Circular Approaches for Thermoset Composites

Abstract

1. Introduction

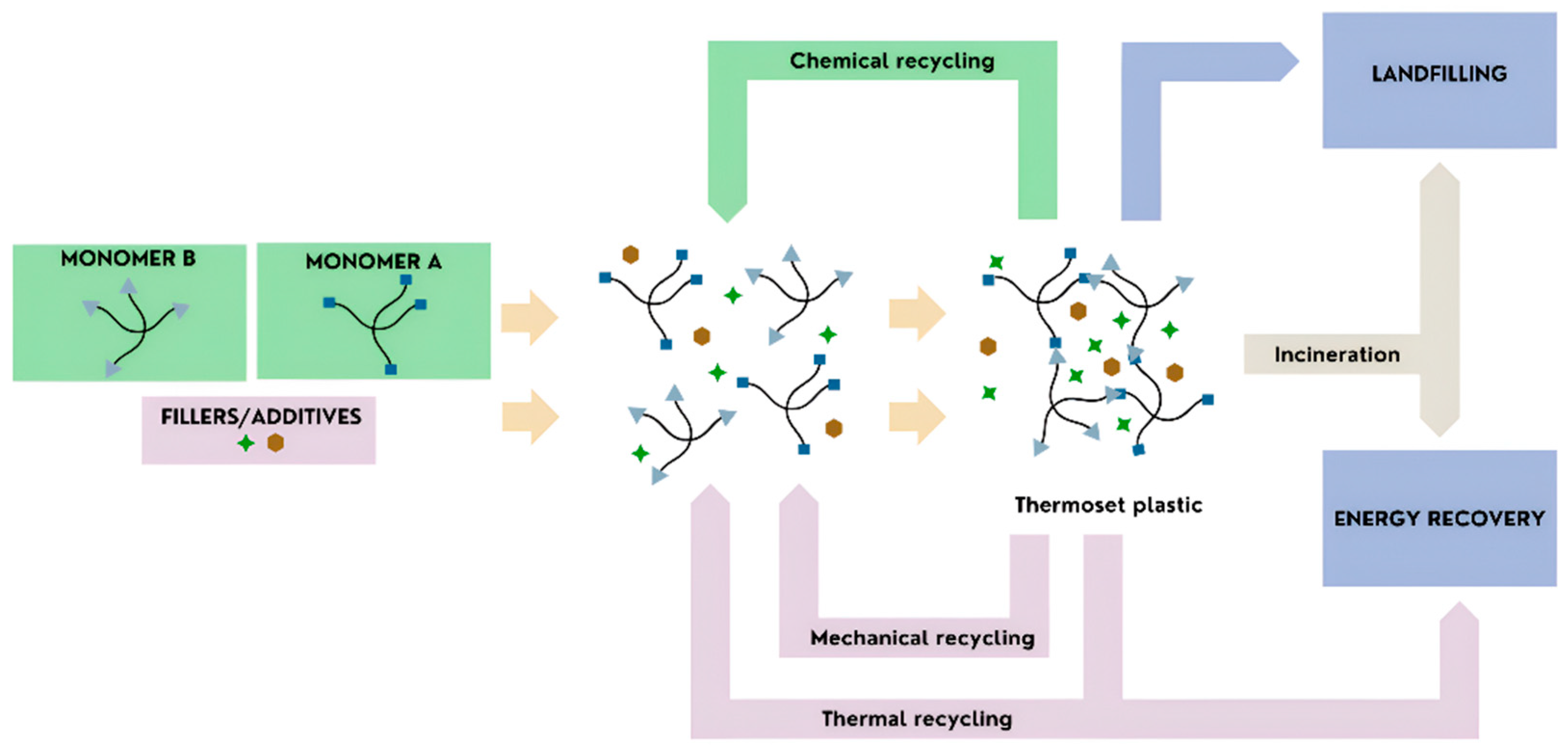

- Prevention. Several strategies have been used to increase the prevention of composite waste generation [16,17,18]. These include the design of composites with a longer service life by decreasing the failure rate, using components that facilitate recycling, improving the separation of components and materials or even optimising and reducing the amount of material required, resulting in less material to recycle [8,19].

- Recycling. There are several techniques proposed and currently used for the recycling of composite materials. These techniques are typically categorised into three main groups: mechanical recycling, chemical recycling, and thermal recycling. A more detailed overview of these methods can be found in Section 2.

- Recovery. Heat or energy recovery is one way to manage composite waste. There are different recovery methods, such as heat recovery by incineration or the use of the recovered polymer fraction in co-processing as fuel.

- Disposal. In this category, the lowest in the hierarchy diagram, landfilling and incineration without heat recovery are considered.

2. Recycling Methods

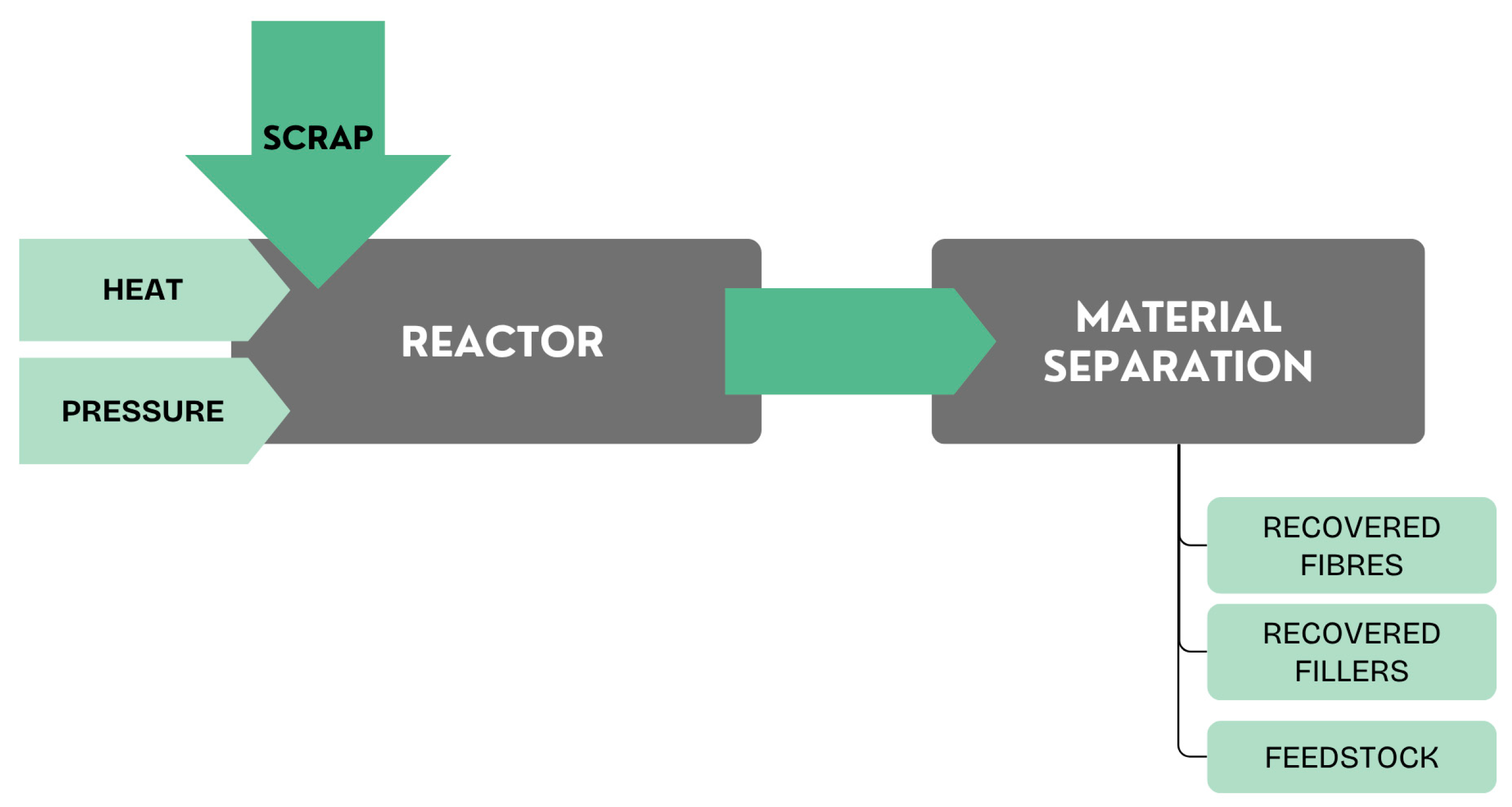

2.1. Chemical Recycling

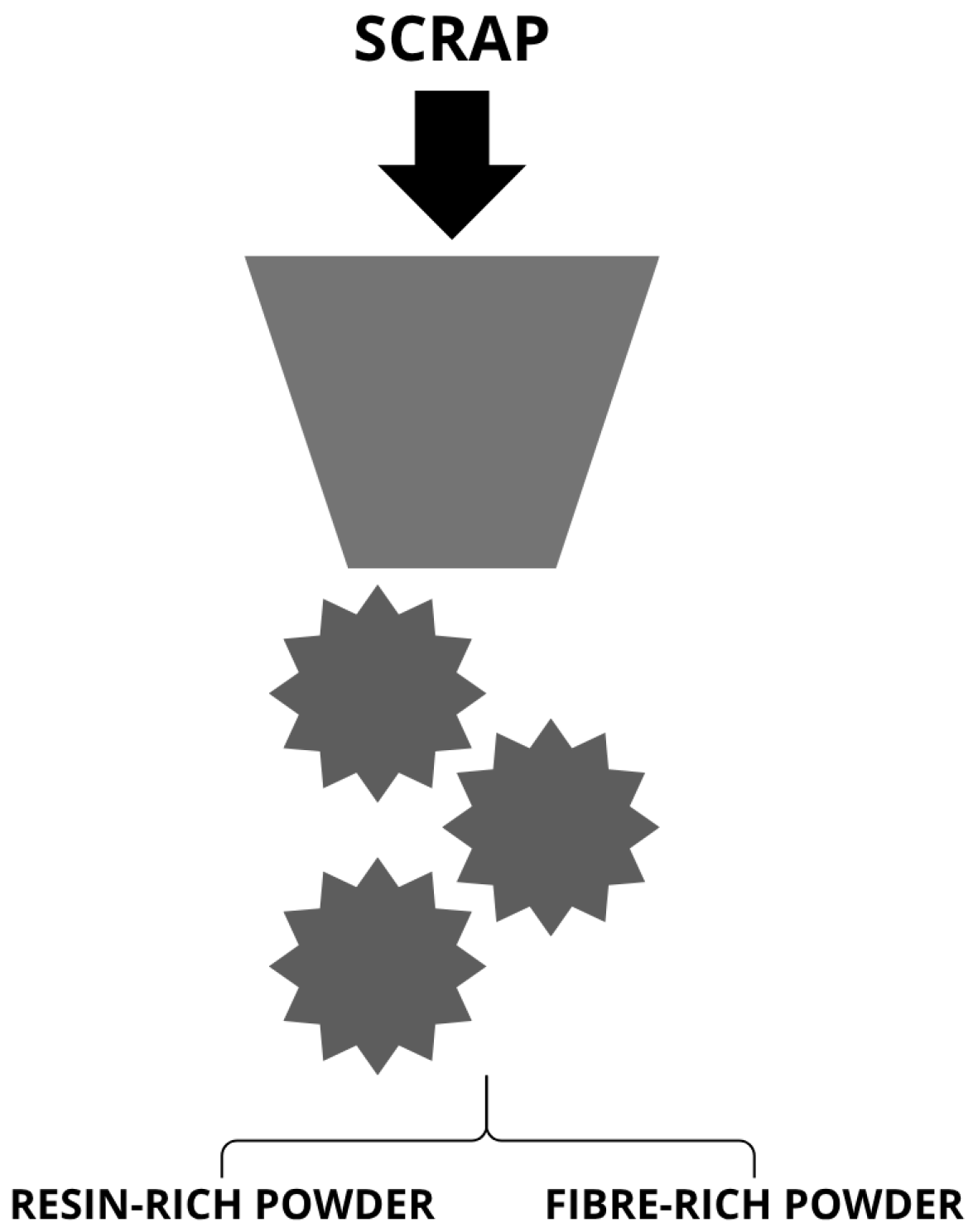

2.2. Mechanical Recycling

2.2.1. Mechanical Grinding

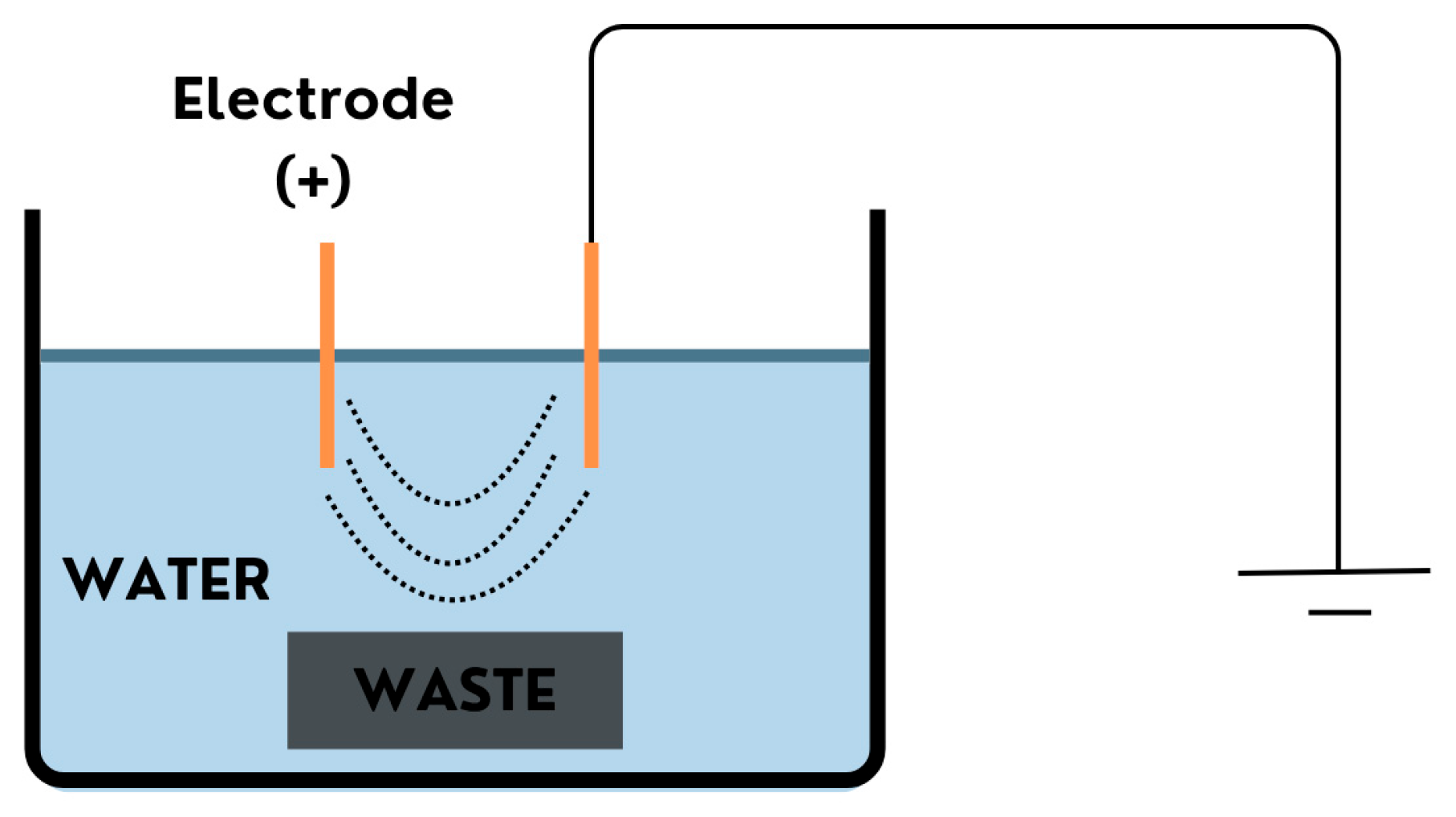

2.2.2. Electrofragmentation

2.3. Thermal Recycling

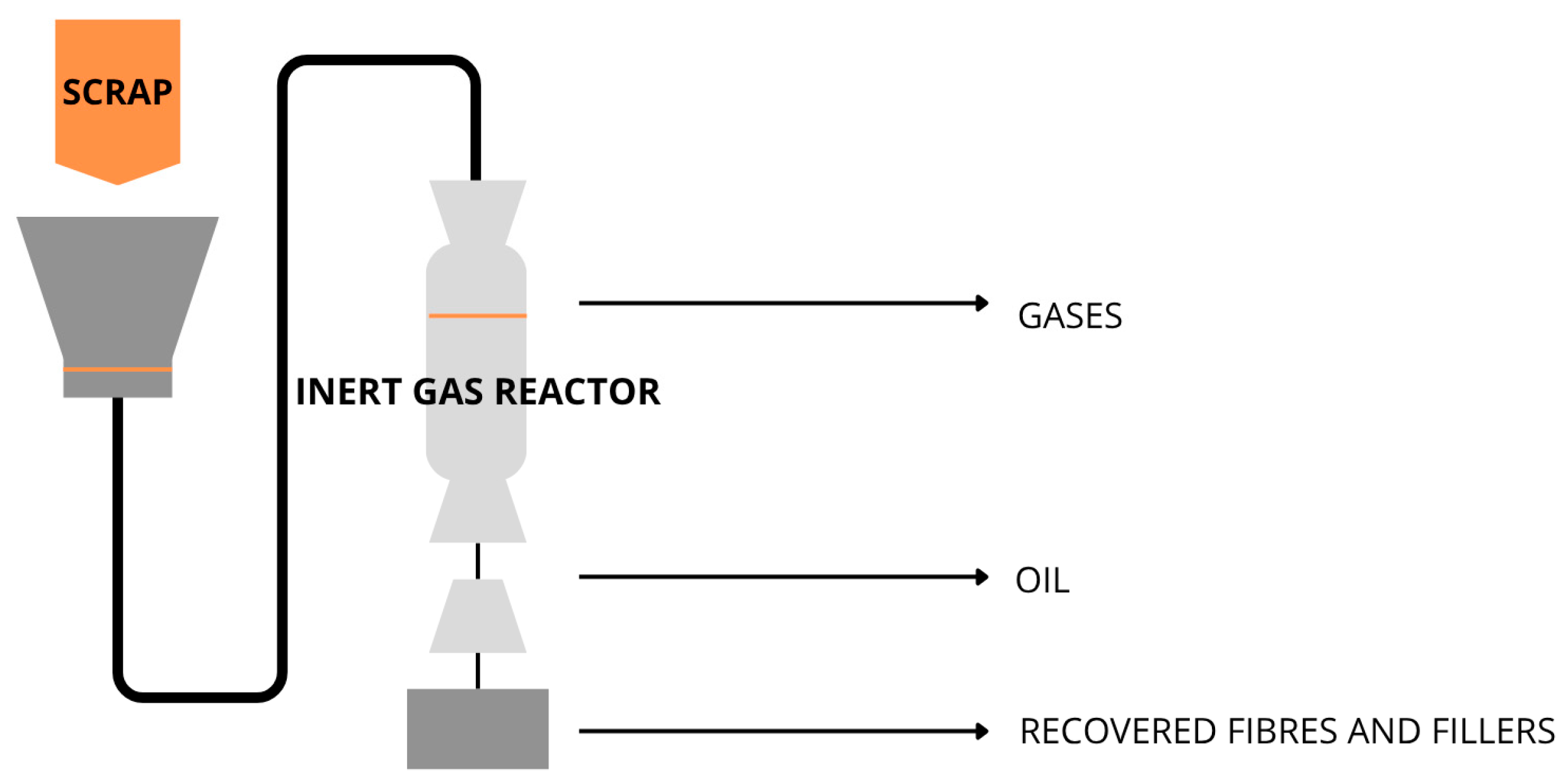

2.3.1. Pyrolysis

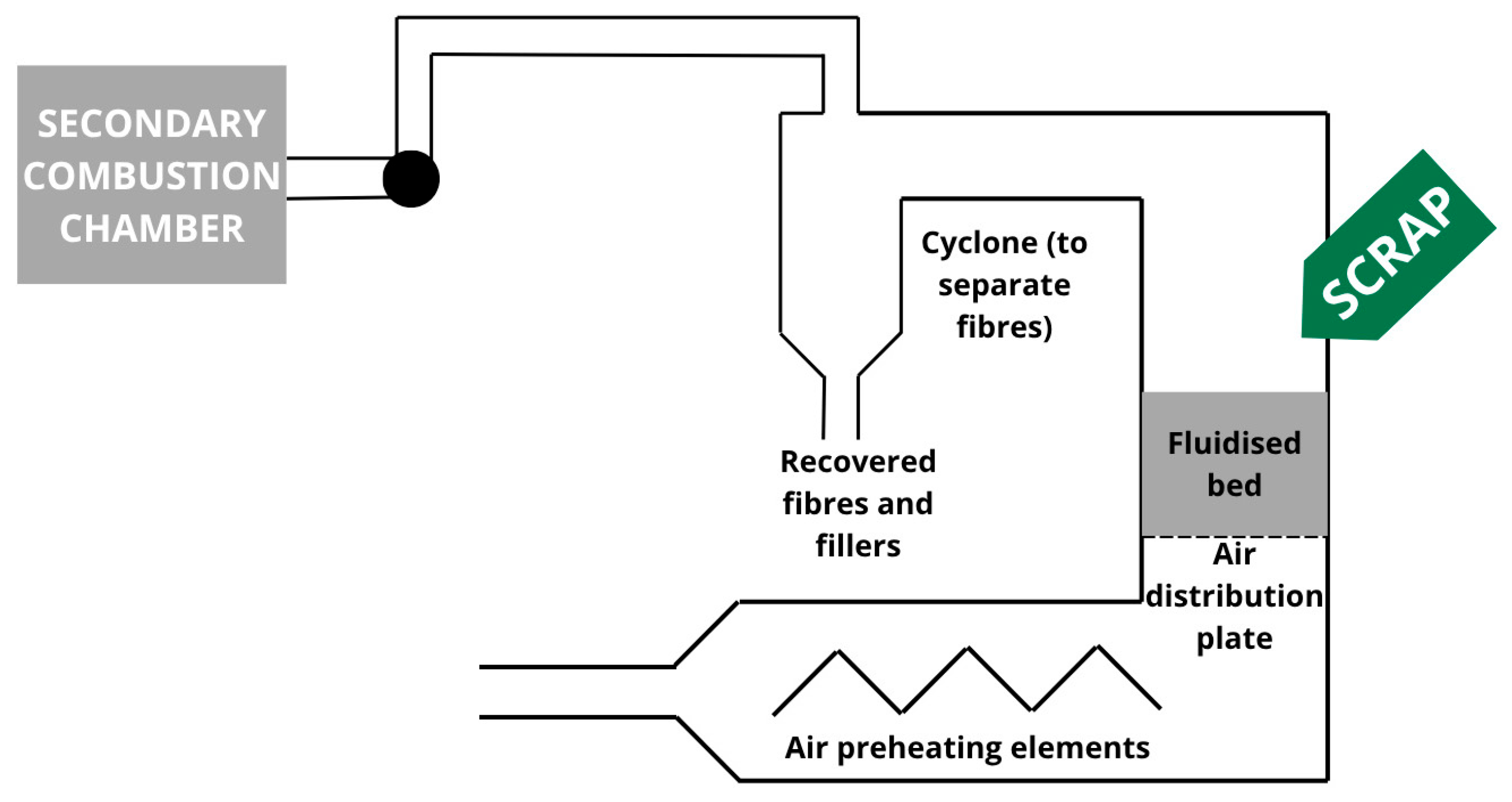

2.3.2. Fluidised Bed Process

2.4. Incipient Recycling Methods

2.4.1. Microwave-Assisted Recycling

2.4.2. Enzymatic Recycling

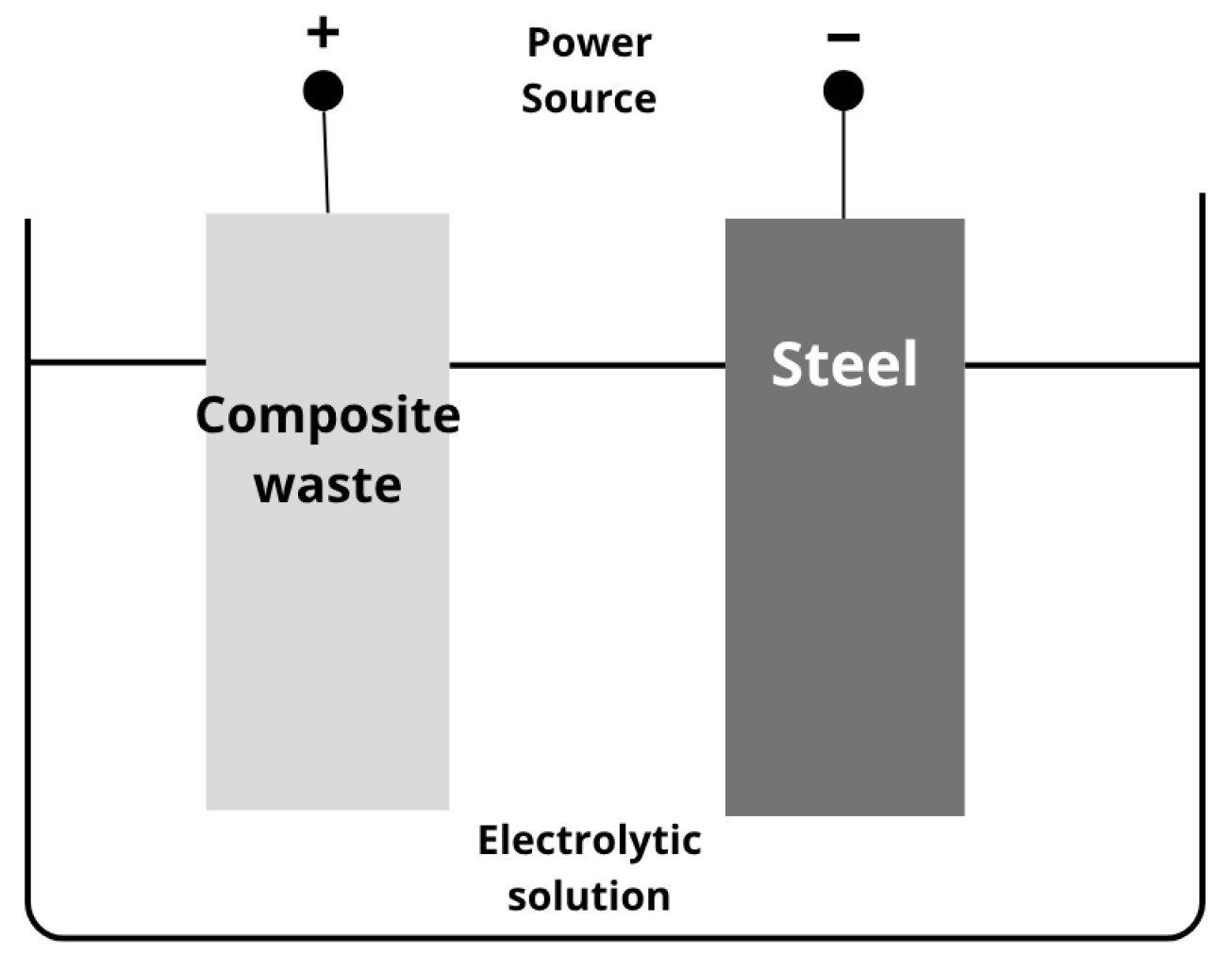

2.4.3. Electrochemical Recycling

2.4.4. Superheated Steam Recycling

2.4.5. Ultrasonic Recycling

3. Repurposing

3.1. Structural Repurposing

3.2. Repurposing in Cementitious Materials

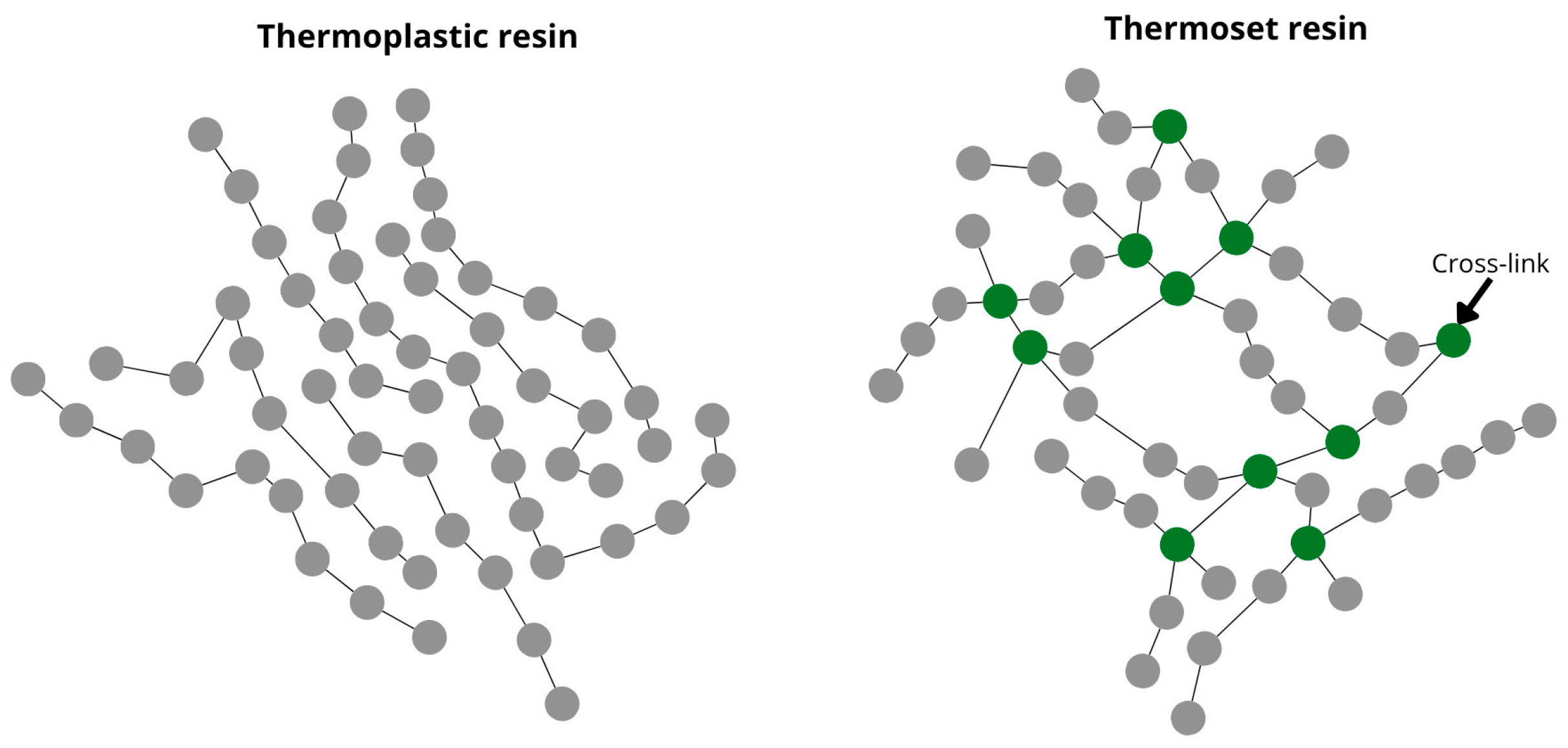

4. Recyclable Resins

4.1. Thermoplastic Resins

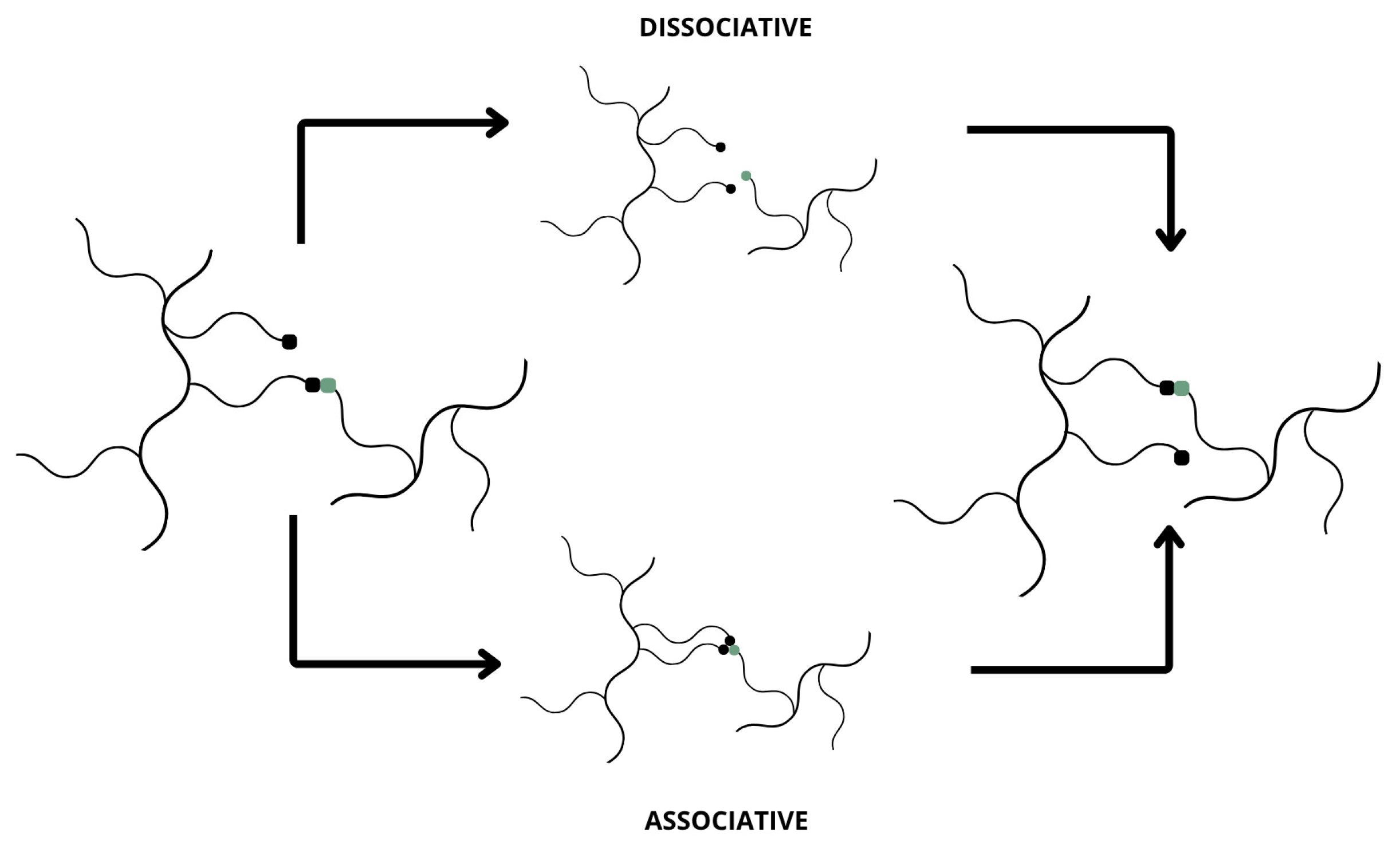

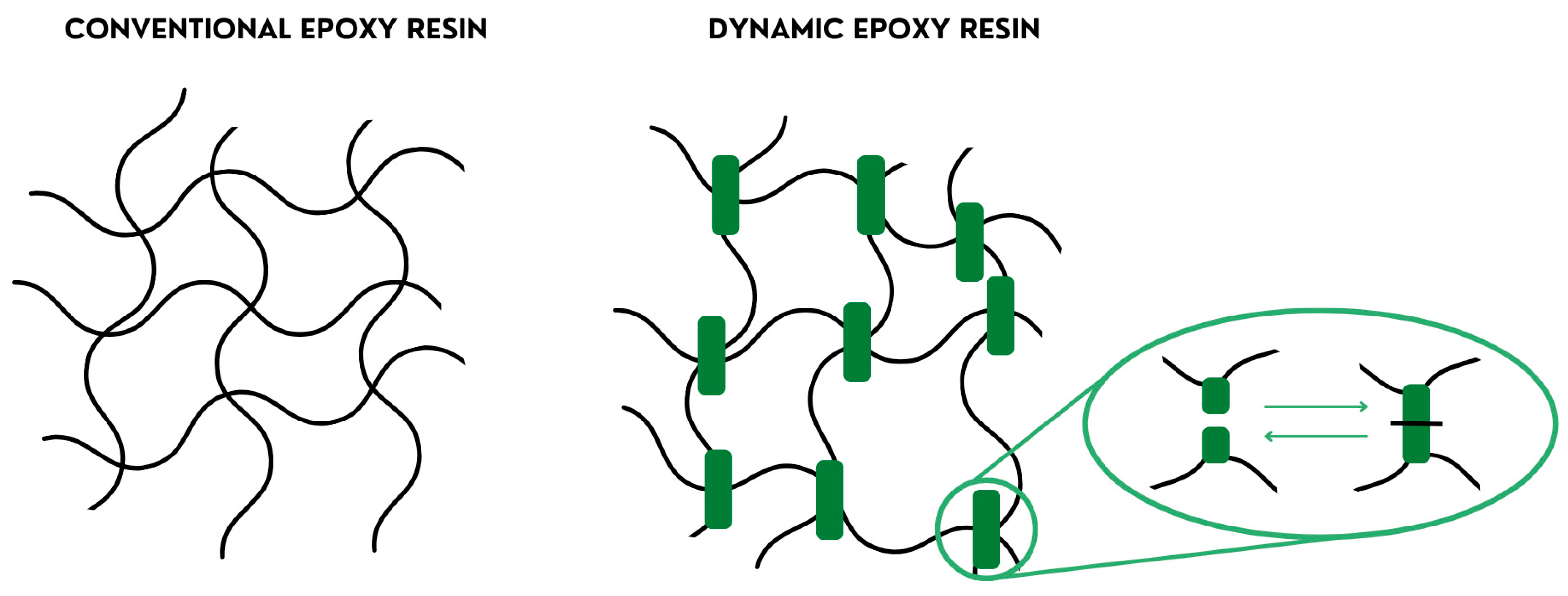

4.2. Recyclable Thermoset Resins

5. Thermoforming of Cured Composite Polymeric Materials

- Heating time and thermal ramp rate;

- Mould temperature;

- Thermoforming velocity;

- Cooling rate.

5.1. Thermoplastic Resin Composites

5.2. Dynamic Cross-Linked Thermoset Resin Composites

5.3. Conventional Thermoset Resins

6. Future Perspectives

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DC | Direct current |

| EoL | End-of-life |

| GF | Glass fibre |

| CAN | Covalent adaptive network |

| Tg | Glass transition temperature |

| FEA | Finite element analysis |

| DMTA | Dynamic Mechanical Thermal Analysis |

| CFRPC | Carbon Fibre-Reinforced Polymer Composite |

| SMP | Shape Memory Polymer |

References

- Arussi, E.; Reiland, J.; Ierides, M.; Borghero, L. Composite Materials: A Hidden Opportunity for the Circular Economy; CSR Europe: Brussels, Belgium, 2022. [Google Scholar]

- Bhong, M.; Khan, T.K.H.; Devade, K.; Vijay Krishna, B.; Sura, S.; Eftikhaar, H.K.; Pal Thethi, H.; Gupta, N. Review of Composite Materials and Applications. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Jani, H.K.; Singh Kachhwaha, S.; Nagababu, G.; Das, A. A Brief Review on Recycling and Reuse of Wind Turbine Blade Materials. Mater. Today Proc. 2022, 62, 7124–7130. [Google Scholar] [CrossRef]

- Morici, E.; Dintcheva, N.T. Recycling of Thermoset Materials and Thermoset-Based Composites: Challenge and Opportunity. Polymers 2022, 14, 4153. [Google Scholar] [CrossRef]

- De, B.; Bera, M.; Bhattacharjee, D.; Ray, B.C.; Mukherjee, S. A Comprehensive Review on Fiber-Reinforced Polymer Composites: Raw Materials to Applications, Recycling, and Waste Management. Prog. Mater. Sci. 2024, 146, 101326. [Google Scholar] [CrossRef]

- Baron, N. JEC Observer—Overview of the Global Composite Market 2024–2029; JEC Group: Paris, France, 2025. [Google Scholar]

- Baron, N. JEC Observer—Overview of the Global Composite Market 2023–2028; JEC Group: Paris, France, 2024. [Google Scholar]

- AEE—Asociaciación Emperasarial Eólica. Economia Circular En El Sector Eólico—Palas de Aerogeneradores; AEE: Madrid, Spain, 2022. [Google Scholar]

- Nehls, G. Autocomposites Market Is Expected to Double Revenue by 2032; CompositesWorld: Cincinnati, OH, USA, 2024. [Google Scholar]

- How Wind Is Going Circular—Blade Recycling. ETIPWind. 2019. Available online: https://etipwind.eu/ (accessed on 5 September 2024).

- Global Fiber-Reinforced Plastic (FRP) Recycling Market (Study Period: 2019—2029). Mordor Intelligence. 2023. Available online: https://www.mordorintelligence.com/market-analysis/composites (accessed on 7 October 2025).

- Costanzo, G.; Brindley, G.; Tardieu, P. Wind Energy in Europe: 2024 Statistics and the Outlook for 2025–2030; Wind Europe: Brussels, Belgium, 2025. [Google Scholar]

- European Commission Waste Framework Directive. Available online: https://environment.ec.europa.eu/topics/waste-and-recycling/waste-framework-directive_en#end-of-waste-criteria (accessed on 6 February 2025).

- Spini, F.; Bettini, P. End-of-Life Wind Turbine Blades: Review on Recycling Strategies. Compos. Part B Eng. 2024, 275, 111290. [Google Scholar] [CrossRef]

- Zorpas, A.A. The Hidden Concept and the Beauty of Multiple “R” in the Framework of Waste Strategies Development Reflecting to Circular Economy Principles. Sci. Total Environ. 2024, 952, 175508. [Google Scholar] [CrossRef]

- Devic, A.-C.; Ierides, M.; Fernandez, V.; Verbenkov, M.; Bax, L. Polymer Composites Circularity; Suschem: Madrid, Spain, 2018. [Google Scholar]

- Boria, S.; Santulli, C.; Raponi, E.; Sarasini, F.; Tirillò, J. Evaluation of a New Green Composite Solution for Wind Turbine Blades. Multiscale Multidiscip. Model. Exp. Des. 2019, 2, 141–150. [Google Scholar] [CrossRef]

- Beauson, J.; Laurent, A.; Rudolph, D.P.; Pagh Jensen, J. The Complex End-of-Life of Wind Turbine Blades: A Review of the European Context. Renew. Sustain. Energy Rev. 2022, 155, 11847. [Google Scholar] [CrossRef]

- Schmid, M.; Gonzalez, N.; Dierckx, A.; Wegman, T. Accelerating Wind Turbine Blade Circularity; WindEurope, EuCIA, Cefic: Brussels, Belgium, 2020. [Google Scholar]

- Branfoot, C.; Folkvord, H.; Keith, M.; Leeke, G.A. Recovery of Chemical Recyclates from Fibre-Reinforced Composites: A Review of Progress. Polym. Degrad. Stab. 2023, 215, 110447. [Google Scholar] [CrossRef]

- Krauklis, A.E.; Karl, C.W.; Gagani, A.I.; Jørgensen, J.K. Composite Material Recycling Technology—State-of-the-Art and Sustainable Development for the 2020s. J. Compos. Sci. 2021, 5, 28. [Google Scholar] [CrossRef]

- WindEurope; EuCIA; UP/VE; EPOXY EUROPE; Cefic; Glass Fibre Europe; EBI; CEMBUREAU. Position Paper: Cement Co-Processing Is a Sustainable Solution for Recycling End-of-Life Composite Materials. 2023. Available online: https://eucia.eu/wp-content/uploads/2023/07/230623-Joint-position-Co-processing-Composites.pdf (accessed on 30 January 2025).

- Gharde, S.; Kandasubramanian, B. Mechanothermal and Chemical Recycling Methodologies for the Fibre Reinforced Plastic (FRP). Environ. Technol. Innov. 2019, 14, 100311. [Google Scholar] [CrossRef]

- Qureshi, J. A Review of Recycling Methods for Fibre Reinforced Polymer Composites. Sustainability 2022, 14, 16855. [Google Scholar] [CrossRef]

- Jacob, A. Composites Can Be Recycled. Reinf. Plast. 2011, 55, 45–46. [Google Scholar] [CrossRef]

- Rajan, R.; Tölli, H.; Valkjärvi, M. Towards a Sustainable Future: Exploring Methods, Technologies, and Applications for Thermoset Composite Recycling; Centria University of Applied Sciences: Ylivieska, Finland, 2024; ISBN 978-952-7173-99-2. [Google Scholar]

- Paulotto, C. Wrokshop. New Trends in Composite Materials. Composite Materials Applied in Infrastructures: Recycling Strategies; Universitat de Girona. Compus Compòsits: Girona, Spain, 2020. [Google Scholar]

- VEOLIA. Converting Household Waste into Energy. Available online: https://www.veolia.com/en/solutions/converting-household-waste-energy (accessed on 30 January 2025).

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current Status of Recycling of Fibre Reinforced Polymers: Review of Technologies, Reuse and Resulting Properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling Carbon Fibre Reinforced Polymers for Structural Applications: Technology Review and Market Outlook. Waste Manag. 2010, 31, 378–392. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; He, E.; Liang, H.; Yang, Z.; Wang, Y.; Yang, Z.; Gao, C.; Wang, G.; Wei, Y.; Ji, Y. Chemical Recycling of Epoxy Thermosets: From Sources to Wastes. Actuators 2024, 13, 449. [Google Scholar] [CrossRef]

- Zhao, X.; Long, Y.; Xu, S.; Liu, X.; Chen, L.; Wang, Y.Z. Recovery of Epoxy Thermosets and Their Composites. Mater. Today 2023, 64, 71–97. [Google Scholar] [CrossRef]

- Tao, Y.; Hadigheh, S.A.; Wei, Y. Recycling of Glass Fibre Reinforced Polymer (GFRP) Composite Wastes in Concrete: A Critical Review and Cost Benefit Analysis. Structures 2023, 53, 1540–1556. [Google Scholar] [CrossRef]

- Guadagno, L.; Longo, R.; Raimondo, M.; Vertuccio, L.; Aliberti, F.; Bonadies, L.; Morciano, S.; Longo, L.; Pantani, R.; Calabrese, E. Chemical Recycling of Bio-Based Thermosetting Epoxy Composite Produced by Vacuum-Assisted Resin Infusion Process. Polymers 2025, 17, 1241. [Google Scholar] [CrossRef]

- Souza, P.R.; Nunes, C.S.; Freitas, A.R.; Belinato, J.R.; Pilau, E.J.; Fajardo, A.R.; da Silva Filho, E.A.; Schreiner, W.H.; Muniz, E.C. Sub- and Supercritical D-Limonene Technology as a Green Process to Recover Glass Fibres from Glass Fibre-Reinforced Polyester Composites. J. Clean. Prod. 2020, 254, 119984. [Google Scholar] [CrossRef]

- De Fazio, D.; Boccarusso, L.; Formisano, A.; Viscusi, A.; Durante, M. A Review on the Recycling Technologies of Fibre-Reinforced Plastic (FRP) Materials Used in Industrial Fields. J. Mar. Sci. Eng. 2023, 11, 851. [Google Scholar] [CrossRef]

- Vincent, G.A.; de Bruijn, T.A.; Wijskamp, S.; Abdul Rasheed, M.I.; van Drongelen, M.; Akkerman, R. Shredding and Sieving Thermoplastic Composite Scrap: Method Development and Analyses of the Fibre Length Distributions. Compos. Part B Eng. 2019, 176, 107197. [Google Scholar] [CrossRef]

- Heibeck, M.; Rudolph, M.; Modler, N.; Reuter, M.; Filippatos, A. Characterizing Material Liberation of Multi-Material Lightweight Structures from Shredding Experiments and Finite Element Simulations. Miner. Eng. 2021, 172, 107142. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling Technologies for Thermoset Composite Materials-Current Status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Uenishi, K.; Shigeno, N.; Sakaguchi, S.; Yamachi, H.; Nakamori, J. Controlled Disintegration of Reinforced Concrete Blocks Based on Wave and Fracture Dynamics. Procedia Struct. Integr. 2016, 2, 350–357. [Google Scholar] [CrossRef][Green Version]

- Mativenga, P.T.; Shuaib, N.A.; Howarth, J.; Pestalozzi, F.; Woisadky, J. High Voltage Fragmentation and Mechanical Recycling of Glass Fibre Thermoset Composite. CIRP Ann. 2016, 65, 45–48. [Google Scholar] [CrossRef]

- Bru, K.; Touzé, S.; Auger, P.; Dobrusky, S.; Tierrie, J.; Parvaz, D.B. Investigation of Lab and Pilot Scale Electric-Pulse Fragmentation Systems for the Recycling of Ultra-High Performance Fi Bre-Reinforced Concrete. Miner. Eng. 2018, 128, 187–194. [Google Scholar] [CrossRef]

- Diani, M.; Torvi, S.; Colledani, M. Application of High Voltage Fragmentation to Treat End-of-Life Wind Blades. Mater. Res. Proc. 2023, 35, 266–274. [Google Scholar] [CrossRef]

- Diani, M.; Torvi, S.; Colledani, M. Exploiting High Voltage Fragmentation to Enable Demand-Driven Recycling of End-of-Life Wind Blades. Procedia CIRP 2024, 122, 837–842. [Google Scholar] [CrossRef]

- Torres, A.; De Marco, I.; Caballero, B.M.; Laresgoiti, M.F.; Legarreta, J.A.; Cabrero, M.A.; González, A.; Chomón, M.J.; Gondra, K. Recycling by Pyrolysis of Thermoset Composites: Characteristics of the Liquid and Gaseous Fuels Obtained. Fuel 2000, 79, 897–902. [Google Scholar] [CrossRef]

- Oudheusden, A.V. Recycling of Composite Materials; Delft University of Technology: Delft, The Netherland, 2019. [Google Scholar]

- Ginder, R.S.; Ozcan, S. Recycling of Commercial E-Glass Reinforced Thermoset Composites via Two Temperature Step Pyrolysis to Improve Recovered Fiber Tensile Strength and Failure Strain. Recycling 2019, 4, 24. [Google Scholar] [CrossRef]

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling Glass Fiber Thermoplastic Composites from Wind Turbine Blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Cheng, L.; Chen, R.; Yang, J.; Chen, X.; Yan, X.; Gu, J.; Liu, Z.; Yuan, H.; Chen, Y. Mechanisms, Technical Optimization, and Perspectives in the Recycling and Reprocessing of Waste Wind Turbine Blades: A Review. Renew. Sustain. Energy Rev. 2025, 218, 115834. [Google Scholar] [CrossRef]

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A Critical Review on Recycling of End-of-Life Carbon Fibre/Glass Fibre Reinforced Composites Waste Using Pyrolysis Towards a Circular Economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef]

- López, F.A.; Martín, M.I.; Alguacil, F.J.; Rincón, J.M.; Centeno, T.A.; Romero, M. Thermolysis of Fibreglass Polyester Composite and Reutilisation of the Glass Fibre Residue to Obtain a Glass-Ceramic Material. J. Anal. Appl. Pyrolysis 2012, 93, 104–112. [Google Scholar] [CrossRef]

- Van De Beld, B.; Holle, E.; Florijn, J. The Use of Pyrolysis Oil and Pyrolysis Oil Derived Fuels in Diesel Engines for CHP Applications. Appl. Energy 2013, 102, 190–197. [Google Scholar] [CrossRef]

- Xu, M.X.; Ji, H.W.; Wu, Y.C.; Di, J.Y.; Meng, X.X.; Jiang, H.; Lu, Q. The Pyrolysis of End-of-Life Wind Turbine Blades under Different Atmospheres and Their Effects on the Recovered Glass Fibers. Compos. Part B Eng. 2022, 251, 110493. [Google Scholar] [CrossRef]

- Jensen, J.P.; Skelton, K. Wind Turbine Blade Recycling: Experiences, Challenges and Possibilities in a Circular Economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- Gonçalves, R.M.; Martinho, A.; Oliveira, J.P. Recycling of Reinforced Glass Fibers Waste: Current Status. Materials 2022, 15, 1596. [Google Scholar] [CrossRef] [PubMed]

- Pickering, S.J.; Kelly, R.M.; Kennerley, J.R.; Rudd, C.D.; Fenwick, N.J. A Fluidised-Bed Process for the Recovery of Glass Fibres from Scrap Thermoset Composites. Compos. Sci. Technol. 2000, 60, 509–523. [Google Scholar] [CrossRef]

- Hyde, J.R.; Lester, E.; Kingman, S.; Pickering, S.; Wong, K.H. Supercritical Propanol, a Possible Route to Composite Carbon Fibre Recovery: A Viability Study. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2171–2175. [Google Scholar] [CrossRef]

- FAIRMAT. Design and Develop Recyclable, High-Performing Products with Recycled Carbon Composites. Available online: https://www.fairmat.tech/ (accessed on 28 July 2025).

- ACCIONA. La Planta de Reciclado de Palas Eólicas de ACCIONA ‘Waste2Fiber®’, Declarada Proyecto de Interés Foral Por El Gobierno de Navarra. Available online: https://www.acciona.com/es/actualidad/noticias/planta-reciclado-palas-eolicas-acciona-waste2fiber-declarada-proyecto-interes-foral-gobierno-navarra (accessed on 28 July 2025).

- Podara, C.; Termine, S.; Modestou, M.; Semitekolos, D.; Tsirogiannis, C.; Karamitrou, M.; Trompeta, A.F.; Milickovic, T.K.; Charitidis, C. Recent Trends of Recycling and Upcycling of Polymers and Composites: A Comprehensive Review. Recycling 2024, 9, 37. [Google Scholar] [CrossRef]

- Islam, K.M.O.; Ahmad, N.; Ummer, A.C.; Ahmed, U.; Siddiqui, M.N.; Millan, M.; Abdul Jameel, A.G. Microwave-Assisted Pyrolysis of Waste Plastics: A Comprehensive Review on Process Parameters, Catalysts, and Future Prospects. Results Eng. 2025, 26, 105571. [Google Scholar] [CrossRef]

- Rani, M.; Choudhary, P.; Krishnan, V.; Zafar, S. Development of Sustainable Microwave-Based Approach to Recover Glass Fibers for Wind Turbine Blades Composite Waste. Resour. Conserv. Recycl. 2022, 179, 106107. [Google Scholar] [CrossRef]

- Cafaro, F.; Ferrari, F.; Carallo, G.A.; Greco, A.; Maffezzoli, A. A Sustainable Microwave-Assisted Process for Chemical Recycling and the Reuse of Epoxy Resin Matrices. Polymers 2025, 17, 989. [Google Scholar] [CrossRef]

- Job, S.; Leeke, G.; Mativenga, P.T.; Oliveux, G.; Pickering, S.; Shuaib, N.A. Composites Recycling: Where Are We Now? Composites UK: Berkhamsted, UK, 2016. [Google Scholar]

- Kazemi, M.; Faisal Kabir, S.; Fini, E.H. State of the Art in Recycling Waste Thermoplastics and Thermosets and Their Applications in Construction. Resour. Conserv. Recycl. 2021, 174, 105776. [Google Scholar] [CrossRef]

- Singh, M.K.; Arora, G.; Zafar, S.; Rangappa, S.M.; Siengchin, S. (Eds.) Composites Science and Technology Composite Materials Processing Using Microwave Heating Technology; Springer: Berlin/Heidelberg, Germany, 2004; ISBN 978-9819727711. [Google Scholar]

- BIZENTE. Project Applying Ligninases to Resolve End-of-Life Issues of the Thermoset Composite Plastics. Available online: https://bizente.eu/ (accessed on 21 January 2025).

- Pathak, G.S.; Hinge, M.; Otzen, D.E. Transdisciplinary Pragmatic Melioration for the Plastic Life Cycle: Why the Social, Natural, and Technical Sciences Should Prioritize Reducing Harm. Sci. Total Environ. 2023, 895, 165154. [Google Scholar] [CrossRef]

- BLADE2CIRC. Forging tha Blades of the Future with Composite Materials with Circular, Safe and Sustainable Design. Available online: https://blade2circ.eu/ (accessed on 27 July 2025).

- Sun, H.; Guo, G.; Memon, S.A.; Xu, W.; Zhang, Q.; Zhu, J.H.; Xing, F. Recycling of Carbon Fibers from Carbon Fiber Reinforced Polymer Using Electrochemical Method. Compos. Part A Appl. Sci. Manuf. 2015, 78, 10–17. [Google Scholar] [CrossRef]

- Cai, G.; Wada, M.; Ohsawa, I.; Kitaoka, S.; Takahashi, J. Interfacial Adhesion of Recycled Carbon Fibers to Polypropylene Resin: Effect of Superheated Steam on the Surface Chemical State of Carbon Fiber. Compos. Part A Appl. Sci. Manuf. 2019, 120, 33–40. [Google Scholar] [CrossRef]

- Das, M.; Varughese, S. A Novel Sonochemical Approach for Enhanced Recovery of Carbon Fiber from CFRP Waste Using Mild Acid-Peroxide Mixture. ACS Sustain. Chem. Eng. 2016, 4, 2080–2087. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Structural Reuse of Wind Turbine Blades through Segmentation. Compos. Part C Open Access 2021, 5, 100137. [Google Scholar] [CrossRef]

- Joustra, J.; Flipsen, B.; Balkenende, R. Structural Reuse of High End Composite Products: A Design Case Study on Wind Turbine Blades. Resour. Conserv. Recycl. 2021, 167, 105393. [Google Scholar] [CrossRef]

- Bank, L.C.; Arias, F.R.; Yazdanbakhsh, A.; Gentry, T.R.; Al-Haddad, T.; Chen, J.F.; Morrow, R. Concepts for Reusing Composite Materials from Decommissioned Wind Turbine Blades in Affordable Housing. Recycling 2018, 3, 3. [Google Scholar] [CrossRef]

- Medici, P.; van den Dobbelsteen, A.; Peck, D. Safety and Health Concerns for the Users of a Playground, Built with Reused Rotor Blades from a Dismantled Wind Turbine. Sustainability 2020, 3, 3626. [Google Scholar] [CrossRef]

- SURUS. Available online: https://www.surusin.com/ (accessed on 24 June 2025).

- Li, X.; Qin, D.; Hu, Y.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A Systematic Review of Waste Materials in Cement-Based Composites for Construction Applications. J. Build. Eng. 2022, 45, 103447. [Google Scholar] [CrossRef]

- Xiong, C.; Li, Q.; Lan, T.; Li, H.; Long, W.; Xing, F. Sustainable Use of Recycled Carbon Fiber Reinforced Polymer and Crumb Rubber in Concrete: Mechanical Properties and Ecological Evaluation. J. Clean. Prod. 2021, 279, 123624. [Google Scholar] [CrossRef]

- Mastali, M.; Dalvand, A.; Sattarifard, A. The Impact Resistance and Mechanical Properties of the Reinforced Self-Compacting Concrete Incorporating Recycled CFRP Fiber with Different Lengths and Dosages. Compos. Part B Eng. 2017, 112, 74–92. [Google Scholar] [CrossRef]

- Santiago Bethencourt, A.; Verdejo Márquez, R.; López Manchado, M.A. Desarrollo de Materiales Compuestos Sostenibles Basados En Polímeros Reforzados Con Fibra Continua. Rev. Plást. Mod. Cienc. Y Tecnol. De Polím. 2022, 775, 3. [Google Scholar]

- Kinvi-Dossou, G.; Matadi Boumbimba, R.; Bonfoh, N.; Garzon-Hernandez, S.; Garcia-Gonzalez, D.; Gerard, P.; Arias, A. Innovative Acrylic Thermoplastic Composites versus Conventional Composites: Improving the Impact Performances. Compos. Struct. 2019, 217, 1–13. [Google Scholar] [CrossRef]

- Carnicero, R.; Cano, L.; Lopez-Manchado, M.A.; Verdejo, R. Manufacturing, Testing and Recycling of a Small Recyclable Wind Turbine Blade. J. Phys. Conf. Ser. 2022, 2265, 032013. [Google Scholar] [CrossRef]

- Tschentscher, C.; Gebhardt, M.; Chakraborty, S.; Meiners, D. Recycling of Elium CFRPs for High Temperature Dissolution: A Study with Different Solvents. In Proceedings of the Symposium Materialtechnik, Clausthal-Zellerfeld, Germany, 25–26 February 2021. [Google Scholar]

- ARKEMA. Recycling Composite Materials: What Are the Possibilities of Elium® Thermoplastic Resins? Available online: https://www.arkema.com/global/en/resources/post/incubator/elium-resin-composites-recycling-options/ (accessed on 16 January 2025).

- Cledat, G. ARKEMA Elium® Resin: A Breakthrough Innovation in Composite Materials. Available online: https://www.arkema.com/global/en/resources/post/incubator/elium-resin-breakthrough-innovation/ (accessed on 16 January 2025).

- Gebhardt, M.; Chakraborty, S.; Manolakis, I.; Meiners, D. Closed-Loop Room Temperature Recycling of Elium CFRPs and Its Influence on the 2nd Generation Composite Properties. Z. Kunststofftechnik 2020, 1, 179–210. [Google Scholar] [CrossRef]

- Sachs, U.; Akkerman, R. Viscoelastic Bending Model for Continuous Fiber-Reinforced Thermoplastic Composites in Melt. Compos. Part A Appl. Sci. Manuf. 2017, 100, 333–341. [Google Scholar] [CrossRef]

- Obande, W.; Stankovic, D.; Bajpai, A.; Devine, M.; Wurzer, C.; Lykkeberg, A.; Garden, J.A.; Ó Brádaigh, C.M.; Ray, D. Thermal Reshaping as a Route for Reuse of End-of-Life Glass Fibre-Reinforced Acrylic Composites. Compos. Part B Eng. 2023, 257, 110662. [Google Scholar] [CrossRef]

- Boufaida, Z.; Farge, L.; André, S.; Meshaka, Y. Influence of the Fiber/Matrix Strength on the Mechanical Properties of a Glass Fiber/Thermoplastic-Matrix Plain Weave Fabric Composite. Compos. Part A Appl. Sci. Manuf. 2015, 75, 28–38. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Mode I Fracture Toughness and Fractographic Investigation of Carbon Fibre Composites with Liquid Methylmethacrylate Thermoplastic Matrix. Compos. Part B Eng. 2018, 134, 246–253. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Pothnis, J.R.; Portela, A.; Gujjala, R.; Ma, H.; O’Higgins, R.M. Flexural and Interlaminar Shear Response of Novel Methylmethacrylate Composites Reinforced with High-Performance Fibres. Polym. Test. 2024, 140, 108578. [Google Scholar] [CrossRef]

- ISO 14125:1998; Fibre-Reinforced Plastic Composites—General Principles of Design and Analysis of Composite Structures. International Organization for Standardization (ISO): Ginebra, Suiza, 1998.

- ARKEMA Elium® Liquid Thermoplastics. Available online: https://www.arkema.com/global/en/products/product-finder/product-range/incubator/elium_resins/ (accessed on 20 January 2025).

- Swancor Launched Recyclable Thermosetting Epoxy Resin. Available online: https://www.jeccomposites.com/news/spotted-by-jec/swancor-launched-recyclable-thermosetting-epoxy-resin-ezciclo-leading-to-zero-carbon-era/?news_type=announcement,business,product-technology&end_use_application=renewable-energy&tax_product=recycling,therm (accessed on 30 June 2025).

- Saitta, L.; Dattilo, S.; Rizzo, G.; Tosto, C.; Blanco, I.; Ferrari, F.; Carallo, G.A.; Cafaro, F.; Greco, A.; Cicala, G. Chemical Recycling of Bio-Based Epoxy Matrices Based on Precursors Derived from Waste Flour: Recycled Polymers Characterization. Polymers 2025, 17, 335. [Google Scholar] [CrossRef]

- Markouti, P.; Tzouma, E.; Paipetis, A.S. Conventional Thermoset Composites and Their Sustainable Alternatives with Vitrimer Matrix—Waste Management/Recycling Options with Focus on Carbon Fiber Reinforced Epoxy Resin Composites. Materials 2025, 18, 351. [Google Scholar] [CrossRef] [PubMed]

- Elling, B.R.; Dichtel, W.R. Reprocessable Cross-Linked Polymer Networks: Are Associative Exchange Mechanisms Desirable? ACS Cent. Sci. 2020, 6, 1488–1496. [Google Scholar] [CrossRef]

- Aranberri, I.; Landa, M.; Elorza, E.; Salaberria, A.M.; Rekondo, A. Thermoformable and Recyclable CFRP Pultruded Profile Manufactured from an Epoxy Vitrimer. Polym. Test. 2021, 93, 106931. [Google Scholar] [CrossRef]

- Montarnal, D.; Capelot, M.; Tournilhac, F.; Leibler, L. Silica-like Malleable Materials from Permanent Organic Networks. Science 2011, 334, 965–968. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, L.; Yang, G.; Yao, Y.; Wei, X.; Pan, T.; Wu, J.; Tian, M.; Yin, P. Recent Advances in Recyclable Thermosets and Thermoset Composites Based on Covalent Adaptable Networks. J. Mater. Sci. Technol. 2021, 92, 75–87. [Google Scholar] [CrossRef]

- Rizzo, G.; Saitta, L.; Dattilo, S.; Tosto, C.; Pergolizzi, E.; Ivankovic, A.; Cicala, G. Thermomechanical Characterization of an Unsaturated Polyester Vitrimer Synthesized Using a Titanium Transesterification Catalyst. ACS Appl. Polym. Mater. 2023, 5, 8326–8338. [Google Scholar] [CrossRef]

- Tao, Y.; Liang, X.; Zhang, J.; Lei, I.M.; Liu, J. Polyurethane Vitrimers: Chemistry, Properties and Applications. J. Polym. Sci. 2023, 61, 2233–2253. [Google Scholar] [CrossRef]

- Ruiz De Luzuriaga, A.; Martin, R.; Markaide, N.; Rekondo, A.; Cabañero, G.; Rodríguez, J.; Odriozola, I. Epoxy Resin with Exchangeable Disulfide Crosslinks to Obtain Reprocessable, Repairable and Recyclable Fiber-Reinforced Thermoset Composites. Mater. Horiz. 2016, 3, 241–247. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, Y.; Ji, Y.; Wei, Y. Functional Epoxy Vitrimers and Composites. Prog. Mater. Sci. 2021, 120, 100710. [Google Scholar] [CrossRef]

- Ares-Elejoste, P.; Seoane-Rivero, R.; Gandarias, I.; Iturmendi, A.; Gondra, K. Sustainable Alternatives for the Development of Thermoset Composites with Low Environmental Impact. Polymers 2023, 15, 2939. [Google Scholar] [CrossRef] [PubMed]

- Mallinda Mallinda. Available online: https://www.mallinda.com/ (accessed on 11 February 2025).

- Schenk, V.; Labastie, K.; Destarac, M.; Olivier, P.; Guerre, M. Vitrimer Composites: Current Status and Future Challenges. Mater. Adv. 2022, 3, 8012–8029. [Google Scholar] [CrossRef]

- García-Lecina, E. Reprocessable, Repairable and Recyclable: Materials with an Endless Lifespan. CIDETEC Surface Engineering. Available online: www.cidetec.es (accessed on 14 February 2025).

- Stack, R.M.; Lai, F. Development in Thermoforming Thermoplastic Composites. Univ. Mass. Lowell 2013, 32, 48–53. [Google Scholar]

- Nouigues, A.; Le Gal La Salle, E.; Bailleul, J.L. Thermo-Mechanical Characterization of Unsaturated Polyester/Glass Fiber Composites for Recycling. Int. J. Mater. Form. 2021, 14, 153–174. [Google Scholar] [CrossRef]

- Post, W.; Susa, A.; Blaauw, R.; Molenveld, K.; Knoop, R.J.I. A Review on the Potential and Limitations of Recyclable Thermosets for Structural Applications. Polym. Rev. 2020, 60, 359–388. [Google Scholar] [CrossRef]

- Weidmann, S.; Volk, P.; Mitschang, P.; Markaide, N. Investigations on Thermoforming of Carbon Fiber Reinforced Epoxy Vitrimer Composites. Compos. Part A Appl. Sci. Manuf. 2021, 154, 106791. [Google Scholar] [CrossRef]

- Pascault, J.P.; Williams, R.J.J. Overview of Thermosets: Structure, Properties and Processing for Advanced Applications; Elsevier eBooks: Amsterdam, The Netherlands, 2012; pp. 3–27. [Google Scholar] [CrossRef]

- Nouigues, A. Recyclage des Pièces en Composite Polyester en Fibres de Verre de Grandes Dimensions par Laminage. Ph.D. Thesis, Université de Nantes (UN), Nantes, France, 2021. [Google Scholar]

| Recycling Methods | Pros | Cons | |

|---|---|---|---|

| Chemical recycling | Solvolysis | - Obtained monomers or oligomers can be used - Mechanical properties of the reinforcement are properly preserved | - High operating cost due to high energy demand (21–91 MJ/kg) - Generation of secondary chemical waste |

| Mechanical recycling | Mechanical grinding | - No high temperature or chemical agent - Low energy consumption (0.1–4.8 MJ/kg) -Low cost and easy to implement | - Large loss in value of recycled material |

| Electrofragmentation | - Good separation of the components (resin and fibre) | - High energy consumption (17.1–89 MJ/kg) | |

| Thermal recycling | Pyrolysis | - Decomposes the resin - In addition to reinforcement, oils and gases are recovered | - Loss of mechanical properties - High operating costs due to low energy efficiency |

| Fluidised bed | - Good performance in the separation of materials - Good energy efficiency | - Recovery of more damaged reinforcement than pyrolysis - Only gases recovered from resin by-products | |

| Recycling Method | Advantages | Limitations | Research Areas |

|---|---|---|---|

| Microwave-assisted Recycling | - Effective and fast volumetric heating - Precise temperature control - High-quality long fibre recovery | - Interaction with materials depending on dielectric properties - Penetration depth and uniformity - Complexity and cost of equipment | - Optimisation of operating conditions - Predictive models using simulation tools - Industrial scaling and pilot validation |

| Enzymatic Recycling | - Production of high-value by-products - Selective process and, therefore, less aggressive | - Limited availability of enzymes - Pre-treatment requirement - Limited thermostability - Slow reaction rates | - Development of specific enzymes to degrade polymer matrices according to their nature - Evaluation of their applicability in full-scale applications |

| Electrochemical Recycling | - Preserving the reinforcing fibres’ geometry - Simple in operation | - Sensitivity to electrolyte concentration and applied current - Long processing times - High energy consumption | - Reduction in energy consumption during the process - Optimisation of electrical and parameters to minimise damage - Combination with other techniques |

| Superheated Steam Recycling | - Efficient fibre recovery - Fast process | - Does not allow for reuse of the matrix - Sensitivity to temperature affecting the recovered reinforcement | - Optimisation of the temperature and times to minimise mechanical deterioration |

| Ultrasonic Recycling | - Scalability - Link selectivity - Energy efficiency | - Environmental concerns due to the acid commonly used | - Optimising process key parameters - Development of hybrid approaches with other recycling methods |

| Property | Unsaturated Polyester | Epoxy | Elium® Resin |

|---|---|---|---|

| Max stress (Mpa) | 210 | 250 | 343 |

| Modulus (Gpa) | 13 | 9 | 11 |

| Elongation at break (%) | 2.7 | 4.8 | >20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camacho-Iglesias, M.; Germán, L.; Iturmendi, A.; Seoane-Rivero, R. Circular Approaches for Thermoset Composites. J. Compos. Sci. 2025, 9, 682. https://doi.org/10.3390/jcs9120682

Camacho-Iglesias M, Germán L, Iturmendi A, Seoane-Rivero R. Circular Approaches for Thermoset Composites. Journal of Composites Science. 2025; 9(12):682. https://doi.org/10.3390/jcs9120682

Chicago/Turabian StyleCamacho-Iglesias, Marta, Lorena Germán, Aitziber Iturmendi, and Rubén Seoane-Rivero. 2025. "Circular Approaches for Thermoset Composites" Journal of Composites Science 9, no. 12: 682. https://doi.org/10.3390/jcs9120682

APA StyleCamacho-Iglesias, M., Germán, L., Iturmendi, A., & Seoane-Rivero, R. (2025). Circular Approaches for Thermoset Composites. Journal of Composites Science, 9(12), 682. https://doi.org/10.3390/jcs9120682