Effect of Phosphogypsum Characteristics on the Properties of Phosphogypsum-Based Binders

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

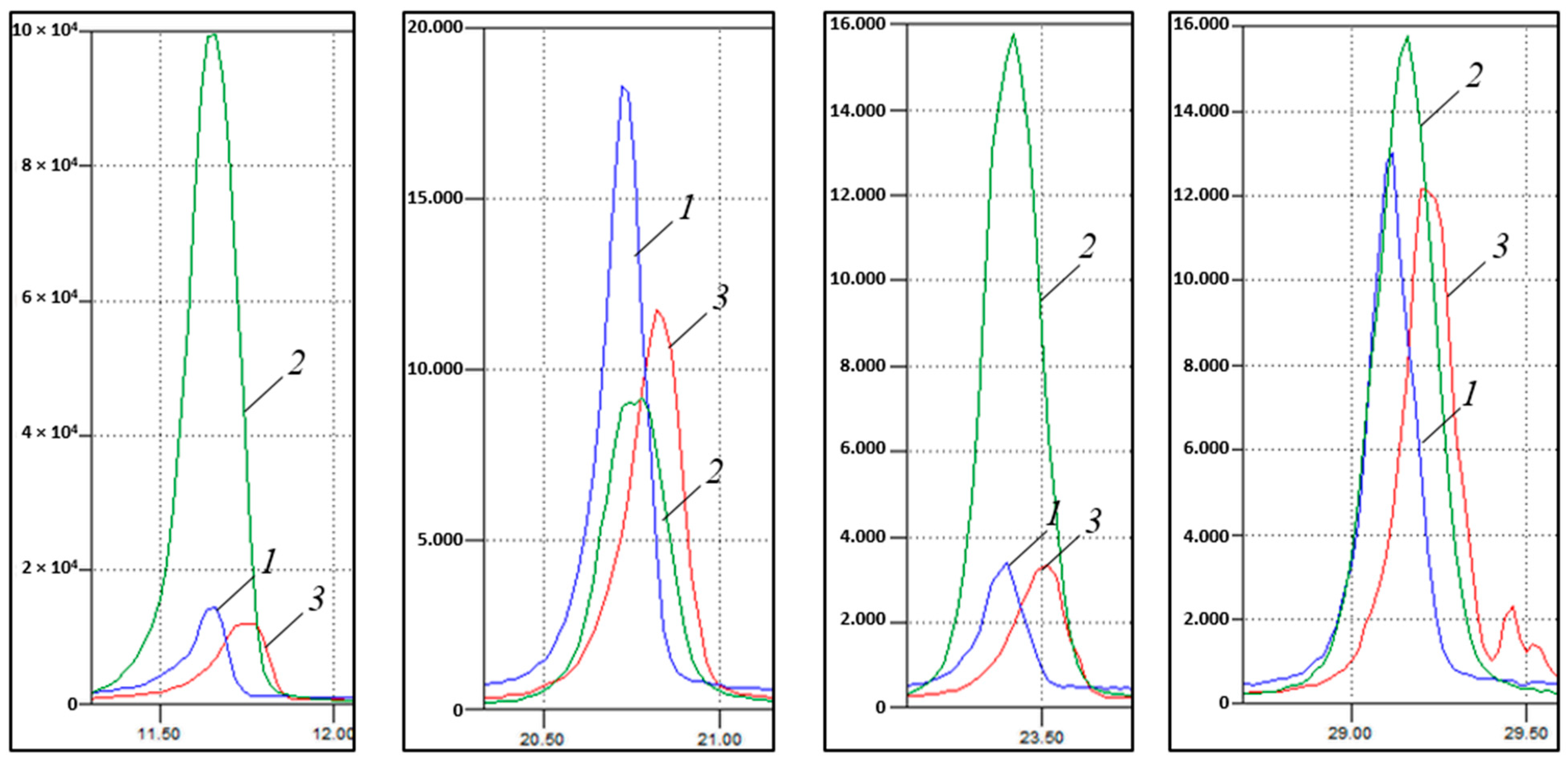

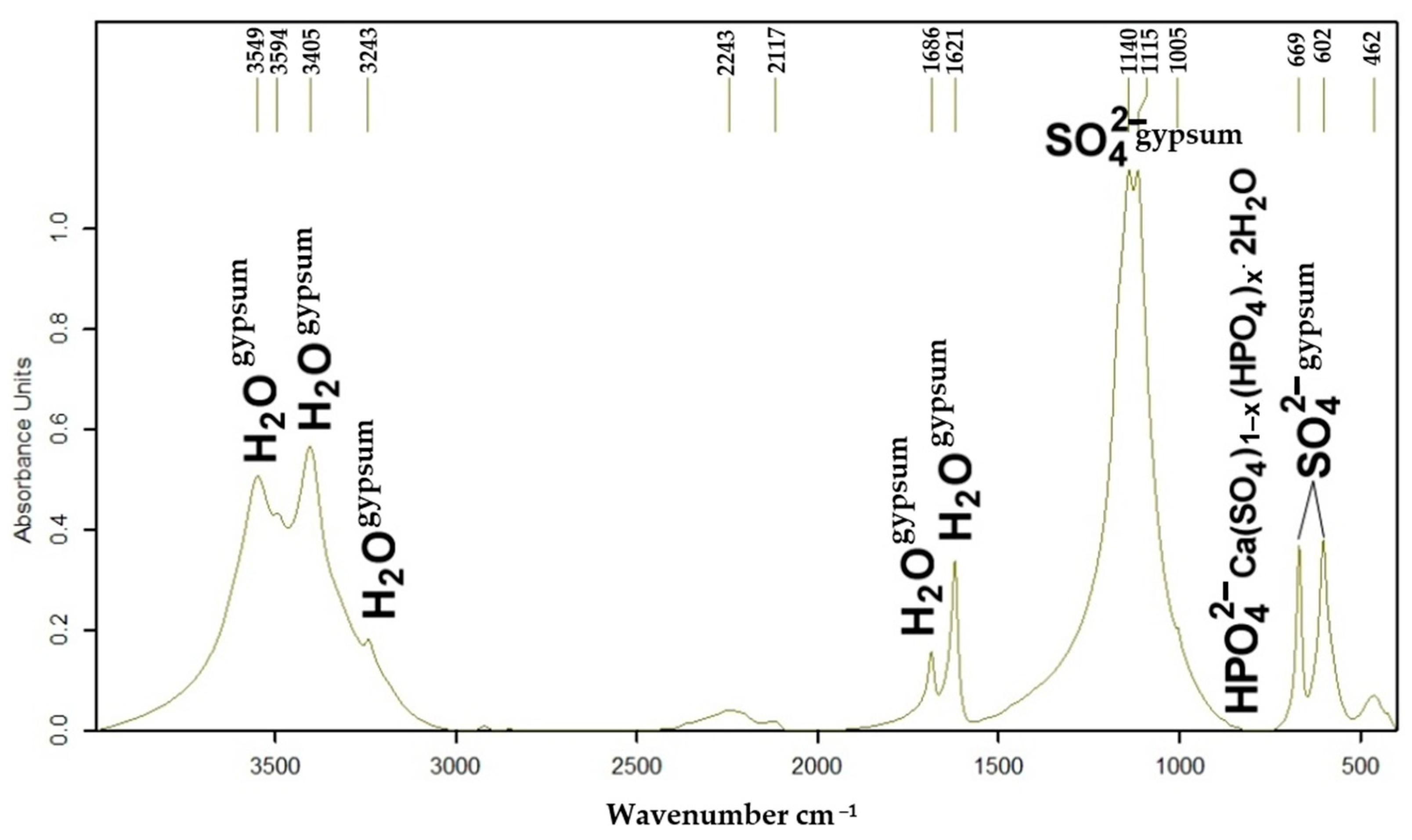

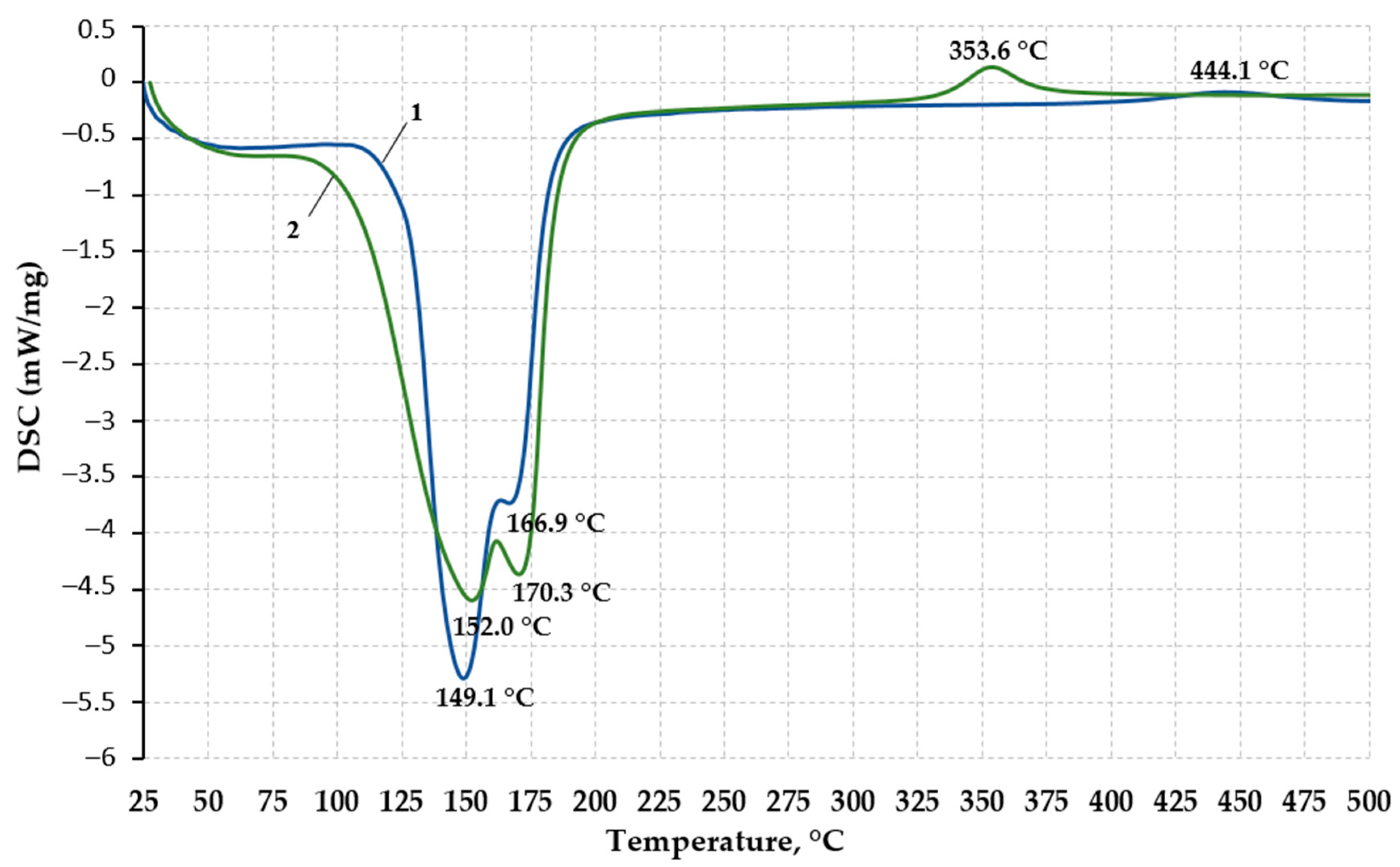

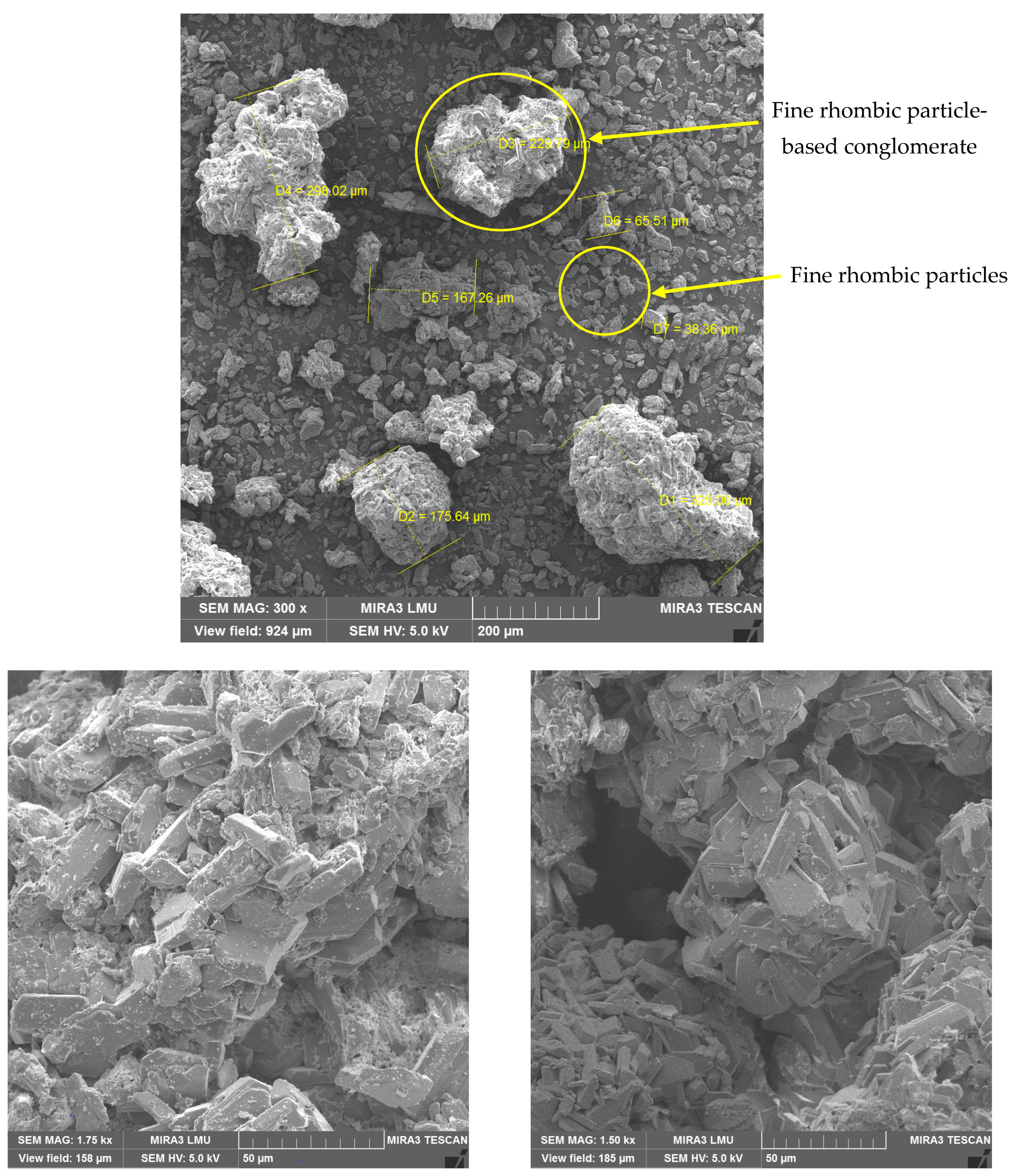

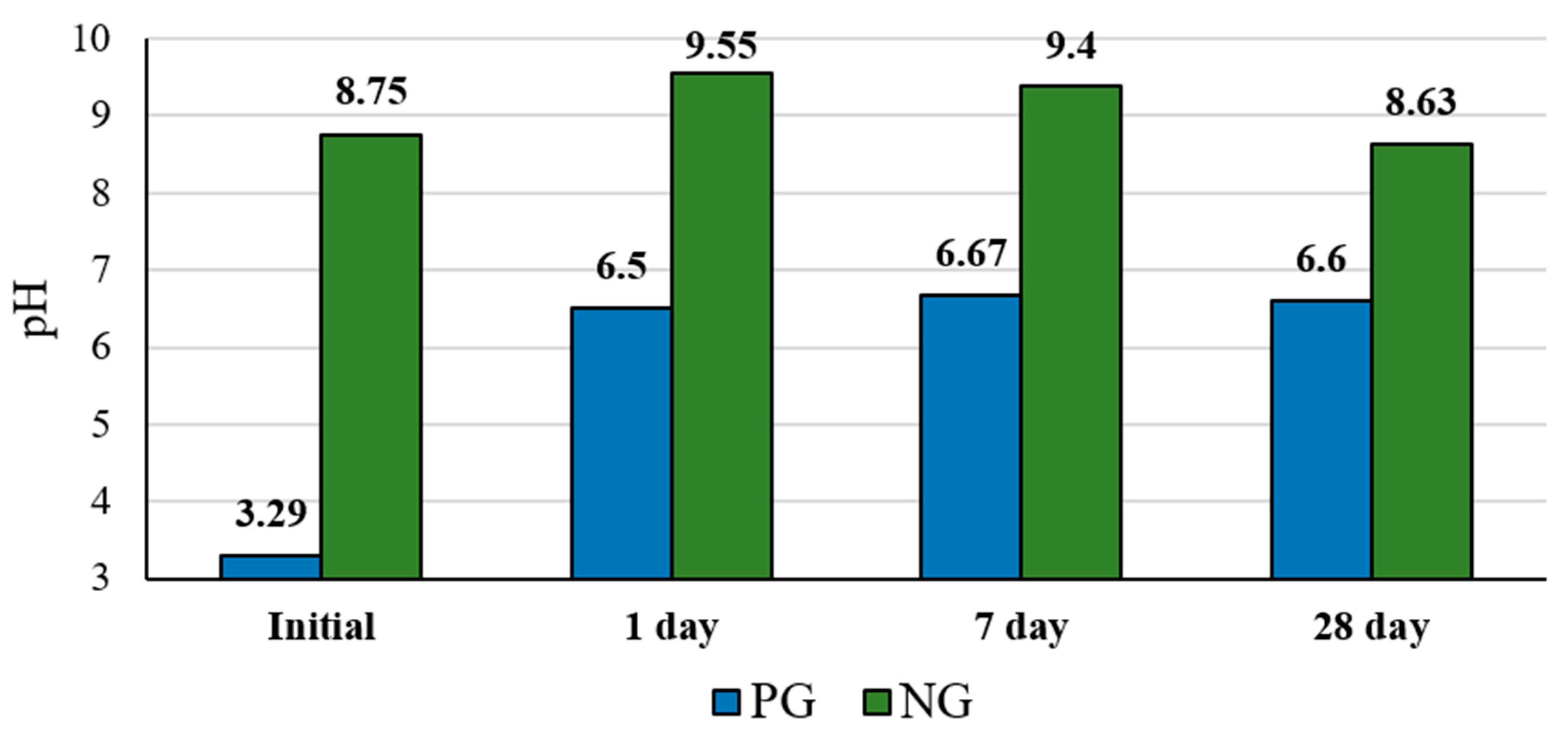

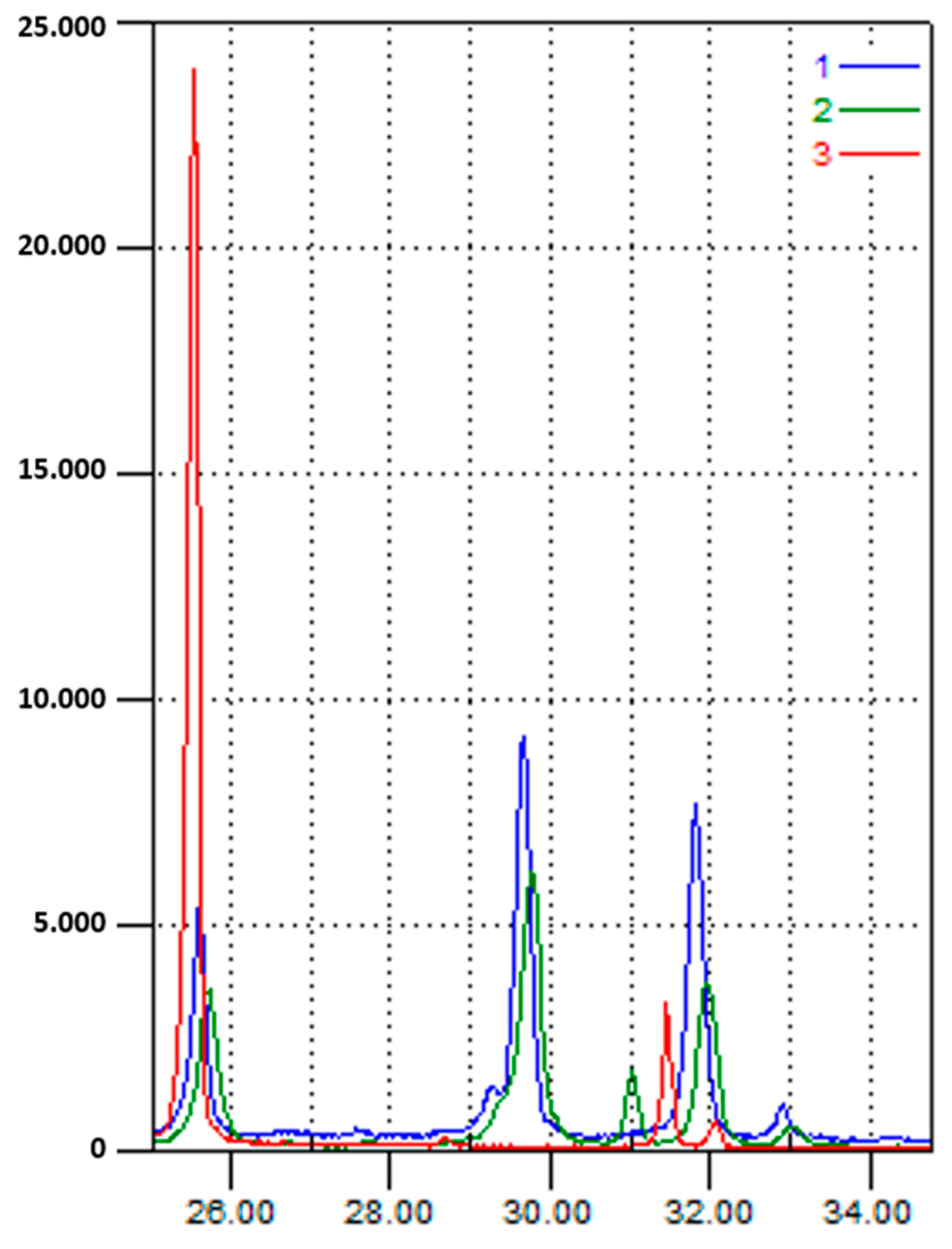

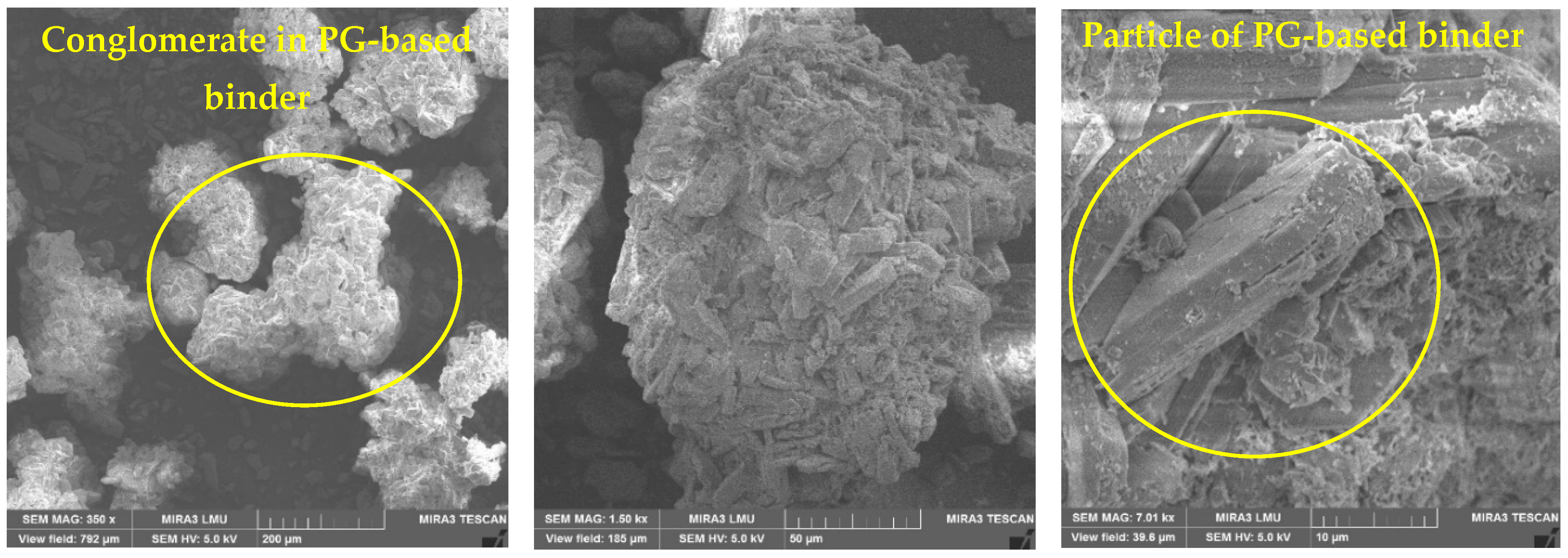

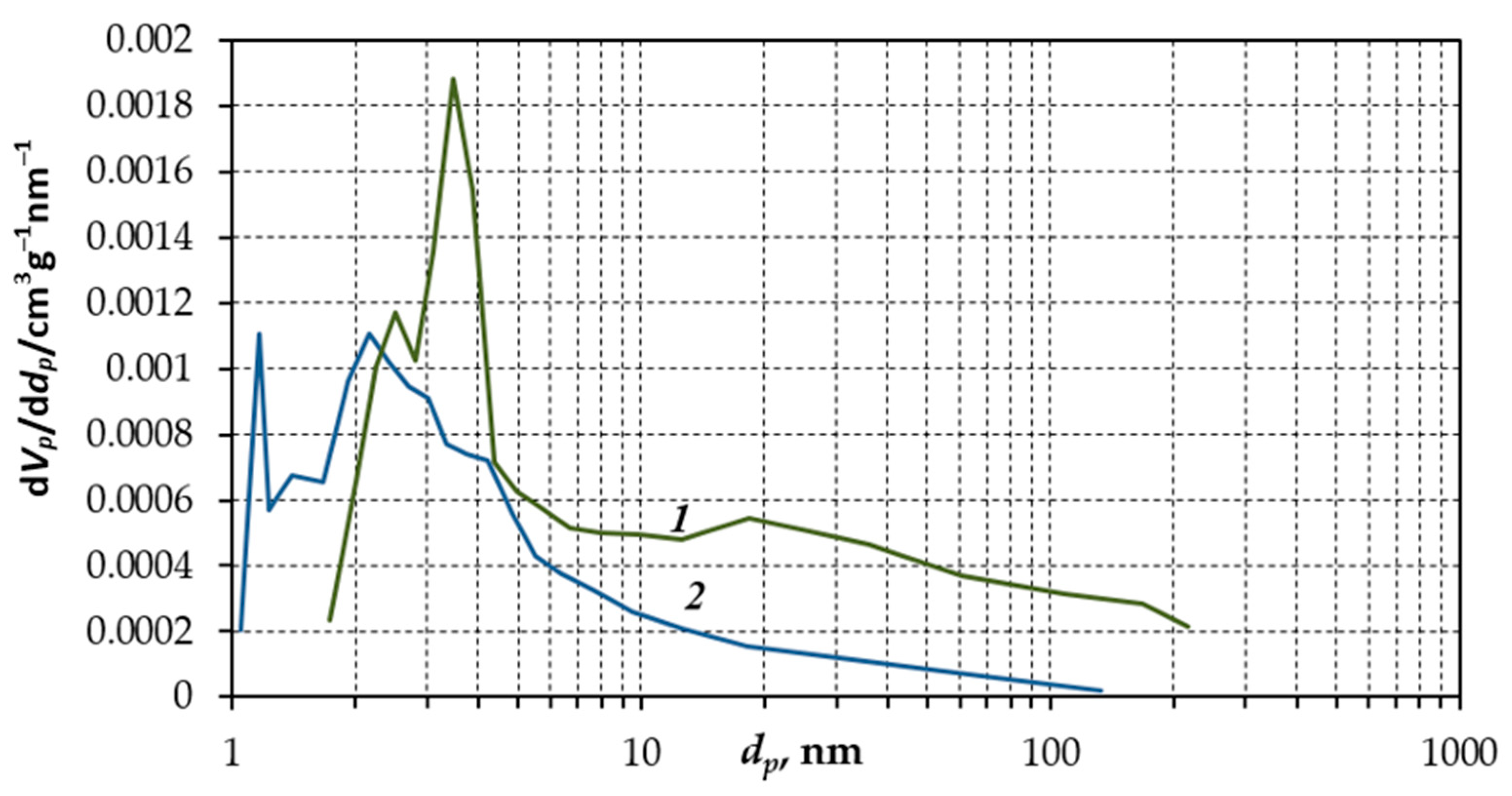

3.1. Analysis of Gypsum-Bearing Raw

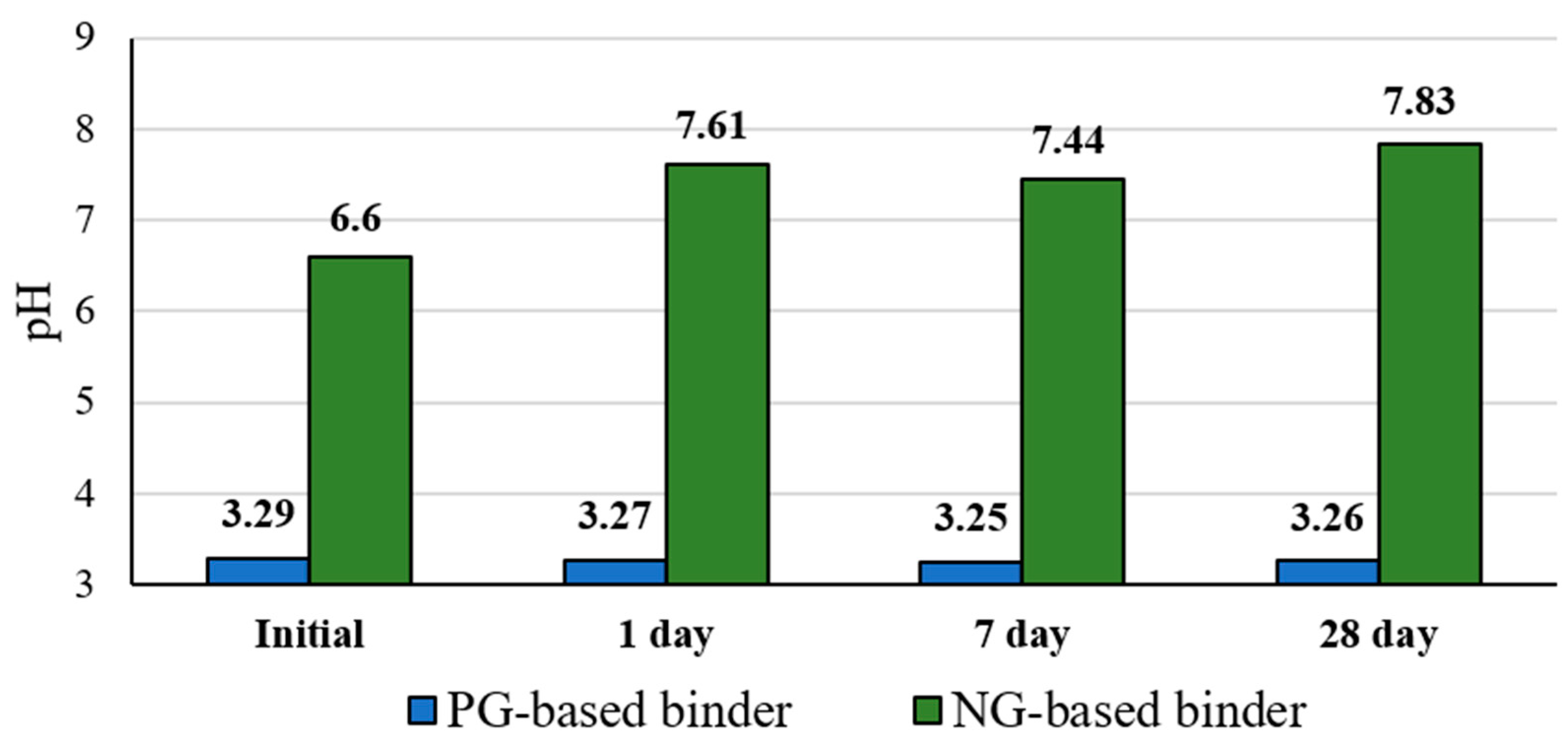

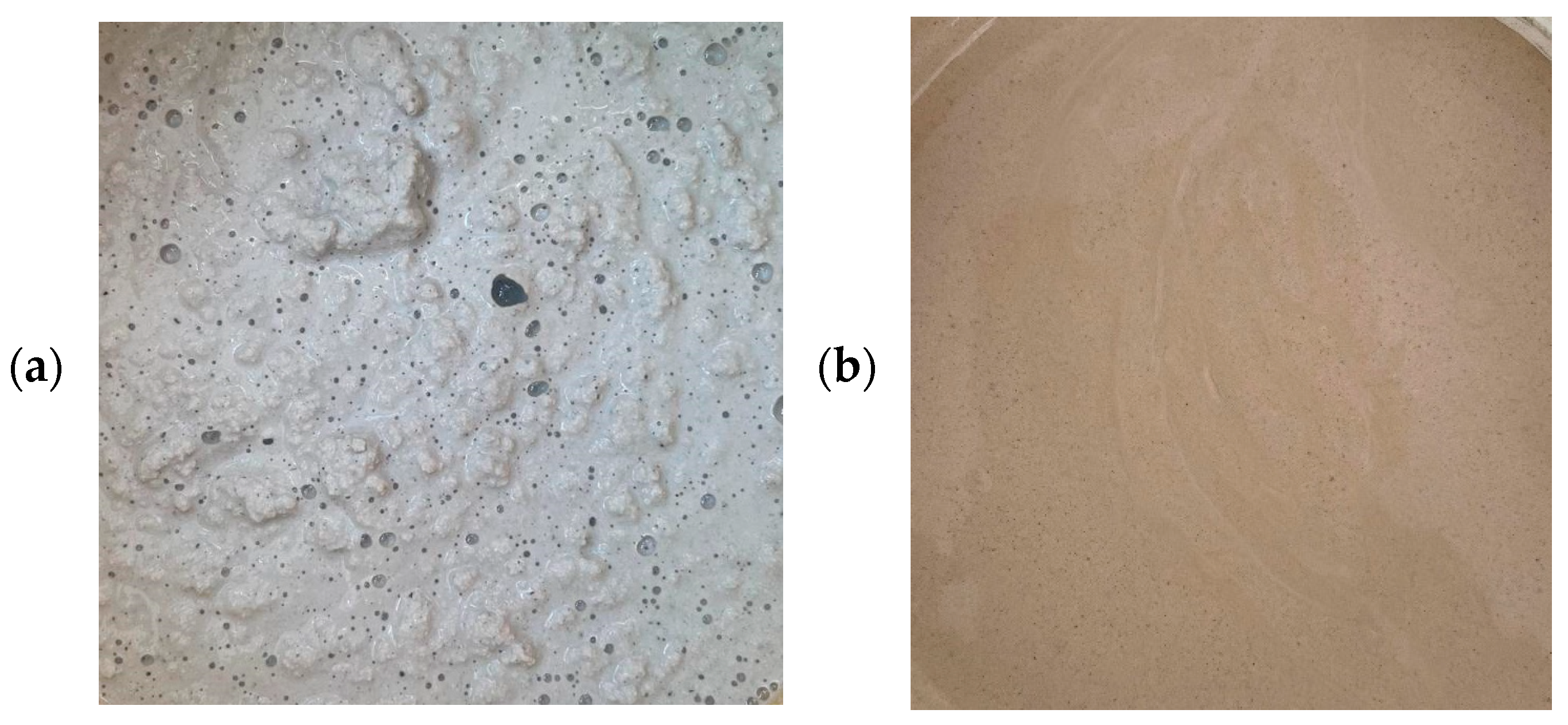

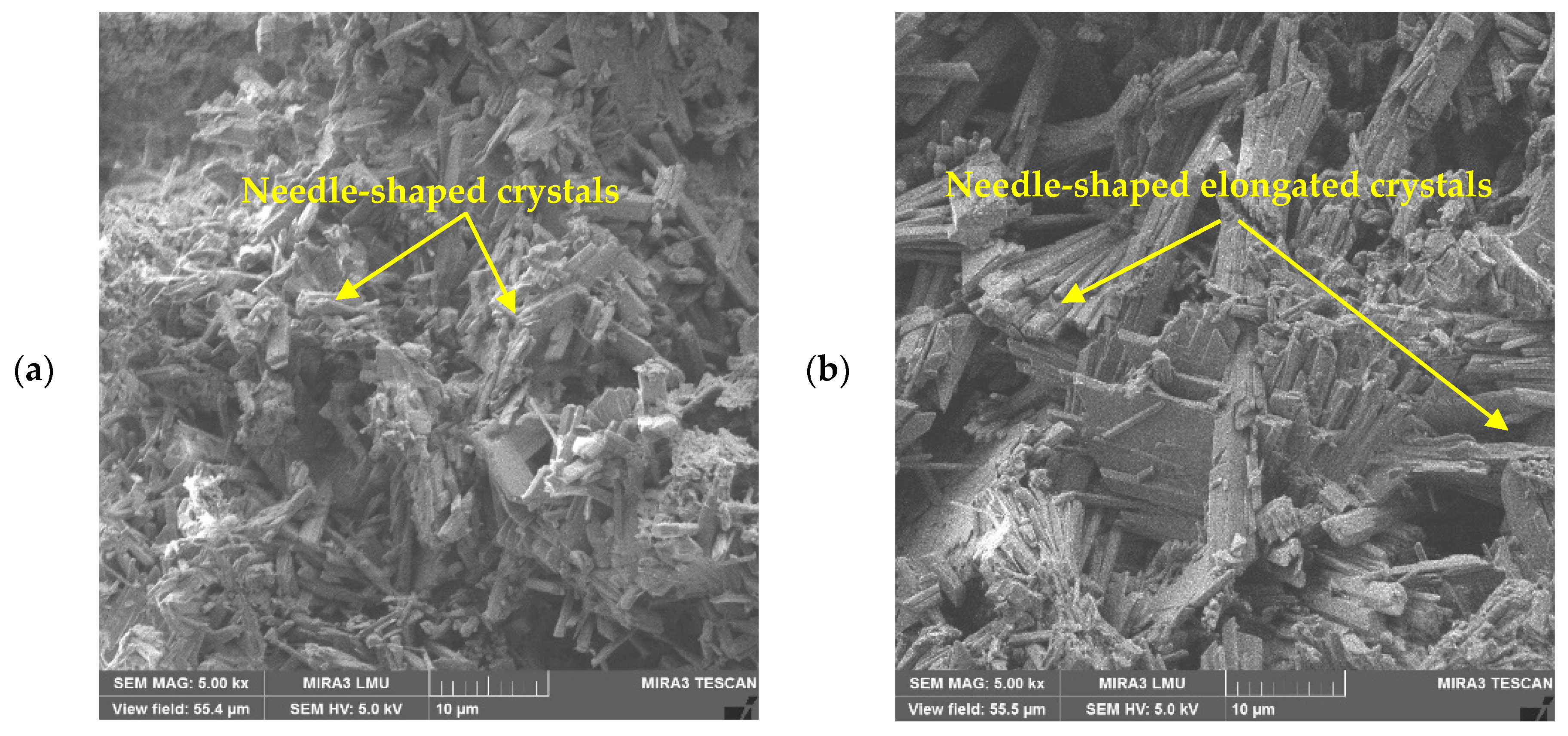

3.2. Analysis of Binders Based on Gypsum Bearing Components

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rashad, A.M. Phosphogypsum as a construction material. J. Clean. Prod. 2017, 166, 732–743. [Google Scholar] [CrossRef]

- Maina, L.; Kiegiel, K.; Zakrzewska-Kołtuniewicz, G. Challenges and Strategies for the Sustainable Environmental Man-agement of Phosphogypsum. Sustainability 2025, 17, 3473. [Google Scholar] [CrossRef]

- Qu, F.; Zhang, Y.; Li, M.; Dong, W.; Li, W.; Tsang, D.C.W. Resource recycling of industrial waste phosphogypsum in cementitious materials: Pretreatment, properties, and applications. J. Environ. Manag. 2025, 376, 124291. [Google Scholar] [CrossRef]

- Shi, X.; Zeng, A.; Duan, H.; Zhang, H.; Yang, J. Status and development trends of phosphogypsum utilization in China. Circ. Econ. 2024, 3, 100116. [Google Scholar] [CrossRef]

- Marchi, G.; Spehar, C.R.; Sousa-Silva, J.C.; Guilherme, L.R.G.; Martins, E.S. Research Perspectives on the Use of Phosphogypsum in the Brazilian Cerrado. J. Agric. Food Dev. 2020, 6, 22–30. [Google Scholar] [CrossRef]

- Bilal, E.; Bellefqih, H.; Bourgier, V.; Mazouz, H.; Dumitraş, D.-G.; Bard, F.; Laborde, M.; Caspar, J.P.; Guilhot, B.; Iatan, E.-L.; et al. Phosphogypsum circular economy considerations: A critical review from more than 65 storage sites worldwide. J. Clean. Prod. 2023, 414, 137561. [Google Scholar] [CrossRef]

- Levickaya, K.; Alfimova, N.; Nikulin, I.; Kozhukhova, N.; Buryanov, A. The Use of Phosphogypsum as a Source of Raw Materials for Gypsum-Based Materials. Resources 2024, 13, 69. [Google Scholar] [CrossRef]

- Chen, L.; Yang, L.; Cao, J. Utilization of phosphogypsum to synthesize α-hemihydrate gypsum in H3PO4-H2O solution. Constr. Build. Mater. 2023, 368, 130453. [Google Scholar] [CrossRef]

- Qi, H.; Ma, B.; Tan, H.; Su, Y.; Chen, P.; Lu, W. Properties of β-HPG pastes in the presence of α-HPG prepared from phosphogypsum. Constr. Build. Mater. 2022, 334, 127414. [Google Scholar] [CrossRef]

- Alfimova, N.; Levickaya, K.; Nikulin, I.; Elistratkin, M.; Kozhukhova, N.; Anosov, N. Effect of Phosphogypsum Origin and Calcination Temperature on Characteristics of Supersulfated Cements. J. Compos. Sci. 2025, 9, 146. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Wu, J.; Gao, Y.; Shao, J.; Wang, C.; Su, T.; Cao, F.; Zhang, W.; Yang, Q.; et al. Preparation of High-Belite Calcium Sulfoaluminate Cement and Calcium Sulfoaluminate Cement from Industrial Solid Waste: A Review. Sustainability 2025, 17, 4269. [Google Scholar] [CrossRef]

- Xu, B.; Zhou, Y.; Wu, Z.; Lu, K.; Wang, H.; Gao, A. Chemical Mechanisms of Cement Stabilization and Durability En-hancement in High-Content Modified Phosphogypsum. Buildings 2025, 15, 723. [Google Scholar] [CrossRef]

- Alfimova, N.I.; Levickaya, K.M.; Elistratkin, M.; Bukhtiyarov, I. Supersulfated cements: A review analysis of the features of properties, raw materials, production and application prospects. Bull. Belgorod State Technol. Univ. Named After V.G. Shukhov 2024, 7, 8–24. [Google Scholar] [CrossRef]

- Ma, B.; Jin, Z.; Su, Y.; Lu, W.; Qi, H.; Hu, P. Utilization of hemihydrate phosphogypsum for the preparation of porous sound absorbing material. Constr. Build. Mater. 2020, 234, 117346. [Google Scholar] [CrossRef]

- Zhang, L.; Mo, K.H.; Tan, T.H.; Hung, C.-C.; Yap, S.P.; Ling, T.-C. Influence of calcination and GGBS addition in preparing β-hemihydrate synthetic gypsum from phosphogypsum. Case Stud. Constr. Mater. 2023, 19, e02259. [Google Scholar] [CrossRef]

- Garg, M.; Pundir, A.; Singh, R. Modifications in water resistance and engineering properties of β-calcium sulphate hemihydrate plaster-superplasticizer blends. Mater. Struct. 2016, 49, 3253–3263. [Google Scholar] [CrossRef]

- GOST 23789-2018 (EN 13279-2: 2004, NEQ); Gypsum Binders. Test Methods. Stroyizdat: Moscow, Russia, 2018.

- Cai, Q.; Jiang, J.; Ma, B.; Shao, Z.; Hu, Y.; Qian, B.; Wang, L. Efficient removal of phosphate impurities in waste phosphogypsum for the production of cement. Sci. Total Environ. 2021, 780, 146600. [Google Scholar] [CrossRef]

- Singh, M. Role of phosphogypsum impurities on strength and microstructure of selenite plaster. Constr. Build. Mater. 2005, 19, 480–486. [Google Scholar] [CrossRef]

- Guan, Q.; Sui, Y.; Yu, W.; Bu, Y.; Zeng, C.; Liu, C.; Zhang, Z.; Gao, Z.; Chi, R. Deep removal of phosphorus and synchronous preparation of high-strength gypsum from phosphogypsum by crystal modification in NaCl-HCl solutions. Sep. Purif. Technol. 2022, 298, 121592. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, Y.; Wang, D.; Liu, B.; Feng, Y.; Song, Z.; Chen, Q. Assessing Fluoride Impact in Phosphogypsum: Strength and Leaching Behavior of Cemented Paste Backfill. Appl. Sci. 2024, 14, 10952. [Google Scholar] [CrossRef]

- Klimenko, V.G.; Pavlenko, V.I.; Gasanov, S.K. Study of pH of the mixing liquid on the strength properties of gypsum binders. Bull. Belgorod State Technol. Univ. Named After V.G. Shukhov 2014, 5, 16–20. [Google Scholar]

- Singh, M.; Garg, M.; Verma, C.L.; Handa, S.K.; Kumar, R. An improved process for the purification of phosphogypsum. Constr. Build. Mater. 1996, 10, 597–600. [Google Scholar] [CrossRef]

- Singh, M. Treating waste phosphogypsum for cement and plaster manufacture. Cem. Concr. Res. 2002, 32, 1033–1038. [Google Scholar] [CrossRef]

| SO3 | CaO | SrO | P2O5 | SiO2 | CeO2 | Na2O | Al2O3 | TiO2 | Nd2O3 | PuO2 | Fe2O3 | MgO | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 47.89 | 46.38 | 2.01 | 1.33 | 0.51 | 0.42 | 0.35 | 0.17 | 0.15 | 0.13 | 0.13 | 0.13 | 0.13 | 0.27 |

| SO3 | CaO | MgO | SrO | SiO2 | Al2O3 | Others |

|---|---|---|---|---|---|---|

| 49.83 | 49.62 | 0.135 | 0.123 | 0.064 | 0.037 | 0.191 |

| Parameter | FG | NG [7] |

|---|---|---|

| Blaine method | ||

| SSA, m2/kg | 133.5 | – |

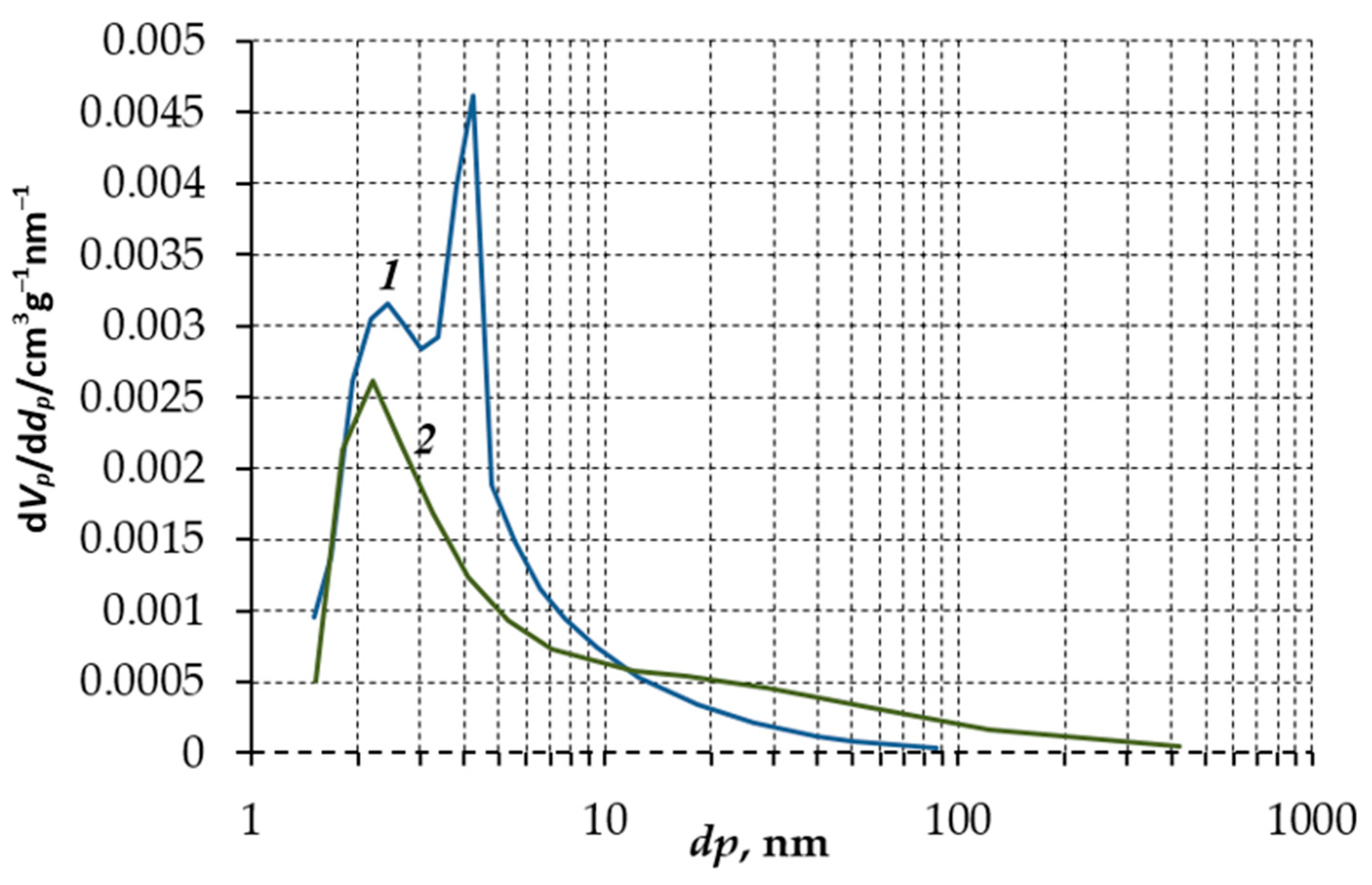

| BET method | ||

| SSA, m2/kg | 18,608 | 14,413 |

| Total pore volume (p/p0 = 0.9900), cm3/g | 0.0282 | 0.053 |

| Average pore diameter, nm | 6.061 | 14.76 |

| BJH method | ||

| SSA, m2/kg | 18,793 | 14,912 |

| Total pore volume, cm3/g | 0.027 | 0.072 |

| Average pore diameter, nm | 5.75 | 19.29 |

| Parameter | FG-Based Binder | NG-Based Binder |

|---|---|---|

| Blaine method | ||

| SSA, m2/kg | 135.8 | 425.6 |

| BET method | ||

| SSA, m2/kg | 7162 | 7594.2 |

| Total pore volume (p/p0 = 0.9900), cm3/g | 0.015 | 0.065 |

| Average pore diameter, nm | 8.11 | 34.10 |

| BJH method | ||

| SSA, m2/kg | 7013.4 | 10,963 |

| Total pore volume, cm3/g | 0.014 | 0.081 |

| Average pore diameter, nm | 78.30 | 29.42 |

| Binder | W/S Ratio | Setting Times, min | Average Density, kg/m3 | Tensile Strength, MPa | Compressive Strength, MPa | ||||

|---|---|---|---|---|---|---|---|---|---|

| Initial | Final | at 2-h Age | at Dry State | at 2-h Age | at Dry State | at 2-h Age | at Dry State | ||

| PG-based | 0.89 | 24 | 30 | 1561 | 1120 | 1.37 | 2.32 | 2.58 | 6.64 |

| NG-based | 0.70 | 18 | 25 | 1570 | 1120 | 3.11 | 5.74 | 4.76 | 11.96 |

| Binder Type | Average Density in a Dry State (kg/m3) for Different W/S Ratio | ||||

|---|---|---|---|---|---|

| 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | |

| PG-based | 1094 | 1170 | 1075 | 1021 | 1005 |

| NG-based (according to [7]) | 1384 | 1255 | 1170 | 1054 | 961 |

| Binder Type | Compressive Strength at a Dry State (kg/m3) for Different W/S Ratio | ||||

|---|---|---|---|---|---|

| 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | |

| PG-based | 7.37 | 11.75 | 9.28 | 7.26 | 5.50 |

| NG-based (according to [7]) | 16.86 | 13.96 | 11.90 | 9.34 | 7.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfimova, N.; Levickaya, K.; Buhtiyarov, I.; Nikulin, I.; Kozhukhova, M.; Strokova, V. Effect of Phosphogypsum Characteristics on the Properties of Phosphogypsum-Based Binders. J. Compos. Sci. 2025, 9, 413. https://doi.org/10.3390/jcs9080413

Alfimova N, Levickaya K, Buhtiyarov I, Nikulin I, Kozhukhova M, Strokova V. Effect of Phosphogypsum Characteristics on the Properties of Phosphogypsum-Based Binders. Journal of Composites Science. 2025; 9(8):413. https://doi.org/10.3390/jcs9080413

Chicago/Turabian StyleAlfimova, Nataliya, Kseniya Levickaya, Il’ya Buhtiyarov, Ivan Nikulin, Marina Kozhukhova, and Valeria Strokova. 2025. "Effect of Phosphogypsum Characteristics on the Properties of Phosphogypsum-Based Binders" Journal of Composites Science 9, no. 8: 413. https://doi.org/10.3390/jcs9080413

APA StyleAlfimova, N., Levickaya, K., Buhtiyarov, I., Nikulin, I., Kozhukhova, M., & Strokova, V. (2025). Effect of Phosphogypsum Characteristics on the Properties of Phosphogypsum-Based Binders. Journal of Composites Science, 9(8), 413. https://doi.org/10.3390/jcs9080413