Mechanics of Interfacial Debonding in FRP Strengthening Systems: Energy Limits and Characteristic Bond Lengths

Abstract

1. Introduction

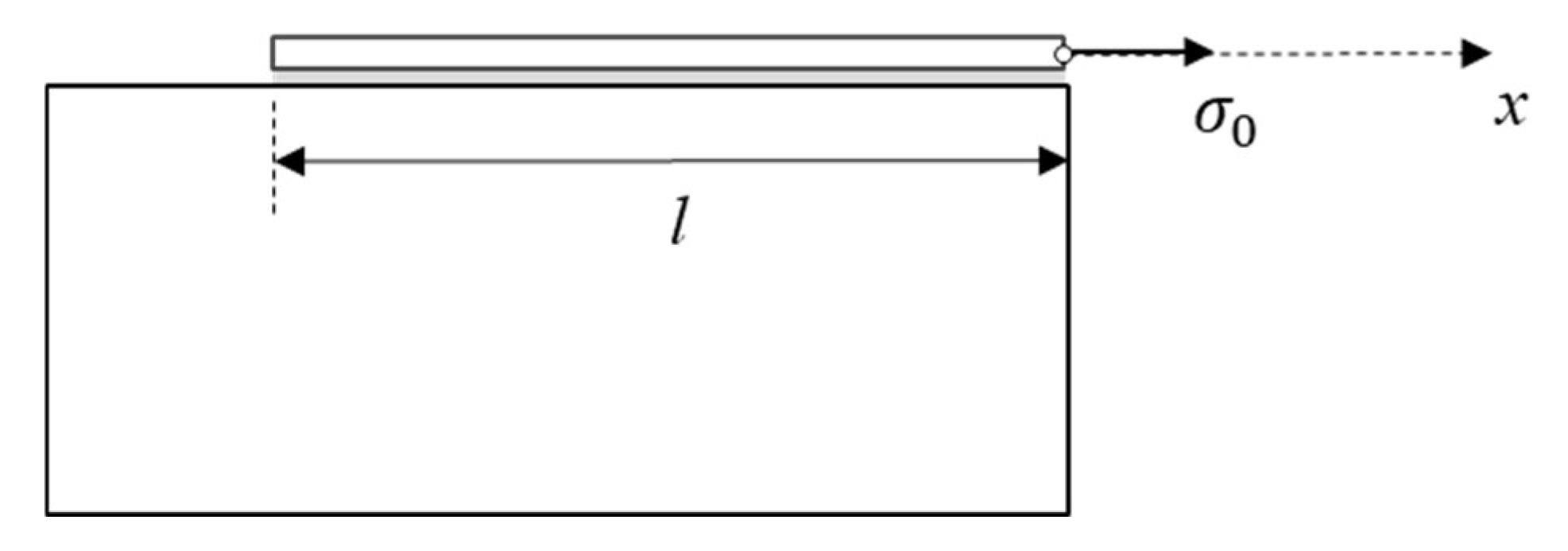

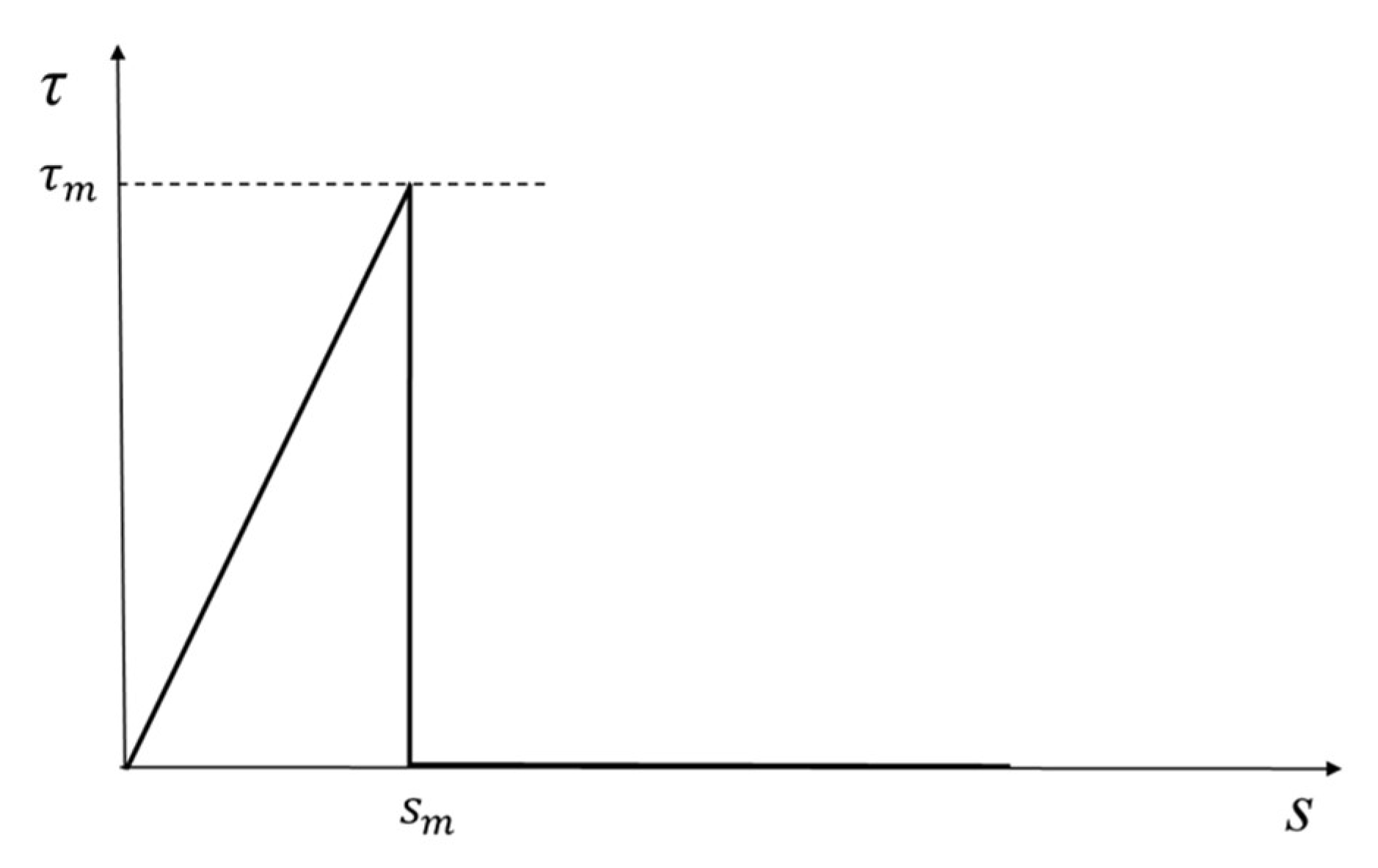

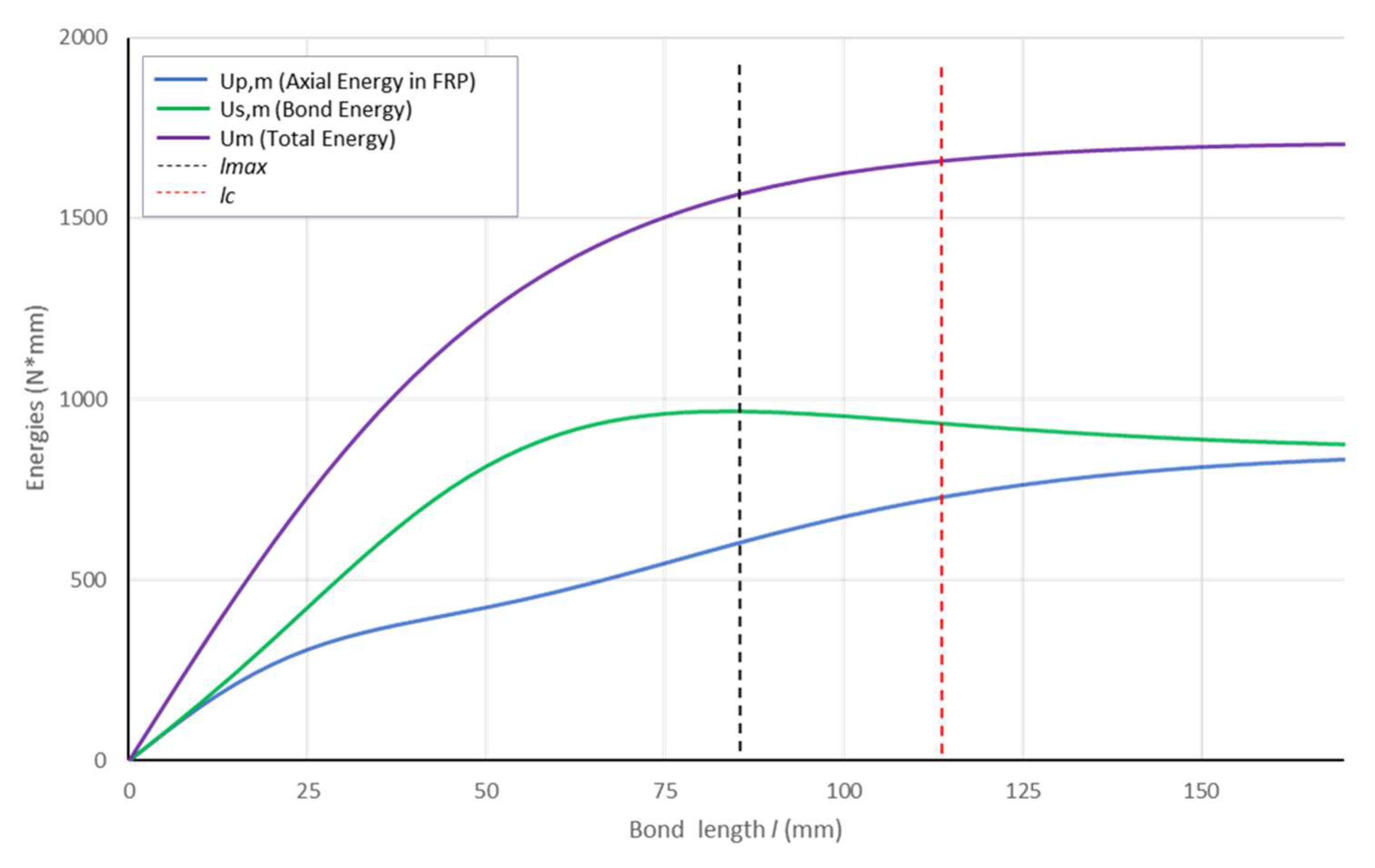

2. The Strengthening System and Its Elastic State

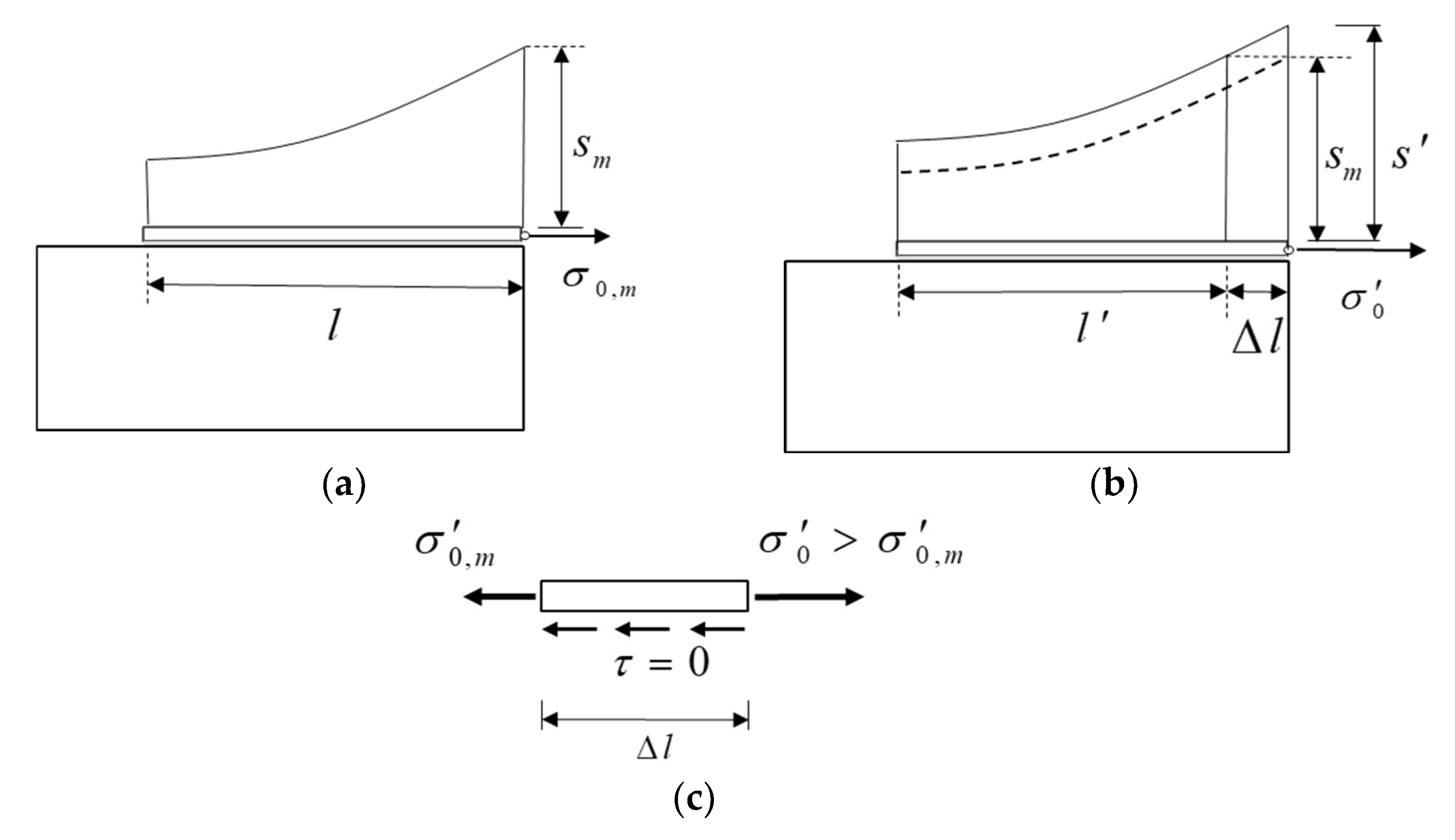

3. The Energy State of the System and the Characteristic Lengths

4. Energy-Based Interpretation of the Sudden Debonding of the FRP Plate

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- American Concrete Institute. Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; ACI 440.2R-17; American Concrete Institute: Farmington Hills, MI, USA, 2017. [Google Scholar]

- ISIS Canada. Design Manual No. 3: Reinforcing Concrete Structures with Fibre Reinforced Polymers; ISIS: Winnipeg, MB, Canada, 2007. [Google Scholar]

- ISIS Canada. Design Manual No. 4: Strengthening Concrete Structures with Externally Bonded Fibre Reinforced Polymers; ISIS: Winnipeg, MB, Canada, 2007. [Google Scholar]

- Zhou, J.K.; Hao, Z.-H.; Zeng, J.J.; Feng, S.-Z.; Liang, Q.J.; Zhao, B.; Feng, R.; Zhuge, Y. Durability assessment of GFRP bars embedded in UHP-ECCs subjected to an accelerated aging environment with sustained loading. Constr. Build. Mater. 2024, 419, 135364. [Google Scholar] [CrossRef]

- Zeng, J.J.; Hao, Z.-H.; Liang, Q.J.; Zhuge, Y.; Liu, Y. Durability assessment of GFRP bars exposed to combined accelerated aging in alkaline solution and a constant load. Eng. Struct. 2023, 297, 116990. [Google Scholar] [CrossRef]

- Saadatmanesh, H.; Ehsani, M.R. RC beams strengthened with FRP plates. I: Experimental study. J. Struct. Eng. 1991, 117, 3417–3433. [Google Scholar]

- Saadatmanesh, H.; Ehsani, M.R. RC beams strengthened with FRP plates. II: Analysis and parametric study. J. Struct. Eng. 1991, 117, 3434–3455. [Google Scholar] [CrossRef]

- Khalifa, A.; Gold, W.J.; Nanni, A.; Abdel Aziz, M.I. Contribution of externally bonded FRP to shear capacity of RC flexural members. J. Compos. Constr. 1998, 2, 195–202. [Google Scholar] [CrossRef]

- Chaallal, O.; Shahawy, M. Performance of fiber-reinforced polymer-wrapped reinforced concrete column under combined axial-flexural. ACI Struct. J. 2000, 97, 659–668. [Google Scholar]

- Malek, A.M.; Saadatmanesh, H.; Ehsani, M.R. Prediction of failure load of R/C beams strengthened with FRP plate due to stress concentration at the plate end. ACI Struct. J. 1998, 95, 142–152. [Google Scholar] [CrossRef]

- Aidoo, J.; Harris, K.; Petrou, M. Fatigue behavior of carbon fiber reinforced polymer-strengthened concrete bridge girders. J. Compos. Constr. 2004, 8, 501–509. [Google Scholar] [CrossRef]

- De Lorenzis, L.; Miller, B.; Nanni, A. Bond of FRP laminates to concrete. ACI Mater. J. 2001, 98, 256–264. [Google Scholar]

- Al-Rousan, R.Z.; Al-Tahat, M.F. Consequence of surface preparation techniques on the bond behavior between concrete and CFRP composites. Constr. Build. Mater. 2019, 212, 362–374. [Google Scholar] [CrossRef]

- Shi, J.W.; Cao, W.H.; Wu, Z.S. Effect of adhesive properties on the bond behaviour of externally bonded FRP-to-concrete joints. Compos. Part B Eng. 2019, 177, 107365. [Google Scholar] [CrossRef]

- Chen, J.F.; Yuan, H.; Teng, J.G. Debonding failure along a softening FRP-to-concrete interface between two adjacent cracks in concrete members. Eng. Struct. 2007, 29, 259–270. [Google Scholar] [CrossRef]

- Zhang, P.; Lei, D.; Ren, Q.; He, J.; Shen, H.; Yang, Z. Experimental and numerical investigation of debonding process of the FRP plate-concrete interface. Constr. Build. Mater. 2020, 235, 117457. [Google Scholar] [CrossRef]

- Yao, J.; Teng, J.G.; Chen, J.F. Experimental study on FRP-to-concrete bonded joints. Compos. Part B Eng. 2005, 36, 99–113. [Google Scholar] [CrossRef]

- Wu, Y.F.; Jiang, C. Quantification of bond-slip relationship for externally bonded FRP-to-concrete joints. J. Compos. Constr. 2013, 17, 673–686. [Google Scholar] [CrossRef]

- Lu, X.Z.; Teng, J.G.; Ye, L.P.; Jiang, J.J. Bond–slip models for FRP sheets/plates bonded to concrete. Eng. Struct. 2005, 27, 920–937. [Google Scholar] [CrossRef]

- Biscaia, H.C.; Chastre, C.; Silva, M.A.G. Linear and nonlinear analysis of bond-slip models for interfaces between FRP composites and concrete. Compos. Part B Eng. 2013, 45, 1554–1568. [Google Scholar] [CrossRef]

- Pan, J.; Wu, Y.F. Analytical modeling of bond behavior between FRP plate and concrete. Compos. Part B Eng. 2014, 61, 17–25. [Google Scholar] [CrossRef]

- Wang, J. Debonding of FRP-plated reinforced concrete beam, a bond-slip analysis. I. Theoretical formulation. Int. J. Solids Struct. 2006, 43, 6649–6664. [Google Scholar] [CrossRef]

- Ascione, F.; Napoli, A.; Realfonzo, R. Interface bond between FRP systems and substrate: Analytical modeling. Compos. Struct. 2021, 257, 112942. [Google Scholar] [CrossRef]

- Calabrese, S.A.; Colombi, P.; D’Antino, T. Analytical solution of the bond behavior of FRCM composites using a rigid-softening cohesive material law. Compos. Part B Eng. 2019, 174, 107051. [Google Scholar] [CrossRef]

- Ferracuti, B.; Savoia, M.; Mazzotti, C. Interface law for FRP–concrete delamination. Compos. Struct. 2007, 80, 523–533. [Google Scholar] [CrossRef]

- Täljsten, B. Strengthening of concrete prisms using the plate-bonding technique. Int. J. Fract. 1996, 82, 253–266. [Google Scholar] [CrossRef]

- Achintha, P.M.M.; Burgoyne, C.J. Fracture mechanics of plate debonding. J. Compos. Constr. 2008, 12, 396–404. [Google Scholar] [CrossRef][Green Version]

- Leung, C.K.Y.; Yang, Y. Energy-based modeling approach for debonding of FRP plate from concrete substrate. J. Eng. Mech. 2006, 132, 583–593. [Google Scholar] [CrossRef]

- Carpinteri, A.; Cornetti, P.; Pugno, N. Edge debonding in FRP strengthened beams: Stress versus energy failure criteria. Eng. Struct. 2009, 31, 2436–2447. [Google Scholar] [CrossRef]

- Gunes, O.; Buyukozturk, O.; Karaca, E. A fracture-based model for FRP debonding in strengthened beams. Eng. Fract. Mech. 2009, 76, 1897–1909. [Google Scholar] [CrossRef]

- Arduini, M.; Di Tommaso, A.; Nanni, A. Brittle failure in FRP plate and sheet bonded beams. ACI Struct. J. 1997, 94, 363–370. [Google Scholar] [CrossRef] [PubMed]

- Diab, H.M.; Farghal, O.A. Bond strength and effective bond length of FRP sheets/plates bonded to concrete considering the type of adhesive layer. Compos. Part B Eng. 2014, 58, 618–624. [Google Scholar] [CrossRef]

- Atunbi, E.O.; Lloyd, A.; Bischoff, P.H. Effective bond length of CFRP sheets externally bonded to reinforced concrete. Build. Tomorrow’s Soc. 2018, 167, 726–738. [Google Scholar]

- Ueda, T.; Dai, J. Interface bond between FRP sheets and concrete substrates: Properties, numerical modeling and roles in member behaviour. Prog. Struct. Eng. Mater. 2005, 7, 27–43. [Google Scholar] [CrossRef]

- Hosseini, A.; Mostofinejad, D. Effective bond length of FRP-to-concrete adhesively-bonded joints: Experimental evaluation of existing models. Int. J. Adhes. Adhes. 2014, 48, 150–158. [Google Scholar] [CrossRef]

- Machello, C.; Rahmati, M.; Bazli, M.; Rajabipour, A.; Arashpour, M.; Hassanli, R.; Shakiba, M. Machine learning-based prediction of bond performance of FRP composite bars in concrete for marine composite structures. Compos. Struct. 2025, 370, 119401. [Google Scholar] [CrossRef]

- Zhang, P.F.; Zhang, D.; Zhao, X.L.; Zhao, X.; Iqbal, M.; Tuerxunmaimaiti, Y.; Zhao, Q. Natural language processing-based deep transfer learning model across diverse tabular datasets for bond strength prediction of composite bars in concrete. Comput.-Aided Civ. Infrastruct. Eng. 2025, 40, 917–939. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitsopoulou, N.; Kattis, M. Mechanics of Interfacial Debonding in FRP Strengthening Systems: Energy Limits and Characteristic Bond Lengths. J. Compos. Sci. 2025, 9, 412. https://doi.org/10.3390/jcs9080412

Mitsopoulou N, Kattis M. Mechanics of Interfacial Debonding in FRP Strengthening Systems: Energy Limits and Characteristic Bond Lengths. Journal of Composites Science. 2025; 9(8):412. https://doi.org/10.3390/jcs9080412

Chicago/Turabian StyleMitsopoulou, Nefeli, and Marinos Kattis. 2025. "Mechanics of Interfacial Debonding in FRP Strengthening Systems: Energy Limits and Characteristic Bond Lengths" Journal of Composites Science 9, no. 8: 412. https://doi.org/10.3390/jcs9080412

APA StyleMitsopoulou, N., & Kattis, M. (2025). Mechanics of Interfacial Debonding in FRP Strengthening Systems: Energy Limits and Characteristic Bond Lengths. Journal of Composites Science, 9(8), 412. https://doi.org/10.3390/jcs9080412