Using Machine Learning for Enhancing the Understanding of Bullwhip Effect in the Oil and Gas Industry

Abstract

1. Introduction

2. Literature Review

2.1. Bullwhip Effect

2.1.1. Overview

2.1.2. Performance Measures, Models, and Methods

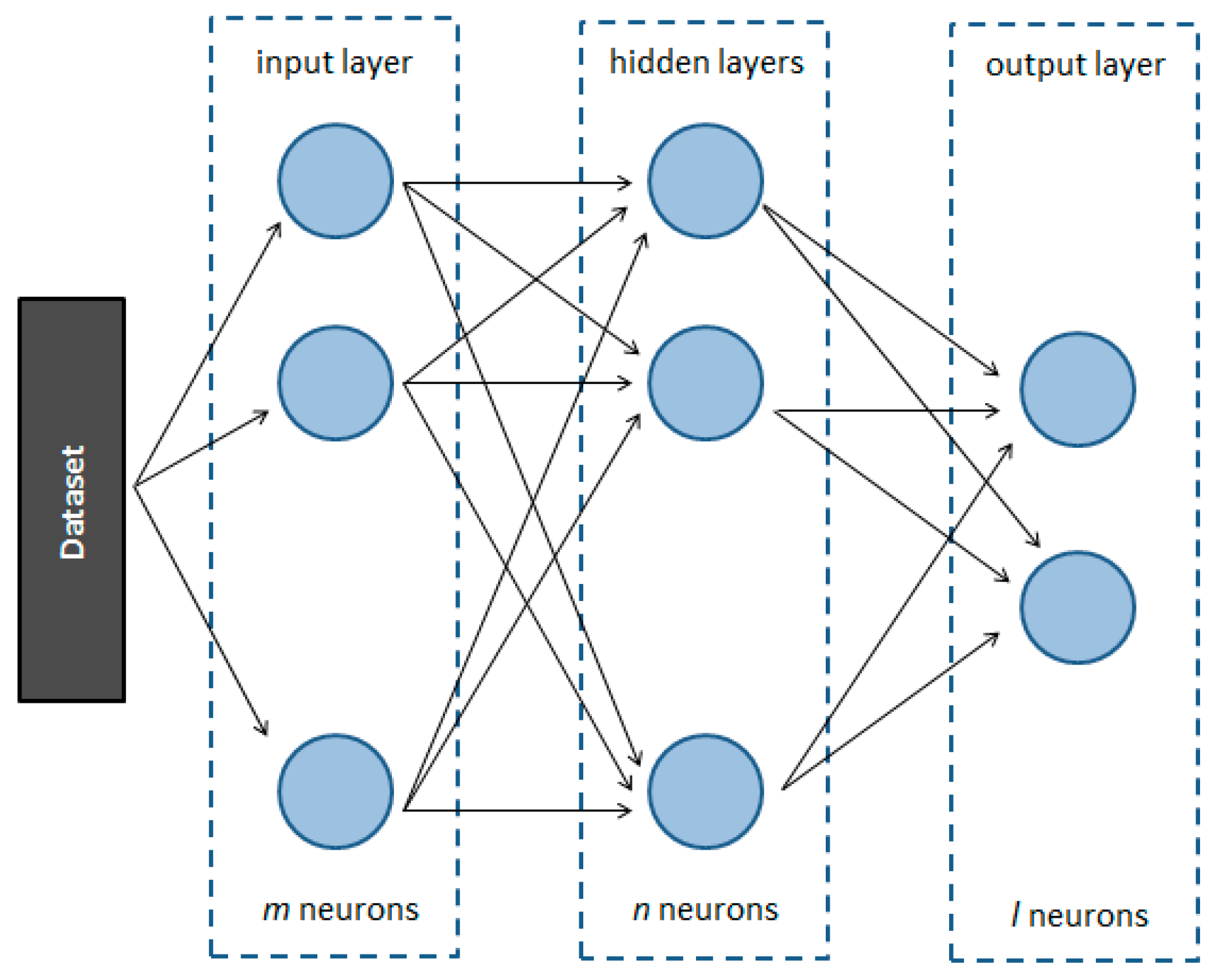

2.2. Artificial Neural Networks

2.2.1. Background

2.2.2. Developing ANN Solutions

2.2.3. Application to Supply Chain Management

2.2.4. Application to Oil and Gas Industry

3. Research Objectives

3.1. Main Goals Delineation

- Does the bullwhip effect occur in the petroleum industry?

- Does the suppliers’ level exhibit the highest demand variability in the supply network?

- Are smaller companies more susceptible to higher variability than larger companies?

- Is it possible to forecast the bullwhip effect using artificial neural network techniques?

- Is it possible to create mathematical models for O & G supply networks’ behavior, so that possible remedial measures for the bullwhip effect can be assessed prior to testing in real conditions?

3.2. Scientific and Social Relevance

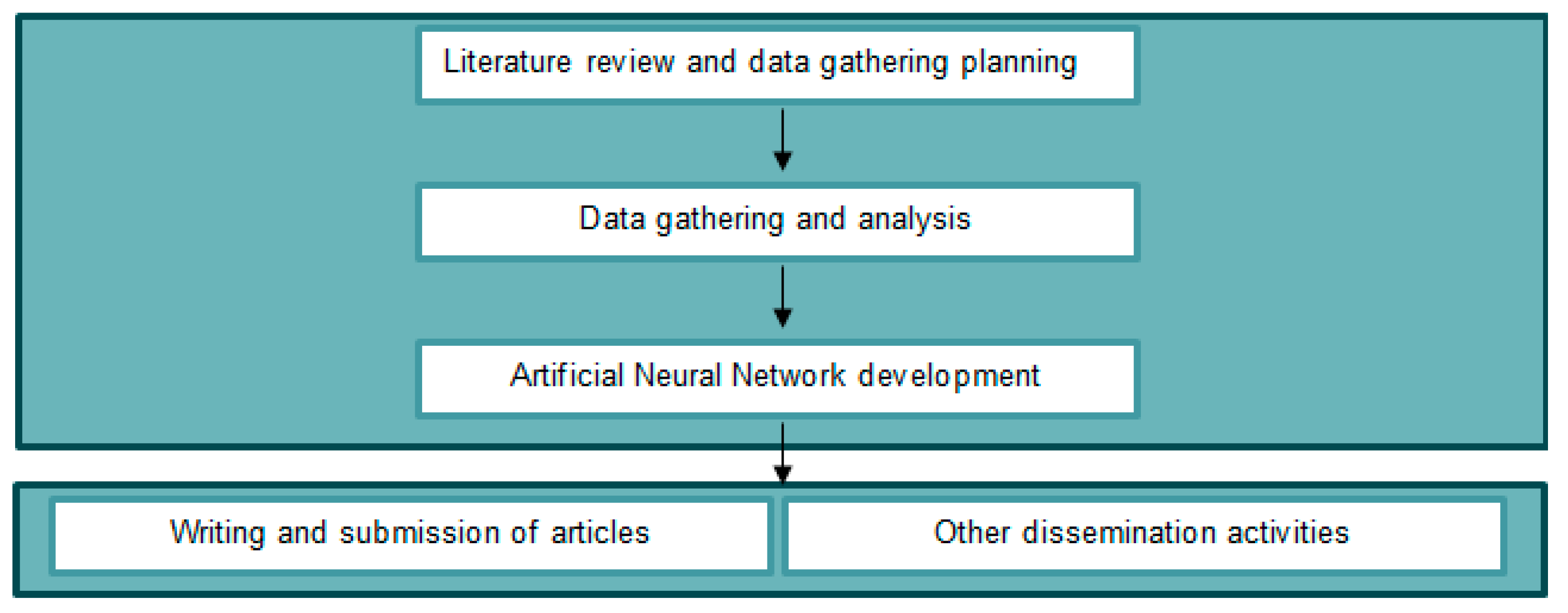

4. Methodology and Planning

4.1. Methodology

4.2. Work Phases

4.2.1. Literature Review and Data Gathering Planning

4.2.2. Data Gathering and Analysis

4.2.3. Artificial Neural Network

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Forrester, J.W. Industrial Dynamics—A major breakthrought for decision makers. Harv. Bus. Rev. 1958, 36, 37–66. [Google Scholar]

- Kadivar, M.; Shirazi, M.A. Analyzing the behavior of the bullwhip effect considering different distribution systems. Appl. Math. Model. 2018, 59, 319–340. [Google Scholar] [CrossRef]

- De Pacheco, E.O.; Cannella, S.; Lüders, R.; Barbosa-Povoa, A.P. Order-up-to-level policy update procedure for a supply chain subject to market demand uncertainty. Comput. Ind. Eng. 2017, 113, 347–355. [Google Scholar] [CrossRef]

- Sousa, A.L.; Matos, H.A.; Guerreiro, L.P. Preventing and removing wax deposition inside vertical wells: A review. J. Pet. Explor. Prod. Technol. 2019, 1–17. [Google Scholar] [CrossRef]

- Stock, T.; Obenaus, M.; Kunz, S.; Kohl, H. Industry 4.0 as enabler for a sustainable development: A qualitative assessment of its ecological and social potential. Process. Saf. Environ. Prot. 2018, 118, 254–267. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.I. What drives the implementation of Industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef]

- Müller, J.M.; Däschle, S. Business Model Innovation of Industry 4.0 Solution Providers Towards Customer Process Innovation. Processes 2018, 6, 260. [Google Scholar] [CrossRef]

- Sodhi, M.S.; Tang, C.S. The incremental bullwhip effect of operational deviations in an arborescent supply chain with requirements planning. Eur. J. Oper. Res. 2011, 215, 374–382. [Google Scholar] [CrossRef]

- Lee, H.L.; Padmanabhan, V.; Whang, S. Information Distortion in a Supply Chain: The Bullwhip Effect. Manag. Sci. 1997, 43, 546–558. [Google Scholar] [CrossRef]

- Wang, X.; Disney, S.M. The bullwhip effect: Progress, trends and directions. Eur. J. Oper. Res. 2016, 250, 691–701. [Google Scholar] [CrossRef]

- Dai, J.; Peng, S.; Li, S. Mitigation of Bullwhip Effect in Supply Chain Inventory Management Model. Procedia Eng. 2017, 174, 1229–1234. [Google Scholar] [CrossRef]

- Tanweer, A.; Li, Y.-Z.; Duan, G.; Song, J.-Y. An Optimization Model for Mitigating Bullwhip-effect in a Two-echelon Supply Chain. Procedia -Soc. Behav. Sci. 2014, 138, 289–297. [Google Scholar] [CrossRef][Green Version]

- Sucky, E. The bullwhip effect in supply chains-An overestimated problem? Int. J. Prod. Econ. 2009, 118, 311–322. [Google Scholar] [CrossRef]

- Birkel, H.S.; Veile, J.W.; Müller, J.M.; Hartmann, E.; Voigt, K.I. Development of a risk framework for Industry 4.0 in the context of sustainability for established manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef]

- Mentzer, J.T.; DeWitt, W.; Keebler, J.S.; Nix, N.W.; Smith, C.D.; Zacharia, Z.G. Defining Supply Chain Management. J. Bus. Logist. 2001, 22, 1–25. [Google Scholar] [CrossRef]

- Forrester, J.W. Industrial dynamics—After the first decade. Manag. Sci. 1968, 14, 398–415. [Google Scholar] [CrossRef]

- Zymelman, M. A Stabilization Policy for the Cotton Textile Cycle. Manag. Sci. 1965, 11, 572–580. [Google Scholar] [CrossRef]

- Tsay, A.A.; Lovejoy, W.S. Quantity Flexibility Contracts and Supply Chain Performance. Manuf. Serv. Oper. Manag. 1999, 1, 89–111. [Google Scholar] [CrossRef]

- Sterman, J.D. Modeling Managerial Behavior: Misperceptions of Feedback in a Dynamic Decision Making Experiment. Manag. Sci. 1989, 35, 321–339. [Google Scholar] [CrossRef]

- Lee, H.L. The triple—A supply chain. Harv. Bus. Rev. 2004, 82, 102–113. [Google Scholar] [PubMed]

- Yu, Z.; Yan, H.; Cheng, T.C.E. Benefits of information sharing with supply chain partnerships. Ind. Manag. Data Syst. 2001, 101, 114–119. [Google Scholar] [CrossRef]

- Simchi-Levi, P.; Kaminsky, P.; Simchi-Levi, E. Barilla Case Study. Available online: http://www2.newpaltz.edu/~liush/MOIT/Barilla%20Case%20Study.pdf (accessed on 6 September 2019).

- Toh, A.K.; Zhang, Q. A conceptual analysis of virtual supply chain collaborative network. Int. J. Soc. Syst. Sci. 2014, 6, 308–330. [Google Scholar] [CrossRef]

- Fu, D.; Ionescu, C.; Aghezzaf, E.-H.; De Keyser, R. Quantifying and mitigating the bullwhip effect in a benchmark supply chain system by an extended prediction self-adaptive control ordering policy. Comput. Ind. Eng. 2015, 81, 46–57. [Google Scholar] [CrossRef]

- Liu, P.; Yi, S.P. Investment Decision-Making and Coordination of Supply Chain: A New Research in the Big Data Era. Discret. Dyn. Nat. Soc. 2016, 2016, 2026715. [Google Scholar] [CrossRef]

- Cannella, S.; Ciancimino, E. On the bullwhip avoidance phase: Supply chain collaboration and order smoothing. Int. J. Prod. Res. 2010, 48, 6739–6776. [Google Scholar] [CrossRef]

- Croson, R.; Donohue, K. Behavioral Causes of the Bullwhip Effect and the Observed Value of Inventory Information. Manag. Sci. 2006, 52, 323–336. [Google Scholar] [CrossRef]

- Ciancimino, E.; Cannella, S.; Bruccoleri, M.; Framinan, J.M. On the Bullwhip Avoidance Phase: The Synchronised Supply Chain. Eur. J. Oper. Res. 2012, 221, 49–63. [Google Scholar] [CrossRef]

- Moyaux, T.; Brahim, C.; D’Amours, S. Information Sharing as a Coordination Mechanism for Reducing the Bullwhip Effect in a Supply Chain. IEEE Trans. Syst. Man Cybern. Part. C 2007, 37, 396–409. [Google Scholar] [CrossRef]

- Lotfi, Z.; Mukhtar, M.; Sahran, S.; Zadeh, A.T. Information Sharing in Supply Chain Management. Procedia Technol. 2013, 11, 298–304. [Google Scholar] [CrossRef]

- Liang, N.Y.; Huang, G.B.; Saratchandran, P.; Sundararajan, N. A fast and accurate online sequential learning algorithm for feedforward networks. IEEE Trans. Neural Netw. 2006, 17, 1411–1423. [Google Scholar] [CrossRef] [PubMed]

- AlSudairi, M.; Vasista, T.G.; Zamil, A.M.; Algharabat, R.S. Mitigating the Bullwhip Effect with eWord of Mouth: eBusiness Intelligence Perspective. Int. J. Manag. Value Supply Chain 2012, 3, 27–41. [Google Scholar] [CrossRef]

- Lampret, T.; Potočan, V. Bullwhip Effect in the Information Flow of a Supply Chain: A Role of Culture. Logist. Sustain. Transp. 2014, 5, 34–45. [Google Scholar] [CrossRef][Green Version]

- Agrawal, S.; Sengupta, R.N.; Shanker, K. Impact of information sharing and lead time on bullwhip effect and on-hand inventory. Eur. J. Oper. Res. 2009, 192, 576–593. [Google Scholar] [CrossRef]

- de Almeida, M.M.K.; Marins, F.A.S.; Salgado, A.M.P.; Santos, F.C.A.; da Silva, S.L. Mitigation of the bullwhip effect considering trust and collaboration in supply chain management: A literature review. Int. J. Adv. Manuf. Technol. 2015, 77, 495–513. [Google Scholar] [CrossRef]

- Shizhengt, G.; Zhen, L.; Xiaoyuan, H. Stochastic Control of Bullwhip Effect in Supply Chain. In Proceedings of the 2006 IEEE International Conference on Service Systems and Service Management, Troyes, France, 25–27 October 2006; Volume 2, pp. 1455–1459. [Google Scholar]

- Huang, X.Y.; Yan, N.N.; Guo, H.F. An H∞ control method of the bullwhip effect for a class of supply chain system. Int. J. Prod. Res. 2007, 45, 207–226. [Google Scholar] [CrossRef]

- Jacoby, D. The oil price ‘bullwhip’: Problem, cost, response. Oil Gas. J. 2010, 108, 20. [Google Scholar]

- Zhang, J.H.; Zhang, Q.Q. The System Dynamics Analyses of Bullwhip Effect in China Processed Oil Supply Chain. Appl. Mech. Mater. 2013, 295, 3310–3317. [Google Scholar] [CrossRef]

- Sherhart, E. The Bullwhip Effect: Recognizing the Phenomenon and Mitigating It Using the Theory of Constraints Illustrated by a Case Study from British Petroleum; Baylor University: Waco, TX, USA, 2013. [Google Scholar]

- Croson, R.; Donohue, K. Impact of Pos Data Sharing on Supply Chain Management: An Experimental Study. Prod. Oper. Manag. 2003, 12, 1–11. [Google Scholar] [CrossRef]

- Caloiero, G.; Strozzi, F.; Comenges, J.M.Z. A supply chain as a series of filters or amplifiers of the bullwhip effect. Int. J. Prod. Econ. 2008, 114, 631–645. [Google Scholar] [CrossRef]

- Geary, S.; Disney, S.M.; Towill, D.R. On bullwhip in supply chains - Historical review, present practice and expected future impact. Int. J. Prod. Econ. 2006, 101, 2–18. [Google Scholar] [CrossRef]

- Springer, M.; Kim, I. Managing the order pipeline to reduce supply chain volatility. Eur. J. Oper. Res. 2010, 203, 380–392. [Google Scholar] [CrossRef]

- Kahn, J.A. Inventories and the Volatility of Production. Am. Econ. Rev. 1987, 77, 667–679. [Google Scholar]

- Carlsson, C.; Fullér, R. Reducing the bullwhip effect by means of intelligent, soft computing methods. In Proceedings of the 34th Annual Hawaii International Conference on System Sciences, Maui, HI, USA, 6 January 2001. [Google Scholar]

- Chen, F.; Drezner, Z.; Ryan, J.K.; Simchi-Levi, D. Quantifying the Bullwhip Effect in a Simple Supply Chain: The Impact of Forecasting, Lead Times, and Information. Manag. Sci. 2000, 46, 436–443. [Google Scholar] [CrossRef]

- Dejonckheere, J.; Disney, S.M.; Lambrecht, M.R.; Towill, D.R. Measuring and avoiding the bullwhip effect: A control theoretic approach. Eur. J. Oper. Res. 2003, 147, 567–590. [Google Scholar] [CrossRef]

- Metters, R. Quantifying the bullwhip effect in supply chains. J. Oper. Manag. 1997, 15, 89–100. [Google Scholar] [CrossRef]

- Zhou, L.; Disney, S.M. Bullwhip and inventory variance in a closed loop supply chain. OR Spectr. 2006, 28, 127–149. [Google Scholar] [CrossRef]

- Nagaraja, C.H.; McElroy, T. The multivariate bullwhip effect. Eur. J. Oper. Res. 2017, 267, 96–106. [Google Scholar] [CrossRef]

- Nienhaus, J.; Ziegenbein, A.; Schoensleben, P. How human behaviour amplifies the bullwhip effect. A study based on the beer distribution game online. Prod. Plan. Control. 2006, 17, 547–557. [Google Scholar] [CrossRef]

- Sarkar, S.; Kumar, S. Demonstrating the Effect of Supply Chain Disruptions through an Online Beer Distribution Game. Decis. Sci. J. Innov. Educ. 2016, 14, 25–35. [Google Scholar] [CrossRef]

- Cachon, G.P.; Randall, T.; Schmidt, G.M. In Search of the Bullwhip Effect. Manuf. Serv. Oper. Manag. 2007, 9, 457–479. [Google Scholar] [CrossRef]

- Chen, F.; Drezner, Z.; Ryan, J.K.; Simchi-Levi, D. The bullwhip effect: Managerial insights on the impact of forecasting and information on variability in a supply chain. Quant. Model. Supply Chain Manag. 1999, 17, 419–439. [Google Scholar]

- Barlas, Y.; Gunduz, B. Demand forecasting and sharing strategies to reduce fluctuations and the bullwhip effect in supply chains. J. Oper. Res. Soc. 2011, 62, 458–473. [Google Scholar] [CrossRef]

- Fu, D.; Ionescu, C.M.; Aghezzaf, E.H.; de Keyser, R. Decentralized and centralized model predictive control to reduce the bullwhip effect in supply chain management. Comput. Ind. Eng. 2014, 73, 21–31. [Google Scholar] [CrossRef]

- Feng, J.; Wang, H. Controlling the bullwhip effect of supply chain system based on the stability analysis. 2010 Int. Conf. Logist. Eng. Manag. Logist. Sustain. Econ. Dev. -Infrastruct. Inf. Integr. ICLEM 2010 2010, 387, 4336–4345. [Google Scholar]

- Chao, Y. The Bullwhip effect in supply chain and countermeasures. Adv. Mater. Res. 2013, 711, 799–804. [Google Scholar] [CrossRef]

- Wright, D.; Yuan, X. Mitigating the bullwhip effect by ordering policies and forecasting methods. Int. J. Prod. Econ. 2008, 113, 587–597. [Google Scholar] [CrossRef]

- Coppini, M.; Rossignoli, C.; Rossi, T.; Strozzi, F. Bullwhip effect and inventory oscillations analysis using the beer game model. Int. J. Prod. Res. 2010, 48, 3943–3956. [Google Scholar] [CrossRef]

- Disney, S.M.; Towill, D.R. Vendor-managed inventory and bullwhip reduction in a two-level supply chain. Int. J. Oper. Prod. Manag. 2003, 23, 625–651. [Google Scholar] [CrossRef]

- Ingalls, R.G.; Foote, B.L.; Krishnamoorthy, A. Reducing the bullwhip effect in supply chains with control-based forecasting. Int. J. Simul. Process. Model. 2005, 1, 90–110. [Google Scholar] [CrossRef]

- Makajić-Nikolić, D.; Panić, B.; Vujošević, M. Bullwhip effect and supply chain modelling and analysis using CPN Tools. In Proceedings of the Fifth Workshop and Tutorial on Practical Use of Coloured Petri Nets and the CPN Tools, Aarhus, Denmark, 8–11 October 2004; pp. 219–234. [Google Scholar]

- Lockwood, A. The Modulation of Wound Healing for Glaucoma Filtration Surgery. Ph.D. Thesis, University College London, London, UK, 2014. [Google Scholar]

- Hahn, C.K.; Duplaga, E.A.; Hartley, J.L. Supply-Chain Synchronization: Lessons from Hyundai Motor Company. Interfaces 2000, 30, 32–45. [Google Scholar] [CrossRef]

- Coleman, J. Extending supply chain synchronisation to upstream tiers: A collaborative approach illustrated with an automotive case study. Int. J. Netw. Virtual Organ. 2010, 7, 257–271. [Google Scholar] [CrossRef]

- Aggelogiannaki, E.; Doganis, P.; Sarimveis, H. An adaptive model predictive control configuration for production-inventory systems. Int. J. Prod. Econ. 2008, 114, 165–178. [Google Scholar] [CrossRef]

- Chaharsooghi, S.K.; Heydari, J. LT variance or LT mean reduction in supply chain management: Which one has a higher impact on SC performance? Int. J. Prod. Econ. 2010, 124, 475–481. [Google Scholar] [CrossRef]

- Chandra, C.; Grabis, J. Application of multi-steps forecasting for restraining the bullwhip effect and improving inventory performance under autoregressive demand. Eur. J. Oper. Res. 2005, 166, 337–350. [Google Scholar] [CrossRef]

- Chatfield, D.C.; Kim, J.G.; Harrison, T.P.; Hayya, J.C. The Bullwhip Effect-Impact of Stochastic Lead Time, Information Quality, and Information Sharing: A Simulation Study. Prod. Oper. Manag. 2009, 13, 340–353. [Google Scholar] [CrossRef]

- Chen, L.; Lee, H.L. Information Sharing and Order Variability Control Under a Generalized Demand Model. Manag. Sci. 2009, 55, 781–797. [Google Scholar] [CrossRef]

- Disney, S.M.; Towill, D.R.; van de Velde, W. Variance amplification and the golden ratio in production and inventory control. Int. J. Prod. Econ. 2004, 90, 295–309. [Google Scholar] [CrossRef]

- Disney, S.M.; Farasyn, I.; Lambrecht, M.; Towill, D.R.; van de Velde, W. Taming the bullwhip effect whilst watching customer service in a single supply chain echelon. Eur. J. Oper. Res. 2006, 173, 151–172. [Google Scholar] [CrossRef]

- Jakšič, M.; Rusjan, B. The effect of replenishment policies on the bullwhip effect: A transfer function approach. Eur. J. Oper. Res. 2008, 184, 946–961. [Google Scholar] [CrossRef]

- Kelepouris, T.; Miliotis, P.; Pramatari, K. The impact of replenishment parameters and information sharing on the bullwhip effect: A computational study. Comput. Oper. Res. 2008, 35, 3657–3670. [Google Scholar] [CrossRef]

- Kim, J.G.; Chatfield, D.; Harrison, T.P.; Hayya, J.C. Quantifying the bullwhip effect in a supply chain with stochastic lead time. Eur. J. Oper. Res. 2006, 173, 617–636. [Google Scholar] [CrossRef]

- Zhang, X. The impact of forecasting methods on the bullwhip effect. Int. J. Prod. Econ. 2004, 88, 15–27. [Google Scholar] [CrossRef]

- Dejonckheere, J.; Disney, S.M.; Lambrecht, M.R.; Towill, D.R. Transfer function analysis of forecasting induced bullwhip in supply chains. Int. J. Prod. Econ. 2002, 78, 133–144. [Google Scholar] [CrossRef]

- Kim, I.; Springer, M. Measuring endogenous supply chain volatility: Beyond the bullwhip effect. Eur. J. Oper. Res. 2008, 189, 172–193. [Google Scholar] [CrossRef]

- Boute, R.N.; Disney, S.M.; Lambrecht, M.R.; van Houdt, B. An integrated production and inventory model to dampen upstream demand variability in the supply chain. Eur. J. Oper. Res. 2007, 178, 121–142. [Google Scholar] [CrossRef]

- Wang, J.L.; Kuo, J.H.; Chou, S.Y.; Wang, S.Z. A comparison of bullwhip effect in a single-stage supply chain for autocorrelated demands when using Correct, MA, and EWMA methods. Expert Syst. Appl. 2010, 37, 4726–4736. [Google Scholar] [CrossRef]

- Cachon, G.P.; Fisher, M. Supply Chain Inventory Management and the Value of Shared Information. Manag. Sci. 2000, 46, 1032–1048. [Google Scholar] [CrossRef]

- Disney, S.M.; Farasyn, I.; Lambrecht, M.R.; Towill, D.R.; van de Velde, W. Controlling bullwhip and inventory variability with the golden smoothing rule. Eur. J. Ind. Eng. 2007, 1, 241. [Google Scholar] [CrossRef]

- Wang, P. Three fundamental misconceptions of Artificial Intelligence. J. Exp. Theor. Artif. Intell. 2007, 19, 249–268. [Google Scholar] [CrossRef]

- Brown, D.J.H. Artificial Intelligence—A New Discipline in the Computer Sciences (A Viewpoint). Kybernetes 1977, 6, 245–256. [Google Scholar] [CrossRef]

- Cucker, F.; Smale, S. On the mathematical foundations of learning. Bull. New. Ser. Am. Math. Soc. 2001, 39, 1–49. [Google Scholar] [CrossRef]

- Bravo, C.E.; Saputelli, L.; Rivas, F.; Pérez, A.G.; Nickolaou, M.; Zangl, G.; De Guzmán, N.; Mohaghegh, S.D.; Nunez, G. State of the Art of Artificial Intelligence and Predictive Analytics in the E & P Industry: A Technology Survey. SPE J. Pet. Technol. 2014, 19, 547–563. [Google Scholar]

- Bello, O.; Oppelt, J.; Holzmann, J.; Obiwanne, A. Application of Artificial Intelligence Techniques in Drilling System Design and Operations: A State of the Art Review and Future Research Pathways. SPE J. Pet. Technol. 2016. [Google Scholar] [CrossRef]

- Litjens, G.; Sánchez, C.I.; Timofeeva, N.; Hermsen, M.; Nagtegaal, I.; Kovacs, I.; Hulsbergen-Van De Kaa, C.; Bult, P.; Van Ginneken, B.; Van Der Laak, J. Deep learning as a tool for increased accuracy and efficiency of histopathological diagnosis. Sci. Rep. 2016, 6, 26286. [Google Scholar] [CrossRef] [PubMed]

- Edwards, R.E.; New, J.; Parker, L.E.; Cui, B.; Dong, J. Constructing large scale surrogate models from big data and artificial intelligence. Appl. Energy 2017, 202, 685–699. [Google Scholar] [CrossRef]

- Carvajal, G.; Maucec, M.; Cullick, S. Intelligent Digital Oil and Gas. Fields. Concepts, Collaboration, and Right-Time Decisions; Gulf Professional Publishing: Houston, TX, USA, 2018. [Google Scholar]

- Abambres, M.; Rajana, K.; Tsavdaridis, K.D.; Ribeiro, T.P. Neural Network-Based Formula for the Buckling Load Prediction of I-Section Cellular Steel Beams. Computers 2018, 8, 2. [Google Scholar] [CrossRef]

- Hertzmann, A.; Fleet, D. Machine Learning and Data Mining Lecture Notes; University of Toronto: Toronto, ON, Canada, 2012. [Google Scholar]

- McCulloch, W.S.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biophys. 1943, 5, 115–133. [Google Scholar] [CrossRef]

- Prieto, A.; Prieto, B.; Ortigosa, E.M.; Ros, E.; Pelayo, F.; Ortega, J.; Rojas, I. Neural networks: An overview of early research, current frameworks and new challenges. Neurocomputing 2016, 214, 242–268. [Google Scholar] [CrossRef]

- Wilamowski, B.M.; Irwin, J.D. The Industrial Electronics Handbook: Intelligent Systems 1; Taylor and Francis Group: Didcot, UK, 2011. [Google Scholar]

- Flood, I. Towards the next generation of artificial neural networks for civil engineering. Adv. Eng. Inform. 2008, 22, 4–14. [Google Scholar] [CrossRef]

- Ferri, M. Why Topology for Machine Learning and Knowledge Extraction? Mach. Learn. Knowl. Extr. 2019, 1, 115–120. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 324, 698–699. [Google Scholar] [CrossRef]

- Hagan, M.T.; Menhaj, M.B. Training Feedforward Networks with the Marquardt Algorithm. IEEE Trans. Neural Netw. 1994, 5, 2–6. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.-B.; Zhu, Q.-Y.; Siew, C.-K. Extreme learning machine: Algorithm, theory and applications. Neurocomputing 2006, 70, 489–501. [Google Scholar] [CrossRef]

- Huang, G.-B.; Chen, L.; Siew, C.-K. Universial approximation using incremental constructive feedforward neural networks with random hidden nodes. IEEE Trans. Neural Netw. 2006, 17, 879–892. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.B.; Chen, L. Convex incremental extreme learning machine. Neurocomputing 2007, 70, 16–18, 3056–3062. [Google Scholar] [CrossRef]

- Hutter, F.; Xu, L.; Hoos, H.H.; Leyton-brown, K. Algorithm runtime prediction: Methods & evaluation. Artif. Intell. 2014, 206, 79–111. [Google Scholar]

- Liu, H. Forecasting Model of Supply Chain Management Based on Neural Network. In Proceedings of the 2015 International Conference on Automation, Mechanical Control and Computational Engineering, Changsha, China, 24–26 April 2015; Volume 124, pp. 177–181. [Google Scholar]

- Musa, A.; Dehmer, M.; Yli-harja, O.; Emmert-streib, F. Exploiting Genomic Relations in Big Data Repositories by Graph-Based Search Methods. Mach. Learn. Knowl. Extr. 2018, 1, 205–210. [Google Scholar] [CrossRef]

- Gholizadeh, S.; Pirmoz, A.; Attarnejad, R. Assessment of load carrying capacity of castellated steel beams by neural networks. J. Constr. Steel Res. 2011, 67, 770–779. [Google Scholar] [CrossRef]

- Kasun, L.L.C.; Yang, Y.; Huang, G.B.; Zhang, Z. Dimension Reduction with Extreme Learning Machine. IEEE Trans. Image Process. 2016, 25, 3906–3918. [Google Scholar] [CrossRef] [PubMed]

- Lachtermacher, G.; Fuller, J.D. Backpropagation in Time-series Forecasting. J. Forecast. 1995, 14, 381–393. [Google Scholar] [CrossRef]

- Pu, Y.; Mesbahi, E. Application of artificial neural networks to evaluation of ultimate strength of steel panels. Eng. Struct. 2006, 28, 1190–1196. [Google Scholar] [CrossRef]

- Tohidi, S. Inelastic lateral-torsional buckling capacity of corroded web opening steel beams using artificial neural networks. IES J. Part. A Civ. Struct. Eng. 2015, 8, 24–40. [Google Scholar] [CrossRef]

- Flood, I.; Kartam, N. Neural Networks in Civil Engineering I: Principles and Understanding. J. Comput. Civ. Eng. 1994, 8, 131–148. [Google Scholar] [CrossRef]

- Mukherjee, A.; Deshpande, J.M.; Anmala, J. Prediction of Buckling Load of Columns using Artificial Neural Networks. J. Struct. Eng. 2006, 122, 1385–1387. [Google Scholar] [CrossRef]

- Dyckhoff, H.; Lackes, R.; Reese, J. Supply Chain Management and Reverse Logistics; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Carbonneau, R.; Laframboise, K.; Vahidov, R. Application of machine learning techniques for supply chain demand forecasting. Eur. J. Oper. Res. 2008, 184, 1140–1154. [Google Scholar] [CrossRef]

- Fradinata, E.; Suthummanon, S.; Suntiamorntut, W. Reducing the bullwhip effect from signal demand of hybrid artificial neural network models of supply chain in Indonesia. Int. J. Adv. Appl. Sci. 2017, 4, 64–75. [Google Scholar] [CrossRef]

- Slimani, I.; El Farissi, I.; Achchab, S. Artificial neural networks for demand forecasting: Application using Moroccan supermarket data. In Proceedings of the 2015 15th International Conference on Intelligent Systems Design and Applications (ISDA), Marrakech, Morocco, 14–16 December 2016; pp. 266–271. [Google Scholar]

- Chawla, A.; Singh, A.; Lamba, A.; Gangwani, N. Demand Forecasting Using Artificial Neural Networks—A Case Study of American Retail Corporation. In Applications of Artificial Intelligence Techniques in Engineering; Springer: Singapore, 2019; Volume 697, pp. 79–89. [Google Scholar]

- Prakash, A.; Chan, F.T.S.; Liao, H.; Deshmukh, S.G. Network optimization in supply chain: A KBGA approach. Decis. Support. Syst. 2012, 52, 528–538. [Google Scholar] [CrossRef]

- Wang, F.; Lai, X.; Shi, N. A multi-objective optimization for green supply chain network design. Decis. Support. Syst. 2011, 51, 262–269. [Google Scholar] [CrossRef]

- Lau, H.C.W.; Ho, G.T.S.; Zhao, Y. A demand forecast model using a combination of surrogate data analysis and optimal neural network approach. Decis. Support. Syst. 2013, 54, 1404–1416. [Google Scholar] [CrossRef]

- Park, H.; Bellamy, M.A.; Basole, R.C. Visual Analytics for Supply Network Management: System Design and Evaluation. Decis. Support. Syst. 2016, 91, 89–102. [Google Scholar] [CrossRef]

- Beheshti, H.M. A decision support system for improving performance of inventory management in a supply chain network. Int. J. Product. Perform. Manag. 2010, 59, 452–467. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Xu, D.; Kumar, K. An ANN-based auditor decision support system using Benford’s law. Decis. Support. Syst. 2011, 50, 576–584. [Google Scholar] [CrossRef]

- Ilie-Zudor, E.; Ekárt, A.; Kemeny, Z.; Buckingham, C.; Welch, P.; Monostori, L. Advanced predictive-analysis-based decision support for collaborative logistics networks. Supply Chain Manag. An. Int. J. 2015, 20, 369–388. [Google Scholar] [CrossRef]

- Kuo, R.J.; Chen, C.H.; Hwang, Y.C. An intelligent stock trading decision support system through integration of genetic algorithm based fuzzy neural network and artificial neural network. Fuzzy Sets Syst. 2001, 118, 21–45. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Soleimani, R.; Lee, M.; Kashiwao, T.; Bahadori, A. Determination of oil well production performance using artificial neural network (ANN) linked to the particle swarm optimization (PSO) tool. Petroleum 2015, 1, 118–132. [Google Scholar] [CrossRef]

- Mahdiani, M.R.; Khamehchi, E. A modified neural network model for predicting the crude oil price. Intellect. Econ. 2016, 10, 71–77. [Google Scholar] [CrossRef]

- Mirzaei-Paiaman, A.; Salavati, S. The application of artificial neural networks for the prediction of oil production flow rate. Energy Sources Part. A Recover. Util. Environ. Eff. 2012, 34, 1834–1843. [Google Scholar] [CrossRef]

- Torabi, F.; Abedini, A.; Abedini, R. The development of an artificial neural network model for prediction of crude oil viscosities. Pet. Sci. Technol. 2011, 29, 804–816. [Google Scholar] [CrossRef]

- Arjun, K.S.; Aneesh, K. Modelling studies by application of artificial neural network using matlab. J. Eng. Sci. Technol. 2015, 10, 1477–1486. [Google Scholar]

- Sage, A.P.; Armstrong, J.E., Jr. Introduction to Systems Engineering; Wiley: Hoboken, NJ, USA, 2000. [Google Scholar]

- Azhar, M. The Study of the Bullwhip Effect in the Oil and Gas. Industry; Oklahoma State University: Stillwater, OK, USA, 2013. [Google Scholar]

- NYSE. New York Stock Exchange Database. Available online: https://www.nyse.com/index (accessed on 30 July 2019).

- Schlumberger. Schlumberger Newsroom. Available online: https://www.slb.com/newsroom/ (accessed on 30 July 2019).

- Encana Corporation. Encana Quarterly Reports. Available online: https://www.encana.com/investors/financial/quarterly-reports/ (accessed on 30 July 2019).

- Sempra Energy. Sempra Energy Quarterly Reports. Available online: https://www.sempra.com/investors (accessed on 30 July 2019).

- Valero Energy Company. Valero Quarterly Earnings. Available online: http://www.investorvalero.com/financial-information/quarterly-results (accessed on 30 July 2019).

- Varco Inc. National Oilwell Varco Quarterly Results. Available online: https://investors.nov.com/financial-information/quarterly-results/ (accessed on 30 July 2019).

- Halliburton. Halliburton Quarterly Results. Available online: http://ir.halliburton.com/financial-information/quarterly-results (accessed on 30 July 2019).

- Baker Hughes. Baker Hughes Investor Center. Available online: https://investors.bhge.com/financial-information/quarterly-results (accessed on 30 July 2019).

- DataHub. Stock Market Data. Available online: https://datahub.io/collections/stock-market-data (accessed on 30 July 2019).

- Equinor. Digitalisation Driving Value Creation. Available online: https://www.equinor.com/en/news/digitalisation-driving-value-creation.html (accessed on 6 September 2017).

- World Economic Forum and Accenture. Digital Transformation Initiative: Oil and Gas Industry. Available online: http://reports.weforum.org/digital-transformation/wp-content/blogs.dir/94/mp/files/pages/files/dti-oil-and-gas-industry-white-paper.pdf (accessed on 6 September 2017).

- Kaisler, S.; Armour, F.; Espinosa, J.A.; Money, W. Big data: Issues and challenges moving forward. In Proceedings of the Annual Hawaii International Conference on System Sciences, Hawaii, HA, USA, 7–10 January 2013; pp. 995–1004. [Google Scholar]

- Yoo, Y. It is not about Size: A Further thought on Big Data. J. Inf. Technol. 2015, 30, 63–65. [Google Scholar] [CrossRef]

| Categories | References |

|---|---|

| Quantification of the bullwhip effect | [10,46,47,48,49,50,51,52] |

| Identifying the causes of the bullwhip effect | [44,53] |

| Observation studies in some industries | [54,55,56] |

| Methods to reduce the bullwhip effect | [57,58,59,60,61] |

| Simulation of the system behavior | [62,63,64,65] |

| Experimental validation of the bullwhip effect | [30,41,66,67,68] |

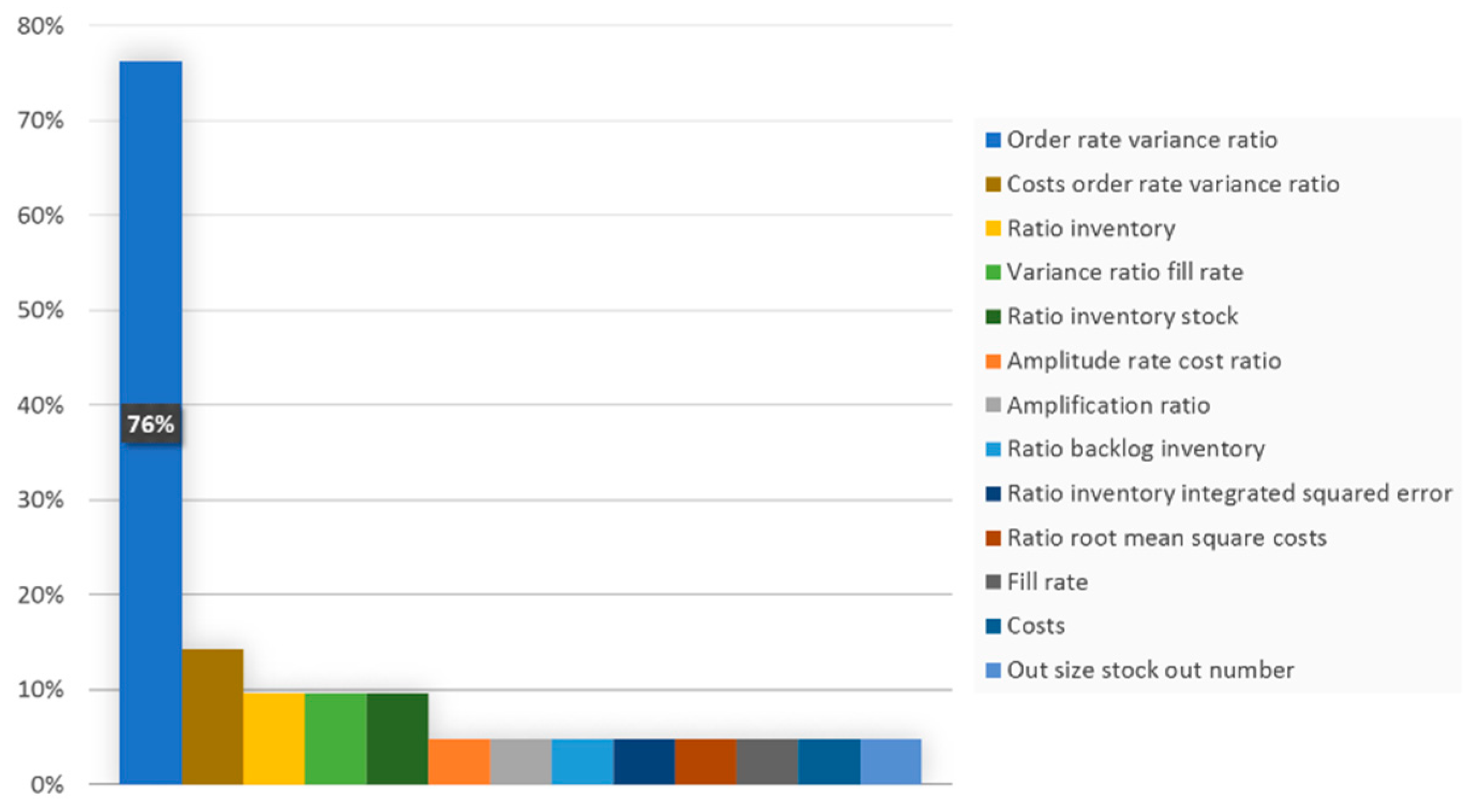

| Performance Metrics | References |

|---|---|

| Order rate variance ratio | [43,48,61,64,69,70,71,72,73,74,75,76,77,78,79] |

| Amplitude rate cost ratio | [80] |

| Amplification ratio | [81] |

| Ratio inventory | [71,75] |

| Ratio backlog inventory | [64] |

| Variance ratio fill rate | [75,77] |

| Ratio inventory integrated squared error | [69] |

| Ratio root mean square costs | [61] |

| Fill rate | [82] |

| Costs order rate variance ratio | [43,73,83] |

| Costs | [84] |

| Ratio inventory stock | [70,74] |

| Out size stock out number | [70] |

| Year | Year 1 | Year 2 | Year 3 | Year 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Semester | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 |

| Literature Review and Data Gathering Planning | ||||||||

| Literature review and data gathering planning | x | x | x | x | x | x | x | x |

| Data Gathering and Analysis | ||||||||

Collecting the data  | x | x | x | |||||

| Statistical analysis | x | x | x | |||||

| Artificial Neural Network | ||||||||

Developing the model  | x | x | x | x | ||||

| Validating the model | x | |||||||

| Implementing the model to the case study | x | x | ||||||

| Writing and Submission of Articles | ||||||||

| Paper I—Quantitative analysis on the bullwhip effect in a supply chain network | x | |||||||

| Paper II—The bullwhip effect: a case study in the oil and gas industry | x | |||||||

| Paper III—Oil and gas supply chain management based on artificial neural network | x | |||||||

| Writing up the thesis | x | x | x | x | x | |||

| Other dissemination activities | ||||||||

| Oral presentation at a conference | x | |||||||

| Poster presentation at a conference | x | |||||||

Critical tasks.

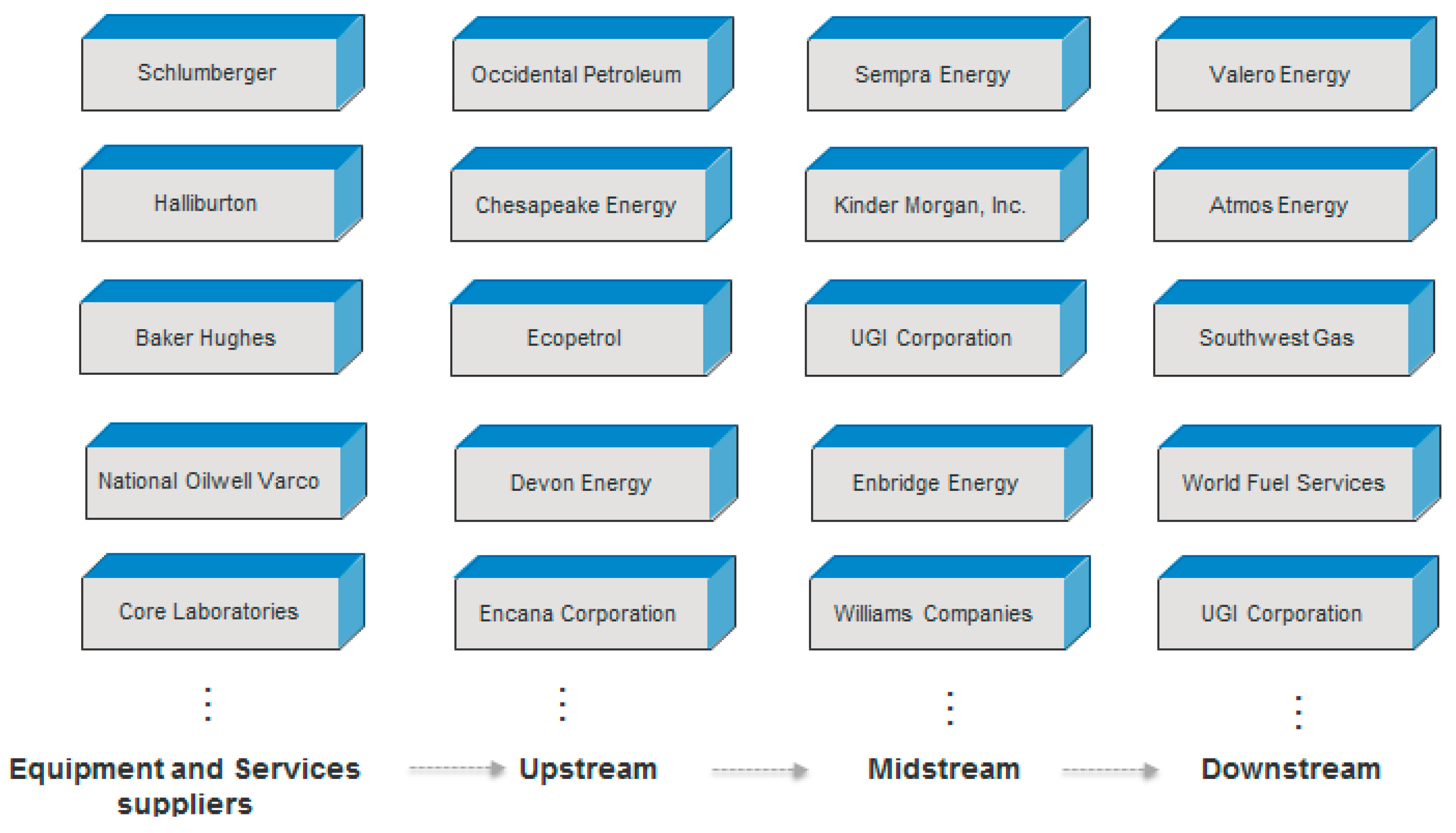

Critical tasks.| Supply Chain Levels | Description |

|---|---|

| Equipment and services suppliers | The population includes companies that provide services and equipment to support all the oil and gas activities, such as drilling, exploration, gathering, storing, and processing the oil and gas. |

| Upstream | Crude oil and natural gas production |

| Midstream | Transportation of oil and gas |

| Downstream | Refine and process crude oil and natural gas to be sold to the consumers |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sousa, A.L.; Ribeiro, T.P.; Relvas, S.; Barbosa-Póvoa, A. Using Machine Learning for Enhancing the Understanding of Bullwhip Effect in the Oil and Gas Industry. Mach. Learn. Knowl. Extr. 2019, 1, 994-1012. https://doi.org/10.3390/make1030057

Sousa AL, Ribeiro TP, Relvas S, Barbosa-Póvoa A. Using Machine Learning for Enhancing the Understanding of Bullwhip Effect in the Oil and Gas Industry. Machine Learning and Knowledge Extraction. 2019; 1(3):994-1012. https://doi.org/10.3390/make1030057

Chicago/Turabian StyleSousa, Ana L., Tiago P. Ribeiro, Susana Relvas, and Ana Barbosa-Póvoa. 2019. "Using Machine Learning for Enhancing the Understanding of Bullwhip Effect in the Oil and Gas Industry" Machine Learning and Knowledge Extraction 1, no. 3: 994-1012. https://doi.org/10.3390/make1030057

APA StyleSousa, A. L., Ribeiro, T. P., Relvas, S., & Barbosa-Póvoa, A. (2019). Using Machine Learning for Enhancing the Understanding of Bullwhip Effect in the Oil and Gas Industry. Machine Learning and Knowledge Extraction, 1(3), 994-1012. https://doi.org/10.3390/make1030057