Processing and Evaluation of an Aluminum Matrix Composite Material

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Melting of the Matrix Alloy

2.3. Preparation of Insert Material and the Samples

2.4. Microstructural Investigation and Tensile Test

3. Experimental Results

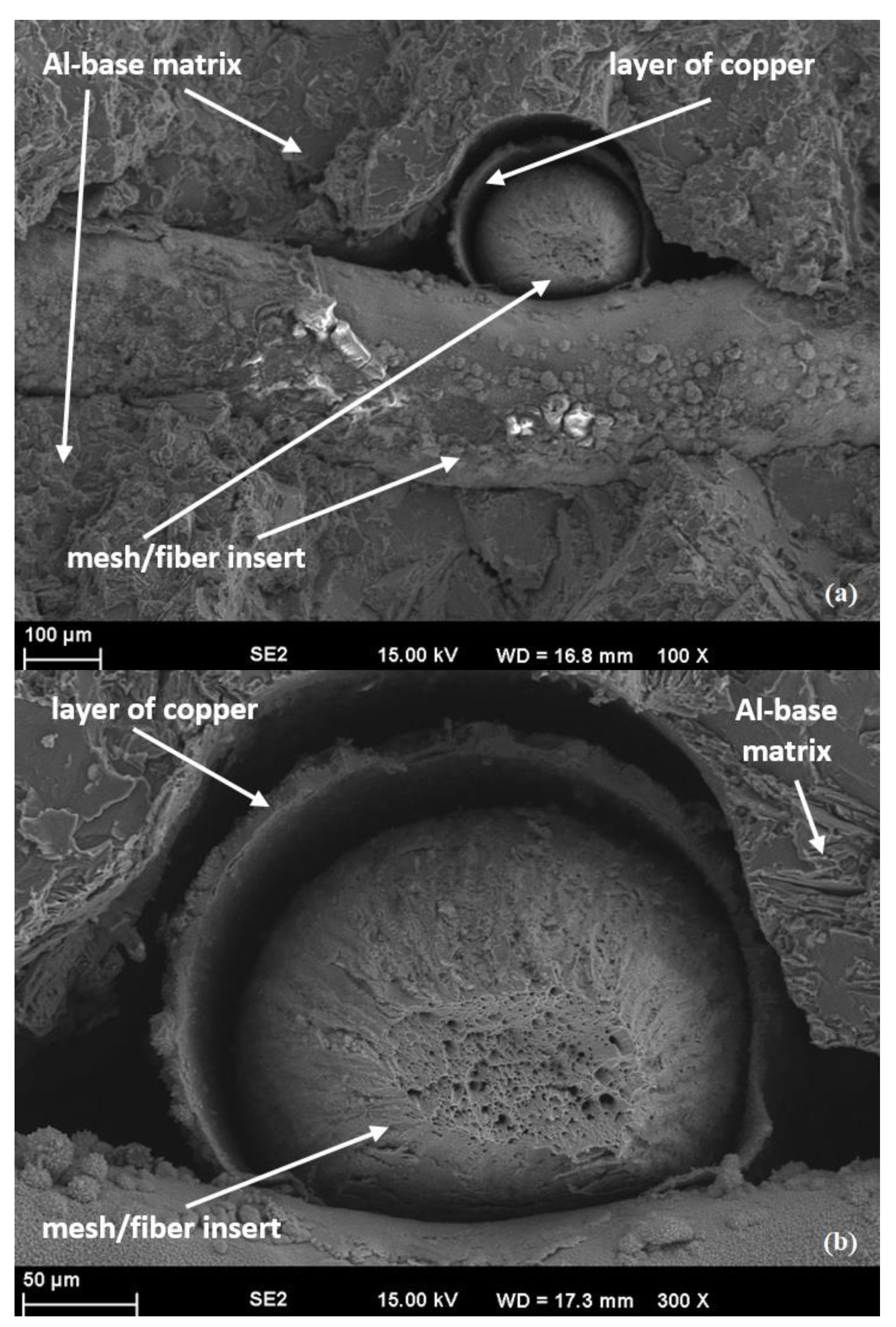

3.1. Microstructural Characterization

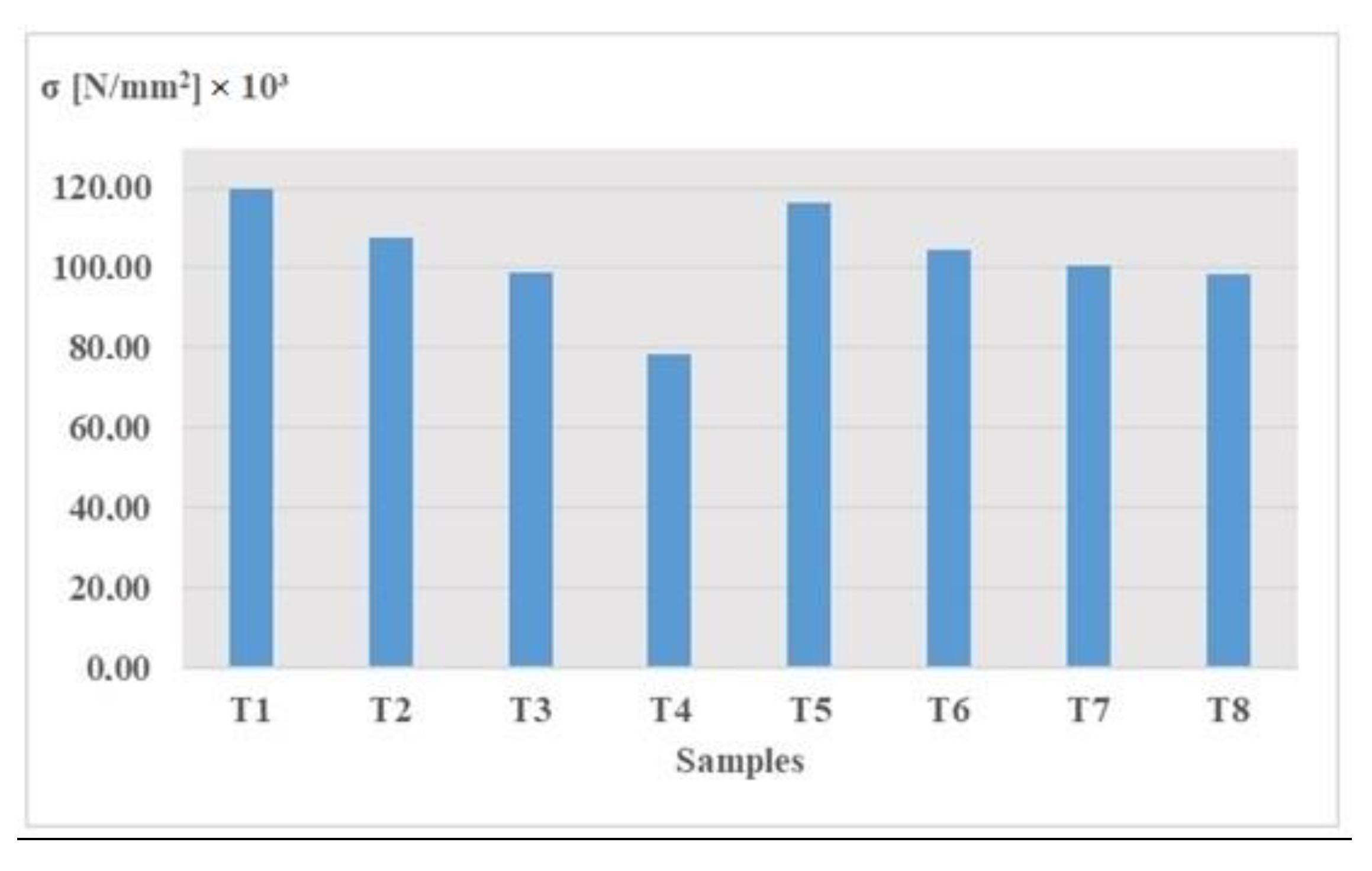

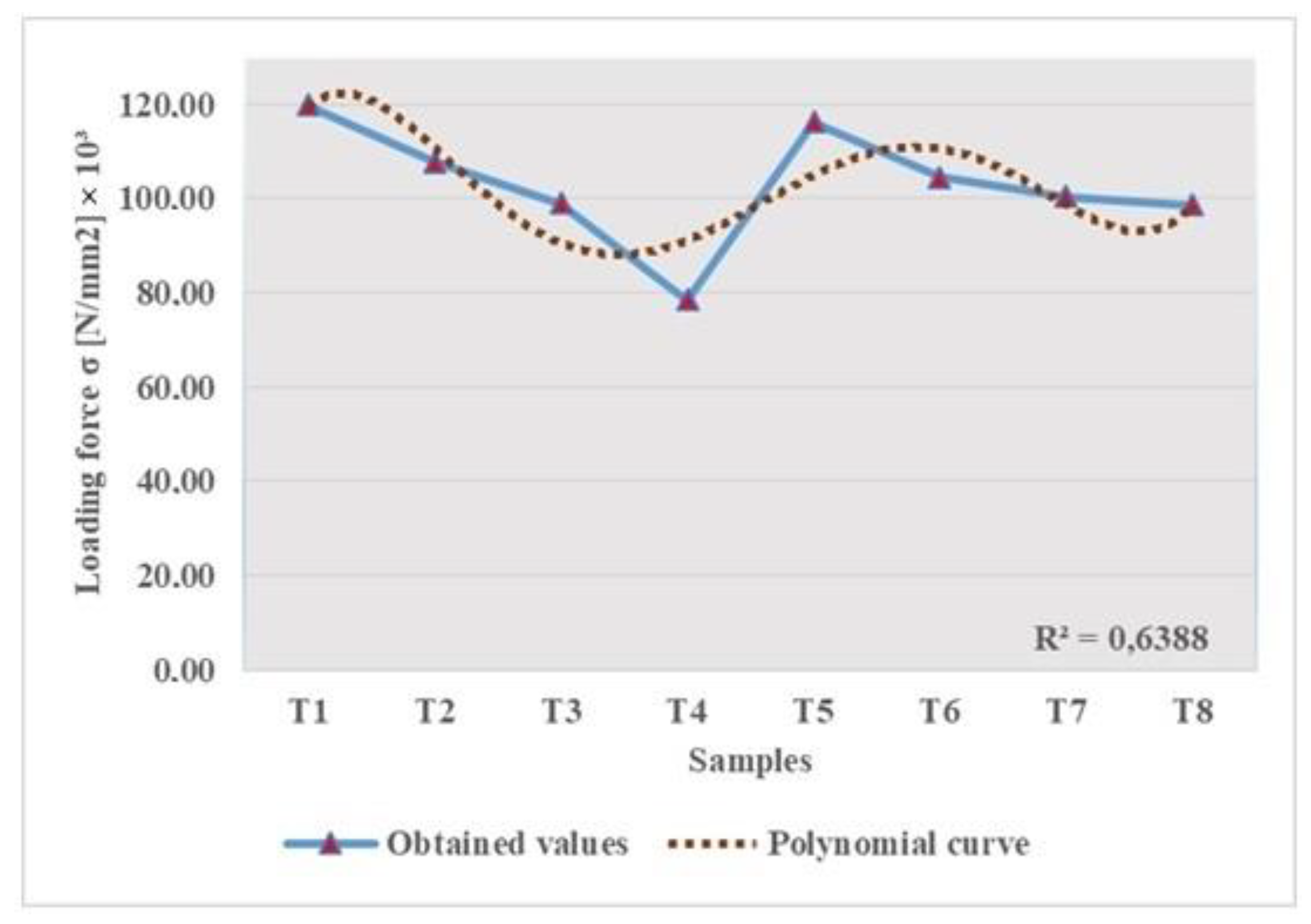

3.2. Tensile Test

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Samal, P.; Vundavilli, P.; Meher, A.; Mahapatra, M. Recent progress in aluminum metal matrix composites: A review on processing, mechanical and wear properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Imran, M.; Khan, A. Characterization of Al-7075 metal matrix composites: A review. J. Mater. Res. Technol. 2019, 8, 3347–3356. [Google Scholar] [CrossRef]

- Ashebir, D.; Mengesha, G.; Sinha, D. An Insight into Mechanical and Metallurgical Behavior of Hybrid Reinforced Aluminum Metal Matrix Composite. Adv. Mater. Sci. Eng. 2022, 2022, 7843981. [Google Scholar] [CrossRef]

- Koli, D.; Agnihotri, G.; Purohit, R. Advanced Aluminium Matrix Composites: The Critical Need of Automotive and Aerospace Engineering Fields. Mater. Today Proc. 2015, 2, 3032–3041. [Google Scholar] [CrossRef]

- Prasad, S.; Asthana, R. Aluminum Metal-Matrix Composites for Automotive Applications: Tribological Considerations. Tribol. Lett. 2004, 17, 445–453. [Google Scholar] [CrossRef]

- Suthar, J.; Patel, K. Processing issues, machining, and applications of aluminum metal matrix composites. Mater. Manuf. Process. 2018, 33, 499–527. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, V.; Singh, R.; Chaudhary, R.; Kumar, D.; Mourad, A. A review of aluminum metal matrix composites: Fabrication route, reinforcements, microstructural, mechanical, and corrosion properties. J. Mater. Sci. 2024, 59, 2644–2711. [Google Scholar] [CrossRef]

- Che, J.; Kim, J.; Lee, H.; Chang, S. Application of carbon/epoxy composites to robot console structure for high stiffness with lightweight. Compos. Struct. 2022, 300, 116121. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H.; Dora, T. A review on fabrication methods, reinforcements and mechanical properties of aluminum matrix composites. J. Manuf. Process. 2020, 56, 1059–1074. [Google Scholar] [CrossRef]

- Tenali, N.; Ganesan, G.; Ravindra Babu, P. An Investigation on the Mechanical and Tribological Properties of an Ultrasonic-Assisted Stir Casting Al-Cu-Mg Matrix-Based Composite Reinforced with Agro Waste Ash Particles. Appl. Eng. Lett. 2024, 9, 46–63. [Google Scholar] [CrossRef]

- Krstić, J.; Jovanović, J.; Gajević, S.; Miladinović, S.; Vaxevanidis, N.; Kiss, I.; Stojanović, B. Application of Metal Matrix Nanocomposites in Engineering. Adv. Eng. Lett. 2024, 3, 180–190. [Google Scholar] [CrossRef]

- Moghadam, A.D.; Schultz, B.F.; Ferguson, J.; Omrani, E.; Rohatgi, P.K.; Gupta, N. Functional Metal Matrix Composites: SelfLubricating, Self-Healing, and Nanocomposites-An Outlook. JOM 2014, 66, 872–881. [Google Scholar] [CrossRef]

- Chelladurai, S.; Kumar, S.; Venugopal, N.; Ray, A.; Manjunath, T.; Gnanasekaran, S. A review on mechanical properties and wear behaviour of aluminium based metal matrix composites. Mater. Today Proc. 2020, 37 Pt 2, 908–916S. [Google Scholar] [CrossRef]

- Sowrabh, B.S.; Gurumurthy, B.M.; Shivaprakash, Y.M.; Sharma, S. Reinforcements, production techniques and property analysis of AA7075 matrix composites—A critical review. Manuf. Rev. 2021, 8, 31. [Google Scholar] [CrossRef]

- Maleque, M.; Adebisi, A. Energy efficient lighter weight aluminium matrix composite automotive brake motor. In Proceedings of the International Conference Harnessing Technology 2011, Singapore, 14–16 July 2011. [Google Scholar]

- Gomilšek, R.; Čuček, L.; Homšak, M.; Tan, R.; Kravanja, Z. Carbon Emissions Constrained Energy Planning for Aluminum Products. Energies 2020, 13, 2753. [Google Scholar] [CrossRef]

- Bhoi, N.; Singh, H.; Pratap, S. Developments in the aluminum metal matrix composites reinforced by micro/nano particles—A review. J. Compos. Mater. 2020, 54, 813–833. [Google Scholar] [CrossRef]

- Vellaichamy, R.D.; Tharisanan, R.; Allahpitchai, M.; Krishnan, B. Investigate the mechanical properties of Aluminium Metal Matrix Composite. J. Phys. Conf. Ser. 2024, 2748, 012009. [Google Scholar] [CrossRef]

- Saravanan, G.; Bhaskar, G.; Elaiyarasan, U.; Alagu, R. A study on mechanical and microstructure behaviour of carbon and glass fibre reinforced Al 2024-T3 laminated composite. Metall. Res. Technol. 2023, 120, 203. [Google Scholar] [CrossRef]

- Ramdani, N.; Razali, M. Processing, Properties, and Uses of Lightweight Glass Fiber/Aluminum Hybrid Structures. In Handbook of Research on Advancements in the Processing, Characterization and Application of Lightweight Materials; IGI Global Scientific Publishing: Hershey, PA, USA, 2022; ISBN 9781799878643. [Google Scholar] [CrossRef]

- Khalid, M.; Arif, Z.; Rashid, A.; Shahid, M.; Ahmed, W.; Tariq, A.; Abbas, Z. Interlaminar shear strength (ILSS) characterization of fiber metal laminates (FMLs) manufactured through VARTM process. Forces Mech. 2021, 4, 100038. [Google Scholar] [CrossRef]

- Samal, P.; Raj, H.; Meher, A.; Surekha, B.; Vundavilli, P.; Sharma, P. Synergistic Effect of B4C and Multi-Walled CNT on Enhancing the Tribological Performance of Aluminum A383 Hybrid Composites. Lubricants 2024, 12, 213. [Google Scholar] [CrossRef]

- Thiraviam, R.; Ravisankar, V.; Pradeep Kumar, K.; Thanigaivelan, R.; Arunachalam, R. A novel approach for the production and characterisation of aluminium–alumina hybrid metal matrix composites. Mater. Res. Express 2020, 7, 046512. [Google Scholar] [CrossRef]

- Ponnusamy, P.; Rashid, R.A.R.; Masood, S.H.; Ruan, D.; Palanisamy, S. Mechanical Properties of SLM-Printed Aluminium Alloys: A Review. Materials 2020, 13, 4301. [Google Scholar] [CrossRef] [PubMed]

- James, J.; Annamalai, A.; Muthuchamy, A.; Jen, C. Effect of Wettability and Uniform Distribution of Reinforcement Particle on Mechanical Property (Tensile) in Aluminum Metal Matrix Composite A Review. Nanomaterials 2021, 11, 2230. [Google Scholar] [CrossRef] [PubMed]

- Kalashnikov, I.; Kobeleva, L.; Bykov, P.; Kolmakov, A.; Katin, I.; Mikheev, R. Estimation of distribution uniformity of Ti2NbAl particles in an aluminum-matrix composite material. Perspekt. Mater. 2022, 5, 40–48. [Google Scholar] [CrossRef]

- Malaki, M.; Tehrani, F.; Niroumand, B.; Gupta, M. Wettability in Metal Matrix Composites. Metals 2021, 11, 1034. [Google Scholar] [CrossRef]

- Yang, X.; Barekar, N.; Ji, S.; Dhindaw, B.; Fan, Z. Influence of reinforcing particle distribution on the casting characteristics of Al-SiCp composites. J. Mater. Process. Technol. 2020, 279, 116580. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J. A Review of the Friction and Wear Behavior of Particle-Reinforced Aluminum Matrix Composites. Lubricants 2023, 11, 317. [Google Scholar] [CrossRef]

- Zhang, X.; Hu, T.; Rufner, J.; Lagrange, T.; Campbell, G.; Lavernia, E.; Schoenung, J.; Van Benthem, K. Metal/ceramic Interface Structures and Segregation Behavior in Aluminum-based Composites. Microsc. Microanal. 2015, 21, 1053–1054. [Google Scholar] [CrossRef][Green Version]

- Gowrishankar, M.C.; Hiremath, P.; Shettar, M.; Sharma, S.; SatishRao, U. Experimental validity on the casting characteristics of stir cast aluminium composites. J. Mater. Res. Technol. 2020, 9, 3340–3347. [Google Scholar] [CrossRef]

- Zhu, J.; Jiang, W.; Li, G.; Guan, F.; Yu, Y.; Fan, Z. Microstructure and mechanical properties of SiCnp/Al6082 aluminum matrix composites prepared by squeeze casting combined with stir casting. J. Mater. Process. Technol. 2020, 283, 116699. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, N.; Lee, S.; Kim, Y.; Cho, S.; Lee, S.; Jo, I. Microstructure and mechanical properties of lightweight TiC-steel composite prepared by liquid pressing infiltration process. Mater. Charact. 2020, 162, 110202. [Google Scholar] [CrossRef]

- Rathee, S.; Maheshwari, S.; Siddiquee, A. Issues and strategies in composite fabrication via friction stir processing: A review. Mater. Manuf. Process. 2018, 33, 239–261. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, V.; Mewar, S.; Pal, S.; Paul, J. Friction stir processing of Al6061-SiC-graphite hybrid surface composites. Mater. Manuf. Process. 2018, 33, 795–804. [Google Scholar] [CrossRef]

- SR EN 1676:2020; Aluminium and Aluminium Alloys. Ingots for Remelting of Aluminum Alloys. Specifications. European Committee for Standardization (CEN): Brussels, Belgium, 2020.

- Belu-Nica, R. Contributions on the Production and Joining by Welding of Thin Sheets Made of Metal Composite Materials with Aluminum Alloy Matrix; Politehnica Publishing House: Timişoara, Romania, 2007; Volume 9. [Google Scholar]

- Szczepanik, S. Composites of Aluminium Alloy Matrix Reinforced by a Steel Mesh. Mater. Today Proc. 2015, 2, S9–S18. [Google Scholar] [CrossRef]

- Ferro, P.; Fabrizi, A.; Bonollo, F.; Berto, F. Microstructural and mechanical characterization of a stainless-steel wire mesh–reinforced Al-matrix composite: Bimatallic components for lightweight design. Frat. Ed Integr. Strutt. 2020, 15, 289–301. [Google Scholar] [CrossRef]

- Chelladurai, S.; Arthanari, R.; Krishnamoorthy, K.; Selvaraj, K.; Govindan, P. Effect of Copper Coating and Reinforcement Orientation on Mechanical Properties of LM6 Aluminium Alloy Composites Reinforced with Steel Mesh by Squeeze Casting. Trans. Indian Inst. Met. 2018, 71, 1041–1048. [Google Scholar] [CrossRef]

- Huang, H.; Wang, J.; Liu, W. Mechanical properties and reinforced mechanism of the stainless steel wire mesh–reinforced Al-matrix composite plate fabricated by twin-roll casting. Adv. Mech. Eng. 2017, 1–9. [Google Scholar] [CrossRef]

- Weng, H.; Wang, J.; Zhu, X.; Lu, X. Effect of heat treatment on interfacial microstructure and mechanical properties of the aluminum/steel joints with copper transition layer. Intermetallics 2025, 178, 108646. [Google Scholar] [CrossRef]

- Wang, G.; Zhou, K.; Ren, B.; Yu, W. Influence of Cu/Ni coating on microstructure and mechanical properties in steel/aluminum single-sided resistance spot welding joint. J. Mater. Process. Technol. 2025, 335, 118675. [Google Scholar] [CrossRef]

- Khoonsari, E.; Jalilian, F.; Paray, F.; Emadi, D.; Drew, R. Interaction of 308 stainless steel insert with A319 aluminium casting alloy. Mater. Sci. Technol. 2010, 26, 833–841. [Google Scholar] [CrossRef]

- SR EN ISO/CEI 17025:2005; General Requirements for the Competence of Testing and Calibration Laboratories. European Committee for Standardization (CEN): Brussels, Belgium, 2005.

- Mănescu, T. Applications of Material Strength; Eftimie Murgu: Reșița, Romania, 2010. [Google Scholar]

| Al | Si | Mn | Mg | Fe | Ti | Zn | Cu |

|---|---|---|---|---|---|---|---|

| 87–89% | 9–10% | 0.3–0.6% | 0.2–0.5% | 0.6% | 0.15% | 0.10% | 0.05% |

| Fe | C | Mn | Si | P | S |

|---|---|---|---|---|---|

| 98.70–99.40% | 0.13–0.22% | 0.3–0.6% | 0.15–0.35% | 0.045% | 0.055% |

| Sample/Parameters | a [mm] | b [mm] | F max [N] | σ [N/mm2] × 103 |

|---|---|---|---|---|

| T1 | 15.7 | 15.1 | 28.40 | 119.80 |

| T2 | 15.4 | 15.0 | 24.89 | 107.75 |

| T3 | 15.5 | 15.0 | 23.01 | 98.97 |

| T4 | 15.6 | 15.1 | 18.50 | 78.54 |

| T5 | 15.3 | 15.0 | 26.69 | 116.30 |

| T6 | 15.2 | 15.1 | 24.00 | 104.57 |

| T7 | 15.6 | 15.0 | 23.50 | 100.43 |

| T8 | 15.4 | 15.1 | 22.92 | 98.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miclosina, C.-O.; Belu-Nica, R.; Ciubotariu, C.R.; Marginean, G. Processing and Evaluation of an Aluminum Matrix Composite Material. J. Compos. Sci. 2025, 9, 335. https://doi.org/10.3390/jcs9070335

Miclosina C-O, Belu-Nica R, Ciubotariu CR, Marginean G. Processing and Evaluation of an Aluminum Matrix Composite Material. Journal of Composites Science. 2025; 9(7):335. https://doi.org/10.3390/jcs9070335

Chicago/Turabian StyleMiclosina, Calin-Octavian, Remus Belu-Nica, Costel Relu Ciubotariu, and Gabriela Marginean. 2025. "Processing and Evaluation of an Aluminum Matrix Composite Material" Journal of Composites Science 9, no. 7: 335. https://doi.org/10.3390/jcs9070335

APA StyleMiclosina, C.-O., Belu-Nica, R., Ciubotariu, C. R., & Marginean, G. (2025). Processing and Evaluation of an Aluminum Matrix Composite Material. Journal of Composites Science, 9(7), 335. https://doi.org/10.3390/jcs9070335