Comprehensive Experimental Optimization and Image-Driven Machine Learning Prediction of Tribological Performance in MWCNT-Reinforced Bio-Based Epoxy Nanocomposites

Abstract

1. Introduction

2. Background Study

2.1. Tribological Performance of MWCNT-Reinforced Epoxy Composites

2.2. Morphological Analysis Using SEM and AFM

2.3. Predictive Modeling in Tribology

3. Materials and Methods

3.1. Materials

3.2. Composite Preparation

3.3. Wear Testing

3.4. Surface Characterization (SEM and AFM Analysis)

3.5. Experimental Design—Taguchi Methodology

3.6. Software and Tools Used

4. Results and Discussion

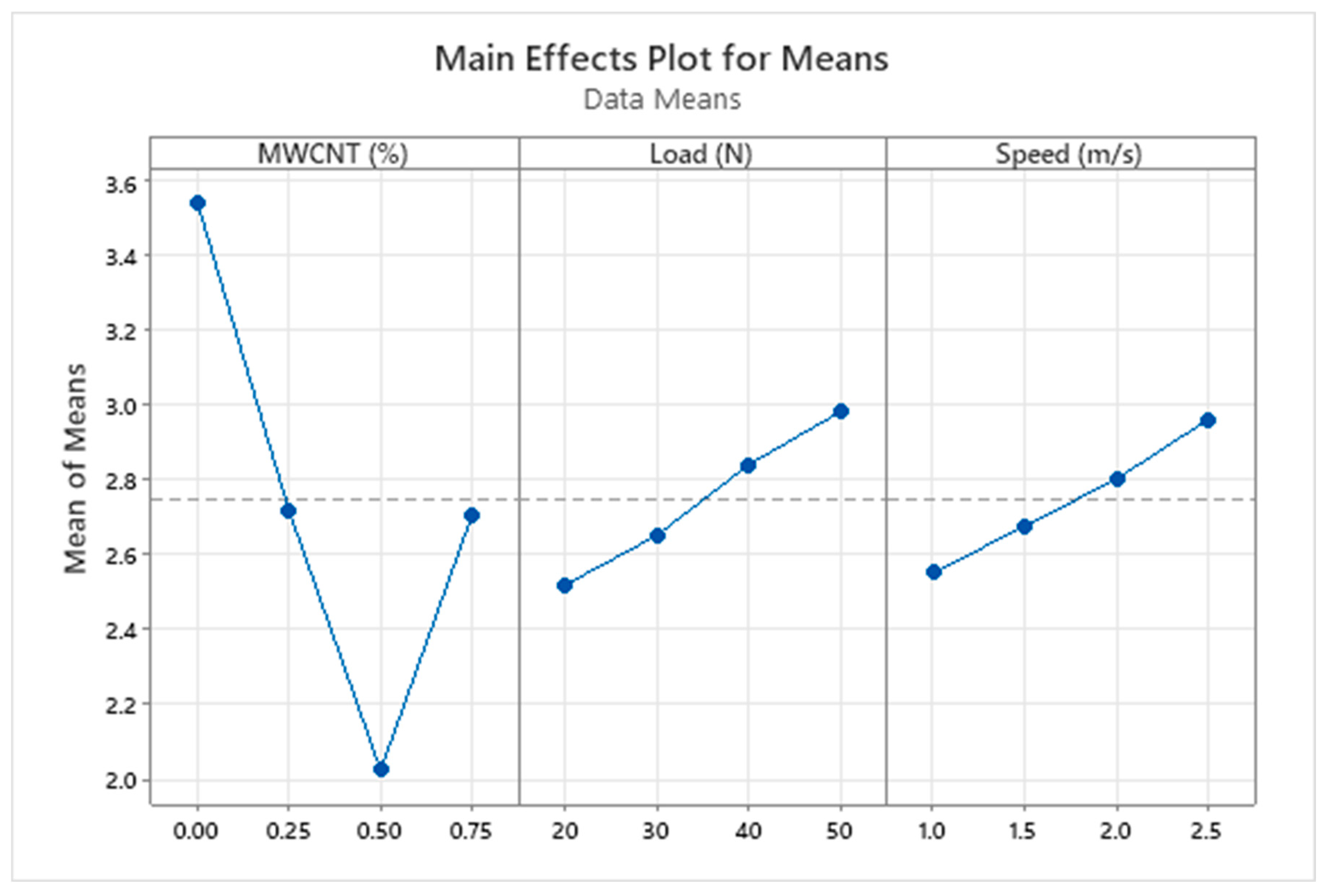

4.1. Taguchi Analysis

4.2. ANOVA and Factor Significance Analysis

4.3. Matrix Plot Analysis

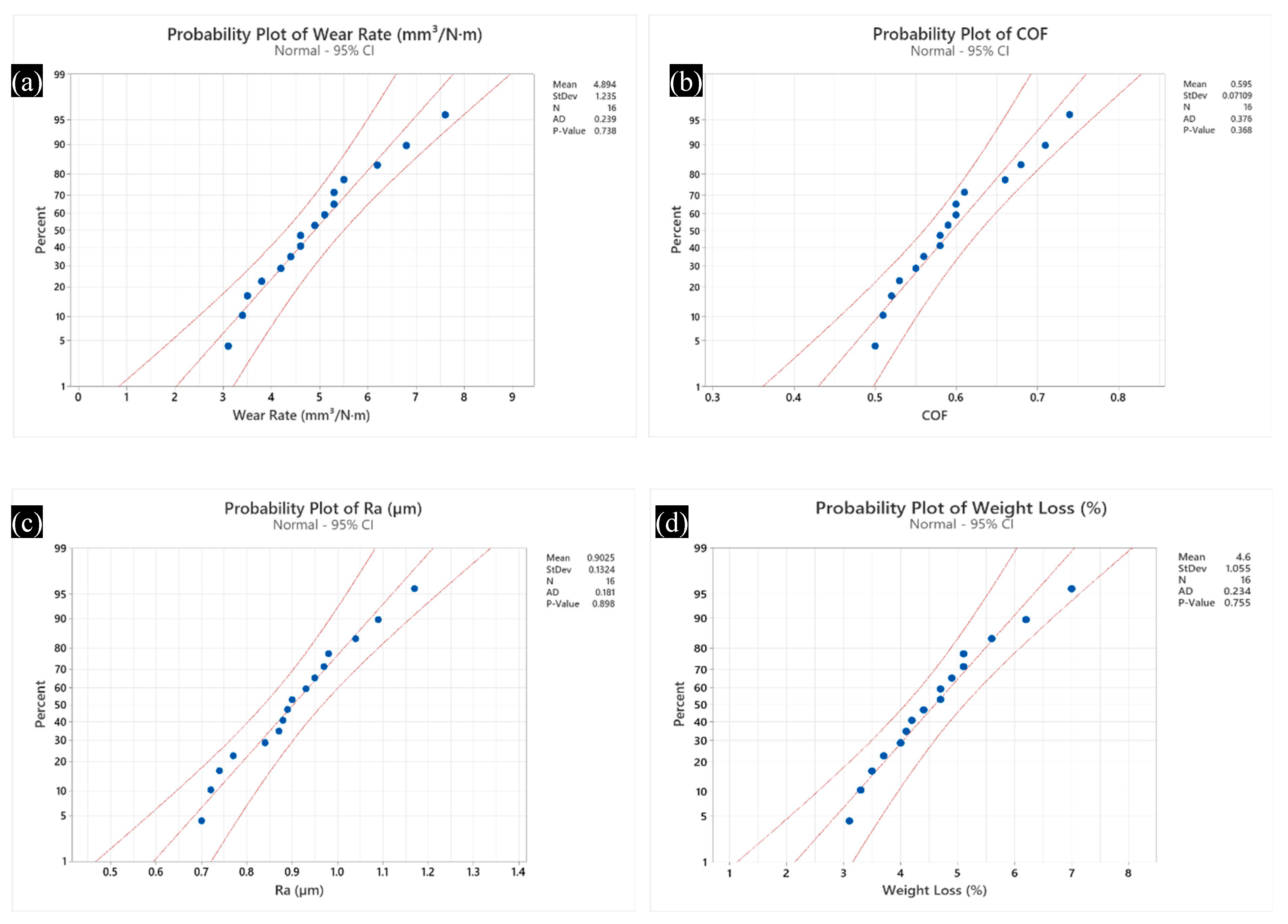

4.4. Normality Assessment of Responses

4.5. Empirical CDF Analysis

4.6. SEM and AFM Analysis

4.7. Mathematical Modeling of Wear Behavior

4.7.1. Linear and Polynomial Regression Analysis

4.7.2. Polynomial Regression Model (Quadratic)

4.7.3. Multiple Linear Regression (MLR) Analysis

4.7.4. Model Performance Evaluation

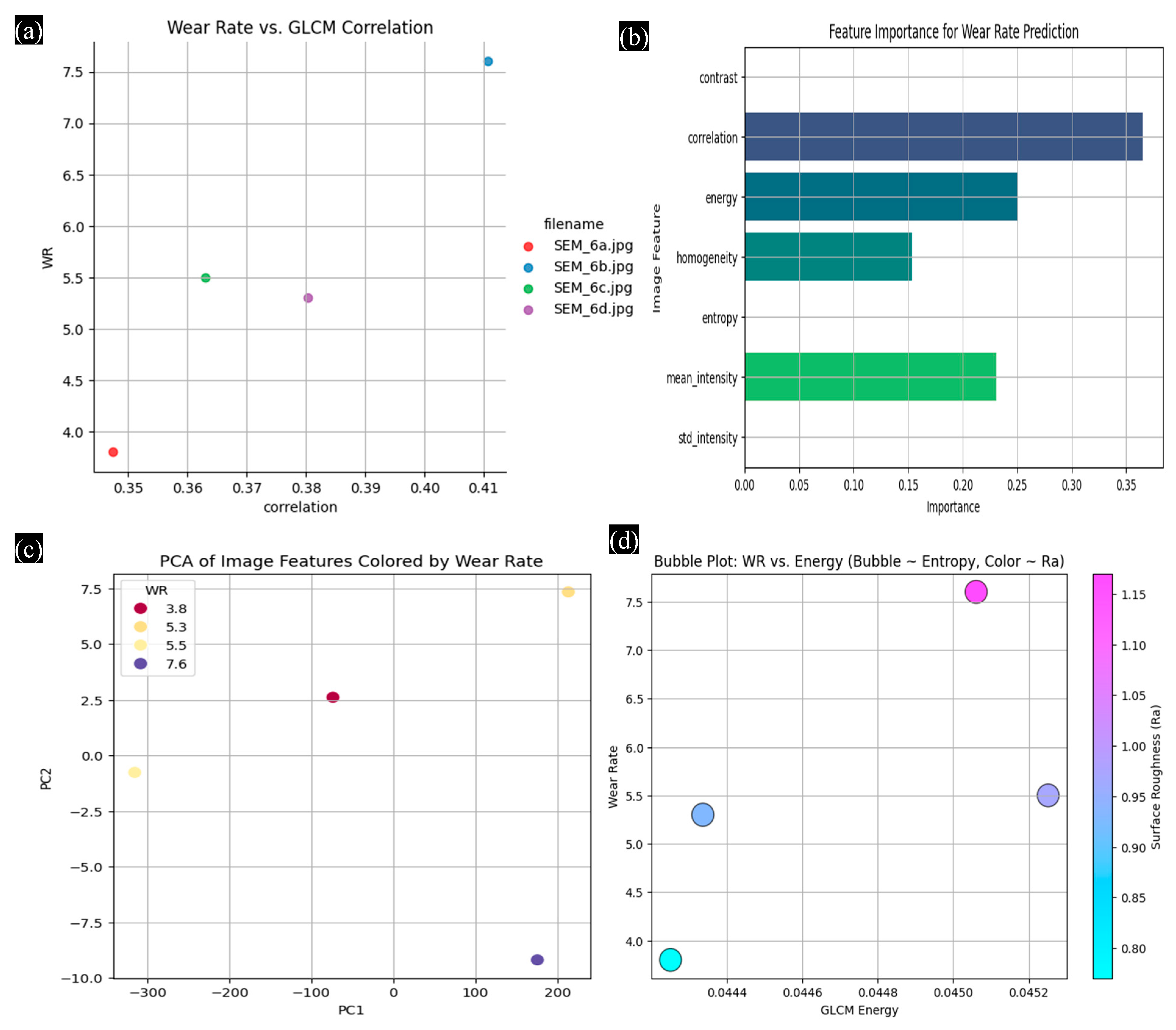

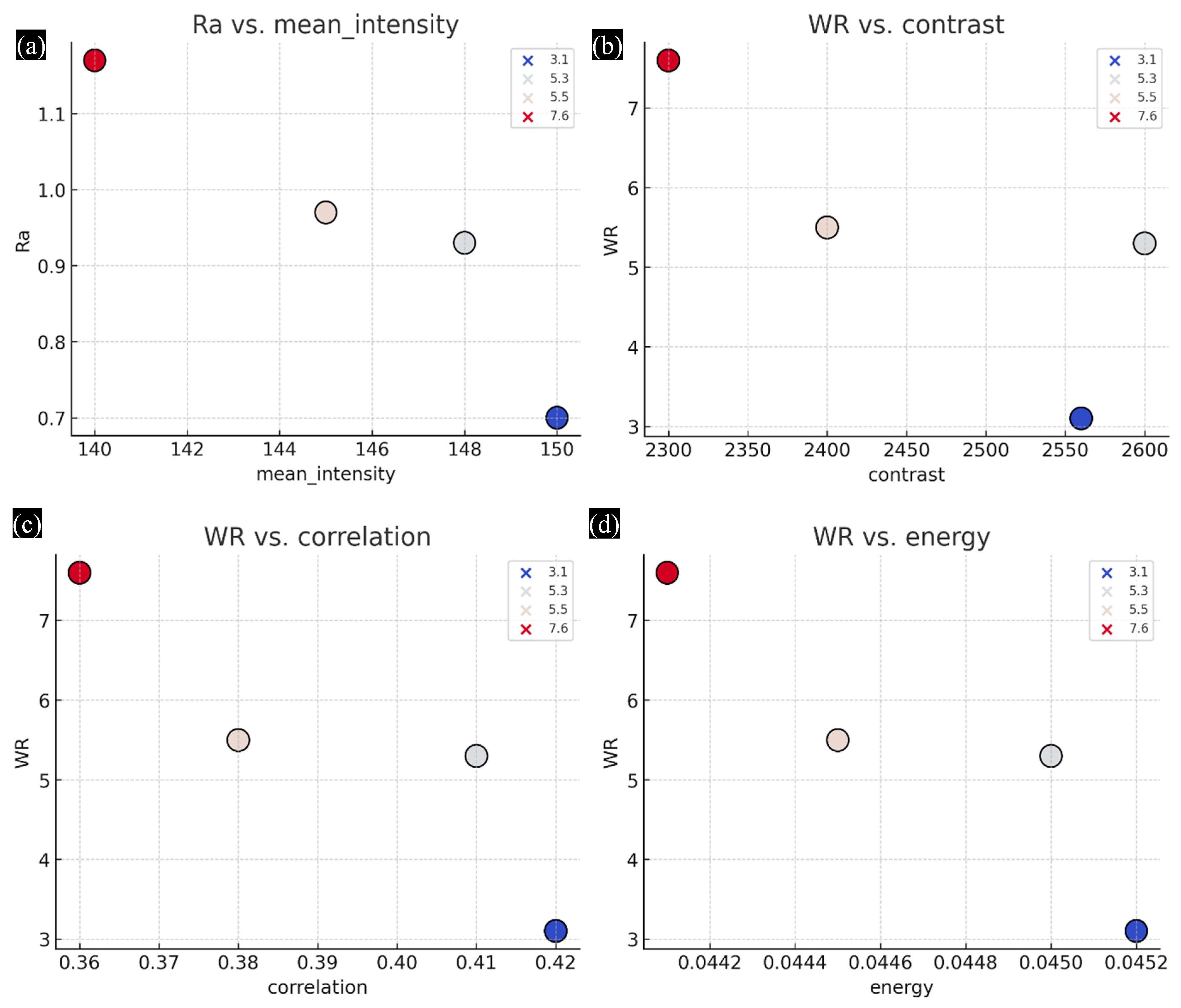

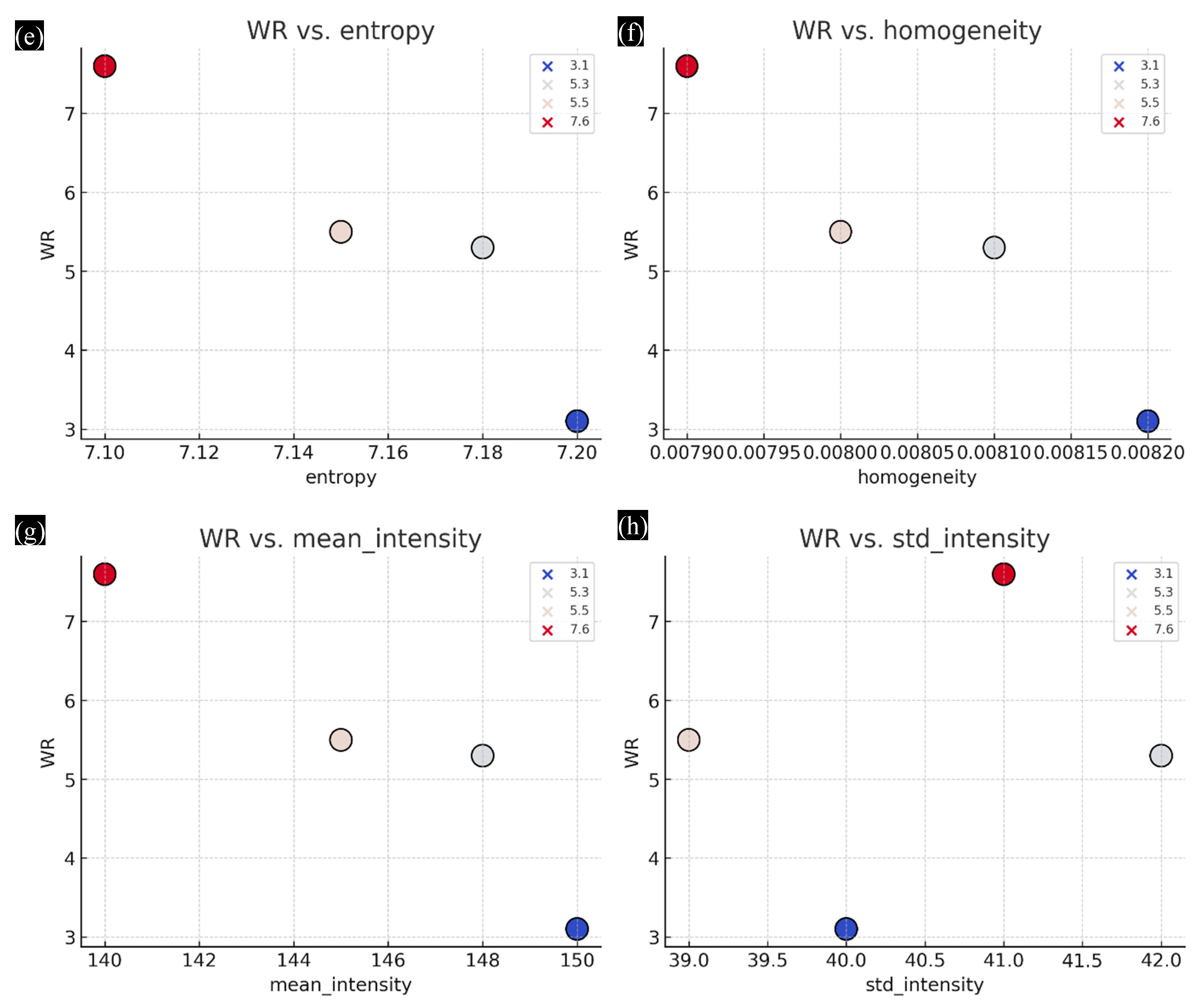

4.8. Image-Based Feature Modeling and Wear Behavior Analysis in Filler-Reinforced Polymers

5. Conclusions

5.1. Taguchi Analysis

5.2. Mathematical Modeling

5.3. Image Processing and Machine Learning-Based Modeling

5.4. Cross-Comparison and Insights

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Babu, R.P.; O’Connor, K.; Seeram, R. Current progress on bio-based polymers and their future trends. Prog. Biomater. 2013, 2, 8. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, F.A.M.M.; Santos, M.; Cernadas, T.; Ferreira, P.; Alves, P. Advances in the development of biobased epoxy resins: Insight into more sustainable materials and future applications. Int. Mater. Rev. 2022, 67, 119–149. [Google Scholar] [CrossRef]

- George, J.S.; Uthaman, A.; Reghunadhan, A.; Lal, H.M.; Thomas, S.; Vijayan, P.P. Bioderived thermosetting polymers and their nanocomposites: Current trends and future outlook. Emergent Mater. 2022, 5, 3–27. [Google Scholar] [CrossRef]

- Prasannakumar, P.; Sankarannair, S.; Prasad, G.; H., H.K.P.; S., P.; P., V.; S., S.; Shanmugam, R. Bio-based additives in lubricants: Addressing challenges and leveraging for improved performance toward sustainable lubrication. Biomass Convers. Biorefinery 2025, 15, 17969–17997. [Google Scholar] [CrossRef]

- Fekiač, J.J.; Krbata, M.; Kohutiar, M.; Janík, R.; Kakošová, L.; Breznická, A.; Eckert, M.; Mikuš, P. Comprehensive Review: Optimization of Epoxy Composites, Mechanical Properties, & Technological Trends. Polymers 2025, 17, 271. [Google Scholar] [CrossRef] [PubMed]

- Ye, W.; Shi, Y.; Zhou, Q.; Xie, M.; Wang, H.; Bou-Saïd, B.; Liu, W. Recent advances in self-lubricating metal matrix nanocomposites reinforced by carbonous materials: A review. Nano Mater. Sci. 2024, 6, 701–713. [Google Scholar] [CrossRef]

- Wang, R.; Xiong, Y.; Yang, K.; Zhang, T.; Zhang, F.; Xiong, B.; Hao, Y.; Zhang, H.; Chen, Y.; Tang, J. Advanced progress on the significant influences of multi-dimensional nanofillers on the tribological performance of coatings. RSC Adv. 2023, 13, 19981–20022. [Google Scholar] [CrossRef] [PubMed]

- Singh, M.; Dodla, S.; Gautam, R.K.; Chauhan, V. Enhancement of mechanical and tribological properties in glass fiber-reinforced polymer composites with multi-walled carbon nanotubes and ANN-based COF prediction. Compos. Interfaces 2024, 32, 439–459. [Google Scholar] [CrossRef]

- Sallakhniknezhad, R.; Ahmadian, H.; Zhou, T.; Weijia, G.; Anantharajan, S.K.; Sadoun, A.M.; Abdelfattah, W.M.; Fathy, A. Recent Advances and Applications of Carbon Nanotubes (CNTs) in Machining Processes: A Review. J. Manuf. Mater. Process. 2024, 8, 282. [Google Scholar] [CrossRef]

- Ujah, C.O.; Von Kallon, D.V.; Aigbodion, V.S. Tribological Properties of CNTs-Reinforced Nano Composite Materials. Lubricants 2023, 11, 95. [Google Scholar] [CrossRef]

- Obada, D.O.; Salami, K.A.; Oyedeji, A.N.; Osuchukwu, O.A.; Abass, J.; Ogwuche, C.; Bansod, N.D.; Ubgaja, M.I.; Ibrahim, I.U.; Abdulkareem, B.; et al. Mechanical and frictional properties of coconut husk powder reinforced polymer immersed in a simulated acidic medium for oil/gas applications. Heliyon 2024, 10, e25026. [Google Scholar] [CrossRef] [PubMed]

- Shah, M.; Ullah, A.; Azher, K.; Rehman, A.U.; Juan, W.; Aktürk, N.; Tüfekci, C.S.; Salamci, M.U. Vat photopolymerization-based 3D printing of polymer nanocomposites: Current trends and applications. RSC Adv. 2023, 13, 1456–1496. [Google Scholar] [CrossRef] [PubMed]

- Karthikeyan, N.; Naveen, J. Progress in adhesive-bonded composite joints: A comprehensive review. J. Reinf. Plast. Compos. 2024, 07316844241248236. [Google Scholar] [CrossRef]

- Abedi, M.; Fangueiro, R.; Correia, A.G. Effects of multiscale carbon-based conductive fillers on the performances of a self-sensing cementitious geocomposite. J. Build. Eng. 2021, 43, 103171. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y. Experimental and modeling analysis of mechanical-electrical behaviors of polypropylene composites filled with graphite and MWCNT fillers. Polym. Test. 2017, 63, 467–474. [Google Scholar] [CrossRef]

- Arunachalam, S.J.; Saravanan, R.; Sathish, T.; Alarfaj, A.A.; Giri, J.; Kumar, A. Enhancing mechanical performance of MWCNT filler with jute/kenaf/glass composite: A statistical optimization study using RSM and ANN. Mater. Technol. 2024, 39, 2381156. [Google Scholar] [CrossRef]

- Zhai, W.; Bai, L.; Zhou, R.; Fan, X.; Kang, G.; Liu, Y.; Zhou, K. Recent Progress on Wear-Resistant Materials: Designs, Properties, and Applications. Adv. Sci. 2021, 8, 2003739. [Google Scholar] [CrossRef] [PubMed]

- Hiremath, P.; Ranjan, R.; DeSouza, V.; Bhat, R.; Patil, S.; Maddodi, B.; Shivamurthy, B.; Perez, T.C.; Naik, N. Enhanced Wear Resistance in Carbon Nanotube-Filled Bio-Epoxy Composites: A Comprehensive Analysis via Scanning Electron Microscopy and Atomic Force Microscopy. J. Compos. Sci. 2023, 7, 478. [Google Scholar] [CrossRef]

- Nečas, D.; Valtr, M.; Klapetek, P. How levelling and scan line corrections ruin roughness measurement and how to prevent it. Sci. Rep. 2020, 10, 15294. [Google Scholar] [CrossRef] [PubMed]

- Bhagath, Y.B.; Lee, S.Y.; Kola, M.; Sharma, T.S.K.; Beulah, A.M.; Reddy, Y.V.M.; Park, T.J.; Park, J.P.; Sahukari, R.; Madhavi, G. Effect of Sulfamerazine on Structural Characteristics of Sodium Alginate Biopolymeric Films. Biotechnol. Bioprocess Eng. 2022, 27, 596–606. [Google Scholar] [CrossRef]

- Chan, J.X.; Wong, J.F.; Petrů, M.; Hassan, A.; Nirmal, U.; Othman, N.; Ilyas, R.A. Effect of Nanofillers on Tribological Properties of Polymer Nanocomposites: A Review on Recent Development. Polymers 2021, 13, 2867. [Google Scholar] [CrossRef] [PubMed]

- Beyanagari, S.R.; Sivalingam, A.; Kandasamy, J.; Katiyar, J.K. Influence of 2D solid lubricants on mechanical and tribological behaviour of Al 7XXX series metal matrix composites: A comprehensive review. Tribol. Mater. Surfaces Interfaces 2024, 18, 145–170. [Google Scholar] [CrossRef]

- Siddiqui, M.A.S.; Hossain, M.A.M.; Ferdous, R.; Rabbi, M.S.; Abid, S.M.S. An Extensive Review on Bibliometric Analysis of Carbon Nanostructure Reinforced Composites. Results Mater. 2025, 25, 100655. [Google Scholar] [CrossRef]

- Vinodhini, J.; Pitchan, M.K.; Bhowmik, S.; Barandun, G.A.; Jousset, P. Effect of different filler reinforcement on poly-ether-ether-ketone based nanocomposites for bearing applications. J. Compos. Mater. 2020, 54, 4709–4722. [Google Scholar] [CrossRef]

- Afolabi, O.A.; Ndou, N. Synergy of Hybrid Fillers for Emerging Composite and Nanocomposite Materials—A Review. Polymers 2024, 16, 1907. [Google Scholar] [CrossRef] [PubMed]

- Upadhyay, A.K.; Goyat, M.S.; Kumar, A. A review on the effect of oxide nanoparticles, carbon nanotubes, and their hybrid structure on the toughening of epoxy nanocomposites. J. Mater. Sci. 2022, 57, 13202–13232. [Google Scholar] [CrossRef]

- Markandan, K.; Lai, C.Q. Fabrication, properties and applications of polymer composites additively manufactured with filler alignment control: A review. Compos. Part B Eng. 2023, 256, 110661. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Steel, K.; Veidt, M.; Heitzmann, M.T. Wear behaviour of polymeric materials reinforced with man-made fibres: A comprehensive review about fibre volume fraction influence on wear performance. J. Reinf. Plast. Compos. 2022, 41, 215–241. [Google Scholar] [CrossRef]

- Shankar, D.; Jambagi, S.C. Improvements in bioactivity, blood compatibility, and wear resistance of thermally sprayed carbon nanotube reinforced hydroxyapatite-based orthopedic implants. Tribol. Int. 2024, 197, 109809. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Żelasko, W. Two-Process Random Textures: Measurement, Characterization, Modeling and Tribological Impact: A Review. Materials 2021, 15, 268. [Google Scholar] [CrossRef] [PubMed]

- Ambilkar, S.C.; Singal, T.; Das, C. Diverse role of zirconia in developing polymeric composites. Polym. Bull. 2024, 81, 6641–6670. [Google Scholar] [CrossRef]

- Singhal, V.; Shelly, D.; Saxena, A.; Gupta, R.; Verma, V.K.; Jain, A. Study of the Influence of Nanoparticle Reinforcement on the Mechanical and Tribological Performance of Aluminum Matrix Composites—A Review. Lubricants 2025, 13, 93. [Google Scholar] [CrossRef]

- Zhang, R.; Li, J.; Jerrams, S.; Hu, S.; Liu, L.; Wen, S.; Zhang, L. Constructing a fine dispersion and chemical interface based on an electrostatic self-assembly and aqueous phase compound in GO/SiO2/SBR composites to achieve high-wear resistance in eco-friendly green tires. Chem. Eng. J. 2023, 452, 139113. [Google Scholar] [CrossRef]

- Xiao, K.; Wang, W.; Wang, K.; Zhang, H.; Dong, S.; Li, J. Improving Triboelectric Nanogenerators Performance Via Interface Tribological Optimization: A Review. Adv. Funct. Mater. 2024, 34, 2404744. [Google Scholar] [CrossRef]

- Yoosefan, F.; Ashrafi, A.; Vaghefi, S.M.M. Corrosion and tribological behavior of CoCrFeMoNi high-entropy alloys as a potential vascular implant material. J. Alloys Compd. 2024, 976, 172964. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Çamur, H.; Savaş, M.A.; Abba, S.I. Optimization and prediction of tribological behaviour of filled polytetrafluoroethylene composites using Taguchi Deng and hybrid support vector regression models. Sci. Rep. 2022, 12, 10393. [Google Scholar] [CrossRef] [PubMed]

- Agunwamba, J.; Tiza, M.T.; Okafor, F. An appraisal of statistical and probabilistic models in highway pavements. Turk. J. Eng. 2024, 8, 300–329. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Irfan, S.A.; Ghazali, S.M.; Rathore, M.F.; Krolczyk, G.M.; Alsaady, A. Machine learning models for prediction and classification of tool wear in sustainable milling of additively manufactured 316 stainless steel. Results Eng. 2024, 22, 102015. [Google Scholar] [CrossRef]

- Kasiviswanathan, S.; Gnanasekaran, S.; Thangamuthu, M.; Rakkiyannan, J. Machine-Learning- and Internet-of-Things-Driven Techniques for Monitoring Tool Wear in Machining Process: A Comprehensive Review. J. Sens. Actuator Netw. 2024, 13, 53. [Google Scholar] [CrossRef]

- Yang, H.; Zheng, H.; Zhang, T. A review of artificial intelligent methods for machined surface roughness prediction. Tribol. Int. 2024, 199, 109935. [Google Scholar] [CrossRef]

- Champa-Bujaico, E.; Díez-Pascual, A.M.; Redondo, A.L.; Garcia-Diaz, P. Optimization of mechanical properties of multiscale hybrid polymer nanocomposites: A combination of experimental and machine learning techniques. Compos. Part B Eng. 2024, 269, 111099. [Google Scholar] [CrossRef]

- Anagun, Y.; Isik, S.; Olgun, M.; Sezer, O.; Basciftci, Z.B.; Arpacioglu, N.G.A. The classification of wheat species based on deep convolutional neural networks using scanning electron microscope (SEM) imaging. Eur. Food Res. Technol. 2023, 249, 1023–1034. [Google Scholar] [CrossRef]

- Li, X.; Nieber, J.L.; Kumar, V. Machine learning applications in vadose zone hydrology: A review. Vadose Zone J. 2024, 23, e20361. [Google Scholar] [CrossRef]

| Sl. No. | MWCNT (%) | Load (N) | Speed (m/s) | Wear Rate (mm3/N·m) | COF | Ra (µm) | Weight Loss (%) |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 20 | 1 | 5.3 | 0.66 | 0.98 | 4.9 |

| 2 | 0 | 30 | 1.5 | 6.2 | 0.68 | 1.04 | 5.6 |

| 3 | 0 | 40 | 2 | 6.8 | 0.71 | 1.09 | 6.2 |

| 4 | 0 | 50 | 2.5 | 7.6 | 0.74 | 1.17 | 7 |

| 5 | 0.25 | 20 | 1.5 | 4.6 | 0.59 | 0.9 | 4.2 |

| 6 | 0.25 | 30 | 1 | 4.2 | 0.58 | 0.88 | 4 |

| 7 | 0.25 | 40 | 2.5 | 5.5 | 0.61 | 0.97 | 5.1 |

| 8 | 0.25 | 50 | 2 | 5.1 | 0.6 | 0.95 | 4.7 |

| 9 | 0.5 | 20 | 2 | 3.5 | 0.52 | 0.74 | 3.5 |

| 10 | 0.5 | 30 | 2.5 | 3.8 | 0.53 | 0.77 | 3.7 |

| 11 | 0.5 | 40 | 1 | 3.1 | 0.5 | 0.7 | 3.1 |

| 12 | 0.5 | 50 | 1.5 | 3.4 | 0.51 | 0.72 | 3.3 |

| 13 | 0.75 | 20 | 2.5 | 4.4 | 0.55 | 0.84 | 4.1 |

| 14 | 0.75 | 30 | 2 | 4.6 | 0.56 | 0.87 | 4.4 |

| 15 | 0.75 | 40 | 1.5 | 4.9 | 0.58 | 0.89 | 4.7 |

| 16 | 0.75 | 50 | 1 | 5.3 | 0.6 | 0.93 | 5.1 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| MWCNT (%) | 3 | 18.382 | 80.31% | 18.382 | 6.1273 | 34.72 | 0 |

| Load (N) | 3 | 1.902 | 8.31% | 1.902 | 0.634 | 3.59 | 0.085 |

| Speed (m/s) | 3 | 1.547 | 6.76% | 1.547 | 0.5156 | 2.92 | 0.122 |

| Error | 6 | 1.059 | 4.63% | 1.059 | 0.1765 | ||

| Total | 15 | 22.889 | 100.00% |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| MWCNT (%) | 3 | 0.06965 | 91.89% | 0.06965 | 0.023217 | 54.63 | 0 |

| Load (N) | 3 | 0.00245 | 3.23% | 0.00245 | 0.000817 | 1.92 | 0.227 |

| Speed (m/s) | 3 | 0.00115 | 1.52% | 0.00115 | 0.000383 | 0.9 | 0.493 |

| Error | 6 | 0.00255 | 3.36% | 0.00255 | 0.000425 | ||

| Total | 15 | 0.0758 | 100.00% |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| MWCNT (%) | 3 | 0.23145 | 87.97% | 0.23145 | 0.07715 | 52.6 | 0 |

| Load (N) | 3 | 0.01305 | 4.96% | 0.01305 | 0.00435 | 2.97 | 0.119 |

| Speed (m/s) | 3 | 0.0098 | 3.72% | 0.0098 | 0.003267 | 2.23 | 0.186 |

| Error | 6 | 0.0088 | 3.34% | 0.0088 | 0.001467 | ||

| Total | 15 | 0.2631 | 100.00% |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| MWCNT (%) | 3 | 12.825 | 76.80% | 12.825 | 4.275 | 23.97 | 0.001 |

| Load (N) | 3 | 1.69 | 10.12% | 1.69 | 0.5633 | 3.16 | 0.107 |

| Speed (m/s) | 3 | 1.115 | 6.68% | 1.115 | 0.3717 | 2.08 | 0.204 |

| Error | 6 | 1.07 | 6.41% | 1.07 | 0.1783 | ||

| Total | 15 | 16.7 | 100.00% |

| Approach | Technique Used | Main Variables | Output Metrics | Key Outcome | Strength |

|---|---|---|---|---|---|

| Taguchi DoE | L16 Orthogonal Array, ANOVA | Load, Speed, Filler % | WR, COF, Ra | Optimal filler: 0.5 wt% MWCNT; WR = 3.1 mm3/N·m; Filler % most influential (85.35%) | Statistically robust optimization |

| Mathematical Modeling | Polynomial Regression | Filler %, Load, Speed | WR (R2 > 0.95) | Accurately models nonlinear wear behavior; validates Taguchi trend; predicts via equation | Equation-based continuous prediction |

| Image-Based ML Modeling | GLCM Features + Random Forest | Correlation, Entropy, Intensity | WR (R2 ≈ 0.93), Ra | Top predictors: correlation, entropy; image features explain wear; enables surface-based diagnosis | Automated, texture-driven wear prediction |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hiremath, P.; Heckadka, S.S.; Anne, G.; Ghadai, R.K.; Deepak, G.D.; Shivamurthy, R.C. Comprehensive Experimental Optimization and Image-Driven Machine Learning Prediction of Tribological Performance in MWCNT-Reinforced Bio-Based Epoxy Nanocomposites. J. Compos. Sci. 2025, 9, 385. https://doi.org/10.3390/jcs9080385

Hiremath P, Heckadka SS, Anne G, Ghadai RK, Deepak GD, Shivamurthy RC. Comprehensive Experimental Optimization and Image-Driven Machine Learning Prediction of Tribological Performance in MWCNT-Reinforced Bio-Based Epoxy Nanocomposites. Journal of Composites Science. 2025; 9(8):385. https://doi.org/10.3390/jcs9080385

Chicago/Turabian StyleHiremath, Pavan, Srinivas Shenoy Heckadka, Gajanan Anne, Ranjan Kumar Ghadai, G. Divya Deepak, and R. C. Shivamurthy. 2025. "Comprehensive Experimental Optimization and Image-Driven Machine Learning Prediction of Tribological Performance in MWCNT-Reinforced Bio-Based Epoxy Nanocomposites" Journal of Composites Science 9, no. 8: 385. https://doi.org/10.3390/jcs9080385

APA StyleHiremath, P., Heckadka, S. S., Anne, G., Ghadai, R. K., Deepak, G. D., & Shivamurthy, R. C. (2025). Comprehensive Experimental Optimization and Image-Driven Machine Learning Prediction of Tribological Performance in MWCNT-Reinforced Bio-Based Epoxy Nanocomposites. Journal of Composites Science, 9(8), 385. https://doi.org/10.3390/jcs9080385