Material Removal in Mycelium-Bonded Composites Through Laser Processing

Abstract

1. Introduction

- Overcoming the technical limitations of MBCs, which currently do not meet all industrial standards [10].

- Increasing applicability beyond artistic installations, such as textiles, furniture, wall coverings, electronics device casings, thermal insulation materials, etc. Implementation barriers for these materials still need to be understood and investigated to assess the feasibility of these applications or what further research and development are required to enable the use of MBCs in creating commercial products [11,12].

- Enhancing cost-effectiveness of MBCs in replacing conventional engineering materials, especially plastics [13].

2. Materials and Methods

2.1. Materials

2.2. Methods

- —the proposed Material Loss Index.

- —the function describing the measured profile of the engraving (represented by the red line in Figure 2).

- —the function describing the reference surface (blue line), which, for convenience in depth measurements, is assumed to be 0.

- and —the start and end points of the engraved region along the measurement path (5 mm/5000 μm in this study).

3. Results and Analysis

3.1. Material Loss Index

3.1.1. Trials A and C

3.1.2. Trial B

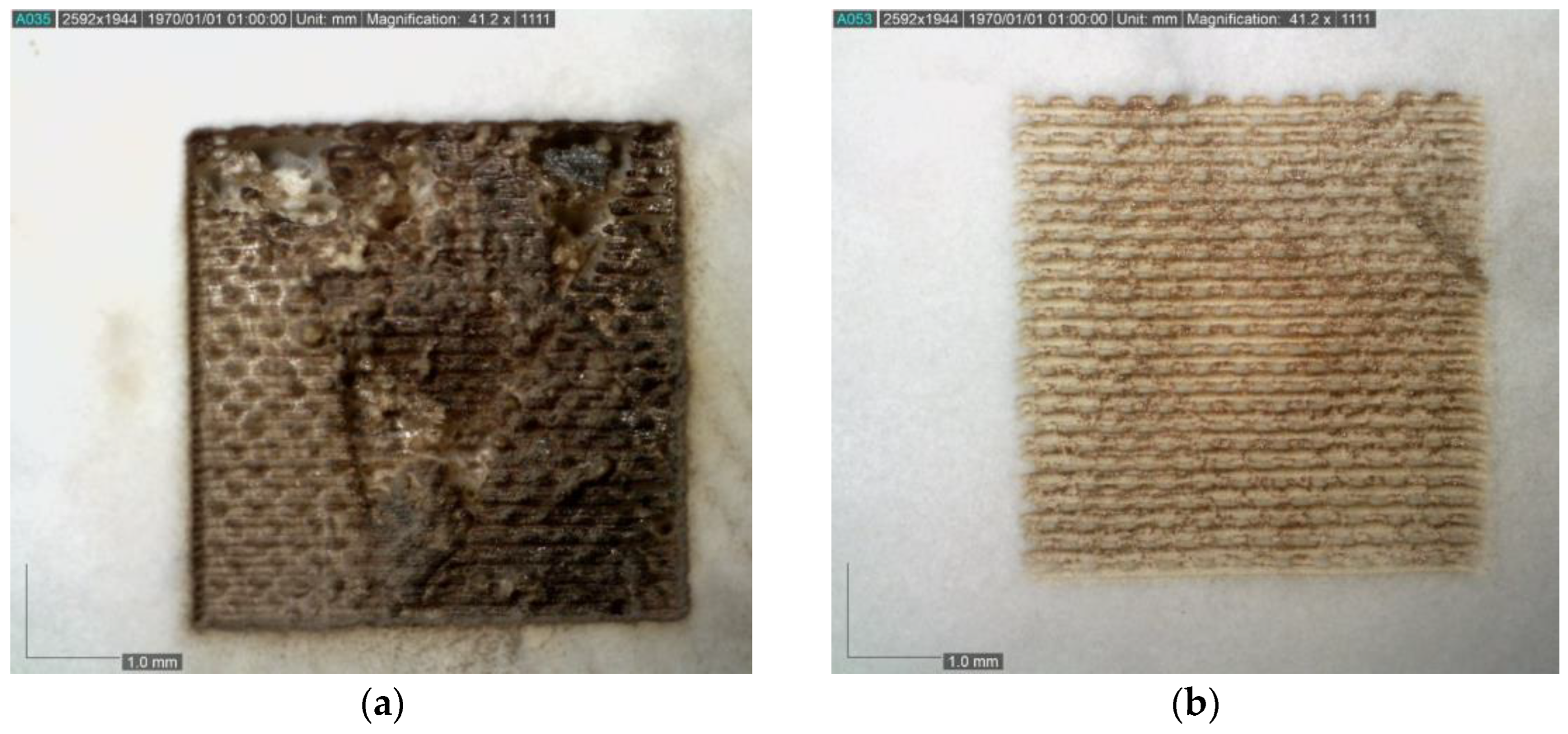

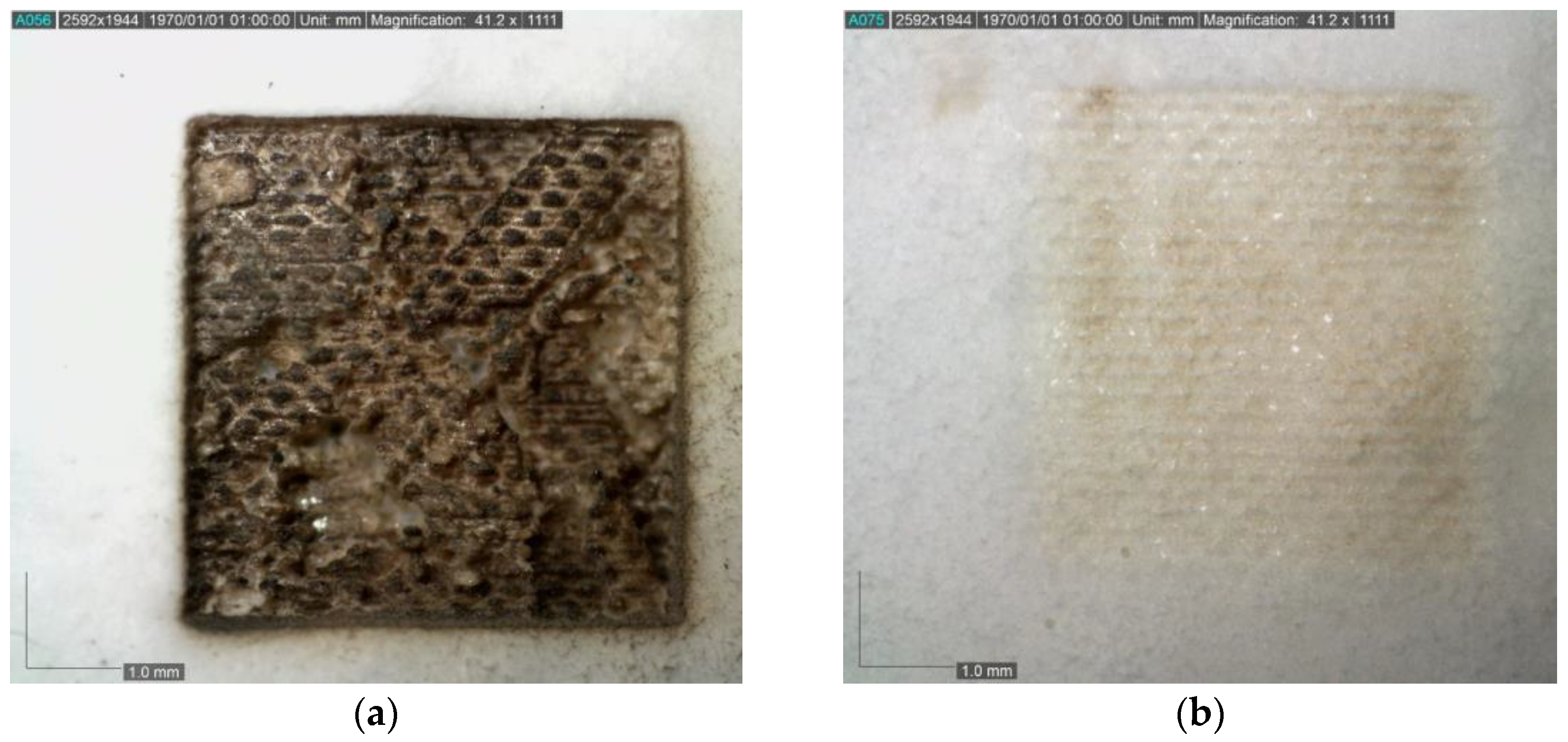

- Higher laser power resulted in more visible engravings with a distinct, blackened outline due to burning, observed in both focused (Sample A) and defocused (Sample C) conditions. As laser power decreased, the visibility and depth of the engravings diminished, eventually reaching a point where material loss was negligible and the engraving became indiscernible. Slower laser head speeds led to greater burn and deeper engravings, attributable to prolonged exposure to the laser beam.

- A linear relationship was observed between laser power and the Material Loss Index () in both Trials A and C. A linear relationship was also found between laser head speed and the IML in Trial B.

4. Discussion

- Consistent appearance across batches of MBCs, regardless of minor variations in the surface topography of the raw composite.

- Reproduction of specific functional patterns (e.g., to improve adhesion for gluing or painting).

- Objective assessment of the quality and thickness of the fungal skin on the surface of the mycelium-based composite.

- Integration into automated or robotic manufacturing workflows during MBC production, characteristic of Industry 4.0 practices [22].

- Replacement of plastic in packaging applications, with customizable branding and informational labeling. This aligns with the growing trend toward biodegradable materials in disposable packaging [23].

- Development of sustainable furniture lines featuring intricate engravings, leveraging laser technology that has long been adopted in the furniture industry [24],

- Implementing environmentally friendly and energy-efficient materials for thermal and acoustic insulation, including use as wall and ceiling coverings, aided by the increasing popularity of laser engraving in the construction sector [25].

- Incorporation of laser-processed biocomposites as product components in textiles, electronics, and consumer goods, supported by laser marking and engraving techniques widely used for materials like wood, leather, and fabrics [26].

- Production of biodegradable pots and other ecological products with customized designs or functional markings for use in agriculture and horticulture [27].

5. Conclusions

- The increasing laser power enhances the material removal rate, leading to more pronounced and deeper engravings. However, when the laser beam is defocused, the intensity of material removal diminishes noticeably. This reduction occurs because a defocused beam spreads energy over a larger area, lowering the energy density required to reach the material’s ablation or vaporization threshold. In contrast, a focused laser beam concentrates thermal energy more effectively, enabling it to consistently meet and exceed this threshold across the entire irradiated zone. Consequently, focused laser processing achieves superior control and efficiency in material removal, making it the preferred configuration for engraving mycelium-bonded composites.

- Based on our observations, a laser power around 20–25 W with a focused beam (zero defocus) and a carefully selected feed rate (e.g., around 1.5–2.0 m/s to avoid excessive burning as seen at very low speeds) appears to offer a promising balance for effective material removal while minimizing charring and optimizing surface quality in mycelium-based composites studied.

- The quality of the laser beam focus is more critical than the power in the engraving of myco-composites. Although increasing laser power contributes to a higher material removal rate, this effect is significantly more pronounced when the beam is properly focused. These findings highlight the importance of precise beam control and focus in achieving optimal engraving results; however, the uneven surface of the myco-composite presents a significant challenge for accurate focus adjustment.

- Optimizing the laser feed rate is crucial for balancing material removal and surface quality in mycelium-based composites. While slower speeds increase dwell time and enhance ablation, excessively low speeds lead to thermal overload, resulting in burning and surface degradation. Therefore, precise control of energy input per unit area—through careful laser power and feed rate adjustment—is essential to achieve effective and clean engraving without exceeding the material’s thermal tolerance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bayer, E.; McIntyre, G.; Swersey, B.L. Method for Producing Grown Materials and Products Made Thereby. U.S. Patent 9,485,917 B2, 8 November 2016. (Filed 12 December 2007, and published as US 2008/0145577 A1 on 19 June 2008). [Google Scholar]

- Armstrong, R. The Post-Epistemological Details of Oceanic Ontologies. Archit. Des. 2014, 84, 112–117. [Google Scholar] [CrossRef]

- Holt, G.A.; Mcintyre, G.; Flagg, D.; Bayer, E.; Wanjura, J.D.; Pelletier, M.G. Fungal Mycelium and Cotton Plant Materials in the Manufacture of Biodegradable Molded Packaging Material: Evaluation Study of Select Blends of Cotton Byproducts. J. Biobased Mat. Bioenergy 2012, 6, 431–439. [Google Scholar] [CrossRef]

- Rapp, R. On Mycohuman Performances: Fungi in Current Artistic Research. Fungal. Biol. Biotechnol. 2019, 6, 22. [Google Scholar] [CrossRef] [PubMed]

- Abhijith, R.; Ashok, A.; Rejeesh, C.R. Sustainable Packaging Applications from Mycelium to Substitute Polystyrene: A Review. Mater. Today Proc. 2018, 5, 2139–2145. [Google Scholar] [CrossRef]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered Mycelium Composite Construction Materials from Fungal Biorefineries: A Critical Review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Rashdan, W.; Fathy Ashour, A. “Growing Design”: The Role of Mycelium-Based Materials in Interior and Furniture Design. Int. J. Des. Objects 2024, 18, 37–62. [Google Scholar] [CrossRef]

- Wattanavichean, N.; Phanthuwongpakdee, J.; Koedrith, P.; Laoratanakul, P.; Thaithatgoon, B.; Somrithipol, S.; Kwantong, P.; Nuankaew, S.; Pinruan, U.; Chuaseeharonnachai, C.; et al. Mycelium-Based Breakthroughs: Exploring Commercialization, Research, and Next-Gen Possibilities. Circ. Econ. Sust. 2025, 1–43. [Google Scholar] [CrossRef]

- Chayaamor-Heil, N.; Houette, T.; Demirci, Ö.; Badarnah, L. The Potential of Co-Designing with Living Organisms: Towards a New Ecological Paradigm in Architecture. Sustainability 2024, 16, 673. [Google Scholar] [CrossRef]

- Le Ferrand, H. Critical Review of Mycelium-Bound Product Development to Identify Barriers to Entry and Paths to Overcome Them. J. Clean. Prod. 2024, 450, 141859. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; De Laet, L. Mechanical, Physical and Chemical Characterisation of Mycelium-Based Composites with Different Types of Lignocellulosic Substrates. PLoS ONE 2019, 14, e0213954. [Google Scholar] [CrossRef] [PubMed]

- Appels, F.V.W.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.B.; Dijksterhuis, J.; Krijgsheld, P.; Wösten, H.A.B. Fabrication Factors Influencing Mechanical, Moisture- and Water-Related Properties of Mycelium-Based Composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Jones, M.; Huynh, T.; Dekiwadia, C.; Daver, F.; John, S. Mycelium Composites: A Review of Engineering Characteristics and Growth Kinetics. J. Bionanosci. 2017, 11, 241–257. [Google Scholar] [CrossRef]

- Bonenberg, A.; Sydor, M.; Cofta, G.; Doczekalska, B.; Grygorowicz-Kosakowska, K. Mycelium-Based Composite Materials: Study of Acceptance. Materials 2023, 16, 2164. [Google Scholar] [CrossRef] [PubMed]

- Lewandowska, A.; Bonenberg, A.; Sydor, M. Mycelium-Based Composites: Surveying Their Acceptance by Professional Architects. Biomimetics 2024, 9, 333. [Google Scholar] [CrossRef] [PubMed]

- Kúdela, J.; Andrejko, M.; Kubovský, I. The Effect of CO2 Laser Engraving on the Surface Structure and Properties of Spruce Wood. Coatings 2023, 13, 2006. [Google Scholar] [CrossRef]

- Gusts, A.S.; Adijāns, I. Investigation of Laser Texturing Parameters and Their Impact on Glue Adhesion Properties on the Surface of Birch Plywood. In Proceedings of the 15th International Scientific and Practical Conference, Rezekne, Latvia, 22 June 2024; Rezekne Academy of Technologies: Rēzekne, Latvia, 2024; Volume 3, pp. 387–392. [Google Scholar]

- Lazov, L.; Deneva, H.; Narica, P. Laser Marking Methods. In Proceedings of the International Scientific and Practical Conference, Rezekne, Latvia, 16 June 2015; Rezekne Academy of Technologies: Rēzekne, Latvia, 2015; Volume 1, pp. 108–115. [Google Scholar]

- Ganeev, R.A. Laser-Surface Interactions; SpringerLink Bücher; Springer Dordrecht: Dordrecht, The Netherlands, 2014; ISBN 978-94-007-7340-0. [Google Scholar] [CrossRef]

- Jurek, M.; Wagnerová, R. Laser Beam Calibration for Wood Surface Colour Treatment. Eur. J. Wood. Prod. 2021, 79, 1097–1107. [Google Scholar] [CrossRef]

- Camere, S.; Karana, E. Fabricating Materials from Living Organisms: An Emerging Design Practice. J. Clean. Prod. 2018, 186, 570–584. [Google Scholar] [CrossRef]

- Nath, A.K.; Sarkar, S.; Muvvala, G.; Karmakar, D.P.; Chakraborty, S.S.; Mullick, S.; Madhukar, Y.K. LASER-Based Manufacturing as a Green Manufacturing Process. In Sustainable Material Forming and Joining; Narayanan, R.G., Gunasekera, J.S., Eds.; CRC Press: Boca Raton, FL, USA, 2019; pp. 303–365. ISBN 978-1-315-16314-7. [Google Scholar]

- Reichert, C.L.; Bugnicourt, E.; Coltelli, M.-B.; Cinelli, P.; Lazzeri, A.; Canesi, I.; Braca, F.; Martínez, B.M.; Alonso, R.; Agostinis, L.; et al. Bio-Based Packaging: Materials, Modifications, Industrial Applications and Sustainability. Polymers 2020, 12, 1558. [Google Scholar] [CrossRef] [PubMed]

- Wieloch, G.; Pohl, P. Use of Lasers in the Furniture Industry. In Proceedings of the Research Trends, Instrumentation, and Applications in Metrology and Materials Processing, Szczecin-Świnoujście, Poland, 1 March 1995; Society of Photo Optical Instrumentation Engineers: Szczecin-Świnoujście, Poland, 1995; Volume 2202, pp. 604–607. [Google Scholar]

- Mehra, R.; Mohal, S.; Singh, H.; Chaubey, S.K. Investigations on Machining of Hybrid Glass Fiber-Reinforced Polymer Using Laser Engraving Machine. J. Materi. Eng. Perform. 2025. [Google Scholar] [CrossRef]

- Angelova, Y.P. Factors Influencing the Laser Treatment of Textile Materials: An Overview. J. Eng. Fiber. Fabr. 2020, 15, 1558925020952803. [Google Scholar] [CrossRef]

- Hall, C.R.; Campbell, B.L.; Behe, B.K.; Yue, C.; Lopez, R.G.; Dennis, J.H. The Appeal of Biodegradable Packaging to Floral Consumers. HortScience 2010, 45, 583–591. [Google Scholar] [CrossRef]

| Test No. | (W) | (m/s) |

|---|---|---|

| 1 | 50 | 2.24 |

| 2 | 45 | |

| 3 | 40 | |

| 4 | 35 | |

| 5 | 30 | |

| 6 | 25 | |

| 7 | 20 | |

| 8 | 15 | |

| 9 | 10 | |

| 10 | 5 |

| Test No. | (W) | (m/s) |

|---|---|---|

| 1 | 50 | 2.24 |

| 2 | 2.10 | |

| 3 | 1.96 | |

| 4 | 1.82 | |

| 5 | 1.68 | |

| 6 | 1.54 | |

| 7 | 1.40 | |

| 8 | 1.26 | |

| 9 | 1.12 | |

| 10 | 0.98 |

| Test No. | (W) | (m/s) | Leaser Defocusing (mm) |

|---|---|---|---|

| 1 | 50 | 2.24 | 1 |

| 2 | 45 | ||

| 3 | 40 | ||

| 4 | 35 | ||

| 5 | 30 | ||

| 6 | 25 | ||

| 7 | 20 | ||

| 8 | 15 | ||

| 9 | 10 | ||

| 10 | 5 |

| (W) | (mm2) | |

|---|---|---|

| Sample A | Sample C (Laser Defocused by 1 mm) | |

| 50 | 2.39 | 1.85 |

| 45 | 2.26 | 0.99 |

| 40 | 1.61 | 0.87 |

| 35 | 1.08 | 0.64 |

| 30 | 0.94 | 0.49 |

| 25 | 0.10 | 0.54 |

| 20 | 0.35 | 0.01 |

| 15 | 0 | 0 |

| 10 | 0 | 0 |

| 5 | 0 | 0 |

| (m/s) | (mm2) |

|---|---|

| 2.24 | 1.21 |

| 2.1 | 1.50 |

| 1.96 | 1.83 |

| 1.82 | 1.69 |

| 1.68 | 1.89 |

| 1.54 | 2.22 |

| 1.4 | 2.31 |

| 1.26 | 2.37 |

| 1.12 | 3.04 |

| 0.98 | 2.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sydor, M.; Pinkowski, G.; Bonenberg, A. Material Removal in Mycelium-Bonded Composites Through Laser Processing. J. Compos. Sci. 2025, 9, 389. https://doi.org/10.3390/jcs9080389

Sydor M, Pinkowski G, Bonenberg A. Material Removal in Mycelium-Bonded Composites Through Laser Processing. Journal of Composites Science. 2025; 9(8):389. https://doi.org/10.3390/jcs9080389

Chicago/Turabian StyleSydor, Maciej, Grzegorz Pinkowski, and Agata Bonenberg. 2025. "Material Removal in Mycelium-Bonded Composites Through Laser Processing" Journal of Composites Science 9, no. 8: 389. https://doi.org/10.3390/jcs9080389

APA StyleSydor, M., Pinkowski, G., & Bonenberg, A. (2025). Material Removal in Mycelium-Bonded Composites Through Laser Processing. Journal of Composites Science, 9(8), 389. https://doi.org/10.3390/jcs9080389