1. Introduction

The advancement of lightweight construction is crucial for the development of sustainable technologies in various industries and for the reduction in carbon dioxide emissions, especially in the automotive sector. Lightweight construction is driven, amongst other things, by the use of lightweight materials, in particular fibre-reinforced polymer composites (FRPs). Among such composites, bio-composites have emerged as an environmentally friendly alternative to some traditional synthetic composites. Such bio-composites are based on fibres or matrices derived from renewable resources [

1,

2]. In particular, plant fibres such as hemp, jute or flax have gained significant attention in lightweight applications due to their sustainable and environmentally friendly properties. These natural fibres offer several advantages over traditional synthetic fibres, such as biodegradability, lower weight and cost-effectiveness, making them suitable for various applications [

3]. As a result, they can be found in the automotive sector, construction and infrastructure, sports and leisure, furniture and consumer goods, as well as in pipes and tanks [

4], whereas most of these applications are considered as non-structural ones [

1,

5].

In Europe, the use of flax (Linum usitatissimum) as a reinforcing fibre is most common due to its good availability, with the world’s leading growing regions being in France and Belgium [

6]. In addition, flax fibres are known for their excellent specific properties (specific strength and stiffness in the range of 300 to 600 MPa and 35 to 50 GPa, respectively) [

7], making them suitable for low-to-medium load-bearing applications. The market offers unidirectional tapes (Dehondt Composites, Notre Dame de Gravenchon, France; EcoTechnilin, Valliquerville, France; FUSE GmbH, Zwenkau, Germany) and woven or stacked fabrics (Bcomp, Fribourg, Switzerland; Dehondt Composites; EcoTechnilin), as well as non-woven mats (EcoTechnilin) of various areal densities, specifically designed for technical applications.

Flax fibre-reinforced polymers (FFRPs), such as flax/PLA composites have shown promising mechanical properties, with strengths up to 72 MPa and stiffness up to 13 GPa, [

8]. The weight reduction associated with the use of polypropylene composites with 35% flax fibre reinforcement is said to result in a 0.4% improvement in fuel efficiency [

9].

Subsequently, the development and characterisation of thermoset flax composites has been widely reported in the literature [

10,

11,

12,

13,

14,

15] in order to achieve a higher mechanical performance. Studies have demonstrated the feasibility of combining flax fibre mats with a petrochemical polyester resin in a vacuum infusion process, also comparing the resulting mechanical performance with a combination of glass fibres and the same polyester resin. The specific tensile and flexural moduli and strengths of the flax–polyester composites were found to be lower than those of glass fibre-reinforced composites (GFRPs) (specific tensile modulus: 3.93 GPa∙cm

3/g for FFRPs vs. 6.94 GPa∙cm

3/g for GFRPs; specific flexural modulus: 5.19 GPa∙cm

3/g for FFRPs vs. 9.10 GPa∙cm

3/g for GFRPs). In contrast, the reinforcement of unsaturated polyester resin with unidirectional flax fibres showed a tensile modulus comparable to that of glass fibre–polyester composites (29.9 ± 1.8 GPa for FFRPs vs. 30.6 ± 2.2 GPa for GFRPs) but a significantly lower tensile stress at break (304 ± 29 MPa vs. 695 ± 60 MPa, respectively) [

11].

The manufacture of plant fibre-reinforced composites presents a number of challenges. Chemical treatment processes aim to improve the interfacial bonding between the hydrophilic plant fibre and the hydrophobic polymer matrix [

16], and thus improve the overall performance of the composite, as reported by Hughes et al. [

17]. In addition, FFRPs have shown poor fire resistance [

18] and low thermal stability [

19] compared to synthetic fibre composites. This limits their use in critical applications where fire safety and high temperature resistance are of concern. Further, the moisture uptake of the fibres, due to their hydrophilic nature, leads to a degradation of the mechanical properties [

20,

21,

22], the increased probability of void formation and warpage during vacuum infusion [

21], and in the case of cobalt-accelerated unsaturated polyester resins, the risk of an incomplete curing reaction [

20,

23]. Therefore, moisture needs to be well controlled prior to manufacturing. Moudood et al. [

21] reported that fabrics conditioned at a relative humidity (RH) above 70% in composites made from unidirectional flax fibres and epoxy resin resulted in significant warpage and large voids at a RH above 50%. Optimum shear strength was further reported for a unidirectional FFRP with an epoxy matrix for pre-conditioning at 35% RH [

15]. Fuentes et al. [

20] worked with unidirectional flax mats and an unsaturated polyester resin without a cobalt accelerator and found an 18% reduction in flexural strength and a 25% reduction in Young’s modulus for composites produced at 100% RH compared to those produced at 0% RH, and also found that production with a cobalt-accelerated polyester resin would result in a low curing degree at high humidity levels. Given the impact of moisture on the mechanical performance of composites, predictive analysis of the expected water uptake and time to saturation after manufacture becomes an important factor. Ladaci et al. [

24] showed that there is a direct relationship between the fibre load (Washingtonia filifera) of the polymer (rHDPE) and the immersion time on water uptake and that this can be modelled using an artificial neural network and response-surface methodology. Accordingly, they found the most considerable water absorption for a fibre content of 30% after 575 h.

In addition to the utilisation of plant fibres as a renewable reinforcement for composites, contemporary endeavours are directed towards the development of bio-based thermosets as a matrix for structural composite applications. Dal Pont et al. [

14] demonstrated that the vacuum-assisted resin infusion (VARI) of flax fibre fabric with a mixture of petrochemical and partially bio-based epoxy resin is a viable approach to achieving a reduced ecological footprint at an acceptable level of mechanical performance.

In comparison with epoxy, unsaturated polyester resins are a cost-effective choice in many automotive components. Market research [

25] has shown that only a few manufacturers are prototyping and preparing unsaturated polyester resin formulations for wider commercial availability with monomers partially or completely derived from biomass. These formulations either utilise a substantial fraction of bio-attributed carbon or rely directly on bio-based raw materials, as in natural resources partially augmented by biological processes (e.g., fermentation or bacteria) [

25,

26]. In another study, Fonseca et al. [

27] synthesised unsaturated polyesters with renewable monomers and considered (hydroxymethyl)methacrylate (HEMA) as a reactive diluent for use in biomedical applications. Rubeš et al. [

28] described the synthesis of styrene- and cobalt-free unsaturated polyesters based on itaconic acid, where styrene was replaced by methyl methacrylate (MMA) during synthesis. The authors also reported that low contents of secondary crosslinking agents, such as ethylene dimethacrylate (EDMA), trimethylolpropane triacrylate (TMPTA) or triethyleneglycol dimethacrylate (TEGDMA) improved the tensile strength and impact resistance. Similarly, Mehta et al. [

29] synthesised unsaturated polyester resin wood coatings from itaconic acid, using MMA, HEMA and isobornyl methacrylate (IBOMA) as reactive diluents. HEMA is described as the preferred alternative in terms of the achieved viscosity, lower exothermic reaction temperature and higher thermal stability compared to styrene.

Grimalt et al. [

30] investigated the addition of different bio-based reactive diluents and styrene to an unsaturated polyester resin with a styrene content of about 35 w%. Of the six reactive diluents tested—ethyl cinnamate (CINN), limonene (LIM), MMA, (TMPTA), epoxidized linseed oil (ELO) and acrylated epoxidized soybean oil (AESO)—CINN, LIM and MMA were selected for further evaluation after preliminary viscosity measurements, at 1, 3 and 5 w% addition, demonstrating a promising viscosity reduction. At 5 w%, the three selected diluents showed an improved impact strength but a reduction of 32% to 45% in flexural modulus compared to styrene. MMA is the closest competitor to styrene achieving a similar Shore D hardness, heat deflection values, reaction times and reaction temperatures. Liu et al. [

31] used N-vinyl-2-pyrrolidone (NVP) and tri(ethylene glycol) divinyl ether (TDE) as reactive diluents with an unsaturated polyester for manufacturing composites reinforced with a randomly oriented hemp fibre mat. They compared formulations with 40% and 50% NVP/TDE to a styrene formulation, finding both improved processability. The 40% NVP composites had a comparable tensile and flexural strength and a slightly improved flexural modulus and impact strength. In another study, Liu et al. presented NVP to also be a suitable reactive diluent in conjunction with soybean oil-based thermosetting resins from acrylated epoxidized soybean oil (AESO) [

32], which in turn could also be copolymerised with bio-based polyester resins [

33]. Schuster et al. further investigated two thermoset polyester matrix systems in combination with unidirectional flax laminate in the vacuum-assisted resin transfer moulding (VARTM) process. Their findings demonstrated that the 70% bio-based Nuplex resin is deemed suitable for industrial application [

12].

However, to the authors’ knowledge, the current bio-based polyester resin systems lack the technical specifications that allow easy and reproducible processing. A significant challenge pertains to the high viscosity of the systems and the intricate impregnation of the plant fibres. Moreover, the fabrication of FFRPs with a bio-based polyester resin as a matrix using the vacuum infusion process has not been previously documented in the extant literature. This study aims to address these challenges by investigating the preparation and processing of commercially available bio-based polyester resins (STRUKTOL® POLYVERTEC®) and flax fibres. The investigation focuses on two novel formulations of unsaturated polyester with a high bio-content, aiming to assess their potential as a matrix for various FFRPs in automotive applications, where GFRPs are a prevalent practice. In contrast to other studies reported in the literature, the resin system was not specially prepared in the laboratory for the purpose of this study. Consequently, the presented study is the first in which the potential of a commercial thermosetting polyester resin system with a high bio-content is examined for use as a matrix for FRPs. To facilitate the adequate processibility of the resin through vacuum infusion, it was necessary to modify the resin and to adjust the processing conditions. The resulting composites were characterised in terms of their mechanical performance. Accordingly, the following research questions are addressed by this study: (i) Can the selected polyester resin STRUKTOL® POLYVERTEC® be processed in a VARI process? (ii) Does the resin need a dilution and by which amount in order to allow infusion processing? (iii) Can FFRPs with STRUKTOL® POLYVERTEC® be applied for exterior automotive components, such as a caravan roof (specifications: glass transition temperature: ≥70 °C; elastic modulus: 6 GPa (±10%); tensile strength: 60 MPa (±10%); flexural strength: 100 MPa (±10%)), and which textile form is able to fulfil the specified requirements?

2. Materials and Methods

Materials. Two different flax fibre reinforcements were used in this study. The 2/2 twill weave flax fibre fabric ampliTex™ 5040 with an areal density of 300 g/m2 was supplied by Bcomp Ltd. (Fribourg, Switzerland). Further, the short flax fibre non-woven FibriMat™ F300 with an areal density of 300 g/m2 was provided by SAS Eco-Technilin (Valliquerville, France).

Two bio-based unsaturated polyester resins, which were similar in composition, were selected as the matrix material for the composites under investigation. These resins were supplied by Schill + Seilacher GmbH (Hamburg, Germany). The first composites were manufactured with STRUKTOL® POLYVERTEC® 3832S, and the second with STRUKTOL® POLYVERTEC® 3831. Due to processing challenges associated with the high viscosity of the 3832S resin, it has been discontinued and further developed by the manufacturer to produce the advanced formulation 3831. Both resins were diluted with the reactive diluent MERACRYL® HEMA 98 (Röhm GmbH, Darmstadt, Germany), a 2-hydroxyethyl methacrylate (HEMA), and reacted with the methyl ethyl ketone peroxide (MEKP) hardener CUROX® M-303, supplied by United Initiators GmbH (Pullach, Germany) and the cobalt octoate accelerator COB 1-TX, provided by United Initiators SAS (Chalon-sur-Saône, France). Hardener and accelerator were added to the resin formulation according to the manufacturer’s recommendation—2% by mass of hardener and 1% by mass of accelerator. The additional amount of reactive diluent was determined based on preliminary studies allowing an acceptable viscosity for the VARI process.

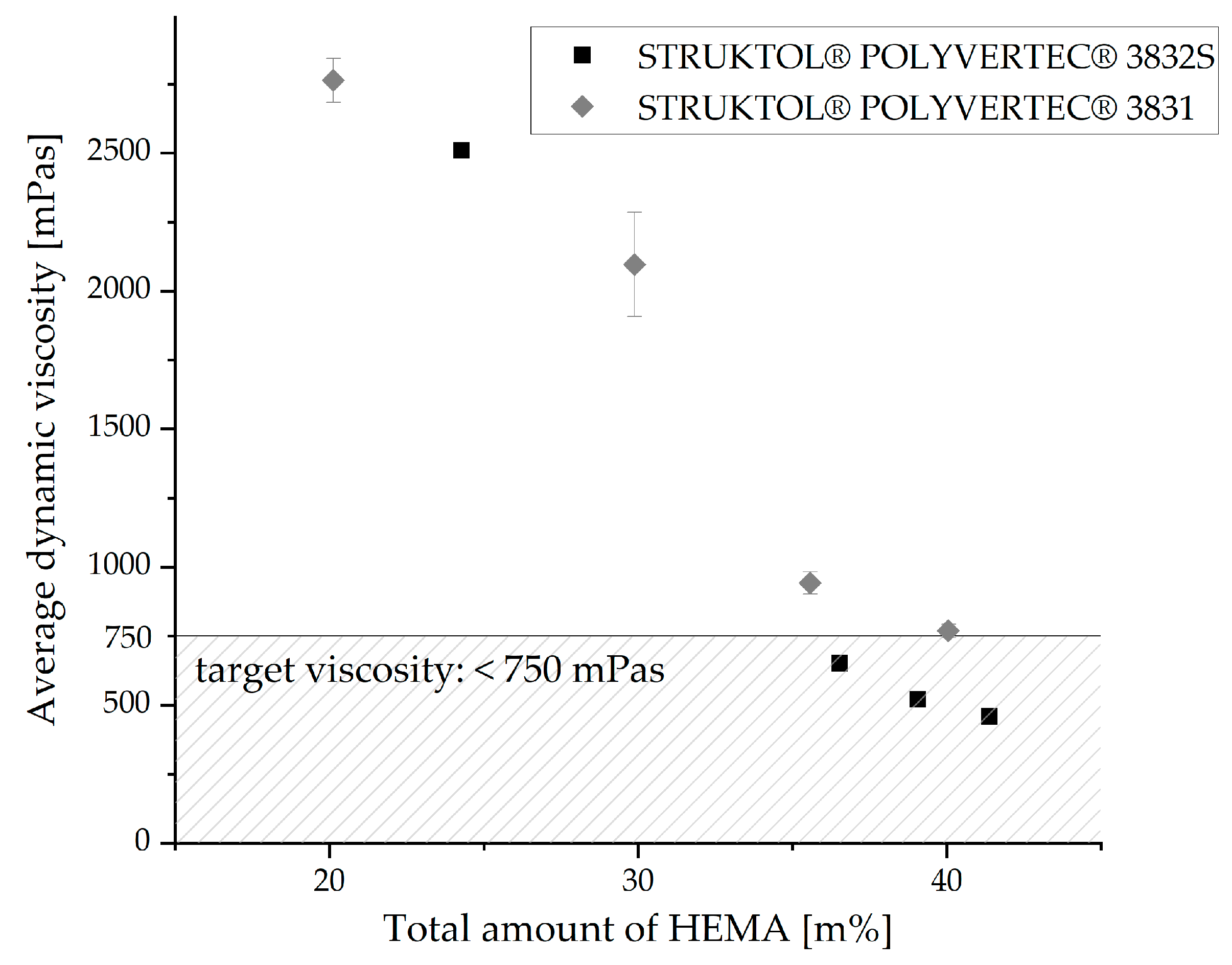

Resin formulation. As delivered, both supplied resin systems had a viscosity deemed too high for processing using the VARI process: STRUKTOL® POLYVERTEC® 3832S is specified as 2000 mPa·s, whereas STRUKTOL® POLYVERTEC® is specified as 14,000 mPa·s. Rheometric trials with different added amounts of HEMA diluent were set up to determine suitable formulations with a target viscosity of ≤750 mPa·s.

Table 1 lists the formulations investigated with an Anton Paar MCR 302 (Anton Paar GmbH, Graz, Austria) rheometer at 20 °C and a shear rate of 10 s

−1 with a cone plate geometry with a diameter of 25 mm and 1° cone angle (CP25-1). Based on the measured dynamic viscosity, the optimum formulation of the resin systems were chosen for further testing and composite manufacturing. Based on that, STRUKTOL

® POLYVERTEC

® 3832S was used with 20 m% HEMA added to the commercial formulation—rendering 36.5 m% HEMA in total—and STRUKTOL

® POLYVERTEC

® 3831 was used with 40 m% added HEMA.

A pure resin plate of the modified STRUKTOL® POLYVERTEC® 3832S formulation was cast for reference purposes at room temperature and ambient pressure of 957.7 hPa in an open aluminium mould, degassing the resin before and after the casting process. After curing for 24 h at room temperature and 8 h at 80 °C, the resin plate was removed from the mould, placed between two cardboards and pressed between two aluminium plates and further tempered for 2 h at 120 °C. The resin plate was levelled to a thickness of 4 mm using a CNC milling machine and test specimens were cut to size using the same mill.

Resin testing. Differential Scanning Calorimetry (DSC) using a Mettler-Toledo DSC 3+ was carried out on pure resin samples to identify the glass transition temperatures Tg of the unaltered commercial formulations and the selected formulations to assess suitability for the automotive sector with a declared target of 70 °C. Samples of 10 mg were cut from the pure resin plates and placed in standard 40 µL aluminium crucibles. The samples were heated in dynamic mode from −80 °C to 250 °C, at a heating/cooling rate of 20 K/min, a purge gas flow (nitrogen) of 60 mL/min and three heating cycles for each sample. The Tg was evaluated using both the midpoint temperature and the inflection point method with the STARe Software (V16.20c). Mean values were calculated from the second and third heating cycles of the dynamic DSC trials.

Tensile tests were carried out according to DIN EN ISO 527-2 [

34] at an ambient temperature of 22 °C and a relative humidity of 42% to determine the tensile properties of the pure resin. The test was carried out using a Shimadzu AG-Xplus tensile testing machine, equipped with a Shimadzu SPL-10KNA 10 kN load cell. The measured data were recorded using the Trapezium X software (version 1.5.6), considering the crosshead position and the TRViewX non-contact digital video extensometer. The tensile modulus was determined within the strain range of 0.05% and 0.25%, which was approached at a test speed of 1 mm/min. The tensile test was then continued without interruption at the DIN EN ISO 527-1 [

35]-compliant test speed of 10 mm/min. The tensile modulus and Poisson’s ratio were finally calculated based on values corresponding to the nominal stress values between 0.05% and 0.25% or 0.3% and 5% of elongation, respectively. A total of 8 type 1B test specimens were tested.

Three-point bending was carried out in accordance with the standard DIN EN ISO 178 [

36] method A at an ambient temperature of 22 °C and a relative humidity of 41% to characterise the flexural properties of the pure resin. In total, 8 specimens of type 1 were used for the test with a Shimadzu AG-Xplus tensile testing machine equipped with a Shimadzu SPL-10KNA 10 kN load cell. The measured data were recorded using the Trapezium X software (version 1.5.6). The radius R1 of the bending anvil and the radius R2 of the supports of the bending device correspond to the 5 mm ± 0.2 mm, as per the aforementioned test standard. The bending anvil and supports were aligned with the aid of a gauge and the support distance was set to the required 64 mm. The specimen was positioned on the supports, with the over-milled side facing upwards. The test specimen was subjected to flexural load at 2 mm/min without interruption until fracture, as specified in procedure A. The flexural strength of the matrix, the related flexural strain, the flexural stress at break, the corresponding flexural strain at break and the deflection were determined. The flexural strain of the specimens was taken from the values derived by Trapezium X from crosshead travel. The flexural modulus was calculated from the values closest to the specified interval of elongation between 0.05% and 0.25%.

The Charpy impact test was performed in accordance with the standard DIN EN ISO 179-1/1fU [

37] at an ambient temperature of 21 °C and 43% relative humidity. The rectangular, unnotched specimen of type 1 (80 ± 2 mm × 10.0 ± 0.2 mm × of 4.0 ± 0.2 mm) is loaded edgewise. In total, 14 specimens were tested with a Zwick 5102 pendulum impact tester, equipped with a 2 J-hammer. The span was set to

mm in accordance with the standard. Three empty strokes were carried out at the beginning of the test to determine the friction value. The respective measured values were documented, and the arithmetic mean was calculated. The 14 test specimens were then positioned into the test rig with the milled side facing the pendulum. The pendulum was released and the energy was recorded and corrected with respect to the pre-evaluated friction losses. Using the calculated mean values for the specimen width b and the specimen thickness h and the corrected working capacity W

c, the Charpy impact strength a

cU was calculated for an unnotched specimen according to the following formula [

36]:

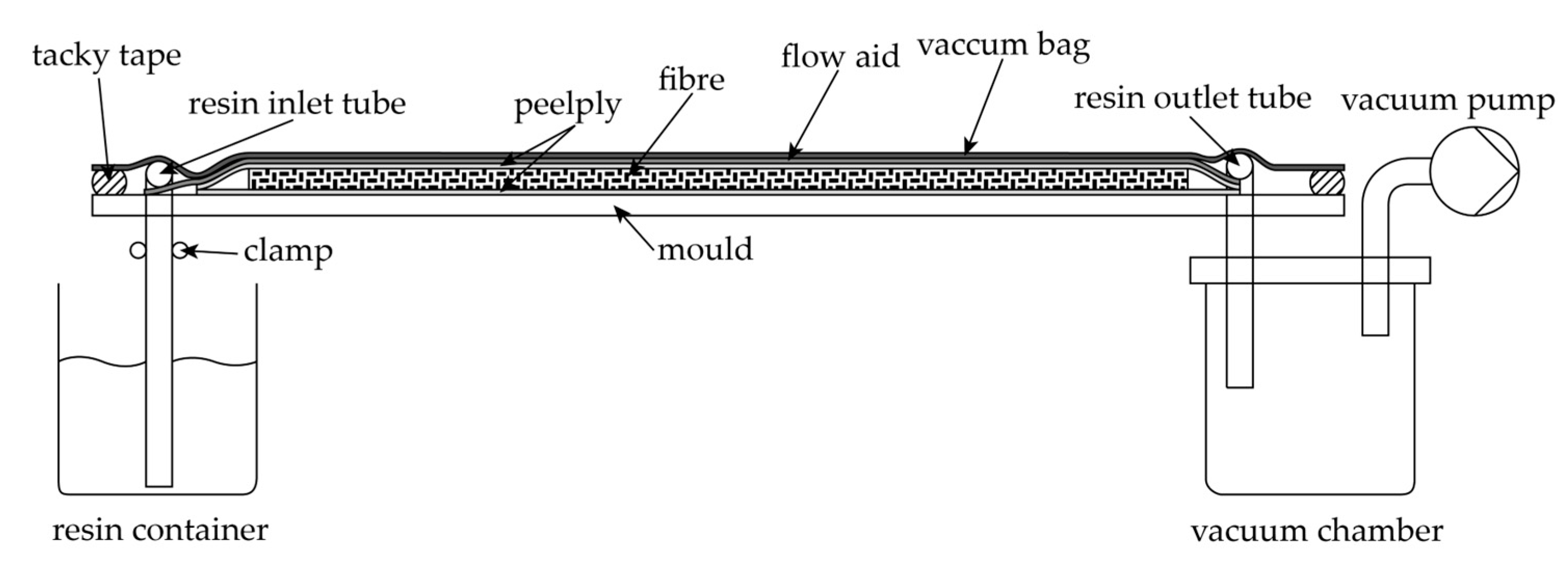

Composite manufacturing. Composite plates of 670 mm × 300 mm were manufactured using the VARI process. In the first stage, a glass plate serving as the lower mould half was treated with at least four layers of release agent, as per the manufacturer’s guidelines. Fibre reinforcements were cut to size—700 mm × 330 mm—using a battery-powered hand cutter and pre-dried in a Memmert UFP 600 (Memmert GmbH + Co. KG, Schwabach, Germany) universal oven for 90 min at 70 °C. The reinforcements were weighed before and after the drying process to estimate the fibre mass content within the final composite. After pre-drying, the composite layup was completed, as schematically illustrated in

Figure 1. A layer of peel-ply was first placed over the released glass mould and fixed in place with masking tape. In the next step, two layers of FibriMat™ F300 or four layers of ampliTex™ 5040 were stacked to reach the targeted material thickness of 2 mm, followed by peel-ply and flow aid. The inlet and outlet spiral tubes were placed along the long edges of the fibre stacks. Finally, the layup was covered with bagging film, and sealed to the mould using bag sealant tape. The setup was checked for leakage using a digital vacuum gauge placed on the inlet side. With the inlet side clamped shut, the mould was then placed back into the oven for at least 20 h at 70 °C with a DVP LC20 9601066/MA vacuum pump (D.V.P. Vacuum Technology S.p.A., San Pietro in Casale, Italy) attached, working at full vacuum power. After the additional drying time, the moulds were removed from the oven and left to cool to room temperature, still with the vacuum pump attached, ready for the infusion.

The resin was prepared prior to the infusion process. The resin, the accelerator and the diluent were pre-mixed in a closed wide-neck bottle by shaking until homogenous. The necessary amount of the pre-mixture was transferred to an open container and the hardener was added. The components were then thoroughly mixed with a stirring propeller and degassed, using the aforementioned vacuum pump with an attached degassing chamber (VEVOR, Shanghai, China), until no bubbles could be observed. The resin was then introduced into the mould through the inlet tube. At the end of the infusion process, the inlet clamp was closed. The resin was left to cure at room temperature for 24 h. During infusion and curing, the vacuum pressure was regulated to maintain a constant differential pressure of 800 hPa. Finally, the setup was transferred to the oven and post-cured for 8 h at 80 °C and an additional 2 h at 120 °C in the case of STRUKTOL

® POLYVERTEC

® 3832S as the matrix resin. The specimens manufactured with STRUKTOL

® POLYVERTEC

® 3831 were post-cured at 80 °C for 8 h. With the post-curing completed, the specimens were demoulded, weighed and measured in thickness every 100 mm around the perimeter, around 30 mm from the edge, using a micrometre.

Table 2 provides an overview of the manufactured test plates. In total, six test plates were manufactured for mechanical testing: two plates with STRUKTOL

® POLYVERTEC

® 3832S, and four with STRUKTOL

® POLYVERTEC

® 3831.

Composite testing. Samples for mechanical testing were cut from the composite plates using a SOROTEC CNC milling machine, equipped with a 2 mm blank cutter. The specimen edges were freed from loose fibres using a 320-grit abrasive cloth: the cut surfaces of the ampliTex™ 5040 were sanded four times, those of the FibriMat™ F300 twice.

Table 3 lists the number of specimens eventually tested in the different mechanical tests.

Tensile testing of the composites was carried out according to DIN EN ISO 527-4 [

38] with rectangular specimens of type III (250 mm × 25 mm) in both the 0°- and 45°-directions. Flax fibre–epoxy tabs with ±45° direction, machined from test plates consisting of 5 layers of ampliTex™ 5043 and Sicomin GreenPoxy

® 56 epoxy resin with Sicomin SD 4770 hardener were positioned on both sides of the specimen ends and bonded using an elastic 2-component epoxy adhesive (Gößl + Pfaff GP49, Karlskron, Germany). After application, the adhesive was tempered according to specification at 65 °C for 2 h. Tensile tests were carried out using a Hegewald & Peschke Inpekt 250 kN universal testing machine equipped with a 250 kN load cell at a crosshead speed of 2 mm/min. Specimens were pre-conditioned at 23 °C and 50% RH for 24 h and at least five specimens were tested for each test plate of the material combinations in both directions; for the 45°-direction, apart from one test plate—consisting of ampliTex™ 5040 and STRUKTOL

® POLYVERTEC

® 3831—6 measurements were recorded.

Flexural tests were carried out using the four-point-bending setup for composites, according to DIN EN ISO 14125 [

39]. The specimens were machined from the test plates in the 0°- and 45°-directions and prepared in the same way as elaborated for the tensile test specimens. The specimen size was 50 mm × 12 mm × 2.7 mm. Five specimens of each material combination and fibre direction were tested with a ZwickRoell Z050 universal testing machine equipped with a 10 kN load cell and a four-point-bending fixture with 2 mm radii. The test speed was set to 1 mm/min.

The apparent interlaminar shear strength (ILSS) was tested according to the short beam three-point-bending method specified in DIN EN ISO 14130 [

40]. Rectangular specimens of 26 mm (10-times specimen thickness) × 13 mm (5-times specimen thickness) were cut out from the test plates in the 0° direction. Specimens were again pre-conditioned at 23 °C and 50% RH for 24 h and at least five were tested for each material combination. For one test plate consisting of ampliTex™ 5040 and STRUKTOL

® POLYVERTEC

® 3831 and both test plates consisting of FibriMat™ + STRUKTOL

® POLYVERTEC

® 3831, 10 specimens were tested. Testing was carried out using a ZwickRoell Z050 universal testing machine equipped with a 1 kN load cell. According to the standard, the radius of the supports was 2 mm, and the radius of the pressure fin was 5 mm. The head speed was set to 1 mm/min.

4. Discussion

One of the main challenges associated with the processing of bio-based resin is the high viscosity that barely allows for the hand lamination of FRPs. The preliminary rheometric measurements indicated the necessity of a substantial addition of HEMA dilution to ensure the dynamic viscosity of the resin formulation falls within the desired processing window for the VARI process. It was hypothesised that higher processing temperatures would reduce the pot life significantly, but that this would be negated by the benefits of reduced viscosity for the VARI process on medium-sized parts due to the accelerated curing reaction. Consequently, the reduction in resin viscosity through the incorporation of a diluent appears to be a viable option. In the absence of information regarding the glass transition temperature provided by the resin manufacturer, it is not possible to confirm the measured values by DSC. Despite the unavailability of direct numerical values, Fonseca et al. [

27] reported a similar increase in the overall glass transition temperature with an increasing proportion of HEMA as a reactive diluent.

The addition of HEMA resulted in a significant effect on the mechanical behaviour of the cured resin. Accordingly, the total content of 36.5% HEMA increased the strain at break under three-point bending mode by 68% with respect to the unmodified resin (strain at break 5.9% as indicated in the manufacturer’s data sheet). Brittle failure was observed in case of the STRUKTOL POLYVERTEC 3832S + 20 m%, which exhibited clear plastic deformation, surrounding the fracture region. This can be attributed to a reduced polymerisation and conversion degree [

41].

The authors are aware of the fact that processibility was improved at the expense of total bio-content in the system. However, it must be noted that with a bio-content of nearly 60% the system under investigation still belongs to those thermosets having the highest bio-content in the market. In the present study, HEMA was used as a reactive diluent, based on the fact that the virgin system already contained HEMA. However, with the target to increase the bio-content within the final cured system, it is important to find bio-based alternatives. First trials have been reported in the literature with acrylated epoxidized soybean oil (AESO), epoxidized linseed oil (ELO) [

30], limonene (LIM) [

30], cinnamates (CINN) [

30], furanic (meth)acrylates [

42], cardanyl acrylate (CA) [

43] and vanillin-derived veratrole monomers (VV and AVV) [

44]. While these generally tend to have a positive effect on the reduction in resin viscosity, they often have a negative impact on the thermal stability (as in the case of LIM) or the mechanical performance (as in the case of CINN). The substitution of HEMA in this study by any of the abovementioned alternatives must thus be carefully investigated, taking into account any interaction with the existing HEMA. It should therefore be a primary goal of the resin manufacturers to produce 100% bio-based resins, further accounting for other additives and accelerators.

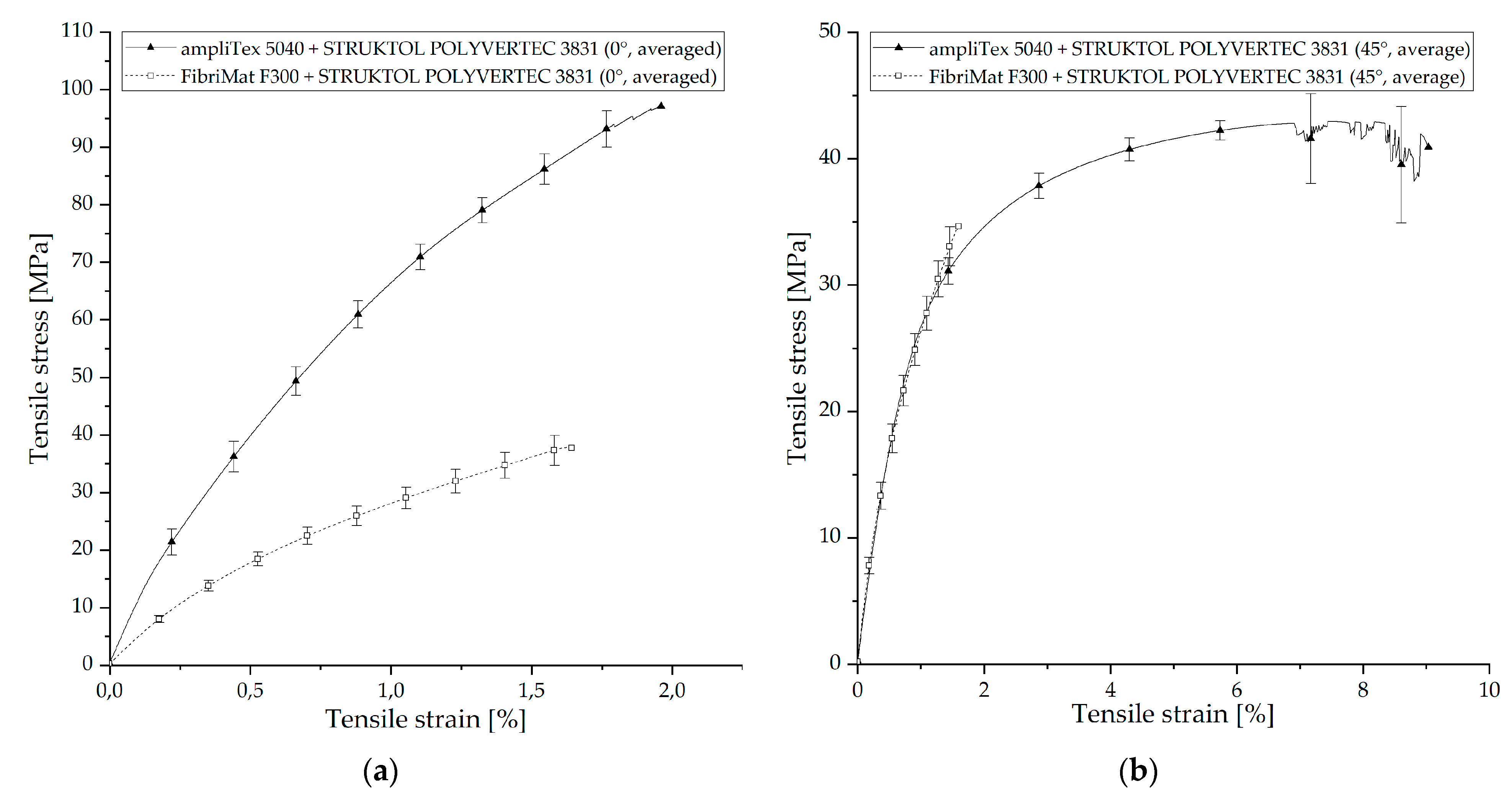

The processing conditions were subjected to a series of experimental trials, leading to final composite test plates of reproducible quality. Despite the viscosity reduction to below 750 mPa∙s achieved by the addition of HEMA, the infusion process remains a lengthy process due to the still relatively high viscosity compared to synthetic polyester. The fibre volume fraction of the plates manufactured with FibriMat™ F300 showed small deviations of 0.6%, whereas those fabricated using woven ampliTex™ 5040 showed even higher reproducibility (deviation of 0.2% in fibre volume fraction). It is imperative to degas the resin prior to infusion and reduce the vacuum pressure to as low as 150 hPa during the infusion process to minimise the void content in the composite laminate. However, inherent quality problems still arise from the VARI process: While the surface of the laminate on the mould side is flat, the vacuum bag side appears uneven, and, especially with the varying local density of non-woven FibriMat™ F300, irregularly so. The negative impact on mechanical performance due to stress concentration is evident, but to be expected given the process used. Consequently, the reinforcement of STRUKTOL

® POLYVERTEC

® 3831 with FibriMat™ F300 resulted in a flexural modulus and flexural strength of 2.95 ± 0.61 GPa and 51.16 ± 7.39 MPa, respectively. The tensile modulus and tensile strength were found to be 4.03 ± 0.29 GPa and 37.88 ± 2.86 MPa, respectively. In contrast, Rodrìguez et al. [

45] reported higher flexural and tensile properties, when combining a similar flax fibre mat, that was comparably pre-dried at 80 °C for 24 h prior to infusion, with a petrochemical unsaturated polyester (Ashland Aeropol FS 6912) in a vacuum infusion process using an acrylic cover as the top mould half (flexural modulus of 4.8 ± 0.1 GPa (+62.7%), flexural strength of 91 ± 4 MPa (+77.9%), tensile modulus of 6.3 ± 0.1 GPa (+56.3%), and tensile strength of 61 ± 1 MPa (+62.1)). It is reasonable to hypothesise that the enhanced surface quality is attributable to the stiffer upper mould and the disparity in the resin. This hypothesis may be supported by the observed superior performance. Dal Pont et al. [

14] also used a flax-twill fabric (FLAX DRY BL300, pre-dried at 110 °C for 1 h), with similar specifications to the ampliTex™ 5040 used in this study and manufactured the composites with a similar vacuum infusion method, using a flexible vacuum bagging film. Although the authors applied a higher-performing bio-based epoxy resin (Sicomin GreenPoxy 56 + SD4771), the lower fibre volume fraction of 30%, compared to 40.61 ± 0.20% in the present study, led to overall lower mechanical properties (tensile modulus of 6.34 ± 0.75 GPa (−27.5%), tensile strength of 71.32 ± 6.06 MPa (−27.8%), and elongation at break of 2.72 ± 0.46% (+38.8%) than those captured in the current study (tensile modulus: 8.74 ± 1.21 GPa; tensile strength: 98.78 ± 2.74 MPa; elongation at break: 1.96 ± 0.12%). The lower scattering in the mechanical properties may be due to the smaller plate size (200 mm × 200 mm, compared to 700 mm × 330 mm in this study), which may result in an improved uniform impregnation of the fibres.

A further challenge that has been identified in relation to FFRPs is the high moisture uptake of the natural fibres. A number of studies have previously focused on the prediction of the water uptake of natural fibre-reinforced composites [

44] and its negative effect on the composites’ mechanical performance [

20,

21,

22]. The present study further illuminates the challenges associated with processing flax fibres in a vacuum infusion process, where the high moisture uptake had a clear impact on the creation of voids within the final composite.

5. Conclusions

A VARI process was utilised to successfully manufacture bio-composites comprising four distinct material combinations. The most efficacious material combination, comprising Bcomp ampliTex™ 5040 and STRUKTOL® POLYVERTEC® 3831, with viscosity modified by 39% HEMA, exhibited a consistent fibre volume content (40.61 ± 0.2%) and thickness (2.17 ± 0.07 mm). For the 0°-direction, the tensile modulus was measured at 8.74 ± 1.21 GPa, the tensile strength at 98.78 ± 2.74 MPa, the elongation at break at 1.96 ± 0.12%, the flexural modulus at 6.81 ± 0.60 GPa and the flexural strength at 94.04 ± 6.77 MPa. Interlaminar shear testing yielded inconclusive results due to the presence of consistent invalid failure mechanisms in the specimen. The bio-based content of the specimen was found to be as high as 74.73%, whilst the glass transition temperature of the resin used was found to be 70 °C, a temperature which limits the overall application of the specimen.

This study indicates that FFRPs with polyester resins have the potential to substitute GFRPs in secondary structures in automotive applications, such as roof panels, door frames or bumpers, for example. However, it is important to acknowledge that bio-based polyester resins currently fall short of the technical standards necessary for large-scale production. To this end, concerted efforts must be made to reduce the viscosity, thereby enabling rapid and stable infusion; to reduce the diluent, thus increasing the bio-content; and to stabilise the formulation, with a view to reducing the development of volatiles under vacuum conditions. Furthermore, the development of plant fibres in the form of technical textiles of homogeneous quality is a crucial aspect for the advancement of natural fibre-reinforced composites. This necessitates maintaining fibre quality, eradicating wood husks, shives and other impurities, and ensuring uniform thickness.

Finally, the authors suggest that laminate fabrication using wet compression moulding or resin transfer moulding would lead to improved composite quality and thus increased mechanical performance.