High-Temperature Tribological Behavior of Polyimide Composites with Dual-Phase MoS2/MXene Lubricants: A Synergistic Effect Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

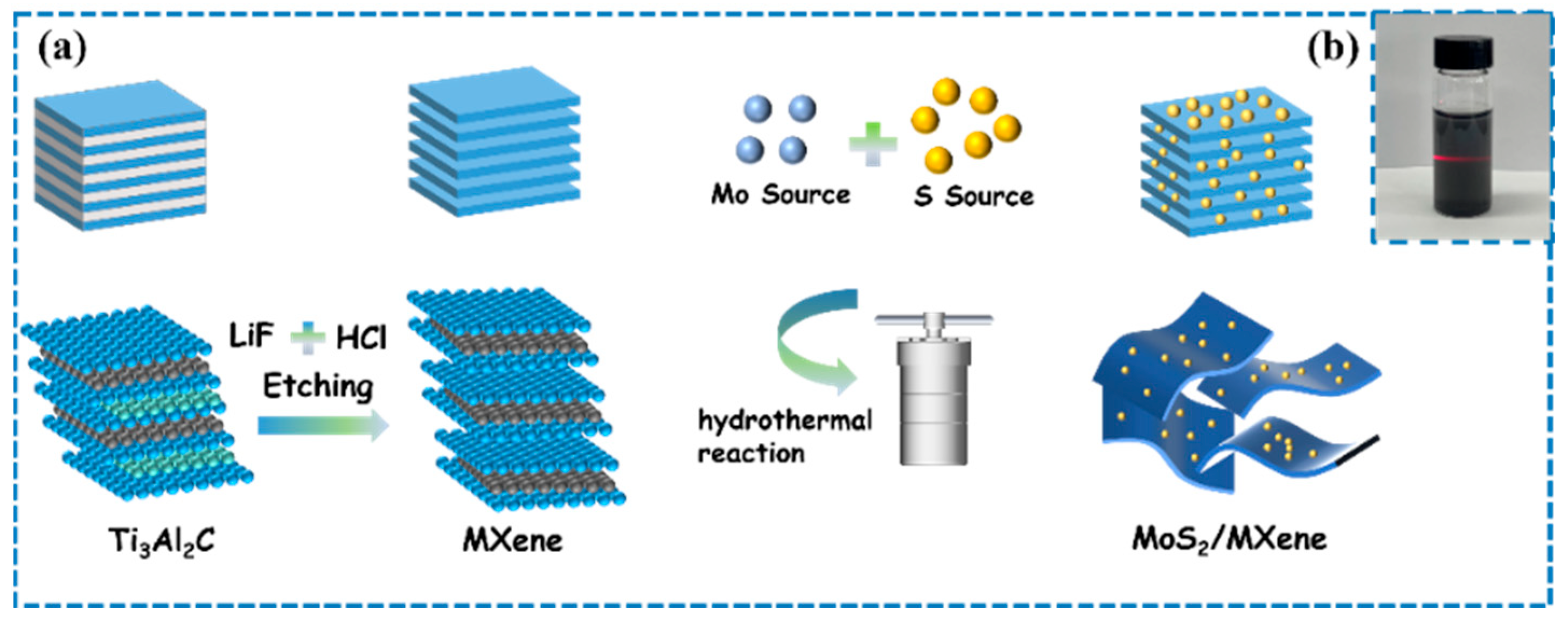

2.2. Preparation of MXene and MoS2/MXene Hybrids

2.3. Preparation of PI Matrix Composites

2.4. Characterization

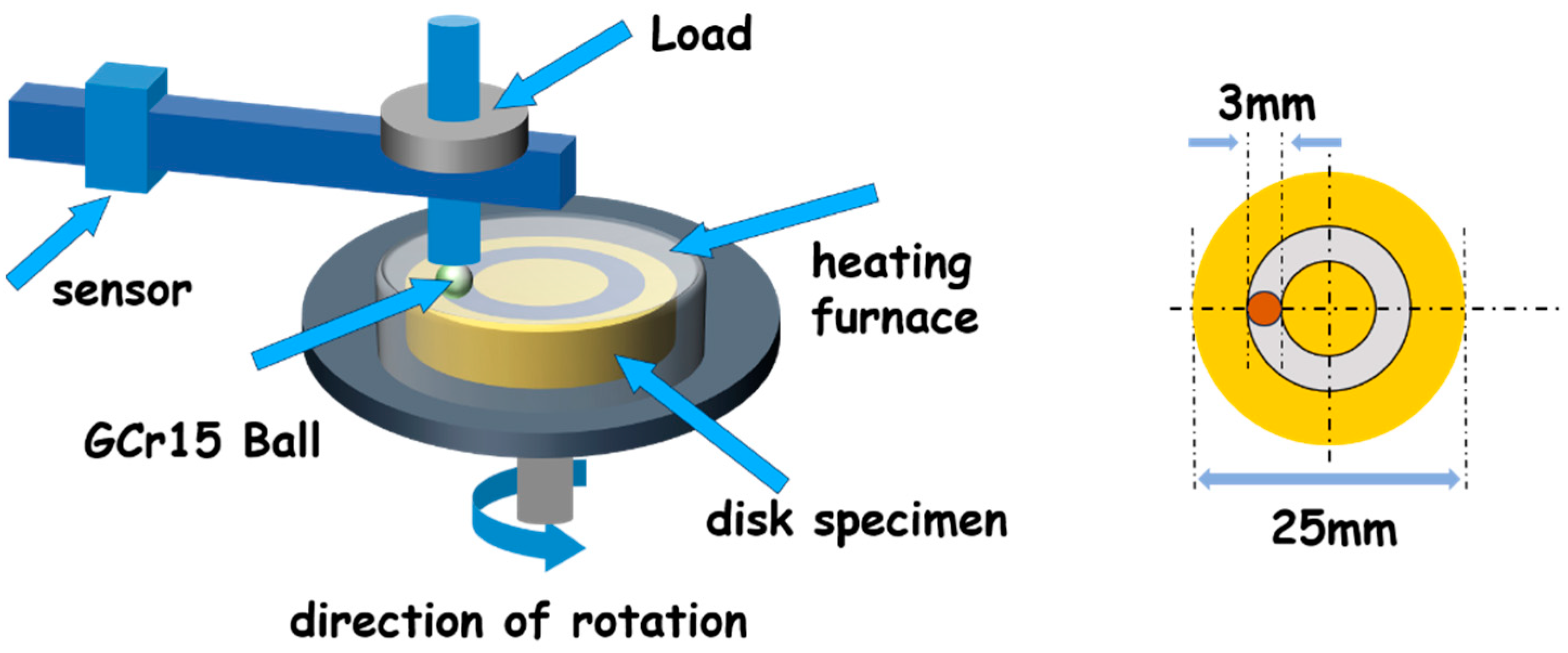

2.5. Tribological Tests

3. Results and Discussion

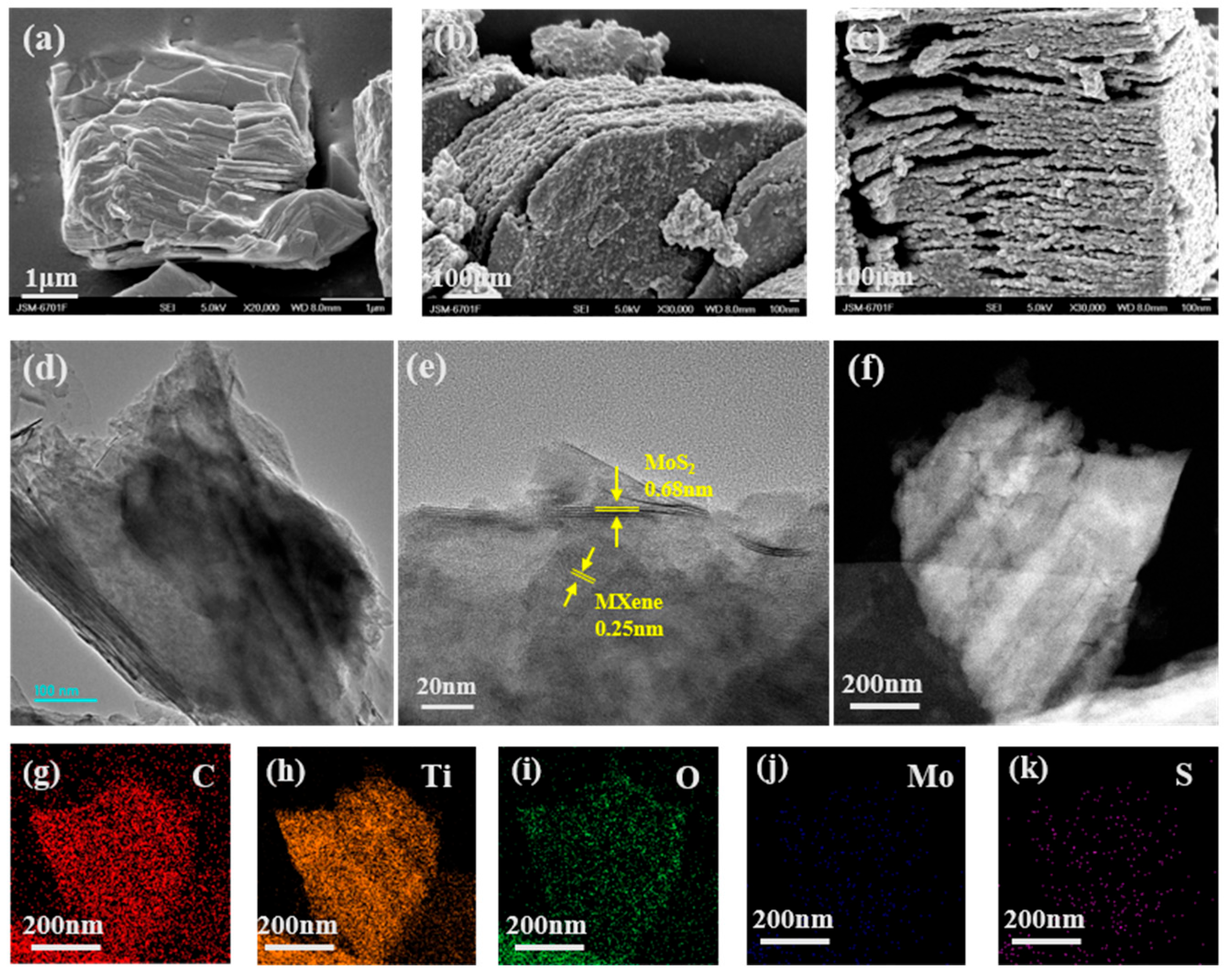

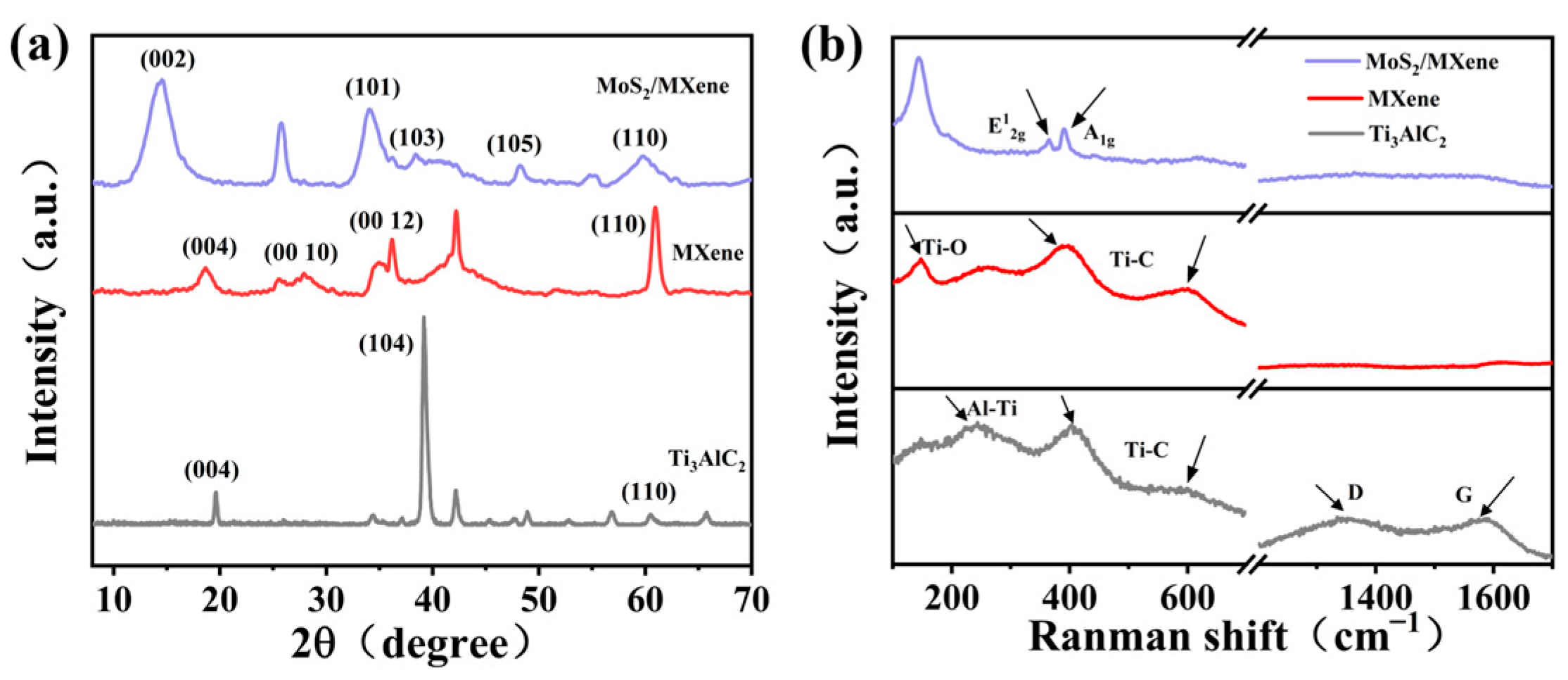

3.1. Characterization of Structures and Properties

3.2. Tribological Performance

4. Conclusions

- 1.

- In terms of thermal stability, the MoS2/MXene hybrid filler demonstrated the most significant enhancement effect, increasing thermal conductivity by 36% compared to pure PI. This improvement was primarily attributed to the high bonding energy of Mo-S covalent bonds within the MoS2 layer.

- 2.

- Regarding mechanical properties, all three fillers substantially enhanced the hardness of the PI matrix, with this improvement being achieved through effective filler–matrix interfacial interactions that concurrently suppressed wear behavior.

- 3.

- In tribological performance studies, all composites exhibited characteristic temperature-dependent friction behavior. The coefficient of friction followed a consistent ‘decrease-then-increase’ trend with rising temperature, reaching a minimum value at 100 °C. The 5% MoS2-PI composite demonstrated a 39% reduction in the coefficient of friction at room temperature compared to pure PI. Meanwhile, the 5% MXene–PI composite exhibited superior wear resistance, achieving a 64% decrease in room temperature wear rate relative to pure PI. MXene’s inherent high hardness and laminated structure provided dual benefits by suppressing abrasive wear while delaying plastic deformation onset through matrix stiffening.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cheng, B.; Duan, H.; Chen, S.; Shang, H.; Li, J.; Shao, T. Phase morphology and tribological properties of PI/UHMWPE blend composites. Polymer 2020, 202, 122658. [Google Scholar] [CrossRef]

- Yang, M.; Zhang, C.; Su, G.; Dong, Y.; Mekuria, T.D. Preparation and wear resistance properties of thermosetting polyimide composites containing solid lubricant fillers. Mater. Chem. Phys. 2020, 241, 122034. [Google Scholar] [CrossRef]

- Wan, C.; Yao, C.; Li, J.; Duan, H.; Zhan, S.; Jia, D.; Li, Y.; Yang, T. Friction and wear behavior of polyimide matrix composites filled with nanographite. J. Appl. Polym. Sci. 2022, 139, 52058. [Google Scholar] [CrossRef]

- Xu, X.; Hu, D.; Ma, W. Synergistic improvement of mechanical and thermal properties in epoxy composites via polyimide microspheres. J. Appl. Polym. Sci. 2021, 138, 50869. [Google Scholar] [CrossRef]

- Guo, D.; Tan, B.; Jiang, X.; Gao, G.; Lin, Y. Multifunctional polyimide/boron nitride nanosheet/Ti3C2Tx MXene composite film with three-dimensional conductive network for integrated thermal conductive, electromagnetic interference shielding, and Joule heating performances. Compos. Sci. Technol. 2024, 254, 110690. [Google Scholar] [CrossRef]

- Davim, J.P. Composite materials: A bibliometric analysis. AIMS Mater. Sci. 2024, 11, 1145–1148. [Google Scholar] [CrossRef]

- Wu, Z.; He, J.; Yang, H.; Yang, S. Progress in aromatic polyimide films for electronic applications: Preparation, structure and properties. Polymers 2022, 14, 1269. [Google Scholar] [CrossRef] [PubMed]

- Dong, F.; Hou, G.; Cao, F.; Yan, F.; Liu, L.; Wang, J. The lubricity and reinforcement of carbon fibers in polyimide at high temperatures. Tribol. Int. 2016, 101, 291–300. [Google Scholar] [CrossRef]

- Shen, S.; Li, H.; Yang, L.; Li, N.; Wu, J.; Zhao, T. High-throughput screening the micro-mechanical properties of polyimide matrix composites at elevated temperatures. Polym. Test. 2022, 107, 107483. [Google Scholar] [CrossRef]

- Tian, H.; Fei, J.; Li, C.; Qi, L.; Cai, X.; Li, B.; Fu, Y. Significant improvement of thermal and tribological performance with polyimide as the matrix of paper-based friction materials. Polym. Compos. 2022, 43, 2303–2317. [Google Scholar] [CrossRef]

- Liu, C.; Song, J.; Zhao, G.; Yin, Y.; Ding, Q. Improving thermal conductivity and tribological performance of polyimide by filling Cu, CNT, and graphene. Micromachines 2023, 14, 616. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Xiao, Q.; Lin, Z.; Li, Y.; Jia, X.; Song, H. Growth of ultra-dense MoS2 nanosheets on carbon fibers to improve the mechanical and tribological properties of polyimide composites. Friction 2021, 9, 1150–1162. [Google Scholar] [CrossRef]

- Ruan, H.; Zhang, Q.; Liao, W.; Li, Y.; Huang, X.; Xu, X.; Lu, S. Enhancing tribological, mechanical, and thermal properties of polyimide composites by the synergistic effect between graphene and ionic liquid. Mater. Des. 2020, 189, 108527. [Google Scholar] [CrossRef]

- Li, H.; Wang, L.; Li, L.; Li, H.; Dai, Y.; Hu, Q.; Zhou, A.; Liu, X. 2D Mo2CTx reinforced polyimide nanocomposites for enhancement of surface tribological performance at elevated temperatures. Adv. Mater. Interfaces 2023, 10, 2201563. [Google Scholar] [CrossRef]

- Ogbonna, V.E.; Popoola, P.I.; Popoola, O.M. Development and characterization of nanoceramic reinforced polyimide-based nanocomposites for high-temperature energy storage applications: A review. Polym. Plast. Technol. Mater. 2024, 63, 1254–1276. [Google Scholar] [CrossRef]

- Ogbonna, V.E.; Popoola, A.P.I.; Popoola, O.M.; Adeosun, S.O. Recent progress on improving the mechanical, thermal and electrical conductivity properties of polyimide matrix composites from nanofillers perspective for technological applications. J. Polym. Eng. 2021, 41, 768–787. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, C.; Chen, S.; Zhang, L.; Liu, Z.; Zhang, W. Preparation of MoS2@PDA-modified polyimide films with high mechanical performance and improved electrical insulation. Polymers 2024, 16, 546. [Google Scholar] [CrossRef] [PubMed]

- Zhen, J.; Han, Y.; Wang, H.; Jiang, Z.; Wang, L.; Huang, Y.; Jia, Z.; Zhang, R. High temperature friction and wear behavior of PTFE/MoS2 composites. Lubricants 2023, 11, 312. [Google Scholar] [CrossRef]

- Zayatzev, A. Antifriction characteristics of the magnetron sputtered MoS2 coating of ITER blanket module bolted joints in high vacuum at elevated temperature T = 250 °C. Vacuum 2024, 230, 113615. [Google Scholar] [CrossRef]

- Babuska, T.F.; Curry, J.F.; Dugger, M.T.; Lu, P.; Xin, Y.; Klueter, S.; Kozen, A.C.; Grejtak, T.; Krick, B. Role of environment on the shear-induced structural evolution of MoS2 and impact on oxidation and tribological properties for space applications. ACS Appl. Mater. Interfaces 2022, 14, 13914–13924. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Jing, H.; Yu, L.; Wu, Z.; Su, C.; Ji, Z.; Shu, J.; Tang, H.; Xia, M.; Xia, X. Tribological Behavior and Mechanism of Silane-Bridged h-BN/MoS2 Hybrid Filling Epoxy Solid Lubricant Coatings. Nanomaterials 2025, 15, 401. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Li, M.; Shen, Q.; Chen, H. Preparation and tribological properties of modified MoS2/SiC/Epoxy composites. Materials 2021, 14, 1731. [Google Scholar] [CrossRef] [PubMed]

- Panin, S.V.; Luo, J.; Buslovich, D.G.; Alexenko, V.O.; Berto, F.; Kornienko, L.A. Effect of transfer film on tribological properties of anti-friction PEI-and PI-based composites at elevated temperatures. Polymers 2022, 14, 1215. [Google Scholar] [CrossRef] [PubMed]

- Gong, K.; Zhou, K.; Qian, X.; Shi, C.; Yu, B. MXene as emerging nanofillers for high-performance polymer composites: A review. Compos. Part B 2021, 217, 108867. [Google Scholar] [CrossRef]

- Li, Y.; Huang, S.; Wei, C.; Zhou, D.; Li, B.; Mochalin, V.N.; Wu, C. Friction between MXenes and other two-dimensional materials at the nanoscale. Carbon 2022, 196, 774–782. [Google Scholar] [CrossRef]

- Wei, P.; Hou, X.; Han, S.; Wen, X.; Zhou, X.; Meng, Y.; Yue, L.; Zhao, H.; Wen, G.; Cao, H. Superlubrication of poly-α-olefin-8 (PAO8) enabled by MXene/PI coating. Friction 2025, 13, 9440967. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, Y.; Wang, J.; He, Y.; Yuan, J.; Men, X. Well-aligned MXene@MoS2/Carbon nanofiber aerogels reinforced epoxy composites with splendid thermal and tribological performance. Carbon 2023, 213, 118222. [Google Scholar] [CrossRef]

- Boidi, G.; Zambrano, D.F.; Jogl, C.; Ripoll, M.R.; Varga, M.; Rosenkranz, A. Vacuum tribology of multi-layer Ti3C2Tx and Ti3C2Tx/MoS2 hybrid coatings. Appl. Mater. Today 2024, 38, 102180. [Google Scholar] [CrossRef]

- Sang, M.; Liu, G.; Liu, S.; Wu, Y.; Xuan, S.; Wang, S.; Xuan, S.; Jiang, W.; Gong, X. Flexible PTFE/MXene/PI soft electrothermal actuator with electromagnetic-interference shielding property. Chem. Eng. J. 2021, 414, 128883. [Google Scholar] [CrossRef]

- Hu, Y.; Pang, S.; Li, J.; Jiang, J.; Papageorgiou, D.G. Enhanced interfacial properties of hierarchical MXene/CF composites via low content electrophoretic deposition. Compos. Part B Eng. 2022, 237, 109871. [Google Scholar] [CrossRef]

- She, K.; Huang, Y.; Fan, W.; Yu, M.; Zhang, J.; Chen, C. 3D flower-like hollow MXene@MoS2 heterostructure for fast sodium storage. J. Colloid Interface Sci. 2024, 656, 270–279. [Google Scholar] [CrossRef] [PubMed]

- Lim, K.R.G.; Shekhirev, M.; Wyatt, B.C.; Anasori, B.; Gogotsi, Y.; Seh, Z.W. Fundamentals of MXene synthesis. Nat. Synth. 2022, 1, 601–614. [Google Scholar] [CrossRef]

- Yuan, X.; Li, S.; Qin, R.; Zhang, M.; Zhu, B.; Cao, W. Advances in constructing Carbon Fiber-MXene multilevel structures to reinforce interfacial properties of carbon fiber reinforced polymer composites. Polym. Compos. 2025, 46, 5041–5063. [Google Scholar] [CrossRef]

- Wang, J.; Liu, L.; Jiao, S.; Ma, K.; Lv, J.; Yang, J. Hierarchical carbon fiber@ MXene@MoS2 core-sheath synergistic microstructure for tunable and efficient microwave absorption. Adv. Funct. Mater. 2020, 30, 2002595. [Google Scholar] [CrossRef]

- Kang, H.; Han, L.; Chen, S.; Xie, S.; Li, M.; Fang, Q.; He, S. Research progress on two-dimensional layered MXene/Elastomer nanocomposites. Polymers 2022, 14, 4094. [Google Scholar] [CrossRef] [PubMed]

- Chu, N.; Luo, C.; Chen, X.; Li, L.; Liang, C.; Chao, M.; Yan, L. Compounds, Ti3C2Tx MXene/polyimide composites film with excellent mechanical properties and electromagnetic interference shielding properties. J. Alloys Compd. 2023, 955, 170241. [Google Scholar] [CrossRef]

- Yan, J.; Wu, C.; Liu, Y.; Shen, W.; Zhang, X.; Li, P.; Wang, G.; Wang, Z.; Che, H.; Wang, Y. Synergetic enhancement of wear resistance of polyimide coatings through the integration of MoS2 nanoflowers and MXene nanosheets. Wear 2024, 558, 205584. [Google Scholar] [CrossRef]

- Liu, Z.; Cui, Y.; Li, Q.; Zhang, Q.; Zhang, B. Fabrication of folded MXene/MoS2 composite microspheres with optimal composition and their microwave absorbing properties. J. Colloid Interface Sci. 2022, 607, 633–644. [Google Scholar] [CrossRef] [PubMed]

- Ma, W.; Yang, K.; Zhou, C.; Li, H. Enhanced dielectric constant and suppressed electrical conductivity in polymer nanocomposite films via loading MXene/TiO2/MoS2 nanosheets. Ceram. Int. 2022, 48, 10447–10457. [Google Scholar] [CrossRef]

- Zeng, Y.; Tang, L. Improved dielectric and mechanical properties in Ti3C2Tx MXene-MoS2/Methylvinyl silicone rubber composites as flexible dielectric materials. J. Alloys Compd. 2023, 948, 169733. [Google Scholar] [CrossRef]

- Zhou, Y.; Liu, M.; Wang, Y.; Yuan, J.; Men, X. Significance of constructed MXene@Ag hybrids for enhancing the mechanical and tribological performance of epoxy composites. Tribol. Int. 2022, 165, 107328. [Google Scholar] [CrossRef]

- Xue, L.L.; Xu, Q.Q.; Meng, C.H.; Lei, S.Y.; Zhang, G.D.; Tang, M.X.; Zhai, W.R.; Yu, H.; Liu, X.Q.; Du, C.F. Achieving the ultra-low friction and wear rate of PEEK-PTFE composites by Ti3C2Tx MXene reinforcement. Tribol. Int. 2024, 199, 110030. [Google Scholar] [CrossRef]

- Chen, B.; Li, X.; Jia, Y.; Li, X.; Yang, J.; Yan, F.; Li, C. MoS2 nanosheets-decorated carbon fiber hybrid for improving the friction and wear properties of polyimide composite. Compos. Part A Appl. Sci. Manuf. 2018, 109, 232–238. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, J.; Zeng, W.; Hu, Y.; Gui, Z. In situ synthesis, morphology, and fundamental properties of polymer/MoS2 nanocomposites. Compos. Sci. Technol. 2015, 107, 120–128. [Google Scholar] [CrossRef]

- Zhang, Y.; Cheng, G.; Tang, Z.; Jin, Q.; Ding, G.; Wan, X. Excellent mechanical and thermal conductivity performance of polyvinyl alcohol film doped SiO2@Ti3C2Tx MXene via electrostatic nano-particle assembly. Colloids Surf. A Physicochem. Eng. Asp. 2025, 713, 136507. [Google Scholar] [CrossRef]

- Wang, M.; Liu, Y.; Zhang, H.; Wu, Y.; Pan, L. Thermal conductivities of Ti3C2Tx MXenes and their interfacial thermal performance in MXene/epoxy composites-a molecular dynamics simulation. Int. J. Heat Mass Transf. 2022, 194, 123027. [Google Scholar] [CrossRef]

- Bilal, A.S.S.; Bilal, M.M.; Fatima, R.; Hasnain, M.; Munir, M.U.; Bano, N.; Hussain, I. Enhancing thermo-physical properties of paraffin wax phase change material with MXene nanoflakes for improved energy storage and heat transfer applications. Results Eng. 2025, 25, 104557. [Google Scholar] [CrossRef]

- Shang, J.; Song, P.; Li, G.; Sun, Q.; Li, Y.; Wei, Z. Crystallization and melting behavior of poly (ether ketone ketone) (PEKK) copolymers synthesized by facile one-step method. J. Therm. Anal. Calorim. 2023, 148, 11727–11741. [Google Scholar] [CrossRef]

- Guo, L.; Tao, L.; Wang, T. Improved Tribological Performance of MOF@MXene/PI under High Temperature. Langmuir 2024, 40, 8862–8871. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.; Wang, Y.; Liu, F.; Zhang, X.; Liu, Y.; Shen, W.; Zhang, Z.; Li, P.; Wang, Y.; Wu, C. Enhancing the tribological performance of polyimide composite coatings with amino-functionalized MXene nanofillers. Tribol. Int. 2024, 200, 110064. [Google Scholar] [CrossRef]

- Chen, G.; Jiang, S.; Huang, Y.; Pang, H.; Yin, X.; Chai, C. Ultra-low wear in multifunctional Ti3C2Tx/PI composite films induced by tribo-chemistry mechanism. React. Funct. Polym. 2023, 193, 105744. [Google Scholar] [CrossRef]

- Wen, G.; Wen, X.; Cao, H.; Bai, P.; Meng, Y.; Ma, L.; Tian, Y. Fabrication of Ti3C2 MXene and tetradecylphosphonic acid@MXene and their excellent friction-reduction and anti-wear performance as lubricant additives. Tribol. Int. 2023, 186, 108590. [Google Scholar] [CrossRef]

- Park, S.; Garcia-Esparza, A.T.; Abroshan, H.; Abraham, B.; Vinson, J.; Gallo, A.; Nordlund, D.; Park, J.; Kim, T.R.; Vallez, L. Operando study of thermal oxidation of monolayer MoS2. Adv. Sci. 2021, 8, 2002768. [Google Scholar] [CrossRef] [PubMed]

| Materials | PI | MoS2 | MXene | MoS2/MXene |

|---|---|---|---|---|

| PI | 100% | 0 | 0 | 0 |

| M-1 | 95% | 5% | 0 | 0 |

| M-2 | 95% | 0 | 5% | 0 |

| M-3 | 95% | 0 | 0 | 5% |

| Materials | Ti (°C) | T5 (°C) | Tp (°C) | Rw (%) | Tg |

|---|---|---|---|---|---|

| PI | 548 | 553 | 579 | 61 | 221 |

| M-1 | 551 | 560 | 581 | 60 | 223 |

| M-2 | 559 | 566 | 584 | 58 | 229 |

| M-3 | 562 | 569 | 586 | 60 | 230 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, X.; Ren, P.; Liu, H.; Shi, Y.; Yan, Y.; Wang, J. High-Temperature Tribological Behavior of Polyimide Composites with Dual-Phase MoS2/MXene Lubricants: A Synergistic Effect Analysis. J. Compos. Sci. 2025, 9, 373. https://doi.org/10.3390/jcs9070373

Ji X, Ren P, Liu H, Shi Y, Yan Y, Wang J. High-Temperature Tribological Behavior of Polyimide Composites with Dual-Phase MoS2/MXene Lubricants: A Synergistic Effect Analysis. Journal of Composites Science. 2025; 9(7):373. https://doi.org/10.3390/jcs9070373

Chicago/Turabian StyleJi, Xingtian, Pengwei Ren, Hao Liu, Yanhua Shi, Yunfeng Yan, and Jianzhang Wang. 2025. "High-Temperature Tribological Behavior of Polyimide Composites with Dual-Phase MoS2/MXene Lubricants: A Synergistic Effect Analysis" Journal of Composites Science 9, no. 7: 373. https://doi.org/10.3390/jcs9070373

APA StyleJi, X., Ren, P., Liu, H., Shi, Y., Yan, Y., & Wang, J. (2025). High-Temperature Tribological Behavior of Polyimide Composites with Dual-Phase MoS2/MXene Lubricants: A Synergistic Effect Analysis. Journal of Composites Science, 9(7), 373. https://doi.org/10.3390/jcs9070373