Effect of Alumina Microparticle-Infused Polymer Matrix on Mechanical Performance of Carbon Fiber Reinforced Polymer (CFRP) Composite

Abstract

1. Introduction

2. Experimentation

2.1. Materials

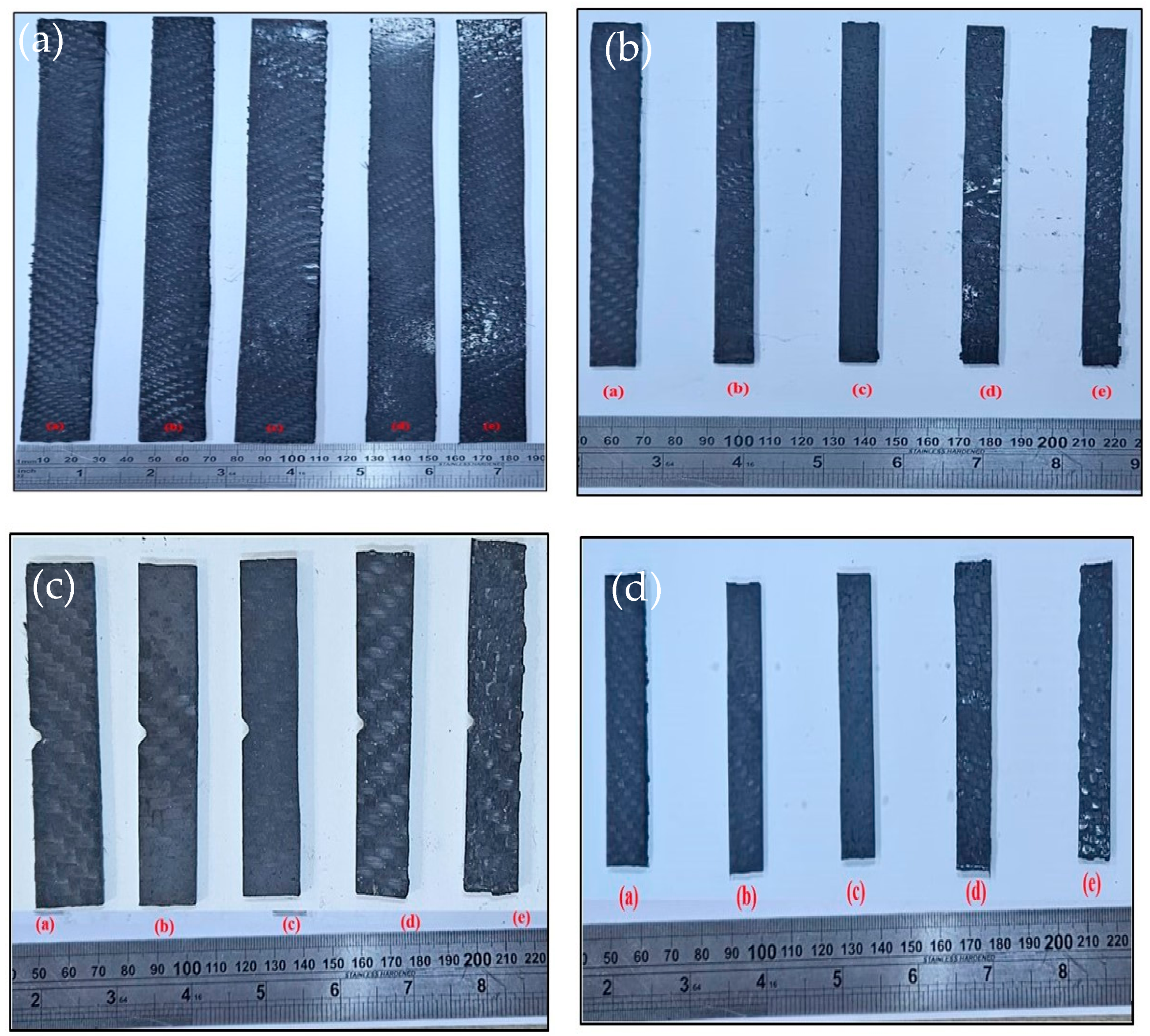

2.2. Fabrication

2.3. Testing

3. Results and Discussions

3.1. Micrographs

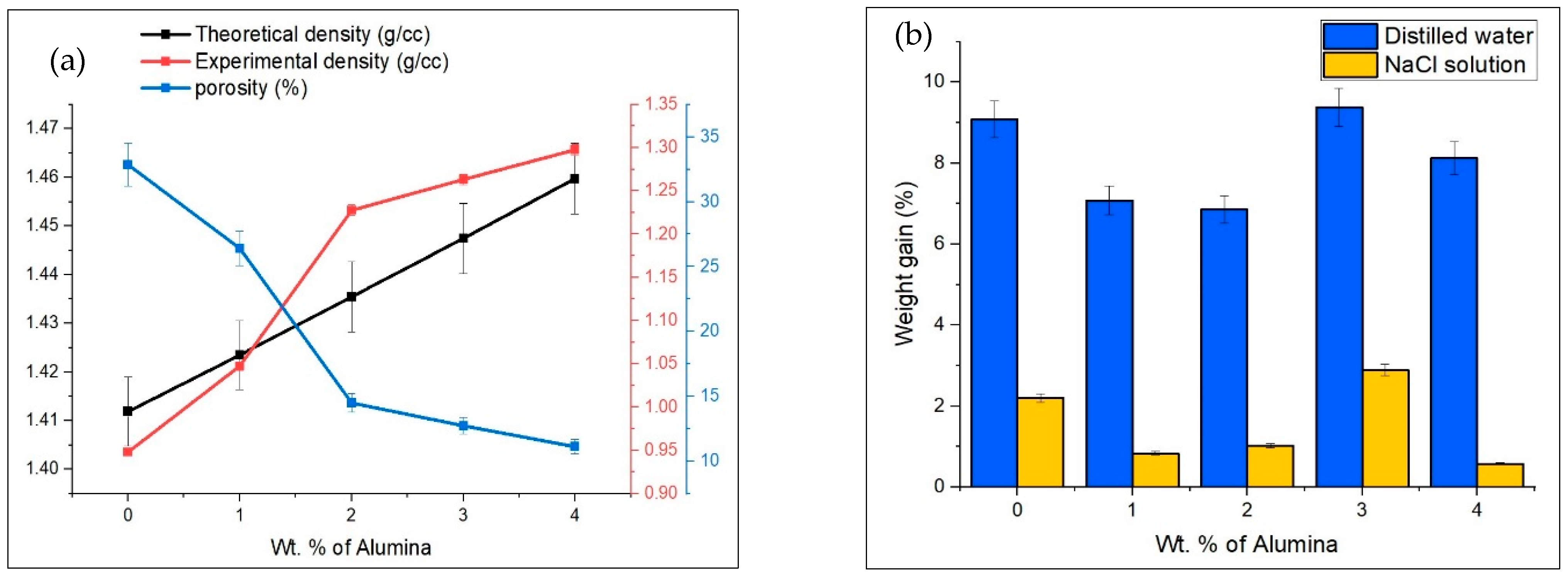

3.2. Mass Density and Porosity

3.3. Water Absorption

3.4. Hardness

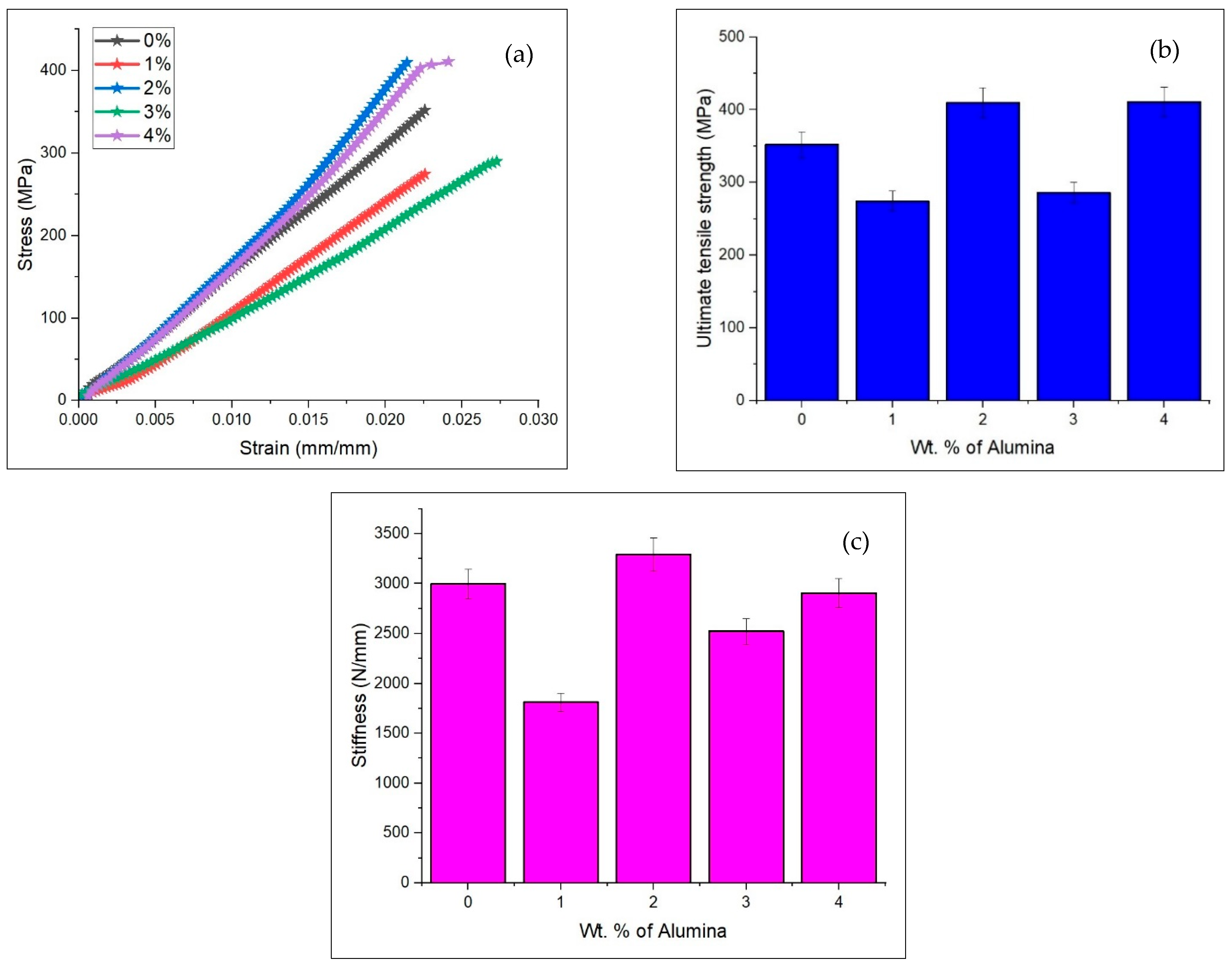

3.5. Tensile Strength

3.6. Flexural Strength

3.7. Inter-Laminar Shear Strength

3.8. Impact Strength

4. Conclusions

- ➢

- The alumina micro particles were uniformly distributed in the matrix pool of the laminate with no significant agglomeration. The carbon fibers and the resin particles were clearly observed in the micrograph. The denser and harder alumina increased the density of the CFRP laminate appreciably. The highest void content of around 32% was observed for CFRP specimen with 0% Al2O3, whereas the lowest was for the CFRP specimen with 4% Al2O3. The irregular structure with a larger surface area of alumina particles resulted in improved mass density and reduced porosity.

- ➢

- The highest hardness of 39.72 kgf/mm2 was observed for CFRP with 4% Al2O3, which was around 60% higher than for 0% laminate due to enhanced strain hardening that occurred at a higher weight fraction of ceramic filler. The water gain % gradually dropped with the increase in the weight % of Al2O3 micro particles. A significant difference in the percentage of water absorption was observed in the CFRP laminates in pure distilled water and 0.9% NaCl solution.

- ➢

- The tensile strength, flexural strength and inter-laminar shear strength were significantly enhanced with the addition of alumina micro particles, except for a drop for tensile behavior at 1% and 3%, which may be due to agglomeration of the micro particles in the matrix pool of the laminate. The carbon fibers in the laminate with improved grain boundary surface by the addition of alumina micro particles, resulted in enhanced shear load capacity of the laminates. The hard ceramic alumina micro particles had affected the toughness of the laminate abruptly by reducing the ductility and softness of the material and in turn reduced the impact strength to a larger extent.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Alaa, M.A.; Saleh, O.A.; Mohammed, S.A.S.; Bandar, M.A.O.; Ibrahim, M.A.A.; Naif, B.A.Q.; Salem, M.A.D.; Sami, S.A.S.; Ahmed, S.H.; Al Anood, A.; et al. Manufacturing of carbon fiber reinforced thermoplastics and its recovery of carbon fiber: A review. Polym. Test. 2023, 122, 108029. [Google Scholar]

- Subhedar, K.M.; Chauhan, G.S.; Singh, B.P.; Dhakate, S.R. Effect of fiber orientation on mechanical properties of carbon fibre composites. Indian J. Eng. Mater. Sci. 2020, 27, 1100–1103. [Google Scholar]

- Agrawal, M.; Prabhakaran, R.T.D. Effect of Fiber Sizing on Mechanical Properties of Carbon Reinforced Composites: A Review. Org. Polym. Mater. Res. 2019, 1, 1–5. [Google Scholar] [CrossRef]

- Karatas, M.A.; Gokkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Ozkan, D.; Gok, M.S.; Karaoglanli, A.C. Carbon Fiber Reinforced Polymer (CFRP) Composite Materials, Their Characteristic Properties, Industrial Application Areas and Their Machinability. Eng. Des. Appl. III 2020, 124, 235–253. [Google Scholar]

- Kennedy, S.M.; Vasanthanathan, A.; Jeen Robert, R.B.; Amudhan, K.; Nagendran, M. Impact of fillers in enhancing the properties of CFRP composites—A comprehensive exploration. Next Res. 2025, 2, 100117. [Google Scholar] [CrossRef]

- Chowdhur, N.; Islam, T.; Faysal, G.M.; Rahman, H. A Study on Mechanical Properties of Carbon Fiber Reinforced Polymer Composite. In Proceedings of the International Conference on Materials, Energy, Environment, and Engineering, Dhaka, Bangladesh, 29–30 November 2020. [Google Scholar]

- Penner, E.; Caylak, I.; Mahnken, R. Experimental Investigations of Carbon Fiber Reinforced Polymer Composites and Their Constituents to determine their elastic material properties and complementary inhomogeneous experiments with local strain considerations. Fibers Polym. 2023, 24, 157–178. [Google Scholar] [CrossRef]

- ASTM E2809; Standard Test Method for Micrographical Analysis of Polymer Composite Laminate. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D792; Standard Test Method for Porosity Test of Polymer Composite Laminate. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D570; Standard Test Method for Water Absorption Test of Polymer Composite Laminate. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E10; Standard Test Method for Brinell Hardness Test of Polymer Composite Laminate. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D3039; Standard Test Method for Tensile Test of Polymer Composite Laminate. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D790; Standard Test Method for Flexural Test of Polymer Composite Laminate. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D2344; Standard test method for inter-laminar shear test of polymer composite laminate. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D256; Standard Test Method for Impact Test of Polymer Composite Laminate. ASTM International: West Conshohocken, PA, USA, 2021.

- Sales, R.; Thim, G.; Brunelli, D. Understanding the water uptake in F-161 glass-epoxy composites using the techniques of luminescence spectroscopy and FT-NIR. Polímeros 2017, 27, 171–182. [Google Scholar] [CrossRef]

- Sales, R.; Brunelli, D. Hygrothermal effect in glass fiber/epoxy by luminescence spectroscopy. Polímeros 2008, 19, 52–56. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Sivasuriyan, A.; Devarajan, P.; Stefanska, A.; Wodzynski, L.; Koda, E. Carbon Fibre-Reinforced Polymer (CFRP) Composites in Civil Engineering Application—A Comprehensive Review. Buildings 2023, 13, 1509. [Google Scholar] [CrossRef]

- Liu, Y.; Zwingman, B.; Schlaich, M. Carbon Fiber Reinforced Polymer for Cable Structures—A Review. Polymers 2015, 7, 2078–2099. [Google Scholar] [CrossRef]

- Qi, X.; Tian, J.; Xian, G. Hydrothermal ageing of carbon fiber reinforced polymer composites applied for construction: A review. J. Mater. Res. Technol. 2023, 27, 1017–1045. [Google Scholar] [CrossRef]

- Ganesh, R.; Al Hattali, A.H.; Al Yahyai, A.M.; Al Riyami, A.M.; Al Hadrami, A.M. Experimental study on the effect of aspect ratio on flexural behavior of Aluminium Sandwich Composite. Eng. Technol. J. 2022, 40, 990–995. [Google Scholar]

- Ganesh, R. Synthesis and characterization of structural metal matrix composite using agricultural waste targeting for environmental sustainability. IOP Conf. Ser. Earth Environ. Sci. 2022, 1055, 012007. [Google Scholar]

- Ganesh, R.; Al Riyami, N.O.; Al Hadhrami, A.M.D.; Kadhavoor; Karthikeyan, R. Influence of Aspect Ratio on the Flexural and Buckling Behavior of an Aluminium Sandwich Composite: A Numerical and Experimental Approach. Materials 2023, 16, 6544. [Google Scholar] [CrossRef] [PubMed]

- Ganesh, R.; Odett Breaz, T.; Al Hinai, A.R.Y.S.; Al Shaibani, K.H.; Al Farqani, M.S.; Al Busaidi, O.S.; Al Adawi, S.M.; Karthikeyan, K.R. Forming behavior during drawing of Aluminium sandwich composite laminate—A comprehensive experimental analysis. Cogent Eng. 2024, 11, 2374504. [Google Scholar]

- Chen, A.Y.; Baehr, S.; Turner, A.; Zhang, Z.; Gu, G.X. Carbon-fiber reinforced polymer composites: A comparison of manufacturing methods on mechanical properties. Int. J. Lightweight Mater. Manuf. 2021, 4, 468–479. [Google Scholar] [CrossRef]

- Karas, B.; Smith, P.J.; Fairclough, J.P.A.; Mumtaz, K. Additive manufacturing of high density carbon fiber reinforced polymer composites. Addit. Manuf. 2022, 58, 103044. [Google Scholar]

- Ganesh, R. Experimental investigation on the effect of process parameters on machinability and surface integrity during end milling of Mg-TiO2 nanocomposite. Int. J. Mater. Prod. Technol. 2023, 66, 312–327. [Google Scholar]

| Composition | Resin (wt.%) | Fiber (wt.%) | Filler (wt.%) |

|---|---|---|---|

| 1 | 40 | 60 | 0 |

| 2 | 39 | 60 | 1 |

| 3 | 38 | 60 | 2 |

| 4 | 37 | 60 | 3 |

| 5 | 36 | 60 | 4 |

| S. No. | Property | Epoxy | Carbon Fiber | Alumina |

|---|---|---|---|---|

| 1 | Mass density (g/cc) | 1.2–1.25 | 1.8 | 3.9 |

| 2 | Viscosity @ 25 °C (cps) | 550 | - | - |

| 3 | Tensile strength (MPa) | 11.14 | 5880 | 262 |

| 4 | Elastic modulus (MPa) | 3100 | 228,000 | 370,000 |

| 5 | Size | - | 8 µm | 75 µm |

| 6 | Color | Transparent | Black | Grey |

| Element | Weight % | |||

|---|---|---|---|---|

| Point 1 | Point 2 | Point 3 | Point 4 | |

| Cu | 0.0 | 0.0 | 0.0 | 0.1 |

| C | 33.6 | 22.4 | 20.0 | 30.0 |

| O | 34.8 | 50.9 | 58.0 | 52.3 |

| Si | 0.5 | 0.3 | 0.4 | 0.2 |

| S | 13.2 | 12.0 | 9.6 | 7.9 |

| Ca | 17.9 | 14.4 | 12.0 | 9.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Radhakrishnan, G.; Breaz, T.O.; Al Hinai, A.H.H.; Al Busaidi, F.H.; Al Sheriqi, L.M.; Al Hattali, M.A.; Al Rawahi, M.I.; Al Rabaani, M.N.; Karthikeyan, K.R. Effect of Alumina Microparticle-Infused Polymer Matrix on Mechanical Performance of Carbon Fiber Reinforced Polymer (CFRP) Composite. J. Compos. Sci. 2025, 9, 360. https://doi.org/10.3390/jcs9070360

Radhakrishnan G, Breaz TO, Al Hinai AHH, Al Busaidi FH, Al Sheriqi LM, Al Hattali MA, Al Rawahi MI, Al Rabaani MN, Karthikeyan KR. Effect of Alumina Microparticle-Infused Polymer Matrix on Mechanical Performance of Carbon Fiber Reinforced Polymer (CFRP) Composite. Journal of Composites Science. 2025; 9(7):360. https://doi.org/10.3390/jcs9070360

Chicago/Turabian StyleRadhakrishnan, Ganesh, Teodora Odett Breaz, Abdul Hamed Hamed Al Hinai, Fisal Hamed Al Busaidi, Laqman Malik Al Sheriqi, Mohammed Ali Al Hattali, Mohammed Ibrahim Al Rawahi, Mohammed Nasser Al Rabaani, and Kadhavoor R. Karthikeyan. 2025. "Effect of Alumina Microparticle-Infused Polymer Matrix on Mechanical Performance of Carbon Fiber Reinforced Polymer (CFRP) Composite" Journal of Composites Science 9, no. 7: 360. https://doi.org/10.3390/jcs9070360

APA StyleRadhakrishnan, G., Breaz, T. O., Al Hinai, A. H. H., Al Busaidi, F. H., Al Sheriqi, L. M., Al Hattali, M. A., Al Rawahi, M. I., Al Rabaani, M. N., & Karthikeyan, K. R. (2025). Effect of Alumina Microparticle-Infused Polymer Matrix on Mechanical Performance of Carbon Fiber Reinforced Polymer (CFRP) Composite. Journal of Composites Science, 9(7), 360. https://doi.org/10.3390/jcs9070360