Determination of the Mechanical Properties of Flax and Its Hybrid Flax/Carbon Composite Laminates with Vinyl Ester Resin for Wind Turbine Rotor Blades

Abstract

1. Introduction

2. Methodology

2.1. Properties of Wind Turbine Blades

- -

- High strength: To support the blades from aerodynamic wind loads, pressure loads, inertial loads and gravitational loads.

- -

- High modulus: To ensure the blade has sufficient rigidity to prevent any kind of deformation during loading, thereby maintaining dimensional stability and structural integrity.

- -

- Impact resistance: To ensure the blade has optimal crack resistance during collision of debris or birds.

- -

- Lightweight: To reduce the effect of the weights of blades acting on the tower in the form of gravitational load.

- -

- Fatigue resistance: To withstand the cyclic loading conditions provided by the combination of all of the loads for around 108 cycles i.e., for more than 20 years].

- -

- Corrosion resistance: To prevent degradation of the blade due to any oxidation reaction or photochemical reaction when exposed to the atmospheric ambiance.

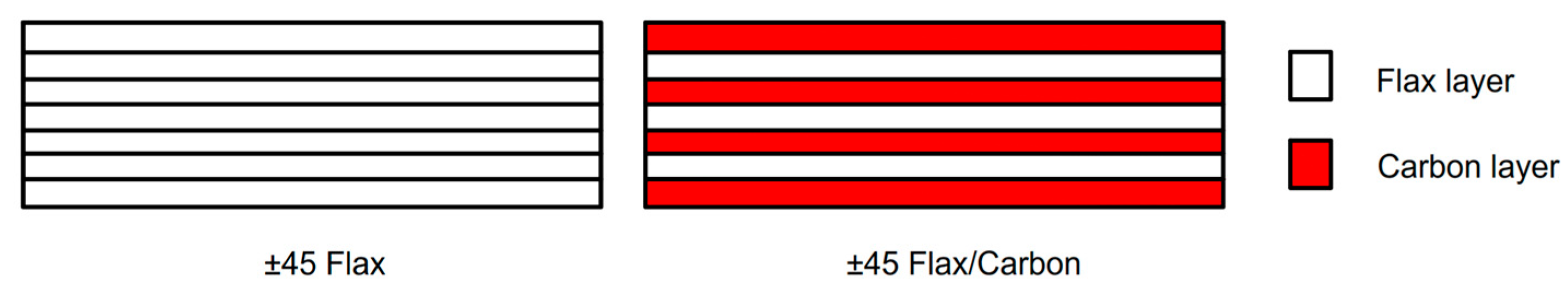

2.2. Composite Material Specification

2.3. Resin System

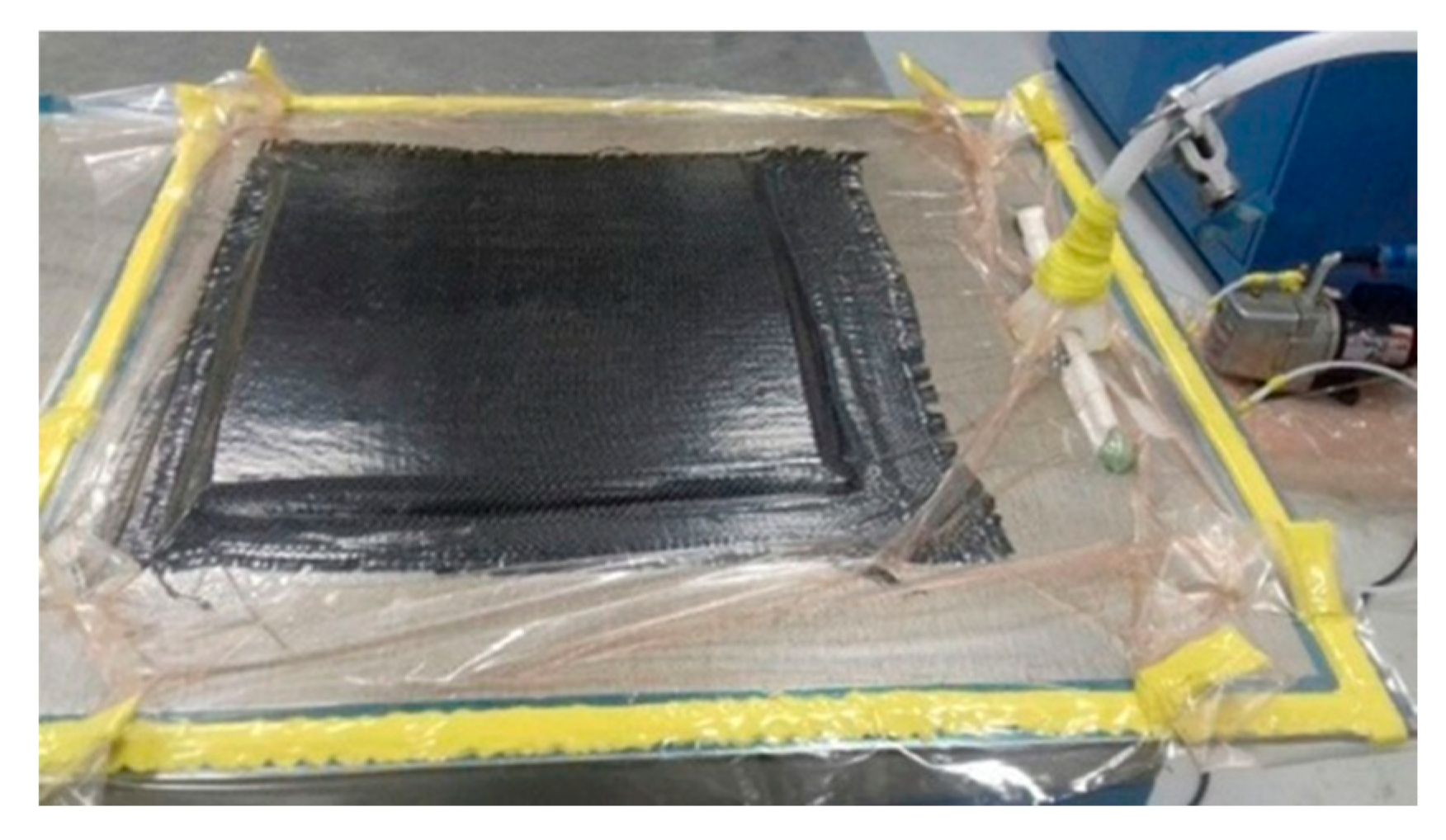

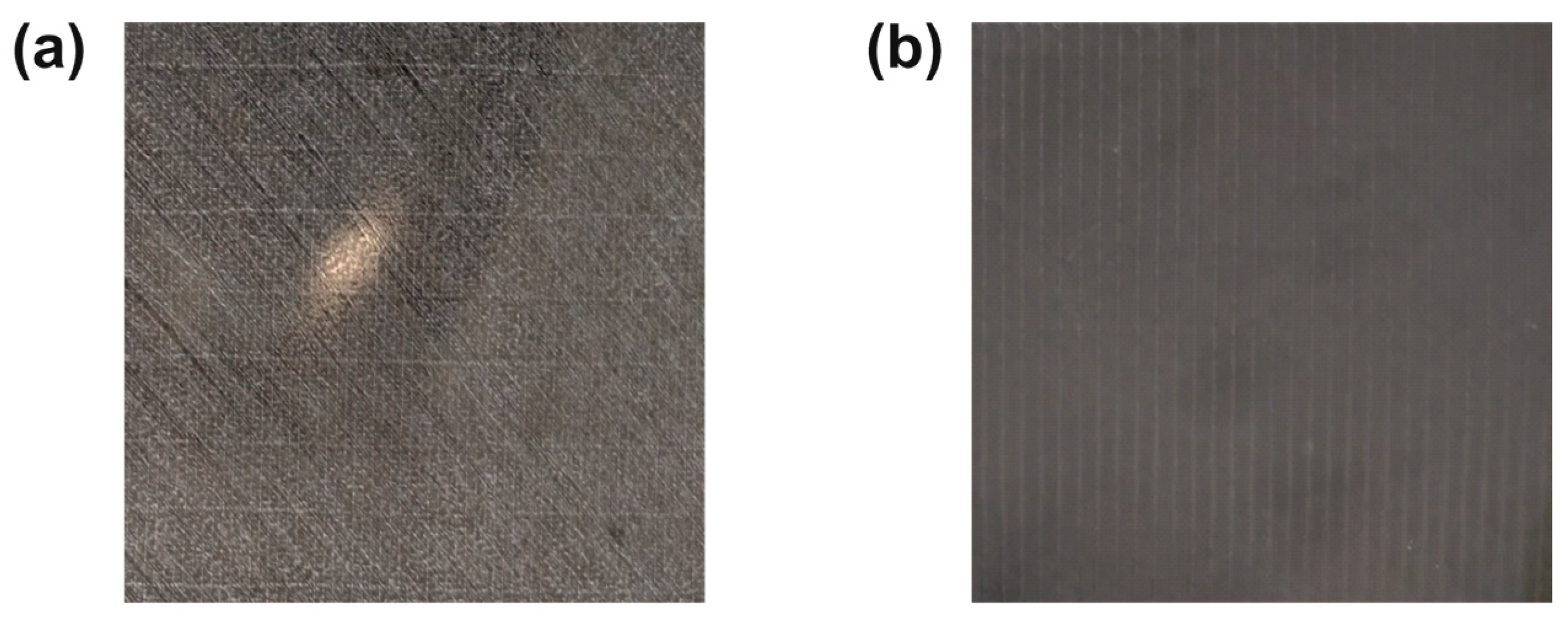

2.4. Manufacturing and Sample Preparation

2.5. Experimental Procedure

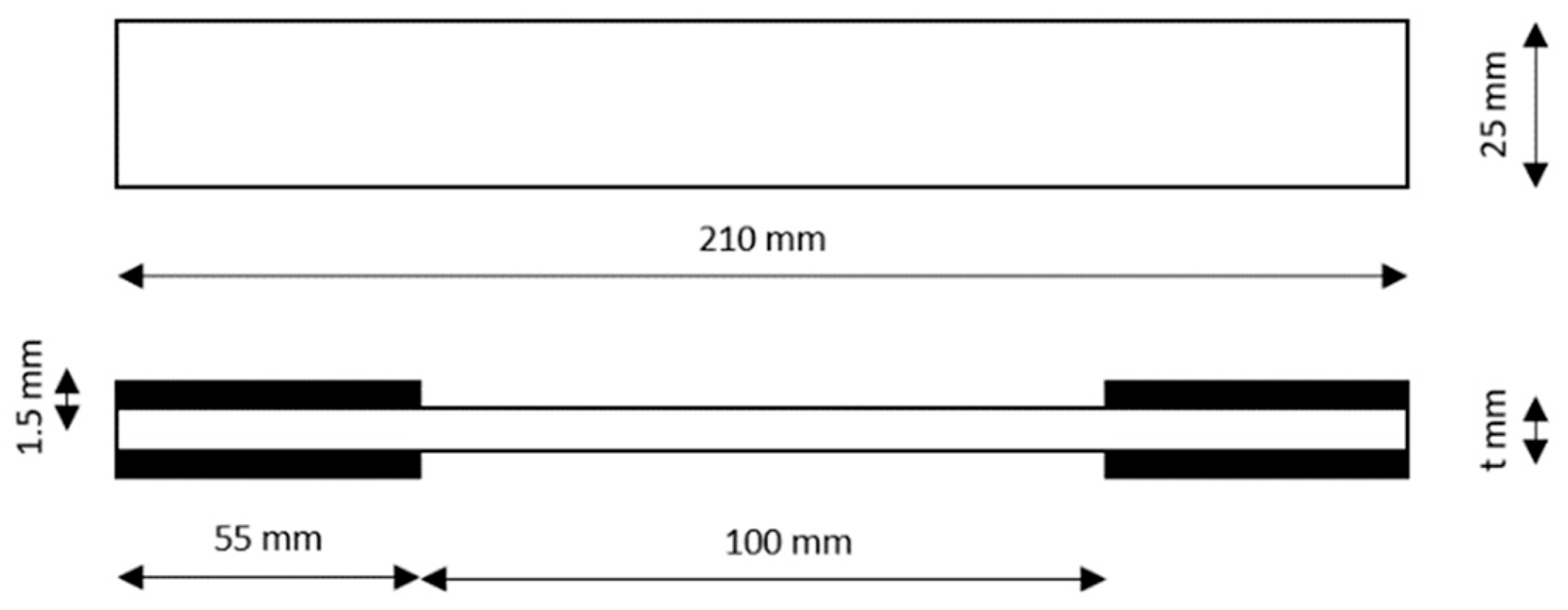

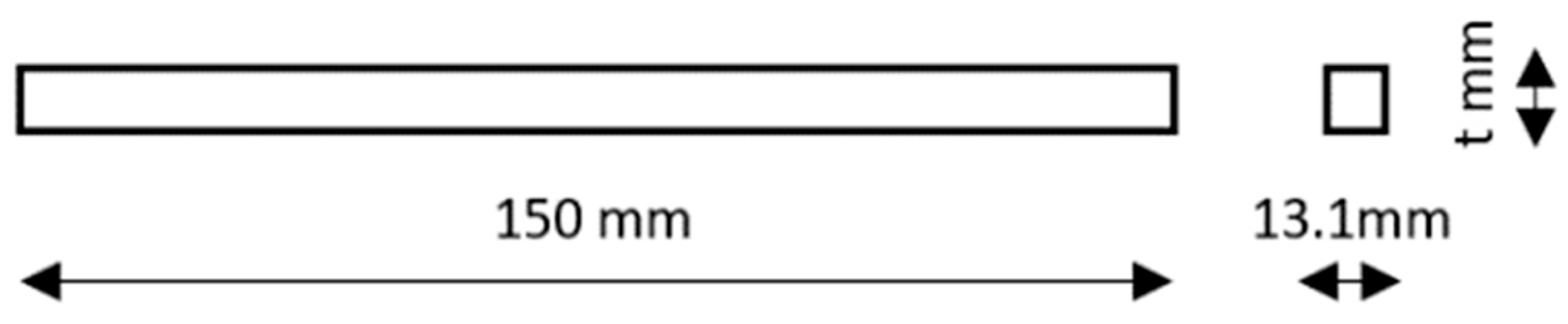

2.5.1. Tensile Test

2.5.2. Flexural Test

2.5.3. Low-Velocity Impact Test

3. Results and Discussions

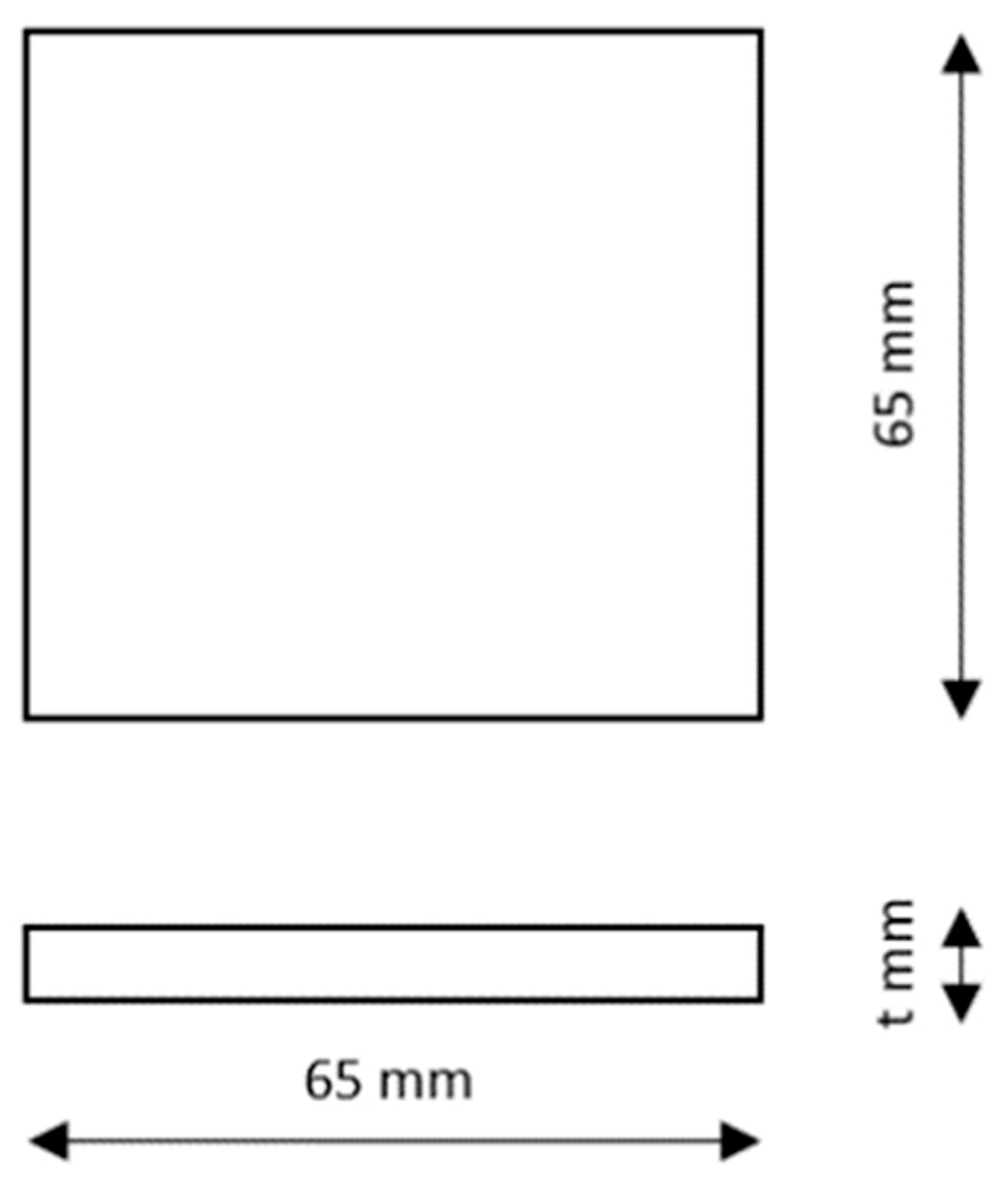

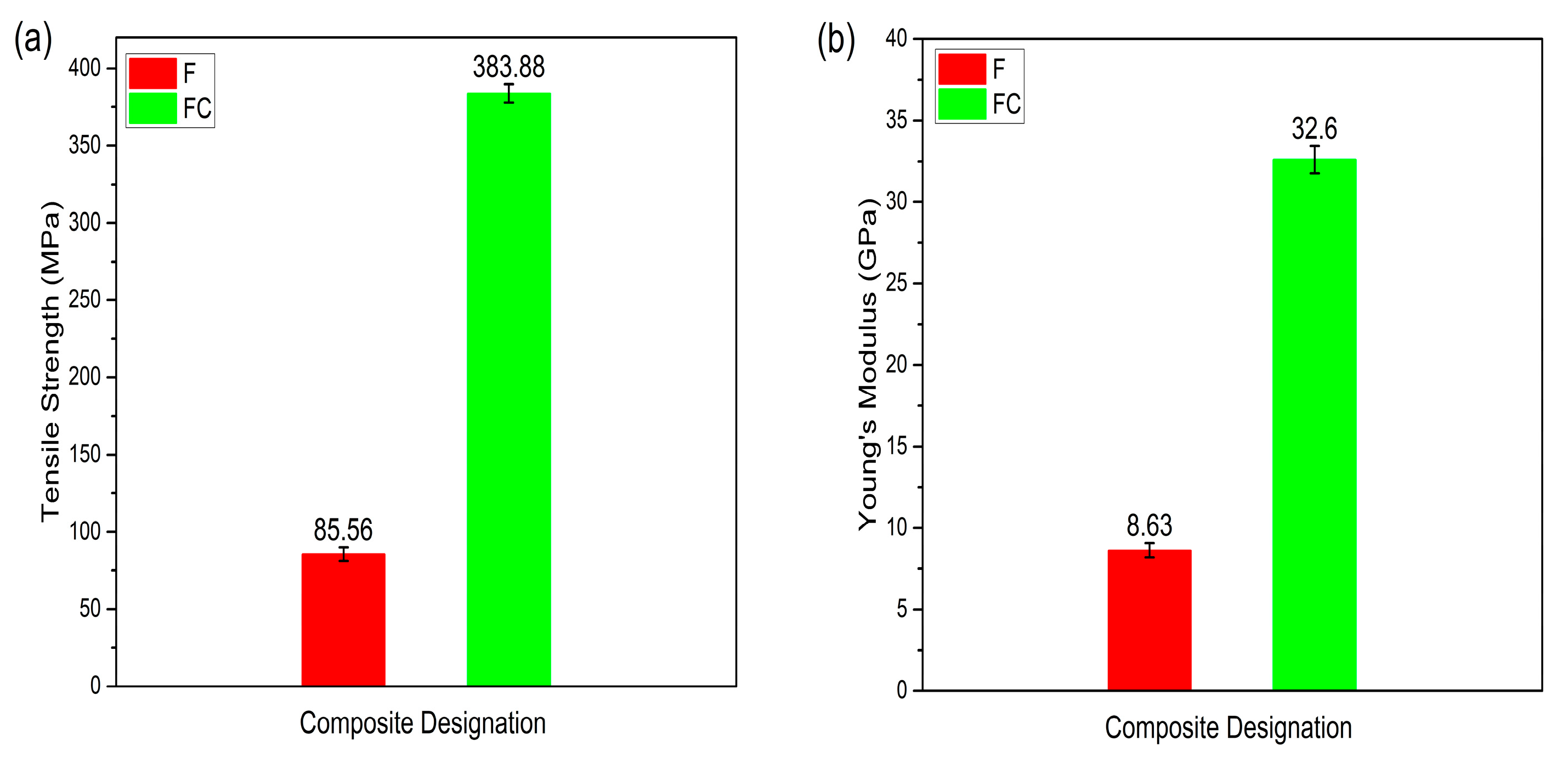

3.1. Tensile Properties

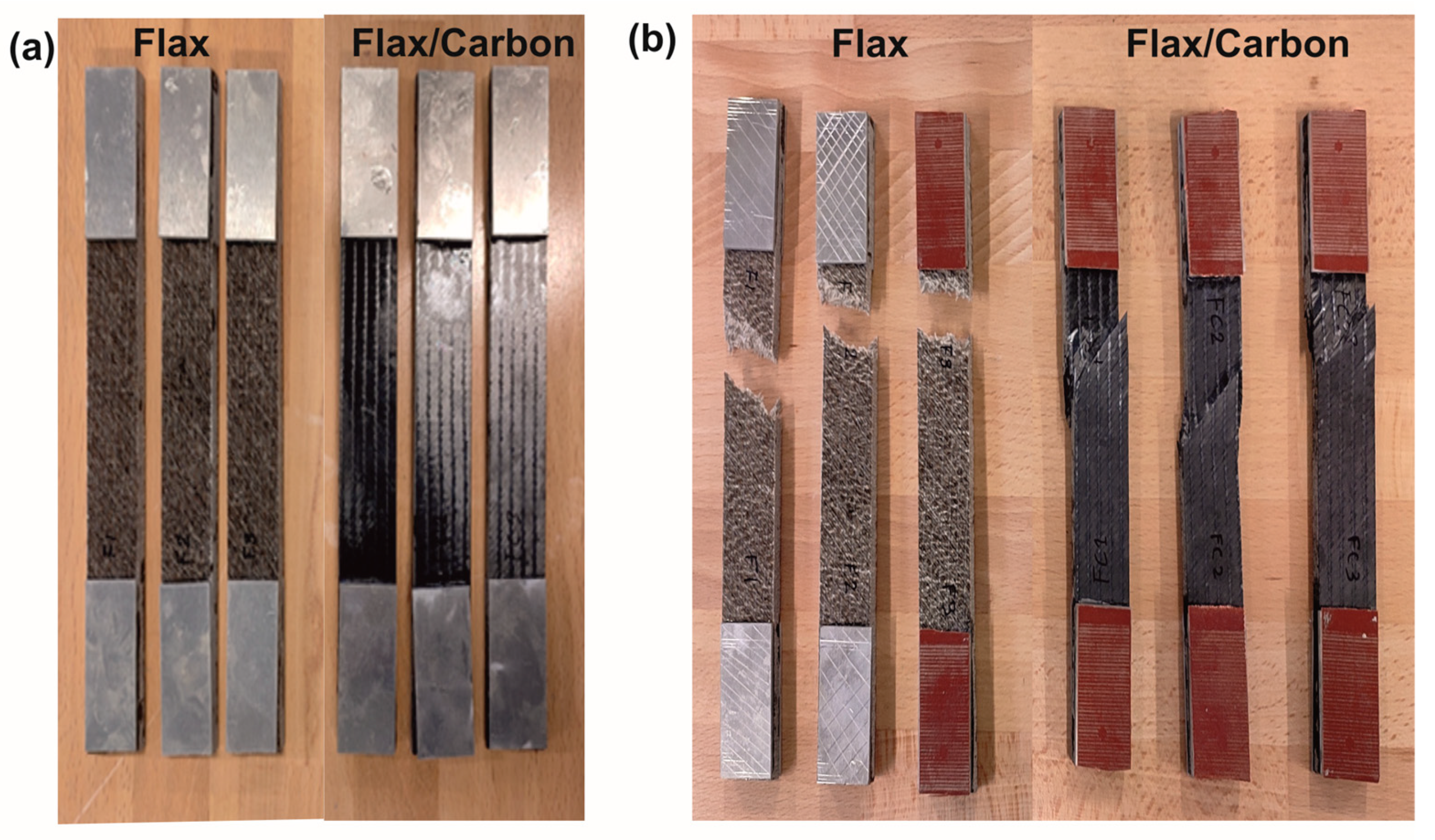

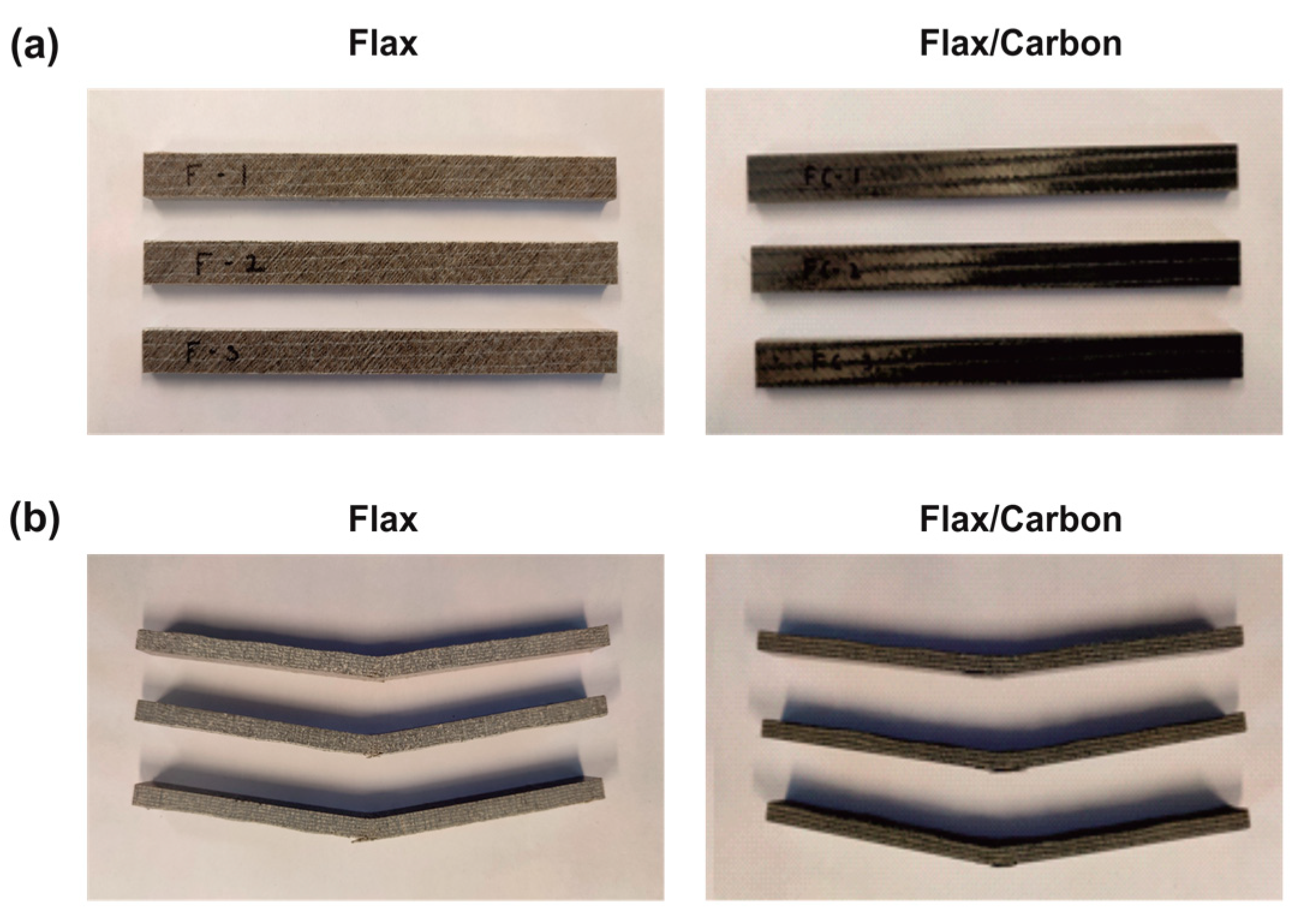

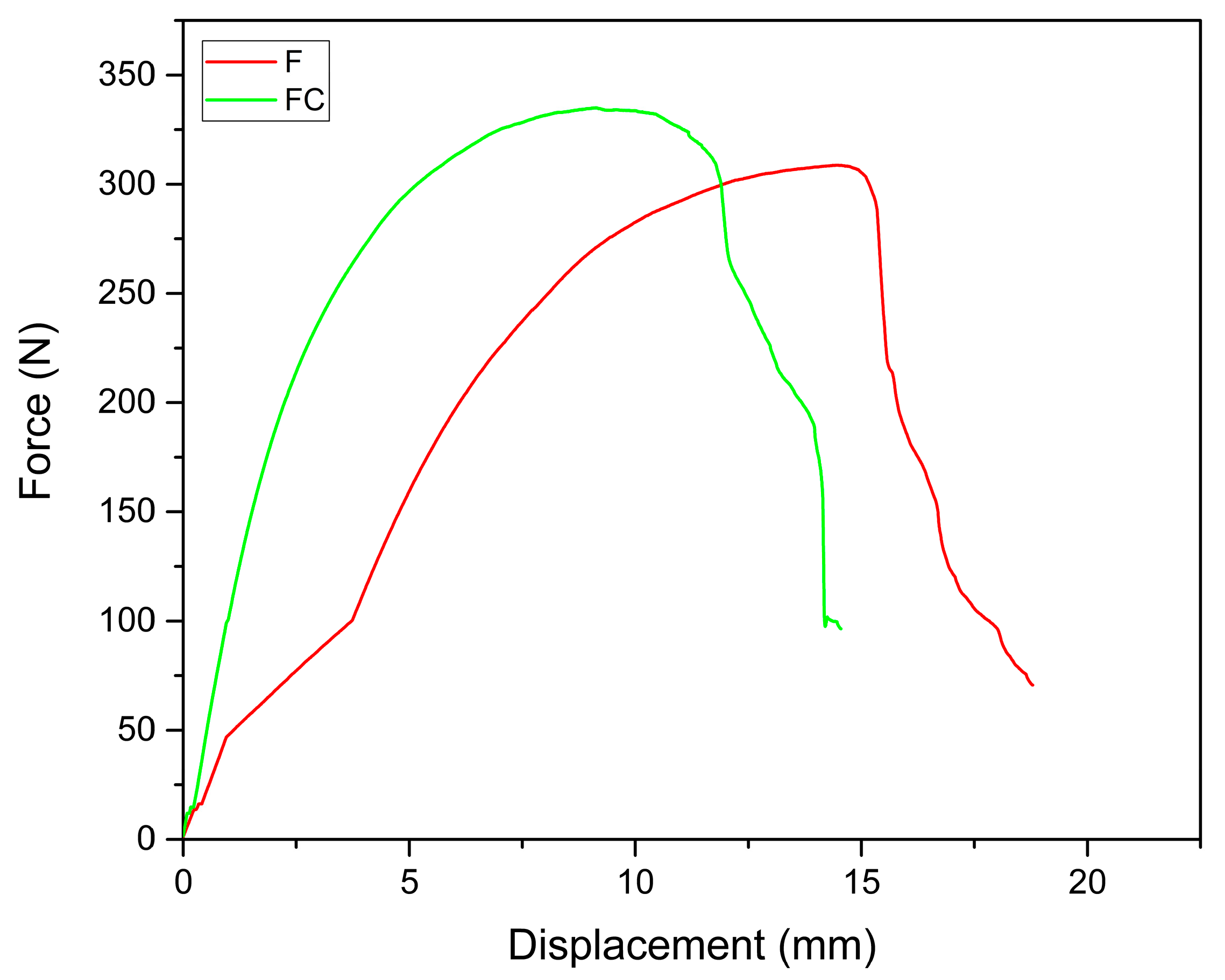

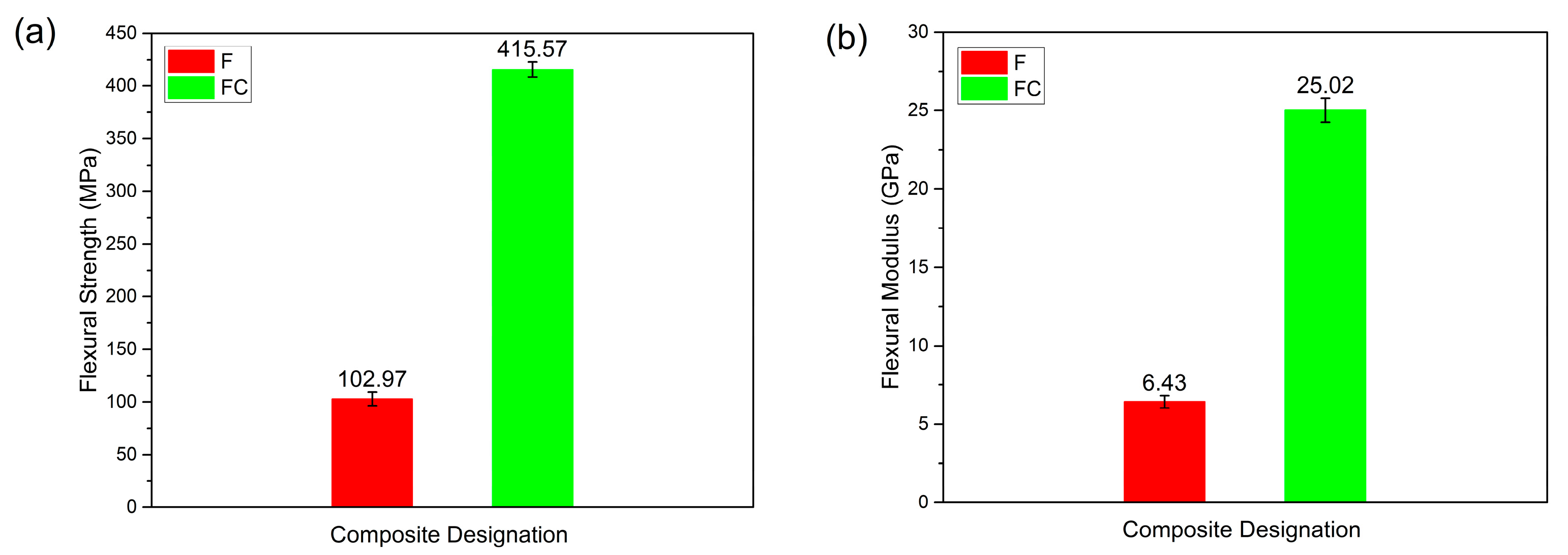

3.2. Flexural Properties

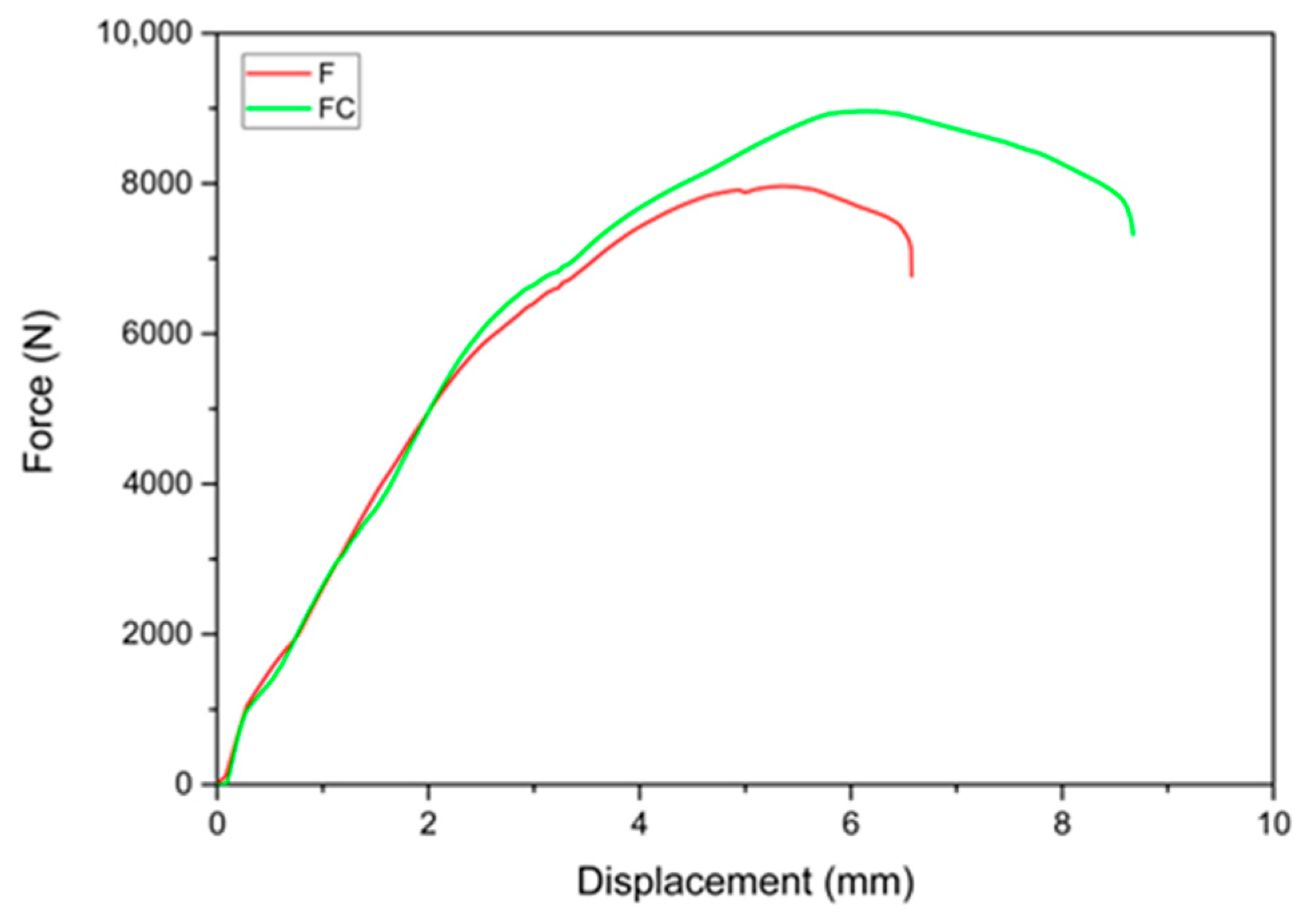

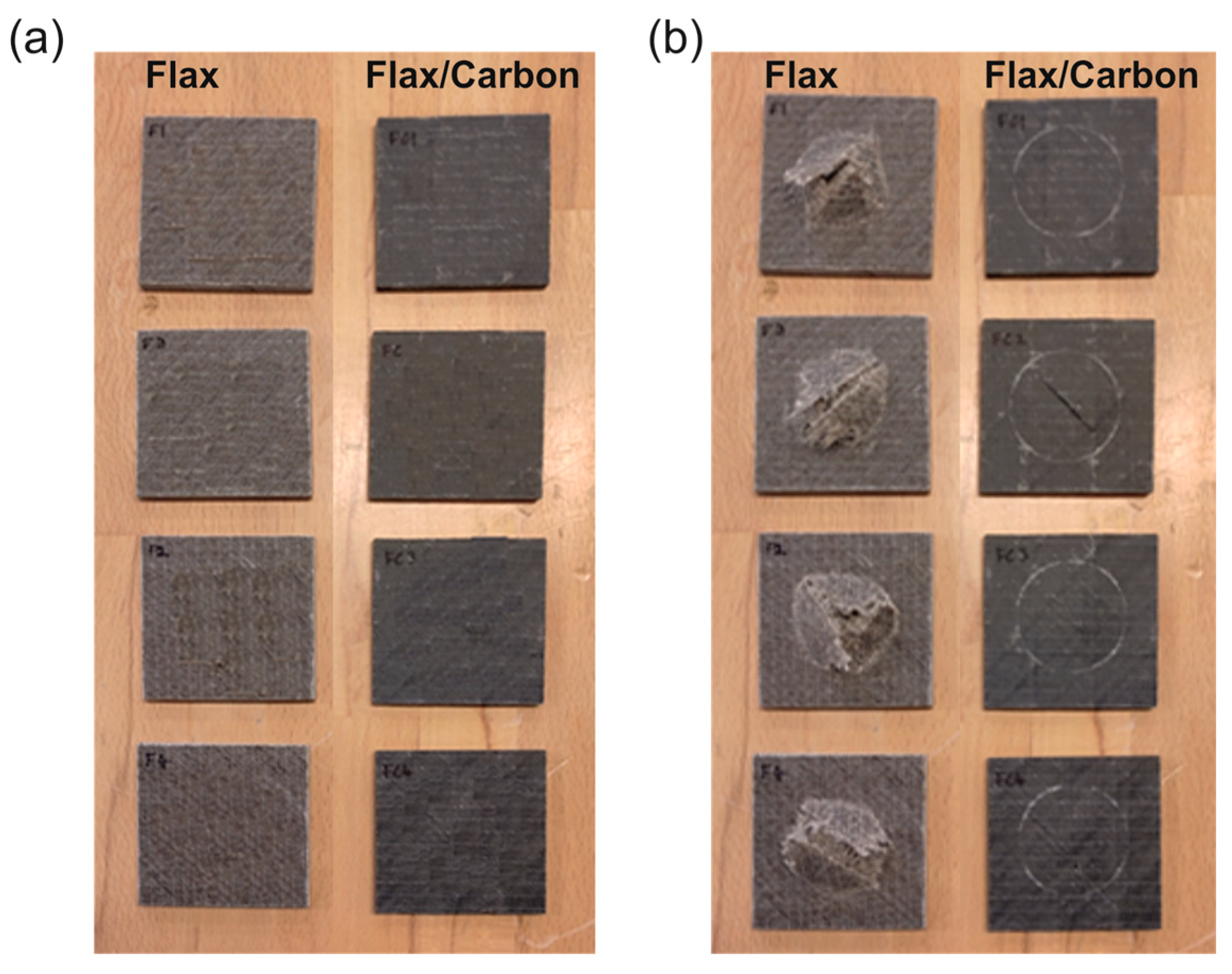

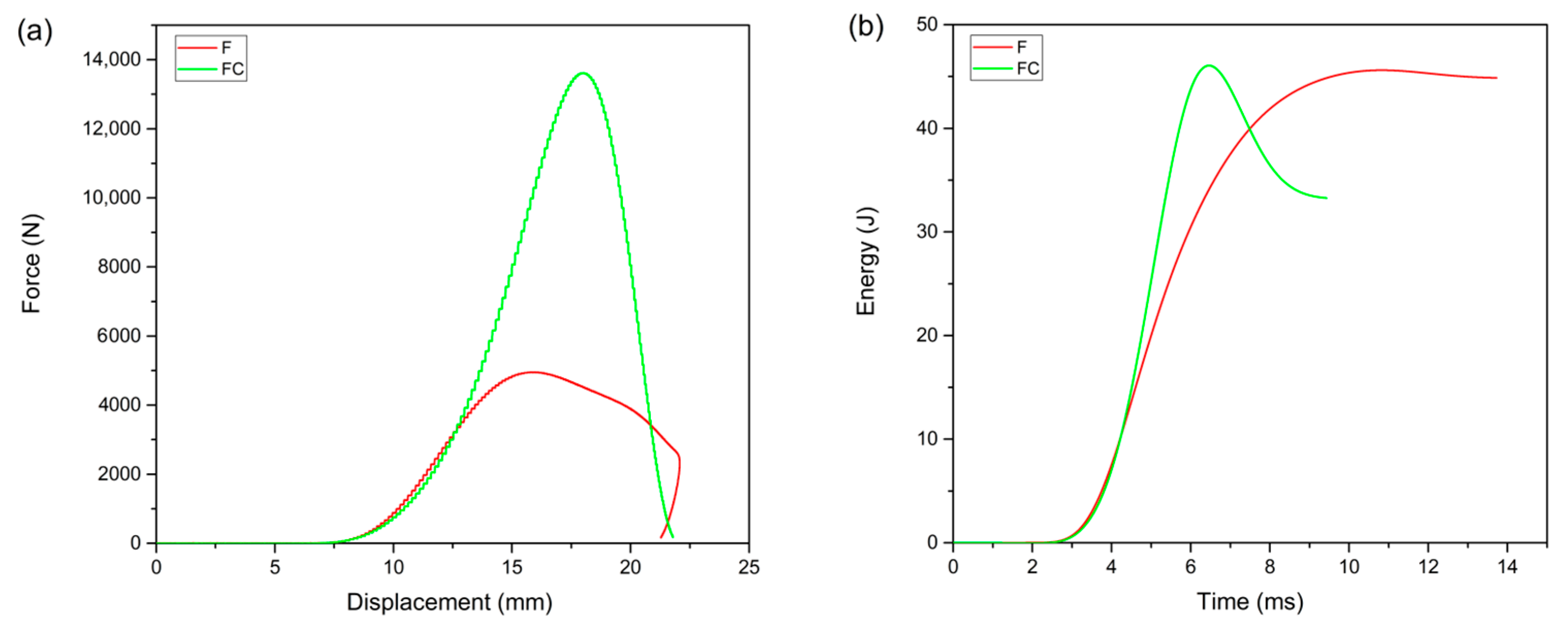

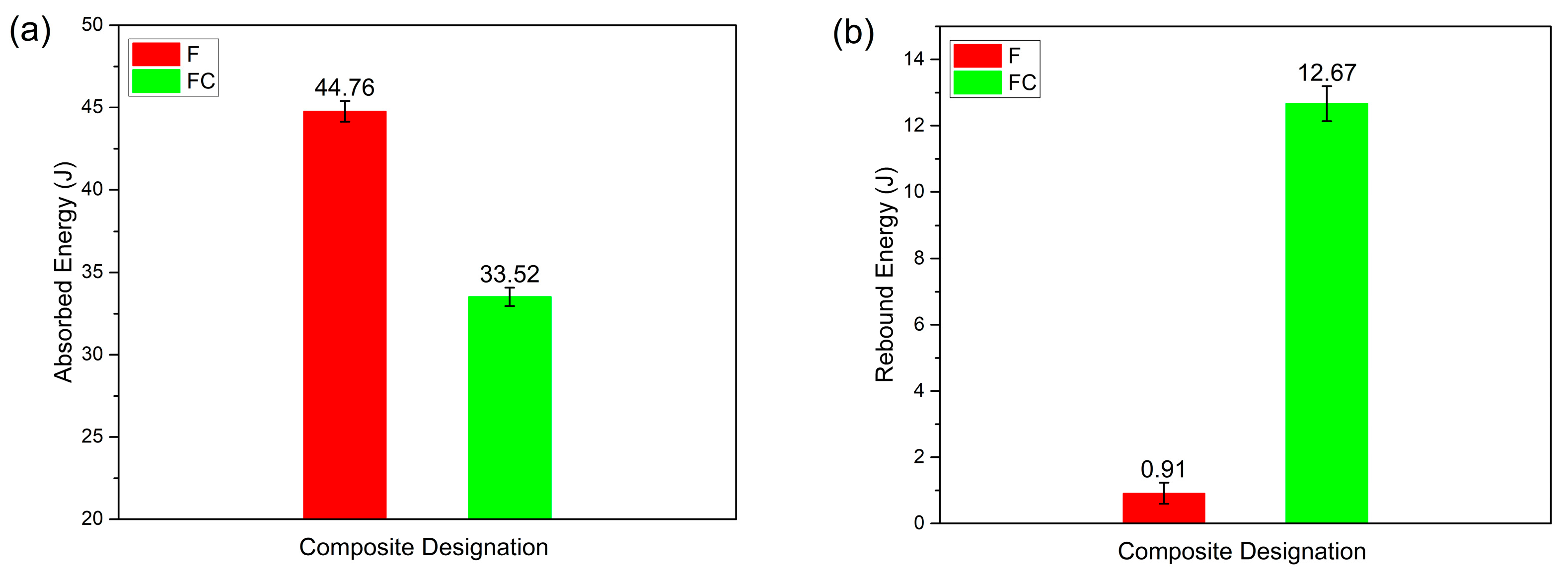

3.3. Low-Velocity Impact Properties

4. Conclusions

- The tensile test results show that the flax/carbon variant exhibited superior tensile strength and excellent Young’s modulus values of 383.88 MPa and 32.60 GPa, respectively, which are about 3.5 and 2.7 times higher than the flax composites.

- In the flexural test, the hybrid flax/carbon composites displayed superior bending performance compared with the flax composite, with flexural strength and flexural modulus values of around 415.57 MPa and 25.02 GPa, respectively.

- The low-velocity impact test showed that flax/carbon composite has excellent impact resistance, with a higher rebound energy of 12.67 J. The flax composite possesses excellent energy absorption capacity despite failing at lower peak loads.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kalagi, G.R.; Patil, R.; Nayak, N. Natural Fiber Reinforced Polymer Composite Materials for Wind Turbine Blade Applications. Int. J. Sci. Res. Dev. 2016, 1, 28–38. Available online: https://www.ijsdr.org/papers/IJSDR1609005.pdf (accessed on 17 March 2025).

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed]

- Reddy, S.S.P.; Suresh, R.; Hanamantraygouda, M.B.; Shivakumar, B.P. Use of composite materials and hybrid composites in wind turbine blades. Mater. Today Proc. 2021, 46, 2827–2830. [Google Scholar] [CrossRef]

- Flynn, J.; Amiri, A.; Ulven, C. Hybridized carbon and flax fiber composites for tailored performance. Mater. Des. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Khandai, S.; Nayak, R.K.; Kumar, A.; Das, D.; Kumar, R. Assessment of Mechanical and Tribological Properties of Flax/Kenaf/Glass/Carbon Fiber Reinforced Polymer Composites. Mater. Today Proc. 2019, 18, 3835–3841. [Google Scholar] [CrossRef]

- Karacor, B.; Ozcanli, M. Analysis of Mechanical Properties of Flax/Carbon Fiber Reinforced Hybrid Composites Produced Using Two Different Production Methods. J. Eng. Sci. Des. 2023, 11, 459–473. [Google Scholar] [CrossRef]

- Bahrami, M.; Enciso, B.; Gaifami, C.M.; Abenojar, J.; Martinez, M.A. Characterization of hybrid biocomposite Poly-Butyl-Succinate/Carbon fibers/Flax fibers. Compos. Part B Eng. 2021, 221, 109033. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Hansen, O.; Endres, H.-J. Review on Hybrid Carbon/Flax Composites and Their Properties. Int. J. Polym. Sci. 2019, 2019, 9624670. [Google Scholar] [CrossRef]

- Guggari, G.S.; Shivakumar, S.; Manjunath, G.A.; Nikhil, R.; Karthick, A.; Edacherian, A.; Saleel, C.A.; Asif, A.; Prasath, S.; Saleh, B. Thermal and Mechanical Properties of Vinyl Ester Hybrid Composites with Carbon Black and Glass Reinforcement. Adv. Mater. Sci. Eng. 2021, 2021, 6030096. [Google Scholar] [CrossRef]

- Gupta, U.S.; Dharkar, A.; Dhamarikar, M.; Choudhary, A.; Wasnik, D.; Chouhan, P.; Tiwari, S.; Namdeo, R. Study on the effects of fiber orientation on the mechanical properties of natural fiber reinforced epoxy composite by finite element method. Mater. Today Proc. 2021, 45, 7885. [Google Scholar] [CrossRef]

- Kalagi, G.R.; Patil, R.; Nayak, N. Experimental Study on Mechanical Properties of Natural Fiber Reinforced Polymer Composite Materials for Wind Turbine Blades. Mater. Today Proc. 2018, 5, 2588–2596. [Google Scholar] [CrossRef]

- Al-Hajaj, Z.; Sy, B.L.; Bougherara, H.; Zdero, R. Impact properties of a new hybrid composite material made from woven carbon fibres plus flax fibres in an epoxy matrix. Compos. Struct. 2018, 208, 346–356. [Google Scholar] [CrossRef]

- Mujahid, Y. Effects of Vacuum-Bag-Only Processing Parameters on Shape Conformation, Void Content and Mechanical Properties of Composites. Master’s Thesis, Khalifa University, Abu Dhabi, United Arab Emirates, 2021. [Google Scholar] [CrossRef]

- Campana, C.; Leger, R.; Sonnier, R.; Ferry, L.; Ienny, P. Effect of post curing temperature on mechanical properties of a flax fiber reinforced epoxy composite. Compos. Part A Appl. Sci. Manuf. 2018, 107, 171–179. [Google Scholar] [CrossRef]

- Mujahid, Y.; Sallih, N.; Abdullah, M.Z.; Mustapha, M. Effects of processing parameters for vacuum-bag-only method on void content and mechanical properties of laminated composites. Polym. Compos. 2020, 42, 567–582. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Sain, M. Enhancement of Mechanical Properties of Flax-Epoxy Composite with Carbon Fibre Hybridisation for Lightweight Applications. Materials 2019, 13, 109. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. Part B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Wang, A.; Wang, X.; Xian, G. Mechanical, low-velocity impact, and hydrothermal aging properties of flax/carbon hybrid composite plates. Polym. Test. 2020, 90, 106759. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Jawaid, M. Tensile and flexural properties of the hybrid flax/carbon-based fibre metal laminate. In Proceedings of the 5th Postgraduate Seminar on Natural Fiber Composites, Serdang, Selangor, Malaysia, 28 December 2016. [Google Scholar]

- Gowda, T.G.Y.; Vinod, A.; Madhu, P.; Rangappa, S.M.; Siengchin, S.; Jawaid, M. Mechanical and thermal properties of flax/carbon/kevlar based epoxy hybrid composites. Polym. Compos. 2022, 43, 5649–5662. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillo, J.; D’Altilia, S.; Valente, T.; Santulli, C.; Touchard, F.; Chocinski-Arnault, L.; Meillier, D.; Lampani, L.; Gaudenzi, P. Damage tolerance of carbon/flax hybrid composites subjected to low velocity impact. Compos. Part B Eng. 2016, 91, 144–153. [Google Scholar] [CrossRef]

- Li, X.; Ma, D.; Liu, H.; Tan, W.; Gong, X.; Zhang, C.; Li, Y. Assessment of failure criteria and damage evolution methods for composite laminates under low-velocity impact. Compos. Struct. 2018, 207, 727–739. [Google Scholar] [CrossRef]

- Bogenfeld, R.; Kreikemeier, J.; Wille, T. Review and benchmark study on the analysis of low-velocity impact on composite laminates. Eng. Fail. Anal. 2017, 86, 72–99. [Google Scholar] [CrossRef]

- Sriman Ram, M.R. Characterization of the Mechanical Properties of Flax and Its Hybrid Flax/Glass, Flax/Carbon Composites for Wind Turbine Blade Applications. Master’s Thesis, University of Portsmouth, Portsmouth, UK, 2022. [Google Scholar]

- Jones, R.M. Mechanics of Composite Materials; Taylor and Francis Inc.: Boca Raton, FL, USA, 1999. [Google Scholar]

- Mabrouk, O.M.; Khair-Eldeen, W.; Hassanin, A.H.; Hassan, M.A. Mechanical Behavior of Hybrid Glass-Flax-Carbon Fiber-Reinforced Polymer Composites Under Static and Dynamic Loading. Polym. Compos. 2024, 45, 16228–16243. [Google Scholar] [CrossRef]

- Balamurugan, T.; Ayyadurai, G.K.; Trilaksana, H.; Palani, G. Enhancing mechanical performance of flax fiber/vinyl ester composites with coconut husk char: A sustainable approach for hybrid composite material. Biomass Convers. Biorefinery 2025, 15, 7561–7570. [Google Scholar] [CrossRef]

- Selvaraj, G.; Kaliyamoorthy, R.; Kirubakaran, R. Mechanical, Thermogravimetric, and Dynamic Mechanical Analysis of Basalt and Flax Fibers Intertwined Vinyl Ester Polymer Composites. Polym. Compos. 2022, 43, 2196–2207. [Google Scholar] [CrossRef]

- Lau, K.-t.; Hung, P.-y.; Zhu, M.-H.; Hui, D. Properties of natural fibre composites for structural engineering applications. Compos. Part B Eng. 2018, 136, 222–233. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Zhao, C.F.; Ren, R.; Sun, C.B.; Ren, J.; Zhong, J.L.; Zhang, Z.D. Compression Mechanics for Carbon-Fiberreinforced Epoxy Resin Composites Under Inplane and Out-Of-Plane Quasi-Static and Dynamic Loadings. Mech. Compos. Mater. 2023, 59, 507–520. [Google Scholar] [CrossRef]

- Zhao, C.; Zhong, J.; Wang, H.; Chen, C. Complete constitutive model of CFRP including continuous damage in low strain rate compression and temperature generation in high strain rate impact. Polym. Compos. 2024, 45, 3965–3989. [Google Scholar] [CrossRef]

- Zhao, C.; Ren, R.; Zhong, J.; Goh, K.L.; Zhang, K.; Zhang, Z.; Le, G. Intralaminar crack propagation of glass fibre reinforced composite laminate. Structures 2022, 41, 787–803. [Google Scholar] [CrossRef]

- Zhao, C.; Goh, K.L.; Lee, H.P.; Yin, C.; Zhang, K.; Zhong, J. Experimental study and finite element analysis on energy absorption of carbon fiber reinforced composite auxetic structures filled with aluminum foam. Compos. Struct. 2023, 303, 116319. [Google Scholar] [CrossRef]

- Zhao, C.; Zhong, J.; Wang, H.; Liu, C.; Li, M.; Liu, H. Impact behaviour and protection performance of a CFRP NPR skeleton filled with aluminum foam. Mater. Des. 2024, 246, 113295. [Google Scholar] [CrossRef]

- Zhong, J.; Zhao, C.; Chen, C.; Lai, W.L.; Wang, Q. Mechanical behaviors of composite auxetic structures under quasi-static compression and dynamic impact. Eur. J. Mech.-A/Solids 2025, 109, 105454. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017.

| S.NO | Property | Flax Fiber | Carbon Fiber |

|---|---|---|---|

| 1 | Density (g/cm3) | 1.4–1.5 | 1.75–1.95 |

| 2 | Tensile strength (MPa) | 500–1100 | 3500–5500 |

| 3 | Young’s modulus (GPa) | 30–60 | 230–600 |

| 4 | Moisture absorption (%) | High | Very low |

| 5 | Thermal stability (°C) | Degrades above ~200 °C | Stable above 400 °C |

| 6 | Sustainability | Renewable, biodegradable | Non-renewable |

| Material | Manufacturer | Form/Weave | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|

| Flax fabric | Net composites Ltd. (Chesterfield, UK) | Plain weave | 500–900 | 50–70 |

| Carbon fiber | Aeron composites pvt Ltd. (Ahmedabad, India) | Unidirectional (UD) | ~4900 | ~230 |

| Vinyl ester resin | INEOS Composites (London, UK) | Liquid resin | ~75 (resin only) | ~3.2 |

| Material | Sample No | Maximum Force (N) | Strain (mm) | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|---|

| Flax (F) | 1 | 7737.77 | 0.08 | 85.82 | 8.51 |

| 2 | 8163.82 | 0.09 | 91.03 | 9.23 | |

| 3 | 7299.09 | 0.07 | 79.94 | 8.17 | |

| Average | 7733.56 | 0.08 | 85.56 | 8.63 | |

| Std. deviation | 0.01 | 4.57 | 0.44 | ||

| Flax/carbon (FC) | 1 | 9183.72 | 0.12 | 382.21 | 32.42 |

| 2 | 9543.41 | 0.14 | 390.56 | 33.53 | |

| 3 | 8761.75 | 0.10 | 378.89 | 31.87 | |

| Average | 9162.96 | 0.12 | 383.88 | 32.60 |

| Material | Sample No. | Max Force (N) | Max Displacement (mm) | Flexural Strength (MPa) | Flexural Modulus (GPa) |

|---|---|---|---|---|---|

| Flax (F) | 1 | 303.71 | 12.26 | 105.21 | 6.51 |

| 2 | 295.33 | 12.01 | 94.18 | 5.92 | |

| 3 | 310.07 | 12.67 | 109.53 | 6.88 | |

| Average | 303.03 | 12.31 | 102.97 | 6.43 | |

| Std. deviation | 0.33 | 6.46 | 0.39 | ||

| Flax/carbon (FC) | 1 | 359.02 | 9.09 | 423.11 | 25.83 |

| 2 | 320.30 | 6.69 | 408.57 | 24.28 | |

| 3 | 341.40 | 6.97 | 415.05 | 24.97 | |

| Average | 340.24 | 7.58 | 415.57 | 25.02 | |

| Std. deviation | 1.31 | 7.28 | 0.77 |

| Material | Specimen No. | Max. Force (N) | Max. Energy (J) | Max. Displacement (mm) |

|---|---|---|---|---|

| Flax (F) | 1 | 5808.97 | 45.47 | 20.47 |

| 2 | 4955.22 | 45.60 | 22.07 | |

| 3 | 5555.16 | 45.48 | 20.53 | |

| 4 | 5220.58 | 46.17 | 22.49 | |

| Average | 5384.98 | 45.68 | 21.39 | |

| Std. deviation | 0.33 | 1.04 | ||

| Flax/carbon (FC) | 1 | 13,942.70 | 46.32 | 17.67 |

| 2 | 13,735.03 | 46.33 | 17.79 | |

| 3 | 13,619.66 | 46.05 | 17.63 | |

| 4 | 13,833.10 | 46.05 | 17.55 | |

| Average | 13,782.62 | 46.19 | 17.66 | |

| Std. deviation | 0.16 | 0.10 |

| Material | Specimen No. | Absorbed Energy (J) | Rebound Energy (J) |

|---|---|---|---|

| Flax (F) | 1 | 44.25 | 1.22 |

| 2 | 44.86 | 0.74 | |

| 3 | 44.33 | 1.15 | |

| 4 | 45.62 | 0.54 | |

| Average | 44.76 | 0.91 | |

| Std. deviation | 0.63 | 0.32 | |

| Flax/carbon (FC) | 1 | 33.05 | 13.28 |

| 2 | 34.34 | 11.99 | |

| 3 | 33.27 | 12.78 | |

| 4 | 33.42 | 12.62 | |

| Average | 33.52 | 12.67 | |

| Std. deviation | 0.56 | 0.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajendran, S.R.M.; Balakrishnan, P.A.; Visvalingam, B. Determination of the Mechanical Properties of Flax and Its Hybrid Flax/Carbon Composite Laminates with Vinyl Ester Resin for Wind Turbine Rotor Blades. J. Compos. Sci. 2025, 9, 229. https://doi.org/10.3390/jcs9050229

Rajendran SRM, Balakrishnan PA, Visvalingam B. Determination of the Mechanical Properties of Flax and Its Hybrid Flax/Carbon Composite Laminates with Vinyl Ester Resin for Wind Turbine Rotor Blades. Journal of Composites Science. 2025; 9(5):229. https://doi.org/10.3390/jcs9050229

Chicago/Turabian StyleRajendran, Sriman Ram Marimuthu, Prem Anand Balakrishnan, and Balasubramanian Visvalingam. 2025. "Determination of the Mechanical Properties of Flax and Its Hybrid Flax/Carbon Composite Laminates with Vinyl Ester Resin for Wind Turbine Rotor Blades" Journal of Composites Science 9, no. 5: 229. https://doi.org/10.3390/jcs9050229

APA StyleRajendran, S. R. M., Balakrishnan, P. A., & Visvalingam, B. (2025). Determination of the Mechanical Properties of Flax and Its Hybrid Flax/Carbon Composite Laminates with Vinyl Ester Resin for Wind Turbine Rotor Blades. Journal of Composites Science, 9(5), 229. https://doi.org/10.3390/jcs9050229