Experimental Study on the Effect of Impactor Hardness and Shape on the Impact Response of Composite Panels

Abstract

1. Introduction

2. Materials and Experimental Details

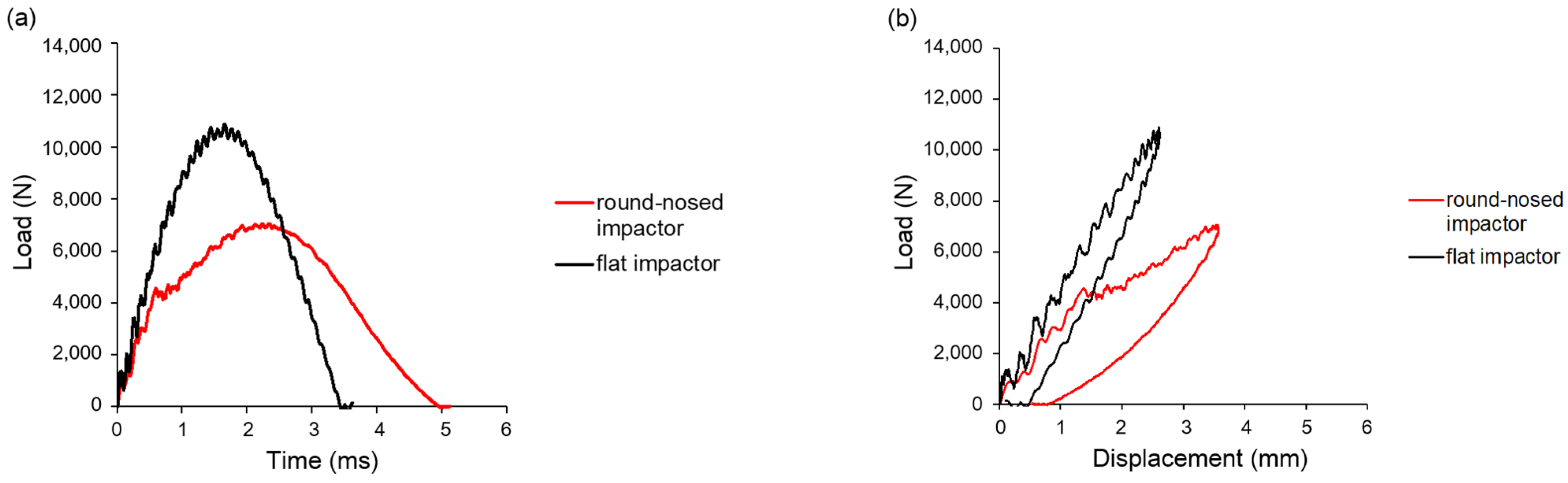

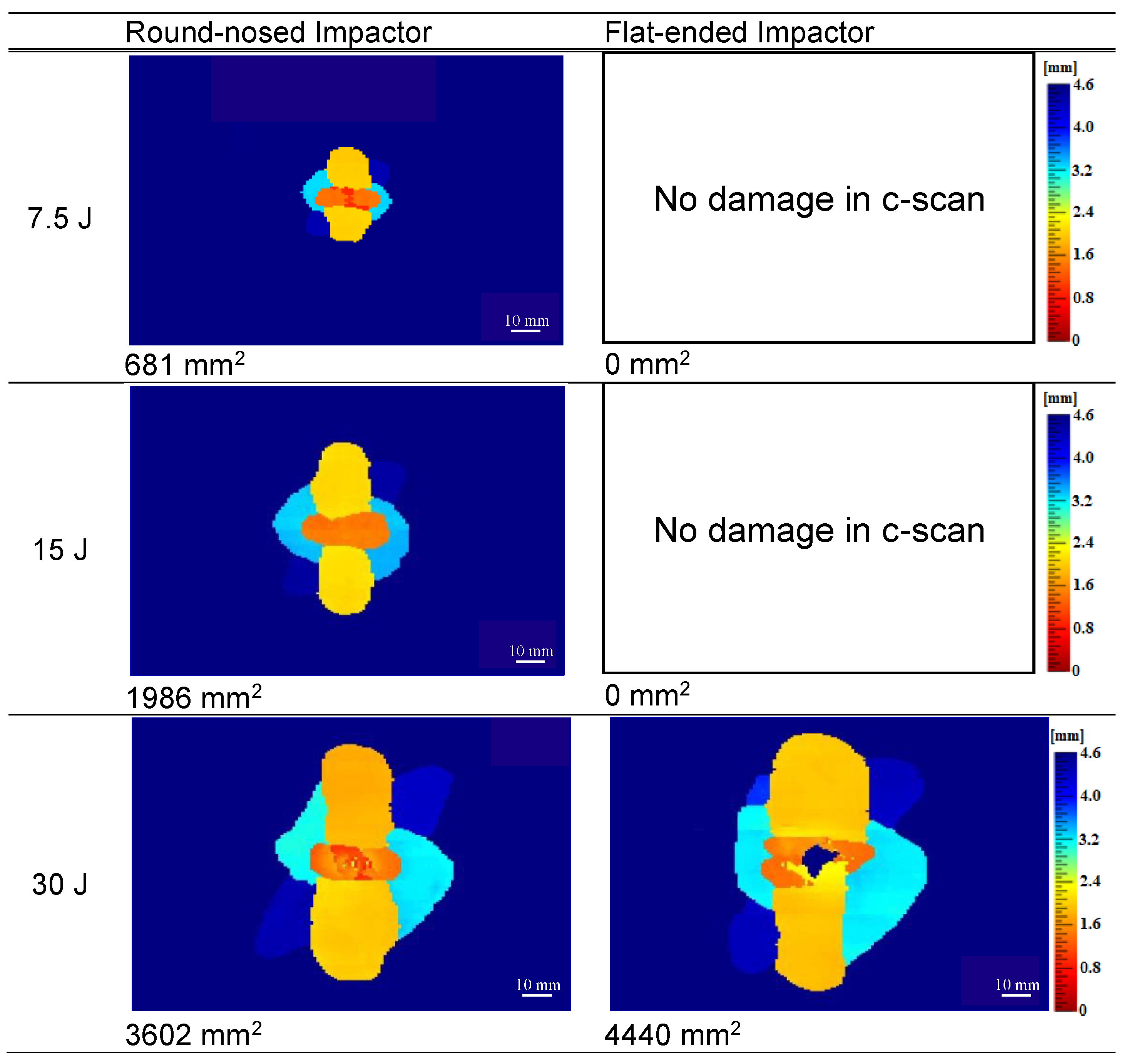

3. Experimental Results: Hard Impacts

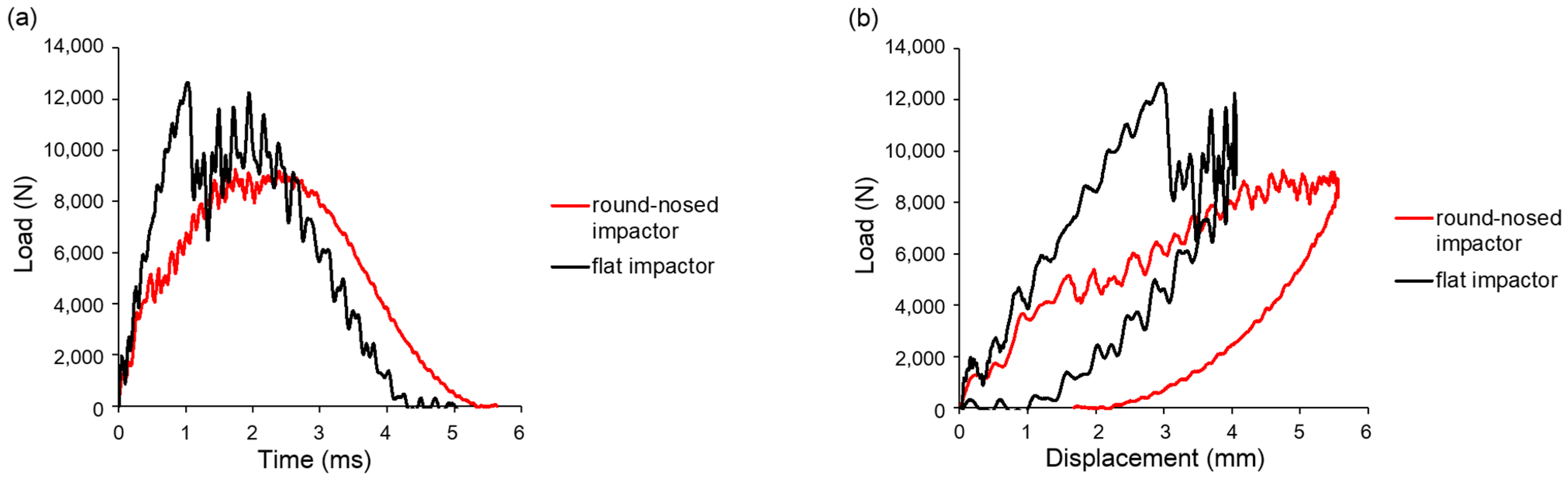

4. Experimental Results: Soft Impacts

5. Discussion

6. Conclusions

- Round-nosed impactors induced damage at significantly lower energy thresholds due to localized stress concentration and early indentation, while flat-ended impactors, although requiring higher energies to initiate damage, resulted in larger damage areas and reduced overall panel deflection.

- The greater out-of-plane deformation allowed by round-nosed impactors enhanced energy absorption and led to smaller damage zones compared to blunter impacts.

- The addition of rubber to the flat-ended impactor reduced both peak and damage onset loads while increasing maximum displacement and marginally decreasing the damage area. This behavior is attributed to the viscoelastic properties of the rubber, which allow it to absorb part of the kinetic energy during impact.

- These findings support the application of soft interfaces—such as rubberized contact surfaces—in aerospace ground equipment, where controlled compliance can mitigate composite damage during accidental impacts.

- Importantly, the experimental dataset (e.g., differences in initiation loads, delamination areas, and time delays) generated in this work provides a robust reference for the validation of future finite element models and simulation-based analyses of impact events in composite laminates. It enables predictive modeling of damage initiation and propagation under different impactor shapes and contact conditions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Griffiths, B. Boeing Sets Pace for Composites Usage in Large Civil Aircraft. 2005. Available online: https://www.compositesworld.com/articles/boeing-sets-pace-for-composite-usage-in-large-civil-aircraft (accessed on 18 January 2022).

- Zachariah, S.A.; Pai, K.D.; Shenoy, B.S. Multi-level hybridization in mitigating impact damages in advanced composites—A review on recent trends. Mater. Today Proc. 2021, 46, 9059–9066. [Google Scholar] [CrossRef]

- Raut, N.P.; Kolekar, A.B.; Gombi, S.L. Methods of damage detection on composites under low velocity impact. Mater. Today Proc. 2020, 27, 2823–2827. [Google Scholar] [CrossRef]

- Kurşun, A.; Şenel, M.; Enginsoy, H.M.; Bayraktar, E. Effect of impactor shapes on the low velocity impact damage of sandwich composite plate: Experimental study and modelling. Compos. Part B Eng. 2016, 86, 143–151. [Google Scholar] [CrossRef]

- Yao, L.; Wang, C.; He, W.; Lu, S.; Xie, D. Influence of impactor shape on low-velocity impact behavior of fiber metal laminates combined numerical and experimental approaches. Thin-Walled Struct. 2019, 145, 106399. [Google Scholar] [CrossRef]

- Mahesh, V.; Joladarashi, S.; Kulkarni, S.M. Influence of laminate thickness and impactor shape on low velocity impact response of jute-epoxy composite: FE study. Mater. Today Proc. 2020, 28, 545–550. [Google Scholar] [CrossRef]

- Mitrevski, T.; Marshall, I.H.; Thomson, R.S.; Jones, R. Low-velocity impacts on preloaded GFRP specimens with various impactor shapes. Compos. Struct. 2006, 76, 209–217. [Google Scholar] [CrossRef]

- Yankelevsky, D. Local response of concrete slabs to low velocity missile impact. Int. J. Impact Eng. 1997, 19, 331–343. [Google Scholar] [CrossRef]

- Koechlin, P.; Potapov, S. Classification of soft and hard impacts—Applications to aircraft crash. Nucl. Eng. Des. 2009, 239, 613–618. [Google Scholar] [CrossRef]

- Clark, G.; Van Blaricum, T.J. Load spectrum modification effects on fatigue of impact-damaged carbon fibre composite coupons. Composites 1987, 18, 243–251. [Google Scholar] [CrossRef]

- Batra, R.C.; Gopinath, G.; Zheng, J.Q. Damage and failure in low energy impact of fiber-reinforced polymeric composite laminates. Compos. Struct. 2012, 94, 540–547. [Google Scholar] [CrossRef]

- Sjogren, A.; Krasnikovs, A.; Varna, J. Experimental determination of elastic properties of impact damage in carbon fibre/epoxy laminates. Compos. Part A 2001, 32, 1237–1242. [Google Scholar] [CrossRef]

- Heimbs, S.; Heller, S.; Middendorf, P.; Hahnel, F.; Weisse, J. Low velocity impact on CFRP plates with compressive preload: Test and modelling. Int. J. Impact Eng. 2009, 36, 1182–1193. [Google Scholar] [CrossRef]

- Hongkarnjanakul, N.; Bouvet, C.; Rivallant, S. Validation of low velocity impact modelling on different stacking sequences of CFRP laminates and influence of fibre failure. Compos. Struct. 2013, 106, 549–559. [Google Scholar] [CrossRef]

- Zhou, J.; Liao, B.; Shi, Y.; Zuo, Y.; Tuo, H.; Jia, L. Low-velocity impact behaviour and residual tensile strength of CFRP laminates. Compos. Part B Eng. 2019, 161, 300–313. [Google Scholar] [CrossRef]

- Caprino, G.; Lopresto, V. On the penetration energy for fibre-reinforced plastics under low-velocity impact conditions. Compos. Sci. Technol. 2001, 61, 65–73. [Google Scholar] [CrossRef]

- Cantwell, W.J.; Morton, J. Impact perforation of carbon fibre reinforced plastic. Compos. Sci. Technol. 1990, 38, 119–141. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Xiong, J. Low-velocity impact performance and damage mechanisms of all-CFRP honeycomb sandwich shell. Int. J. Impact Eng. 2025, 199, 105231. [Google Scholar] [CrossRef]

- Jing, K.; Zhou, H.; Wang, H.; Yan, H.; Xie, S. Multiscale damage and low-velocity impact study of three-dimensional woven composites. Thin-Walled Struct. 2024, 202, 112132. [Google Scholar] [CrossRef]

- Jackson, W.C.; Poe, C.C., Jr. The use of impact force as a scale parameter for the impact response of composite laminates. Compos. Technol. Res. 1993, 15, 282–289. [Google Scholar] [CrossRef]

- Ambur, D.; Kemmerly, H. Influence of impactor mass on the damage characteristics and failure strength of laminated composite plates. In Proceedings of the 39th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference and Exhibit, Long Beach, CA, USA, 20–23 April 1998; p. 1784. [Google Scholar] [CrossRef]

- Hakim, M.L.; Nafianto, R.; Nugraha, A.D.; Wiranata, A.; Supriyanto, E.; Nugroho, G.; Muflikhun, M.A. Advanced FEA simulation of GFRP and CFRP responses to low velocity impact: Exploring impactor diameter variations and damage mechanisms. Compos. Part C Open Access 2024, 15, 100541. [Google Scholar] [CrossRef]

- Qiu, J. Research and analysis on low-velocity impact of composite materials. Sci. Eng. Compos. Mater. 2023, 30, 20220209. [Google Scholar] [CrossRef]

- Artero-Guerrero, J.A.; Pernas-Sánchez, J.; López-Puente, J.; Varas, D. Experimental study of the impactor mass effect on the low velocity impact of carbon/epoxy woven laminates. Compos. Struct. 2015, 133, 774–781. [Google Scholar] [CrossRef]

- Dau, F.; Dano, M.-L.; Duplessis-Kergomard, Y. Experimental investigations and variability considerations on 3D interlock textile composites used in low velocity soft impact loading. Compos. Struct. 2016, 153, 369–379. [Google Scholar] [CrossRef]

- Liu, J.; Liu, H.; Kaboglu, C.; Kong, X.; Ding, Y.; Chai, H.; Blackman, B.R.K.; Kinloch, A.J.; Dear, J.P. The impact performance of woven-fabric thermoplastic and thermoset composites subjected to high-velocity soft- and hard-impact loading. Appl. Compos. Mater. 2019, 26, 1389–1410. [Google Scholar] [CrossRef]

- Mitrevski, T.; Marshall, I.H.; Thomsom, R.; Jones, R.; Whittingham, B. The effect of impactor shape on the impact response of composite laminates. Compos. Struct. 2005, 67, 139–148. [Google Scholar] [CrossRef]

- Kazemianfar, B.; Esmaeeli, M.; Nami, M.R. Response of 3D woven composites under low velocity impact with different impactor geometries. Aerosp. Sci. Technol. 2020, 102, 105849. [Google Scholar] [CrossRef]

- Lv, T.; Yuan, B.; Liu, Y.; Wang, D. Comparative Analysis of Damage and Energy Absorption Mechanisms in Various Plain-weave Fiber Reinforced Composites under Multi-Angle Low-Velocity Impact. Thin-Walled Struct. 2025, 210, 113040. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Neto, M.A.; Amaro, A.M. Multi-impact behaviour of composite laminates under constant and different energy levels. Compos. Struct. 2022, 294, 115788. [Google Scholar] [CrossRef]

- ASTM D7136/D7136M; Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event. American Society for Testing and Materials: Conshohocken, PA, USA, 2005. [CrossRef]

- Liu, H.; Liu, J.; Ding, Y.; Hall, Z.E.; Kong, X.; Zhou, J.; Blackman, B.R.K.; Kinloch, A.J.; Dear, J.P. A three-dimensional elastic-plastic damage model for predicting the impact behaviour of fibre-reinforced polymer-matrix composites. Compos. Part B Eng. 2020, 201, 108389. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Ding, Y.; Zheng, J.; Kong, X.; Zhou, J.; Harper, L.; Blackman, B.R.K.; Kinloch, A.J.; Dear, J.P. The behaviour of thermoplastic and thermoset carbon-fibre composites subjected to low-velocity and high-velocity impact. J. Mater. Sci. 2020, 55, 15751–15768. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Ding, Y.; Zhou, J.; Kong, X.; Blackman, B.R.K.; Kinloch, A.J.; Falzon, B.G.; Dear, J.P. Effects of impactor geometry on the low velocity impact behaviour of fibre-reinforced composites: An experimental and theoretical investigation. Appl. Compos. Mater. 2020, 27, 533–553. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Huang, M.; Zhang, Y.; Lu, Y.; Yue, Q. Numerical analysis of low-velocity impact damage in fiber metal laminate (FML) by introducing plasticity of fiber composite materials. Compos. Struct. 2025, 357, 118912. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Li, J.; Wang, B.; Liao, Y. Experimental-numerical analysis of failure of adhesively bonded lap joints under transverse impact and different temperatures. Int. J. Impact Eng. 2020, 140, 103541. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Huang, M.; Zhang, Y.; Lu, Y.; Dong, L. Prediction of low-velocity impact mechanical response and damage in thermoplastic composites considering elastoplastic behavior. Int. J. Impact Eng. 2024, 194, 105099. [Google Scholar] [CrossRef]

- PVC Tube Online Ltd. Neoprene Rubber Sheet. Available online: http://www.pvctubeonline.co.uk/neoprene_rubber_sheet.htm (accessed on 16 November 2021).

- Liu, X.; Kong, W.; Song, S.; Wang, A. Impact properties and damage assessment of unidirectional aramid/carbon fiber hybrid reinforced polymer composites. Thin-Walled Struct. 2025, 209, 112898. [Google Scholar] [CrossRef]

- Patil, S.; Reddy, D.M. Impact damage assessment in carbon fiber reinforced composite using vibration-based new damage index and ultrasonic C-scanning method. Structures 2020, 28, 638–650. [Google Scholar] [CrossRef]

| Property | Value | Units | Test Method |

|---|---|---|---|

| Indentation hardness | 60 shore A −4 +5 | Degrees | ASTM D2240 00 |

| Specific gravity | 1.5 +/− 0.05 | g/cm3 | ASTM D792 |

| Tensile strength (minimum) | 3 | MPa | ASTM D412 |

| Elongation at break (minimum) | 250 | % | - |

| Minimum continuous working temperature | −20 | °C | - |

| Maximum continuous working temperature | 65 | °C | - |

| Maximum intermittent working temperature | 70 | °C | - |

| Compression set 70 °C 22 h | 35% max | % | ASTM D395 Method B |

| Impactor | Impact Energy (J) | Drop-Weight Traces | Damage Area (mm2) | Variation in Damage Area | |||

|---|---|---|---|---|---|---|---|

| Damage Onset Load (N) | Damage Onset Time (ms) | Peak Load (N) | Max. Displacement (mm) | ||||

| Round-nosed | 7.5 | 4445 | 1.0 | 5071 | 2.4 | 681 | - |

| Flat-ended | 7.5 | - | - | 7649 | 1.9 | - | - |

| Round-nosed | 15 | 4558 | 0.6 | 7054 | 3.6 | 1986 | - |

| Flat-ended | 15 | - | - | 10,879 | 2.6 | - | - |

| Round-nosed | 30 | 4115 | 0.4 | 9248 | 5.6 | 3602 | - |

| Flat-ended | 30 | 12,641 | 1.0 | 12,641 | 4.0 | 4440 | - |

| Flat-ended w/1 mm rubber | 30 | 11,406 | 1.0 | 11,406 | 4.5 | 4308 | ±2.1% |

| 30 | 11,530 | 1.0 | 11,530 | 4.4 | 4490 | ||

| Flat-ended w/1.5 mm rubber | 30 | 11,183 | 1.2 | 11,330 | 4.6 | 4250 | ±5.1% |

| 30 | 10,822 | 1.1 | 10,822 | 4.6 | 4711 | ||

| Flat-ended w/2 mm rubber | 30 | 11,431 | 1.3 | 11,431 | 4.6 | 4144 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hall, Z.E.C.; Yang, Y.; Dear, J.P.; Liu, J.; Brooks, R.A.; Ding, Y.; Liu, H.; Dear, J.P. Experimental Study on the Effect of Impactor Hardness and Shape on the Impact Response of Composite Panels. J. Compos. Sci. 2025, 9, 230. https://doi.org/10.3390/jcs9050230

Hall ZEC, Yang Y, Dear JP, Liu J, Brooks RA, Ding Y, Liu H, Dear JP. Experimental Study on the Effect of Impactor Hardness and Shape on the Impact Response of Composite Panels. Journal of Composites Science. 2025; 9(5):230. https://doi.org/10.3390/jcs9050230

Chicago/Turabian StyleHall, Zoe E. C., Yuancheng Yang, James P. Dear, Jun Liu, Richard A. Brooks, Yuzhe Ding, Haibao Liu, and John P. Dear. 2025. "Experimental Study on the Effect of Impactor Hardness and Shape on the Impact Response of Composite Panels" Journal of Composites Science 9, no. 5: 230. https://doi.org/10.3390/jcs9050230

APA StyleHall, Z. E. C., Yang, Y., Dear, J. P., Liu, J., Brooks, R. A., Ding, Y., Liu, H., & Dear, J. P. (2025). Experimental Study on the Effect of Impactor Hardness and Shape on the Impact Response of Composite Panels. Journal of Composites Science, 9(5), 230. https://doi.org/10.3390/jcs9050230