Damage Mechanism Characterization of Glass Fiber-Reinforced Polymer Composites: A Study Using Acoustic Emission Technique and Unsupervised Machine Learning Algorithms †

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Unsupervised Analysis Methods

2.2.1. Principal Component Analysis

2.2.2. Kohonen’s Self-Organizing Map

- Initialization of the neuron weights Wq considering the average values of the columns of matrix [X].

- Random sampling of an input vector xji from matrix [X].

- Finding the best matching unit, which means obtaining the neuron whose weight vector is closest to the input vector by measuring the Euclidean equation as follows:where xji represents each observation in matrix [X], and Wq represents each element in the weight vector.

- Adaptation of the weight of this best-matching neuron as well as those of its similar neighbors so they are close to the input vector following the rulewhere N(q) is the neighborhood of the best-matching neuron, η is the learning rate, and t represents the iteration number.

- Continuation by increasing the number of iterations t and repeating the previous steps with the random sample of an input vector xji until a stopping criterion is met, such as reaching several iterations or a stable rate of the map.

2.3. Acoustic Emission and Experimental Setup

- Fiber-breaking force measurement: As depicted in Figure 1b, fiber tensile tests were conducted at room temperature with special Capstan grips made for fiber testing, adopting standards ASTM D 2256M-21 and ASTM D2343-17 [28,29]. All tests were performed with a displacement rate of 250 mm/min and a gauge length of up to approximately 250 mm. At least ten specimens were tested. A considerable drop in testing load indicated specimen failure. The maximum load from the load–displacement curve was taken as the breaking load.

3. Results

3.1. Implementation of Principal Component Analysis

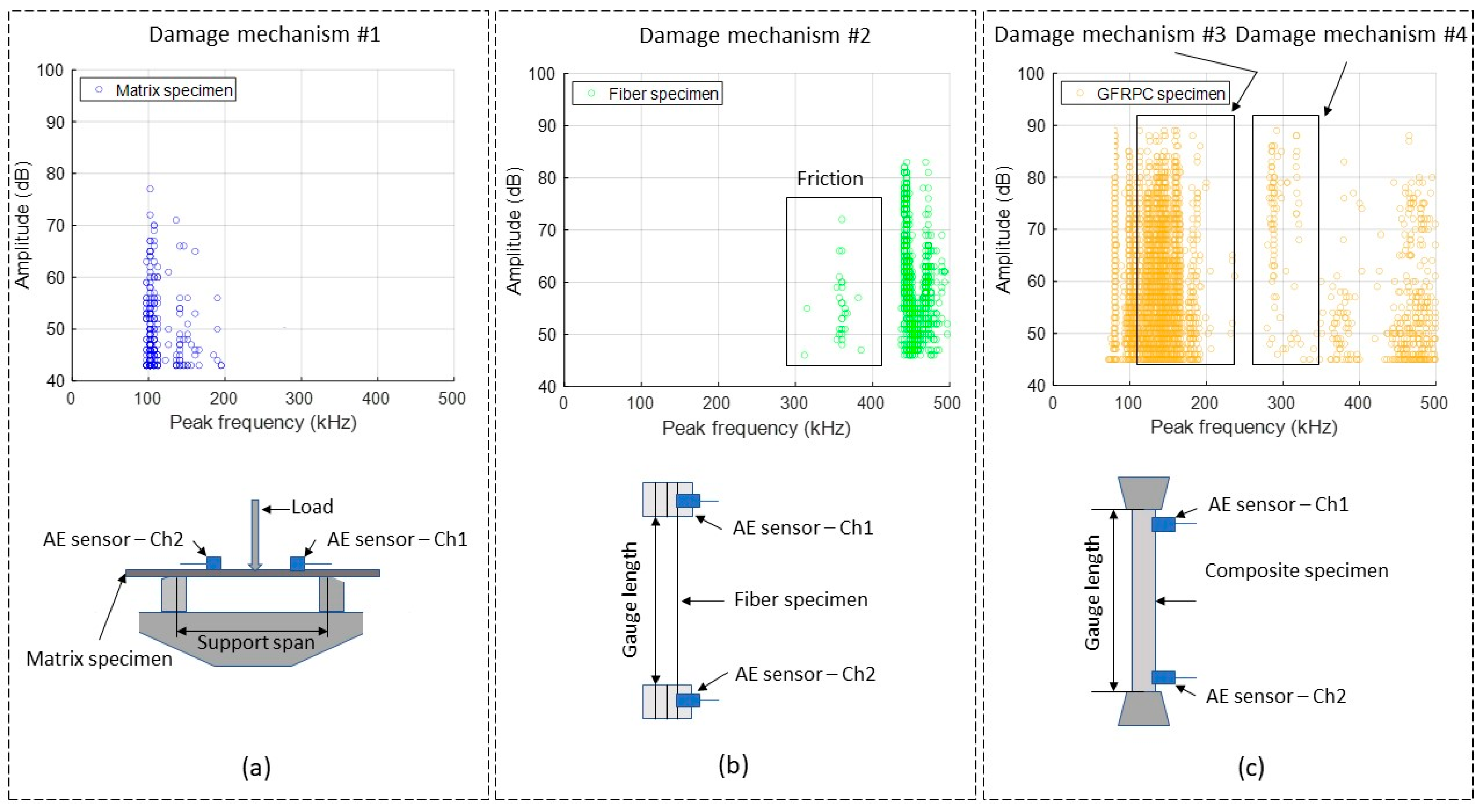

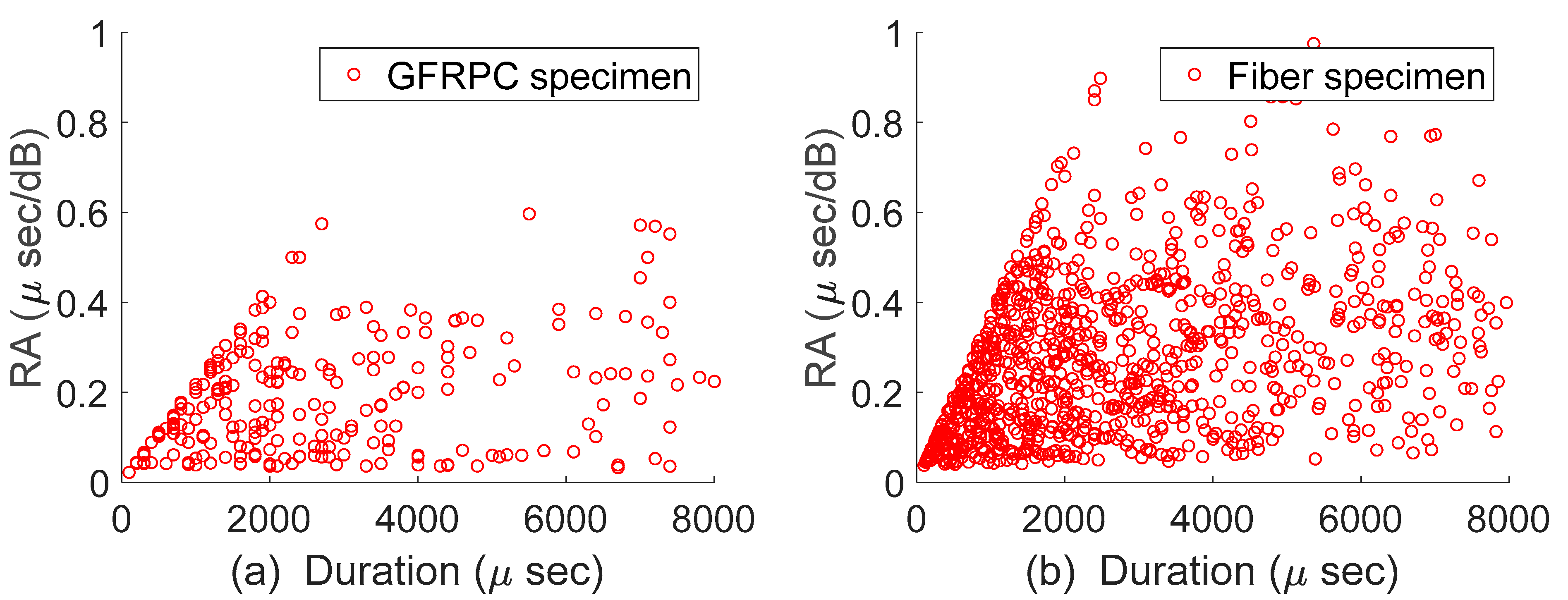

3.2. AE Data of Each Conducted Experiment

3.3. Clustering Based on Kohonen’s Self-Organizing Map

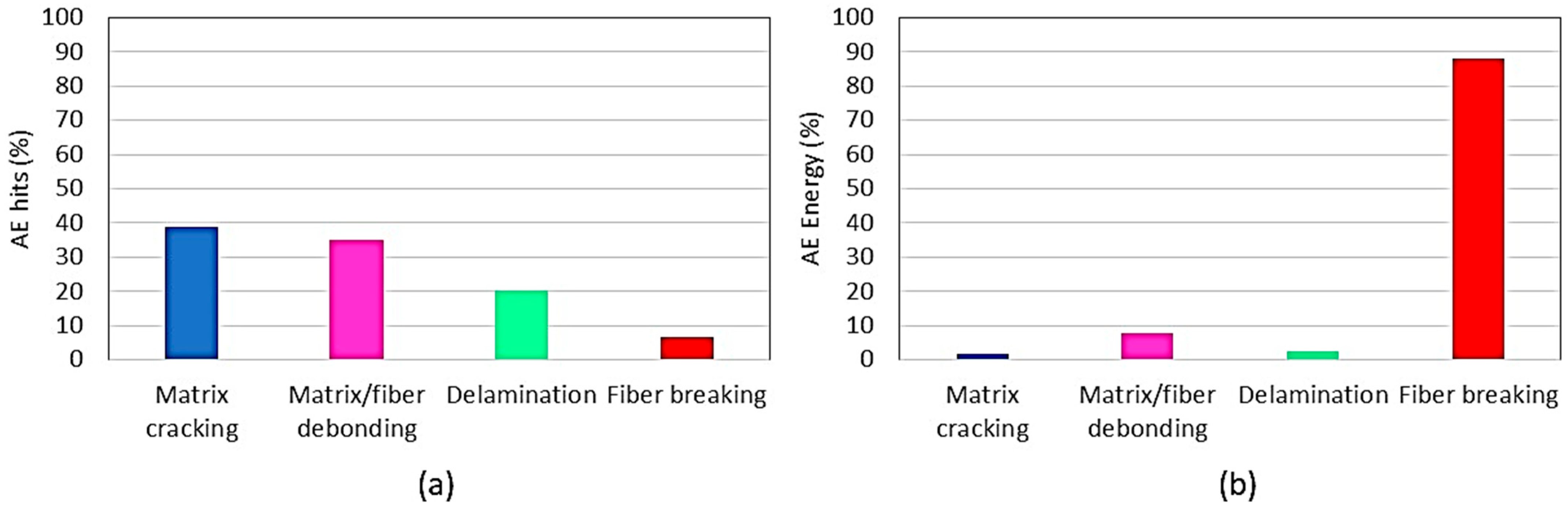

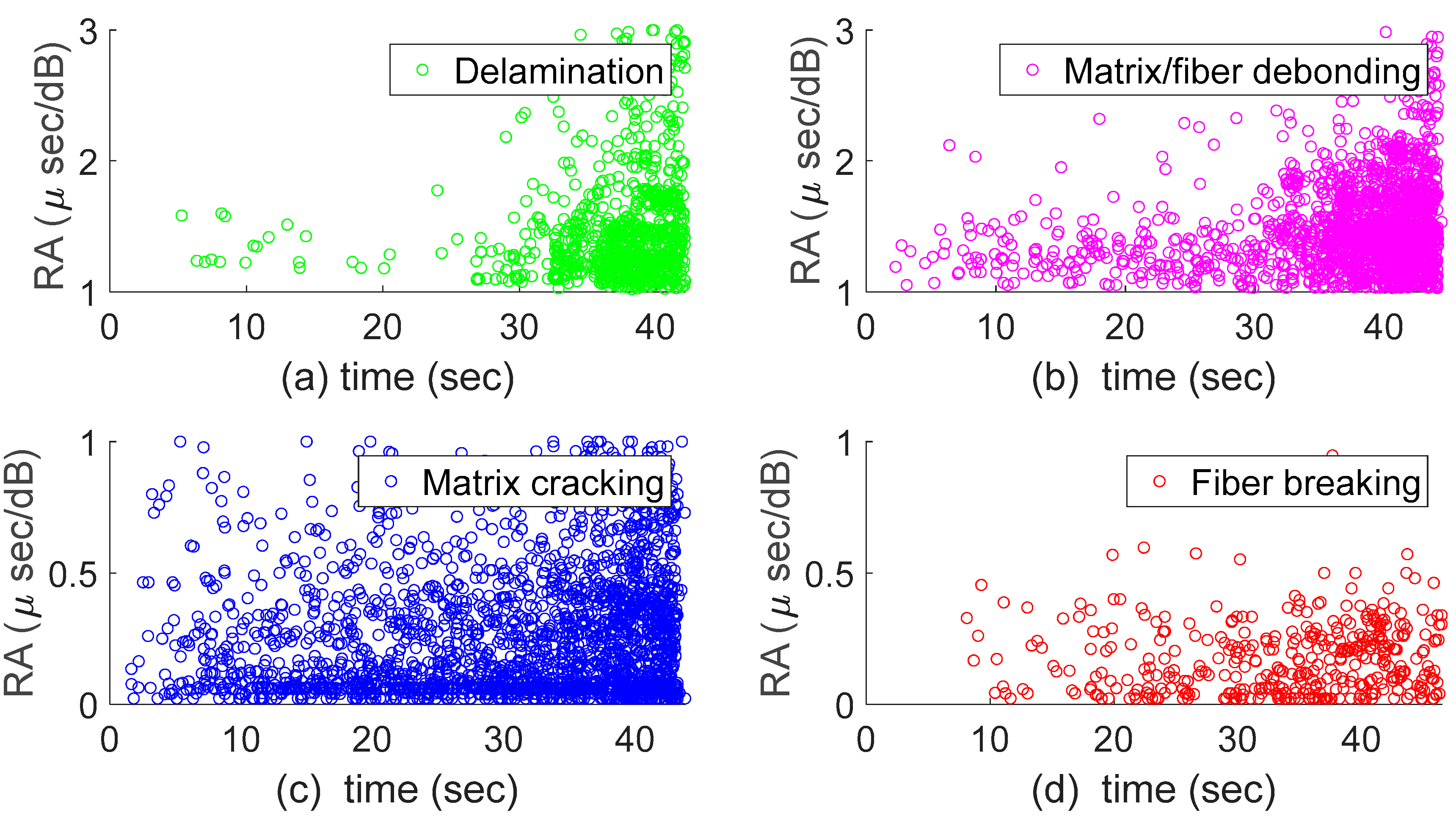

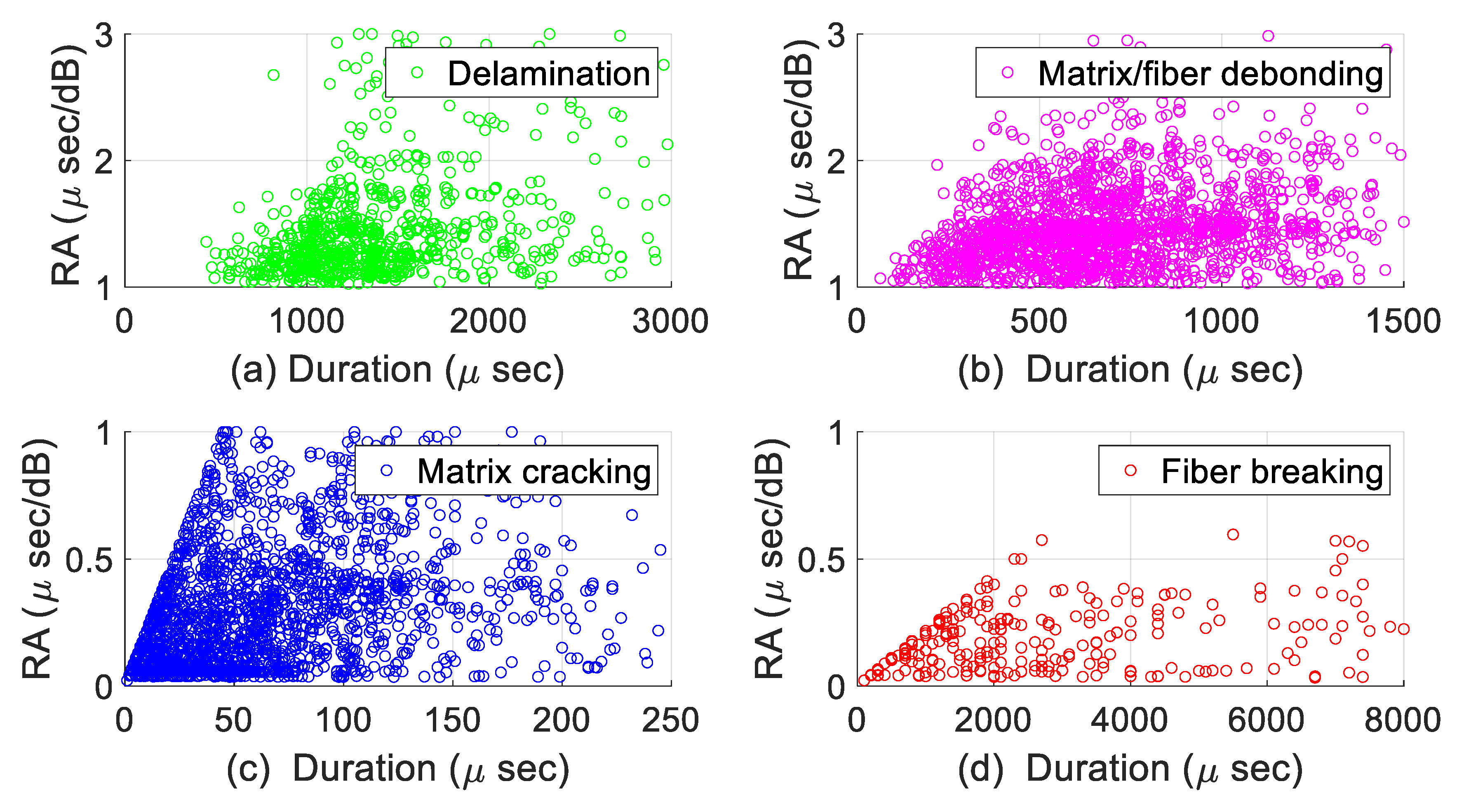

3.4. Cluster Analysis Based on AE Descriptors

3.5. SEM Observations and Correlation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rajak, D.K.; Pagar, D.D.; Menezes, P.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing Technologies of Carbon/Glass Fiber-Reinforced Polymer Composites and Their Properties: A Review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef] [PubMed]

- Alabtah, F.A.; Mahdi, E.; Eliyan, F.F. The use of fiber reinforced polymeric composites in pipelines: A review. Compos. Struct. 2021, 276, 114595. [Google Scholar] [CrossRef]

- Rubio-González, C.; del Pilar de Urquijo-Ventura, M.; Rodríguez-González, J.A. Damage progression monitoring using self-sensing capability and acoustic emission on glass fiber/epoxy composites and damage classification through principal component analysis. Compos. B Eng. 2023, 254, 110608. [Google Scholar] [CrossRef]

- Duchene, P.; Chaki, S.; Ayadi, A.; Krawczak, P. A review of non-destructive techniques used for mechanical damage assessment in polymer composites. J. Mater. Sci. 2018, 53, 7915–7938. [Google Scholar] [CrossRef]

- Barre, S.; Benzeggagh, M.L. On the use of acoustic emission to investigate damage mechanisms in glass-fiber-reinforced-polypropylene. Compos. Sci. Technol. 1994, 52, 369–376. [Google Scholar] [CrossRef]

- Kotsikos, G.; Evans, J.T.; Gibson, A.G.; Hale, J.M. Environmentally enhanced fatigue damage in glass fibre reinforced composites characterised by acoustic emission. Compos. Part A Appl. Sci. Manuf. 2000, 31, 969–977. [Google Scholar] [CrossRef]

- Ceysson, O.; Salvia, M.; Vincent, L. Damage mechanisms characterisation of carbon fiber/epoxy composite laminates by both electrical resistance measurements and acoustic emission signals. Scr. Mater. 1996, 34, 1273–1280. [Google Scholar] [CrossRef]

- Kim, S.-T.; Lee, Y.-T. Characteristics of damage and fracture process of carbon fiber reinforced plastic under loading-unloading test by using AE method. Mater. Sci. Eng. 1997, 234–236, 322–326. [Google Scholar] [CrossRef]

- Harizi, W.; Chaki, S.; Bourse, G.; Ourak, M. Damage mechanisms assessment of Glass Fiber-Reinforced Polymer (GFRP) composites using multivariable analysis methods applied to acoustic emission data. Compos. Struct. 2022, 289, 115470. [Google Scholar] [CrossRef]

- Fotouhi, M.; Heidary, H.; Ahmadi, M.; Pashmforoush, F. Characterization of composite materials damage under quasi-static three-point bending test using wavelet and fuzzy C-means clustering. J. Compos. Mater. 2012, 46, 1795–1808. [Google Scholar] [CrossRef]

- Bohmann, T.; Schlamp, M.; Ehrlich, I. Acoustic emission of material damages in glass fibre-reinforced plastics. Compos. B Eng. 2018, 155, 444–451. [Google Scholar] [CrossRef]

- Ali, H.Q.; Tabrizi, I.E.; Khan, R.M.A.; Tufani, A.; Yildiz, M. Microscopic analysis of failure in woven carbon fabric laminates coupled with digital image correlation and acoustic emission. Compos. Struct. 2019, 230, 111515. [Google Scholar] [CrossRef]

- Das, A.K.; Suthar, D.; Leung, C.K. Machine learning based crack mode classification from unlabeled acoustic emission waveform features. Cem. Concr. Res. 2019, 121, 42–57. [Google Scholar] [CrossRef]

- Godin, N.; Huguet, S.; Gaertner, R. Integration of the Kohonen's self-organising map and k-means algorithm for the segmentation of the AE data collected during tensile tests on cross-ply composites. Ndt E Int. 2005, 38, 299–309. [Google Scholar] [CrossRef]

- Kharrat, M.; Placet, V.; Ramasso, E.; Boubakar, M.L. Influence of damage accumulation under fatigue loading on the AE-based health assessment of composite materials: Wave distortion and AE-features evolution as a function of damage level. Compos. Part A Appl. Sci. Manuf. 2018, 109, 615–627. [Google Scholar] [CrossRef]

- Godin, N.; Huguet, S.; Gaertner, R.; Salmon, L. Clustering of acoustic emission signals collected during tensile tests on unidirectional glass/polyester composite using supervised and unsupervised classifiers. Ndt E Int. 2004, 37, 253–264. [Google Scholar] [CrossRef]

- Johnson, M. Waveform based clustering and classification of AE transients in composite laminates using principal component analysis. Ndt E Int. 2002, 35, 367–376. [Google Scholar] [CrossRef]

- Marec, A.; Thomas, J.H.; El Guerjouma, R. Damage characterization of polymer-based composite materials: Multivariable analysis and wavelet transform for clustering acoustic emission data. MSSP 2008, 22, 1441–1464. [Google Scholar] [CrossRef]

- Zhou, W.; Zhao, W.-Z.; Zhang, Y.-N.; Ding, Z.-J. Cluster analysis of acoustic emission signals and deformation measurement for delaminated glass fiber epoxy composites. Compos. Struct. 2018, 195, 349–358. [Google Scholar] [CrossRef]

- Roundi, W.; El Mahi, A.; El Gharad, A.; Rebiere, J.-L. Acoustic emission monitoring of damage progression in Glass/Epoxy composites during static and fatigue tensile tests. Appl. Acoust. 2018, 132, 124–134. [Google Scholar] [CrossRef]

- Almeida, R.S.M.; Magalhães, M.D.; Karim, M.N.; Tushtev, K.; Rezwan, K. Identifying damage mechanisms of composites by acoustic emission and supervised machine learning. Mater. Des. 2023, 227, 111745. [Google Scholar] [CrossRef]

- Palacios Moreno, J.; Nazaripoor, H.; Mertiny, P. Damage Assessment and Classification of Glass Fiber-Reinforced Composite Materials During Tensile Tests Based on Acoustic Emission and Unsupervised Learning Approaches. In Proceedings of the American Society for Composites-Thirty-Eight Technical Conference, Boston, MS, USA, 17–20 September 2023. [Google Scholar]

- Abdi, H.; Williams, L.J. Principal component analysis. WIREs Comp. Stats. 2010, 2, 433–459. [Google Scholar] [CrossRef]

- Miljković, D. Brief review of self-organizing maps. In Proceedings of the 40th International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, 22–26 May 2017. [Google Scholar]

- Nazaripoor, H.; Ashrafizadeh, H.; Schultz, R.; Runka, J.; Mertiny, P. Acoustic Emission Damage Detection during Three-Point Bend Testing of Short Glass Fiber Reinforced Composite Panels: Integrity Assessment. J. Compos. Sci. 2022, 6, 48. [Google Scholar] [CrossRef]

- ASTM D7264; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D2256M-10; Standard Test Method for Tensile Properties of Yarns by the Single-Strand Method. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D2343-17; Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced Plastics. ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D3039-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- Kalteremidou, K.; Murray, B.R.; Tsangouri, E.; Aggelis, D.G.; Hemelrijck, D.V.; Pyl, L. Multiaxial damage characterization of carbon/epoxy angle-ply laminates under static tension by combining in situ microscopy with acoustic emission. Appl. Sci. 2018, 8, 2021. [Google Scholar] [CrossRef]

- Davies, D.L.; Bouldin, D.W. A Cluster Separation Measure. IEEE Trans. Pattern Anal. Mach. Intell. 2009, 2, 224–227. [Google Scholar] [CrossRef]

- Rousseeuw, P.J. Silhouettes: A graphical aid to the interpretation and validation of cluster analysis. J. Comput. Appl. Math. 1987, 20, 53–65. [Google Scholar] [CrossRef]

- Nikbakht, M.; Yousefi, J.; Hosseini-Toudeshky, H.; Minak, G. Delamination evaluation of composite laminates with different interface fiber orientations using acoustic emission features and micro visualization. Compos. B Eng. 2017, 113, 185–196. [Google Scholar] [CrossRef]

- Amenabar, I.; Mendikute, A.; López-Arraiza, A.; Lizaranzu, M.; Aurrekoetxea, J. Comparison and analysis of non-destructive testing techniques suitable for delamination inspection in wind turbine blades. Compos. B Eng. 2011, 42, 1298–1305. [Google Scholar] [CrossRef]

- Beheshtizadeh, N.; Mostafapour, A.; Davoodi, S. Three point bending test of glass/epoxy composite health monitoring by acoustic emission. Alex. Eng. J. 2019, 58, 567–578. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Barkoula, N.; Matikas, T.E.; Paipetis, A.S. Acoustic structural health monitoring of composite materials: Damage identification and evaluation in cross ply laminates using acoustic emissions and ultrasonics. Compos. Technol. 2012, 72, 1127–1133. [Google Scholar] [CrossRef]

- Gates, A.J.; Ahn, Y.-Y. The Impact of Random Models on Clustering Similarity. JMLR 2017, 18, 1–28. [Google Scholar]

- Muir, C.; Tulshibagwale, N.; Furst, A.; Swaminathan, B.; Almansour, A.S.; Sevener, K.; Presby, M.; Kiser, J.D.; Pollock, T.M.; Daly, S.; et al. Quantitative Benchmarking of Acoustic Emission Machine Learning Frameworks for Damage Mechanism Identification. IMMI 2023, 12, 70–81. [Google Scholar] [CrossRef]

| Test | Number of Samples | Dimensions | Expected Damage Mechanisms |

|---|---|---|---|

| Polymer matrix bending test | 5 | Length = 250 mm Mid-span width = 25 mm Mid-span thickness = 5 mm | Matrix crack initiation and propagation |

| Fiber tensile test | 10 | n/a | Fiber breakage |

| Composite tensile test | 5 | Length = 250 mm Width = 25 mm Thickness = 5 mm | Delamination and matrix/fiber debonding |

| Principal Component | Variance (%) | Most Influential AE Descriptors |

|---|---|---|

| 1 | 41.18 | Peak frequency, amplitude and duration |

| 2 | 36.02 | Amplitude, risetime and energy |

| 3 | 13.54 | Reverberation frequency, amplitude and centroid frequency |

| 4 | 8.28 | Centroid, peak and reverberation frequencies |

| 5 | 0.92 | Duration, energy and signal strength |

| 6 | 0.02 | Absolute energy, signal strength and energy |

| Reference | Fiber/Matrix Type | Matrix Cracking | Fiber/Matrix Debonding | Delamination | Fiber Breakage |

|---|---|---|---|---|---|

| Present work | 97–194 | 119–234 | 250–340 | 380–500 | |

| [34] | GF/Epoxy | 50–200 | - | - | - |

| [35] | GF/Polyester | 10–150 | 150–250 | <120 | 350–500 |

| [36] | GF/Epoxy | 62.5–125 | 125–187.5 | - | 187.5–250 |

| [11] | GF/Epoxy | 100–190 | - | 200–320 | 380–430 |

| [20] | GF/Epoxy | <60 | - | 200–320 | 380–430 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Palacios Moreno, J.; Nazaripoor, H.; Mertiny, P. Damage Mechanism Characterization of Glass Fiber-Reinforced Polymer Composites: A Study Using Acoustic Emission Technique and Unsupervised Machine Learning Algorithms. J. Compos. Sci. 2025, 9, 426. https://doi.org/10.3390/jcs9080426

Palacios Moreno J, Nazaripoor H, Mertiny P. Damage Mechanism Characterization of Glass Fiber-Reinforced Polymer Composites: A Study Using Acoustic Emission Technique and Unsupervised Machine Learning Algorithms. Journal of Composites Science. 2025; 9(8):426. https://doi.org/10.3390/jcs9080426

Chicago/Turabian StylePalacios Moreno, Jorge, Hadi Nazaripoor, and Pierre Mertiny. 2025. "Damage Mechanism Characterization of Glass Fiber-Reinforced Polymer Composites: A Study Using Acoustic Emission Technique and Unsupervised Machine Learning Algorithms" Journal of Composites Science 9, no. 8: 426. https://doi.org/10.3390/jcs9080426

APA StylePalacios Moreno, J., Nazaripoor, H., & Mertiny, P. (2025). Damage Mechanism Characterization of Glass Fiber-Reinforced Polymer Composites: A Study Using Acoustic Emission Technique and Unsupervised Machine Learning Algorithms. Journal of Composites Science, 9(8), 426. https://doi.org/10.3390/jcs9080426