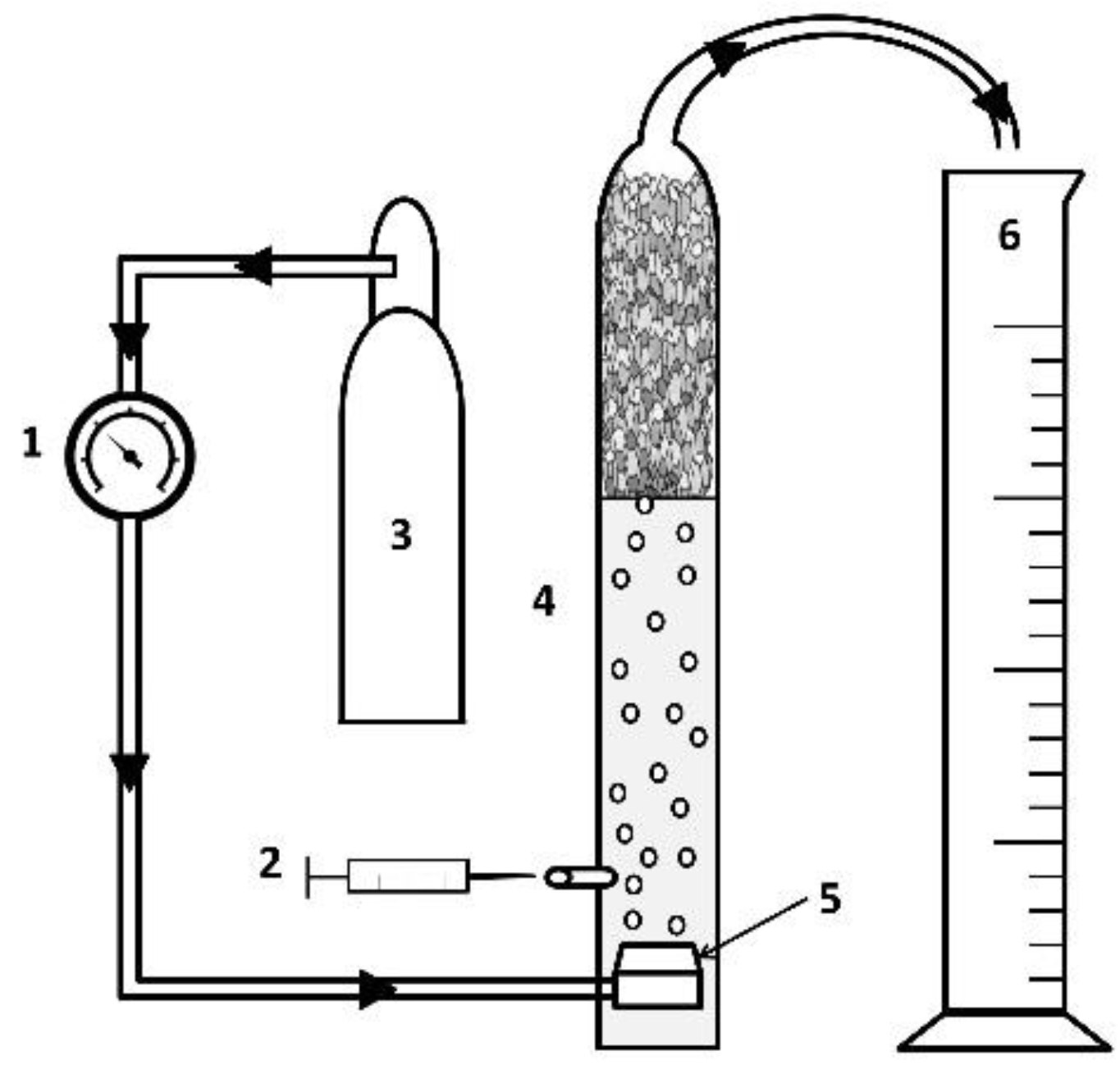

2.3. Flotation Apparatus

2.4. Ion Flotation Experiments

2.4.1. Collector-to-Colligend Ratio Effect

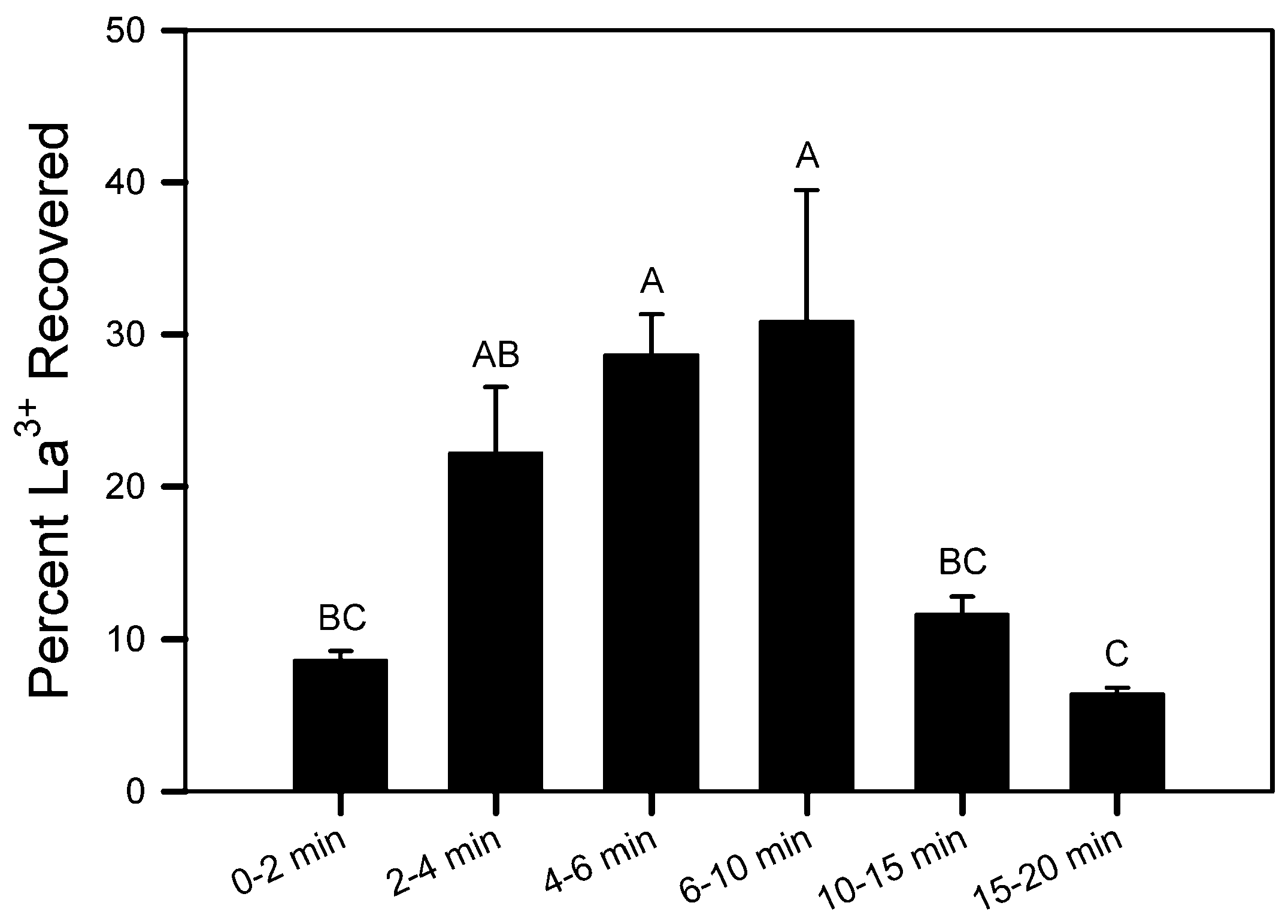

2.4.2. Metal Removal Measured by Foamate Fractions

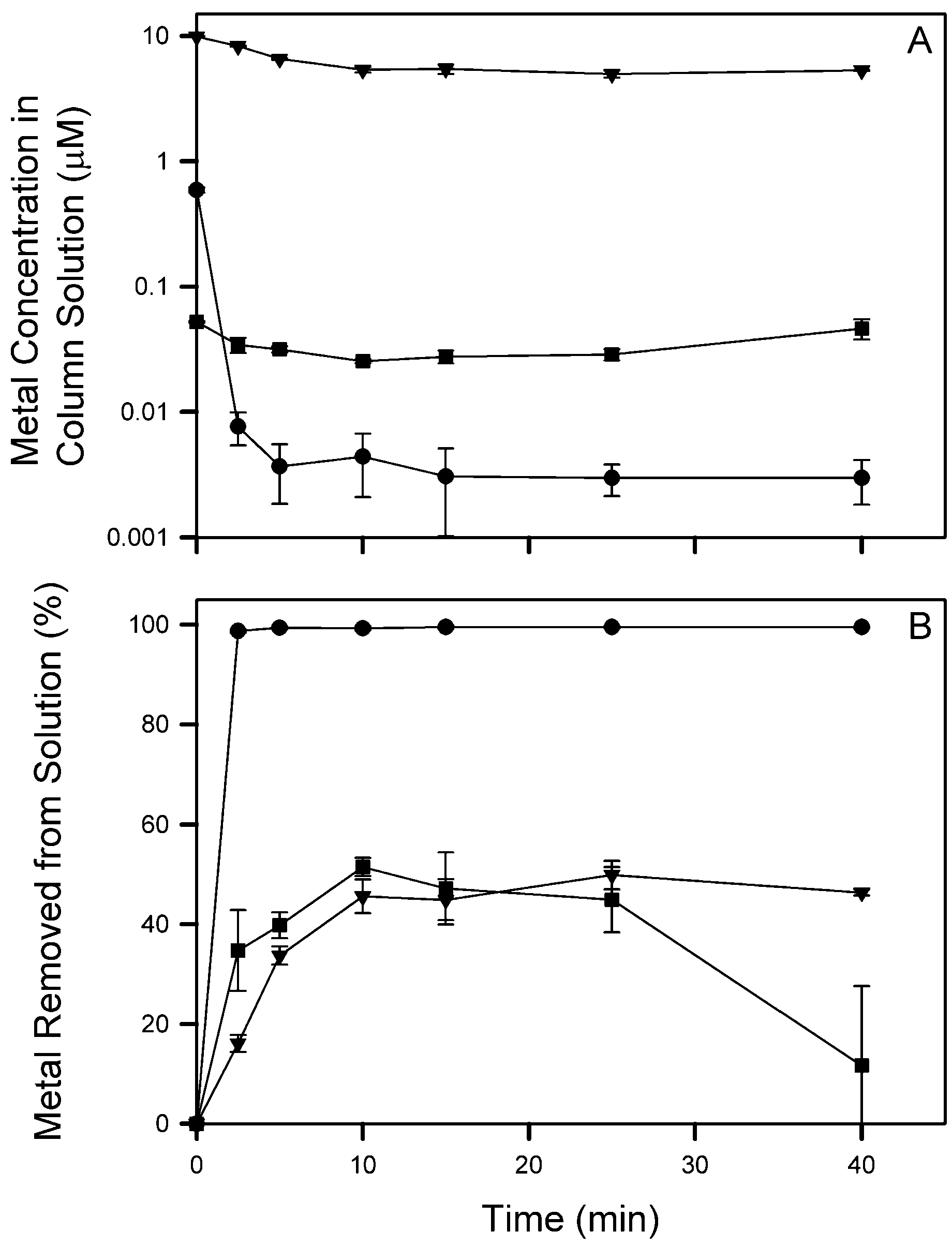

2.4.3. Flotation in Mixed Metal Systems

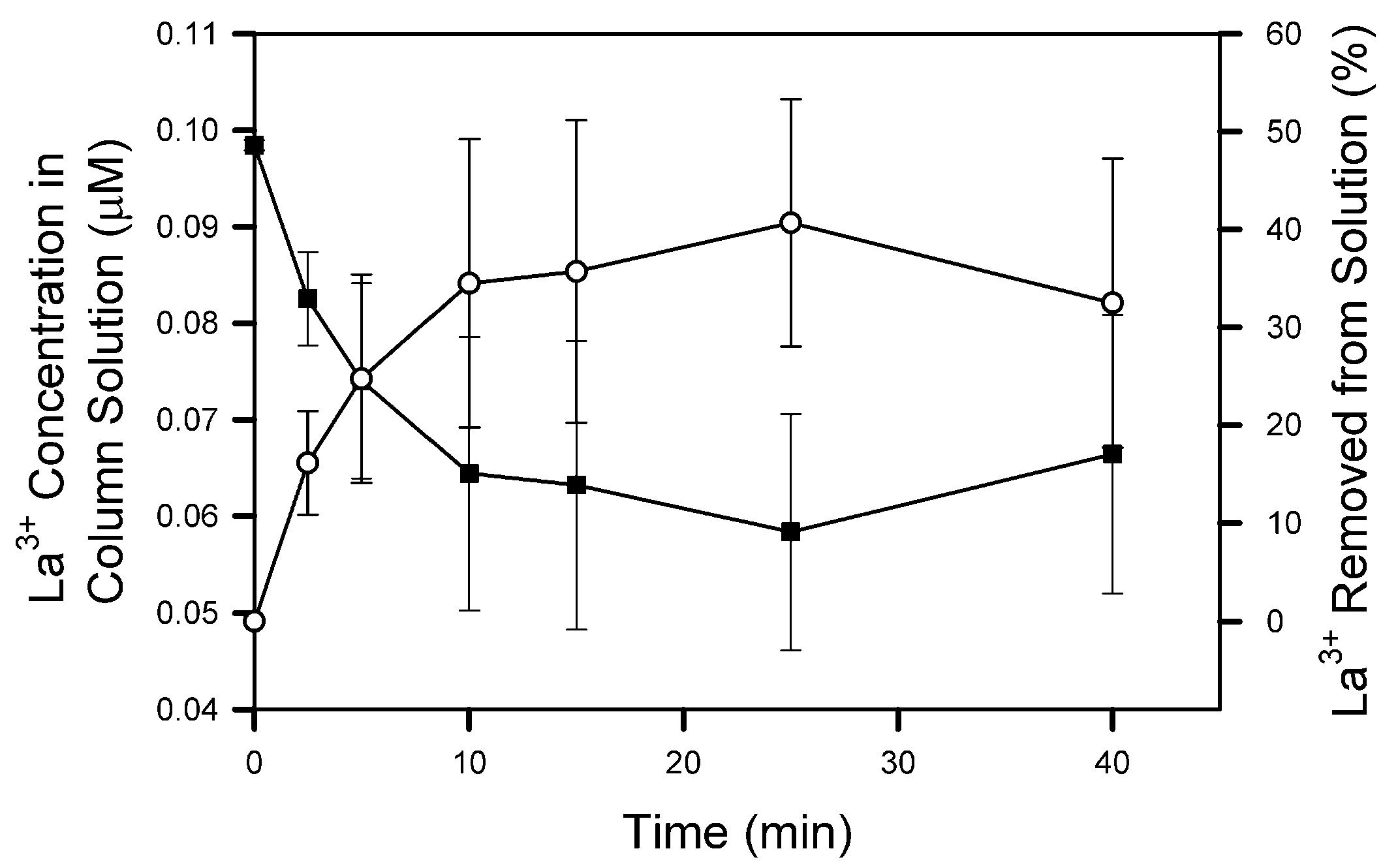

2.4.4. Low Concentration La3+

2.5. Calculations

3. Results and Discussion

3.1. Collector-to-colligend Ratio Effect

3.2. Metal Removal Measured by Foamate Fractions

3.3. Flotation in Mixed Metal Systems

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- United Nations Water. Coping with Water Scarcity: A Strategic Issue and Priority for System-Wide Action. 2006. Available online: http://www.unwater.org/publications/coping-water-scarcity/ (accessed on 27 August 2018).

- Hoekstra, A.Y.; Mekonnen, M.M.; Chapagain, A.K.; Mathews, R.E.; Richter, B.D. Global monthly water scarcity: Blue water footprints versus blue water availability. PLoS ONE 2012, 7, e32688. [Google Scholar] [CrossRef] [PubMed]

- Mekonnen, M.M.; Hoekstra, A.Y. Global Water Scarcity: Monthly Blue Water Footprint Compared to Blue Water Availability for the World’s Major River Basins. Value of Water Research Report Series No 53. 2011. Available online: http://waterfootprint.org/media/downloads/Report53-GlobalBlueWaterScarcity.pdf (accessed on 27 August 2018).

- Fuller, A.C.; Harhay, M.O. Population growth, climate change and water scarcity in the southwestern United States. Am. J. Environ. Sci. 2010, 6, 249–252. [Google Scholar] [CrossRef] [PubMed]

- Gerten, D.; Lucht, W.; Ostberg, S.; Heinke, J.; Kowarsch, M.; Kreft, H.; Kundzewicz, Z.W.; Rastgooy, J.; Warren, R.; Schellnhuber, H.J. Asynchronous exposure to global warming: Freshwater resources and terrestrial ecosystems. Environ. Res. Lett. 2013, 8, 034032. [Google Scholar] [CrossRef]

- Rock, C.; McLain, J.E.; Gerrity, D. Water Recycling FAQs; The University of Arizona Cooperative Extension: Tucson, AZ, USA, 2012; Available online: https://extension.arizona.edu/sites/extension.arizona.edu/files/pubs/az1568.pdf (accessed on 27 August 2018).

- Addams, L.; Boccaletti, G.; Kerlin, M.; Stuchtey, M. Charting Our Water Future: Economic Framework to Inform Decision-Making. 2030 Water Resources Group, 2009. Available online: https://www.mckinsey.com/~/media/mckinsey/dotcom/client_service/sustainability/pdfs/charting%20our%20water%20future/charting_our_water_future_full_report_.ashx (accessed on 27 August 2018).

- Merten, D.; Buchel, G. Determination of rare earth elements in acid mine drainage by inductively coupled plasma mass spectrometry. Microchim. Acta 2004, 148, 163–170. [Google Scholar] [CrossRef]

- Cravotta, C.A. Dissolved metals and associated constituents in abandoned coal-mine discharges, Pennsylvania, USA. Part 1: Constituent quantities and correlations. Appl. Geochem. 2008, 23, 166–202. [Google Scholar] [CrossRef]

- Fu, F.; Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef] [PubMed]

- Kiddee, P.; Naidu, R.; Wong, M.H.; Hearn, L.; Muller, J.F. Field investigation of the quality of fresh and aged leachates from selected landfills receiving e-waste in an arid climate. Waste Manag. 2014, 34, 2292–2304. [Google Scholar] [CrossRef] [PubMed]

- Verplanck, P.L.; Furlong, E.T.; Gray, J.L.; Phillips, P.J.; Wolf, R.E.; Esposito, K. Evaluating the behavior of gadolinium and other rare earth elements through large metropolitan sewage treatment plants. Environ. Sci. Technol. 2010, 44, 3876–3882. [Google Scholar] [CrossRef] [PubMed]

- Barakat, M.A. New trends in removing heavy metals from industrial wastewater. Arab. J. Chem. 2011, 4, 361–377. [Google Scholar] [CrossRef]

- Zhang, W.; Honaker, R.Q. Rare earth elements recovery using staged precipitation from a leachate generated from coarse coal refuse. Int. J. Coal Geol. 2018, 195, 189–199. [Google Scholar] [CrossRef]

- Lemlich, R. Adsorptive Bubble Separation Techniques; Academic Press: New York, NY, USA, 1972; ISBN 9780124433502. [Google Scholar]

- Klassen, V.I.; Mokrousov, V.A. An Introduction to the Theory of Flotation; Butterworths: London, UK, 1963. [Google Scholar]

- Feng, Q.; Zhao, W.; Wen, S. Surface modification of malachite with ethanediamine and its effect on sulfidization flotation. Appl. Surf. Sci. 2018, 436, 823–831. [Google Scholar] [CrossRef]

- Sebba, F. Concentration by ion flotation. Nature 1959, 184, 1062–1063. [Google Scholar] [CrossRef]

- Pinfold, T.A. Ion flotation. In Adsorptive Bubble Separation Techniques; Lemlich, R., Ed.; Academic Press: New York, NY, USA, 1972; pp. 53–73. ISBN 9780124433502. [Google Scholar]

- Matis, K.; Mavros, P. Recovery of metals by ion flotation from dilute aqueous solutions. Sep. Purif. Methods 1991, 20, 1–48. [Google Scholar] [CrossRef]

- Hogan, D.E.; Veres-Schalnat, T.A.; Pemberton, J.E.; Maier, R.M. Biosurfactant Complexation of Metals and Applications for Remediation. In Biosurfactants: Research Trends and Applications; Mulligan, C.N., Mudhoo, A., Sharma, S.K., Eds.; CRC Press: London, UK, 2014; pp. 277–308. ISBN 9781466518230. [Google Scholar]

- Franzetti, A.; Gandolfi, I.; Fracchia, L.; Van Hamme, J.; Gkorezis, P.; Marchant, R.; Banat, I.M. Biosurfactant use in heavy metal removal from industrial effluents and contaminated sites. In Biosurfactants: Production and Utilization—Processes, Technologies, and Economics; Kosaric, N., Vardar-Sukan, F., Eds.; CRC Press: New York, NY, USA, 2014; Volume 159, pp. 361–369. ISBN 9781466596696. [Google Scholar]

- Tan, H.; Champion, J.T.; Artiola, J.F.; Brusseau, M.L.; Miller, R.M. Complexation of cadmium by a rhamnolipid biosurfactant. Environ. Sci. Technol. 1994, 28, 2402–2406. [Google Scholar] [CrossRef] [PubMed]

- Herman, D.C.; Artiola, J.F.; Miller, R.M. Removal of cadmium, lead, and zinc from soil by a rhamnolipid biosurfactant. Environ. Sci. Technol. 1995, 29, 2280–2285. [Google Scholar] [CrossRef] [PubMed]

- Ochoa-Loza, F.J.; Artiola, J.F.; Maier, R.M. Stability constants for the complexation of various metals with a rhamnolipid biosurfactant. J. Environ. Qual. 2001, 30, 479–485. [Google Scholar] [CrossRef] [PubMed]

- Hogan, D.E.; Curry, J.E.; Pemberton, J.E.; Maier, R.M. Rhamnolipid biosurfactant complexation of rare earth elements. J. Hazard Mater. 2017, 340, 171–178. [Google Scholar] [CrossRef] [PubMed]

- El Zeftawy, M.A.M.; Mulligan, C.N. Use of rhamnolipid to remove heavy metals from wastewater by micellar-enhanced ultrafiltration (MEUF). Sep. Purif. Technol. 2011, 77, 120–127. [Google Scholar] [CrossRef]

- Verma, S.P.; Sarkar, B. Simultaneous removal of Cd (II) and p-cresol from wastewater by micellar-enhanced ultrafiltration using rhamnolipid: Flux decline, adsorption kinetics and isotherm studies. J. Environ. Manag. 2018, 213, 217–235. [Google Scholar] [CrossRef] [PubMed]

- Abyaneh, A.S.; Fazaelipoor, M.H. Evaluation of rhamnolipid (RL) as a biosurfactant for the removal of chromium from aqueous solutions by precipitate flotation. J. Environ. Manag. 2016, 165, 184–187. [Google Scholar] [CrossRef] [PubMed]

- Bodagh, A.; Khoshdast, H.; Sharafi, H.; Zahiri, H.S.; Noghabi, K.A. Removal of cadmium(II) from aqueous solution by ion flotation using rhamnolipid biosurfactant as an ion collector. Ind. Eng. Chem. Res. 2013, 52, 3910–3917. [Google Scholar] [CrossRef]

- Lebron-Paler, A.; Pemberton, J.E.; Becker, B.A.; Otto, W.H.; Larive, C.K.; Maier, R.M. Determination of the acid dissociation constant of the biosurfactant monorhamnolipid in aqueous solution by potentiometric and spectroscopic methods. Anal. Chem. 2006, 78, 7649–7658. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Miller, R. Effect of a Pseudomonas rhamnolipid biosurfactant on cell hydrophobicity and biodegradation of octadecane. Appl. Environ. Microbiol. 1994, 60, 2101–2106. [Google Scholar] [PubMed]

- Lebron-Paler, A. Solution and Interfacial Characterization of Rhamnolipid Biosurfactant from P. aeruginosa ATCC 9027. Ph.D. Thesis, The University of Arizona, Tucson, AZ, USA, 2008. [Google Scholar]

- Zhang, L.; Pemberton, J.E.; Maier, R.M. Effect of fatty acid substrate chain length on Pseudomonas aeruginosa ATCC 9027 monorhamnolipid yield and congener distribution. Process. Biochem. 2014, 49, 989–995. [Google Scholar] [CrossRef]

- Geological Survey of Japan. Atlas of Eh-pH diagrams: intercomparison of thermodynamic databases. Report 419. 2005. Available online: http://www.eosremediation.com/download/Chemistry/Chemical%20Properties/Eh_pH_Diagrams.pdf (accessed on 27 September 2018).

- Hogan, D.E. Biosurfactant (Monorhamnolipid) Complexation of Metals and Applications for Aqueous Metalliferous Waste Remediation. Ph.D. Thesis, University of Arizona, Tucson, AZ, USA, 2016. [Google Scholar]

- Thalody, B.; Warr, G.G. Ion flotation: A laboratory experiment linking fundamental and applied chemistry. J. Chem. Educ. 1999, 76, 956–958. [Google Scholar] [CrossRef]

- Jacobelli-Turi, C.; Maracci, F.; Margani, A.; Palmera, M. Separation of metallic ions by foaming: Studies in Italy. In Adsorptive Bubble Separation Techniques; Lemlich, R., Ed.; Academic Press: New York, NY, USA, 1972; pp. 265–272. ISBN 9780124433502. [Google Scholar]

- Eismin, R.J.; Munusamy, E.; Kegel, L.L.; Hogan, D.E.; Maier, R.M.; Schwartz, S.D.; Pemberton, J.E. Evolution of aggregate structure in solutions of anionic monorhamnolipids: Experimental and computational results. Langmuir 2017, 33, 7412–7424. [Google Scholar] [CrossRef] [PubMed]

- Salmani, M.H.; Davoodi, M.; Ehrampoush, M.H.; Ghaneian, M.T.; Fallahzadah, M.H. Removal of cadmium (II) from simulated wastewater by ion flotation technique. Iran. J. Environ. Health Sci. Eng. 2013, 10, 16. [Google Scholar] [CrossRef] [PubMed]

- Myers, D. Foams. In Surfactant Science and Technology, 2nd ed.; VCH Publishers, Inc.: New York, NY, USA, 1992; pp. 249–265. ISBN 1560815868. [Google Scholar]

- Myers, D. Surfactants in solution: Micellization and related association phenomena. In Surfactant Science and Technology, 2nd ed.; VCH Publishers, Inc.: New York, NY, USA, 1992; pp. 81–131. ISBN 1560815868. [Google Scholar]

- Walkowiak, W. Mechanism of selective ion flotation. 1. Selective flotation of transition metal cations. Sep. Sci. Technol. 1991, 26, 559–568. [Google Scholar] [CrossRef]

- Zouboulis, A.I.; Matis, K.A.; Lazaridis, N.K.; Golyshin, P.N. The use of biosurfactants in flotation: Application for the removal of metal ions. Miner. Eng. 2003, 16, 1231–1236. [Google Scholar] [CrossRef]

- Doyle, F.M. Ion flotation—Its potential for hydrometallurgical operations. Int. J. Miner. Process. 2003, 72, 387–399. [Google Scholar] [CrossRef]

- Jorné, J.; Rubin, E. Ion fractionation by foam. Sep. Sci. Technol. 1969, 4, 313–324. [Google Scholar] [CrossRef]

- Huang, R.C.; Talbot, F.D. The removal of copper, cadmium, and lead ions from dilute aqueous solutions using foam fractionation. Can. J. Chem. Eng. 1973, 51, 709–713. [Google Scholar] [CrossRef]

- Kubota, K.; Hayashi, S. The removal of sodium, cadmium and chromium ions from dilute aqueous solutions using foam fractionation. Can. J. Chem. Eng. 1977, 55, 286–292. [Google Scholar] [CrossRef]

- Grieves, R.B.; Burton, K.E.; Craigmyle, J.A. Experimental foam fractionation selectivity coefficients for the alkali (Group IA) metals. Sep. Sci. Technol. 1987, 22, 1597–1608. [Google Scholar] [CrossRef]

- Ehrampoush, M.H.; Salmani, M.H.; Ghaneian, M.T.; Davoudi, M.; Fallahzadeh, M.H. Selectivity in removal of cadmium (II) from mixed metal effluents using ion flotation. World Appl. Sci. J. 2011, 13, 52–59. [Google Scholar]

- Liu, Z.; Doyle, F.M. A thermodynamic approach to ion flotation. II. Metal ion selectivity in the SDS–Cu–Ca and SDS–Cu–Pb systems. Colloids Surf. Physicochem. Eng. Asp. 2001, 178, 93–103. [Google Scholar] [CrossRef]

- Grieves, R.B.; Kyle, R.N. Models for interactions between ionic surfactants and nonsurface-active ions in foam fractionation processes. Sep. Sci. Technol. 1982, 17, 465–483. [Google Scholar] [CrossRef]

- Yuan, X.Z.; Meng, Y.T.; Zeng, G.M.; Fang, Y.Y.; Shi, J.G. Evaluation of tea-derived biosurfactant on removing heavy metal ions from dilute wastewater by ion flotation. Colloid Surf. A-Physicochem. Eng. Asp. 2008, 317, 256–261. [Google Scholar] [CrossRef]

- Schalnat, T.A. Metal Complexation and Interfacial Behavior of the Microbially-Produced Surfactant Monorhamnolipid by Pseudomonas aeruginosa ATCC 9027. Ph.D. Thesis, University of Arizona, Tucson, AZ, USA, 2012. [Google Scholar]

- Liu, Z.; Doyle, F.M. A thermodynamic approach to ion flotation. I. Kinetics of cupric ion flotation with alkylsulfates. Colloids Surf. Physicochem. Eng. Asp. 2001, 178, 79–92. [Google Scholar] [CrossRef]

- Wace, P.F.; Banfield, D.L. Foam separation. Chem. Process. Eng. 1966, 47, 70–76, 90. [Google Scholar]

- Palos Pacheco, R.; Eismin, R.J.; Coss, C.S.; Wang, H.; Maier, R.M.; Polt, R.; Pemberton, J.E. Synthesis and characterization of four diastereomers of monorhamnolipids. J. Am. Chem. Soc. 2017, 139, 5125–5132. [Google Scholar] [CrossRef] [PubMed]

| Metal | Target φ a | Column Solution Concentration (μM) | Water Transfer to Foamate (mL) | Foamate Concentration (μM) | Metal Removal Efficiency b (%) | Enrichment Factor c | |

|---|---|---|---|---|---|---|---|

| Initial | Final | ||||||

| Cs+ | 2 | 54.1 | 34.0 | 59.9 | 104.0 | 37.1 | 1.9 |

| 5 | 21.1 | 12.6 | 82.8 | 39.1 | 40.6 | 1.8 | |

| 10 | 10.5 | 5.7 | 105.9 | 16.1 | 46.2 | 1.5 | |

| Cd2+ | 2 | 46.2 | 4.6 | 6.1 | 1257.5 | 90.1 | 27.2 |

| 5 | 15.4 | 0.04 | 84.3 | 54.7 | 99.8 | 15.4 | |

| 10 | 7.9 | 0.02 | 106.2 | 22.0 | 99.8 | 2.8 | |

| La3+ | 2 d | 34.4 | 13.2 | 0.0 | -- | 0.0 | 0.0 |

| 5 | 15.5 | 0.2 | 45.2 | 92.8 | 98.6 | 6.0 | |

| 10 | 7.5 | 0.3 | 73.9 | 28.5 | 96.3 | 3.8 | |

| Metal | Target φ a | Column Solution Concentration (μM) | Water Transfer to Foamate (mL) | Foamate Concentration (μM) | Metal Removal Efficiency b (%) | Enrichment Factor c | |

|---|---|---|---|---|---|---|---|

| Initial | Final | ||||||

| Cs+ | 10 | 3.45 ± 0.11 | 2.09 ± 0.04 | 54.16 ± 7.59 | 7.80 ± 0.27 | 39.4 ± 2.7 | 2.3 |

| Cd2+ | 2.61 ± 0.17 | 0.04 ± 0.02 | 13.19 ± 1.62 | 98.4 ± 0.7 | 5.1 | ||

| La3+ | 2.69 ± 0.04 | 0.32 ± 0.05 | 11.60 ± 1.24 | 88.1 ± 2.1 | 4.3 | ||

| Metal | Target φ a | Column Solution Concentration (μM) | Water Transfer to Foamate (mL) | Concentration of Foamate (μM) | Metal Removal Efficiency b (%) | Enrichment Factor c | |

|---|---|---|---|---|---|---|---|

| Initial | Final | ||||||

| Cs+ | 10 | 9.88 ± 0.13 | 5.30 ± 0.04 | 51.51 ± 10.58 | 24.91 ± 3.45 | 46.4 ± 0.6 | 2.5 |

| Cd2+ | 0.59 ± 0.03 | 0.00 ± 0.00 | 3.76 ± 0.78 | 99.5 ± 0.2 | 6.4 | ||

| La3+ | 0.052 ± 0.001 | 0.046 ± 0.008 | 1.05 ± 0.43 | 11.7 ± 16.0 | 20.0 | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hogan, D.E.; Curry, J.E.; Maier, R.M. Ion Flotation of La3+, Cd2+, and Cs+ using Monorhamnolipid Collector. Colloids Interfaces 2018, 2, 43. https://doi.org/10.3390/colloids2040043

Hogan DE, Curry JE, Maier RM. Ion Flotation of La3+, Cd2+, and Cs+ using Monorhamnolipid Collector. Colloids and Interfaces. 2018; 2(4):43. https://doi.org/10.3390/colloids2040043

Chicago/Turabian StyleHogan, David E., Joan E. Curry, and Raina M. Maier. 2018. "Ion Flotation of La3+, Cd2+, and Cs+ using Monorhamnolipid Collector" Colloids and Interfaces 2, no. 4: 43. https://doi.org/10.3390/colloids2040043

APA StyleHogan, D. E., Curry, J. E., & Maier, R. M. (2018). Ion Flotation of La3+, Cd2+, and Cs+ using Monorhamnolipid Collector. Colloids and Interfaces, 2(4), 43. https://doi.org/10.3390/colloids2040043