UV-Accelerated Aging of PLA and PP-Based Biocomposites: A Spectral and Colorimetric Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials—Biocomposite Samples

2.2. Methods—Biocomposite Manufacturing

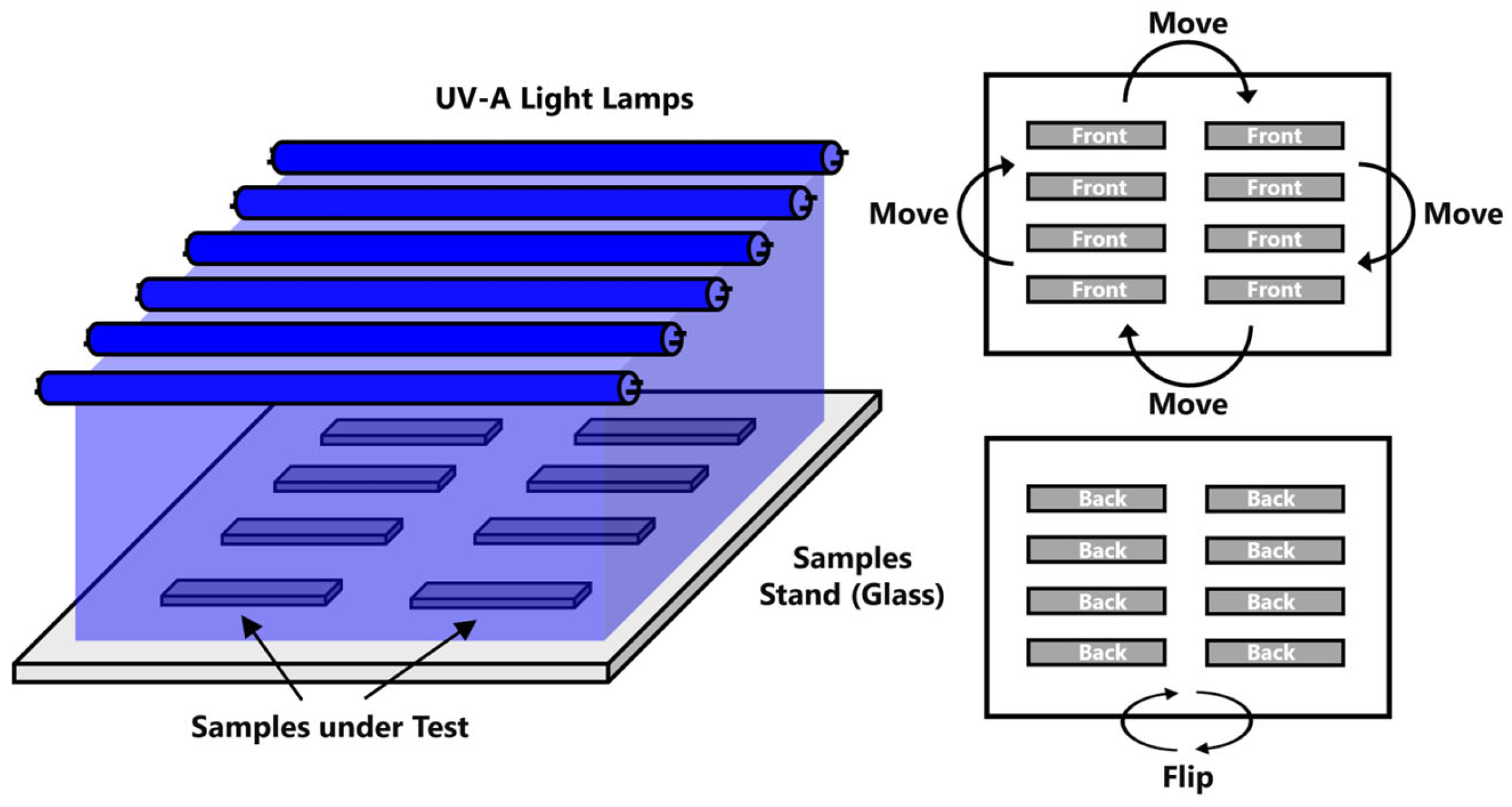

2.3. Methods—UV Aging Chamber

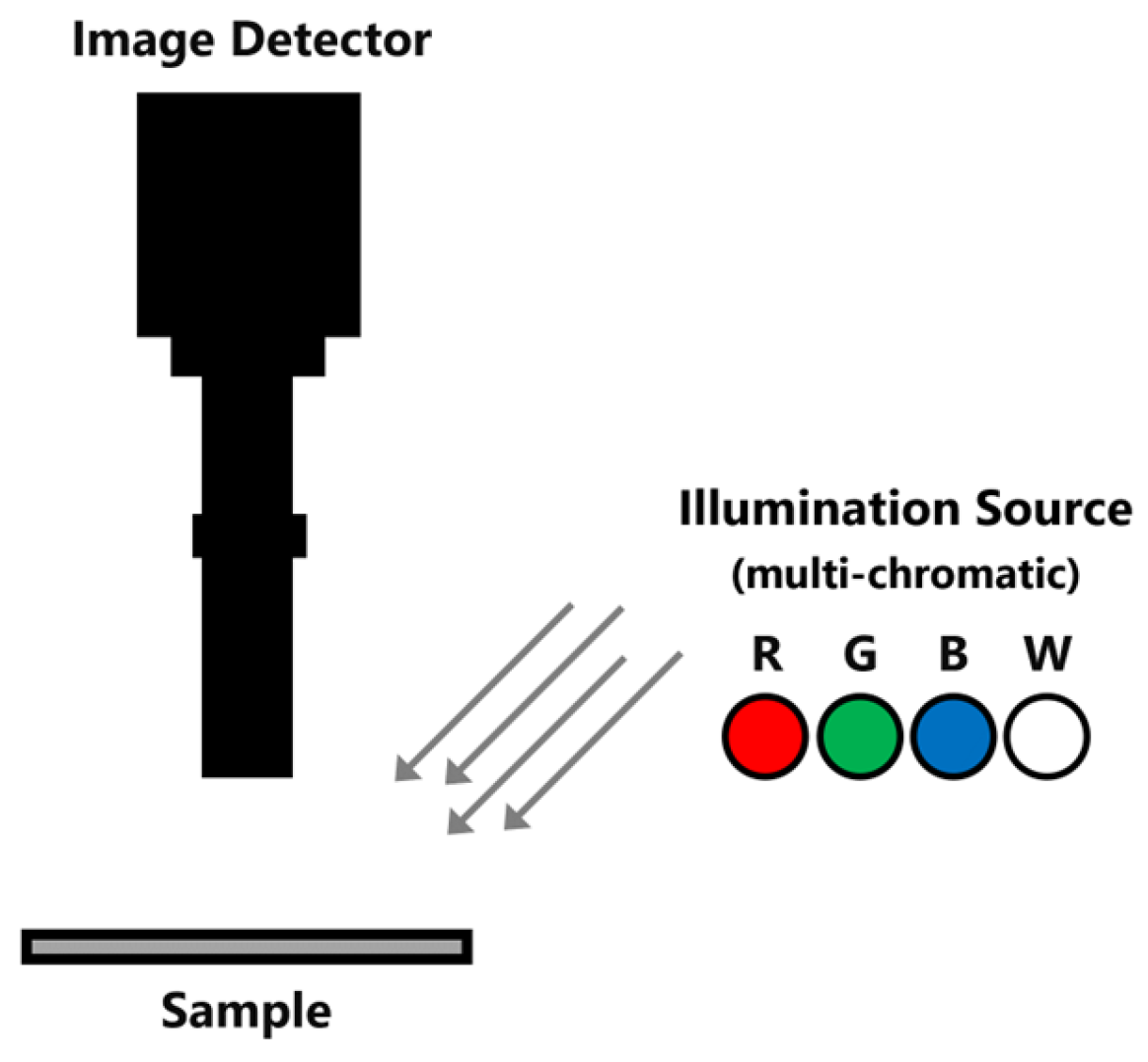

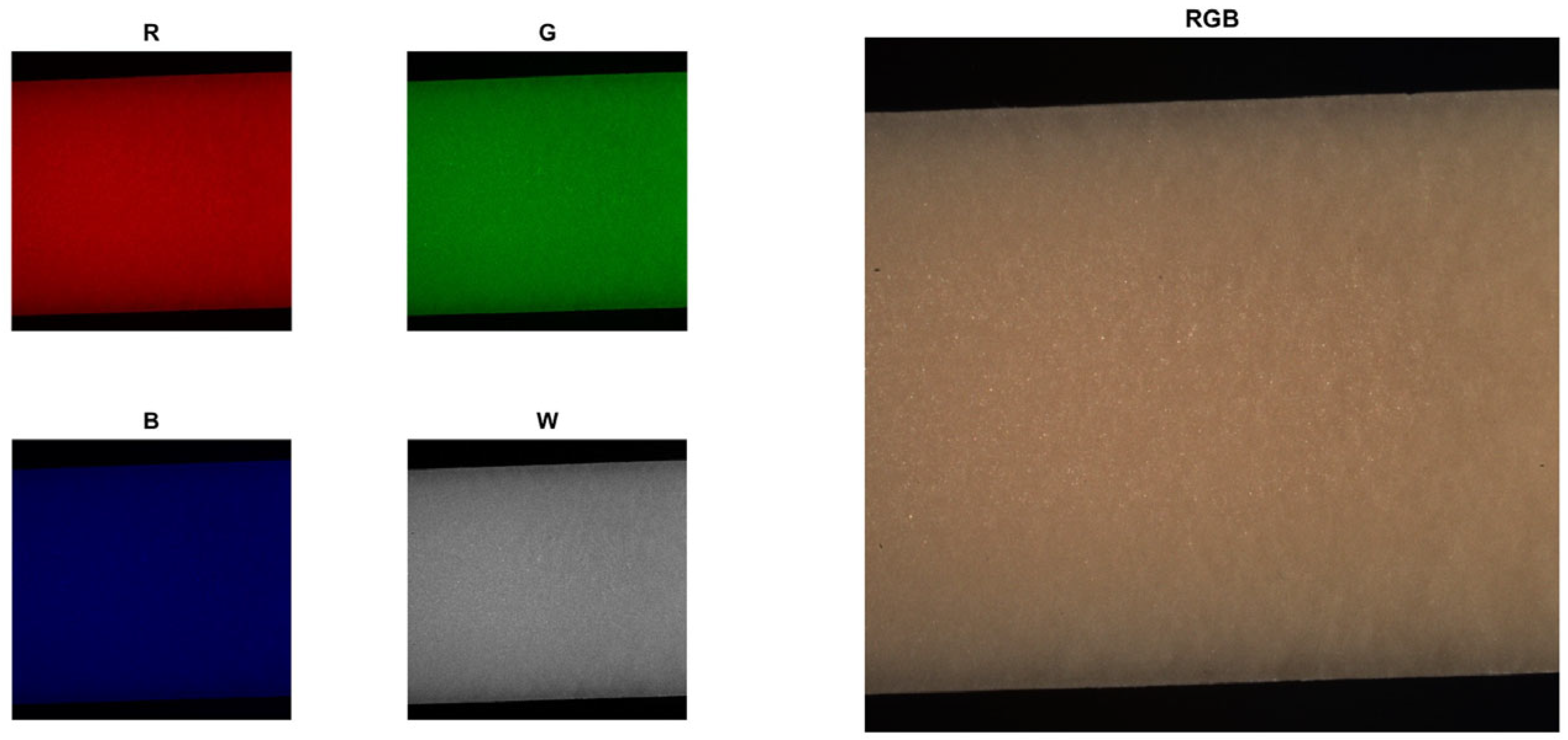

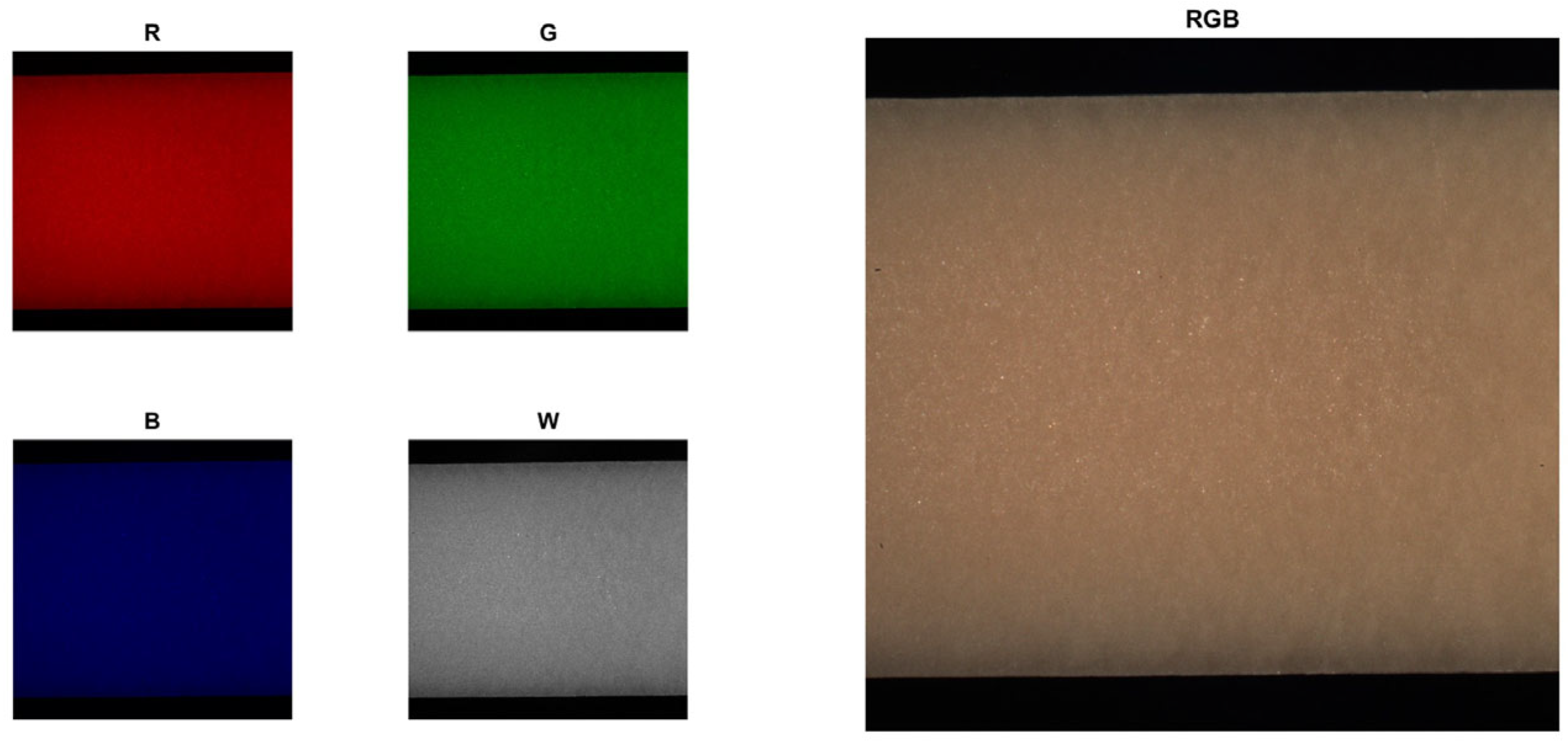

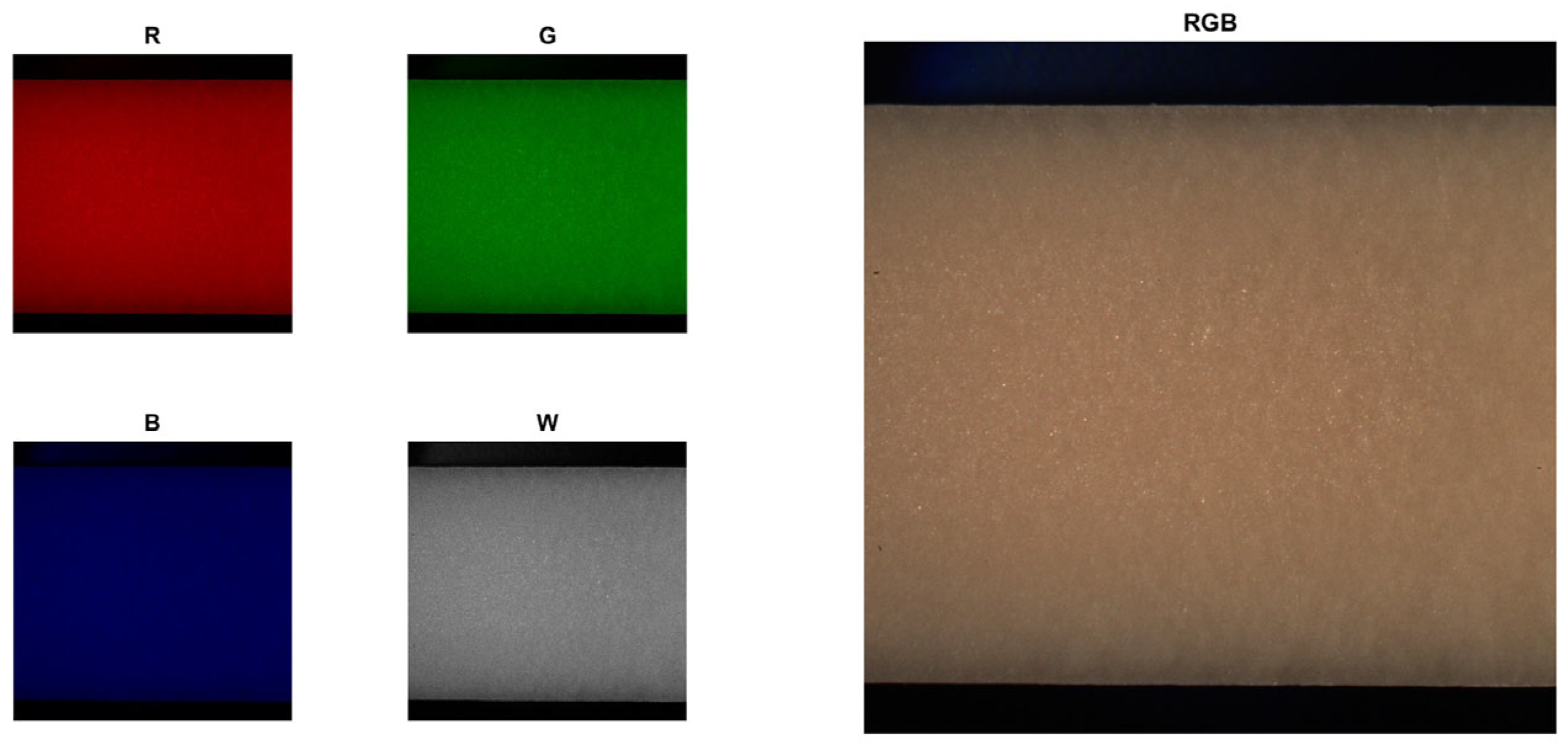

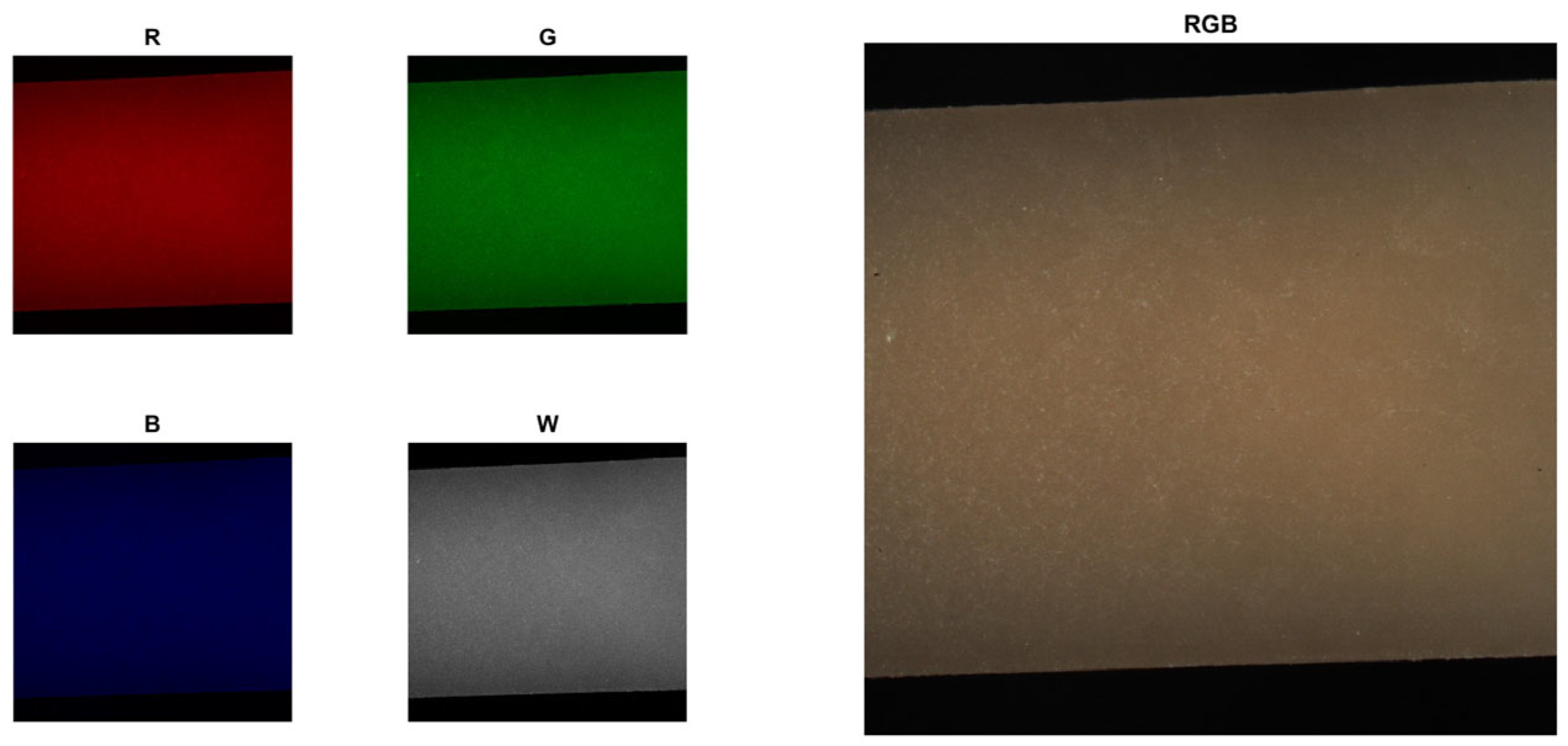

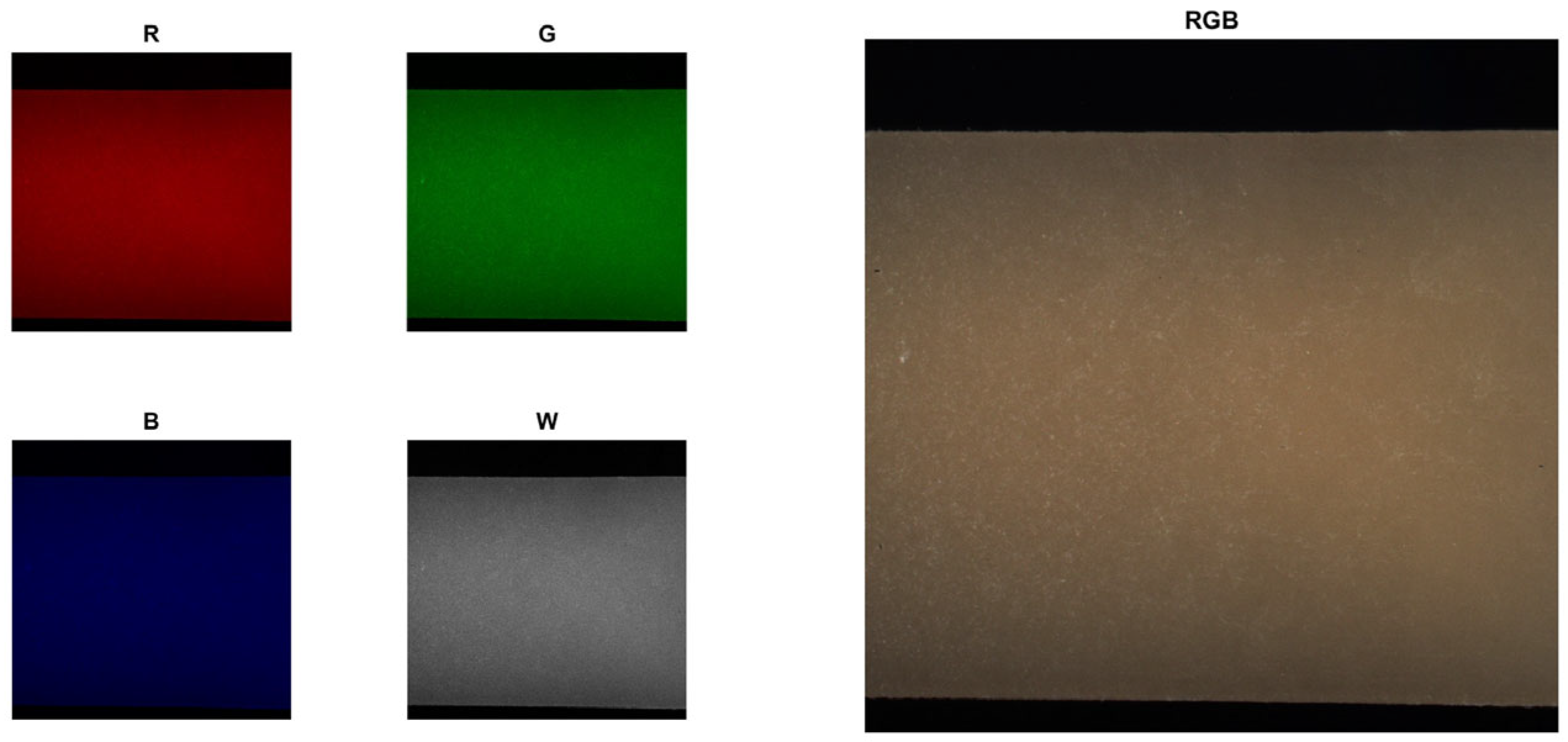

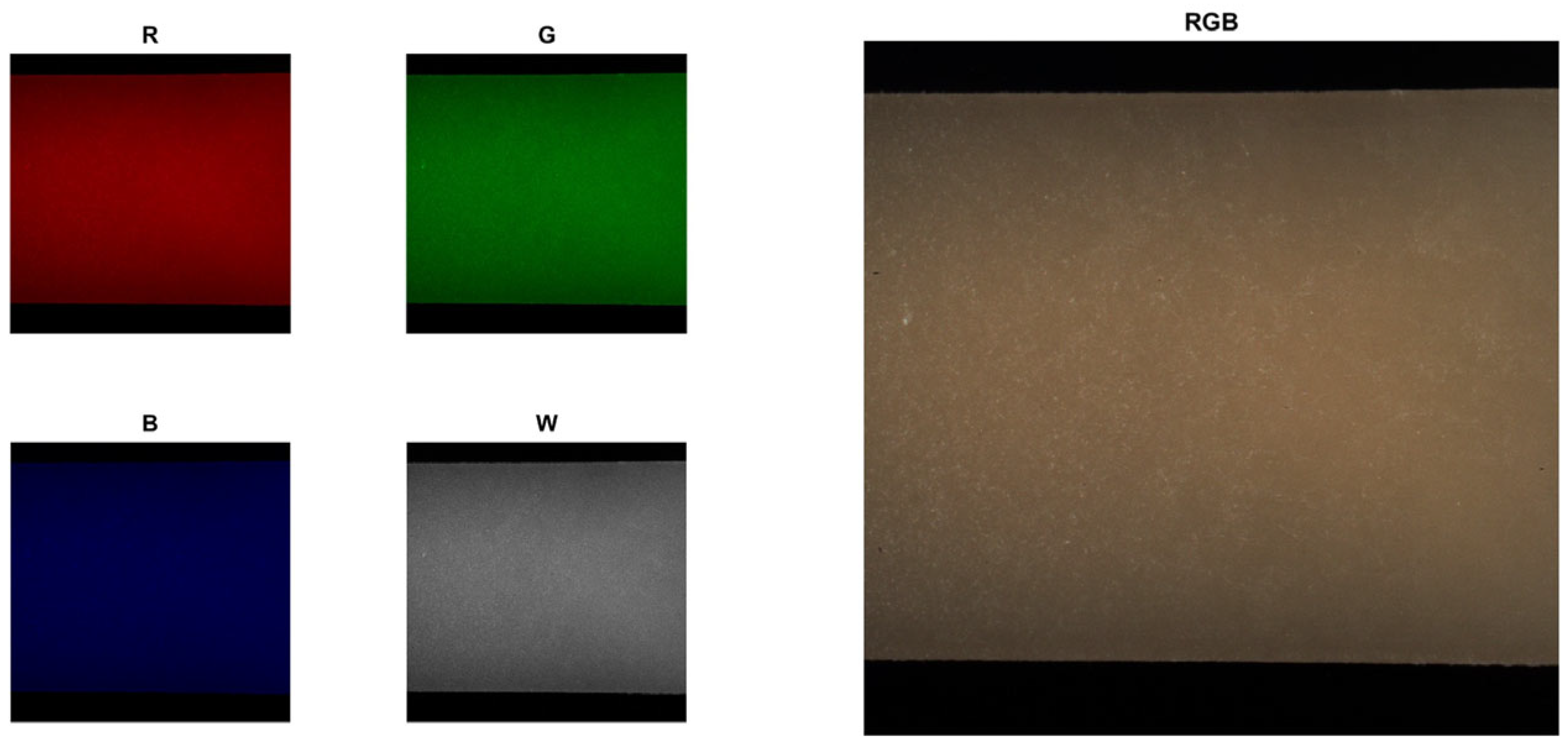

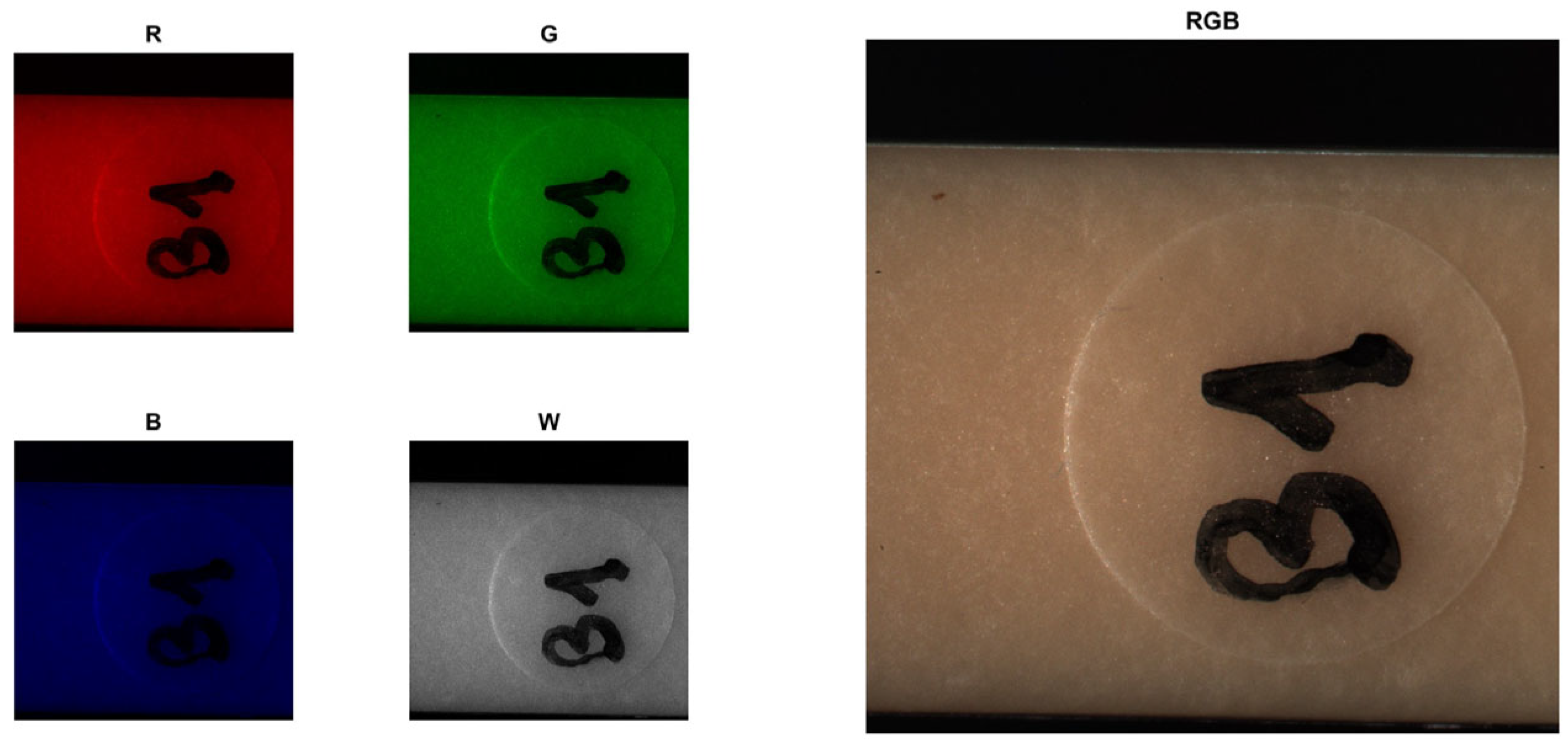

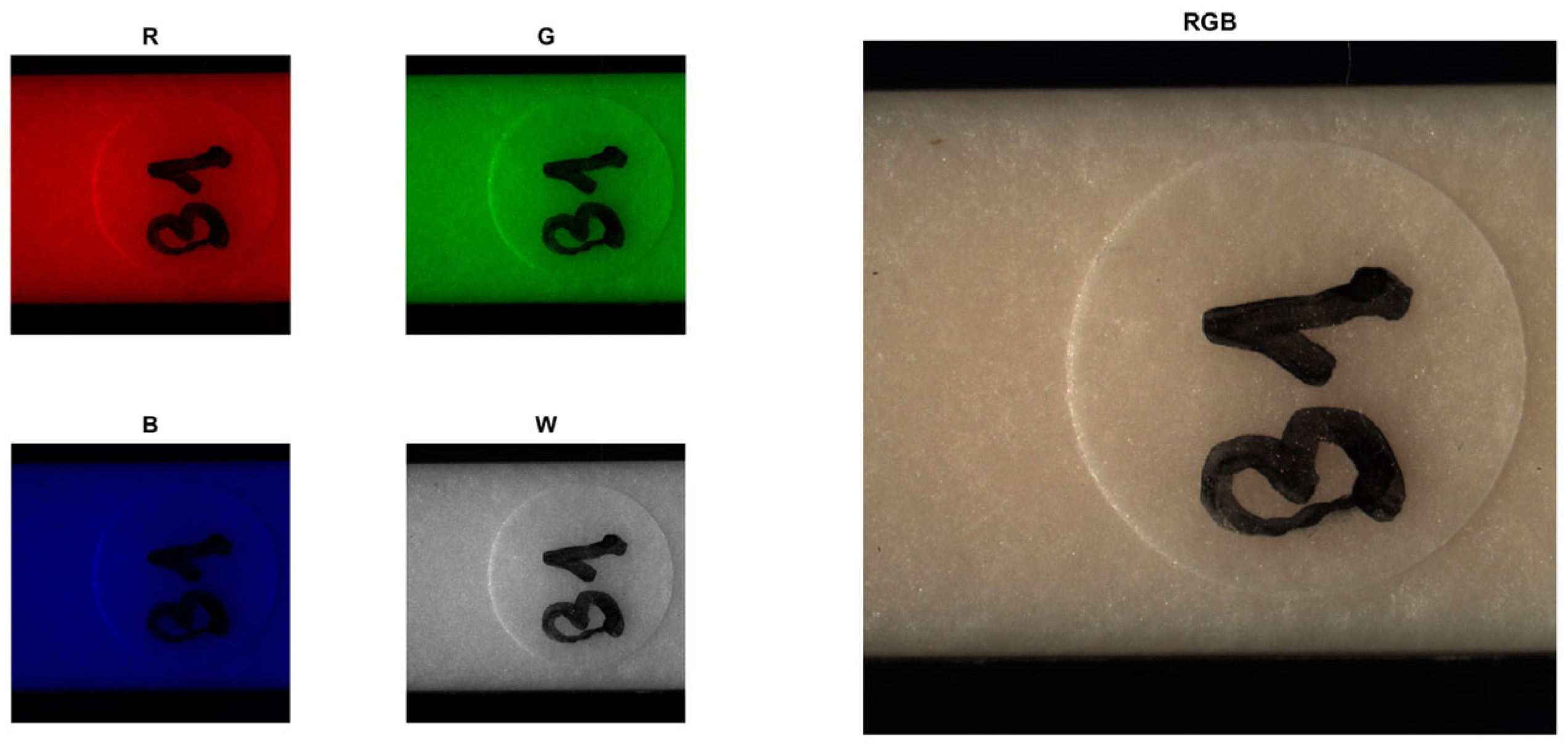

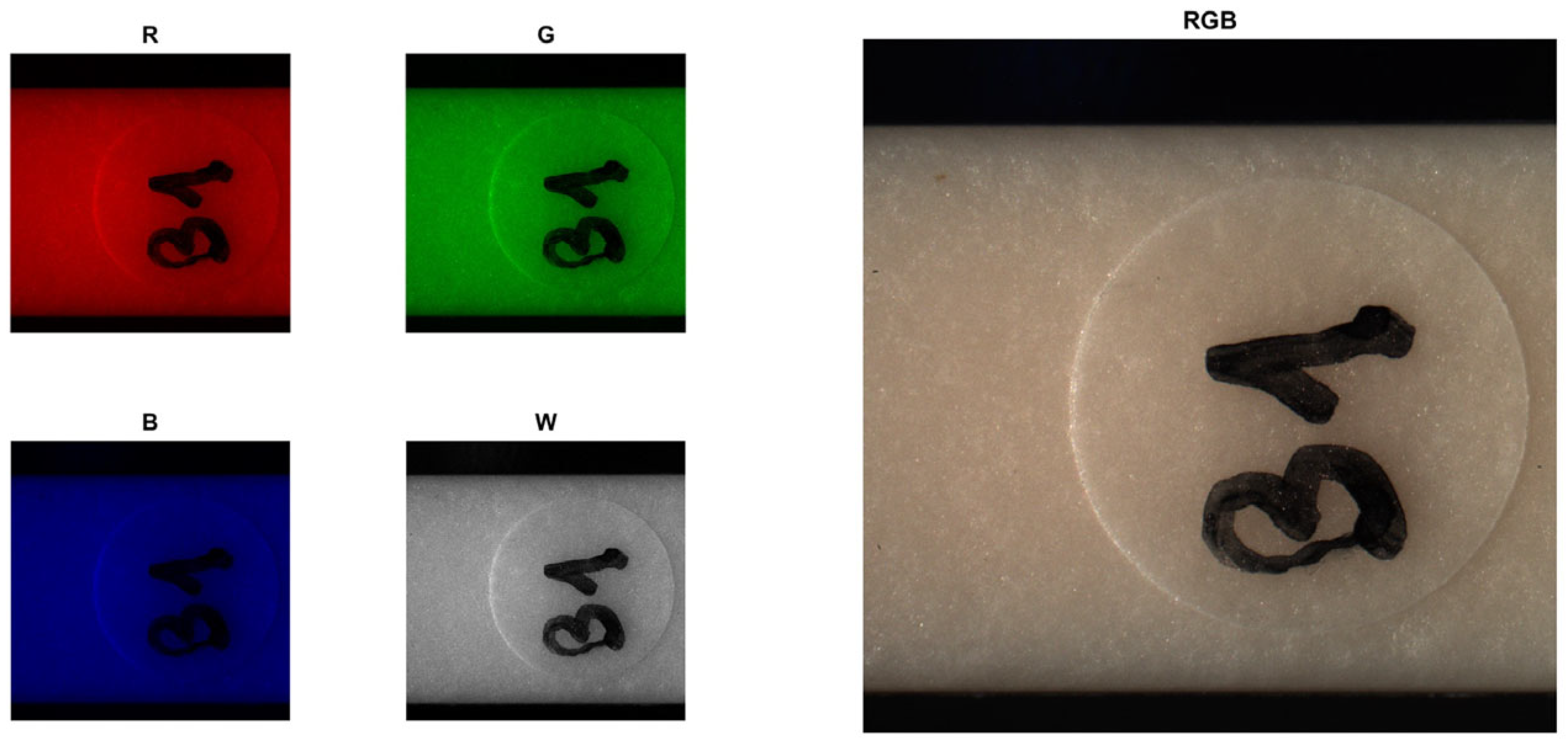

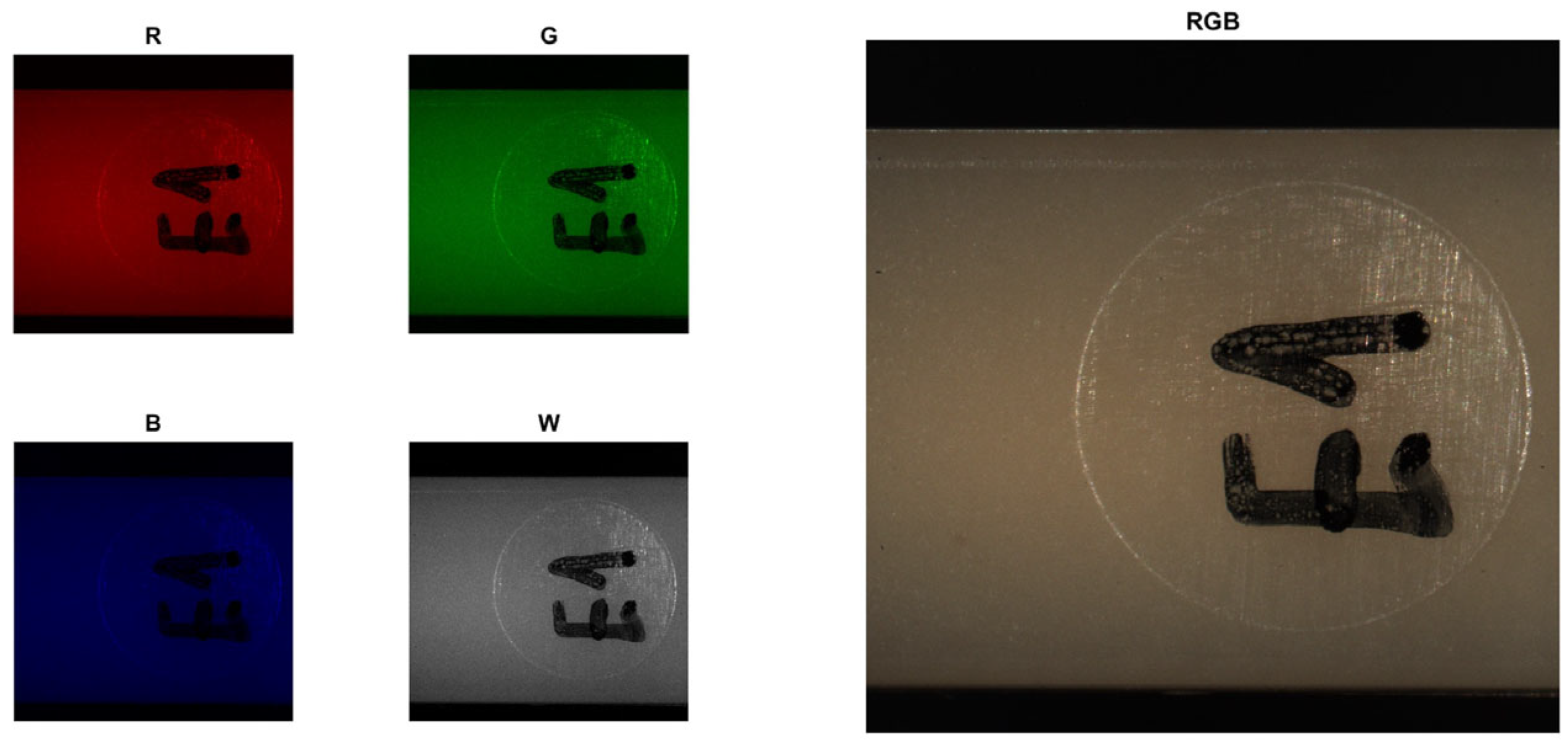

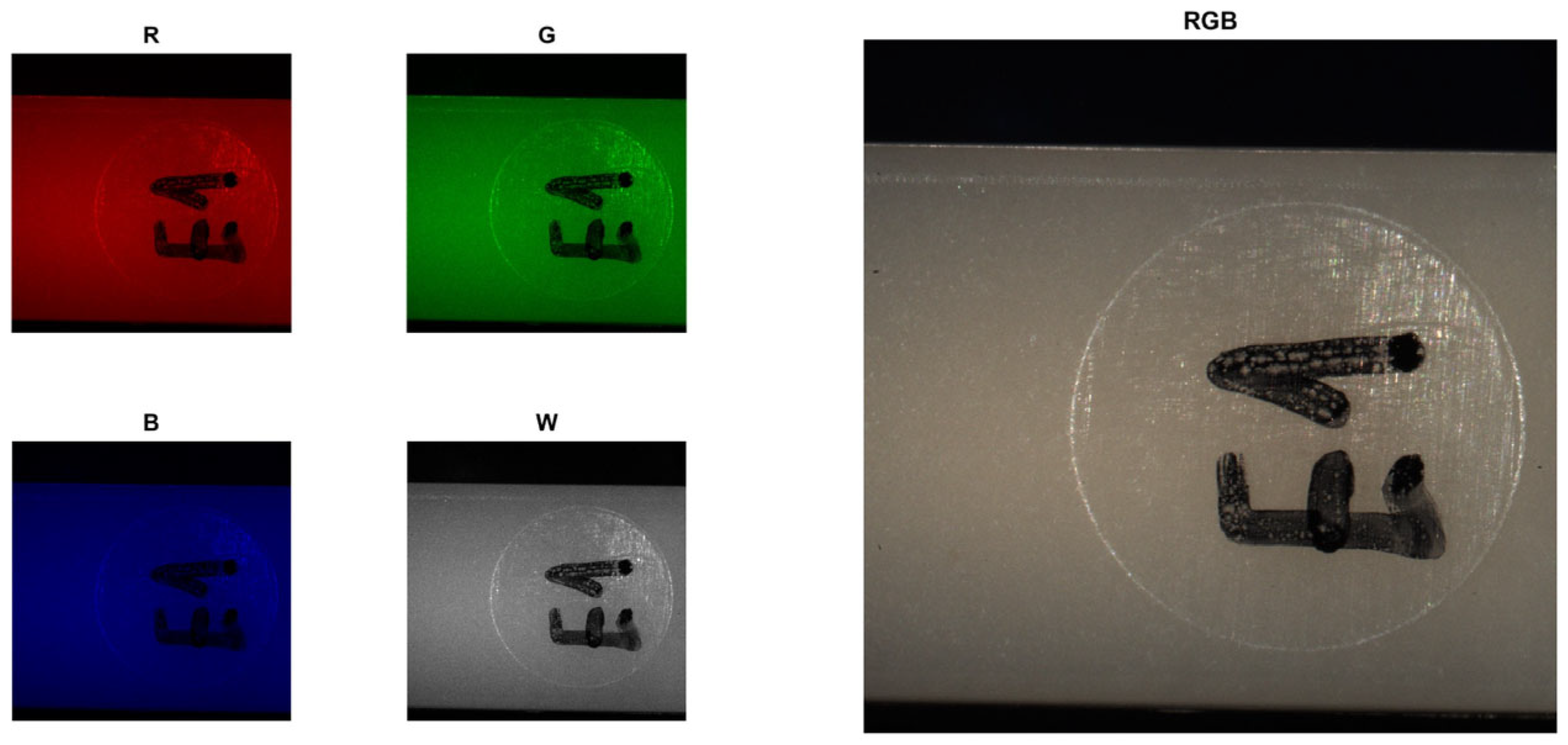

2.4. Methods—Optical System

2.5. Methods—Spectrophotometer

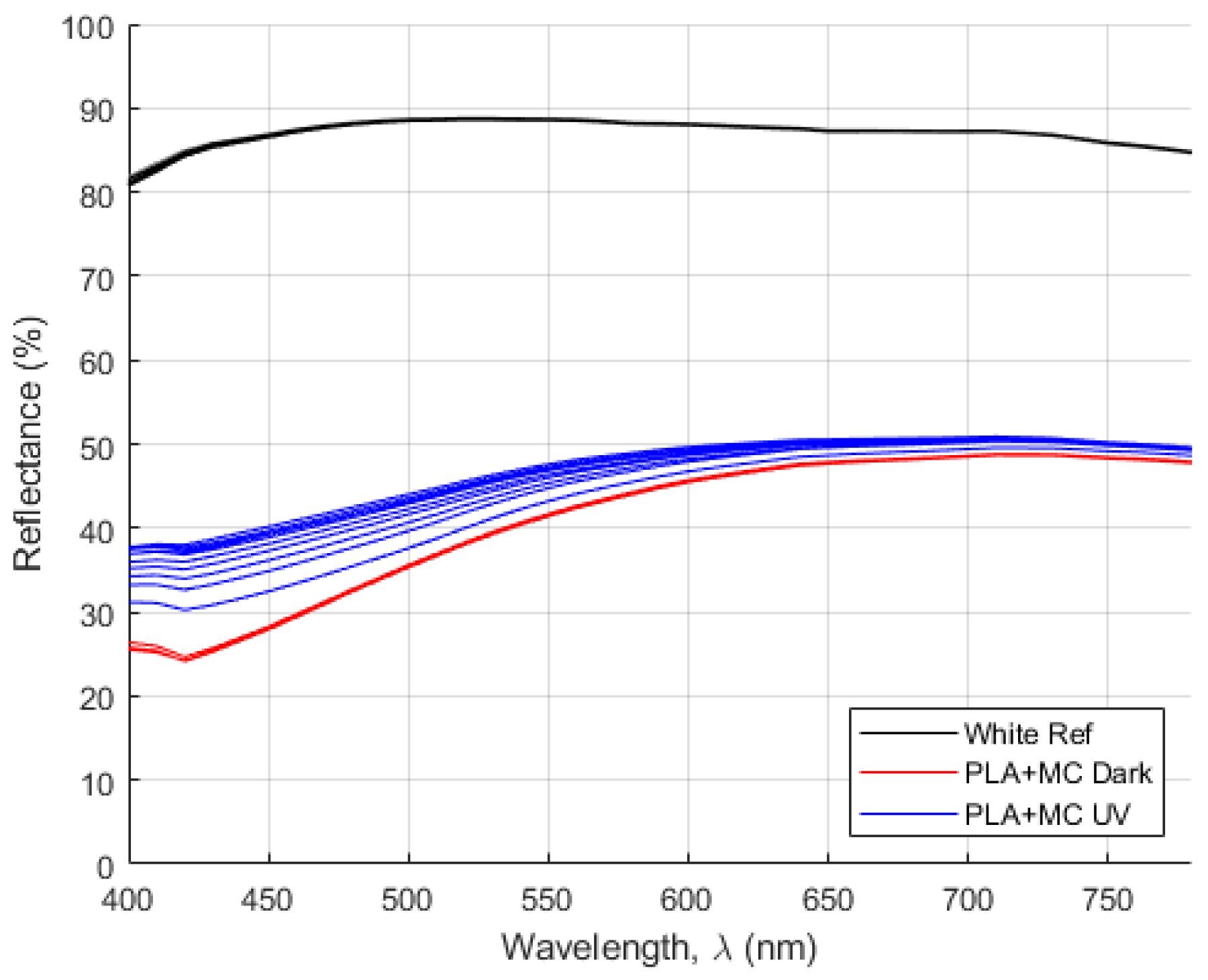

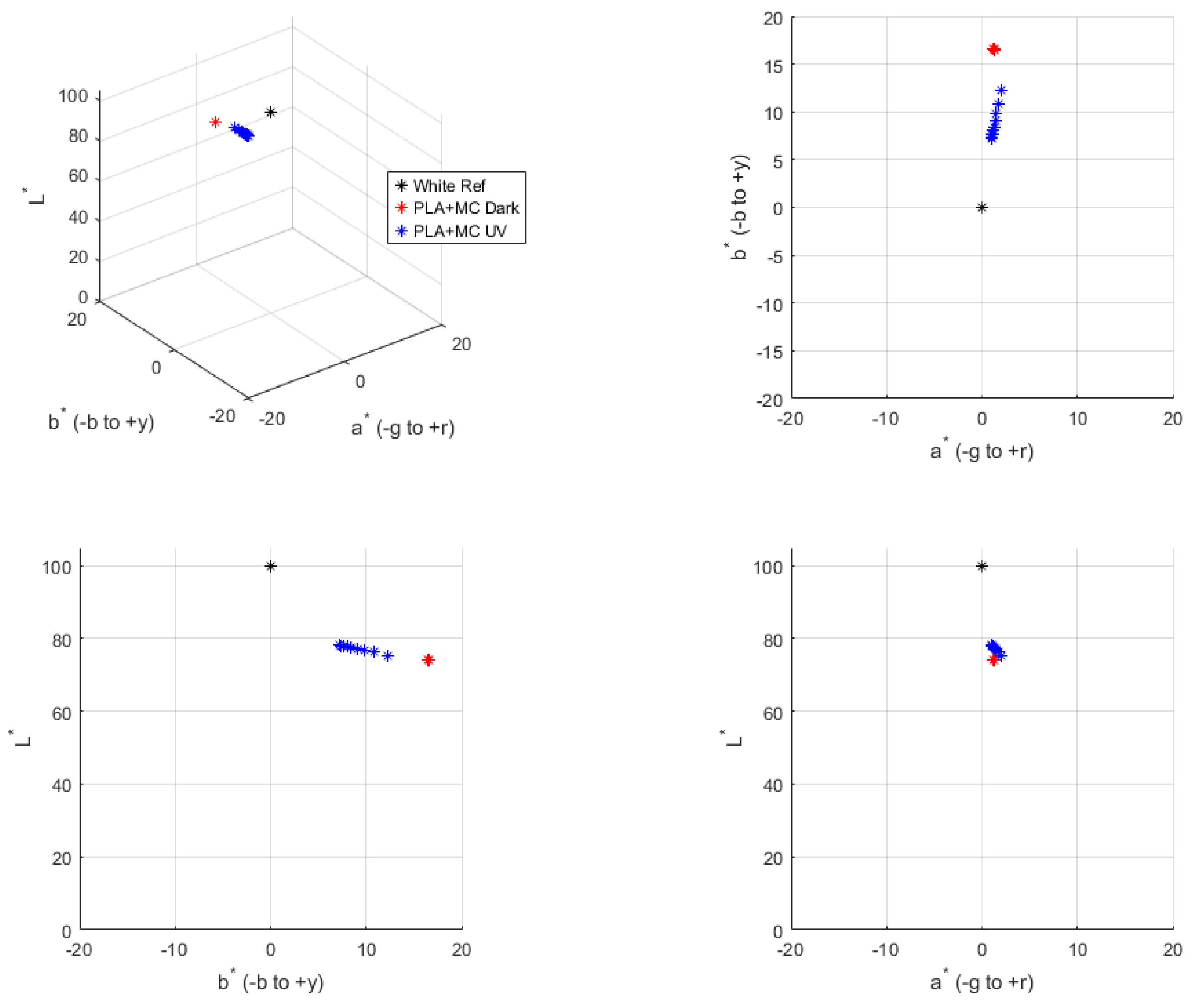

3. Results and Discussion

4. Conclusions

- As expected, the specimens that did not receive any UV radiation showed no relevant color changes throughout the entire UV test period.

- On the other hand, the specimens that were exposed to UV radiation showed noticeable changes, revealing color fading and a lighter appearance over time.

- This effect was observed in the images captured from the tested samples as well as in the spectral reflectance and colorimetric measurements taken during the 10 week test period.

- The color fading was more pronounced in the PLA + MC specimens compared to the PP + MC specimens.

- The images captured during the UV test revealed that in addition to the color fading experienced by the PP, the specimens of this material also exhibited signs of surface damage. There was a slight crazing present on the surface of the specimens that were exposed to UV light, which was consistent with other research found in the literature on this topic.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| B | blue |

| CIE | International Commission on Illumination |

| DK | dark |

| DNA | deoxyribonucleic acid |

| G | green |

| h | hour(s) |

| IR | infrared |

| ISO | International Organization for Standardization |

| MC | micronized cellulose |

| MFI | melt flow index |

| PLA | polylactic acid |

| PP | polypropylene |

| R | red |

| Ref | reference |

| RGB | red–green–blue |

| rpm | revolutions per minute |

| UV | ultraviolet |

| UV-A | ultraviolet subtype A |

| UV-B | ultraviolet subtype B |

| UV-C | ultraviolet subtype C |

| vs. | versus |

| W | white |

| WK | week |

Appendix A

| λ (nm) | DK 01 | DK 05 | DK 10 | WK 01 | WK 02 | WK 03 | WK 04 | WK 05 | WK 06 | WK 07 | WK 08 | WK 09 | WK 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 400 | 80.87 | 81.82 | 80.71 | 80.85 | 80.85 | 80.76 | 80.78 | 80.86 | 81.16 | 81.53 | 80.92 | 81.05 | 80.72 |

| 410 | 82.57 | 83.45 | 82.39 | 82.51 | 82.53 | 82.48 | 82.44 | 82.50 | 82.82 | 83.13 | 82.57 | 82.62 | 82.44 |

| 420 | 84.30 | 84.98 | 84.22 | 84.34 | 84.29 | 84.36 | 84.30 | 84.41 | 84.62 | 84.73 | 84.24 | 84.37 | 84.25 |

| 430 | 85.30 | 85.86 | 85.35 | 85.41 | 85.31 | 85.36 | 85.31 | 85.48 | 85.55 | 85.76 | 85.37 | 85.41 | 85.29 |

| 440 | 85.90 | 86.39 | 85.93 | 85.96 | 85.95 | 85.97 | 85.92 | 86.04 | 86.13 | 86.27 | 85.91 | 85.94 | 85.93 |

| 450 | 86.52 | 86.94 | 86.50 | 86.53 | 86.51 | 86.56 | 86.56 | 86.62 | 86.71 | 86.84 | 86.51 | 86.54 | 86.52 |

| 460 | 87.14 | 87.49 | 87.13 | 87.18 | 87.11 | 87.16 | 87.19 | 87.20 | 87.28 | 87.43 | 87.17 | 87.15 | 87.12 |

| 470 | 87.60 | 87.96 | 87.65 | 87.67 | 87.64 | 87.65 | 87.65 | 87.68 | 87.79 | 87.88 | 87.67 | 87.67 | 87.63 |

| 480 | 88.00 | 88.32 | 88.01 | 88.04 | 88.01 | 88.04 | 88.05 | 88.06 | 88.17 | 88.21 | 88.06 | 88.08 | 88.01 |

| 490 | 88.27 | 88.56 | 88.29 | 88.34 | 88.26 | 88.32 | 88.32 | 88.35 | 88.44 | 88.49 | 88.33 | 88.37 | 88.30 |

| 500 | 88.46 | 88.69 | 88.50 | 88.51 | 88.46 | 88.47 | 88.49 | 88.51 | 88.60 | 88.68 | 88.52 | 88.56 | 88.46 |

| 510 | 88.54 | 88.73 | 88.57 | 88.55 | 88.53 | 88.51 | 88.58 | 88.54 | 88.64 | 88.73 | 88.57 | 88.62 | 88.51 |

| 520 | 88.60 | 88.81 | 88.64 | 88.65 | 88.63 | 88.61 | 88.68 | 88.63 | 88.73 | 88.81 | 88.65 | 88.69 | 88.60 |

| 530 | 88.58 | 88.81 | 88.63 | 88.66 | 88.65 | 88.62 | 88.67 | 88.65 | 88.72 | 88.80 | 88.65 | 88.69 | 88.59 |

| 540 | 88.53 | 88.76 | 88.59 | 88.61 | 88.60 | 88.59 | 88.61 | 88.62 | 88.67 | 88.76 | 88.61 | 88.65 | 88.55 |

| 550 | 88.52 | 88.75 | 88.57 | 88.57 | 88.58 | 88.58 | 88.57 | 88.59 | 88.65 | 88.71 | 88.58 | 88.63 | 88.55 |

| 560 | 88.48 | 88.69 | 88.52 | 88.51 | 88.50 | 88.52 | 88.52 | 88.52 | 88.60 | 88.64 | 88.52 | 88.59 | 88.49 |

| 570 | 88.32 | 88.52 | 88.36 | 88.37 | 88.33 | 88.37 | 88.36 | 88.35 | 88.44 | 88.48 | 88.36 | 88.44 | 88.31 |

| 580 | 88.08 | 88.28 | 88.11 | 88.11 | 88.10 | 88.15 | 88.12 | 88.13 | 88.20 | 88.23 | 88.11 | 88.18 | 88.09 |

| 590 | 88.04 | 88.26 | 88.08 | 88.08 | 88.05 | 88.10 | 88.10 | 88.09 | 88.16 | 88.19 | 88.08 | 88.13 | 88.07 |

| 600 | 87.98 | 88.17 | 88.02 | 88.02 | 87.97 | 88.01 | 88.04 | 88.04 | 88.10 | 88.11 | 88.02 | 88.06 | 88.00 |

| 610 | 87.87 | 88.04 | 87.89 | 87.90 | 87.84 | 87.89 | 87.94 | 87.92 | 87.97 | 87.98 | 87.88 | 87.93 | 87.87 |

| 620 | 87.75 | 87.90 | 87.73 | 87.74 | 87.69 | 87.74 | 87.77 | 87.74 | 87.81 | 87.82 | 87.72 | 87.76 | 87.72 |

| 630 | 87.59 | 87.78 | 87.61 | 87.60 | 87.55 | 87.61 | 87.64 | 87.61 | 87.69 | 87.69 | 87.58 | 87.62 | 87.58 |

| 640 | 87.45 | 87.66 | 87.51 | 87.49 | 87.45 | 87.50 | 87.54 | 87.48 | 87.57 | 87.60 | 87.47 | 87.51 | 87.48 |

| 650 | 87.18 | 87.38 | 87.24 | 87.22 | 87.20 | 87.24 | 87.28 | 87.20 | 87.30 | 87.32 | 87.21 | 87.26 | 87.22 |

| 660 | 87.19 | 87.38 | 87.20 | 87.21 | 87.19 | 87.23 | 87.26 | 87.19 | 87.28 | 87.30 | 87.19 | 87.26 | 87.20 |

| 670 | 87.21 | 87.37 | 87.21 | 87.22 | 87.21 | 87.23 | 87.27 | 87.21 | 87.29 | 87.31 | 87.21 | 87.27 | 87.22 |

| 680 | 87.18 | 87.34 | 87.20 | 87.20 | 87.19 | 87.20 | 87.25 | 87.19 | 87.25 | 87.28 | 87.19 | 87.23 | 87.20 |

| 690 | 87.15 | 87.30 | 87.19 | 87.18 | 87.18 | 87.17 | 87.23 | 87.18 | 87.22 | 87.26 | 87.17 | 87.19 | 87.18 |

| 700 | 87.15 | 87.32 | 87.22 | 87.20 | 87.19 | 87.19 | 87.25 | 87.20 | 87.23 | 87.27 | 87.20 | 87.20 | 87.21 |

| 710 | 87.15 | 87.33 | 87.24 | 87.22 | 87.21 | 87.20 | 87.27 | 87.22 | 87.25 | 87.28 | 87.23 | 87.21 | 87.25 |

| 720 | 86.92 | 87.12 | 87.02 | 86.99 | 86.98 | 86.98 | 87.05 | 86.99 | 87.03 | 87.05 | 87.00 | 86.98 | 87.02 |

| 730 | 86.69 | 86.90 | 86.80 | 86.76 | 86.74 | 86.75 | 86.82 | 86.76 | 86.82 | 86.82 | 86.78 | 86.76 | 86.80 |

| 740 | 86.22 | 86.44 | 86.33 | 86.29 | 86.28 | 86.29 | 86.36 | 86.29 | 86.37 | 86.37 | 86.31 | 86.33 | 86.32 |

| 750 | 85.73 | 85.96 | 85.84 | 85.79 | 85.78 | 85.81 | 85.87 | 85.81 | 85.89 | 85.90 | 85.81 | 85.85 | 85.82 |

| 760 | 85.42 | 85.65 | 85.52 | 85.48 | 85.45 | 85.50 | 85.55 | 85.50 | 85.56 | 85.59 | 85.50 | 85.53 | 85.50 |

| 770 | 85.06 | 85.28 | 85.11 | 85.11 | 85.07 | 85.12 | 85.15 | 85.13 | 85.16 | 85.21 | 85.12 | 85.14 | 85.15 |

| 780 | 84.64 | 84.84 | 84.66 | 84.67 | 84.64 | 84.68 | 84.72 | 84.71 | 84.72 | 84.77 | 84.69 | 84.70 | 84.73 |

| λ (nm) | DK 01 | DK 05 | DK 10 | WK 01 | WK 02 | WK 03 | WK 04 | WK 05 | WK 06 | WK 07 | WK 08 | WK 09 | WK 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 400 | 24.57 | 25.44 | 24.73 | 30.33 | 32.15 | 33.45 | 34.37 | 35.17 | 36.14 | 36.83 | 36.24 | 36.84 | 36.86 |

| 410 | 24.19 | 24.98 | 24.35 | 30.23 | 32.16 | 33.52 | 34.53 | 35.39 | 36.38 | 37.05 | 36.55 | 37.13 | 37.17 |

| 420 | 23.03 | 23.66 | 23.29 | 29.43 | 31.57 | 33.01 | 34.10 | 35.13 | 35.99 | 36.56 | 36.27 | 36.82 | 37.02 |

| 430 | 24.08 | 24.63 | 24.34 | 30.04 | 32.18 | 33.56 | 34.67 | 35.72 | 36.49 | 37.05 | 36.86 | 37.32 | 37.61 |

| 440 | 25.38 | 25.85 | 25.62 | 30.78 | 32.92 | 34.27 | 35.41 | 36.39 | 37.16 | 37.67 | 37.52 | 37.98 | 38.30 |

| 450 | 26.65 | 27.08 | 26.90 | 31.59 | 33.68 | 35.02 | 36.15 | 37.10 | 37.84 | 38.32 | 38.22 | 38.66 | 38.99 |

| 460 | 28.09 | 28.48 | 28.34 | 32.52 | 34.54 | 35.80 | 36.94 | 37.83 | 38.57 | 39.04 | 38.97 | 39.39 | 39.70 |

| 470 | 29.53 | 29.91 | 29.81 | 33.48 | 35.43 | 36.64 | 37.75 | 38.61 | 39.31 | 39.75 | 39.70 | 40.13 | 40.42 |

| 480 | 31.00 | 31.35 | 31.26 | 34.49 | 36.38 | 37.53 | 38.60 | 39.43 | 40.09 | 40.49 | 40.47 | 40.88 | 41.16 |

| 490 | 32.38 | 32.72 | 32.63 | 35.49 | 37.29 | 38.39 | 39.43 | 40.20 | 40.86 | 41.23 | 41.23 | 41.62 | 41.89 |

| 500 | 33.76 | 34.10 | 34.03 | 36.57 | 38.28 | 39.33 | 40.34 | 41.01 | 41.66 | 42.02 | 42.01 | 42.37 | 42.65 |

| 510 | 35.04 | 35.37 | 35.31 | 37.66 | 39.30 | 40.26 | 41.22 | 41.83 | 42.45 | 42.79 | 42.77 | 43.13 | 43.38 |

| 520 | 36.33 | 36.66 | 36.60 | 38.86 | 40.40 | 41.29 | 42.17 | 42.74 | 43.31 | 43.63 | 43.60 | 43.94 | 44.18 |

| 530 | 37.52 | 37.84 | 37.80 | 40.02 | 41.45 | 42.26 | 43.08 | 43.58 | 44.11 | 44.40 | 44.37 | 44.68 | 44.90 |

| 540 | 38.62 | 38.92 | 38.90 | 41.08 | 42.43 | 43.16 | 43.91 | 44.37 | 44.85 | 45.11 | 45.06 | 45.37 | 45.58 |

| 550 | 39.62 | 39.91 | 39.89 | 42.02 | 43.30 | 43.96 | 44.66 | 45.06 | 45.51 | 45.74 | 45.68 | 45.98 | 46.19 |

| 560 | 40.55 | 40.82 | 40.82 | 42.88 | 44.08 | 44.67 | 45.35 | 45.68 | 46.12 | 46.29 | 46.26 | 46.54 | 46.72 |

| 570 | 41.36 | 41.63 | 41.61 | 43.62 | 44.73 | 45.27 | 45.90 | 46.19 | 46.60 | 46.77 | 46.72 | 47.00 | 47.15 |

| 580 | 42.13 | 42.40 | 42.37 | 44.30 | 45.35 | 45.85 | 46.41 | 46.67 | 47.04 | 47.19 | 47.13 | 47.40 | 47.55 |

| 590 | 42.89 | 43.16 | 43.14 | 44.98 | 45.96 | 46.41 | 46.94 | 47.15 | 47.50 | 47.63 | 47.55 | 47.80 | 47.96 |

| 600 | 43.56 | 43.81 | 43.79 | 45.57 | 46.48 | 46.88 | 47.39 | 47.55 | 47.87 | 47.99 | 47.91 | 48.13 | 48.29 |

| 610 | 44.10 | 44.34 | 44.32 | 46.05 | 46.91 | 47.26 | 47.74 | 47.87 | 48.18 | 48.28 | 48.18 | 48.40 | 48.54 |

| 620 | 44.60 | 44.83 | 44.78 | 46.50 | 47.31 | 47.61 | 48.05 | 48.16 | 48.45 | 48.52 | 48.41 | 48.63 | 48.76 |

| 630 | 45.06 | 45.28 | 45.23 | 46.91 | 47.67 | 47.94 | 48.36 | 48.43 | 48.71 | 48.77 | 48.65 | 48.86 | 48.98 |

| 640 | 45.49 | 45.71 | 45.66 | 47.32 | 48.05 | 48.28 | 48.67 | 48.71 | 48.98 | 49.03 | 48.90 | 49.11 | 49.21 |

| 650 | 45.69 | 45.90 | 45.85 | 47.51 | 48.21 | 48.41 | 48.78 | 48.80 | 49.06 | 49.10 | 48.96 | 49.16 | 49.25 |

| 660 | 45.89 | 46.09 | 46.03 | 47.70 | 48.36 | 48.54 | 48.90 | 48.90 | 49.15 | 49.18 | 49.03 | 49.23 | 49.32 |

| 670 | 46.02 | 46.20 | 46.14 | 47.83 | 48.47 | 48.62 | 48.99 | 48.97 | 49.20 | 49.21 | 49.09 | 49.26 | 49.36 |

| 680 | 46.16 | 46.33 | 46.27 | 47.97 | 48.59 | 48.72 | 49.07 | 49.05 | 49.27 | 49.28 | 49.15 | 49.32 | 49.41 |

| 690 | 46.30 | 46.45 | 46.40 | 48.11 | 48.71 | 48.82 | 49.16 | 49.14 | 49.34 | 49.34 | 49.21 | 49.37 | 49.46 |

| 700 | 46.47 | 46.61 | 46.55 | 48.28 | 48.86 | 48.94 | 49.27 | 49.25 | 49.44 | 49.43 | 49.29 | 49.46 | 49.54 |

| 710 | 46.63 | 46.77 | 46.71 | 48.45 | 49.02 | 49.07 | 49.39 | 49.37 | 49.54 | 49.52 | 49.38 | 49.54 | 49.63 |

| 720 | 46.62 | 46.76 | 46.69 | 48.44 | 48.98 | 49.02 | 49.33 | 49.31 | 49.48 | 49.45 | 49.31 | 49.47 | 49.54 |

| 730 | 46.61 | 46.75 | 46.67 | 48.42 | 48.95 | 48.97 | 49.27 | 49.24 | 49.42 | 49.38 | 49.23 | 49.39 | 49.46 |

| 740 | 46.45 | 46.59 | 46.49 | 48.26 | 48.76 | 48.78 | 49.06 | 49.03 | 49.21 | 49.17 | 49.01 | 49.19 | 49.23 |

| 750 | 46.26 | 46.41 | 46.30 | 48.07 | 48.56 | 48.57 | 48.83 | 48.80 | 48.98 | 48.95 | 48.78 | 48.96 | 48.98 |

| 760 | 46.15 | 46.30 | 46.17 | 47.95 | 48.42 | 48.44 | 48.69 | 48.67 | 48.82 | 48.80 | 48.63 | 48.81 | 48.82 |

| 770 | 45.98 | 46.13 | 46.00 | 47.76 | 48.24 | 48.27 | 48.51 | 48.48 | 48.62 | 48.60 | 48.43 | 48.59 | 48.62 |

| 780 | 45.77 | 45.92 | 45.78 | 47.54 | 48.02 | 48.05 | 48.28 | 48.26 | 48.39 | 48.37 | 48.20 | 48.33 | 48.39 |

| λ (nm) | DK 01 | DK 05 | DK 10 | WK 01 | WK 02 | WK 03 | WK 04 | WK 05 | WK 06 | WK 07 | WK 08 | WK 09 | WK 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 400 | 19.91 | 21.03 | 20.01 | 24.81 | 26.61 | 27.48 | 27.56 | 27.66 | 28.36 | 28.48 | 28.12 | 28.47 | 28.65 |

| 410 | 19.82 | 20.85 | 19.90 | 24.93 | 26.81 | 27.72 | 27.81 | 27.91 | 28.62 | 28.68 | 28.41 | 28.73 | 28.94 |

| 420 | 19.38 | 20.20 | 19.54 | 24.77 | 26.81 | 27.76 | 27.90 | 28.00 | 28.59 | 28.59 | 28.40 | 28.68 | 29.02 |

| 430 | 20.32 | 21.03 | 20.47 | 25.39 | 27.40 | 28.28 | 28.48 | 28.55 | 29.07 | 29.01 | 28.93 | 29.16 | 29.55 |

| 440 | 21.38 | 22.05 | 21.54 | 25.98 | 27.98 | 28.82 | 29.06 | 29.09 | 29.62 | 29.50 | 29.46 | 29.68 | 30.10 |

| 450 | 22.35 | 22.99 | 22.52 | 26.61 | 28.58 | 29.43 | 29.65 | 29.65 | 30.19 | 30.04 | 30.06 | 30.25 | 30.68 |

| 460 | 23.43 | 24.02 | 23.56 | 27.28 | 29.20 | 30.01 | 30.24 | 30.23 | 30.76 | 30.58 | 30.65 | 30.86 | 31.30 |

| 470 | 24.46 | 25.03 | 24.59 | 27.94 | 29.81 | 30.56 | 30.81 | 30.79 | 31.31 | 31.13 | 31.19 | 31.43 | 31.90 |

| 480 | 25.46 | 26.00 | 25.57 | 28.59 | 30.41 | 31.14 | 31.40 | 31.36 | 31.88 | 31.70 | 31.79 | 32.03 | 32.51 |

| 490 | 26.37 | 26.87 | 26.43 | 29.22 | 30.97 | 31.68 | 31.95 | 31.91 | 32.44 | 32.24 | 32.36 | 32.59 | 33.09 |

| 500 | 27.24 | 27.72 | 27.31 | 29.86 | 31.55 | 32.23 | 32.52 | 32.44 | 32.98 | 32.80 | 32.90 | 33.14 | 33.69 |

| 510 | 28.01 | 28.47 | 28.08 | 30.43 | 32.07 | 32.72 | 33.03 | 32.93 | 33.48 | 33.31 | 33.42 | 33.66 | 34.24 |

| 520 | 28.74 | 29.22 | 28.82 | 31.05 | 32.61 | 33.23 | 33.54 | 33.44 | 33.99 | 33.81 | 33.95 | 34.18 | 34.78 |

| 530 | 29.38 | 29.85 | 29.46 | 31.58 | 33.06 | 33.66 | 33.97 | 33.87 | 34.41 | 34.22 | 34.39 | 34.62 | 35.22 |

| 540 | 29.92 | 30.37 | 30.00 | 32.02 | 33.45 | 34.02 | 34.31 | 34.22 | 34.75 | 34.56 | 34.74 | 34.97 | 35.59 |

| 550 | 30.38 | 30.81 | 30.45 | 32.39 | 33.77 | 34.31 | 34.59 | 34.49 | 35.03 | 34.83 | 35.02 | 35.26 | 35.89 |

| 560 | 30.79 | 31.21 | 30.84 | 32.71 | 34.03 | 34.54 | 34.84 | 34.72 | 35.26 | 35.05 | 35.25 | 35.48 | 36.14 |

| 570 | 31.14 | 31.54 | 31.17 | 32.98 | 34.25 | 34.72 | 35.03 | 34.90 | 35.43 | 35.23 | 35.43 | 35.67 | 36.33 |

| 580 | 31.44 | 31.84 | 31.46 | 33.18 | 34.41 | 34.87 | 35.17 | 35.04 | 35.55 | 35.36 | 35.55 | 35.79 | 36.46 |

| 590 | 31.71 | 32.12 | 31.74 | 33.39 | 34.56 | 35.01 | 35.30 | 35.16 | 35.68 | 35.49 | 35.68 | 35.91 | 36.59 |

| 600 | 31.90 | 32.30 | 31.93 | 33.51 | 34.64 | 35.07 | 35.36 | 35.21 | 35.72 | 35.53 | 35.72 | 35.95 | 36.64 |

| 610 | 32.03 | 32.43 | 32.06 | 33.58 | 34.67 | 35.08 | 35.38 | 35.21 | 35.72 | 35.52 | 35.72 | 35.95 | 36.65 |

| 620 | 32.13 | 32.52 | 32.13 | 33.62 | 34.68 | 35.06 | 35.36 | 35.19 | 35.70 | 35.49 | 35.69 | 35.92 | 36.63 |

| 630 | 32.21 | 32.60 | 32.21 | 33.64 | 34.67 | 35.04 | 35.33 | 35.16 | 35.67 | 35.47 | 35.65 | 35.88 | 36.61 |

| 640 | 32.28 | 32.66 | 32.28 | 33.67 | 34.67 | 35.03 | 35.31 | 35.13 | 35.64 | 35.45 | 35.63 | 35.86 | 36.59 |

| 650 | 32.21 | 32.59 | 32.20 | 33.56 | 34.54 | 34.89 | 35.17 | 34.99 | 35.50 | 35.29 | 35.49 | 35.73 | 36.44 |

| 660 | 32.14 | 32.52 | 32.12 | 33.48 | 34.43 | 34.77 | 35.06 | 34.87 | 35.37 | 35.17 | 35.36 | 35.61 | 36.32 |

| 670 | 32.06 | 32.43 | 32.04 | 33.39 | 34.33 | 34.65 | 34.94 | 34.76 | 35.24 | 35.04 | 35.24 | 35.49 | 36.20 |

| 680 | 32.00 | 32.37 | 31.98 | 33.31 | 34.23 | 34.55 | 34.83 | 34.66 | 35.13 | 34.94 | 35.13 | 35.38 | 36.09 |

| 690 | 31.94 | 32.30 | 31.91 | 33.24 | 34.13 | 34.44 | 34.72 | 34.57 | 35.02 | 34.84 | 35.02 | 35.28 | 35.99 |

| 700 | 31.91 | 32.26 | 31.87 | 33.19 | 34.06 | 34.37 | 34.65 | 34.50 | 34.95 | 34.77 | 34.95 | 35.21 | 35.92 |

| 710 | 31.88 | 32.22 | 31.84 | 33.14 | 33.98 | 34.30 | 34.57 | 34.44 | 34.88 | 34.70 | 34.87 | 35.14 | 35.85 |

| 720 | 31.74 | 32.09 | 31.70 | 33.00 | 33.82 | 34.13 | 34.40 | 34.27 | 34.71 | 34.53 | 34.69 | 34.97 | 35.67 |

| 730 | 31.61 | 31.96 | 31.56 | 32.86 | 33.65 | 33.96 | 34.23 | 34.10 | 34.54 | 34.36 | 34.52 | 34.81 | 35.50 |

| 740 | 31.36 | 31.72 | 31.30 | 32.59 | 33.36 | 33.66 | 33.94 | 33.81 | 34.24 | 34.07 | 34.22 | 34.53 | 35.20 |

| 750 | 31.11 | 31.46 | 31.04 | 32.32 | 33.08 | 33.39 | 33.65 | 33.53 | 33.95 | 33.79 | 33.94 | 34.25 | 34.91 |

| 760 | 30.93 | 31.29 | 30.85 | 32.13 | 32.89 | 33.21 | 33.45 | 33.33 | 33.74 | 33.59 | 33.75 | 34.04 | 34.70 |

| 770 | 30.75 | 31.10 | 30.67 | 31.92 | 32.69 | 33.03 | 33.25 | 33.12 | 33.53 | 33.38 | 33.56 | 33.81 | 34.48 |

| 780 | 30.56 | 30.91 | 30.47 | 31.71 | 32.49 | 32.83 | 33.04 | 32.90 | 33.31 | 33.16 | 33.35 | 33.58 | 34.26 |

| CIE1976 | DK 01 | DK 05 | DK 10 | WK 01 | WK 02 | WK 03 | WK 04 | WK 05 | WK 06 | WK 07 | WK 08 | WK 09 | WK 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L* | 72.81 | 72.96 | 72.99 | 74.55 | 75.45 | 75.90 | 76.38 | 76.65 | 76.93 | 77.06 | 77.07 | 77.25 | 77.41 |

| a* | 1.32 | 1.29 | 1.26 | 2.07 | 1.87 | 1.68 | 1.53 | 1.41 | 1.33 | 1.28 | 1.21 | 1.19 | 1.12 |

| b* | 16.49 | 16.24 | 16.38 | 12.20 | 10.78 | 9.79 | 9.09 | 8.35 | 7.92 | 7.59 | 7.57 | 7.32 | 7.19 |

| CIE1976 | DK 01 | DK 05 | DK 10 | WK 01 | WK 02 | WK 03 | WK 04 | WK 05 | WK 06 | WK 07 | WK 08 | WK 09 | WK 10 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L* | 65.09 | 65.41 | 65.12 | 66.85 | 68.01 | 68.44 | 68.68 | 68.59 | 69.00 | 68.82 | 69.00 | 69.18 | 69.72 |

| a* | −0.64 | −0.60 | −0.63 | −0.01 | −0.12 | −0.19 | −0.21 | −0.23 | −0.25 | −0.21 | −0.25 | −0.25 | −0.26 |

| b* | 11.32 | 10.92 | 11.12 | 7.23 | 6.08 | 5.56 | 5.60 | 5.47 | 5.40 | 5.38 | 5.52 | 5.49 | 5.72 |

References

- Manu, T.; Nazmi, A.R.; Shahri, B.; Emerson, N.; Huber, T. Biocomposites: A review of materials and perception. Mater. Today Commun. 2022, 31, 103308. [Google Scholar] [CrossRef]

- Aaliya, B.; Sunooj, K.V.; Lackner, M. Biopolymer composites: A review. Int. J. Biobased Plast. 2021, 3, 40–84. [Google Scholar] [CrossRef]

- Babaremu, K.; Oladijo, O.P.; Akinlabi, E. Biopolymers: A suitable replacement for plastics in product packaging. Adv. Ind. Eng. Polym. Res. 2023, 6, 333–340. [Google Scholar] [CrossRef]

- Mahmud, M.Z.A. Exploring the versatile applications of biocomposites in the medical field. Bioprinting 2023, 36, e00319. [Google Scholar] [CrossRef]

- Faheed, N.K. Advantages of natural fiber composites for biomedical applications: A review of recent advances. Emergent Mater. 2024, 7, 63–75. [Google Scholar] [CrossRef]

- Udayakumar, G.P.; Muthusamy, S.; Selvaganesh, B.; Sivarajasekar, N.; Rambabu, K.; Banat, F.; Sivamani, S.; Sivakumar, N.; Hosseini-Bandegharaei, A.; Show, P.L. Biopolymers and composites: Properties, characterization and their applications in food, medical and pharmaceutical industries. J. Environ. Chem. Eng. 2021, 9, 105322. [Google Scholar] [CrossRef]

- Phiri, R.; Rangappa, S.M.; Siengchin, S.; Oladijo, O.P.; Dhakal, H.N. Development of sustainable biopolymer-based composites for lightweight applications from agricultural waste biomass: A review. Adv. Ind. Eng. Polym. Res. 2023, 6, 436–450. [Google Scholar] [CrossRef]

- Andrew, J.J.; Dhakal, H.N. Sustainable biobased composites for advanced applications: Recent trends and future opportunities—A critical review. Compos. Part C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Graupner, N.; Müssig, J. Cellulose Fiber-Reinforced PLA versus PP. Int. J. Polym. Sci. 2017, 2017, 6059183. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S.; Tábi, T.; Kovács, J. Comparison of injection moulded, natural fibre-reinforced composites with PP and PLA as matrices. J. Thermoplast. Compos. Mater. 2012, 25, 927–948. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed]

- Trivedi, A.K.; Gupta, M.K.; Singh, H. PLA based biocomposites for sustainable products: A review. Adv. Ind. Eng. Polym. Res. 2023, 6, 382–395. [Google Scholar] [CrossRef]

- Wen-Dong, T.; Guang-Jian, H.; Wei-Tao, H.; Xin-Liang, Z.; Xian-Wu, C.; Xiao-Chun, Y. The reactive compatibilization of PLA/PP blends and improvement of PLA crystallization properties induced by in situ UV irradiation. CrystEngComm 2021, 23, 864–875. [Google Scholar] [CrossRef]

- Andrady, A.L.; Hamid, H.; Torikai, A. Effects of solar UV and climate change on materials. Photochem. Photobiol. Sci. 2011, 10, 292–300. [Google Scholar] [CrossRef]

- Andrady, A.L.; Heikkilä, A.M.; Pandey, K.K.; Bruckman, L.S.; White, C.C.; Zhu, M.; Zhu, L. Effects of UV radiation on natural and synthetic materials. Photochem. Photobiol. Sci. 2023, 22, 1177–1202. [Google Scholar] [CrossRef]

- Kowalski, W. Ultraviolet Germicidal Irradiation Handbook UVGI for Air and Surface Disinfection, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Sklar, L.R.; Almutawa, F.; Lim, H.W.; Hamzavi, I. Effects of ultraviolet radiation, visible light, and infrared radiation on erythema and pigmentation: A review. Photochem. Photobiol. Sci. 2013, 12, 54–64. [Google Scholar] [CrossRef]

- Herndon, J.M.; Hoisington, R.D.; Whiteside, M. Deadly Ultraviolet UV-C and UV-B Penetration to Earth’s Surface: Human and Environmental Health Implications. J. Geogr. Environ. Earth Sci. Int. 2018, 14, 40245. [Google Scholar] [CrossRef]

- Czachor-Jadacka, D.; Pilch-Pitera, B. Progress in development of UV curable powder coatings. Prog. Org. Coat. 2021, 158, 106355. [Google Scholar] [CrossRef]

- Ou, Y.; Petersen, P.M. Application of ultraviolet light sources for in vivo disinfection. Jpn. J. Appl. Phys. 2021, 60, 100501. [Google Scholar] [CrossRef]

- Guillet, J.E. Fundamental Processes in the UV Degradation and Stabilization of Polymers. In Chemical Transformations of Polymers, 1st ed.; Rado, R., Ed.; Butterworth-Heinemann: Oxford, UK, 1972; pp. 135–144. [Google Scholar]

- Zaaba, N.F.; Jaafar, M. A review on degradation mechanisms of polylactic acid: Hydrolytic, photodegradative, microbial, and enzymatic degradation. Polym. Eng. Sci. 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Niu, Z.; Curto, M.; Gall, M.L.; Demeyer, E.; Asselman, J.; Janssen, C.R.; Dhakal, H.N.; Davies, P.; Catarino, A.I.; Everaert, G. Accelerated fragmentation of two thermoplastics (polylactic acid and polypropylene) into microplastics after UV radiation and seawater immersion. Ecotoxicol. Environ. Saf. 2024, 271, 115981. [Google Scholar] [CrossRef] [PubMed]

- Gijsman, P.; Meijers, G.; Vitarelli, G. Comparison of the UV-degradation chemistry of polypropylene, polyethylene, polyamide 6 and polybutylene terephthalate. Polym. Degrad. Stab. 1999, 65, 433–441. [Google Scholar] [CrossRef]

- Ali, S.S.; Elsamahy, T.; Koutra, E.; Kornaros, M.; El-Sheekh, M.; Abdelkarim, E.A.; Zhu, D.; Sun, J. Degradation of conventional plastic wastes in the environment: A review on current status of knowledge and future perspectives of disposal. Sci. Total Environ. 2021, 771, 144719. [Google Scholar] [CrossRef] [PubMed]

- Gulmine, J.V.; Janissek, P.R.; Heise, H.M.; Akcelrud, L. Degradation profile of polyethylene after artificial accelerated weathering. Polym. Degrad. Stab. 2003, 79, 385–397. [Google Scholar] [CrossRef]

- Senatova, S.I.; Senatov, F.S.; Kuznetsov, D.V.; Stepashkin, A.A.; Issi, J.P. Effect of UV-radiation on structure and properties of PP nanocomposites. J. Alloys Compd. 2017, 707, 304–309. [Google Scholar] [CrossRef]

- Rios, A.d.S.; Júnior, W.F.d.A.; Moura, E.P.d.; Deus, E.P.d.; Feitosa, J.P.d.A. Effects of accelerated aging on mechanical, thermal and morphological behavior of polyurethane/epoxy/fiberglass composites. Polym. Test. 2016, 50, 152–163. [Google Scholar] [CrossRef]

- Janutėnienė, J.; Vasylius, M.; Tadžijevas, A.; Kartašovas, V.; Šapalas, D.; Grigaliūnienė, S. Influence of Recycling and UV Exposure on the Properties of 3D Printing Polymer Materials. Polymers 2024, 16, 3292. [Google Scholar] [CrossRef]

- François-Heude, A.; Richaud, E.; Desnoux, E.; Colin, X. Influence of temperature, UV-light wavelength and intensity on polypropylene photothermal oxidation. Polym. Degrad. Stab. 2014, 100, 10–20. [Google Scholar] [CrossRef]

- Andrady, A.L.; Barnes, P.W.; Bornman, J.F.; Gouin, T.; Madronich, S.; White, C.C.; Zepp, R.G.; Jansen, M.A.K. Oxidation and fragmentation of plastics in a changing environment; from UV-radiation to biological degradation. Sci. Total Environ. 2022, 851, 158022. [Google Scholar] [CrossRef]

- Yousif, E.; Haddad, R. Photodegradation and photostabilization of polymers, especially polystyrene: Review. SpringerPlus 2013, 2, 398. [Google Scholar] [CrossRef]

- Virág, A.D.; Tóth, C.; Molnár, K. Photodegradation of polylactic acid: Characterisation of glassy and melt behaviour as a function of molecular weight. Int. J. Biol. Macromol. 2023, 252, 126336. [Google Scholar] [CrossRef] [PubMed]

- Man, C.; Zhang, C.; Liu, Y.; Wang, W.; Ren, W.; Jiang, L.; Reisdorffer, F.; Nguyen, T.P.; Dan, Y. Poly (lactic acid)/titanium dioxide composites: Preparation and performance under ultraviolet irradiation. Polym. Degrad. Stab. 2012, 97, 856–862. [Google Scholar] [CrossRef]

- Iñiguez, M.E.; Conesa, J.A.; Fullana, A. Recyclability of four types of plastics exposed to UV irradiation in a marine environment. Waste Manag. 2018, 79, 339–345. [Google Scholar] [CrossRef] [PubMed]

- Kuyyakanont, A.; Iwata, M. Study of different degradation effects in UV-sensitive polymers using xenon lamp and deuterium lamp to simulate UV irradiation in space environment. Nucl. Instrum. Methods Phys. Res. Sect. B 2024, 549, 165267. [Google Scholar] [CrossRef]

- Jansen, M.A.K.; Andrady, A.L.; Bornman, J.F.; Aucamp, P.J.; Bais, A.F.; Banaszak, A.T.; Barnes, P.W.; Bernhard, G.H.; Bruckman, L.S.; Busquets, R.; et al. Plastics in the environment in the context of UV radiation, climate change and the Montreal Protocol: UNEP Environmental Effects Assessment Panel, Update 2023. Photochem. Photobiol. Sci. 2024, 23, 629–650. [Google Scholar] [CrossRef]

- Maraveas, C.; Kyrtopoulos, I.V.; Arvanitis, K.G.; Bartzanas, T. The Aging of Polymers under Electromagnetic Radiation. Polymers 2024, 16, 689. [Google Scholar] [CrossRef]

- Lu, T.; Solis-Ramos, E.; Yi, Y.; Kumosa, M. UV degradation model for polymers and polymer matrix composites. Polym. Degrad. Stab. 2018, 154, 203–210. [Google Scholar] [CrossRef]

- Mikac, L.; Csáki, A.; Zentai, B.; Rigó, I.; Veres, M.; Tolić, A.; Gotić, M.; Ivanda, M. UV Irradiation of Polyethylene Terephthalate and Polypropylene and Detection of Formed Microplastic Particles Down to 1 μm. ChemPlusChem 2024, 89, e202300497. [Google Scholar] [CrossRef]

- ISO 4892-1; Third Edition. Plastics—Methods of Exposure to Laboratory Light Sources—Part 1: General Guidance. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 4892-3; Fourth Edition. Plastics—Methods of Exposure to Laboratory Light Sources—Part 3: Fluorescent UV Lamps. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO/CIE 11664-4; First Edition. Colorimetry—Part 4: CIE 1976 L*a*b* Colour Space. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO/CIE 11664-2; First Edition. Colorimetry—Part 2: CIE Standard Illuminants. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 4582; Fourth Edition. Plastics—Determination of Changes in Colour and Variations in Properties After Exposure to Glass-Filtered Solar Radiation, Natural Weathering or Laboratory Radiation Sources. International Organization for Standardization: Geneva, Switzerland, 2017.

| Color Differences | DK 05 vs. DK 01 | DK 10 vs. DK 05 | DK 10 vs. DK 01 | |||

|---|---|---|---|---|---|---|

| PLA + MC | PP + MC | PLA + MC | PP + MC | PLA + MC | PP + MC | |

| ΔL* | 0.1 | 0.3 | 0.0 | −0.3 | 0.2 | 0.0 |

| Δa* | 0.0 | 0.0 | 0.0 | 0.0 | −0.1 | 0.0 |

| Δb* | −0.3 | −0.4 | 0.1 | 0.2 | −0.1 | −0.2 |

| ΔE*ab | 0.3 | 0.5 | 0.1 | 0.4 | 0.2 | 0.2 |

| Color Differences | WK 01 vs. DK 01 | WK 05 vs. DK 01 | WK 10 vs. DK 01 | |||

|---|---|---|---|---|---|---|

| PLA + MC | PP + MC | PLA + MC | PP + MC | PLA + MC | PP + MC | |

| ΔL* | 1.7 | 1.8 | 3.8 | 3.5 | 4.6 | 4.6 |

| Δa* | 0.7 | 0.6 | 0.1 | 0.4 | −0.2 | 0.4 |

| Δb* | −4.3 | −4.1 | −8.1 | −5.8 | −9.3 | −5.6 |

| ΔE*ab | 4.7 | 4.5 | 9.0 | 6.8 | 10.4 | 7.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mendes, A.d.O.; Costa, V.L.D.; Vieira, J.C.; Videira, P.E.M.; Nunes, M.J.R.M.; Gaspar, A.; Pinto, P.; Baldaia, J.; Curto, J.M.R.; Amaral, M.E.; et al. UV-Accelerated Aging of PLA and PP-Based Biocomposites: A Spectral and Colorimetric Study. J. Compos. Sci. 2025, 9, 317. https://doi.org/10.3390/jcs9070317

Mendes AdO, Costa VLD, Vieira JC, Videira PEM, Nunes MJRM, Gaspar A, Pinto P, Baldaia J, Curto JMR, Amaral ME, et al. UV-Accelerated Aging of PLA and PP-Based Biocomposites: A Spectral and Colorimetric Study. Journal of Composites Science. 2025; 9(7):317. https://doi.org/10.3390/jcs9070317

Chicago/Turabian StyleMendes, António de O., Vera L. D. Costa, Joana C. Vieira, Pedro E. M. Videira, Maria J. R. M. Nunes, Alexandre Gaspar, Paula Pinto, Joana Baldaia, Joana M. R. Curto, Maria E. Amaral, and et al. 2025. "UV-Accelerated Aging of PLA and PP-Based Biocomposites: A Spectral and Colorimetric Study" Journal of Composites Science 9, no. 7: 317. https://doi.org/10.3390/jcs9070317

APA StyleMendes, A. d. O., Costa, V. L. D., Vieira, J. C., Videira, P. E. M., Nunes, M. J. R. M., Gaspar, A., Pinto, P., Baldaia, J., Curto, J. M. R., Amaral, M. E., Costa, A. P., & Fiadeiro, P. T. (2025). UV-Accelerated Aging of PLA and PP-Based Biocomposites: A Spectral and Colorimetric Study. Journal of Composites Science, 9(7), 317. https://doi.org/10.3390/jcs9070317