Analysis and Modeling of Thermogravimetric Curves of Chemically Modified Wheat Straw Filler-Based Biocomposites Using Machine Learning Techniques

Abstract

1. Introduction

2. Materials and Methods

2.1. Composite Sample Preparation

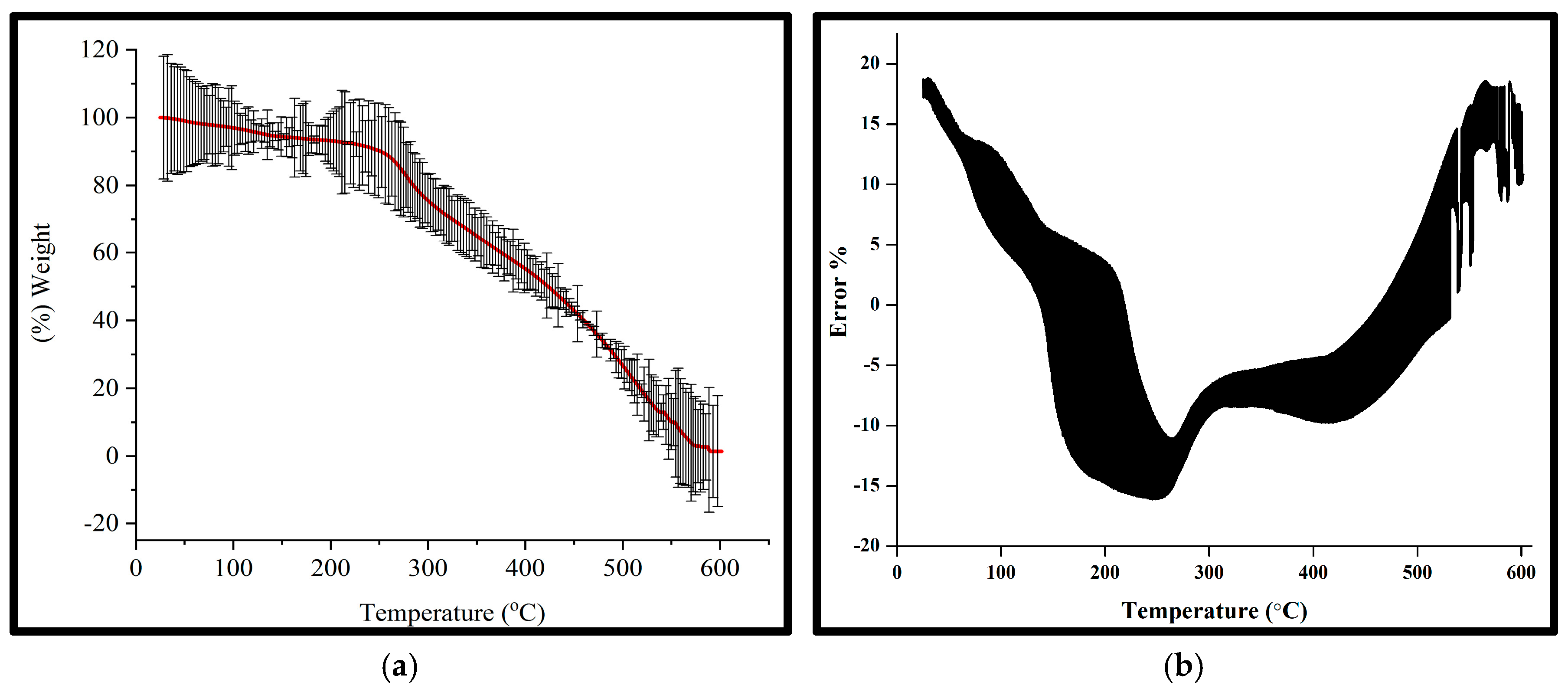

2.2. Thermogravimetric (TGA) Analysis

2.3. Scanning Electron Microscopy (SEM)

2.4. Mechanical Properties

2.5. Software and System

2.6. Dataset and Attributes

2.7. Parameter Settings of the Models

- K-Nearest Neighbor (KNN)

- Random Forest

- Multilayer Perceptron (MLP)

- Support Vector Machine (SVM) with Sequential Minimal Optimization Regression (SMOreg)

- Decision Trees and Ensemble Methods

- Cross-Validation and Parameter-Tuning

- Justification for Parameter Choices

3. Results and Discussion

4. Conclusions and Limitations

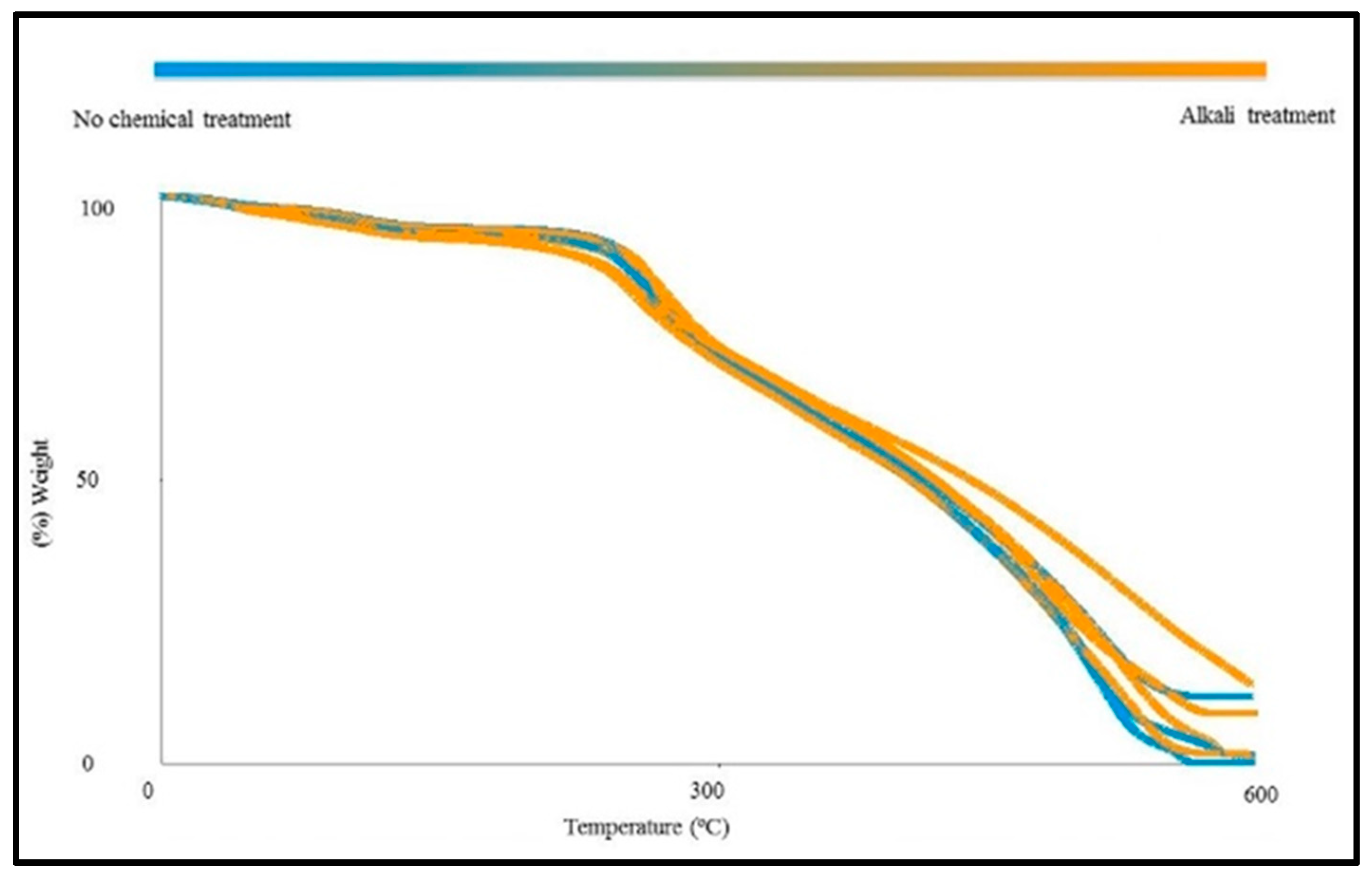

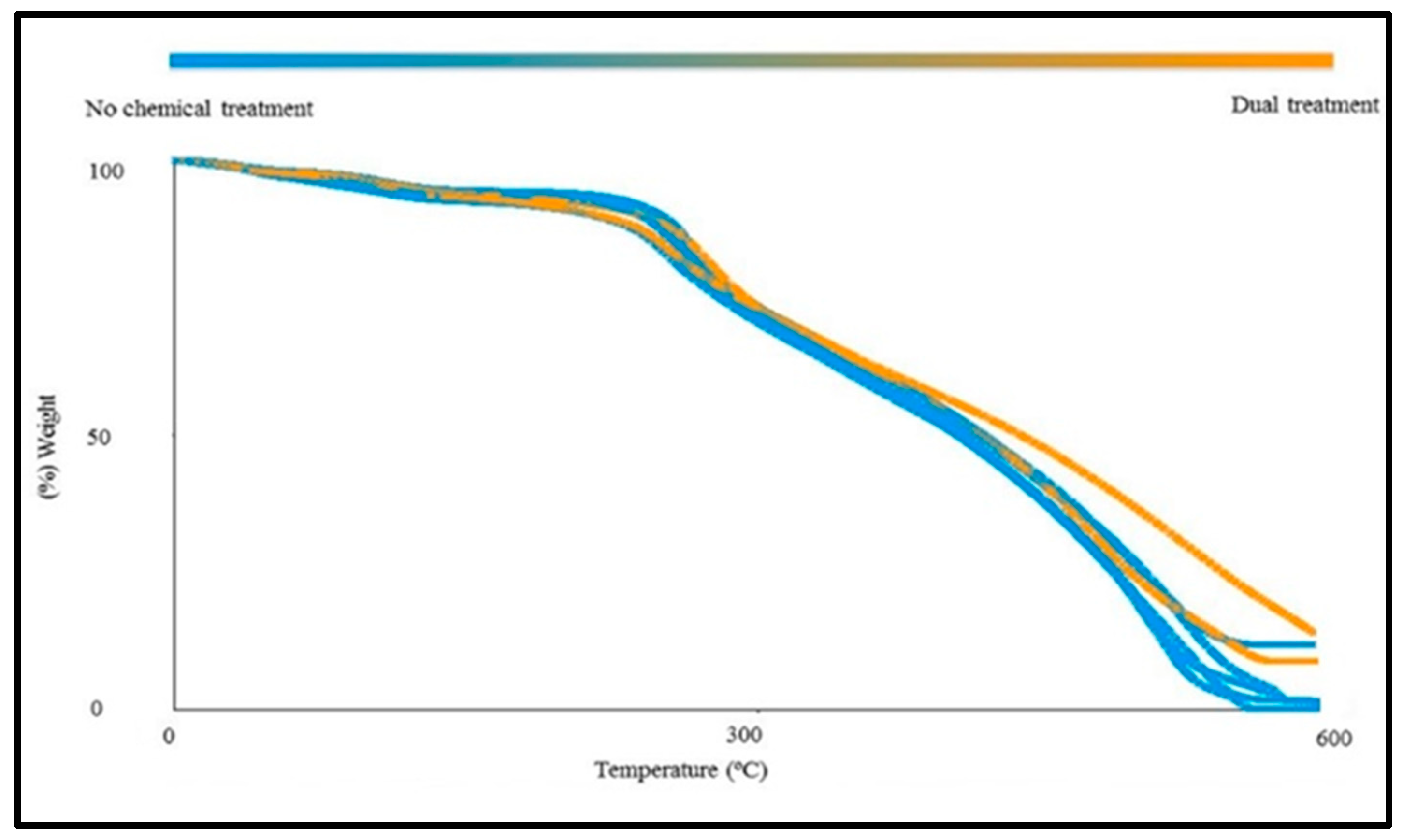

- The thermal properties of the biocomposite samples were assessed through thermogravimetric analysis (TGA), and the results clearly demonstrated that the dual treatment involving silane and alkali for the wheat straw fibers led to a significant improvement in the thermal stability of the biocomposites when compared to both untreated and alkali-treated fibers.

- Furthermore, the study highlighted that as the loading of wheat straw fibers increased; the thermal-degradation stability exhibited a diminishing trend. To predict the thermal performance of the wheat straw biocomposite samples, 16 machine-learning algorithms were used to analyze the datasets.

- A comparative analysis of the performance of these 16 algorithms has been made. It is found that the accuracy of the KNN algorithm is the best among all in predicting the thermal performance of the biocomposites.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dhakal, H.N.; Ismail, S.O.; Zhang, Z.; Barber, A.; Welsh, E.; Maigret, J.-E.; Beaugrand, J. Development of Sustainable Biodegradable Lignocellulosic Hemp Fiber/Polycaprolactone Biocomposites for Light Weight Applications. Compos. Part A Appl. Sci. Manuf. 2018, 113, 350–358. [Google Scholar] [CrossRef]

- Garimella, A.; Bandhu Ghosh, S.; Bandyopadhyay-Ghosh, S. A Comprehensive Study of the Impact on the Microstructure and Corrosion Behavior of Magnesium Alloy-Based Porous Bone Implants. Mater. Today Proc. 2023, in press. [CrossRef]

- Garimella, A.; Manohar, R.; Ghosh, S.B.; Bandyopadhyay-Ghosh, S.; Agrawal, A.K. Bioactive Fluorcanasite Reinforced Magnesium Alloy-Based Porous Bio-Nanocomposite Scaffolds with Tunable Mechanical Properties. J. Biomed. Mater. Res. 2023, 111, 463–477. [Google Scholar] [CrossRef]

- Garimella, A.; Awale, G.; Parai, R.; Ghosh, S.B.; Bandyopadhyay-Ghosh, S. An Integrated Approach to Develop Engineered Metal Composite Bone Scaffold with Controlled Degradation. Mater. Technol. 2019, 34, 858–866. [Google Scholar] [CrossRef]

- Fayomi, O.S.I.; Babaremu, K.O.; Akande, I.G.; Agboola, O.; Anyanwu, B.U. Potential of Bio-Wastes in the Development of Composites for Manufacturing Application. Mater. Today Proc. 2021, 38, 2353–2357. [Google Scholar] [CrossRef]

- Shaik, S.A.; Schuster, J.; Shaik, Y.P.; Kazmi, M. Manufacturing of Biocomposites for Domestic Applications Using Bio-Based Filler Materials. J. Compos. Sci. 2022, 6, 78. [Google Scholar] [CrossRef]

- Roy, S.B.; Shit, S.C.; Gupta, R.A.S.; Shukla, P.R. A Review on Bio-Composites: Fabrication, Properties and Applications. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 16814–16824. [Google Scholar] [CrossRef]

- Duque-Acevedo, M.; Belmonte-Ureña, L.J.; Cortés-García, F.J.; Camacho-Ferre, F. Agricultural Waste: Review of the Evolution, Approaches and Perspectives on Alternative Uses. Glob. Ecol. Conserv. 2020, 22, e00902. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Krishnaraj, V.; Kumar, M.S.; Zitoune, R. Sound and Vibration Damping Properties of Flax Fiber Reinforced Composites. Procedia Eng. 2014, 97, 573–581. [Google Scholar] [CrossRef]

- Akampumuza, O.; Wambua, P.M.; Ahmed, A.; Li, W.; Qin, X. Review of the Applications of Biocomposites in the Automotive Industry. Polym. Compos. 2017, 38, 2553–2569. [Google Scholar] [CrossRef]

- Gholampour, A.; Ozbakkaloglu, T. A Review of Natural Fiber Composites: Properties, Modification and Processing Techniques, Characterization, Applications. J. Mater. Sci. 2020, 55, 829–892. [Google Scholar] [CrossRef]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural Fiber–Reinforced Composites: A Review on Material, Manufacturing, and Machinability. J. Thermoplast. Compos. Mater. 2021, 34, 238–284. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A Review on the Degradability of Polymeric Composites Based on Natural Fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Samanth, M.; Subrahmanya Bhat, K. Conventional and Unconventional Chemical Treatment Methods of Natural Fibres for Sustainable Biocomposites. Sustain. Chem. Clim. Action 2023, 3, 100034. [Google Scholar] [CrossRef]

- Chavhan, G.R.; Wankhade, L.N. Improvement of the Mechanical Properties of Hybrid Composites Prepared by Fibers, Fiber-Metals, and Nano-Filler Particles—A Review. Mater. Today Proc. 2020, 27, 72–82. [Google Scholar] [CrossRef]

- Sanjay, M.R.; Siengchin, S.; Parameswaranpillai, J.; Jawaid, M.; Pruncu, C.I.; Khan, A. A Comprehensive Review of Techniques for Natural Fibers as Reinforcement in Composites: Preparation, Processing and Characterization. Carbohydr. Polym. 2019, 207, 108–121. [Google Scholar] [CrossRef]

- Wazalwar, R.; Sahu, M.; Raichur, A.M. Mechanical Properties of Aerospace Epoxy Composites Reinforced with 2D Nano-Fillers: Current Status and Road to Industrialization. Nanoscale Adv. 2021, 3, 2741–2776. [Google Scholar] [CrossRef]

- Mittal, V.; Sinha, S. Effect of Alkali Treatment on the Thermal Properties of Wheat Straw Fiber Reinforced Epoxy Composites. J. Compos. Mater. 2017, 51, 323–331. [Google Scholar] [CrossRef]

- Hejna, A.; Formela, K.; Saeb, M.R. Processing, Mechanical and Thermal Behavior Assessments of Polycaprolactone/Agricultural Wastes Biocomposites. Ind. Crops Prod. 2015, 76, 725–733. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Fan, M. Differential Behaviour of Nodes and Internodes of Wheat Straw with Various Pre-Treatments. Biomass Bioenergy 2015, 83, 373–382. [Google Scholar] [CrossRef]

- Tan, F.; Xu, J. Simulation of Biochemical Reactions with ANN-Dependent Kinetic Parameter Extraction Method. Electronics 2022, 11, 216. [Google Scholar] [CrossRef]

- Conesa, J.A.; Caballero, J.A.; Reyes-Labarta, J.A. Artificial Neural Network for Modelling Thermal Decompositions. J. Anal. Appl. Pyrolysis 2004, 71, 343–352. [Google Scholar] [CrossRef]

- Xie, C.; Liu, J.; Zhang, X.; Xie, W.; Sun, J.; Chang, K.; Kuo, J.; Xie, W.; Liu, C.; Sun, S.; et al. Co-Combustion Thermal Conversion Characteristics of Textile Dyeing Sludge and Pomelo Peel Using TGA and Artificial Neural Networks. Appl. Energy 2018, 212, 786–795. [Google Scholar] [CrossRef]

- Yıldız, Z.; Uzun, H.; Ceylan, S.; Topcu, Y. Application of Artificial Neural Networks to Co-Combustion of Hazelnut Husk–Lignite Coal Blends. Bioresour. Technol. 2016, 200, 42–47. [Google Scholar] [CrossRef] [PubMed]

- Shen, J. Linear Regression. In Encyclopedia of Database Systems; Liu, L., Özsu, M.T., Eds.; Springer: Boston, MA, USA, 2009; p. 1622. ISBN 9780387355443. [Google Scholar]

- Tang, J.; Deng, C.; Huang, G.-B. Extreme Learning Machine for Multilayer Perceptron. IEEE Trans. Neural Netw. Learn. Syst. 2016, 27, 809–821. [Google Scholar] [CrossRef] [PubMed]

- Altman, N.; Krzywinski, M. Simple Linear Regression. Nat. Methods 2015, 12, 999–1000. [Google Scholar] [CrossRef]

- Al-Shamery, E.S.; Al-Gashamy, H.A. Enhanced Evolutionary Sequential Minimal Optimization Model for Inflation Prediction. Int. J. Eng. Technol. 2018, 7, 788–793. [Google Scholar] [CrossRef]

- Cunningham, P.; Delany, S.J. K-Nearest Neighbour Classifiers—A Tutorial. ACM Comput. Surv. 2022, 54, 1–25. [Google Scholar] [CrossRef]

- Keshavarzi, A.; Toroghi Haghighat, A.; Bohlouli, M. Enhanced Time-Aware QoS Prediction in Multi-Cloud: A Hybrid k-Medoids and Lazy Learning Approach (QoPC). Computing 2020, 102, 923–949. [Google Scholar] [CrossRef]

- Nakanishi, J.; Farrell, J.A.; Schaal, S. Composite Adaptive Control with Locally Weighted Statistical Learning. Neural Netw. 2005, 18, 71–90. [Google Scholar] [CrossRef][Green Version]

- Nakanishi, J.; Farrell, J.A.; Schaal, S. A Locally Weighted Learning Composite Adaptive Controller with Structure Adaptation. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and System, Lausanne, Switzerland, 30 September–4 October 2002; IEEE: New York, NY, USA, 2002; Volume 1, pp. 882–889. [Google Scholar] [CrossRef]

- Totton, S.C.; Farrar, A.M.; Wilkins, W.; Bucher, O.; Waddell, L.A.; Wilhelm, B.J.; McEwen, S.A.; Rajić, A. The Effectiveness of Selected Feed and Water Additives for Reducing Salmonella Spp. of Public Health Importance in Broiler Chickens: A Systematic Review, Meta-Analysis, and Meta-Regression Approach. Prev. Vet. Med. 2012, 106, 197–213. [Google Scholar] [CrossRef] [PubMed]

- Lira, M.M.S.; De Aquino, R.R.B.; Ferreira, A.A.; Carvalho, M.A.; Neto, O.N.; Santos, G.S.M. Combining Multiple Artificial Neural Networks Using Random Committee to Decide upon Electrical Disturbance Classification. In Proceedings of the 2007 International Joint Conference on Neural Networks, Orlando, FL, USA, 12–17 August 2007; IEEE: New York, NY, USA, 2007; pp. 2863–2868. [Google Scholar]

- Zareapoor, M.; Shamsolmoali, P. Application of Credit Card Fraud Detection: Based on Bagging Ensemble Classifier. Procedia Comput. Sci. 2015, 48, 679–685. [Google Scholar] [CrossRef]

- Arnaiz-González, Á.; Díez-Pastor, J.F.; Rodríguez, J.J.; García-Osorio, C.I. Instance Selection for Regression by Discretization. Expert Syst. Appl. 2016, 54, 340–350. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, G.; Yang, J.; Milton, J.C.; Alcántara, A. “Dely” An Explanatory Analysis of Driver Injury Severity in Rear-End Crashes Using a Decision Table/Naïve Bayes (DTNB) Hybrid Classifier. Accid. Anal. Prev. 2016, 90, 95–107. [Google Scholar] [CrossRef]

- Ayaz, Y.; Kocamaz, A.F.; Karakoç, M.B. Modeling of Compressive Strength and UPV of High-Volume Mineral-Admixtured Concrete Using Rule-Based M5 Rule and Tree Model M5P Classifiers. Constr. Build. Mater. 2015, 94, 235–240. [Google Scholar] [CrossRef]

- Biau, G.; Scornet, E. A Random Forest Guided Tour. TEST 2016, 25, 197–227. [Google Scholar] [CrossRef]

- Jagannathan, G.; Pillaipakkamnatt, K.; Wright, R.N. A Practical Differentially Private Random Decision Tree Classifier. In Proceedings of the 2009 IEEE International Conference on Data Mining Workshops, Miami, FL, USA, 6 December 2009; pp. 114–121. [Google Scholar]

- Chandra, S.; Maheshkar, S. Verification of Static Signature Pattern Based on Random Subspace, REP Tree and Bagging. Multimed. Tools Appl. 2017, 76, 19139–19171. [Google Scholar] [CrossRef]

- Kibrete, F.; Trzepieciński, T.; Gebremedhen, H.S.; Woldemichael, D.E. Artificial Intelligence in Predicting Mechanical Properties of Composite Materials. J. Compos. Sci. 2023, 7, 364. [Google Scholar] [CrossRef]

- Sorour, S.S.; Saleh, C.A.; Shazly, M. A Review on Machine Learning Implementation for Predicting and Optimizing the Mechanical Behaviour of Laminated Fiber-Reinforced Polymer Composites. Heliyon 2024, 10, e33681. [Google Scholar] [CrossRef]

- Wei, H.; Zhao, S.; Rong, Q.; Bao, H. Predicting the Effective Thermal Conductivities of Composite Materials and Porous Media by Machine Learning Methods. Int. J. Heat Mass Transf. 2018, 127, 908–916. [Google Scholar] [CrossRef]

- Chai, B.X.; Eisenbart, B.; Nikzad, M.; Fox, B.; Blythe, A.; Bwar, K.H.; Wang, J.; Du, Y.; Shevtsov, S. Application of KNN and ANN Metamodeling for RTM Filling Process Prediction. Materials 2023, 16, 6115. [Google Scholar] [CrossRef] [PubMed]

- Jabbar, M.A.; Deekshatulu, B.L.; Chandra, P. Classification of Heart Disease Using K-Nearest Neighbor and Genetic Algorithm. Procedia Technol. 2013, 10, 85–94. [Google Scholar] [CrossRef]

- Zhang, Y.; Cao, G.; Wang, B.; Li, X. A Novel Ensemble Method for K-Nearest Neighbor. Pattern Recognit. 2019, 85, 13–25. [Google Scholar] [CrossRef]

- Faroque, F.A.; Kakati, S.; Ghosh, S.B.; Bandyopadhyay-Ghosh, S. Investigating Synergistically Modified Wheat Straw Residual Filler-Based Biocomposite Tiles. Jordan J. Civ. Eng. 2022, 16, 320–334. [Google Scholar]

- ISO:178; Plastics—Determination of Flexural Properties. International Organization of Standardization: Geneva, Switzerland, 2019.

- Kruse, R.; Mostaghim, S.; Borgelt, C.; Braune, C.; Steinbrecher, M. Multi-Layer Perceptrons. In Computational Intelligence; Springer International Publishing: Cham, Switzerland, 2022; pp. 53–124. ISBN 9783030422264. [Google Scholar] [CrossRef]

- Hope, T.M.H. Linear Regression. In Machine Learning; Elsevier: Amsterdam, The Netherlands, 2020; pp. 67–81. [Google Scholar] [CrossRef]

- Marill, K.A. Advanced Statistics: Linear Regression, Part I: Simple Linear Regression. Acad. Emerg. Med. 2004, 11, 87–93. [Google Scholar] [CrossRef]

- Huang, B.; Cai, Z.; Gu, Q.; Chen, C. Using Support Vector Regression for Classification. In Advanced Data Mining and Applications; Tang, C., Ling, C.X., Zhou, X., Cercone, N.J., Li, X., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; Volume 5139, pp. 581–588. [Google Scholar]

- Kramer, O. K-Nearest Neighbors. In Dimensionality Reduction with Unsupervised Nearest Neighbors; Springer: Berlin/Heidelberg, Germany, 2013; Volume 51, pp. 13–23. [Google Scholar] [CrossRef]

- Zhang, Z. Introduction to Machine Learning: K-Nearest Neighbors. Ann. Transl. Med. 2016, 4, 218. [Google Scholar] [CrossRef] [PubMed]

- Khosravi, K.; Farooque, A.A.; Bateni, S.M.; Jun, C.; Dhiman, J. Prediction of Three Vital Rainfall Characteristics: Advanced Hybrid Tree- or Lazy-Based Learner? Results Eng. 2025, 25, 103840. [Google Scholar] [CrossRef]

- Aha, D.W. Feature Weighting for Lazy Learning Algorithms. In Feature Extraction, Construction and Selection; Liu, H., Motoda, H., Eds.; Springer: Boston, MA, USA, 1998; pp. 13–32. [Google Scholar] [CrossRef]

- Van Rijn, J.N.; Holmes, G.; Pfahringer, B.; Vanschoren, J. Having a Blast: Meta-Learning and Heterogeneous Ensembles for Data Streams. In Proceedings of the 2015 IEEE International Conference on Data Mining, Atlantic City, NJ, USA, 14–17 November 2015; IEEE: New York, NY, USA, 2015; pp. 1003–1008. [Google Scholar]

- Khiari, J.; Moreira-Matias, L.; Shaker, A.; Ženko, B.; Džeroski, S. MetaBags: Bagged Meta-Decision Trees for Regression. In Machine Learning and Knowledge Discovery in Databases; Berlingerio, M., Bonchi, F., Gärtner, T., Hurley, N., Ifrim, G., Eds.; Springer International Publishing: Cham, Switzerland, 2019; Volume 11051, pp. 637–652. [Google Scholar] [CrossRef]

- Al-Mukhtar, M.; Srivastava, A.; Khadke, L.; Al-Musawi, T.; Elbeltagi, A. Prediction of Irrigation Water Quality Indices Using Random Committee, Discretization Regression, REPTree, and Additive Regression. Water Resour. Manag. 2024, 38, 343–368. [Google Scholar] [CrossRef]

- Becker, B.G. Visualizing Decision Table Classifiers. In Proceedings of the IEEE Symposium on Information Visualization (Cat. No.98TB100258), Research Triangle, CA, USA, 19–20 October 1998; IEEE Comput. Soc.: New York, NY, USA, 1998; pp. 102–105. [Google Scholar]

- Duggal, H.; Singh, P. Comparative Study of the Performance of M5-Rules Algorithm with Different Algorithms. J. Softw. Eng. Appl. 2012, 5, 270–276. [Google Scholar] [CrossRef]

- Geurts, P.; Ernst, D.; Wehenkel, L. Extremely randomized trees. Mach. Learn. 2006, 63, 3–42. [Google Scholar] [CrossRef]

- Nidhya, M.S.; Shah, P.K. Acquiring Knowledge by Performing Classification and Clustering of Datasets Using WEKA: Intelligence Through MLP, RF, DT, and RepTree. In Proceedings of the 2023 International Conference on Communication, Security and Artificial Intelligence (ICCSAI), Greater Noida, India, 23 November 2023; IEEE: New York, NY, USA, 2023; pp. 833–837. [Google Scholar]

| Sample | Epoxy Resin (grams) | Biofiber (grams) | Alkali Mercerization | Silicane Mercerization |

|---|---|---|---|---|

| Epoxy | 100 | 0 | - | - |

| X1 | 100 | 10 | not treated | not treated |

| X2 | 100 | 10 | treated | not treated |

| X3 | 100 | 10 | treated | treated |

| Y1 | 100 | 15 | not treated | not treated |

| Y1 | 100 | 15 | treated | not treated |

| Y3 | 100 | 15 | treated | treated |

| Attributes | Description |

|---|---|

| Fiber loading | Two loadings (10 phr and 15 phr) of wheat straw fiber were taken in the experiment |

| No treatment | Raw fibers were directly used to fabricate the biocomposites |

| Alkali treatment | Raw fibers were subjected to NaOH treatment before being used in the epoxy matrix |

| Dual treatment (Alkali and silane treatment) | After NaOH treatment, silane coupling agent Si 69 was used to modify the fiber |

| Temperature | In an ambient setting, the temperature was changed from room temperature to 800 °C at a rate of 10 °C/min |

| Sl. No | Model/Classifier | Description |

|---|---|---|

| 1 | Linear regression [25] | Attribute selection method—M5 method; batch size—100; ridge—1.0 × 10−8; debug—false; eliminate collinear attributes—true; output additional stats—false; use QR decomposition—false |

| 2 | Multilayer perceptron [50] | GUI—false; batch size—100; debug—false; decay—false; hidden layers—a; learning rate—0.3; momentum—0.2; nominal to binary filter—true; normalize attributes—true; normalize numerical class—true; seed—0; training time—500; validation set size—0; validation threshold—20 |

| 3 | Simple linear regression [51,52] | Batch size—100; debug—false; output additional stats—false |

| 4 | SVM—Sequential minimal optimization regression (SMOreg) [53] | Batch size—100; C—1.0; debug—false; filter type—normalize training data; kernel—poly kernel; reg optimizer—RegSMOImproved |

| 5 | K-nearest neighbor classifier [54,55] | KNN—1; batch size—100; cross validate—false; debug—false; distance weighting—no distance weighting; mean squared—false; nearest neighbor search algorithm—Linear NN search; window size—0 |

| 6 | Lazy K star [56] | Batch size—100; debug—false; entropic auto blend—false; global blend—20; missing mode—average column entropy curves |

| 7 | Lazy locally weighted learning [57] | Batch size—100; classifier—decision stump; debug—false; nearest neighbor search algorithm—linear NN search; weighting kernel—0 |

| 8 | Meta-additive regression [58] | Batch size—100; classifier—decision stamp; debug—false; minimize absolute error—false; number of iterations—10; shrinkage—1.0 |

| 9 | Meta-bagging [59] | Bag size percent—100; batch size—100; calculation out of bag—0; classifier—REPTree; debug—false; number of execution slots—1; number of iterations—10; seed—1 |

| 10 | Random committee [60] | Batch size—100; classifier—J48; debug—false; number of execution slots—1; number of iterations—10; seed—1 |

| 11 | Regression by discretization [61] | Batch size—100; classifier—J48; debug—false; estimator—Univariate equal frequency histogram estimator; minimize absolute error—false; number of bins—10; delete empty bins—false; use equal frequency—false |

| 12 | Decision table [62] | Batch size—100; cross-validation—1; debug—false; display rules—false; evaluation measure—accuracy (discrete class); RMSE (numeric class); search—best first |

| 13 | M5 Rules [62] | Batch size—100; building regression tree—false; debug—false; minimum number of instances—4; unpruned—false; use unsmoothed—false |

| 14 | Random forest [39] | Bag size percent—100; batch size—100; break ties randomly—false; calculation out of bag—0; compute attribute importance—false; debug—false; maximum depth—0; number of execution slots—1; number of iterations—100; output out of bag complexity statistics—false |

| 15 | Random tree [63] | K value—0; allow unclassified instances—false; batch size—100; break ties randomly—false; debug—false; maximum depth—0; minimum number—1; minimum variance proportion—0.001; number of folds—0; seed—1 |

| 16 | REPTree [64] | Batch size—100; debug—false; initial count—0.0; maximum depth—(−1); minimum number—2; minimum variance proportion—0.001; no pruning—false; number of folds—3; seed—1; spread initial count—false |

| Code of the Sample | Char Values (% Residual Weight) at Various Temperature | |||||

|---|---|---|---|---|---|---|

| 100 °C | 200 °C | 300 °C | 400 °C | 500 °C | 600 °C | |

| X1 | 97.55 | 94.25 | 74.87 | 53.79 | 20.30 | 1.25 |

| X2 | 97.57 | 93.99 | 76.47 | 56.11 | 26.85 | 2.97 |

| X3 | 97.34 | 93.10 | 77.47 | 58.09 | 37.37 | 12.18 |

| Y1 | 96.46 | 93.24 | 74.92 | 53.40 | 21.39 | 0.95 |

| Y1 | 95.62 | 91.76 | 73.77 | 53.13 | 21.41 | 2.35 |

| Y3 | 96.85 | 92.15 | 75.90 | 56.21 | 24.88 | 10.86 |

| Sl. No | Model/Classifier | Correlation Co-Efficient | Mean Absolute Error | Root Mean Square Error | Relative Absolute Error | Root Relative Squared Error |

|---|---|---|---|---|---|---|

| 1 | Linear regression | 0.9605 | 7.7788 | 8.9331 | 27.8368 | 27.8414 |

| 2 | Multilayer perceptron | 0.9965 | 2.2441 | 2.7524 | 8.0305 | 8.5783 |

| 3 | Simple linear regression | 0.9588 | 7.9483 | 9.1132 | 28.4435 | 28.4028 |

| 4 | Sequential minimal optimization regression (SMO-reg) | 0.9603 | 7.6463 | 9.205 | 27.3625 | 28.6887 |

| 5 | K-nearest neighbor classifier | 0.9999 | 0.0282 | 0.0358 | 0.1008 | 0.1116 |

| 6 | Lazy K star | 0.9982 | 1.6495 | 2.497 | 5.9027 | 7.7822 |

| 7 | Lazy locally weighted learning | 0.9028 | 11.7833 | 12.8062 | 42.1672% | 43.0291 |

| 8 | Meta-additive regression | 0.9816 | 4.599 | 6.1612 | 16.4577 | 19.2024 |

| 9 | Meta-bagging | 0.9998 | 0.4842 | 0.6182 | 1.7327 | 1.9267 |

| 10 | Random committee | 0.9999 | 0.3744 | 0.4767 | 1.34 | 1.4858 |

| 11 | Regression by discretization | 0.9963 | 2.4113 | 2.7736 | 8.6289 | 8.6444 |

| 12 | Decision table | 0.9940 | 2.4277 | 3.5203 | 8.6875 | 10.9715 |

| 13 | M5 Rules | 0.9995 | 0.7547 | 1.0213 | 2.7007 | 3.1831 |

| 14 | Random forest | 0.9999 | 0.2753 | 0.3644 | 0.9852 | 1.1358 |

| 15 | Random tree | 0.9997 | 0.6636 | 0.8237 | 2.3746 | 2.5673 |

| 16 | REPTree | 0.9997 | 0.676 | 0.8322 | 2.4192 | 2.5938 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faroque, F.A.; Garimella, A.; Naganna, S.R. Analysis and Modeling of Thermogravimetric Curves of Chemically Modified Wheat Straw Filler-Based Biocomposites Using Machine Learning Techniques. J. Compos. Sci. 2025, 9, 221. https://doi.org/10.3390/jcs9050221

Faroque FA, Garimella A, Naganna SR. Analysis and Modeling of Thermogravimetric Curves of Chemically Modified Wheat Straw Filler-Based Biocomposites Using Machine Learning Techniques. Journal of Composites Science. 2025; 9(5):221. https://doi.org/10.3390/jcs9050221

Chicago/Turabian StyleFaroque, Firoz Alam, Adithya Garimella, and Sujay Raghavendra Naganna. 2025. "Analysis and Modeling of Thermogravimetric Curves of Chemically Modified Wheat Straw Filler-Based Biocomposites Using Machine Learning Techniques" Journal of Composites Science 9, no. 5: 221. https://doi.org/10.3390/jcs9050221

APA StyleFaroque, F. A., Garimella, A., & Naganna, S. R. (2025). Analysis and Modeling of Thermogravimetric Curves of Chemically Modified Wheat Straw Filler-Based Biocomposites Using Machine Learning Techniques. Journal of Composites Science, 9(5), 221. https://doi.org/10.3390/jcs9050221